An Image-Based Technique for Measuring Velocity and Shape of Air Bubbles in Two-Phase Vertical Bubbly Flows

Abstract

1. Introduction

2. Methodology

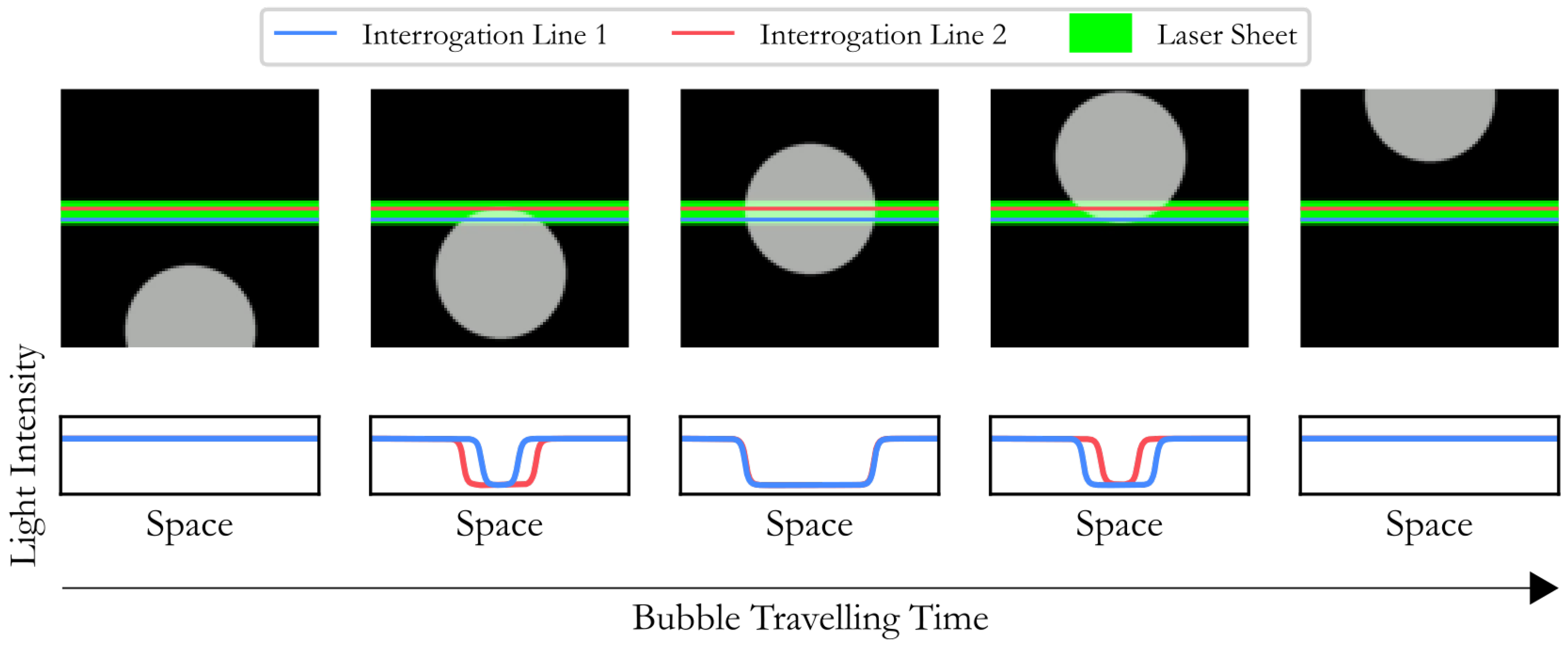

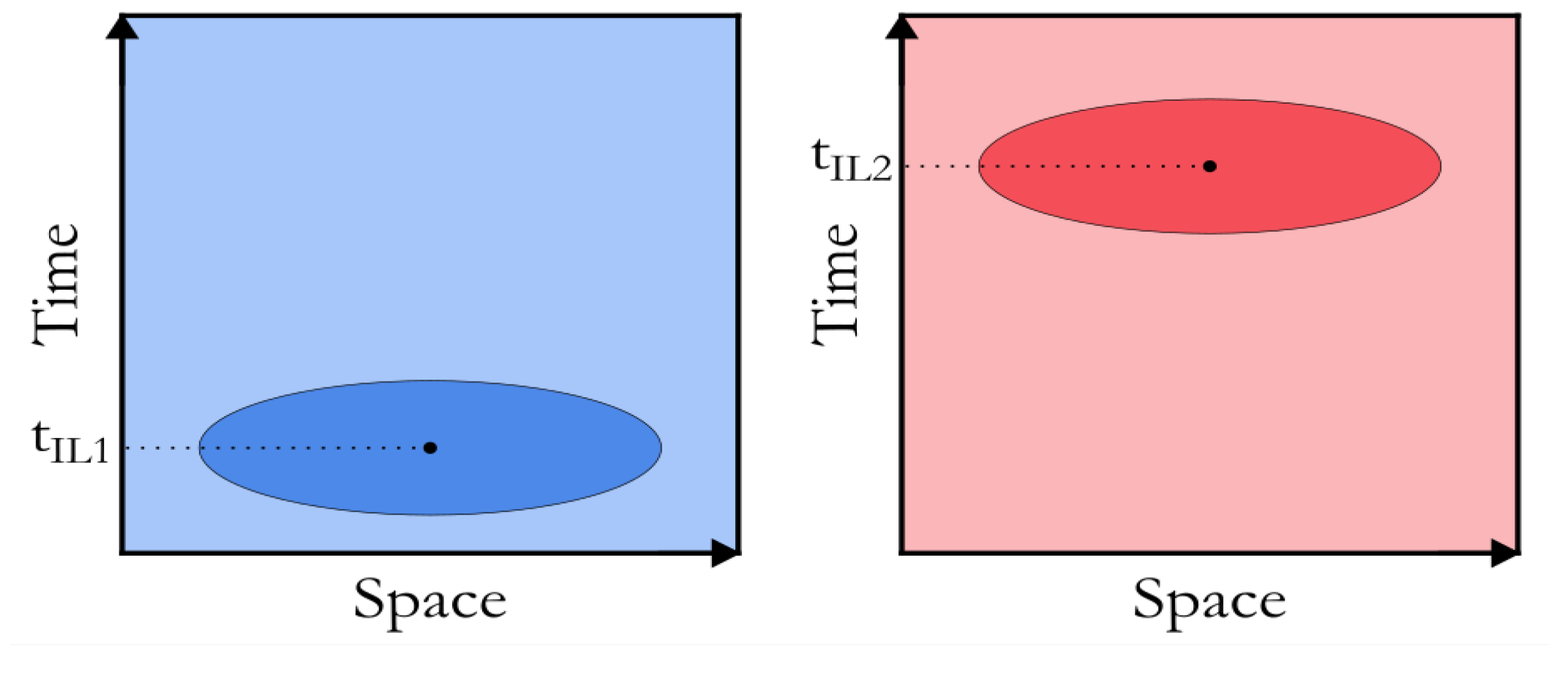

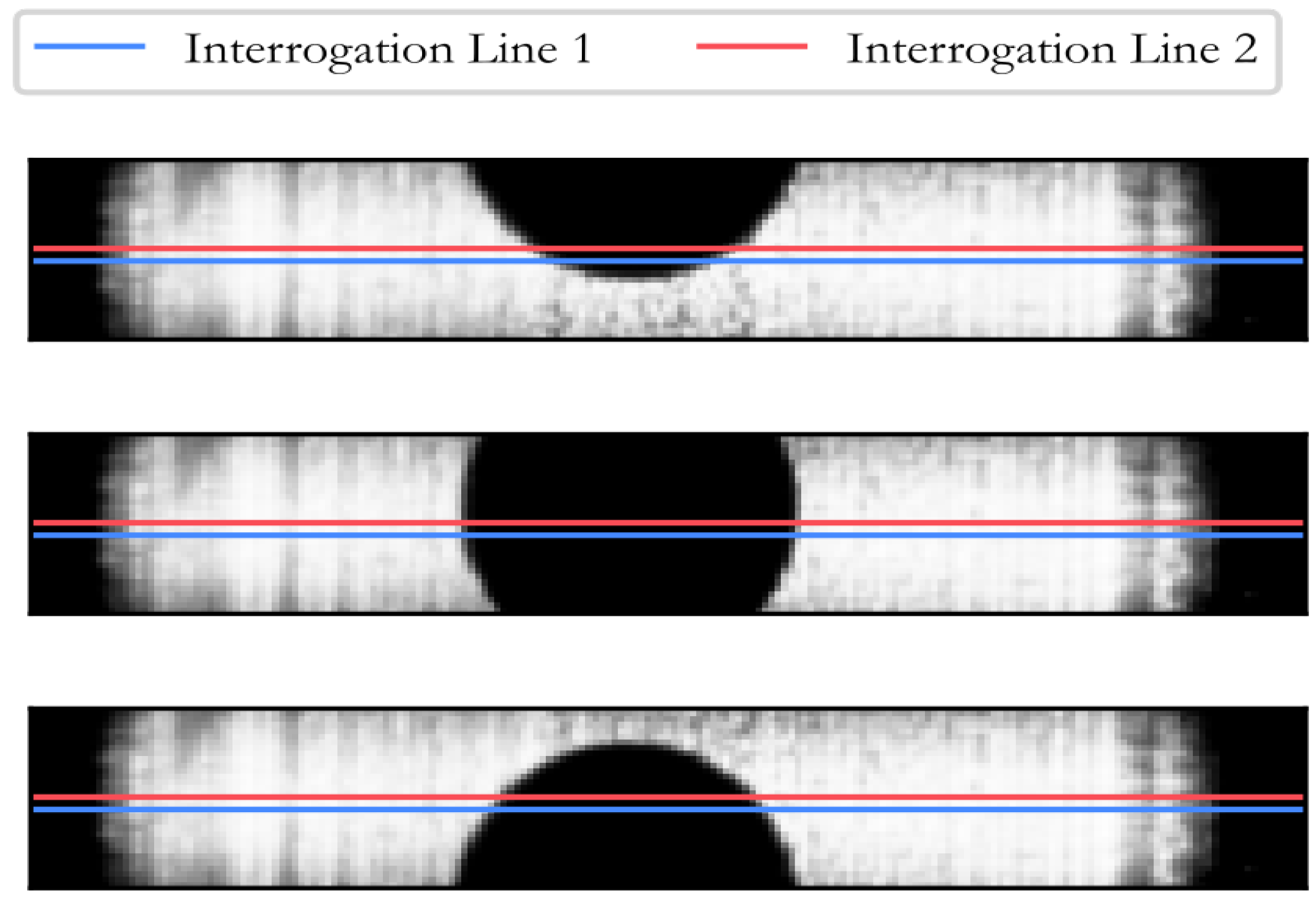

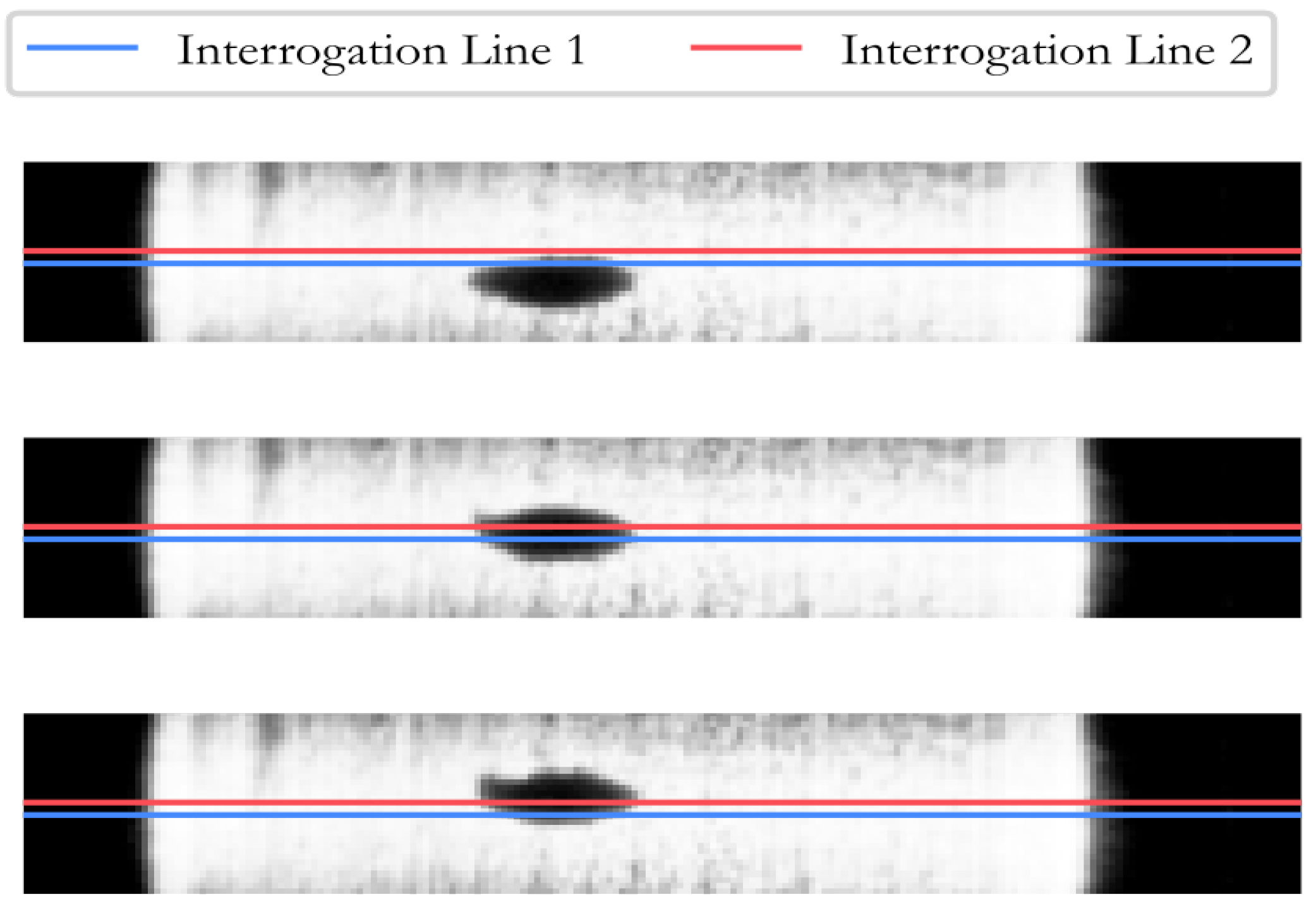

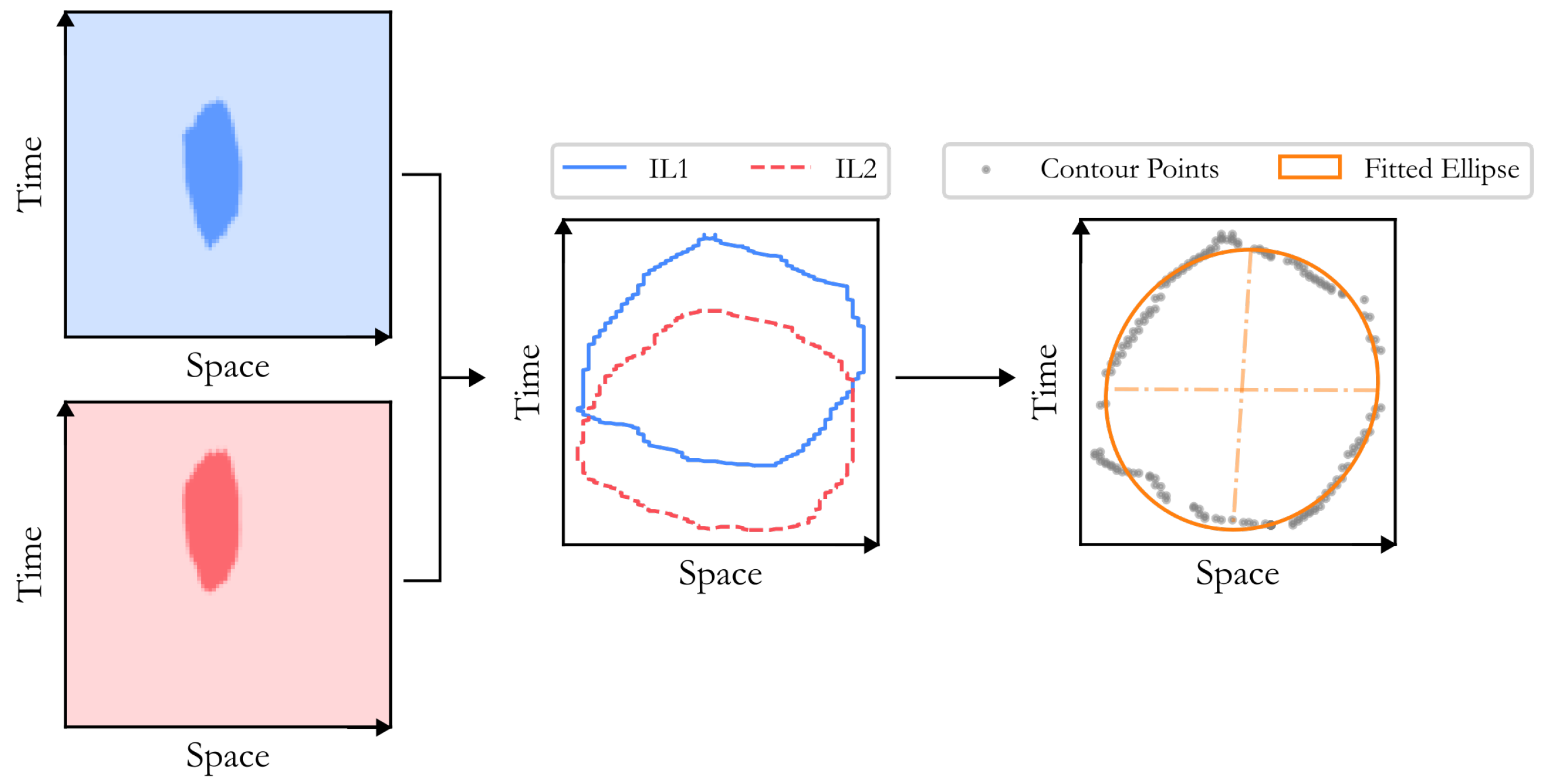

2.1. Bubble Matching

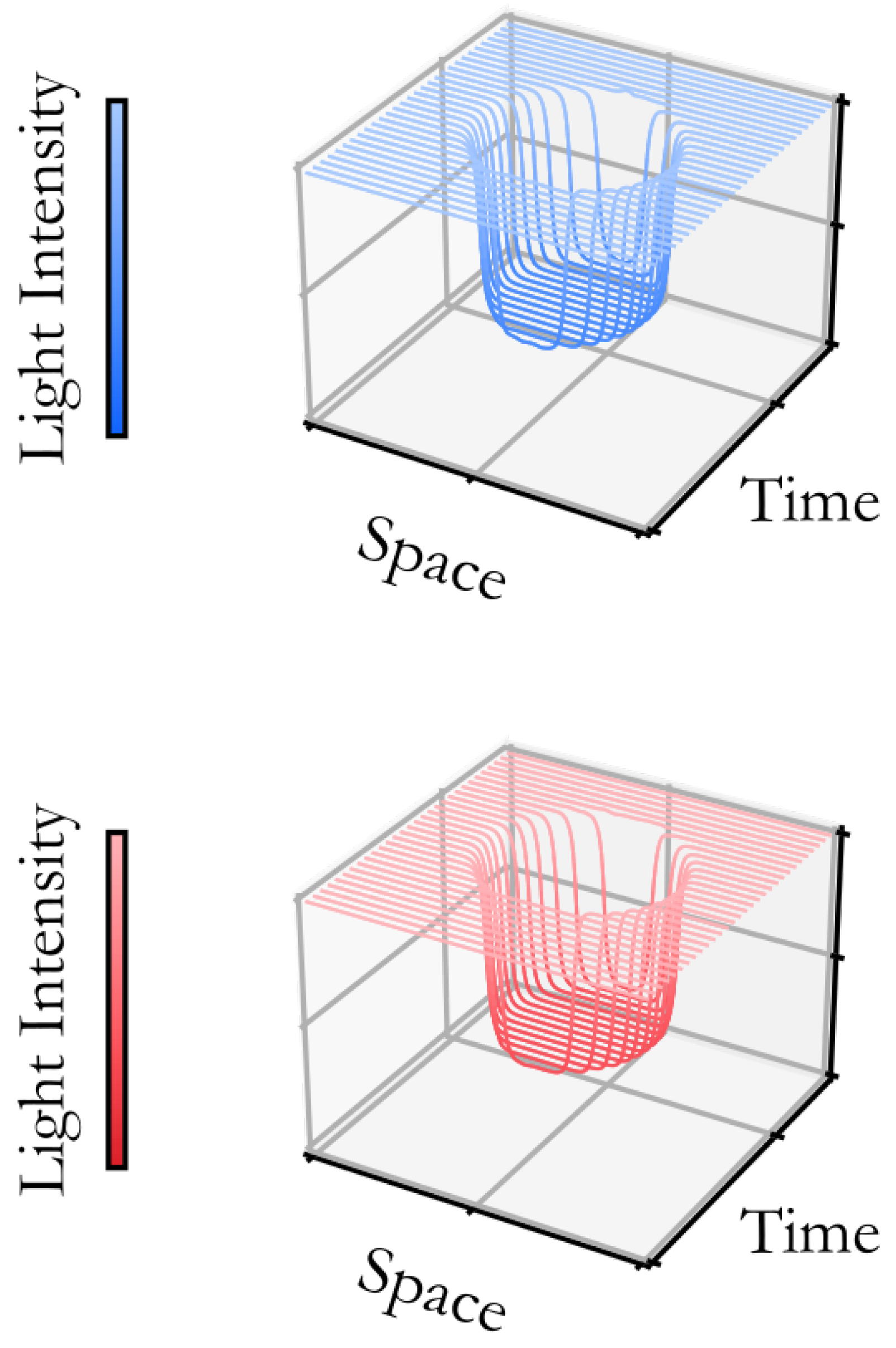

2.2. Measuring the Velocity of the Bubble

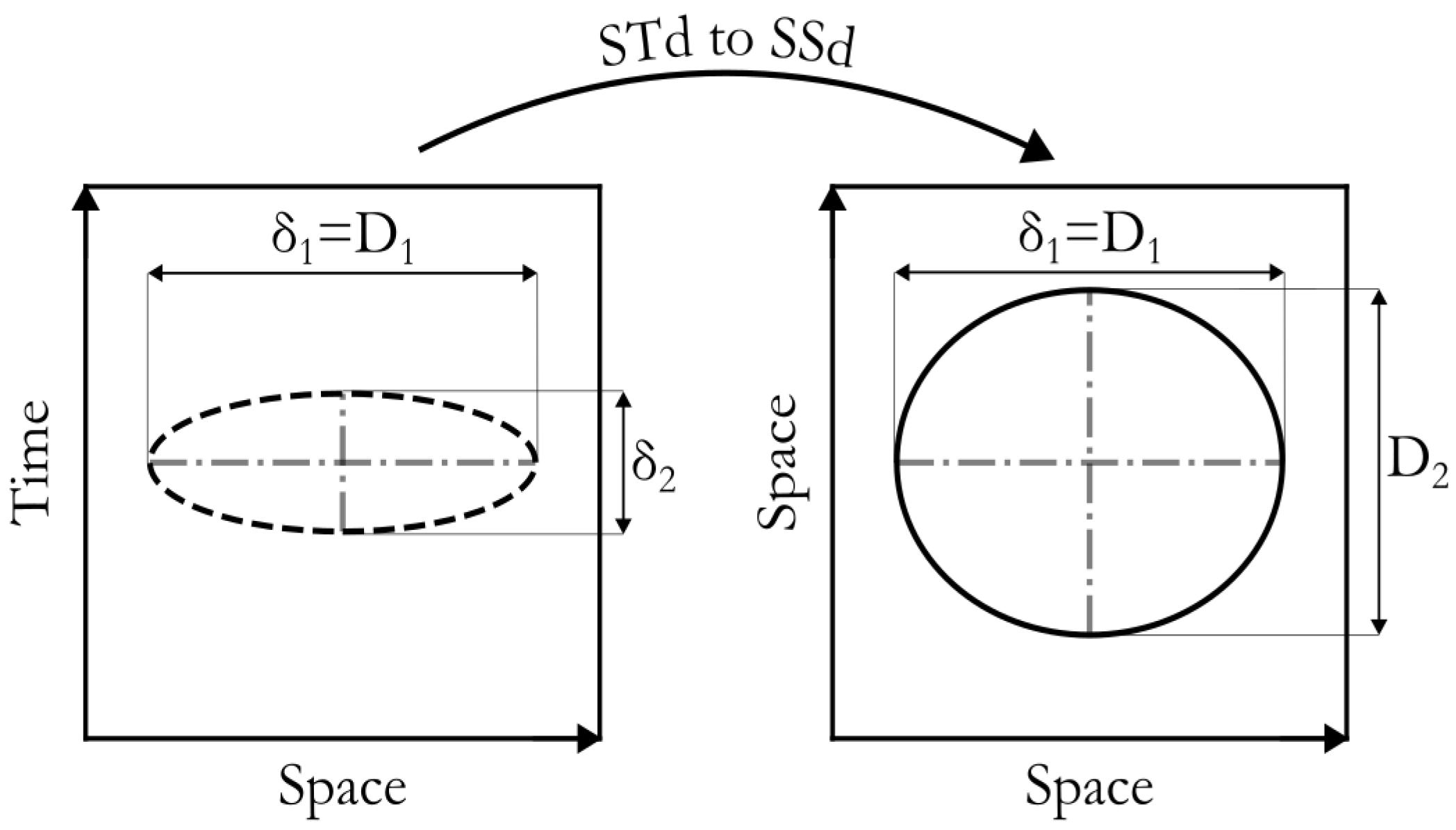

2.3. Reconstructing Shape and Volume of the Bubble

3. Materials and Methods

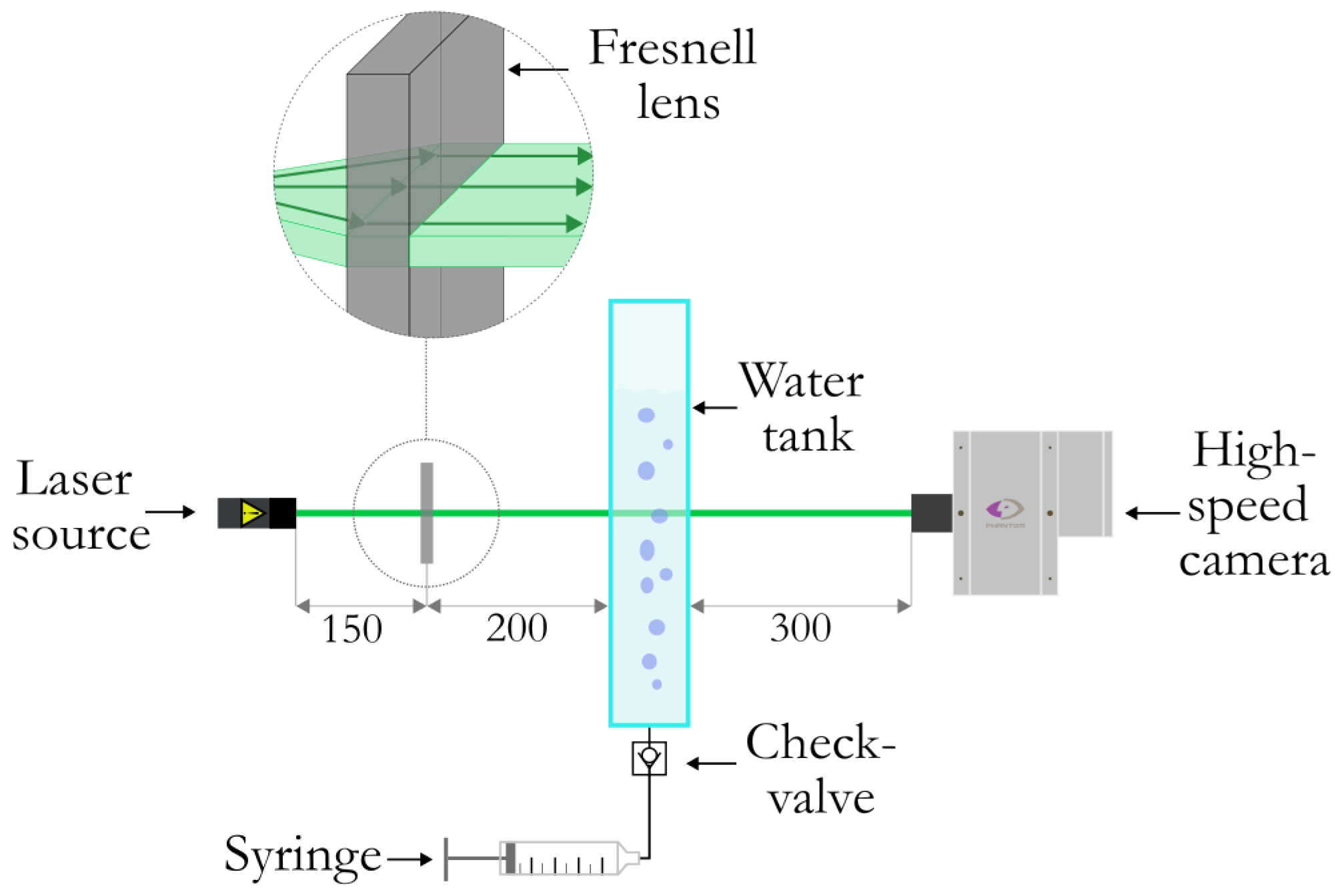

3.1. Measurement Setup

3.2. Experimental Campaign

4. Results and Discussions

4.1. Reference on Velocity and Volume

4.2. Application on Bubbly Flow

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akashi, M.; Keplinger, O.; Shevchenko, N.; Anders, S.; Reuter, M.A.; Eckert, S. X-ray radioscopic visualization of bubbly flows injected through a top submerged lance into a liquid metal. Metall. Mater. Trans. B 2020, 51, 124–139. [Google Scholar] [CrossRef]

- Tentner, A.; Lo, S.; Ioilev, A.; Samigulin, M.; Ustinenko, V. Computational fluid dynamics modeling of two-phase flow in a boiling water reactor fuel assembly. In Proceedings of the International Conference on Mathematics and Computations, American Nuclear Society, Avignon, France, 12–15 September 2005; pp. 12–15. [Google Scholar]

- Nedeltchev, S. New methods for flow regime identification in bubble columns and fluidized beds. Chem. Eng. Sci. 2015, 137, 436–446. [Google Scholar] [CrossRef]

- Shaikh, A.; Al-Dahhan, M.H. A review on flow regime transition in bubble columns. Int. J. Chem. React. Eng. 2007, 5. [Google Scholar] [CrossRef]

- Mi, Y.; Ishii, M.; Tsoukalas, L. Flow regime identification methodology with neural networks and two-phase flow models. Nucl. Eng. Des. 2001, 204, 87–100. [Google Scholar] [CrossRef]

- Akita, K.; Yoshida, F. Bubble size, interfacial area, and liquid-phase mass transfer coefficient in bubble columns. Ind. Eng. Chem. Process. Des. Dev. 1974, 13, 84–91. [Google Scholar] [CrossRef]

- Mohanty, R.L.; Das, M.K. A critical review on bubble dynamics parameters influencing boiling heat transfer. Renew. Sustain. Energy Rev. 2017, 78, 466–494. [Google Scholar] [CrossRef]

- Ellingsen, K.; Risso, F. On the rise of an ellipsoidal bubble in water: Oscillatory paths and liquid-induced velocity. J. Fluid Mech. 2001, 440, 235–268. [Google Scholar] [CrossRef]

- Chen, L.; Garimella, S.V.; Reizes, J.A.; Leonardi, E. The development of a bubble rising in a viscous liquid. J. Fluid Mech. 1999, 387, 61–96. [Google Scholar] [CrossRef]

- Calderbank, P.; Lochiel, A. Mass transfer coefficients, velocities and shapes of carbon dioxide bubbles in free rise through distilled water. Chem. Eng. Sci. 1964, 19, 485–503. [Google Scholar] [CrossRef]

- Besagni, G.; Inzoli, F. Comprehensive experimental investigation of counter-current bubble column hydrodynamics: Holdup, flow regime transition, bubble size distributions and local flow properties. Chem. Eng. Sci. 2016, 146, 259–290. [Google Scholar] [CrossRef]

- Besagni, G.; Brazzale, P.; Fiocca, A.; Inzoli, F. Estimation of bubble size distributions and shapes in two-phase bubble column using image analysis and optical probes. Flow Meas. Instrum. 2016, 52, 190–207. [Google Scholar] [CrossRef]

- Lage, P.; Espósito, R. Experimental determination of bubble size distributions in bubble columns: Prediction of mean bubble diameter and gas hold up. Powder Technol. 1999, 101, 142–150. [Google Scholar] [CrossRef]

- Khan, I.; Wang, M.; Zhang, Y.; Tian, W.; Su, G.; Qiu, S. Two-phase bubbly flow simulation using CFD method: A review of models for interfacial forces. Prog. Nucl. Energy 2020, 125, 103360. [Google Scholar] [CrossRef]

- Neogi, A.; Mohanta, H.K.; Sande, P.C. Particle image velocimetry investigations on multiphase flow in fluidized beds: A review. Flow Meas. Instrum. 2023, 89, 102309. [Google Scholar] [CrossRef]

- Bakshi, A.; Altantzis, C.; Bates, R.B.; Ghoniem, A.F. Multiphase-flow Statistics using 3D Detection and Tracking Algorithm (MS3DATA): Methodology and application to large-scale fluidized beds. Chem. Eng. J. 2016, 293, 355–364. [Google Scholar] [CrossRef]

- Falcone, G. Key multiphase flow metering techniques. Dev. Pet. Sci. 2009, 54, 47–190. [Google Scholar]

- Reimann, J.; Kusterer, H.; John, H. Two-phase mass flow rate measurements with Pitot tubes and density measurements. In Proceedings of the Measuring Techniques in Gas-Liquid Two-Phase Flows: Symposium, Nancy, France, 5–8 July 1983; Springer: Berlin/Heidelberg, Germany, 1984; pp. 625–650. [Google Scholar]

- Meribout, M.; Azzi, A.; Ghendour, N.; Kharoua, N.; Khezzar, L.; AlHosani, E. Multiphase flow meters targeting oil & gas industries. Measurement 2020, 165, 108111. [Google Scholar]

- Vatanakul, M.; Zheng, Y.; Couturier, M. Application of ultrasonic technique in multiphase flows. Ind. Eng. Chem. Res. 2004, 43, 5681–5691. [Google Scholar] [CrossRef]

- Tan, C.; Murai, Y.; Liu, W.; Tasaka, Y.; Dong, F.; Takeda, Y. Ultrasonic Doppler technique for application to multiphase flows: A review. Int. J. Multiph. Flow 2021, 144, 103811. [Google Scholar] [CrossRef]

- Bekraoui, A.; Hadjadj, A. Thermal flow sensor used for thermal mass flowmeter. Microelectron. J. 2020, 103, 104871. [Google Scholar] [CrossRef]

- Ashwood, A.; Hogen, S.V.; Rodarte, M.; Kopplin, C.; Rodríguez, D.; Hurlburt, E.; Shedd, T. A multiphase, micro-scale PIV measurement technique for liquid film velocity measurements in annular two-phase flow. Int. J. Multiph. Flow 2015, 68, 27–39. [Google Scholar] [CrossRef]

- Cerqueira, R.; Paladino, E.; Ynumaru, B.; Maliska, C. Image processing techniques for the measurement of two-phase bubbly pipe flows using particle image and tracking velocimetry (PIV/PTV). Chem. Eng. Sci. 2018, 189, 1–23. [Google Scholar] [CrossRef]

- Yang, Y.; Jia, J. An image reconstruction algorithm for electrical impedance tomography using adaptive group sparsity constraint. IEEE Trans. Instrum. Meas. 2017, 66, 2295–2305. [Google Scholar] [CrossRef]

- Aliseda, A.; Heindel, T.J. X-ray flow visualization in multiphase flows. Annu. Rev. Fluid Mech. 2021, 53, 543–567. [Google Scholar] [CrossRef]

- Tan, C.; Jia, H.; Liang, G.; Wang, X.; Niu, W.; Dong, F. Combinational multi-modality tomography system for industrial multiphase flow imaging. IEEE Trans. Instrum. Meas. 2023, 72, 4506610. [Google Scholar] [CrossRef]

- Tan, C.; Zhang, Z.; Liu, H.; Fu, R.; Yang, G.; Dong, F. Ultrasonic phased array process tomography system for multiphase medium imaging. IEEE Trans. Instrum. Meas. 2023, 72, 4503810. [Google Scholar] [CrossRef]

- Yao, J.; Takei, M. Application of process tomography to multiphase flow measurement in industrial and biomedical fields: A review. IEEE Sens. J. 2017, 17, 8196–8205. [Google Scholar] [CrossRef]

- Leppinen, D.; Dalziel, S. A light attenuation technique for void fraction measurement of microbubbles. Exp. Fluids 2001, 30, 214–220. [Google Scholar] [CrossRef]

- Rana, K.; Agrawal, G.; Mathur, J.; Puli, U. Measurement of void fraction in flow boiling of ZnO–water nanofluids using image processing technique. Nucl. Eng. Des. 2014, 270, 217–226. [Google Scholar] [CrossRef]

- Liu, J.; Xue, T. Investigation on influencing factors of film bubbles in vertical upward annular flow based on fluorescence imaging. IEEE Trans. Instrum. Meas. 2022, 71, 5021309. [Google Scholar] [CrossRef]

- Xue, T.; Xu, L.; Wang, Q.; Wu, B.; Huang, J. A 3-D reconstruction method of dense bubbly plume based on laser scanning. IEEE Trans. Instrum. Meas. 2019, 69, 2145–2154. [Google Scholar] [CrossRef]

- Mithran, N.; Muniyandi, V. IR transceiver irradiation characteristics on bubble/slug flow regimes in conventional and minichannels. IEEE Trans. Instrum. Meas. 2018, 68, 240–249. [Google Scholar] [CrossRef]

- Guet, S.; Fortunati, R.V.; Mudde, R.F.; Ooms, G. Bubble velocity and size measurement with a four-point optical fiber probe. Part. Part. Syst. Charact. Meas. Descr. Part. Prop. Behav. Powders Other Disperse Syst. 2003, 20, 219–230. [Google Scholar] [CrossRef]

- Li, X.; Yang, C.; Yang, S.; Li, G. Fiber-optical sensors: Basics and applications in multiphase reactors. Sensors 2012, 12, 12519–12544. [Google Scholar] [CrossRef]

- Rossi, G. Error analysis based development of a bubble velocity measurement chain. Flow Meas. Instrum. 1996, 7, 39–47. [Google Scholar] [CrossRef]

- Rossi, G. A new intensity modulation based fiber optic probe for bubble shape detection, velocity, and diameter measurements. Rev. Sci. Instrum. 1996, 67, 2541–2544. [Google Scholar] [CrossRef]

- Real, R.; Vargas, J.M. The probabilistic basis of Jaccard’s index of similarity. Syst. Biol. 1996, 45, 380–385. [Google Scholar] [CrossRef]

- Teague, M.R. Image analysis via the general theory of moments. Josa 1980, 70, 920–930. [Google Scholar] [CrossRef]

- ISO. Guide to the Expression of Uncertainty in Measurement; Aenor: Madrid, Spain, 1993. [Google Scholar]

| [mm] | [mm] | V | v [m/s] | |

|---|---|---|---|---|

| Test 1 | 14.658 | 14.710 | 1660.8 | 1.786 |

| Test 2 | 15.014 | 14.687 | 1733.4 | 1.786 |

| Test 3 | 15.170 | 14.681 | 1768.9 | 1.786 |

| Test 4 | 15.264 | 14.628 | 1784.6 | 1.786 |

| Test 5 | 14.858 | 14.754 | 1705.4 | 1.786 |

| 14.993 | 14.692 | 1730.6 | 1.786 | |

| 0.21 | 0.04 | 44.6 | 0.000 | |

| REF | 15 | 15 | 1767 | 1.715 |

| u (REF) | 0.005 | 0.005 | 0.3 | 0.006 |

| [%] | 1.24 | 2.05 | 2.5 | 4.09 |

| Test | Reconstructed Volume [mL] |

|---|---|

| Test 1 | 5.37 |

| Test 2 | 5.86 |

| Test 3 | 5.18 |

| 5.47 | |

| 0.28 | |

| REF | 5 |

| [%] | 9.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tribbiani, G.; Capponi, L.; Tocci, T.; Mengoni, M.; Marrazzo, M.; Rossi, G. An Image-Based Technique for Measuring Velocity and Shape of Air Bubbles in Two-Phase Vertical Bubbly Flows. Fluids 2025, 10, 69. https://doi.org/10.3390/fluids10030069

Tribbiani G, Capponi L, Tocci T, Mengoni M, Marrazzo M, Rossi G. An Image-Based Technique for Measuring Velocity and Shape of Air Bubbles in Two-Phase Vertical Bubbly Flows. Fluids. 2025; 10(3):69. https://doi.org/10.3390/fluids10030069

Chicago/Turabian StyleTribbiani, Giulio, Lorenzo Capponi, Tommaso Tocci, Martina Mengoni, Marco Marrazzo, and Gianluca Rossi. 2025. "An Image-Based Technique for Measuring Velocity and Shape of Air Bubbles in Two-Phase Vertical Bubbly Flows" Fluids 10, no. 3: 69. https://doi.org/10.3390/fluids10030069

APA StyleTribbiani, G., Capponi, L., Tocci, T., Mengoni, M., Marrazzo, M., & Rossi, G. (2025). An Image-Based Technique for Measuring Velocity and Shape of Air Bubbles in Two-Phase Vertical Bubbly Flows. Fluids, 10(3), 69. https://doi.org/10.3390/fluids10030069