Abstract

Plasma from electric discharges can be used in the abatement of volatile organic compounds (VOCs). The application of gas-phase pulsed corona discharge (PCD) in air–water mixtures provides favorable conditions for the oxidation of VOCs at unsurpassed energy efficiency. This research investigates the impact of water sprinkling on PCD performance in the oxidation of m-xylene as a model compound. Experimental research into the plasma treatment of continuous air flow was undertaken using the PCD reactor in dry and water-sprinkled modes. Water sprinkling more than doubled the m-xylene oxidation rate, which can be attributed to abundant OH-radicals produced at the plasma–water interface. Water sprinkling substantially reduced the formation of nitrous oxide, which is considered to be a secondary pollutant in the outlet air. Ozone is considered a by-product helping the subsequent photocatalytic oxidation of potential residues and photocatalyst maintenance. The use of water-sprinkled PCD is a promising approach to energy-efficient abatement of VOCs.

1. Introduction

Volatile organic compounds (VOCs) of toxic character both indoors and outdoors present an increasingly relevant health hazard to be addressed for proper elimination [1]. Countries in the European Union have obligated themselves to reduce the emissions of non-methane VOCs by 40% by 2030 [2]. The problem is solved by a variety of methods, requiring systematic analysis for a feasible choice. Of the two categories of VOC-treatment technologies, i.e., recovering VOCs when they are utilized and in situ destruction of VOCs, the latter is focused on air purification [3]. Technologies for destroying VOCs include thermal and catalytic incineration, biological oxidative filtering, and advanced oxidation processes (AOPs), including non-thermal plasma treatment. Incineration uses supplemental fuel that produces significant amounts of CO2, while catalytic incineration is vulnerable to sulfur, phosphorus, and halogens deactivating the catalysts. Non-thermal plasmas are innovative solutions that can tackle the issue at hand. A concentration–flow rate disposition for air treatment methods was given by Revah and Morgan-Sagastume [4]. There is some overlap of plasma treatment with adsorption and bio-filtration, with plasma treatment substantially less costly than adsorption and far more compact than biological filtration.

Sustainable and environmentally friendly VOC control may be provided by AOPs, including pulsed corona discharge (PCD) as a non-thermal plasma treatment [5,6,7]. Amongst AOPs, PCD is particularly attractive for its potential in degrading VOCs in an energy-efficient way: in a study on the removal of pollutants in water, PCD has shown outstanding performance [8,9]. Plasma technology has also been studied for air purification [10,11], showing that PCD also as the most energy-efficient AOP for the oxidation of airborne benzene and toluene [5,12]. The remarkable results of PCD applications are linked to the formation of reactive oxygen species (ROS), mostly hydroxyl radicals, predominantly on the surface of the water sprinkled into the plasma zone [13,14]. It has also been stated that increased humidity plays a crucial role in gas phase oxidation of VOCs with plasma technology, which improves radical production and the overall effectiveness of the process [6,15]. In air treatment, most of the studies with plasma technology have been conducted with dry or ambient air. To fill the knowledge gap and take full advantage of ROS, a new prototype plug flow PCD reactor with water sprinkling was built and tested for the oxidation of VOCs. m-Xylene was used as a model pollutant in a continuous airstream treated at various pulse repetition frequencies, with and without water sprinkling. By choosing m-xylene for experiments, the authors addressed the need for the removal of chemicals of aromatic structure that are often considered to be carcinogenic, mutagenic and neurotoxic. This also applies for m-xylene, which is widely used as a solvent in many industries, resulting in emissions into the environment [16,17,18]. The U.S. Department of Labor Occupational Safety and Health Administration set an exposure limit for xylene (all isomers) at a maximum of 100 ppm for an 8 h standard workday. In Europe, the exposure limit is 50 ppm [19]. Yet some scientists suggest that the exposure limits are too high [20]. With sprinkling, m-xylene conversion in both gas and aqueous phases was studied to understand the effect of ROS formed at the water surface. In addition, ozone and N2O by-products of air molecule interactions occurring in a plasma environment were quantified.

2. Materials and Methods

2.1. Chemicals

Analytical grade m-xylene (C8H10, 99+% from Thermo Scientific Chemicals, Waltham, MA, USA) was used as the model pollutant. For high-performance liquid chromatography (HPLC), methanol (CH3OH, ≥99.9% from Honeywell International Inc., Charlotte, NC, USA) and Milli-Q water obtained from a Millipore ultrapure water UV system (Simplicity®, EMD Millipore Corporation, Burlington, MA, USA), were used as eluents. Distilled water was used in PCD experiments with sprinkling. For pH regulation, sulfuric acid (H2SO4, 96%, Lach:Ner, Neratovice, Czech Republic) and sodium hydroxide (NaOH, puriss p.a., STANCHEM Sp. Z o.o, Niemce, Poland) were used.

2.2. PCD Reactor

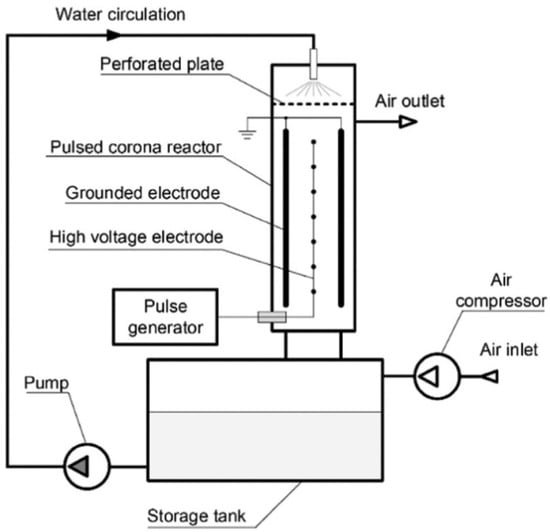

The schematics of the PCD reactor (Flowrox Oy, Lappeenranta, Finland) can be seen in Figure 1. The PCD reactor with a total volume of 75.9 L consists of an inter-electrode zone (1275 mm × 550 mm × 35 mm) and two side boxes, in which high-voltage electrodes are attached to tension devices. The electrode system consists of two vertical grounded electrode plates and horizontal high-voltage electrode wires between them. The perforated plate (565 mm × 97 mm) with 24 holes (3 mm in diameter) on top of the reactor ensures the uniform distribution of water droplets and jets across the plasma zone. The 12.7 L water storage tank was filled with 5.0 L of distilled water with adjusted pH. For water circulation, a magnet drive water circulation pump (Iwaki Co. Ltd., Tokyo, Japan) was used. The pump feeds water to the top of the reactor onto a perforated plate. The plate is 565 mm × 97 mm in size and has 24 holes with a diameter of 3 mm. As the water passes through the holes it showers down to the water tank, passing through the plasma zone that is 0.011 m3 in volume. The application of high voltage pulses between electrodes generated low-temperature gas-phase plasma of PCD in air. The amplitude of voltage and current and the duration of each pulse were 18 kV, 380 A and 100 ns, respectively. The pulse repetition frequency applied in the experiments varied between 25 and 800 pulses per second (pps) corresponding to the power delivered to the reactor of 3.0 to 100 W, respectively.

Figure 1.

Pulsed corona discharge reactor schematics [12].

2.3. Experimental Procedure

The pollutant was dosed into the air stream by means of liquid m-xylene evaporation from a bubble column (400–600 mL). To regulate the concentration of the pollutant, the bubble column was connected to the main flow in a bypass mode (Figure S1 in the Supplementary Materials) [21]. This arrangement provided a steady air stream of 6.0 m3 h−1, where the pollutant concentration could be varied from 10 to 50 ppm. The assessment of pollutant degradation performance was made by measuring input (Cin) and output (Cout) concentrations of m-xylene in the air stream. Air samples were collected using a 4 L metal body gas cell (Specac, Orpington, UK) and subjected to FT-IR spectrometry analysis (Interspec 200-X, Interspectrum OÜ, Tõravere, Estonia) for the presence of m-xylene and other compounds in the air. m-Xylene was measured at a bandwidth between 770 and 766 cm−1, and N2O at a bandwidth between 2256 and 2223 cm−1, which had the least interference from other substances while a distinctive spike on the specter was still visible (Figure S2). The FT-IR data interpretation was accomplished using Essential FTIR v.2.00.045 (Operant LCC) software with FDM HiRes VPFTIR for the Quant database. All air samples were withdrawn at least 15 min after the experiment started to ensure a steady state in all experimental parameters.

The aqueous concentrations of nitrites and nitrates were measured using ion chromatograph (Metrohm®, 761CompactIC, Metrohm AG, Herisau, Switzerland) equipped with a suppressed conductivity detector and analytical ion separation column (Metrosep A Supp 5, 150 mm × 4.0 mm inner diameter, Metrohm AG, Herisau, Switzerland).

In PCD experiments with water sprinkling, water was continuously recirculated at a flow rate of 3 to 18 L min−1, and regulated by adjusting the recirculation pump rotation frequency. Aqueous samples were withdrawn from the reactor and analyzed for m-xylene concentration using HPLC (Shimadzu LC-2030D, Shimadzu Corporation, Kyoto, Japan) equipped with a PDA detector and a Luna Omega column (150 mm, polar C18, p.s. = 5 μm). Isocratic elution was applied using 60% methanol and 40% water at the flowrate of 0.2 mL min−1. The column temperature was kept at 40 °C. Quantification of aqueous m-xylene was impossible in water samples at pH exceeding 9.5 due to the tolerance limit of the stationary phase of HPLC columns. Time-consuming manipulations with samples containing m-xylene for the pH adjustment were also impossible for the quick evaporation of volatile m-xylene. Gaseous ozone concentration was measured in the reactor’s outflow air using an ozone analyzer (Anseros Klaus Nonnenmacher GmbH, Tübingen, Germany). The pH of sprinkled water was measured by using SevenCompact pH-meter (Mettler-Toledo® Solutions, Columbus, OH, USA).

3. Results and Discussion

3.1. PCD Oxidation of Airborne m-Xylene

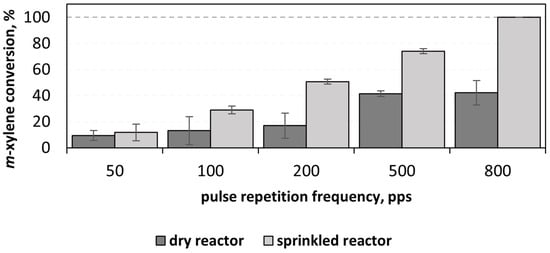

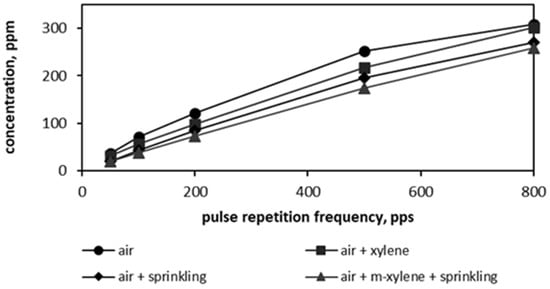

The pulse repetition frequency and, consequently, the input power affected the m-xylene oxidation rate in both the water-sprinkled and dry PCD reactor. Figure 2 presents the difference in m-xylene conversion depending on the pulse repetition frequency. It is evident that the sprinkling of water into the plasma environment induced the oxidative degradation of m-xylene. The difference is explained by different ROS formation in dry and humid air. Khadem et al. [22] suggested different oxidation pathways, pointing to the formation of hydroxyl radicals OH• in humid air. The radical plays a crucial role as the most powerful oxidant, with a redox potential as high as 2.8 V [15,23,24]. One can presume that water serves as the source of hydrogen-containing ROS (HO•, HO2•), which contribute to the radical-mediated oxidation.

Figure 2.

Oxidation of airborne m-xylene dependent on pulse repetition frequency: m-xylene input concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, water circulation rate 9 L min−1, pH 6.0–6.5.

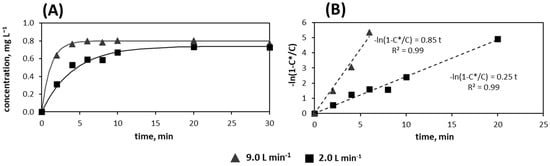

3.2. m-Xylene Absorption and Oxidation in Water

Water sprinkling in the PCD reactor provides physical absorption of m-xylene dissolved in water. The absorption experiments were conducted by purging air containing m-xylene through the sprinkled PCD reactor with frequent sampling for the first 5 to 20 min of the experiment. The content of m-xylene was determined in the water samples. In the absence of pollutant oxidation, the liquid phase is saturated with m-xylene (Figure 3A) in accordance with Henry’s law, in which an aqueous concentration of the VOC at the saturation point is proportional to its partial pressure in the reactor chamber (Equation (1)):

where kH and Pi are Henry’s constant and m-xylene partial pressure, respectively.

Figure 3.

(A) m-Xylene absorption by water in time at various water recirculation rates, (B) linearized form of absorption kinetics: gaseous m-xylene input concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, pH 6.0–6.5.

The driving force of mass transfer is the concentration gradient between two phases (Equation (2)):

where kLa, CL, and are the mass transfer coefficient, and the aqueous m-xylene concentrations at time t and at the saturation point, respectively. Because of continuous gas inflow and the low solubility of m-xylene in water (146 mg L−1 at 25 °C), the VOC’s partial pressure remains constant during absorption, providing constant . As a result, the differential Equation (2) can be solved with boundary conditions: t = 0 to t and corresponding CL = 0 to . This allows the linearized form of the dependence of the aqueous concentration on time (Equation (3)) occurring during absorbance (Figure 3B) to be obtained:

The slopes of the linear paths characterize mass transfer coefficients kLa, which were found to be 0.85 and 0.24 at flowrates of 9.0 and 2.0 L min−1, respectively. One can see that the water recirculation rate affects the absorption kinetics through the specific surface area a incorporated in the kLa coefficient (Equation (3)), which depends on the number of droplets per unit of time delivered through the perforated plate, and the size of droplets. In turn, the liquid-film mass transfer coefficient kL is mostly compound-specific, and thus, depends on the turbulence of the gas–liquid mixture, which is intensified with the flow rate.

In such a design, the PCD reactor acts as a wet scrubber, absorbing gaseous pollutants in liquid. It is reasonable to assume that vapors of hydrophilic compounds such as formaldehyde, methoxyethanol, low-molecular alcohols etc., would be susceptible to absorption, and thus, favorable for such an application. However, the present study was ultimately focused on a hydrophobic compound to stress out the non-selectivity and versatility of PCD in the chemical degradation of recalcitrant pollutants in air.

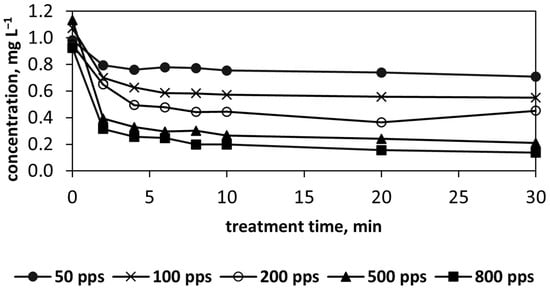

After saturation of the recirculating water with m-xylene, the PCD generator was switched on, decreasing the concentration of the aqueous VOC, and reaching an equilibrium concentration dependent on the pulsed power input (Figure 4).

Figure 4.

Aqueous m-xylene concentration vs. experimental run time dependent on the pulse repetition frequency: airborne m-xylene input concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, water circulation rate 9 L min−1, pH 6.0–6.5.

The different equilibrium states of m-xylene in water dependent on the pulse repetition frequency can be explained from two reinforcing points of view: (i) higher power input oxidizes more of m-xylene in the gas phase, reducing the amount of m-xylene absorbed by water; and (ii) at a higher power input, more m-xylene is also oxidized in water by the increased amount of ROS at the plasma–liquid interface [25].

3.3. Ozone Generation in PCD Reactor

The dependence of ozone gaseous concentration on the pulse repetition frequency in the plasma reactor is given in Figure 5. Ozone concentration in the air outflow was measured in the absence and presence of m-xylene vapors with and without water sprinkling 7 to 10 min after the start of the experiment. Ozone concentration remained stable within 15 to 20 min of measurements.

Figure 5.

Airborne ozone concentration dependent on water sprinkling and presence of m-xylene vapors vs. pulse repetition frequency: airborne m-xylene concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, water circulation rate 9 L min−1, pH 6.0–6.5.

In a plasma environment, air oxygen is prone to ionization, forming ozone. One can see that the discharge power input almost linearly affects the ozone yield, i.e., higher pulse frequency results in higher concentrations of ozone in the air outflow. The linear growth in ozone production is explained by the difference between the ozone concentration and its maximum achievable concentration at the equilibrium state in the sprinkled PCD reactor with no air flow, reaching about 3000 ppm (5 mg L−1) [26]. Increased pulsed power input naturally improves ozone production at the air flow rate applied in the experiments.

Greater ozone yield in the absence of sprinkling is explained by the discharge energy lost, since electrodes are partly covered by water droplets, as was concluded by Lukes et al. [27] and developed by Kornev et al. in research with conductive liquids. They also suggested how to construct the PCD reactor with minimal losses [28]. Another reason for reduced ozone output is the higher concentration of water vapor in the reactor. Water vapor plays a crucial role in ozone formation in corona discharge [29], reducing the lifetime of atomic oxygen and, therefore, ozone production [24].

The presence of m-xylene in the gas mixture also reduced ozone production, which can be explained either by ozone directly oxidizing the VOC, or, more likely, by competitive reactions of active species in ozone formation and m-xylene oxidation: the short residence time and relatively slow reactions of molecular ozone makes the second explanation more plausible.

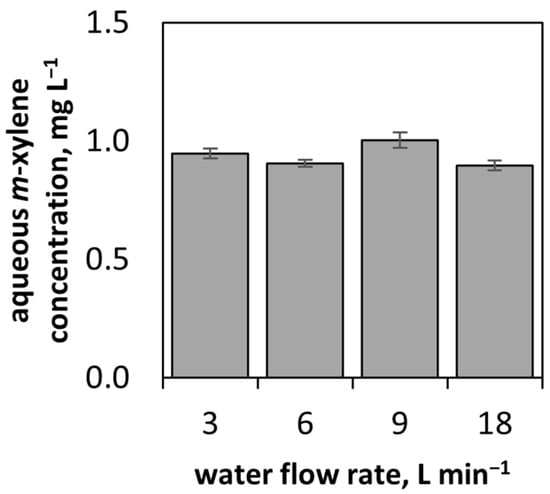

3.4. m-Xylene Oxidation: Impact of Water Circulation Rate

The impact of the water circulation rate, i.e., the gas–liquid interface area linearly growing with the flow rate, on aqueous m-xylene oxidation is illustrated in Figure 6, showing that at 100 pps, the substrate concentration is practically independent at the experimental flow rates from 3 to 18 L min−1. This concentration corresponds with the m-xylene conversion rate observed for the pulse repetition frequency of 100 pps, comprising about 40% (Figure 4). This observation leads us to conclude that within the studied sprinkling range, the VOC was oxidized at a constant rate determined by the amount of ROS generated by the pulsed power input. In other words, the oxidation rate is limited by the input power spread over a bigger or smaller area of the contact surface without any impact on the overall oxidation rate. This agrees with the hydroxyl radicals predominantly formed at the gas–liquid interface, as described by Ajo et al. [30] and studied by Onga et al. [31]. Thus, the intense water circulation only promotes the absorption rate of target vapors (Figure 3), but not the PCD oxidation rate.

Figure 6.

m-Xylene concentration in water dependent on water flow rate with airborne xylene input concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, pulse repetition frequency 100 pps, pH 6.0–6.5.

The ozone generation rate slightly decreased with increasing sprinkling intensity (Figure S3). This is most likely linked to the loss of discharge energy, which was increased by more intense watering of the electrodes, as described above.

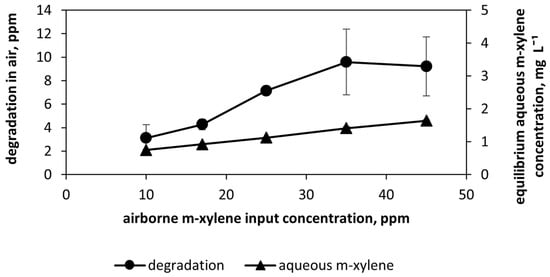

3.5. m-Xylene Oxidation: Impact of Airborne m-Xylene Concentration

The effect of m-xylene input concentration on its removal rate was studied within the interval of 10 to 45 ppm at 100 pps. At m-xylene input concentrations of 35 and 45 ppm, the net degradation, i.e., the difference between influent and effluent concentrations of m-xylene, approached its maximum of about 10 ppm, showing no more growth in the VOC removal. This points to the limit in the amount of ROS available at this input power of 12.5 W. This observation is supported by the higher aqueous concentration of m-xylene at its higher content in air, i.e., the gaseous VOC concentration continued to grow (Figure 7).

Figure 7.

Dependents on m-xylene input concentration: air flow rate 6 m3 h−1, water circulation rate 9 L min−1, pulse repetition frequency 100 pps, pH 6.0–6.5.

Ozone concentration moderately decreased by 12% with higher m-xylene input concentrations, which supports the assumption made earlier–ozone plays minor role in m-xylene oxidation. Small decrease in ozone concentration may be explained either by direct reaction of the VOC with ozone, or by competitive reactions of short-living ROS forming ozone with m-xylene. Some ozone reacted with higher concentrations of aqueous m-xylene, which may also explain the minor loss.

3.6. m-Xylene Oxidation: Impact of Sprinkling Water pH

The formation of hydroxyl radicals from aqueous ozone in alkaline media may contribute to m-xylene oxidation and ozone decomposition in water [32]. Changes in airborne m-xylene conversion, however, were too subtle, indicating no practical effect of alkaline sprinkling, showing only a 3% increase in m-xylene oxidation with water pH 2 compared to pH 7 and pH 12 (Figure S4). This observation is evidence of the minor role of aqueous m-xylene oxidation with dissolved ozone.

With respect to ozone concentration in the gas phase, alkaline sprinkling water caused no change, although modest degradation was observed in the presence of m-xylene, where ozone generation was decreased to 31.5 ppm at pH 12 compared to 36.0 ppm at pH 7 (Figure S5). Apparently, some decomposition of ozone took place in the presence of the dissolved VOC in alkaline solution, although a slight improvement in gaseous m-xylene conversion is evidence of the minor role of slowly-reacting ozone in oxidation.

In all experiments, the presence of m-xylene in the airstream results in a decreased gaseous ozone output. As observed in this study, ozone is a rather slow oxidant in the gas phase, requiring long residence times and taking several hours to oxidize aromatic molecules [33], thus excluding gas-phase ozone from ROS from contributing to oxidation. The small amount of alkaline sprinkling in m-xylene oxidation also indicated the minor role of dissolved ozone, although it made the aqueous ozone decomposition slightly faster. These observations show that the gas-phase oxidation of m-xylene with short-living ROS in PCD plasma is predominant.

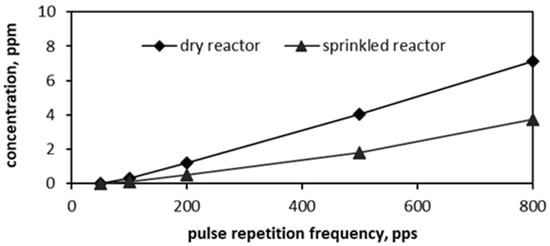

3.7. Nitrogen Oxidation

In air pollution control with electric discharges, secondary pollutants, ozone and nitrogen oxides must be considered for process safety and possible down-flow arrangements [21]. In a plasma environment, excitation and ionization of airborne nitrogen produce active species, radicals and ions, including N•, N2• and N2+, which are able to react with oxygen, forming nitrogen oxides [34,35]. In this study, the formation of N2O was detected in both dry and sprinkled PCD reactors. The discharge at pulse repetition frequencies below 200 pps produces insignificant amounts of N2O, rendering the issue moot. Other nitrogen oxides, NO and NO2, were detected neither in the dry nor in the sprinkled gas phase: the absence of NO is easily explained by its fast-reactive character, whereas the absence of NO2 is caused by further reaction with OH-radical forming nitric acid in ambient air at relative humidity of 30–40% at 20 °C. In both wet and dry conditions, N2O concentration followed a linear growth with growing pulse repetition frequency, yet water sprinkling substantially reduced the N2O concentration (Figure 8). As it is low enough even at the highest pulsed energy input, the nitrous oxide concentration decreased more than two-fold, reaching 3 ppm at 800 pps in the air–water mixtures. This is evidence of its more effective oxidation to nitric oxides of a higher oxidation state at the air–water interface, and that it is a gathering place for short-living ROS.

Figure 8.

Airborne N2O concentration in air in dry and water-sprinkled PCD reactors dependent on the pulse repetition frequency: m-xylene input concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, water circulation rate 9 L min−1, pH 6.0–6.5.

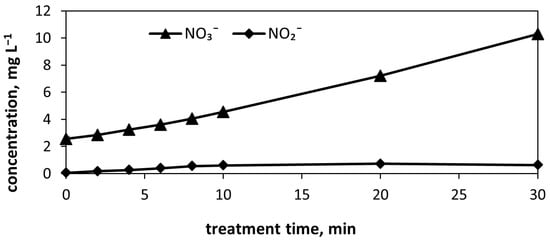

Nitrous oxide experiences either a hydroxyl-radical attack at the gas–liquid interface, producing nitrites identified in the aqueous phase (Figure 9) and reducing the N2O concentration in treated air (Figure 8); or the formation of nitrous oxide may be reduced in water-sprinkled PCD due to straightforward oxidation of nitrogen to NO and further to NO2 and, ultimately, to nitrate, thus providing lower concentrations of N2O. Nitrites are formed as intermediates determined in the aqueous phase in low concentrations, whereas nitrates tend to grow continuously (Figure 9).

Figure 9.

Aqueous nitrite and nitrate concentrations dependent on treatment time: m-xylene concentration 20 ± 5 ppm, pulse repetition frequency 100 pps, air flow rate 6 m3 h−1, water circulation rate 9 L min−1, pH 6.0–6.5.

The amount of nitrates quantified in the sprinkled reactor at 100 pps, i.e., 12.5 W of pulsed power, equals approximately 50 mg, meaning the amount of nitrogen bond in the aqueous phase was around 11.3 mg, which is an order of magnitude higher than the amount of nitrogen carried in the N2O form with air flow for 30 min—1.9 and 0.9 mg N in the dry and the sprinkled reactor, respectively. The nitrate production energy efficiency observed in the sprinkled reactor experiments comprises 8.0 g kW−1 h−1, which is an agreement with data obtained earlier by Preis et al. [36]. The energy efficiency of N2O production in the dry reactor reaches a maximum of 0.94 g kW−1 h−1 at 7.5 ppm in outlet air (Figure 10), i.e., an order of magnitude smaller than nitrate production. Considering the downstream removal of N2O, studies of photocatalytic oxidation may be promising for further research [37].

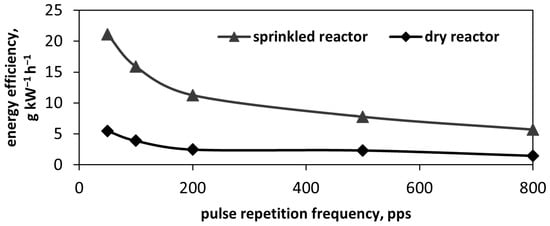

Figure 10.

Energy efficiency of m-xylene degradation in air with and without sprinkling dependent on pulse repetition frequency: m-xylene concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, water circulation rate 9 L min−1, pH 6.0–6.5.

3.8. Energy Efficiency of m-Xylene Oxidation

The energy efficiency of airborne m-xylene oxidation was calculated for both dry and water-sprinkled PCD (Figure 10). The energy efficiency was calculated using Equation (4):

where E—energy efficiency, g kW−1 h−1, ΔC—the difference between m-xylene concentrations in inlet and outlet air streams, g m−3, Q—air volumetric flow rate, m3 h−1, P—pulsed power input, kW. One can see a significant difference in energy efficiency, with oxidation in the sprinkled reactor surpassing that in dry conditions by four to six times at 50 and 800 pps, respectively. This indicates the crucial role of water in accelerating m-xylene oxidation, and shows the advantageous character of pulsed discharge techniques in providing safe oxidation of airborne pollutants in air–water mixtures that is impossible for DC and AC coronas.

The fact that the energy efficiency of m-xylene oxidation depends on the pulse repetition frequency deserves to be discussed. Concerning oxidation of m-xylene in the dry reactor, maximum energy efficiency was achieved at 50 pps, equaling 5.5 g kW−1 h−1. Other studies reported similar results: Shang et al. [38] used positive DC corona degrading benzene with energy yields of up to 3.6 g kW−1 h−1 at the initial benzene concentration of 100 ppm, degrading to 86.5%. Jiang et al. [11] degraded nearly 70% of benzene at its 400 ppm initial concentration, reaching an energy yield of 8.5 g kW−1 h−1. This was attributed to the starting concentration, which was twenty times higher than the one used in this study. Kask et al. [12] treated 1.2 mg L−1 (323.8 ppm) of toluene in a batch process PCD reactor and reached an energy efficiency of 29.6 g kW−1 h−1 with 32 W input power and 40% degradation. In the water-sprinkled continuous flow PCD, the energy efficiency at 50 pps was 21.1 g kW−1 h−1, which was the highest energy efficiency achieved in this study.

Efficiency in m-xylene oxidation, however, dropped to 5.7 g kW−1 h−1 at 800 pps. Explanations given for similar observations in PCD oxidation of aqueous pollutants relied on the role of long-living ozone, realizing its oxidation potential in the time between pulses—longer pauses give ozone time to dissolve in treated water, and to contribute to oxidation. In this study, however, molecular ozone played a minor role in the oxidation of m-xylene, whether gaseous or aqueous. The higher efficiency of low pulse repetition frequency is explained by the short-living ROS synthesis and utilization in plasma, proceeding in competition between VOC vapor oxidation reactions, and ozone synthesis and decomposition: the higher the ozone concentration at a higher pulse repetition frequency, which requires energy for synthesis and decomposition, the smaller the fraction of the pulse energy available for direct oxidation of the VOC. Rare pulses thus utilize more energy in m-xylene oxidation at low ozone concentration (Figure 5) instead of wasting it in ozone synthesis and decomposition at higher frequencies and, consequently, higher ozone concentrations. In other words, the tendency of lower pulse repetition rates to be more energy-efficient remains analogous with the oxidation of aqueous pollutants, although due to different mechanism of action. In the gas phase, the intense power input results in higher concentrations of synthesized molecular ozone, which, being less reactive with the VOC in both phases, wastes a part of the pulsed energy for synthesis and decomposition, reducing the overall efficiency of VOC oxidation.

4. Conclusions

A prototype PCD reactor with water sprinkling was tested in m-xylene oxidation as a model pollutant of air flow. Water sprinkling increased the oxidation efficiency of the VOC by four to six times compared to PCD in dry air, indicating that oxidation reactions are significantly accelerated at the plasma–water interface. The pulsed power input acted as the key factor in the oxidation rate and its energy efficiency: it proceeded faster at a high pulse repetition rate; i.e., at a higher power input, oxidation demonstrated an energy yield more than three times higher than at a lower frequency, which sets up an optimization task in practical applications. The difference in m-xylene oxidation efficiency at different power inputs is explained by the competitive reactions of short-living reactive oxygen species in plasma, when the target pollutant and long-living ozone are present at higher concentrations and at higher pulsed power inputs. Ozone itself showed a poor oxidation ability towards the target VOC.

The m-xylene oxidation energy efficiency appeared to be comparable to those observed for benzene and toluene, thus confirming its unequalled character in relation to other AOPs.

The variation on other process parameters provided a better understanding of the oxidation pattern, inlet concentration of airborne m-xylene, water flow rates, and sprinkled water pH. The increased airborne concentration of m-xylene resulted in faster degradation of the VOC. However, it reached a certain limit in the oxidation rate; e.g., a maximum of 10 ppm was degraded at a pulse repetition frequency of 100 pps, providing pulsed power input of 12.5 W. The higher oxidation rates achieved with higher power inputs are accompanied, however, by lower energy yields, thus offering an optimization task for engineering solutions. The sprinkling water flow rate and its pH had a negligible effect on the degradation of gas-phase m-xylene, conveniently minimizing the expense in these process parameters.

Secondary pollutants, ozone and N2O are inevitably formed in PCD treatment of air. Water-sprinkling reduced the formation of nitrous oxide approximately twofold, whereas ozone formation was only slightly affected by water sprinkling in the absence or presence of the target VOC. Ultimately, nitric oxides end up as nitrates absorbed by the sprinkling water. The N2O residues are likely removable downstream in photocatalytic oxidation.

This research shows that water sprinkling in a PCD reactor significantly contributes to the efficiency of VOC oxidation in a continuous flow mode. Further research is needed on degrading other classes of pollutants, including water-soluble hydrophilic compounds. This study of the conductivity of sprinkling water caused by the accumulation of nitrates and its performance is necessary for practical adoption of the technology.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/chemengineering8050099/s1, Figure S1: Flow chart of experimental setup: 1—main flow control valve, 2—main flow rotameter, 3—m-xylene bubble column, 4—rotameter and control valve for the bypass air flow saturated with m-xylene, 5—stopcock valve for m-xylene bypass flow, 6—control valve for air inflow sampling, 7—control valve for air outflow sampling, 8—sampling line rotameter, Figure S2. FT-IR specter of gas sample, post PCD treatment (sprinkled). m-Xylene input concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, pulse repetition frequency 200 pps, pH 6.0–6.5. Red line—standard for 20 ppm of N2O, black line—standard for 50 ppm m-xylene, green line—air sample. Figure S3: Airborne ozone concentration dependent on sprinkling water flow rate in absence and presence of m-xylene vapors: airborne m-xylene input concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, pulse repetition frequency 100 pps, pH 6.0–6.5, Figure S4: Airborne m-xylene conversion dependent on sprinkling water pH: gaseous m-xylene input concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, pulse repetition frequency 100 pps, sprinkling water flow rate 9 L min−1, Figure S5: Airborne ozone concentration dependent on sprinkling water pH in absence and presence of m-xylene vapors: airborne m-xylene concentration 20 ± 5 ppm, air flow rate 6 m3 h−1, pulse repetition frequency 100 pps, water flow rate 9 L min−1.

Author Contributions

Conceptualization, K.A., M.K., S.P. and J.B.; methodology, K.A., M.K., S.P. and J.B.; validation, K.A., M.K., S.P. and J.B.; formal analysis, K.A., M.K., S.P. and J.B.; data curation, K.A. and J.B.; writing—original draft preparation, K.A., M.K., S.P. and J.B.; supervision, M.K., S.P. and J.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Ministry of Education and Research through Centre of Excellence in Circular Economy for Strategic Mineral and Carbon Resources (1 January 2024–31 December 2030, TK228).

Data Availability Statement

Experimental data will be made public on request.

Acknowledgments

We thank Kristjan Rikas for assistance in the laboratory and for supporting the experimental data acquisition.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pearson, J.K. European solvent VOC emission inventories based on industry-wide information. Atmos. Environ. 2019, 204, 118–124. [Google Scholar] [CrossRef]

- European Parliament and of the Council of the European Union. Directive (EU) 2016/2284 of the European Parliament and of the Council of 14 December 2016 on the reduction of national emissions of certain atmospheric pollutants, amending Directive 2003/35/EC and repealing Directive 2001/81/EC. Off. J. Eur. Union. 2016. Available online: https://eur-lex.europa.eu/eli/dir/2016/2284/oj (accessed on 15 September 2024).

- Hirota, K.; Sakai, H.; Washio, M.; Kojima, T. Application of Electron Beams for the Treatment of VOC Streams. Ind. Eng. Chem. Res. 2004, 43, 1185–1191. [Google Scholar] [CrossRef]

- Revah, S.; Morgan-Sagastume, J.M. Biotechnology for Odor and Air Pollution Control; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Kornev, I.; Preis, S. Aqueous Benzene Oxidation in Low-Temperature Plasma of Pulsed Corona Discharge. J. Adv. Oxid. Technol. 2016, 19, 284–289. [Google Scholar] [CrossRef][Green Version]

- Du, C.; Gong, X.; Lin, Y. Decomposition of volatile organic compounds using corona discharge plasma technology. J. Air Waste Manag. Assoc. 2019, 69, 879–899. [Google Scholar] [CrossRef]

- Hezami, L.; Nguyen-Tri, P.; Saoud, W.A.; Bouzaza, A.; El Jery, A.; Nguyen, D.D.; Gupta, V.K.; Assadi, A.A. Assadi, Recent progress in air treatment with combined photocatalytic/plasma processes: A review. J. Environ. Manag. 2021, 299, 113588. [Google Scholar] [CrossRef]

- Onga, L.; Kattel-Salusoo, E.; Preis, S.; Dulova, N. Degradation of anti-inflammatory drug dexamethasone by pulsed corona discharge: The effect of peroxycompounds addition. J. Environ. Chem. Eng. 2022, 10, 108042. [Google Scholar] [CrossRef]

- Tikker, P.; Nikitin, D.; Preis, S. Oxidation of aqueous bisphenols A and S by pulsed corona discharge: Impacts of process control parameters and oxidation products identification. Chem. Eng. J. 2022, 438, 135602. [Google Scholar] [CrossRef]

- Sobacchi, M.G.; Saveliev, A.V.; Fridman, A.A.; Gutsol, A.F.; Kennedy, L.A. Experimental Assessment of Pulsed Corona Discharge for Treatment of VOC Emissions. Plasma Chem. Plasma Process. 2003, 23, 347–370. [Google Scholar] [CrossRef]

- Jiang, N.; Lu, N.; Shang, K.; Li, J.; Wu, Y. Innovative approach for benzene degradation using hybrid surface/packed-bed discharge plasmas. Environ. Sci. Technol. 2013, 47, 9898–9903. [Google Scholar] [CrossRef]

- Kask, M.; Krichevskaya, M.; Preis, S.; Bolobajev, J. Oxidation of Aqueous Toluene by Gas-Phase Pulsed Corona Discharge in Air-Water Mixtures Followed by Photocatalytic Exhaust Air Cleaning. Catalysts 2021, 11, 549. [Google Scholar] [CrossRef]

- Bruggeman, P.J.; Kushner, M.J.; Locke, B.R.; Gardeniers, J.G.E.; Graham, W.G.; Graves, D.B.; Hofman-Caris, R.C.H.M.; Maric, D.; Reid, J.P.; Ceriani, E.; et al. Plasma-liquid interactions: A review and roadmap. Plasma Sources Sci. Technol. 2016, 25, 053002. [Google Scholar] [CrossRef]

- Sato, M.; Ohgiyama, T.; Clements, J.S. Formation of chemical species and their effects on microorganisms using a pulsed high voltage discharge in water. In Proceedings of the 1994 IEEE Industry Applications Society Annual Meeting, Denver, CO, USA, 2–6 October 1994. [Google Scholar] [CrossRef]

- Schiorlin, M.; Marotta, E.; Rea, M.; Paradisi, C. Comparison of toluene removal in air at atmospheric conditions by different corona discharges. Environ. Sci. Technol. 2009, 43, 9386–9392. [Google Scholar] [CrossRef] [PubMed]

- Zoveidavianpoor, M.; Samsuri, A.; Shadizadeh, S.R. Safety, and Environmental Challenges of Xylene in Upstream Petroleum Industry. Energy Environ. 2012, 23, 1339–1352. [Google Scholar] [CrossRef]

- Agency for Toxic Substances and Disease Registry. Public Health Statement Xylene. 2007. Available online: www.atsdr.cdc.gov/ (accessed on 28 July 2024).

- Niaz, K.; Bahadar, H.; Maqbool, F.; Abdollahi, M. A review of environmental and occupational exposure to xylene and its health concerns. EXCLI J. 2015, 14, 1167–1186. [Google Scholar] [CrossRef]

- European Chemicals Agency, Substance Infocard (Xylene). 2024. Available online: https://Echa.Europa.Eu/et/Substance-Information/-/Substanceinfo/100.014.124 (accessed on 28 July 2024).

- Bolden, A.L.; Kwiatkowski, C.F.; Colborn, T. New look at BTEX: Are ambient levels a problem. Environ. Sci. Technol. 2015, 49, 5261–5276. [Google Scholar] [CrossRef]

- Altof, K.; Krichevskaya, M.; Preis, S.; Tähemaa, T.; Bolobajev, J. Ozone-assisted degradation of 2-methoxyethanol in a prototype plug flow photocatalytic reactor. Chem. Eng. J. 2024, 481, 148488. [Google Scholar] [CrossRef]

- Khadem, A.; Khani, M.R.; Rad, R.H.; Shokri, B.; Rashnoo, S.; Ghobadian, B. Experimental analysis of volatile organic compounds conversion by a dielectric barrier discharge reactor to study the main products: Hydrogen, CO, CO2, NOx and hydrocarbons. Chem. Eng. Process. Process Intensif. 2019, 145, 107660. [Google Scholar] [CrossRef]

- Chen, J.; Xie, Z.; Tang, J.; Zhou, J.; Lu, X.; Zhao, H. Oxidation of toluene by dielectric barrier discharge with photo-catalytic electrode. Chem. Eng. J. 2016, 284, 166–173. [Google Scholar] [CrossRef]

- Carey, J.H. An Introduction to Advanced Oxidation Processes (AOP) for Destruction of Organics in Wastewater. Water Qual. Res. J. 1992, 27, 103466. [Google Scholar] [CrossRef]

- Tikker, P.; Kornev, I.; Preis, S. Oxidation energy efficiency in water treatment with gas-phase pulsed corona discharge as a function of spray density. J. Electrost. 2020, 106, 103466. [Google Scholar] [CrossRef]

- Preis, S.; Panorel, I.C.; Kornev, I.; Hatakka, H.; Kallas, J. Pulsed corona discharge: The role of ozone and hydroxyl radical in aqueous pollutants oxidation. Water Sci. Technol. 2013, 68, 1536–1542. [Google Scholar] [CrossRef] [PubMed]

- Lukes, P.; Clupek, M.; Babicky, V.; Janda, V.; Sunka, P. Generation of ozone by pulsed corona discharge over water surface in hybrid gas-liquid electrical discharge reactor. J. Phys. D Appl. Phys. 2005, 38, 409–416. [Google Scholar] [CrossRef]

- Kornev, I.; Saprykin, F.; Preis, S. Stability and energy efficiency of pulsed corona discharge in treatment of dispersed high-conductivity aqueous solutions. J. Electrost. 2017, 89, 42–50. [Google Scholar] [CrossRef]

- Ono, R.; Oda, T. Dynamics of ozone and OH radicals generated by pulsed corona discharge in humid-air flow reactor measured by laser spectroscopy. J. Appl. Phys. 2003, 93, 5876–5882. [Google Scholar] [CrossRef]

- Ajo, P.; Kornev, I.; Preis, S. Pulsed Corona Discharge Induced Hydroxyl Radical Transfer Through the Gas-Liquid Interface. Sci. Rep. 2017, 7, 16152. [Google Scholar] [CrossRef]

- Onga, L.; Kattel-Salusoo, E.; Trapido, M.; Preis, S. Oxidation of Aqueous Dexamethasone Solution by Gas-Phased Pulsed Corona Discharge. Water 2022, 14, 467. [Google Scholar] [CrossRef]

- Gottschalk, C.; Libra, J.A.; Saupe, A. Ozonation of Water and Waste Water; Wiley-VCH: Weinheim, Germany, 2009. [Google Scholar] [CrossRef]

- Ridgway, H.F.; Mohan, B.; Cui, X.; Chua, K.J.; Islam, M.R. Molecular dynamics simulation of gas-phase ozone reactions with sabinene and benzene. J. Mol. Graph. Model. 2017, 74, 241–250. [Google Scholar] [CrossRef]

- Fan, X.; Kang, S.; Li, J.; Zhu, T. Formation of Nitrogen Oxides (N2O, NO, and NO2) in Typical Plasma and Plasma-Catalytic Processes for Air Pollution Control. Water Air Soil Pollut. 2018, 229, 351. [Google Scholar] [CrossRef]

- Sakakura, T.; Murakami, N.; Takatsuji, Y.; Morimoto, M.; Haruyama, T. Contribution of Discharge Excited Atomic N, N2*, and N2+ to a Plasma/Liquid Interfacial Reaction as Suggested by Quantitative Analysis. ChemPhysChem 2019, 20, 1467–1474. [Google Scholar] [CrossRef]

- Preis, S.; Panorel, I.; Coll, S.L.; Kornev, I. Formation of Nitrates in Aqueous Solutions Treated with Pulsed Corona Discharge: The Impact of Organic Pollutants. Ozone Sci. Eng. 2014, 36, 94–99. [Google Scholar] [CrossRef]

- Kočí, K.; Krejčíková, S.; Šolcová, O.; Obalová, L. Photocatalytic decomposition of N2O on Ag-TiO2. Catal. Today 2012, 191, 134–137. [Google Scholar] [CrossRef]

- Shang, K.; Wang, X.; Zhou, X.; Wang, N. Diagnosis of electron temperature in Ar/O2 mixed gas and destruction of toluene/benzene by positive dc discharge plasma. J. Electrost. 2009, 67, 746–750. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).