Abstract

Background: This paper examines how logistics mangers increase performance by incorporating VAS in their distribution centres in the context of different natures of customer demand. The study is underpinned by the principles of lean and agile strategies as two key concepts that can be applied to respond to different customer expectations. Methods: Based on the phenomenological interpretivist paradigm, an empirical multiple-case study was conducted in German distribution centres operated by six companies. The empirical data were collected through semi-structured interviews, built on the triangulation of sources. Open, axial, and selective coding were employed to analyse data collected through eighteen in-depth interviews with managers from the distribution centres. Results: The findings indicated that the construct of customer demand forms different benefits that the logistics service providers can achieve through VAS. Simultaneously, various customer demands on VAS requires the distribution centres to focus on developing different operational capabilities to gain superior performance. Conclusions: Based on the research findings, a conceptual model was created. This model can support logistics service providers in improving company performance through effectively managing VAS in their distribution centres. The high dynamic VAS customer demand can bring more financial and non-financial benefits but needs higher flexibility in the warehouse operation system. Stable and predictable VAS, in turn, require a higher degree of standardisation.

1. Introduction

Well-organised logistics operations are one of the main criteria of superior company performance [1]. Thus, the performance of logistics service providers is crucial for the entire supply chain. In this context, the central element of achieving high performance is the distribution centre, whose function is to “… accumulate and consolidate products from various points of manufacture within a single firm, or from several firms, for combined shipment to common customers…” [2] (p. 3).

“Inbound”, “storage”, and “outbound” operations can be considered the main activities which underpin the flow of goods within distribution centre facilities [3]. However, apart from these traditional warehouse operations, different customer-specific services can also be performed in distribution centres. These services are often referred to as value-added services [4,5,6], with other terms such as value-added processing [7] or value-added logistics [3].

Provision of different VAS leads to an increase in customer satisfaction, demarcation from competitors, and higher returns [8,9,10]. Moreover, a higher capability of logistics service providers to manage different VAS can positively contribute to their performance [11,12] as well as to the performance of their customers [13,14]. Hence, it is no surprise that the availability of VAS in the portfolio of LSP is one of the major factors when choosing a logistics service partner [15]. Over the past decades, numerous surveys and studies have confirmed that incorporating different VAS in distribution centres is an increasing trend [9,16,17,18,19].

A high diversity of customer requirements; however, can lead to a higher degree of complexity in warehouse processes [20,21,22,23]. This complexity implies difficulty in forecasting needed resources or avoiding the interruptions of the material flow within distribution centres. Thus, such complexities challenge maintaining high efficiency in operational processes. To achieve a high level of performance with dynamic customer demands, the warehouse management structure needs to be adapted to the context of customer demand [24]. Furthermore, distribution centres need to develop those supply attributes which can make it possible to respond to customer demand adequately [25]. It can be suggested that VASs lead to an increase in the heterogeneity of customer demands in distribution centres, as these services are characterised by a high degree of customisation [8]. The VAS customer demand needs to be deeply understood by the logistics service providers [26]. Therefore, to ensure a sufficient level of company performance by offering different VASs, it is important that customer demand is responded to by logistics service providers in the most appropriate way.

Lean and agile concepts are two commonly adopted strategies that managers should refer to, depending on the context of action [27]. Leanness implies “developing a value stream to eliminate all waste, including time, and to ensure a level schedule…” [28] (p. 108), whereas agility can be described as “…the ability to efficiently change operating states in response to uncertain and changing demands placed upon it” [29] (p. 443). Based on the framework of lean and agile paradigms, the research aim is to understand how logistics managers align their strategy to increase performance with the different natures of VAS customer demand in distribution centres.

2. Literature Review

2.1. Definitions of VAS

Value-added services (VAS) are customer-specific services; therefore, it is difficult to provide a universal definition of the term. According to Berglund [30], for example, VAS in the logistics context can be understood as… “services that add extra features, form, or function to the basic service” (p. 83). Bowersox and Closs [31] suggested that the term VAS can be demarcated into five performance areas: customer-focused (e.g., customised labelling or packaging, such as packing the products into special bins according to the OEM standards, to supply customers of the automotive industry), promotion-focused (e.g., making point-of-sales displays), manufacturing-focused (e.g., postponement assembly), time-focused (e.g., just-in-time), and basis service (e.g., reverse logistics or quality control). The logistics service providers; however, can also develop different types of VASs that go beyond these five categories. According to Soinio, Tanskanen, and Finne [32], for example, services such as ”3PL with planning”, “consulting”, and “outsourced chief logistics officers” can also be offered by logistics service providers. Herrera and Yang [10] suggested that in the case of “non-material” VAS, logistics service providers can extend their service portfolio with VAS such as IT assistance, e-commerce, purchasing, consulting, or financial support. Shi et al. [33] and Shi, Arthanari, and Wood [34], in turn, highlighted third-party purchasing (TPP) as a potential type of VAS.

These VAS definitions concern the field of logistics in general and, therefore, are more appropriate when considering this term at the level of a logistics service provider. A more distribution centre dedicated demarcation of VAS was proposed by Furmans and Deml [9] (p. 20):

“… Value-Added-Services in distribution centres are all additional services that go beyond classic warehouse activities such as product receiving, storage, order picking, packaging and shipping.”(Translated from German by authors).

This definition refers to the material-related VASs (e.g., customised packaging, kitting, labelling, small assembly). A frequent reason for developing such services on the site of logistics service providers is the requirement that production companies strive to place different VAS at the last possible stage of the supply chain, which is often located in the distribution centre. This approach refers to the so-called postponement strategy, which implies a delay in the final processing or manufacturing activities to the latest possible decoupling point in the supply chain in order to respond to customer demands in the most appropriate way [35]. This strategy can provide both cost reduction by lower inventories [36] and higher efficiency by increased flexibility [37].

According to Furmans and Deml [9], apart from material-related services, VAS in distribution centres can also be associated with information-related activities. In this respect, Furmans and Deml [9] mentioned the invoicing and organisation of transport as possible VASs that can be performed in distribution centres.

2.2. Lean and Agile in Warehouse Logistics

Previous studies in the field of warehouse logistics indicated that customer demand in distribution centres can be quite heterogeneous, making it necessary to develop different supply attributes depending on each specific business case. Anderson et al. [38], for example, showed that for some clients of LSPs, price is the vital component, while other companies attached more importance to the delivery performance. Mokadem [39] concluded that if manufacturing companies pursue a lean strategy, they will select suppliers who can help to improve efficiency, while the companies that are focused on an agile strategy will give preference to suppliers who can contribute to their responsiveness.

Examining the literature concerning lean and agile paradigms in the context of warehouse logistics, it becomes clear that the lean paradigm remains a dominant researched concept. Many contemporary studies continue to indicate the opportunity for performance increase by applying different lean methods in the warehouse logistics environment [40,41,42]. Moreover, the positive effects of a lean approach for warehouse logistics were recently investigated by Abushaikha, Salhieh, and Towers [43], who identified the causal relationship between waste reduction based on the lean strategy and warehouse operational performance.

On the other hand, the concept of agility seems to also be important in the warehouse logistics field. The adoption of agile supply attributes across the supply chain leads to a situation where the distribution centres need to be able to adequately support such strategies. For example, the responsive supply chain strategy may require an increase in warehouse stock in order to respond to the customer demand, which would mean that distribution centres must be able to provide a higher storage capacity [44]. In turn, the result of a study by Jermsittiparsert, Sutduean, and Sriyakul [45] shows that the warehouse attributes in terms of responsiveness can play a significant role in the performance of warehouses. A statistical analysis indicated that the ability to quickly respond to customer orders can contribute to warehouse supply chain efficiency. In this respect, Baker [46] provided a framework that can support distribution centre capability in aligning themselves to perform in an agile environment.

Several studies indicated the importance of aligning warehouse strategies with the customer demand [21,24,25,47]. However, when considering studies dealing with the strategic aspects of distribution centres, it becomes clear that they are mainly focused on the traditional warehouse operations such as storage, pick, pack, and ship activities [48,49,50,51]. The few studies on VASs which explore the performance of VASs from the perspectives of logistics service providers are presented below.

2.3. VAS Research

Soinio, Tannskanen, and Finne [32]; Lv and Chen [52]; and Shi, Arthanari, and Wood [34] are concerned with more strategic perspectives of developing peculiar types of VAS which go beyond the border of the physical supplementary activities. Protic et al. [53], Andersson and Roso [54], and Menegaki and Alexopoulos [55] investigate VAS opportunities in specific industrial contexts beyond the frame of warehouse logistics. Tang, Qian, and Wang [56] deal with the understanding of the role of VAS in a specific geographical context (Yunnan Province in China).

Some studies are quantitative in nature and strive to identify causal relationships between different factors in the context of VAS. For example, Chen and Notteboom [57,58,59] deal with the effects of the VAS characteristics on the decision regarding the location of VAS. Rivera, Sheffi, and Knoppen [6] showed that within the context of logistics clusters, agglomeration in logistics parks and training can positively impact the provision of VAS. Okorie, Tipi, and Hubbard [14] provided evidence for the increase in port attractiveness by a higher range of offered VASs. Russo and Gronalt [60] find out that offering VASs can positively impact the performance of intermodal inland terminals.

By contrast, the studies by Atkacuna and Furlan [5], Furmans and Deml [9], Herrera and Yang [10], and Jum’a and Basheer [61] are more explorative in nature and based on the data gathered through surveys and interviews of managers of logistics service providers (and their customers). These studies are concerned with the performance of VAS in distribution centres from the perspectives of logistics service providers and thus provide a valuable basis for this particular study. A summary of previous studies on VASs in logistics is shown in Table 1 below.

Table 1.

Previous Studies on VAS in Logistics.

2.4. Research Gap

The limitation of previous studies refers to the fact that the nature of customer requirements explored by VAS performance in distribution centres was generalised. Thus, some conclusions derived from previous studies need to be further verified. Firstly, previous studies provide evidence that VAS can provide LSPs with a number of different advantages and also bring a higher degree of complexity into warehouse processes, which can lead to a decrease in efficiency. However, these effects can be different depending on the context and the different nature of customer demands. Secondly, existing research suggests that improving leanness and agility is an appropriate strategy for distribution centres. Yet, in this case, the characteristics of customer demands can require a different strategic focus. Thus, this study strives to gain a new insight into the scientific knowledge on VAS performance by answering the following research questions:

- -

- What benefits can distribution centres gain by incorporating VAS with different customer demands?

- -

- How can distribution centres increase the performance of VAS with different customer demands?

3. Theoretical Modelling

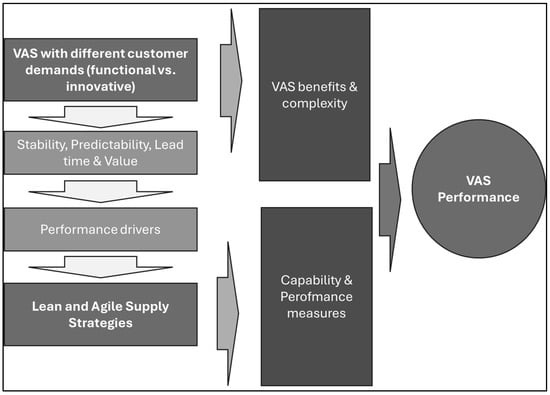

The underlying basis of developing a conceptual framework is a detailed analysis of the knowledge gained by conducting the literature review on the topic in question. Key topics and issues that stem from the literature review represent different theoretical concepts which are transformed into one model. The key variables of the explored topic are VAS performance in distribution centres and supply strategies, which are connected by the concept of customer demand.

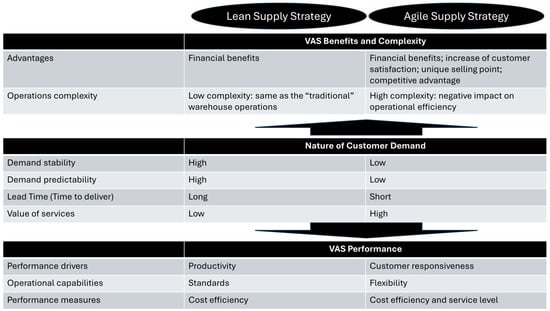

The differing nature of customer demand is attributable to different characteristics of the products or services, which are either “functional” or “innovative” [62]. The “functional” or “innovative” products and services have different characteristics of customer demand, which can be determined by criteria such as demand stability, demand predictability, lead time, and value of the customer orders [59,63,64]. These two types of products and services require different strategies, which are typified by the application of different capabilities [65] and different performance measures [66,67,68].

The conceptual framework was determined based on this theoretical paradigm and serves as an underpinning construct for further development of the data collection procedure shown in Figure 1 below.

Figure 1.

Conceptual Framework.

This leads us to the following three research objectives which are as follows:

- To understand the different characteristics of VASs in warehouse logistics depending on the nature of customer demands.

- To identify the supply strategies necessary to respond to VAS customer demand in DC.

- To investigate how managers of distribution centres align operational strategies to VAS capability performance.

4. Methodology

4.1. Research Paradigm

As there is no prior theory on the supply strategies in the context of VAS performance in distribution centres, the research aim is explorative in nature. This research highlights the necessity to gain knowledge and insight through understanding the perspective of logistics experts on the performance of VASs in distribution centres with different customer demands. In this way, this study is not striving to achieve a generalisable result but is rather attempting to comprehend the underlying construct of VAS performance realities using an inductive-based approach. The perspectives of phenomenological interpretivism served as a basis for the research design of this study as it provided greater-detailed insight into the subject under investigation [69]. These perspectives make it possible to understand the explored issues within their contexts. As a result, a qualitative multiple case study was chosen as the research strategy for the empirical process. In terms of data collection and analysis, the method of semi-structured interviews by a quota sampling technique and a grounded analysis procedure were determined to be the most suitable approaches.

4.2. Research Sampling

This study aimed to obtain the necessary empirical data to acquire an extensive knowledge of the topic of VASs in distribution centres. Therefore, it was crucial that the design of research sampling groups considers different perspectives, adopting a triangulation of sources approach. For this purpose, principles of the triangulation method were applied. Triangulation in research implies the collection of data by multiple methods or use of multiple data sources in order to gain a greater understanding of phenomena [70]. Hence, the procedure of including different experts in the interview process was not a random approach but was based on predetermined types of research participant groups. Such a strategy made it possible to collect data from different expert groups with heterogeneous attributes. Following this strategy, three groups of experts, namely “distribution centre managers”, “customer managers”, and “operations managers” were determined for the purpose of gathering data.

The distribution centre managers group included those company experts who have overall responsibility for one or more distribution centres in their organisations. In some cases, such managers are logistics unit leaders, in others these managers can be in the role of CEO or even owner of the company. The data collected from these groups of research participants made it possible to gain an understanding of how distribution centre executives perceive the contribution of supply attributes in the performance of VASs in distribution centres and hence, to consider the strategic perspectives of logistics service providers.

The group of research participants defined as customer managers consisted of managers in charge of handling customer demand. Therefore, those managers who interact with customers on daily business-related or project-related levels were selected for this particular group. Including managers with a wide customer expertise in the process of data collection helped this study gain a better understanding of customer perspectives on the topic.

The research participants group, operations managers, in contrast, included managers who are partly or fully responsible for the daily operational process in terms of VASs in distribution centres. This group consisted of different operational supervisors, such as operations managers, warehouse managers, or team leaders. The data gathered from this group of research participants helped this study to understand the operational practises in distribution centres and see how distribution centres align their strategy with customer demands in order to achieve superior VAS performance.

4.3. Semi-Structured Interviews

The creation of interview questions was based on the reflection of the research objectives and the conceptual framework. As a result, each of the developed interview questions was linked to one of three research objectives and the content of the questions addressed the concepts represented in the conceptual framework. In order to justify and refine the questions before gathering the necessary data, pilot interviews with three managers (who were not included in the main process of data collection) were carried out. The aim of the pilot interviews was to understand how appropriate the questions were and which adjustments were necessary before proceeding with the main stage of data collection. Based on this approach, thirteen final interview questions were determined shown in Table 2 below.

Table 2.

Interview Questions.

4.4. Data Analysis

For the purpose of data analysis, the attributes of the company experts participating in this study were pre-coded. The managers of the six companies were coded as “C” (for company), followed by the company number. The roles of the managers in their organisation, namely distribution centre manager, customer manager, and operations manager, were accordingly referred to as “DM”, “CM”, and “OM”. Thus, the combination of company codes and manager roles represented the coded attributes of the research participants (Table 3).

Table 3.

Attributes of Research Participants.

The analysis of data was based on the coded procedure, which included an analysis of the transcribed interviews according to open, axial and selective coding steps [71]. In the first step of analysis, transcripts unloaded in Nvivo were read line-by-line and conceptualised as Open Codes. Additionally, ‘Word Cloud’ and ‘Word Tree’ tools were utilised. In the second phase of the data analysis, the open codes were transformed according to an axial coding procedure. This means that some open codes with similar characteristics were created as one code, thus reducing the overall number of codes. These new codes were used to analyse the data in the context of the predefined attributes represented. In the last phase of the data analysis, selective coding, the main concept of the analysed data was identified, and the other codes were logically connected to this concept.

4.5. Data Saturation

The selection of companies in this study was conducted via a random approach, whereby two selection criteria needed to be fulfilled. Firstly, the company operated its own distribution centres, and secondly, different types of VASs were performed in these centres. To maintain confidentiality as part of the ethical principles underlying this research, the actual names of the companies were coded (Company 1, Company 2, etc.).

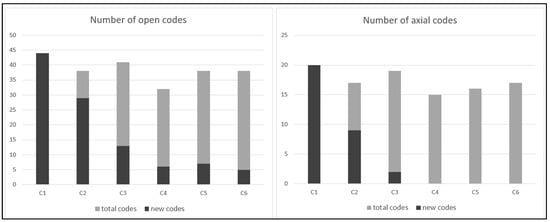

The number of companies included in the data collection was determined by data saturation. Generally, data saturation refers to the idea that the data collection process can cease when the last analysed data do not provide new information [72]. Thus, on identifying that the empirical data would not lead to new codes, the collection of data in this study was completed, as shown in Figure 2 below. The main indicator of data saturation was the lack of new codes identified during an evaluation of the codes created using the axial coding procedure. Indeed, there were a few new open codes that could be derived from previous transcripts. However, when it came to the level of axial coding, no new codes were identified after the data of Company 3 had been examined. Fundamentally, this means that the data from Company 4, Company 5, and Company 6 provided no new concepts in the context of axial coding. Therefore, the data collection was terminated, and the case size of this empirical study was restricted to these six companies.

Figure 2.

Data Saturation.

4.6. Companies

Company 1 is a US manufacturing corporation specialising in motion and control technology. At the time of data collection, around 60,000 people were working for this company worldwide. The company runs its own distribution centres, where the finished products are stored and shipped to the distributor or to the end customers. The distribution centre which took part in this particular study is a central distribution centre of EMEA logistics chain of Company 1 (EMEA: Europe, the Middle East, and Africa.) This distribution centre mainly focuses on storage activities, although different supplementary logistical services are also performed in this distribution centre. The portfolio of VASs in this distribution centre can be divided into two groups: different “postponement” activities which are triggered by the production sites of Company 1, who outsourced their storage operations, and VASs which are driven by the OEM business requirements. Activities such as “kitting”, “relabelling”, and “repacking” are the most frequently performed VASs in this distribution centre. While Company 1 is a production enterprise, the other five companies involved in this study are third-party logistics (TPLs).

Company 2 is a relatively small TPL with about 230 employees that concentrates on offering different logistics solutions. The distribution centre in this study is one of three distribution centres this company is operating in Germany. The distribution centre of Company 2 participating in this study is driven by various customised services. Thus, the main driver of the company turnover is not simple warehousing but VASs. Apart from relabelling and repackaging, different rework activities such as inlaying country-specific power cords or warranty cards are among the VASs offered in this distribution centre.

Company 3 is a big, international service enterprise. This company owns 85 locations in 20 countries with more than 70,000 associates worldwide. Apart from CRM, IT, and finance fields, logistics are considered an important segment of Company 3. When it comes to logistical solutions, the company is active in different industries like fashion, tech, healthcare, telecommunication, and automotive. The distribution centre participating in this study is the largest logistics location where the products of all these industries are represented. The VASs in form of “postponement” activities are performed in the distribution centres of Company 3.

Company 4 is a family enterprise and resembles mid-size TPLs, with around 4,500 workers in 42 locations throughout Germany, Europe, the United States, and the Arabian Peninsula. Both transport logistics and warehouse logistics are included in the portfolio of the company’s services, which are offered in different business segments. The distribution centre, which was the primary focus of this particular study, concentrates on the storing and distribution of products from the field of trade logistics. Apart from the simple labelling and packaging VAS, the range of VASs offered in this distribution centre includes quality control, which occurs in the inbound as well as in the outbound areas.

Company 5 is a TPL which owns 10 logistics sites in Germany with a large logistics surface and its own fleet. This company it has its biggest focus on the e-commerce fulfilment business and can be seen as a fast-growing company. The range of VASs offered in the distribution centre used for the data obtainment process is quite wide. Primarily, the activities run in this distribution centre in terms of VASs include services such as the pre-assembly, refinement, and neutralisation of the products which are stored in this warehouse.

Company 6 is a TPL which is known in Germany as an expert in transport logistics. The difference between Company 6 and the other five companies in question is that this company has long-term experience in transport logistics but can be seen as a relatively new player in terms of warehousing. Today, the company strives to develop different logistics services for their customers. The distribution centre included in this study represents a location where outsourced warehouse activities from a customer are carried out by Company 6. As this type of logistics service is quite novel for Company 6, there is no fixed portfolio of VASs provided by this distribution centre. Indeed, the development of VASs can be seen as an ongoing learning process in this distribution centre. The main part of such VASs includes basic supplementary activities, such as customised labelling and packaging.

5. Results of Data Analysis

The process of gathering data from these six companies involved conducting eighteen interviews with the managers of the distribution centres. Some interviews were undertaken at the company whilst others were carried out using Microsoft Teams software because of access restrictions caused by the COVID-19 pandemic. All interviews were documented via an audio recorder and then transcribed. The analysis of the transcripts was underpinned by the open, axial, and selective coding procedures.

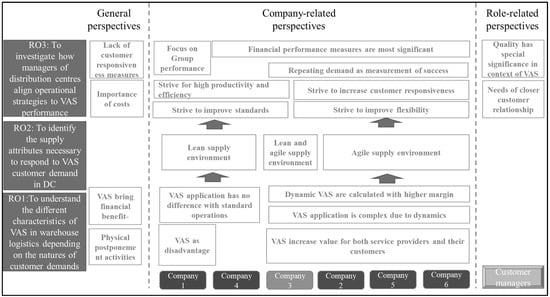

As a result of open coding, 104 codes were developed with the assistance of Nvivo software. Grouping these codes according to their similarity led to the transformation of the codes to axial codes (See Appendix A). The final analysis of these codes in the context of research participant attributes (company and function of managers) showed that these codes could be grouped according to the “general”, “company-related”, “role-related”, and “individual” perspectives.

The axial codes and their grouping were used for the selective coding process. In this context, the nature of customer demand, which (according to company-related codes) varies between different distribution centres, was determined as the central concept of the coded data. In particular, the nature of customer demand in the distribution centres of Company 1 and Company 4 is connected with the “lean business environment”. This means that the VASs in their distribution centres are associated with rather stable and predictable demand. In contrast, the nature of customer demands in the distribution centres of Company 2, Company 5, and Company 6 was associated with the “agile business environment”, as the customer demand for VASs tends to be unstable and unpredictable. In turn, the nature of customer demand for VASs in the distribution centres of Company 3 depends on the particular business case.

Based on the concept of lean and agile environments, all other codes regarding the category of “company-related perspectives” were integrated into the scheme of selective coding. Additionally, the codes concerning “general perspectives” and “role-related perspectives” were also placed into this scheme. Moreover, the codes were structured according to the research objectives. Following this approach, a final scheme of the selective coding procedure was developed, as shown in Figure 3 below. The final scheme highlighted the research findings, which provide novel contributions to the knowledge about VASs in distribution centres.

Figure 3.

Results of Data Analysis—Final Scheme.

6. Findings

6.1. Research Objective 1

The nature of customer demand has a general impact on the expectations of advantages linked to VAS incorporation. While the financial advantages were generally perceived as the most crucial aspect of VAS application, the role of non-financial benefits, according to the research findings of this study had a more contextual nature. The research findings indicated the alignment between the construct of customer demand and the opportunity to gain marketing advantages such as “unique selling point”, “customer loyalty”, or “competitive advantages”. These points were only highlighted by the managers of distribution centres dealing with more dynamic customer orders. Therefore, it can be concluded that the concept of agility in the context of the construct of customer demand is a crucial factor, which enables logistic service providers to gain different non-financial benefits by providing VASs. This conclusion is a novel view on the question of what capability advantages VASs can have for logistics service providers. While the non-financial value-added advantages of applying VASs were previously considered as an objective effect [5,8,10], the results of this study contradict this position by emphasising the importance of a contextual perspective on this topic.

Moreover, according to the empirical data, different contexts in which VASs in distribution centres are performed can also impact how managers see the possible increased complexities of their operational processes. While previous researchers considered how and what impact the application of different services in warehouse logistics can have [20,22,23], this study identified under which conditions this effect might occur. In particular, it was identified that the level of complexity of VAS applications is linked to the nature of customer demand. This conclusion is based on the fact that in response to the interview questions, the increased complexity was not understood by DC managers focusing solely on cost but was only understood by those operating in an agile customer focused environment. This perspective provides a new contextual insight to the discussion of the possible negative effects that can result from the application of VASs in cost-driven warehouse operations.

6.2. Research Objective 2

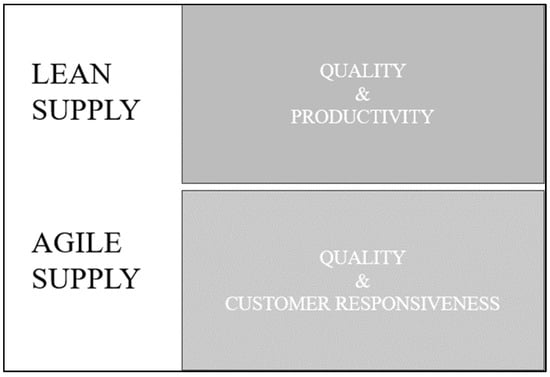

The outcomes of this study showed that different managers focused on different strategies when performing VASs in their distribution centres. According to the research findings, one of the factors that influenced manager positions was specific to the VAS business of each distribution centre taking part in this study. The managers of some distribution centres stressed productivity as the most decisive aspect of the VAS’ performance. Others, in contrast, emphasised the necessity of being able to react quickly to VAS customer orders. A third group suggested that it is crucial to focus on both aspects when supplying VAS. Such different positions, in turn, correlated with different structures of VAS customer demand in different distribution centres. Thus, productivity was highlighted by the managers of those distribution centres dealing with stable and predictable customer orders. The aspect of customer responsiveness, in contrast, was pointed out by the managers who were faced with more dynamic customer demand. Therefore, the findings of this study clearly indicated that the fundamental principles of Fisher’s theory [62] of the supply attribute’s alignment with the customer’s demand is a crucial component of VAS supply strategies in distribution centres.

Additionally, the research findings indicated that the aspect of quality plays a significant role in the context of VAS performance in distribution centres independent of the nature of customer demand. Such perspectives were primarily provided by the company experts who were referred to as customer managers in this study. The managers stressed that the issue of quality always requires a special consideration in the context of VAS as such services have a higher degree of diversity and customisation in contrast to traditional warehouse operations.

Thus, when considering the VAS supply attributes in distribution centres in the context of the concept of “market winners” [73], the “VAS lean supply” area includes “quality” and “productivity”, while in the area of “VAS agile supply” these are “quality” and “customer responsiveness”, as shown in Figure 4 below. As there is no prior theory in the context of the VAS supply attributes in distribution centres, this model represents a novel theoretical contribution.

Figure 4.

Market Winners in the Context of VAS in DCs.

6.3. Research Objective 3

The research findings indicated that in terms of adopting capabilities, two fundamental concepts of lean and agile strategies are integrated into the operational strategies of distribution centres. In particular, the interpretation of the data showed that the managers of distribution centres that focus on productivity highlighted the concept of standard as the most important element in their operations when performing VASs. The managers of distribution centres that focus on customer responsiveness performance identified different aspects of flexibility (flexibility in manpower, place, and methods) in providing solutions to changing customer requirements as the most significant criterion of success. The capabilities of distribution centres that develop solutions according to either cost or VASs are seen as a focus on standardisation or on flexibility as two contradictory approaches of operation. This means that that adoption of lean cost-driven warehousing principles for the purpose of efficiency increase suggested by the previous studies [40,41,42,43] only has limited relevance in the context of VAS performance in distribution centres.

Moreover, research findings showed that distribution centres independent of their performance aims are mainly cost driven in the context of VAS performance measurements. This is evident from the fact that all company experts emphasised the importance of the cost efficiency measures in their distribution centres and, at the same time, indicated the lack of performance measures relating to customer responsiveness. Such a conclusion corresponds with the result of the study by Laosirihongthong et al. [47], who explored the significance of different performance measure categories in warehouses of “manufacturing”, “TPLs”, and “retailers”, and found that the categories related to the costs are the most dominant. While the study by Laosirihongthong et al. [47] considered the performance measures of warehouse operations in general, this study indicated that the cost measures in the particular context of VASs in distribution centres are also dominant. Therefore, the research findings suggested that distribution centres dealing with innovative VASs have some areas for improvement in terms of their performance measurements relating to customer responsiveness.

6.4. Reflected Conceptual Framework

Based on the reflection of the findings discussed above, a new framework of VAS performance in distribution centres was developed and presented in Figure 5 below. Three blocks presented in this framework (“VAS benefits and complexity, “nature of customer demand”, and “VAS Performance”) are in accordance with the reflexion of the findings relating to the three research objectives. The arrows in these blocks show how the findings are connected.

Figure 5.

Reflected Conceptual Framework.

Thus, the findings show that lean and agile supply strategies are two concepts that can be used to respond to VASs with different customer demand. The lean strategy is appropriate for working with more stable and predictable customer orders which need to be responded to by the standardisation and efficiency of processes. The agile concept, in contrast, is an adequate supply strategy for reacting to high dynamic demands. Such kinds of VASs are more beneficial, but require higher flexibility in terms of place, manpower, and method used.

7. Conclusions

This study developed a novel understanding of the underlying constructs of VAS customer demands and showed that an understanding of the nature of customer demand can help managers to increase performance by the incorporating VASs in distribution centres. The high dynamic VAS customer demand can bring more financial and non-financial benefits but needs higher flexibility in the warehouse operation system. Stable and predictable VASs, in turn, require a higher degree of standardisation. Thus, lean and agile supply strategies are two concepts that make it possible to respond to different VAS customer demands. The findings addressed the limitations of previous research and contributed a conceptual model that can support managers of distribution centres to improve performance by incorporating different VASs.

This study is limited by the principles of qualitative research, which imply that the research findings are context-specific in nature and cannot be generalised to all circumstances. Thus, a statistical evaluation of this topic in a broader context is required. Furthermore, as VASs in the ‘real’ business world are closely connected with the strategies regarding the ‘traditional’ services of distribution centres, further research on VASs in the context of the general business systems of distribution centres will be required too.

Author Contributions

Conceptualization, E.K., N.T. and K.B.; methodology, E.K., N.T. and K.B.; validation, E.K., N.T. and K.B.; formal analysis, E.K. and N.T. and K.B.; investigation, E.K., N.T. and K.B.; resources, E.K., N.T. and K.B.; data curation, E.K., N.T. and K.B.; writing—original draft preparation, E.K., N.T. and K.B.; writing—review and editing, E.K., N.T. and K.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data is not publicly available due to commercial confidentiality restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

| Axial Codes | Open Codes | No. of Interview Question |

| “Physical postponement activities” | “Customized, beyond standard”; “Physical change of outbound specification”; “Additional services”; “Technical quality check”; “Logistic quality check” | 1 |

| “VAS as disadvantage for internal logistic service provider”; | “Disadvantage for internal service provider (RO1_Q2)”; “Higher costs and less advantage”; “Disadvantage for internal service provider (RO2_Q7)”; | 3 |

| “VAS increase value for both service providers and their customers”; | “Customer loyalty”; “Unique selling point”; “Competitive advantage” | 2 |

| “VAS bring financial benefit” | “Financial benefit”; “Higher profit derived from VAS”; “High value” | 7 |

| “VAS application has no difference with standard operations” | “VAS as standard”; “No big challenge”; | 3 |

| “VAS application is complex due to dynamics” | “Dynamic workload”; “Time pressure”; “Heterogeneous, dynamic VAS”; “Quality issues through short lead time” | 3 |

| “Strive for high productivity and efficiency” | “Capacity planning accuracy”; “Lower productivity”; “Higher costs”; “Productivity (RO3_Q8)”; “Productivity is the main driver of competitive advantage”; “Productivity (RQ3_Q10); “Productivity (RQ3_11); “Productivity of new VAS”; “High productivity is necessary”; “Complexity of productivity evaluation”; “Strive to decrease costs” | 8 |

| “Quality has special significance in context of VAS” | “Quality issue”; “Quality emphasis”; | 8 |

| “Needs of physical and IT resources” | “Manpower”; “Adoptable IT systems”; “Place”; “Physical resources”; “Management team”; | 8 |

| “Needs of VAS knowhow” | “VAS expertise”; “Experts and expertise”; “Knowledge of product”; “IT expertise”; | 8 |

| “Needs of closer customer relationship” | “Understanding of customer needs”; “Closer customer relationship”; “Importance of tracking customers’ performance measures” | 8 |

| “Lean environment” | “Rather stable demand”; “Rather predictable demand”; “Rather long lead time”; | 4; 5; 6 |

| “Agile environment” | “Seasonality”; “Rather unstable demand”; “Rather less predictable demand”; “Unstable demand due to e-commerce”; “Rather short lead time”; “Order spontaneously”; | 4; 5; 6 |

| “Lean and agile environment” | “Stable and unstable depending on customer”; “Predictability depends on the customer”; “Long and short depending on the customer”; “Flexibility importance”; | 4; 5; 6 |

| “Strive to improve flexibility in operation process” | “Flexibility in manpower”; “Flexibility in process”; “Place flexibility”; | 8; 9 |

| “Strive to increase customer responsiveness” | “Acceptance of ad hoc customer orders”; “Reliability and on time delivery are more important than price”; “Ability of high customer responsiveness”; “Quick reaction”; “Quick reaction and attractive price at the same time”; “Quick implementation (price not important)”; “Quick implementation of VAS”; “Production time”; “No productivity per hours”; “Monitoring daily production progressing” | 8; 9 |

| “Strive to improve standard in operation process” | “Standard importance” | 8; 9 |

| “Strive to improve both standard and flexibility in operation process” | “Both standard and flexibility are necessary”; “Lean—productivity & quality vs. flexibility & quick reaction” | 8; 9 |

| “Importance of costs” | “Cost calculation”; “Ability to estimate effort”; “Yearly increase of fix costs” | 10, 11; 12 |

| “Financial performance measures are most significant” | “Financial performance”; “Impact on financial performance”; “Financial performance measures”; | 10, 11 |

| “Triangle performance measures” | “Cost measures” (RO3_Q10); “On time delivery measures”; “Quality measures”; “Quality, on time delivery, costs” (RO3_Q10); “Quality, on-time delivery, costs (RO3_Q12); “Cost measures” (RO3_Q12); “Service quality” | 10, 11 |

| “Customer feedback as measurement of customer satisfaction” | “Questionnaires (Surveys)”; “Customer feedback” | 13 |

| “Lack of customer responsiveness measures” | “No need to react quickly”; “No performance alignment”; “No customer responsiveness measures”; | 12 |

| “Repeating demand as measurement of success” | “Increasing demand of VAS”; “Repeating business” (RO3_Q10); “Repeating business” (RO3_Q13); | 13 |

| “Dynamic VAS are calculated with high margin” | “Higher costs are covered by price calculation”; “Dynamic VAS have higher value”; “Order simulation and time calculation”; | 7 |

| “Focus on Group performance” | “Supply chain planning accuracy”; “Performance categories determined by Group”; “Supply chain financial performance” | 10 |

| “Needs to go beyond standard as a challenge” | “Needs to go beyond standard” | 3 |

| “Wide range of VAS as a challenge” | “Wide range of VAS” | 3 |

| “Process determination as challenge” | “Process determination” | 3 |

| “Importance of tracking customers’ performance measures” | “Customers’ performance measures” | 10 |

| “Increasing demand as measurement of success” | “Increasing demand of VAS” | 13 |

References

- Rushton, A.; Croucher, P.; Baker, P. The Handbook of Logistics and Distribution Management; Kogan Page: London, UK, 2014; Volume 5. [Google Scholar]

- Frazelle, E. World-Class Warehousing and Material Handling; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Van Den Berg, J. Integral Warehouse Management: The Next Generation in Transparency, Collaboration and Warehouse Management System; Management Outlook: Utrecht, The Netherlands, 2007. [Google Scholar]

- Foulds, L.; Luo, Y. Value-added services for sustainable third-party warehousing. Int. J. Logist. Syst. Manag. 2006, 2, 194–216. [Google Scholar] [CrossRef]

- Atkacuna, I.; Furlan, K. Value-Added Services in Third-Party Logistics: A Study from the TPL Providers’ Perspective about Value-Added Service Development, Driving Forces and Barriers. Jönköping International Business School. 2009. Available online: http://www.diva-portal.org/smash/get/diva2:233689/FULLTEXT01.pdf (accessed on 1 June 2024).

- Rivera, L.; Sheffi, Y.; Knoppen, D. Logistics clusters: The impact of further agglomeration, training and firm size on collaboration and value added services. Int. J. Prod. Econ. 2016, 179, 285–294. [Google Scholar] [CrossRef]

- Bartholdi, J.; Hackman, S. Warehouse & Distribution Science; Supply Chain and Logistics Institute, School of Industrial and Systems Engineering, Georgia Institute of Technology: Atlanta, GA, USA, 2011. [Google Scholar]

- Bowersox, D.; Closs, D.; Cooper, M. Supply Chain Logistics Management; McGraw-Hill: New York, NY, USA, 2010; Volume 3. [Google Scholar]

- Furmans, K.; Deml, B. Systematische Bewertung von Value-Added-Services in Distributionszentren. Karlsruhe. 2014. Available online: https://www.bvl.de/files/1951/2125/2131/2133/Abschlussbericht_Projekt174836__SyVaDis.pdf (accessed on 1 June 2024).

- Herrera, A.; Yang, L. Understanding Value-Added Service Offering by 3PL Providers: VAS as a Source of Competitive Advantage for the Provider and the Customer; Jönköping University: Jönköping, Switzerland, 2017. [Google Scholar] [CrossRef]

- Ho, L.-H.; Chang, P.-Y. Innovation Capabilities, Service Capabilities and Corporate Performance in Logistics Service. Int. J. Organ. Innov. 2015, 7, 24–33. [Google Scholar]

- Aziz, Z.; Razak, R.; Hussin, N.; Yaacob, M.; Merican, R. The Relationship of Logistics Flexibility and Value-Added Capability on Logistics Performance in Logistics Services; University of Malaysia Kelantan: Kelantan, Malaysia, 2017. [Google Scholar]

- Tian, Y.; Elinger, A.; Chen, H. Third-party logistics provider customer orientation and customer firm logistics improvement in China. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 356–376. [Google Scholar] [CrossRef]

- Okorie, C.; Tipi, N.; Hubbard, N. Analysis of the potential contribution of value-adding services to the competitive logistics strategy of ports. Marit. Econ. Logist. 2016, 18, 158–173. [Google Scholar] [CrossRef]

- Langley, C. The State of Logistics Outsourcing 2007 third-party logistics. In Results and Findings of the 12th Annual Study; Capgemini, Georgia Institute of Technology: Atlanta, GA, USA, 2007. [Google Scholar]

- Straube, F. Trends und Strategien in der Logistik: Ein Blick auf die Agenda des Logistik-Managements 2010; Deutscher Verkehrs-Verl: Hamburg, Germany, 2005. [Google Scholar]

- Mayer, S.; Thirty, E.; Frank, C. 6 Europäische, A.T. Kearney-/ELALogistik Studie 2008/2009: Supply-Chain Excellence in der Globalen Wirtschaftskrise; European Logistics Association: Brussels, Belgium, 2009. [Google Scholar]

- Michel, R. Warehouse/Distribution Center Survey: In the Thick of E-Commerce Adjustments. Supply Chain Management Review. 2017. Available online: https://www.scmr.com/article/2017_warehouse_distribution_center_survey_in_the_thick_of_e_commerce_adjust (accessed on 1 June 2024).

- Michel, R. 2020 Warehouse/DC Operations Survey: COVID-19 Pandemic Hits, Operations Respond. Logistcis Management. 2020. Available online: https://www.logisticsmgmt.com/article/2020_warehouse_dc_operations_survey (accessed on 1 June 2024).

- Karagiannaki, A.; Papakiriakopoulos, D.; Bardaki, C. Warehouse contextual factors affecting the impact of RFID. Ind. Manag. Data Syst. 2011, 111, 714–734. [Google Scholar] [CrossRef]

- Faber, N.; De Koster, R.; Smidts, A. Organizing warehouse management. Int. J. Oper. Prod. Manag. 2013, 33, 1230–1256. [Google Scholar] [CrossRef]

- Lao, S.; Choy, K.; Ho, G.; Yam, R. An RFRS that combines RFID and CBR technologies. Ind. Manag. Data Syst. 2012, 112, 385–404. [Google Scholar] [CrossRef]

- Jaaron, A.; Backhouse, C. A systems approach for forward and reverse logistics design: Maximising value from customer involvement. Int. J. Logist. Manag. 2016, 27, 947–971. [Google Scholar] [CrossRef][Green Version]

- Faber, N.; De Koster, R.; Smidts, A. Survival of the fittest: The impact of fit between warehouse management structure and warehouse context on warehouse performance. Int. J. Prod. Res. 2018, 56, 120–139. [Google Scholar] [CrossRef]

- Huang, S.-H.; Hsu, W.-K. A knowledge gap model for improving service quality of international distribution centers. Marit. Econ. Logist. 2016, 18, 476–495. [Google Scholar] [CrossRef]

- Guo, Z. A Study on the Core Competence of the Third Party Logistics Enterprises—Taking Rongqing Logistics as an Example. Int. J. Acad. Res. Bus. Soc. Sci. 2017, 7, 222–232. [Google Scholar] [CrossRef]

- Putnik, G.; Putnik, Z. Lean vs agile in the context of complexity management in organizations. Learn. Organ. 2012, 19, 248–266. [Google Scholar] [CrossRef]

- Naylor, J.; Naim, M.; Berry, D. Leagility: Integrating the lean and agile manufacturing paradigms in the total supply chain. Int. J. Prod. Econ. 1999, 62, 107–118. [Google Scholar] [CrossRef]

- Narasimhan, R.; Swink, M.; Kim, S. Disentangling leanness and agility: An empirical investigation. J. Oper. Manag. 2006, 24, 440–457. [Google Scholar] [CrossRef]

- Berglund, M. Strategic Positioning of the Emerging Third-Party Logistics Providers; Linköping University: Linköping, Switzerland, 2000. [Google Scholar]

- Bowersox, D.; Closs, D. Logistical Management: The Integrated Supply Chain Process; The McGraw-Hill Companies, Inc.: New York, NY, USA, 1996. [Google Scholar]

- Soinio, J.; Tanskanen, K.; Finne, M. How logistics-service providers can develop value-added services for SMEs: A dyadic perspective. Int. J. Logist. Manag. 2012, 23, 31–49. [Google Scholar] [CrossRef]

- Shi, Y.; Zang, A.; Arthanari, T.; Liu, Y.; Cheng, T. Third-party purchase: An empirical study of third-party logistics providers in China. Int. J. Prod. Econ. 2016, 171, 189–200. [Google Scholar] [CrossRef]

- Shi, Y.; Arthanari, T.; Wood, L. Developing third-party purchase (3PP) services: New Zealand third-party logistics providers’ perspectives. Supply Chain Manag. 2017, 22, 40–57. [Google Scholar] [CrossRef]

- Jafari, H.; Eslami, M.; Paulraj, A. Postponement and logistics flexibility in retailing: The moderating role of logistics integration and demand uncertainty. Int. J. Prod. Econ. 2022, 243, 108319. [Google Scholar] [CrossRef]

- Seth, D.; Panigrahi, A. Application and evaluation of packaging postponement strategy to boost supply chain responsiveness: A case study. Prod. Plan. Control Manag. Oper. 2015, 26, 1068–1089. [Google Scholar] [CrossRef]

- Jafari, H.; Nuberg, A.; Hillethofth, P. Postponement and logistics flexibility in retailing: A multiple case study from Sweden. Ind. Manag. Data Syst. 2016, 116, 445–465. [Google Scholar] [CrossRef]

- Anderson, E.; Coltman, T.; Devinney, T.; Keating, B. What drives the choice of a third-party logistics provider? J. Supply Chain Manag. 2011, 47, 97–115. [Google Scholar] [CrossRef]

- Mokadem, M. The classification of supplier selection criteria with respect to lean or agile manufacturing strategies. J. Manuf. Technol. Manag. 2017, 28, 232–249. [Google Scholar] [CrossRef]

- Baby, B.; Prasanth, N.; Jebadurai, D. Implementation of lean principles to improve the operations of a sales warehouse in the manufacturing industry. International. J. Technol. 2018, 1, 46–54. [Google Scholar]

- Freitas, A.; Silva, F.; Ferreira, L.; Sa, J.; Pereira, M.; Pereira, J. Improving efficiency in a hybrid warehouse: A case study. Procedia Manuf. 2019, 38, 1074–1084. [Google Scholar] [CrossRef]

- Abideen, A.; Mohamad, F. Supply chain lead time reduction in a pharmaceutical production warehouse—A case study. Int. J. Pharm. Healthc. 2020, 14, 61–88. [Google Scholar] [CrossRef]

- Abushaikha, I.; Salhieh, L.; Towers, N. Improving distribution and business performance through lean warehousing. Int. J. Retail Distrib. Manag. 2018, 46, 780–800. [Google Scholar] [CrossRef]

- Ikechukwu, A. Assessment of organizational performance of private manufacturing companies: The impact of supply chain management responsiveness. J. Syst. Manag. Sci. 2019, 9, 26–44. [Google Scholar]

- Jermsittiparsert, K.; Sutduean, J.; Sriyakul, T. Role of warehouse attributes in supply chain warehouse efficiency in Indonesia. Int. J. Innov. Creat. Chang. 2019, 5, 786–802. [Google Scholar]

- Baker, P. The Role, Design and Operation of Distribution Centres in Agile Supply Chain. 2008. Available online: http://hdl.handle.net/1826/3022 (accessed on 1 June 2024).

- Laosirihongthong, T.; Adebanjo, D.; Samaranayake, P.; Subramanian, N.; Boon-itt, S. Prioritizing warehouse performance measures in contemporary supply chains. Int. J. Product. Perform. 2018, 67, 1703–1726. [Google Scholar] [CrossRef]

- Johnson, A.; McGinnis, L. Performance measurement in the warehousing industry. IIE Trans. 2011, 43, 220–230. [Google Scholar] [CrossRef]

- Ramaa, A.; Subramanya, K.; Rangaswamy, T. Impact of warehouse management system in a supply chain. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=faff485f479ec9f8fa0c280a4c1f977697f23ebe (accessed on 1 June 2024).

- Kursini, E.; Novendri, F.; Helia, V. Determining key performance indicators for warehouse performance measurement–a case study in construction materials warehouse. MATEC Web Conf. 2018, 154, 01058. [Google Scholar]

- Salhieh, L.; Alswaer, W. A proposed maturity model to improve warehouse performance. Int. J. Product. Perform. Manag. 2022, 71, 3724–3746. [Google Scholar] [CrossRef]

- Lv, C.; Chen, X. The Extension of Third-Party Logistics Value-Added Services in the Financial Field. LISS 2013, 2012, 203–207. [Google Scholar]

- Protic, S.; Fikar, C.; Voegl, J.; Gronalt, M. Analysing the impact of value added services at intermodal inland terminals. Int. J. Logist. Res. Appl. 2020, 23, 159–177. [Google Scholar] [CrossRef]

- Andersson, D.; Roso, V. Developing dry ports through the use of value-added services. Commer. Transp. 2016, 191–203. [Google Scholar] [CrossRef]

- Menegaki, A.; Alexopoulos, A. Evolution of logistics centers and value-added services offered in port areas and the importance of marketing. Strateg. Innov. Mark. 2017, 291–297. [Google Scholar] [CrossRef]

- Tang, K.; Qian, M.; Wang, B. Analysis on the Development of Value-added Services of Logistics Enterprises in Yunnan. In Proceedings of the 3rd International Conference on Politics, Economics and Law (ICPEL 2018), Weihai, China, 9–11 October 2018; Atlantis Press: Amsterdam, The Netherlands, 2018; pp. 390–392. [Google Scholar]

- Chen, L.; Notteboom, T. Distribution and value added logistics in the cold chain product market with application to the role of seaports. In Proceedings of the Asian Logistics Round Table 2012 Conference University of British Columbia (UBC), Vancouver, BC, Canada, 14–15 June 2012. [Google Scholar]

- Chen, L.; Notteboom, T. Determinants for Assigning Value-added Logistics Services to Logistics Centers Within A Supply Chain Configuration. J. Int. Logist. Trade 2012, 10, 3–41. [Google Scholar] [CrossRef]

- Chen, L.; Notteboom, T. A cost perspective on the location of value-added logistics services in supply chains. Int. J. Logist. Syst. Manag. 2014, 18, 24–48. [Google Scholar] [CrossRef]

- Russo, S.; Gronalt, M. Value added services at intermodal inland terminals and the importance of choosing a moderate innovation path. Res. Transp. Bus. Manag. 2021, 41, 100694. [Google Scholar] [CrossRef]

- Jum’a, L.; Basheer, M. Analysis of warehouse value-added services using pareto as a quality tool: A case study of third-party logistics service provider. Adm. Sci. 2023, 13, 51. [Google Scholar] [CrossRef]

- Fisher, M. What is the right supply chain for your product? Harv. Bus. Rev. 1997, 75, 105–116. [Google Scholar]

- Mason-Jones, R.; Naylor, B.; Towill, D. Engineering the leagile supply chain. Int. J. Agil. Manag. Syst. 2000, 2, 54–61. [Google Scholar] [CrossRef]

- Bruce, M.; Daly, L.; Towers, N. Lean or agile: A solution for supply chain management in the textiles and clothing industry? Int. J. Oper. Prod. Manag. 2004, 24, 151–170. [Google Scholar] [CrossRef]

- Morash, E. Supply Chain Strategies, Capabilities, and Performance. Transp. J. 2001, 41, 37–54. [Google Scholar]

- Griffis, S.; Cooper, M.; Goldsby, T.; Closs, D. Performance measurement: Measure selection based upon firm goals and information reporting needs. J. Bus. Logist. 2004, 25, 95–118. [Google Scholar] [CrossRef]

- Nel, J.; Badenhorst-Weiss, J. Supply chain design: Some critical questions. J. Transp. Supply Chain Manag. 2010, 4, 198–223. [Google Scholar] [CrossRef]

- Ambe, I. Determining an optimal supply chain strategy. J. Transp. Supply Chain Manag. 2012, 6, 126–147. [Google Scholar] [CrossRef]

- Towers, N.; Abushaikha, I.; Ritchie, J.; Holter, A. The impact of phenomenological methodology development in supply chain management research. Supply Chain. Manag. Int. J. 2020, 25, 443–456. [Google Scholar] [CrossRef]

- Platton, M. Enhancing the Quality and Credibility of Qualitative Analysis. HSR Health Serv. Res. 1999, 34 Pt II, 1189–1208. [Google Scholar]

- Easterby-Smith, M.; Thorpe, R.; Jackson, P. Management Research; Sage: Thousand Oaks, CA, USA, 2012. [Google Scholar]

- Faulkner, S.; Trotter, S. Data Saturation. 2017. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9781118901731.iecrm0060 (accessed on 1 June 2024).

- Mason-Jones, R.; Naylor, B.; Towill, D. Lean, agile or leagile? Matching your supply chain to the marketplace. Int. J. Prod. Res. 2000, 38, 4061–4070. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).