Research on the Structural Model of Welding Process Specifications for Aviation Products Based on Trade-Off Design

Abstract

1. Introduction

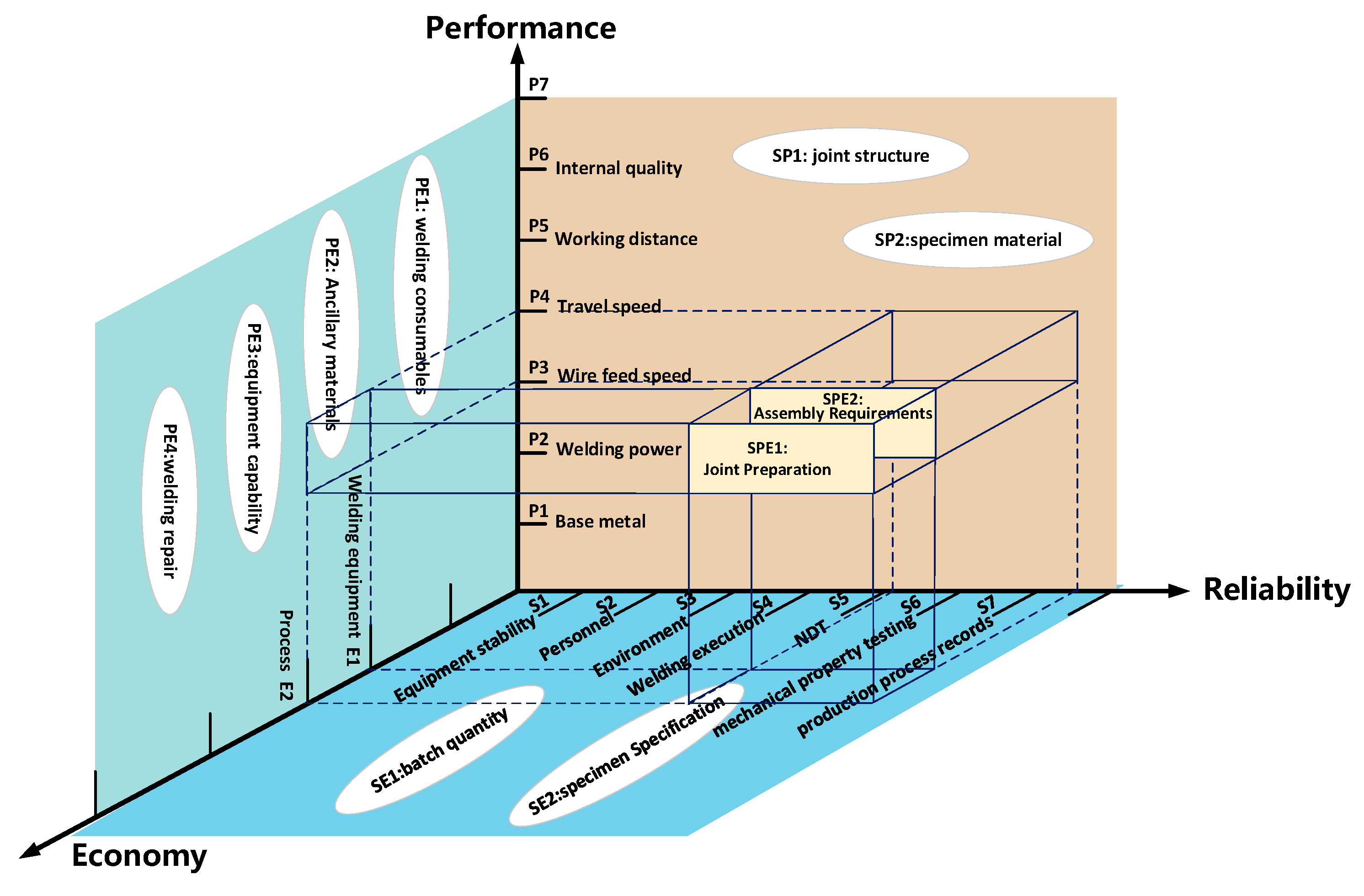

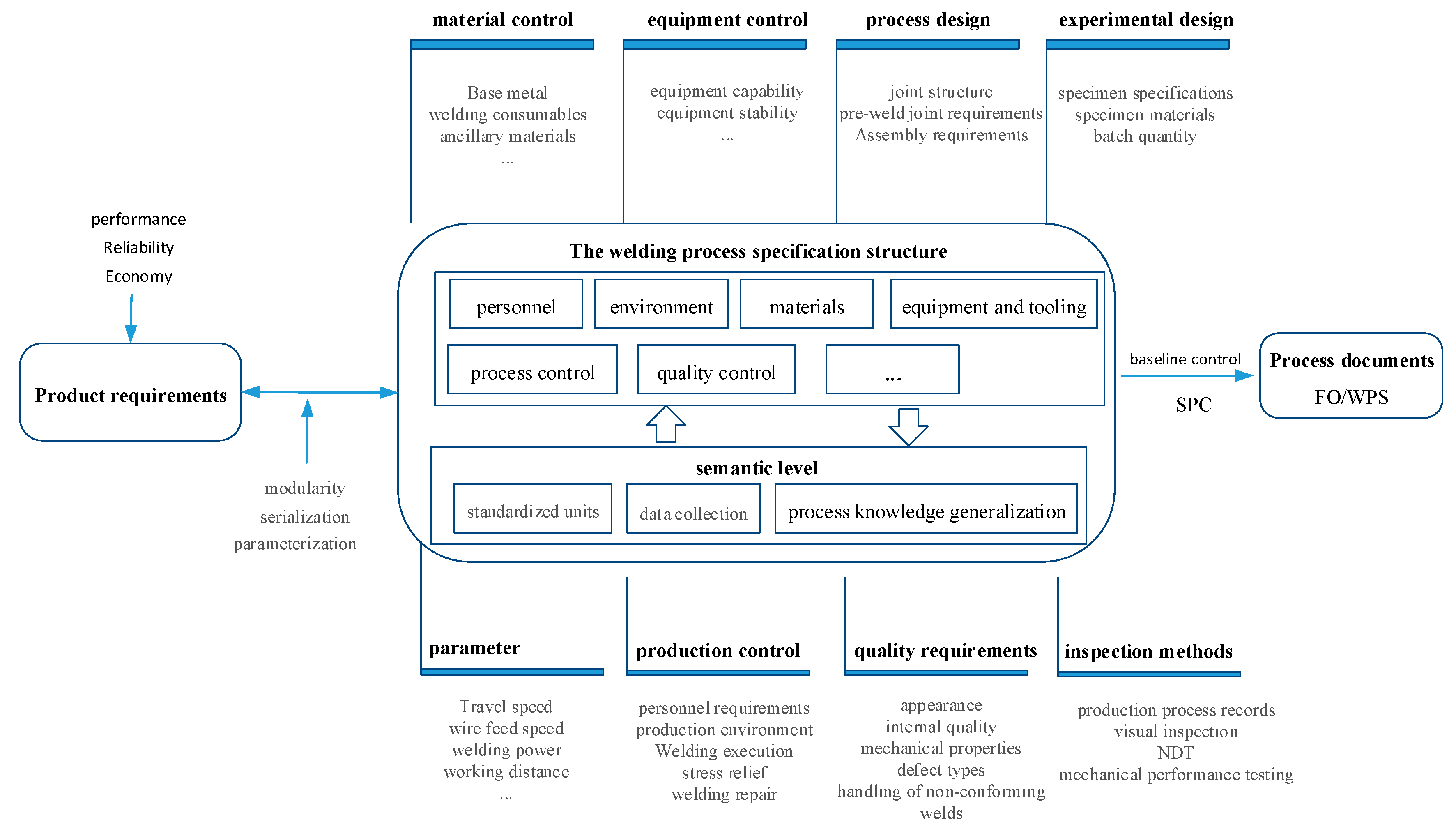

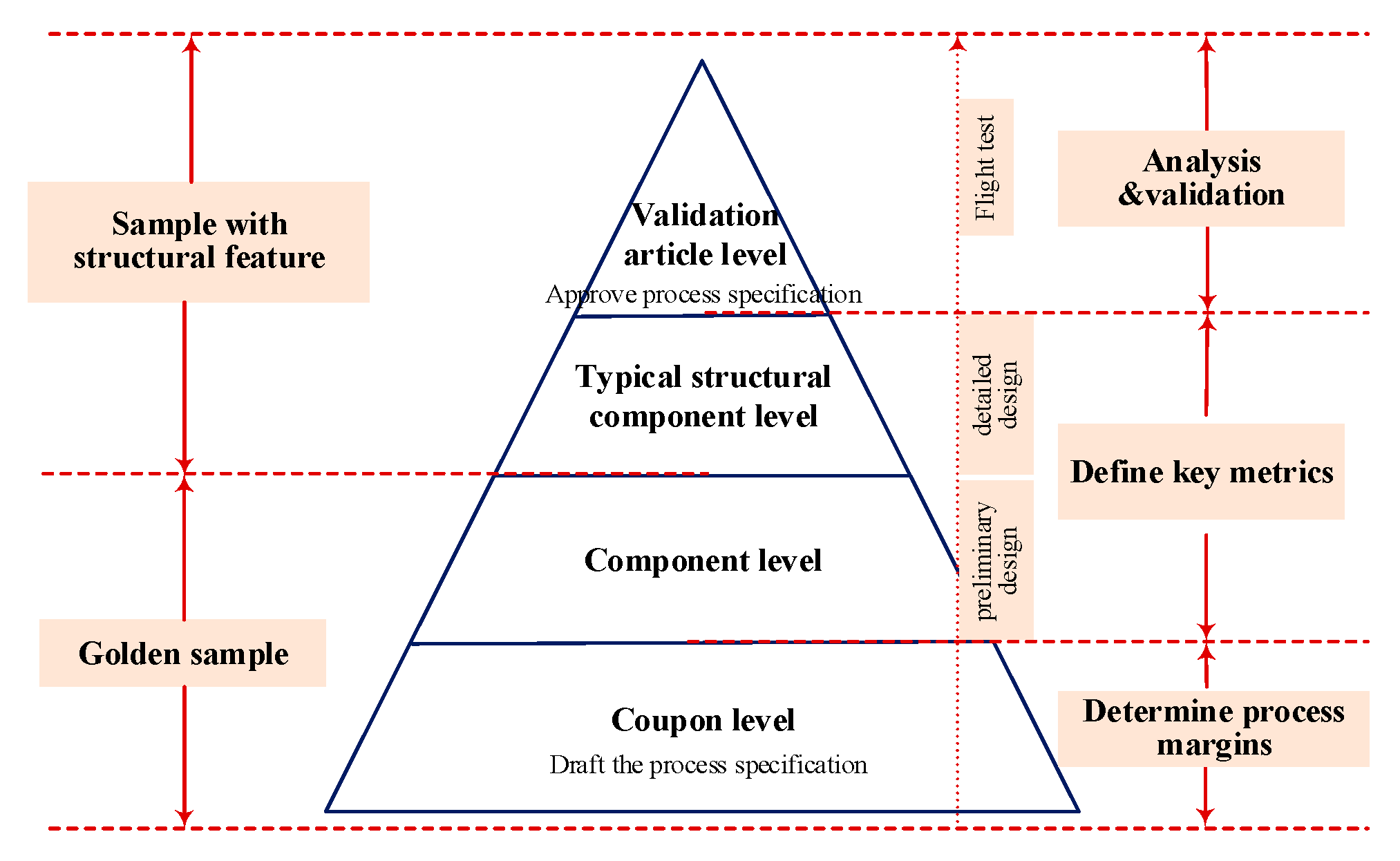

2. Construction of WPS Structure Model

2.1. Comprehensive Element Analysis of the Structural Model Based on Requirement-Driven and Trade-Off Design

2.2. Composition of the WPS Structure Model

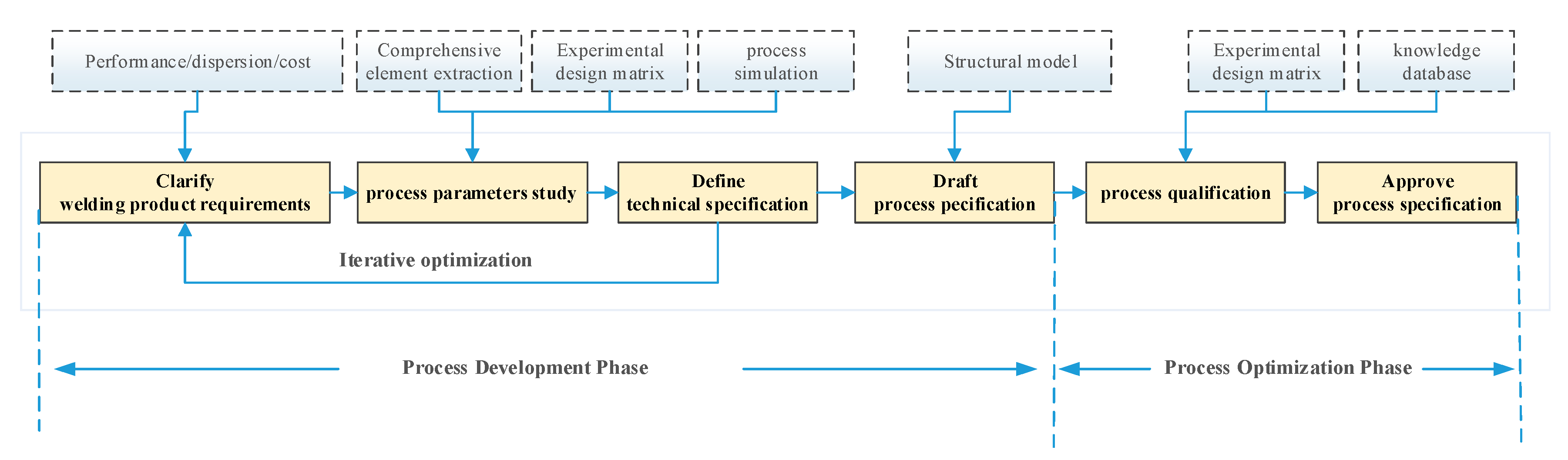

3. Knowledge-Driven WPS Validation

3.1. Standard Validation Workflow

- −

- Standardized process requirements;

- −

- Parameter ranges;

- −

- Performance dispersion characteristics;

- −

- A process knowledge database.

- −

- Development phase focuses on fundamental parameter establishment;

- −

- Optimization phase verifies production applicability through representative components.

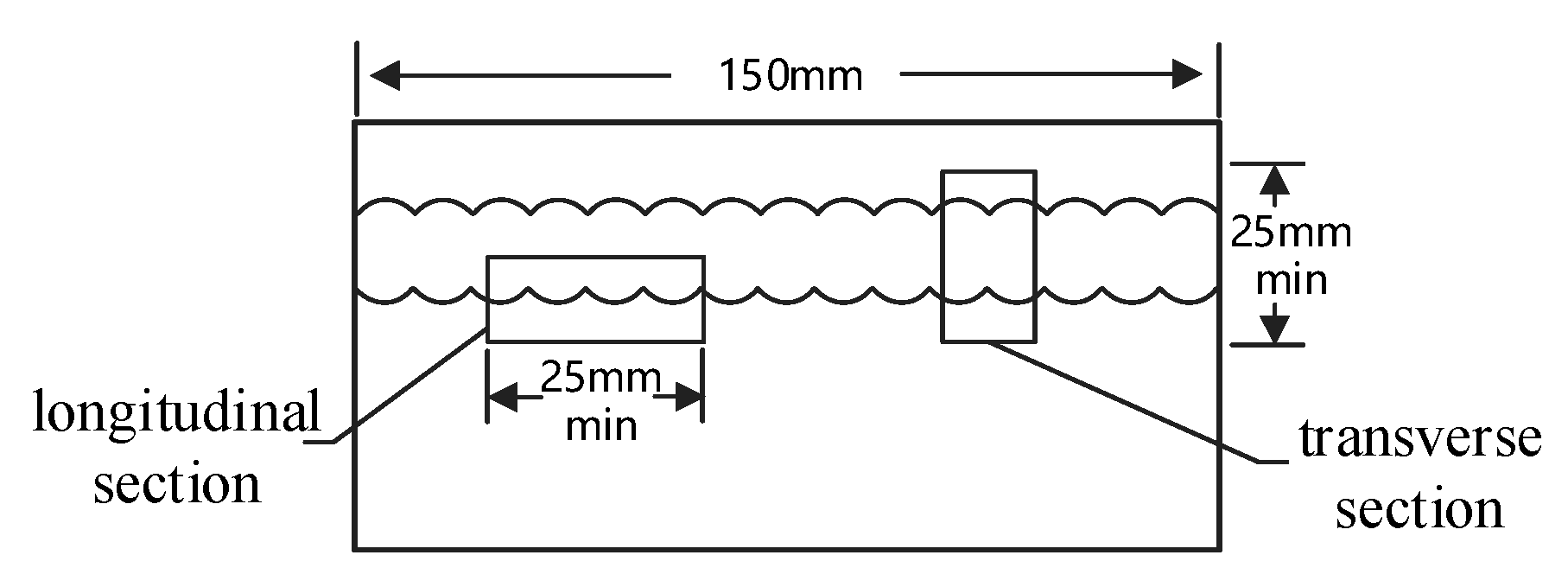

3.2. Key Indicator Acquisition Method

| Process Method | Weld Class | Minimum Sample Quantity | ||||

|---|---|---|---|---|---|---|

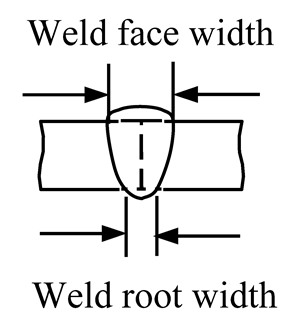

| Tensile Properties | Radiographic Inspection | Weld Microscopic a | Weld Macroscopic b | Weld Width c | ||

| Laser Welding, Electron Beam Welding, etc. | I | 10 | All | 5 (3 transverse, 2 longitudinal) | — | 3 (Refer to Table 2) |

| II | 5 | — | — | 3 (1 transverse, 2 longitudinal) | — | |

| III | 3 | — | — | 2 (1 transverse, 1 longitudinal) | — | |

| Material Thickness (mm) | Weld Face Width Max (mm) | Weld Face Width Min (mm) |  |

|---|---|---|---|

| ~0.8 | 0.8 | 0.5 | |

| 0.8~1.2 | 1 | 0.8 | |

| 1.2~2.5 | 1.2 | 1 | |

| 2.5~5 | 1.5 | 1 | |

| 5~8 | 2 | 1.2 | |

| 8~20 | 2.2 | 1.5 | |

| 20~ | 2.5 | 1.8 |

3.3. Validation Result Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alhajhamoud, M.; Al-Sayyed, A.; Alkattan, M.; Candan, L.; Cinar, I.; Vukotić, M.; Corović, S.; Miljavec, D.; Kayahan, E. Laser welding of Ti6Al4V titanium alloy in air and a water environment. Materials 2022, 15, 9088. [Google Scholar] [CrossRef]

- Fakhri, M.S.; Al-Mukhtar, A.M.; Mahmood, I.A. Comparative study of the mechanical properties of spot welded joints. In Materials Science Forum; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2022; Volume 1079. [Google Scholar]

- Li, Y.; Xiong, M.; He, Y.; Xiong, J. Multi-objective optimization of laser welding process parameters: The trade-offs between energy consumption and welding quality. Opt. Laser Technol. 2022, 149, 107861. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Xu, G. A Method for Establishing Process Specifications in Process Industries Based on Statistical Process Control. J. Mech. Eng. 2019, 55, 208–215. [Google Scholar] [CrossRef]

- Zheng, Q.; Lv, R.; Cui, B.; Zuo, R. A Process Knowledge Generalization Based on Standardized Expression of Process Data. China Mech. Eng. 2025, 3, 1–13. Available online: https://link.cnki.net/urlid/42.1294.TH.20250310.1748.005 (accessed on 6 November 2025).

- Elangovan, K.; Balasubramanian, V.; Valliappan, M. Effect of tool pin profile and tool rotational speed on mechanical properties of FSW AA6061. Mater. Manuf. Process. 2008, 23, 251–260. [Google Scholar] [CrossRef]

- Padmanaban, G.; Balasubramanian, V. Optimization of laser beam welding process parameters to attain maximum tensile strength in AZ31B magnesium alloy. Opt. Laser Technol. 2010, 42, 1253–1260. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Peyre, P. Yb-YAG laser offset welding of AA5754 and T40 butt joint. J. Mater. Process. Technol. 2015, 223, 139–149. [Google Scholar] [CrossRef]

- Li, L.; Liu, D.; Liu, J.; Zhou, H.G.; Zhou, J. Quality prediction and control of assembly and welding process for ship group product based on digital twin. Scanning 2020, 1, 3758730. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Jing, X.; Lu, X.; Liu, J.; Li, H.; Cao, X.; Du, C.; Li, J.; Li, L. Process knowledge graph modeling techniques and applications methods for ship heterogeneous models. Sci. Rep. 2022, 12, 2911. [Google Scholar] [CrossRef] [PubMed]

- Guan, K.; Du, L.; Yang, X. Relationship extraction and processing for knowledge graph of welding manufacturing. IEEE Access 2022, 10, 103089–103098. [Google Scholar] [CrossRef]

- AWS B2.1; Standard for Welding Procedure and Performance Qualification S. American Welding Society (AWS): Doral, FL, USA, 2021.

- ISO 15614-1; Specification and Qualification of Welding Procedures for Metallic Materials—Welding Procedure Test—Part 1: Arc and Gas Welding of Steels and Arc Welding of Nickel and Nickel Alloys S. International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- Su, P.; Zou, X.; An, L. Research on Quality Evaluation of Standard Source Data for the Digital Construction of Civil Aircraft Assembly Process Specifications. Inf. Technol. 2024, 11, 36–46. Available online: https://journals.istic.ac.cn/qbgc/ch/reader/view_abstract.aspx?file_no=202404004 (accessed on 6 November 2025).

- Soltan, H.; Abdel-Monem, A.; El-Tantawy, R. A roadmap for selection of metal welding process: A review. Weld. World 2022, 66, 2075–2108. [Google Scholar] [CrossRef]

- ISO 13919-1:2019; Electron and Laser-Beam Welded Joints—Requirements and Recommendations on Quality Levels for Imperfections—Part 1: Steel, Nickel, Titanium and Their Alloys. International Organization for Standardization (ISO): Geneva, Switzerland, 2019.

- Montgomery, D.C. Introduction to Statistical Quality Control; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- ISO 22514-1; 2014 Statistical Methods in Process Management—Capability and Performance—Part 1: General Principles and Concepts. International Organization for Standardization (ISO): Geneva, Switzerland, 2014.

| Cpk Range | Grade | Process Capability Evaluation Reference |

|---|---|---|

| Cpk ≥ 1.67 | I | Excellent welding process capability, indicating superb processing performance |

| 1.67 > Cpk ≥ 1.33 | II | Fully capable welding process, demonstrating strong processing performance that should be maintained |

| 1.33 > Cpk ≥ 1.0 | III | Adequate welding process capability, showing marginal processing performance that requires improvement |

| 1.0 > Cpk ≥ 0.67 | IV | Insufficient welding process capability, failing to meet product quality requirements |

| 0.67 > Cpk | V | Critically inadequate welding process capability, requiring immediate corrective actions and comprehensive inspection |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Li, G.; Zeng, Y.; Wang, X.; Lyu, X.; Cao, Y. Research on the Structural Model of Welding Process Specifications for Aviation Products Based on Trade-Off Design. Standards 2025, 5, 31. https://doi.org/10.3390/standards5040031

Wang X, Li G, Zeng Y, Wang X, Lyu X, Cao Y. Research on the Structural Model of Welding Process Specifications for Aviation Products Based on Trade-Off Design. Standards. 2025; 5(4):31. https://doi.org/10.3390/standards5040031

Chicago/Turabian StyleWang, Xichang, Guangli Li, Yuansong Zeng, Xufeng Wang, Xiaochun Lyu, and Yukun Cao. 2025. "Research on the Structural Model of Welding Process Specifications for Aviation Products Based on Trade-Off Design" Standards 5, no. 4: 31. https://doi.org/10.3390/standards5040031

APA StyleWang, X., Li, G., Zeng, Y., Wang, X., Lyu, X., & Cao, Y. (2025). Research on the Structural Model of Welding Process Specifications for Aviation Products Based on Trade-Off Design. Standards, 5(4), 31. https://doi.org/10.3390/standards5040031