Abstract

The nature of fluid mechanics makes experimentation an important part of a course taught on the subject. Presented here is the application of a novel, large-scale multidisciplinary model of practical education in a fluids engineering laboratory. The advantages of this approach include efficiencies through the economy of scale leading to better pedagogy for students. The scale justifies dedicated academic resources to focus on developing laboratory classes and giving specific attention to designing activities that meet learning outcomes. Four examples of applying this approach to fluid mechanics experiments are discussed, illustrating tactics that have been developed and honed through many repeated instances of delivery. “The measurement lab” uses a flow measurement context to teach identifying and managing general experimental uncertainty. In this lab, new students, unfamiliar with fluid mechanics, are guided through a process to gain understanding that can be applied to all future experimental activities. The “pressure loss in pipes” lab discusses the advantage of and process for sharing equipment and teaching resources between multiple cohorts. Here, the provision for students is adapted for context, such as the degree program or year of study. The “weirs big and small” lab provides a methodology for teaching the power of dimensional analysis to mechanical engineers using a field of fluid mechanics that is outside their usual theoretical studies. Finally, the “spillway design” lab discusses mechanisms for delivering independent, open-ended student experiments at scale, without excessive staff resource requirements.

1. Introduction

Laboratory practicals are often included as part of the scheduled delivery for courses teaching physical principles. They allow students an opportunity to understand the physical manifestation of underlying concepts and compare theoretical models to real world results and can cater for alternative learning styles. These justifications are pertinent for courses in fluid mechanics. The nature of the subject often involves the understanding of qualitative or counterintuitive concepts that are best understood through a tactile experience. It can be argued that a visceral instinct for the behaviour of fluids can only be obtained with sufficient experience of its application in the real world. In addition, teaching fluid mechanics usually involves understanding concepts and models to predict the behaviour of a fluid for specific scenarios, for example, flow in a pipe or around a wing. As these scenarios become more complex, models rely increasingly on the use of empiricism in order to overcome the inability of analytical methods to model the flow. Indeed, compared to in other engineering disciplines, the requirement to introduce empirical correlations into predictive models occurs for even relatively simple physical systems, such a turbulent flow in a straight, horizontal pipe. Understanding the value of experimental affirmation and validation is critical for the development of well-rounded students studying fluid mechanics. This has been clearly voiced in a recent publication, where the authors describe a blended approach to experimentation [1]. Within a university, each department is traditionally responsible for the delivery of laboratory teaching alongside a range of other teaching methods, such as lectures, tutorials, problem classes, design classes etc, which combine to provide students with courses in a particular subject discipline. The Faculty of Engineering at the University of Sheffield have adopted an alternative approach. One department, Multidisciplinary Engineering Education (MEE), is only responsible for the laboratory practicals of all 10 subject-specific degree programmes in the Faculty of Engineering, allowing the other departments increased time and resources to focus on classroom-based teaching methods and academic research. The volume of practical teaching delivered by MEE is consequently an order of magnitude greater than that which would typically be undertaken by departments offering individual degree programmes.

There are a number of advantages to this teaching model [2], such as the increased efficiency of infrastructure in common business processes, the reuse of teaching resources across similar activities and consistent experiences for students across the practical portion of their curriculum. The collective purchasing allows the possibility of buying many identical copies of experimental equipment and justifying the operation of large-capacity laboratories, with a related pedagogical advantage.

MEE is housed in the University of Sheffield’s purpose-built Diamond building. Among the facilities is the Fluids Engineering Laboratory, which is used by Mechanical, Civil, Aerospace, Chemical, Bio and General Engineering students, in the order of 1000 students per year group. The laboratory has capacity for 80 students, typically working in groups of four, and is staffed by dedicated members of academic and technical staff. The laboratory is equipped with 20 identical copies of each of the pieces of experimental apparatus used for different aspects of fluid mechanics, including 20 hydraulic benches, on which a variety of internal flow experiments can be performed, and 20 wind tunnels, with which external flow experiments can be performed. The capacity provides three advantages of particular relevance to learning and teaching.

- Large class sizes, with students performing the same experiment at the same time, result in laboratory teaching being temporally aligned with other classroom-based teaching, such as lectures and seminars. For example, if a cohort of 240 aerospace engineers required access to a single piece of experimental equipment, working in groups of 4, it would require 60 individual timetabled sessions. There is little chance of all sessions occurring at a specific time within the teaching calendar for the majority of students, which will impact on the effectiveness of their learning [3,4]. With 20 copies of the same equipment, all students can be provided with the same laboratory activity in three sessions. Thus, the design of the course structure, where and when topics will be taught, can be made by strategic design, rather than being constrained by timetable availability. Students can experience the reality of a practical laboratory simultaneously with being introduced to the physics in the classroom. In this context, a lecture can also be the introduction to an experiment that in turn shows the validity and application of the physics. An alternative approach could be to record practicals or use demonstrations, but this removes the engagement from the activity [5].

- Laboratory sessions occurring in a predictable order due to Reason 1 makes it possible to sequence activities in the laboratory to be of increasing rigour and complexity, employing the principles of spiral learning. This would not be possible if all activities occurred in varying orders for different groups of students. It also makes assessment easier, as a single hand-in date is used for all students, and they all have the same amount of background to the topic.

- The capacity of the laboratory and scale of the teaching load justifies a dedicated member of teaching staff focusing on laboratory education. With attention focused exclusively on the pedagogy of teaching fluid mechanics using experimentation, without the need to divert attention to other academic tasks such as the writing of exams, delivering lectures or providing feedback for assignments etc., significant effort can be placed in professionalising the laboratory activities. Similarly, the volume of teaching provides considerable opportunities to learn from and refine teaching methodologies to make them as effective as possible.

The Fluids Engineering Laboratory in the Diamond has been operating since 2015. The subsequent period of delivery has allowed a great deal of expertise to be developed in the teaching of practical fluid mechanics classes. Presented here are four examples of lab classes that have been honed through many repeated instances of running the activities.

2. The Measurement Lab

This laboratory is taught to all engineering students as one of the first tasks they perform when arriving at the University (typically in the first or second week). It is designed to equip students with a healthy scepticism for the results displayed on instrumentation and a toolkit for dealing with the uncertainty inherent in all forms of experimentation. A hydraulic bench is connected to a fluidic circuit containing a series of flow measurement devices. Although, at this stage in their programmes, students will be unfamiliar with almost all fluid mechanics concepts, including those that underpin flow measurement, it is explicitly stated and reinforced throughout the teaching that the activity is about understanding and managing general experimental uncertainty. Part of the intention is to imply the universality of error and uncertainty of techniques for any experimental set up, even ones for which the concepts under investigation or the outcomes are unknown.

Despite the lack of technical understanding of fluid mechanics principles, it is reasonably straightforward to explain the concepts of the conservation of mass and, for an incompressible flow, conservation of the volume flow rate. Students are aware that they will be studying fluid mechanics as part of the engineering programmes and are keen to understand these basic concepts early as well as be introduced to real-world instrumentation that they may not have previously been exposed to in schools. As water passes from one device to another in series through the hydraulic circuit, it is evident to the students that the volume flow rate through each device must be identical. The students are tasked with predicting if the various devices will all record identical readings for the flow rate.

Prior to starting the activity, students are given a briefing and watch an instructional video discussing the methods for capturing uncertainty for various pieces of instrumentation, how to record it and how it can be propagated when raw data are processed. The activity involves applying these principles to unfamiliar equipment.

Students record raw data from the instrumentation: the heights from water columns attached to a Venturi meter and an orifice plate, the flow rate from a calibrated rotameter measuring in litres per minute and the timing of water collection using a measuring tank. In order to compare the measured flow rates, the raw data from each device need to be converted. This requires students to consider that, in order to compare, the same measuring unit is required for each device and provides an opportunity to discuss the relative merits of the more commonly used litres/minute over the S.I. unit of meters cubed per second. While UK students are often trained to habitually convert into S.I. units, there is little justification for doing so in this case, particularly as it eliminates the need to convert the results of the rotameter.

Students need to process the height difference between the water columns of the Venturi meter and the orifice plate into a flow rate, the physics of which will not yet be known to them. For the Venturi meter, a pre-prepared spreadsheet is provided, which outputs the flow rate when the water column heights are input. The spreadsheet solves Equation (1), which is provided to students to allow understanding of the mathematical relationship, but the process of manual calculation is not required. The spreadsheet provides the opportunity to repeatedly calculate different answers quickly and determine the relative impact of the uncertainty for different parameters. The square root function within this equation makes this process more interesting.

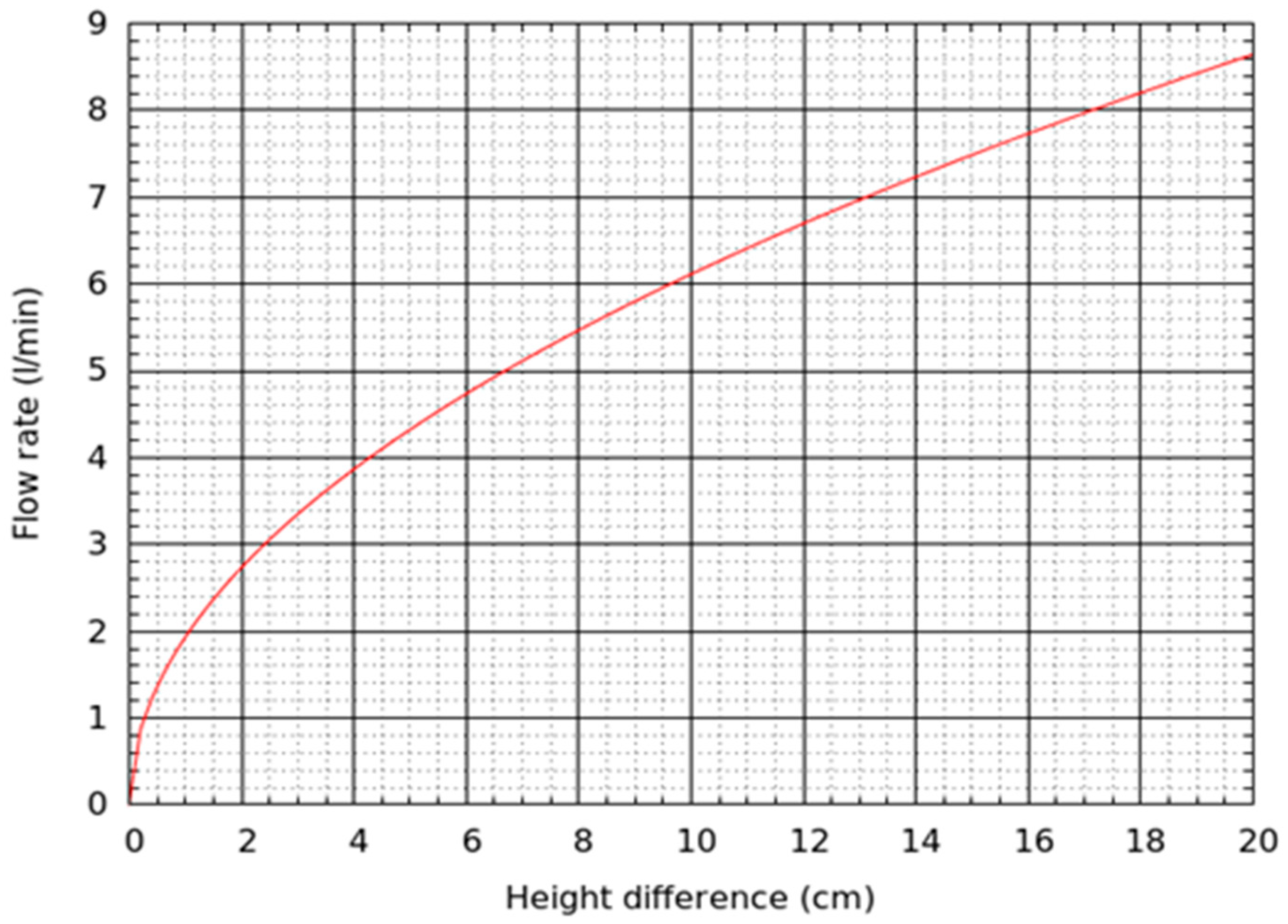

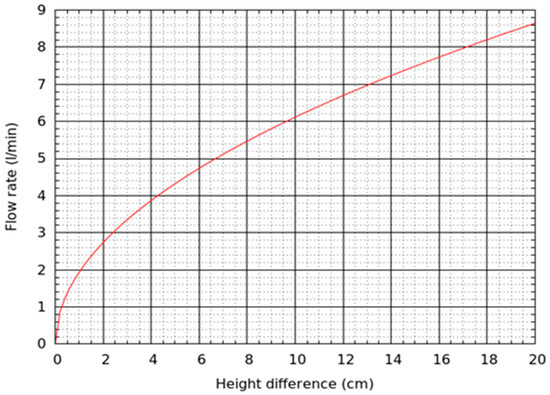

A calibration chart, shown in Figure 1, is provided to convert the raw data from the orifice plate. The process of reading and extrapolating results from the graph introduces additional uncertainty in processing the raw data, and students are encouraged to consider how to best incorporate this into their calculated flow rates. This facilitates an opportunity for students to become comfortable with a limited availability of precision in a calculation, which is a common occurrence in the application of practical engineering.

Figure 1.

Calibration chart for an orifice plate provided to students.

Students are guided through a process of calculating flow rates and the associated uncertainty of their results for the four flow measurement devices and then through a process of presenting this information graphically with an introduction to the concept of error bars. If conducted correctly, the results show that all the devices will record different values of the flow rate but, when the error bars are considered, all the results overlap within a certain region. Further discussion can be had about the methods for reducing uncertainty in the raw data and the advantages of in-line flow measurement compared to the volume displacement of the measuring tank.

This lab has been designed to achieve the specific learning outcomes of introducing the concepts of, methods to record and process for handling error and uncertainty in experimentation. Students are clearly made aware of this expectation and achieve these explicit learning outcomes as a result of participating in the activity. The same learning outcomes could have been achieved with a paper-based exercise, delivered outside a laboratory. However, the act of learning through doing is more likely to result in the concepts being retained by students and provides a real-world context in which to apply these skills in an engaging form that enhances the student experience.

As this activity is delivered to all undergraduate engineers, typically, in excess of 1000 students per year, the investment of time to develop high-quality instructional material and training teaching assistants is easily justified and makes the activity very resource efficient.

3. Pressure Loss in Pipes Lab

The pressure loss in horizontal pipes is measured in an experiment run in the Fluids Engineering Lab for Mechanical, Aerospace, Civil and Chemical Engineering students. This is an important part of the engineering curriculum [6]. The reuse of teaching material and equipment for multiple cohorts results in efficient resource utilization. However, teaching material is adapted and contextualized for specific degree programmes. Subject-specific nomenclature or units should be used appropriately for different engineering disciplines. For example, civil engineers would measure, record and process pressure in the units of meters of head, whereas aerospace engineers would typically use Pascals. In addition, the level of academic rigour and expectation for the students is adapted depending on the placement of the activity within the degree programme. At the University of Sheffield, mechanical engineering students perform the experiment in the first year, and civil engineering students, in the second. For civil engineers, less prescriptive instructions are provided, and more independence is expected while conducting the experiment.

During the experiment, the students will collect raw data from manometers to measure the pressure drop and a measuring tank to measure the flow rate. A range of different-diameter and roughness pipes are available on each of the 20 hydraulic benches. The raw data are processed into Reynolds numbers and empirically derived friction factors, allowing students to generate their own Moody diagram that can be compared to a published version. The objective of the laboratory experiment is not to develop expertise in performing the mathematics. Students are provided with a “guided calculation”, where the steps to process the raw data into a processed result are described in the instructions and executed by students on one piece of data, to ensure they understand the mathematical methods. Breaking each part of the calculation into defined steps makes the debugging of errors, by the students or teaching assistants, more straightforward, which is necessary when dealing with large class sizes. Once students have demonstrated they understand the process, a spreadsheet to automate the calculations on the remaining data points is released.

Mandating students to complete the hand calculation before using the spreadsheet opens the opportunity for discussion with students that perceive the activity to be a trivial task only required to access the spreadsheet. Performing the hand calculation and using a tool to perform the calculations allows a two-way validation of each process, by comparing the results from each. When using any tool that has been provided, it is wise to ensure it operates as expected. Articulating the general merit of a validation approach, and how it can be applied to a student’s future engineering tasks, can be used to place value on performing the task. In addition, digital collection allows an individual student’s data to be pooled into a larger dataset that can be shared with the cohort, for the purposes of error and reproducibility analysis.

Having multiple benches to support a large class size presents an opportunity to improve efficiency beyond the economy-of-scale issues previously described. In this experiment, to determine the influence of the pipe specimen (diameter and roughness) on the friction factor, multiple pipes should be investigated. With one hydraulic bench or a small number of hydraulic benches, pipes need to be installed and removed to test the full range. With as many benches as specimens, benches can be set up with particular specimens, and students can move around the laboratory to each piece of apparatus. Learning the procedure, executing it and performing the subsequent bleeding of air all consume student time and cognitive capacity in ways that do not directly relate to the intended learning.

As the students come into a session well prepared and the lectures on the subject are fresh in their minds, they do not require much assistance to conduct the laboratory. Hence, it can be taught by four staff (Academic, Technical and Teaching Assistants). These staff are able to spend the time discussing the work and providing feedback to the students, resulting in a much richer experience for everyone.

4. Weirs Big and Small Lab

One of the hardest fluid mechanics topics for students to understand is the importance and power of dimensional analysis. This is because there are a number of difficult concepts when contemplating scales, which can be simplified through the correct application of dimensionless numbers. These include the fact that experiments are needed to be able to obtain the constants for every geometry in a given situation. An understanding of dimensional analysis is needed for studying aerodynamics and heat transfer, but the teaching of it generally suffers from two deficiencies: firstly, students typically become very tangled up in the details of the subject rather than the method application, and secondly, almost all of the work and examples involve Reynolds numbers (as in the Pressure Loss in Pipes lab described above). Thus, an interesting approach to illuminating this topic has to have two requirements: not using Reynolds number and extracting some constants that are then applied to different scales of equipment. If it could be engaging, challenging and fun as well, that would be even better.

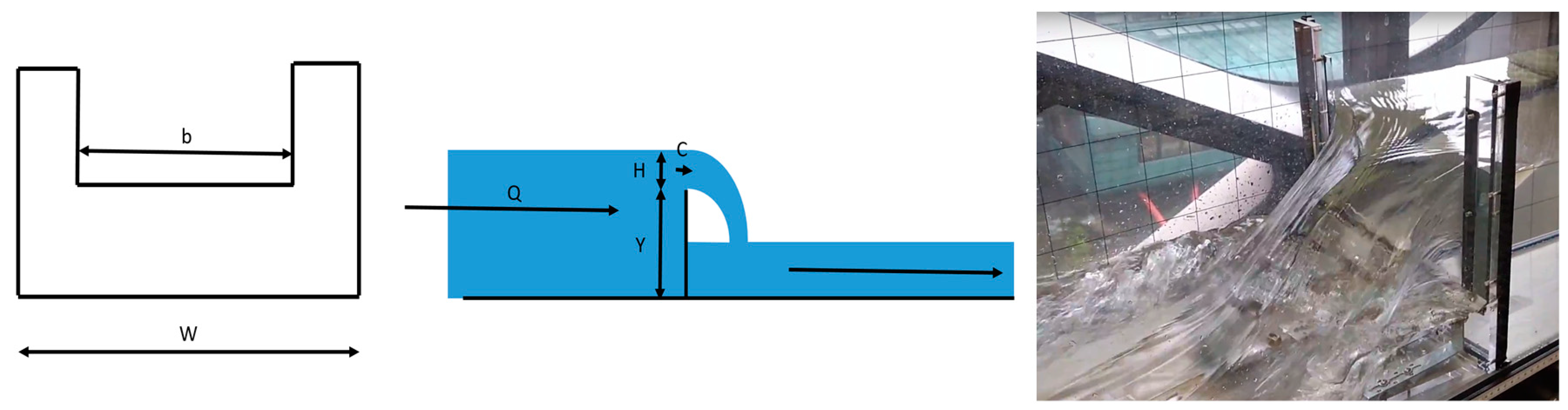

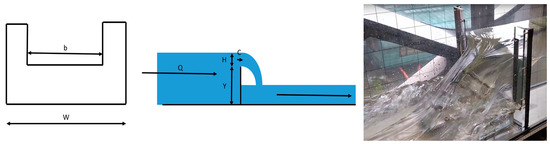

The hydraulic benches can be configured to allow students to perform open channel flow experiments with sharp-edged weir plates (square and triangular) and can measure the water height over the weir and water flow rate. The cohort for whom the lab was created are second year Mechanical Engineers whose curriculum does not contain free surface flow. This presents an ideal opportunity to introduce this topic to these students while showing the power of dimensionless groups. Students are shown, using the tools from their lectures (Buckingham π theory), that the dimensionless groups involved in this type of flow are the Froude number and length ratio , as shown in Figure 2, and that the volumetric flow rate (Q, m3·s−1) can be derived from Equation (2):

where is the discharge coefficient and must be experimentally ascertained for the given geometry. The objective of this experiment is to experimentally determine the discharge coefficient for the small weirs and see how this scales to a geometrically equivalent, larger weir that is installed in the lab’s 10 m flume. The main learning outcome of this activity is for students to be able to see both the power of dimensionless numbers and how extracting the constants experimentally is a required part of the process.

Figure 2.

Dimensions used in weir calculations and the experimental apparatus.

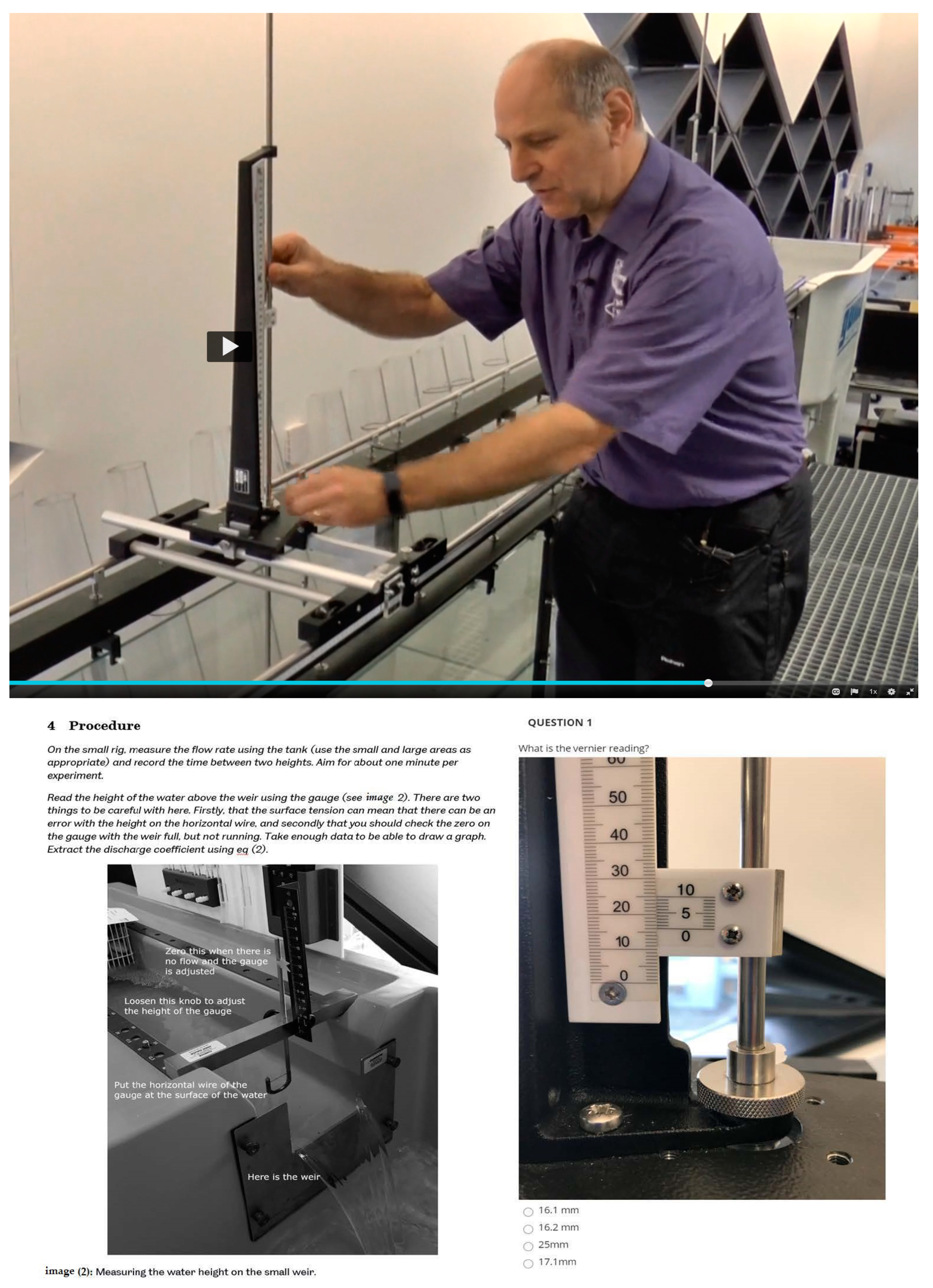

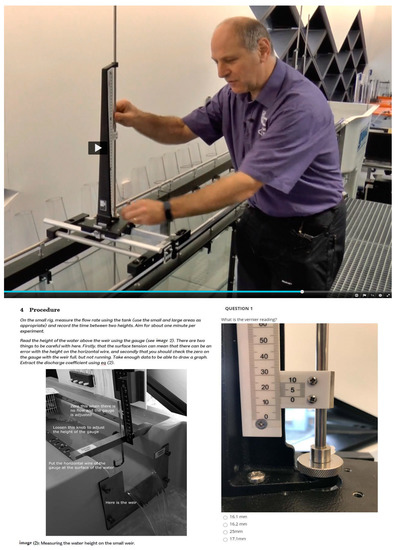

In order to optimise the time students spend in the laboratory, a comprehensive pre-experimental activity was created, material from which can be seen in Figure 3. This consisted of a series of presentations. These were either recorded with overheads and voiceovers for theory (the flow over weirs, which Mechanical Engineers do not cover as part of their course). Another online lecture on fitting exponentials to a series of x and y data was created to help students understand one way of turning experimental data into equations, which they need to do to extract the constants in this experiment. Short quizzes created in the Virtual Learning Environment using adaptive release ensure that the students engage with each presentation prior to moving on to a subsequent section. The students are presented with three videos on using the large flume, operating the small flow rigs and reading the Vernier scale on the large flume. This culminates in a quiz on reading the Vernier and finally a compulsory test on Health and Safety issues relevant to the experiment and laboratory space. The use of adaptive release means that students cannot get to the final test without completing all the previous ones.

Figure 3.

Examples of instructional material, including pre-experimental videos, provided to students.

This preparation works well. Students move on very quickly to the practical experiment. As required, they calculate the on the small rigs from the flow and height measurements they recorded. For each session, the laboratory leader sets a different flow rate for the large flume, and the students predict the height above the weir that the water should reach before they measure it. This, in effect, gamifies the lab, as they are ascertaining their own experimental accuracy and are able to compare it with their peers’. They are thus able to grasp the power and value of dimensionless numbers and scaling in engineering. It shows them that methods such as the Buckingham π theory are merely tools to be used to solve real problems. It also illuminates the way that researchers need to use experiments to be able to create a set of results to identify and extract generalities. It is also a good way to use our facilities, as they only perform a single experiment on the large, unique rig but can perform a large number on the multiple small rigs.

By the end of the experiment, it was noted that the students appreciated how it was possible to scale between different sizes of models, but how one needed to be aware of all the important parameters. In a more general sense, the intellectual understanding that this journey provides through models and sizes acts as a conceptual bridge towards a better understanding of the dimensionless numbers that they will use in their fluid mechanics and thermodynamics careers and education.

5. Spillway Design Lab

Teaching large cohorts presents a tension: investing significant resources in activities that can be reused by many students is efficient and provides a high-quality, professional laboratory experience, but prescribed activities can limit the opportunity for students to explore open-ended activities and, for example, learn through failure. This tension can be partially overcome with the application of a multidisciplinary approach. Within MEE’s portfolio of practical engineering education is manufacturing and fabrication. This provides a holistic integration of making that is available to staff and students.

With significant manufacturing capability, department-based workshop staff and tools, in-house builds of bespoke teaching equipment are feasible. Typically, engineering teaching equipment for use with students would have been bought from suppliers. The two significant downsides of this approach are that it is extremely expensive compared to an in-house build (if full-time staff time for design, fabrication and prototyping is excluded) and the equipment is not designed to achieve specific learning outcomes.

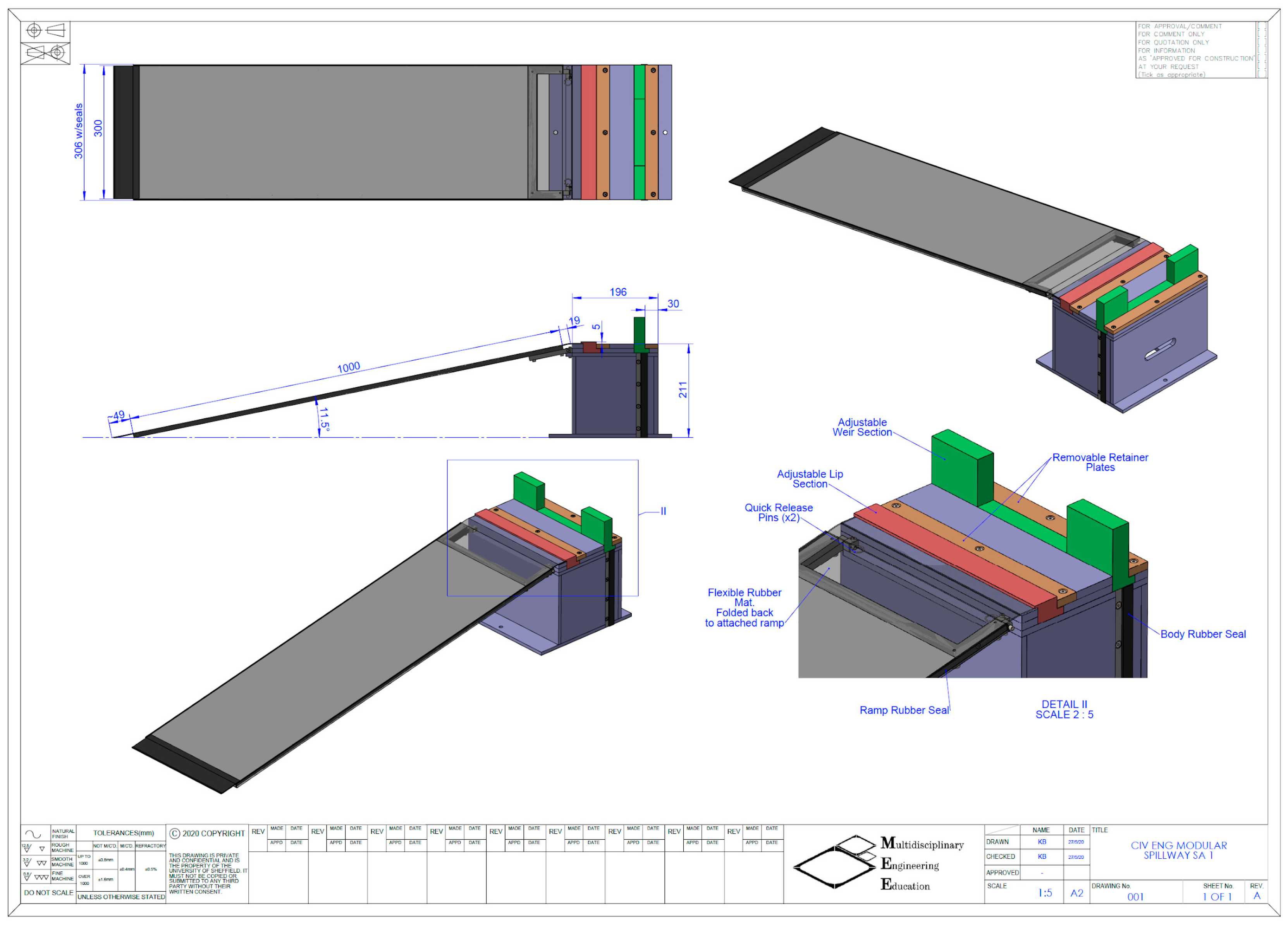

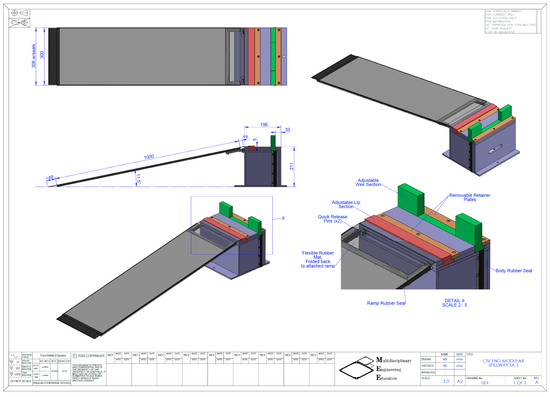

Unlike their Mechanical counterparts, second year Civil Engineering students study open channel flow and the design of flow control devices during their second semester. As they are reasonably advanced students, having been prescriptively taught the fundamentals of operating in a laboratory environment in preceding years, their practical activities are designed to be conducted independently, open ended and genuinely experimental, i.e., conducting empirical work to discover something previously unknown. To achieve these outcomes, a bespoke experimental rig was conceived, as shown in Figure 4.

Figure 4.

Bespoke rig for teaching spillway design.

The teaching of design principles is outside the remit of a fluid mechanics course, but a holistic approach to a programme can be used to apply previously learned design principles to the design of a weir and spillway to fulfil specific problem specifications. As such, the bespoke rig was designed to provide a constrained number of parameters that can be adjusted. Designated adjustable parts can be fabricated by students using readily available equipment, such as laser cutters or 3D printers, and inserted into the rig for testing in the fluids lab flume. Students are expected to design their adjustable parts based on theory delivered during lectures, predict the flow and test their predictions in the laboratory.

Prior to being given access to the flume, students are provided with extensive equipment and Health and Safety training to be allowed access to the laboratory without staff supervision. Compliance is established with online tests, and keys to the room/equipment are provided by reception staff who check for completion of the test. Students are able to book use of the equipment at a time convenient to them, and academic staff time input is minimised. This approach provides students with an opportunity to exert agency over their own learning.

Without a dedicated team of staff focused on providing students with an exemplary practical experience and the multidisciplinary team of academics and technicians working collaboratively, the development of practical teaching and bespoke equipment that is unobtainable from suppliers would be significantly more difficult for departments to justify resourcing.

6. Discussion and Conclusions

Historically, fluid mechanics laboratories have been run as a type of cottage industry, with lecturers specifying and delivering a couple of labs across the year on a single piece or possibly a couple of pieces of equipment. This meant that students could receive this laboratory at any time over a year. Each experiment had to be free standing; many students would conduct the experiment long before or after they were introduced to the theory, missing a crucial window for learning reinforcement. This meant that different students would, in effect, obtain different learning outcomes depending on their understanding of the background to the topic. The staff members responsible for the delivery of the lectures, tutorials, exams etc. set their own labs; they tended to be similar in difficulty, scope and assessment (usually a report). There was no coherence or progression along the course and, without the capacity to focus exclusively on the laboratory activities, very little in the way of designing teaching with constructive alignment towards the overall learning objectives.

MEE’s multidisciplinary approach of professionalising and integrating the practical experience of the students allows many of these common issues to be obviated. The scale of the laboratories allows entire cohorts to perform an experiment in a short time period so that practical and theoretical work can be interwoven and used to support each other. In many cases, the formal lecture becomes the introduction to the laboratory. Many Electrical Engineering departments have rooms set up with multiples of equipment, but this approach is rare outside engineering. Having dedicated staff who deliver the only practical experience to a cohort, it is possible to curate an entire, progressive student experience starting from the closed and didactic (such as the Measurement Lab) and progressing to open-ended investigations such as the Spillway Design Lab. The result is that students receive an integrated and progressive learning experience culminating, after their first two years, in them becoming capable, reflective and autonomous experimenters ready to start independent project work.

As well as the efficient use of space and staff time, the experiments form a portfolio of work that can be renewed and repurposed as and when required. For example, within weeks of the creation (and delivery) of the Weirs laboratory, a lecturer from Civil Engineering asked if there was a laboratory for open channel flow for their MSc students. Not only was the answer “yes”, but a version of all of the teaching and introductory material was ready for use. The laboratory sheet only needed updating to reflect the different approach to the theory and nomenclature used by a different discipline, but this was a minor investment of time and allowed the students to have an excellent practical experience to support their learning that would have been impossible under a different organisation.

There are, however, two potential drawbacks to the multidisciplinary approach, but these can be ameliorated if properly anticipated. Firstly, when the practical and theoretical teaching on a single module is delivered independently by different members of staff in different departments, the experience and messaging received by the students could become disconnected and incoherent. MEE overcomes these issues by setting up communication channels between the academics delivering classroom and practical teaching, allowing them to agree on how the labs are presented within the context of a module and ensure that the messaging to students is consistent. The tactics for achieving this include using material presented in lectures as part of laboratory tuition and vice versa. Secondly, there is a requirement for strong leadership within the faculty. The multidisciplinary model will only work if all the departments benefiting from the service agree to contribute to its resourcing. With any shared resource, issues of perceived value and equity for contributors can cause tension if not carefully managed.

Thus, in conclusion, there are a number of major advantages to teaching at scale in fluids laboratories, such as the efficiency, temporal proximity to lectures and scalability. Due to the integration and professionalisation of the practical teaching, it allows an integrated, progressive approach to student practical skills development to be implemented. Progressing from the usual method of teaching practical fluid mechanics to the new one demonstrated in the examples above is a difficult, long and potentially extremely expensive journey. We hope that we have shown you that the outcomes from it are worthwhile.

Author Contributions

Conceptualization, S.B., A.G. and K.B.; Methodology, S.B., A.G. and K.B.; writing—review and editing, S.B., A.G. and K.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chowdhury, H.; Alam, F.; Mustary, I. Development of an innovative technique for teaching and learning of laboratory experiments for engineering courses. Energy Procedia 2019, 160, 806–811. [Google Scholar] [CrossRef]

- Garrard, A.; Beck, S.B.M. Pedagogical and cost advantages of a multidisciplinary approach to delivering practical teaching. In The Interdisciplinary Future of Engineering Education Breaking Through Boundaries in Teaching and Learning; Kapranos, P., Ed.; Routledge: Abingdon, UK, 2018. [Google Scholar]

- Goodwin-Jones, J.; Nortcliffe, A.; Vernon-Parry, K. What does good engineering laboratory pedagogy look like? In Proceedings of the 44th Annual Conference of the European Society for Engineering Education—Engineering Education on Top of the World: Industry-University Cooperation, SEFI 2016, Tampere, Finland, 12–15 September 2016; SEFI: Brussels, Belgium, 2016. [Google Scholar]

- Hofstein, A.; Lunetta, V. The role of the laboratory in science teaching. Rev. Educ. Res. 1982, 54, 201–217. [Google Scholar] [CrossRef]

- Hesketh, R.P.; Farrell, S.; Stewart Slater, C. The Role of Experiments in Inductive Learning. In Proceedings of the 2002 American Society for Engineering Education Annual Conference & Education Conference, Session M4C, San Diego, CA, USA, 16–19 June 2002; p. 3613. [Google Scholar]

- Krestae, S.M. Hands-on Demonstrations: An Alternative to Full Scale Lab Experiments. J. Eng. Educ. 2013, 87, 7–9. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).