Analysis of Thermal Effects in Yb:YAG Laser Amplifiers with Active-Mirror Structure

Abstract

1. Introduction

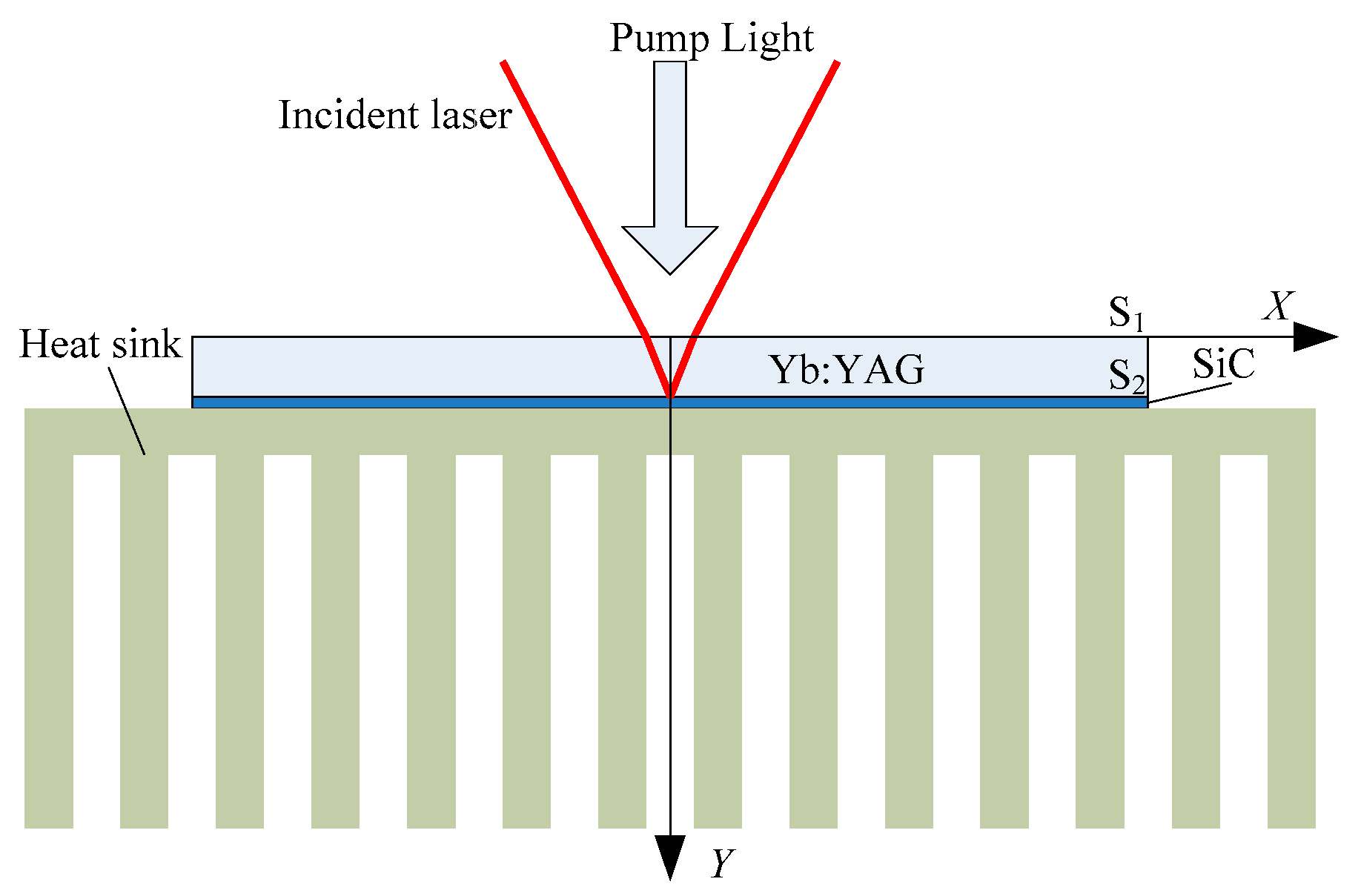

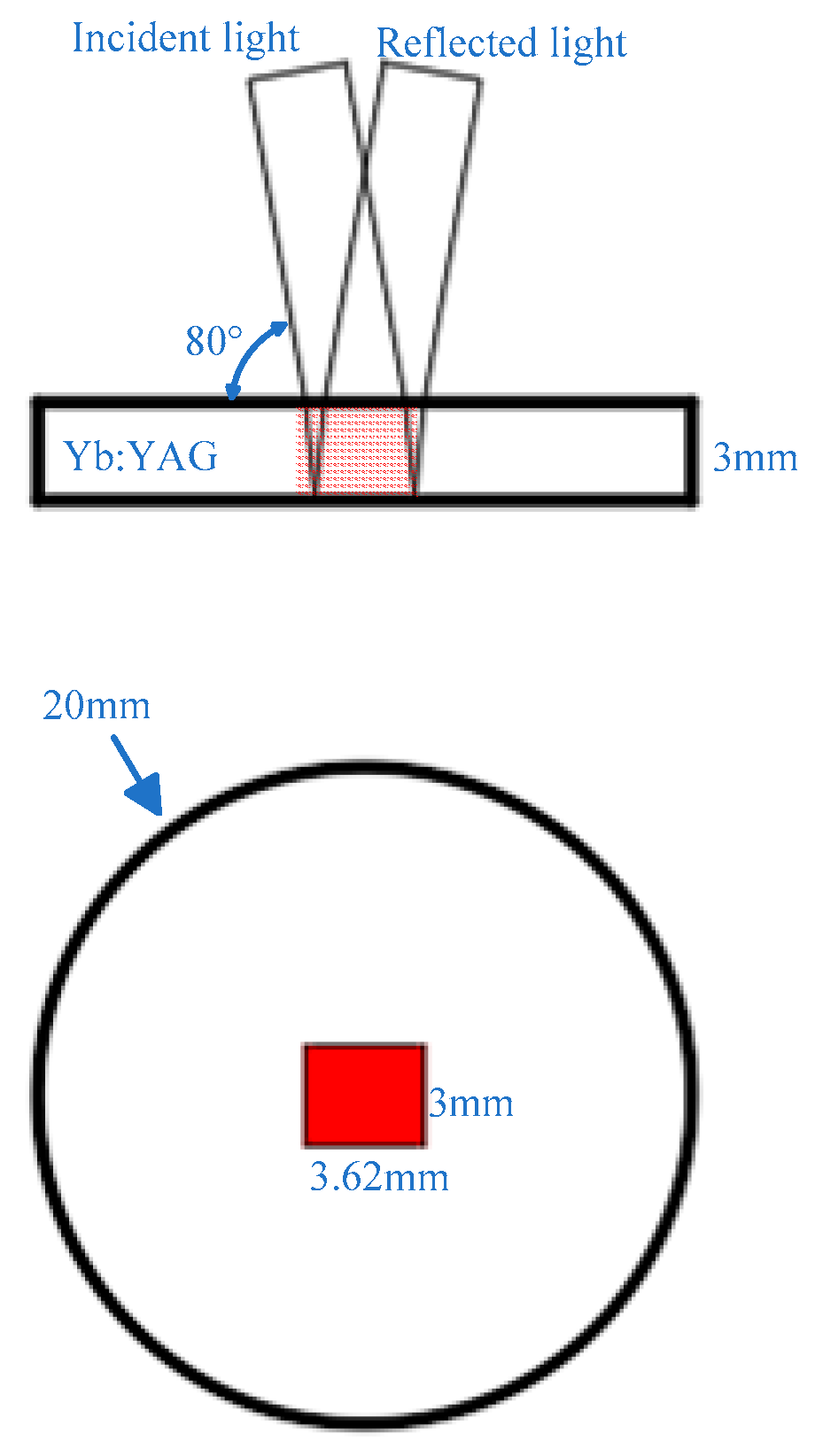

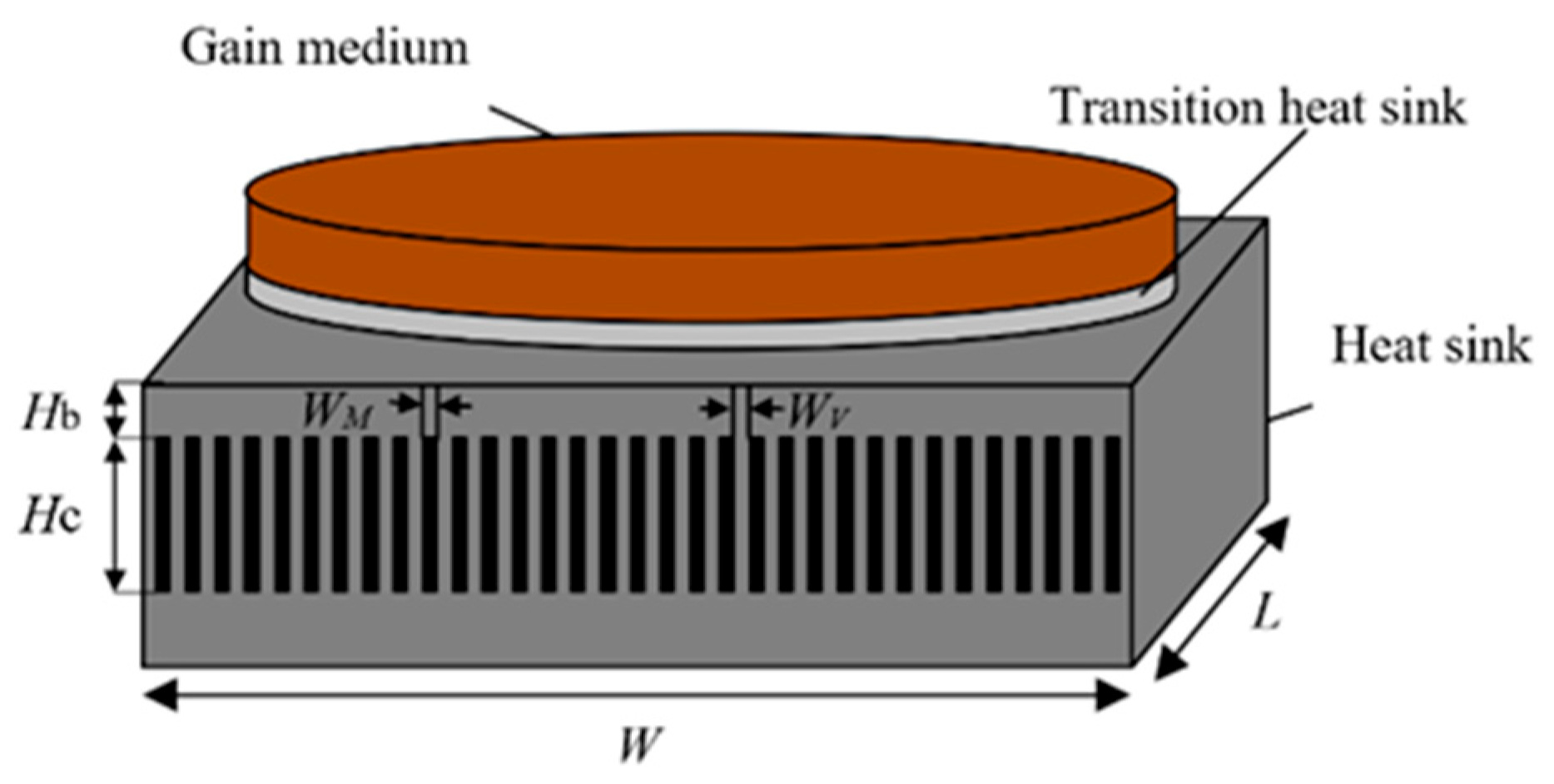

2. Theoretical Model

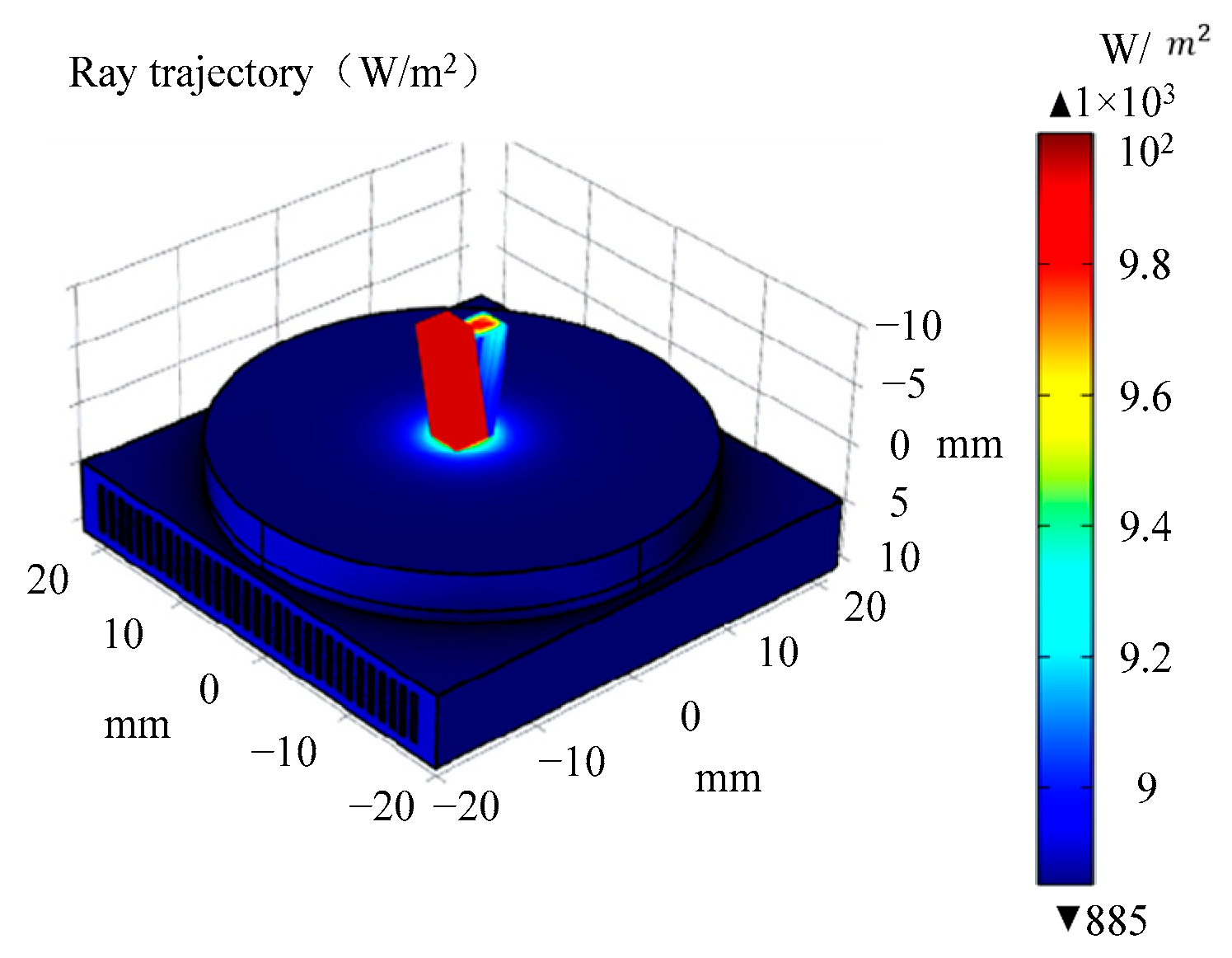

3. Design of Amplifier

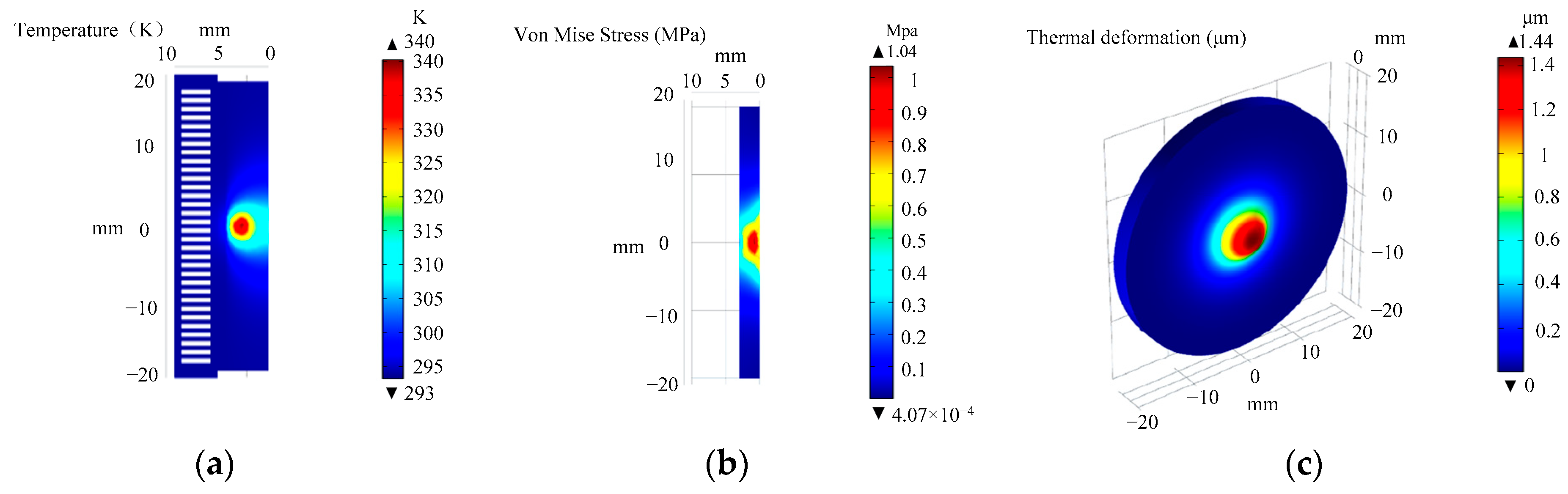

4. Results and Discussion

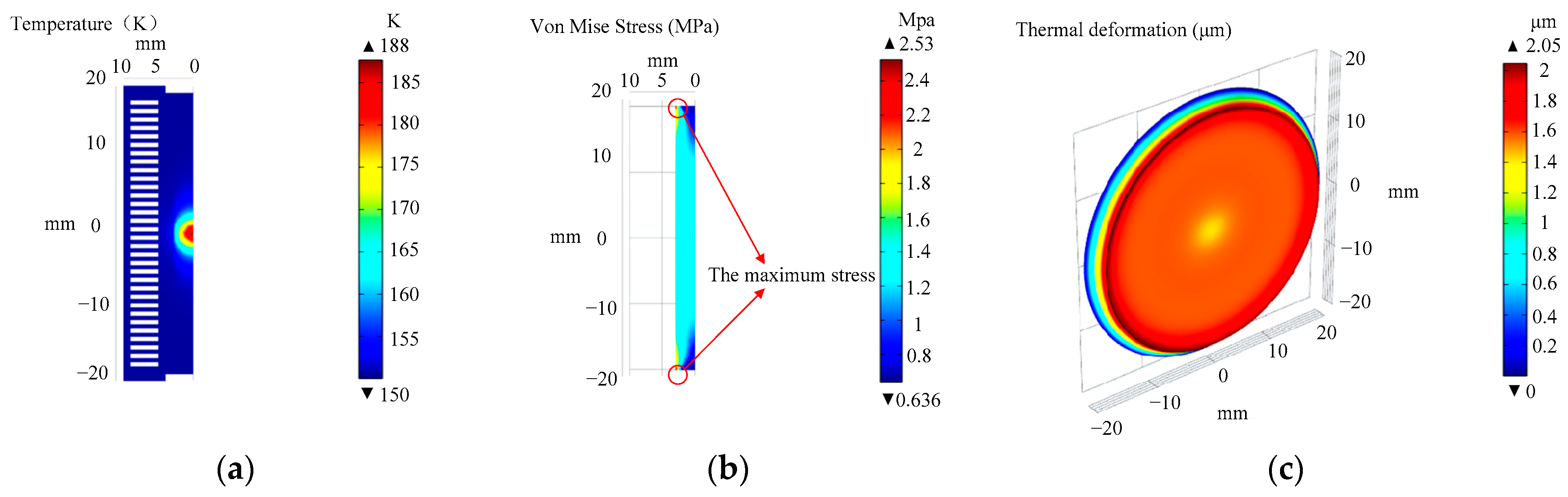

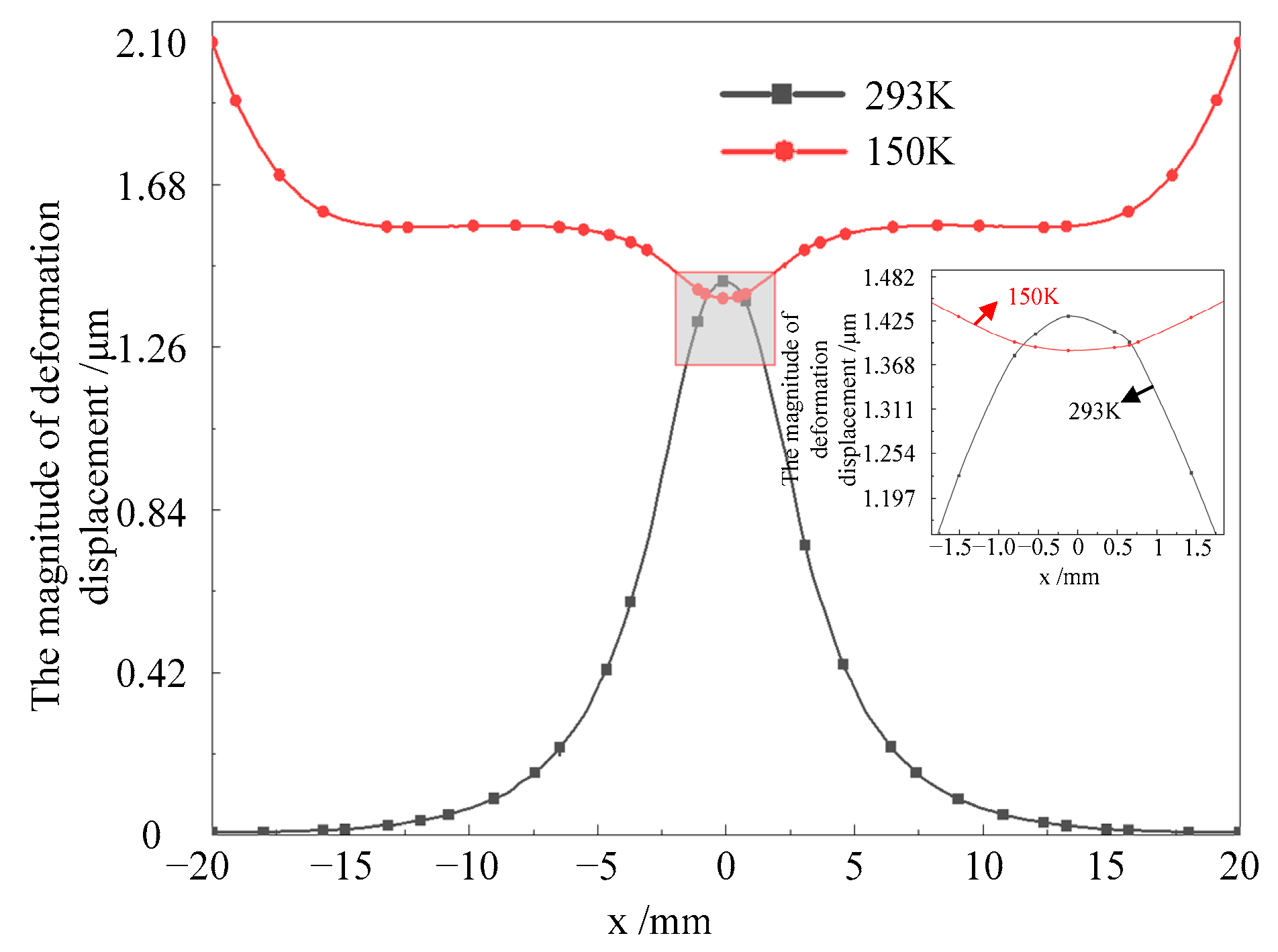

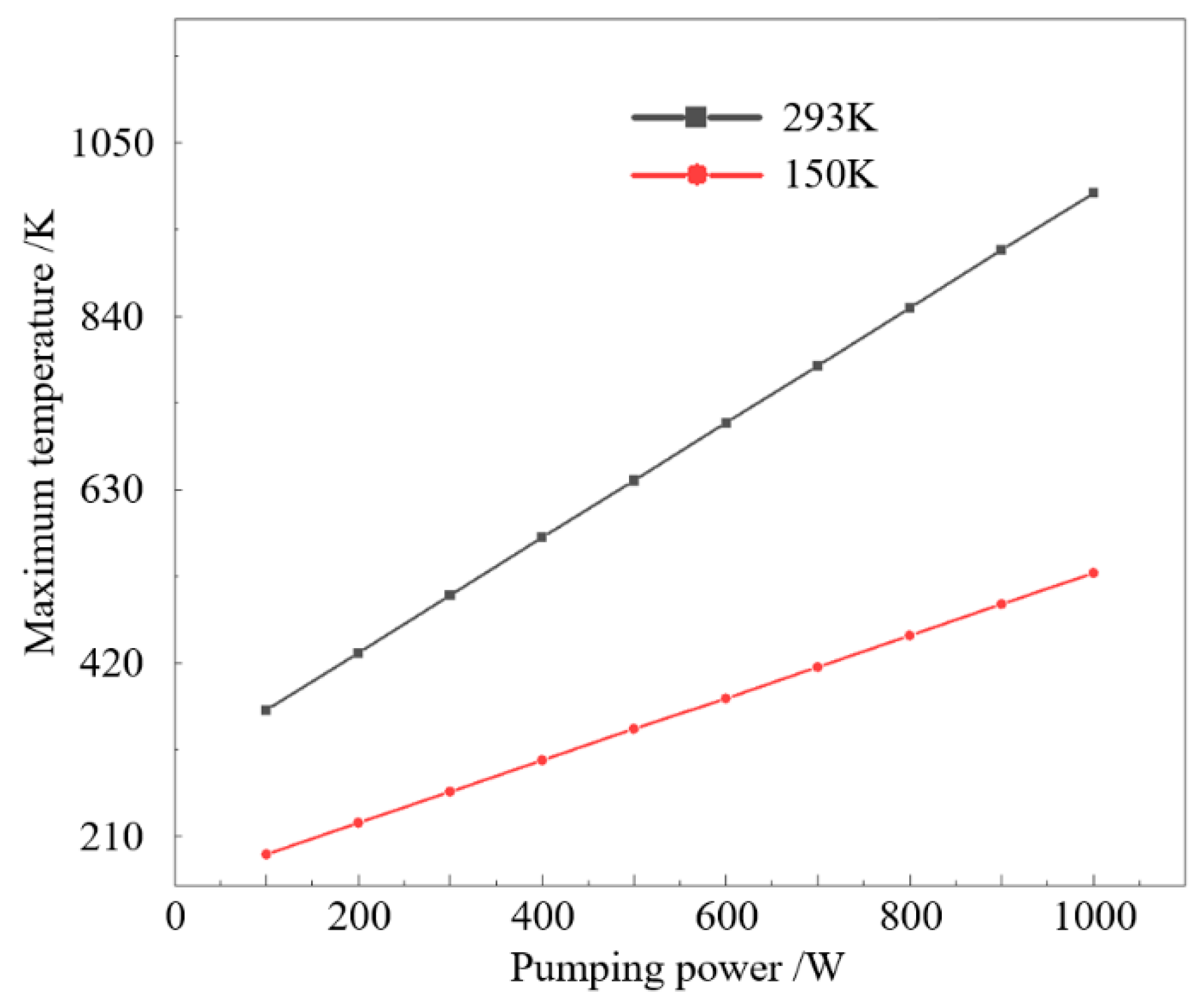

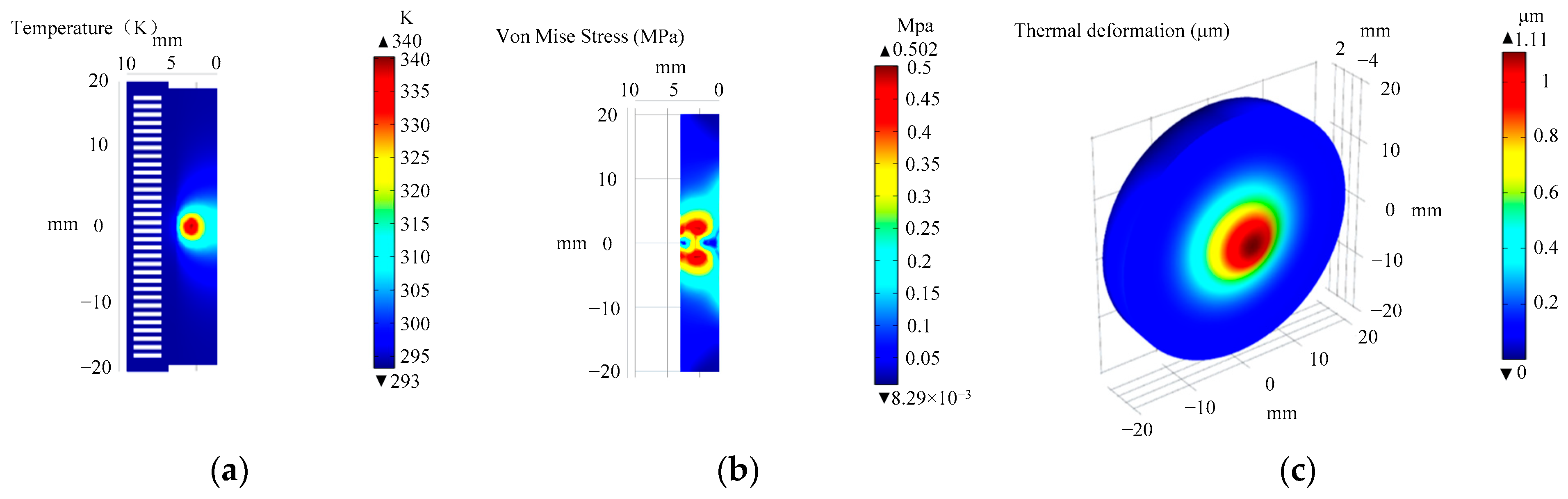

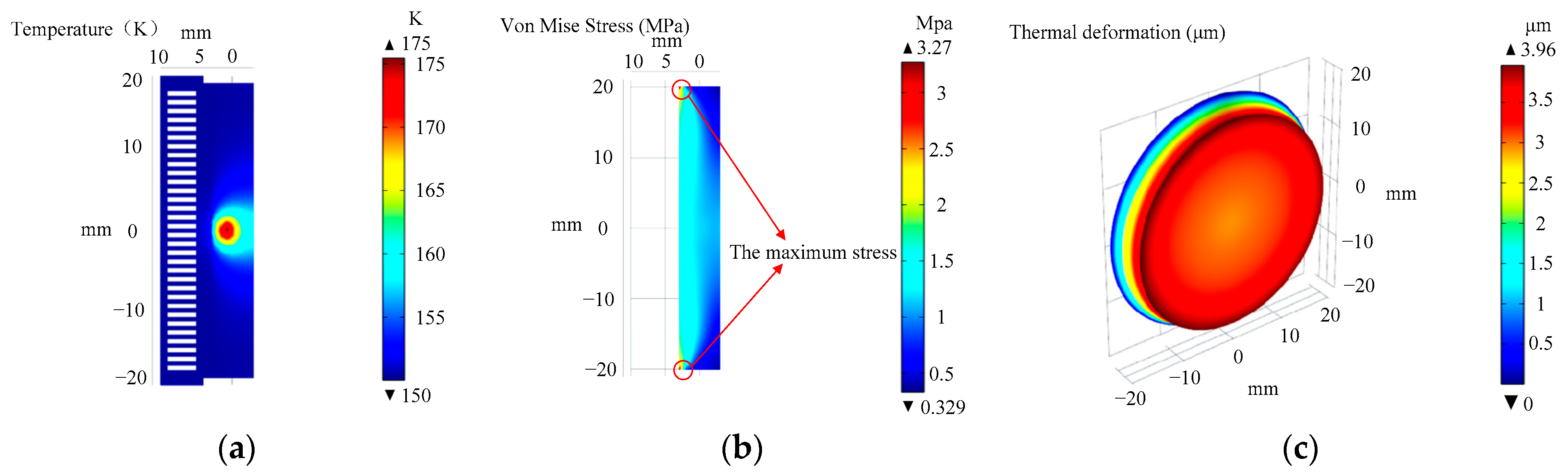

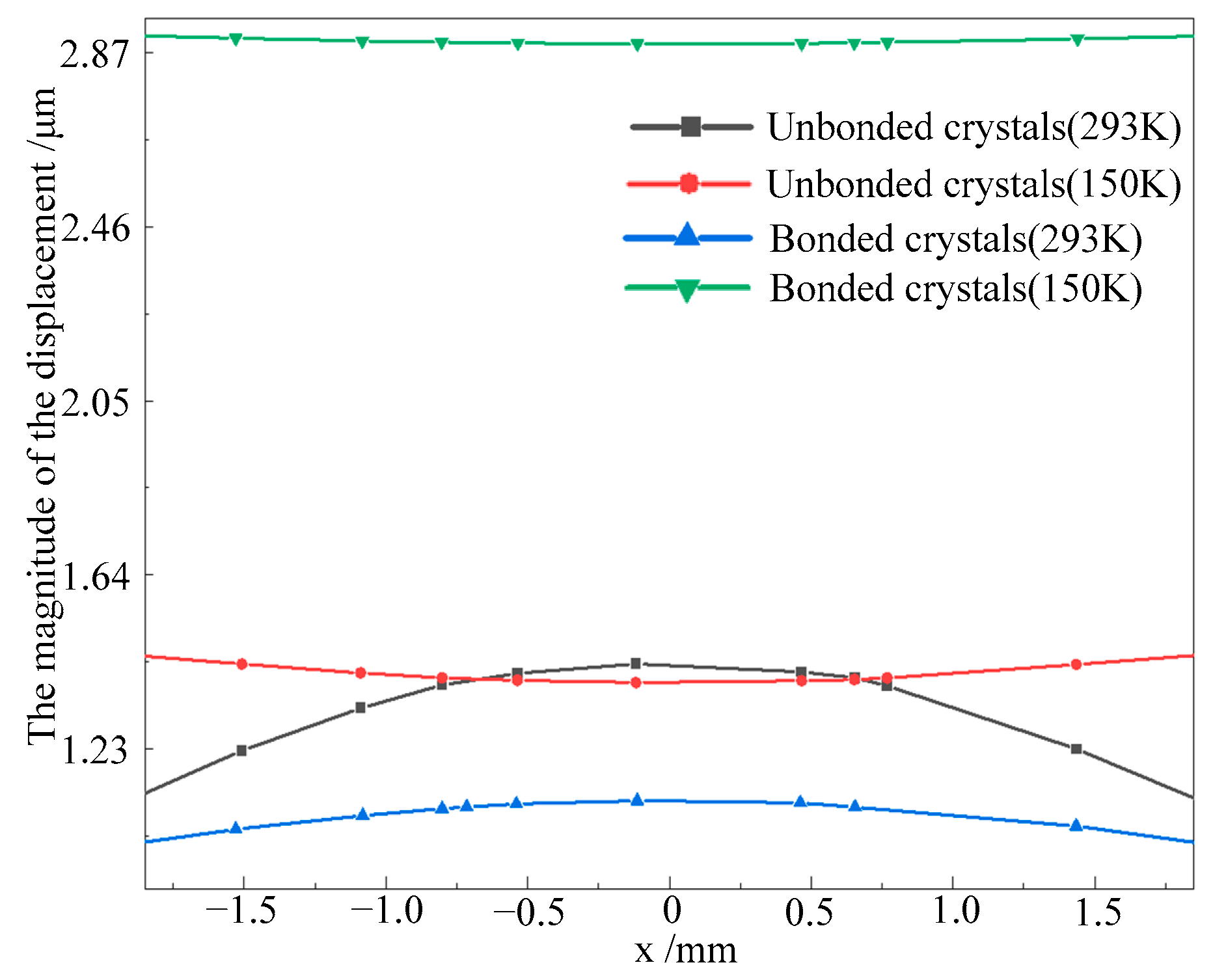

4.1. Temperature, Thermal Stress and End-Face Deformation

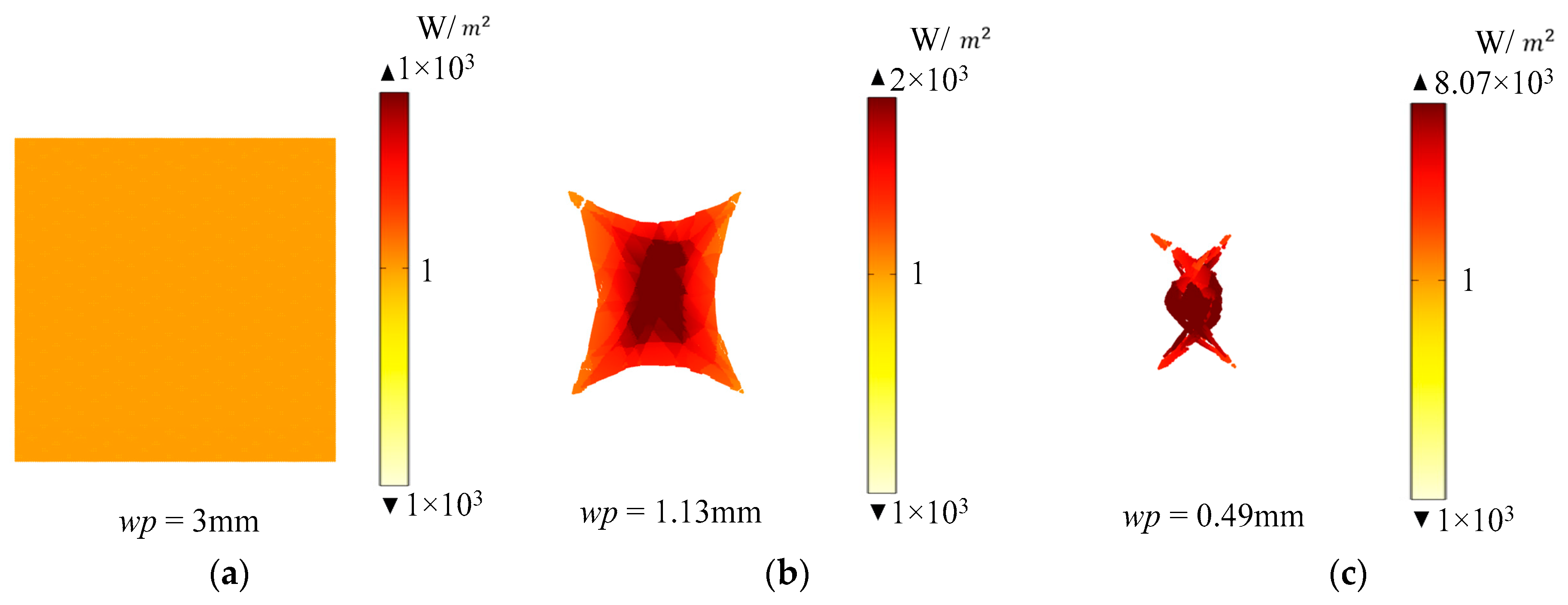

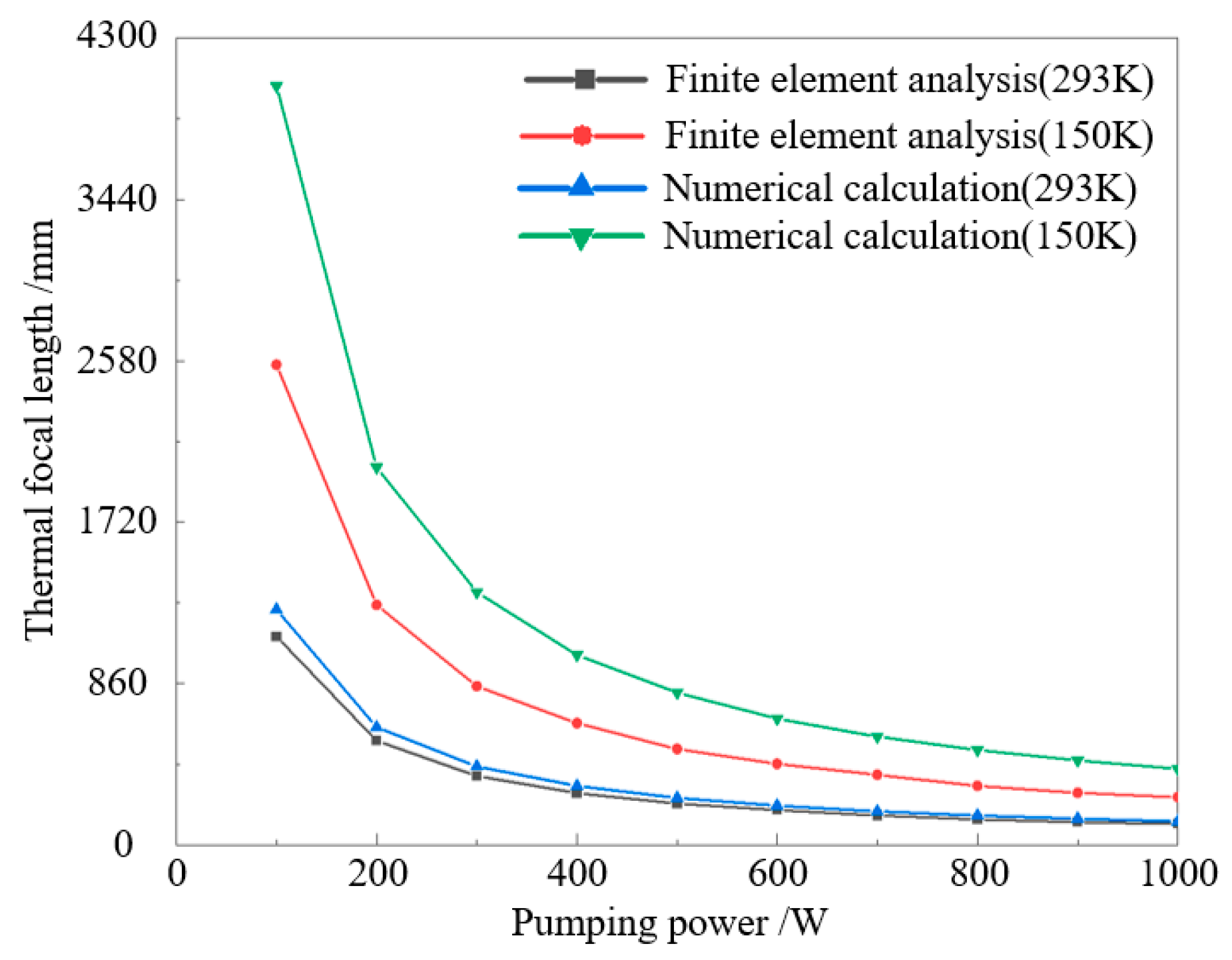

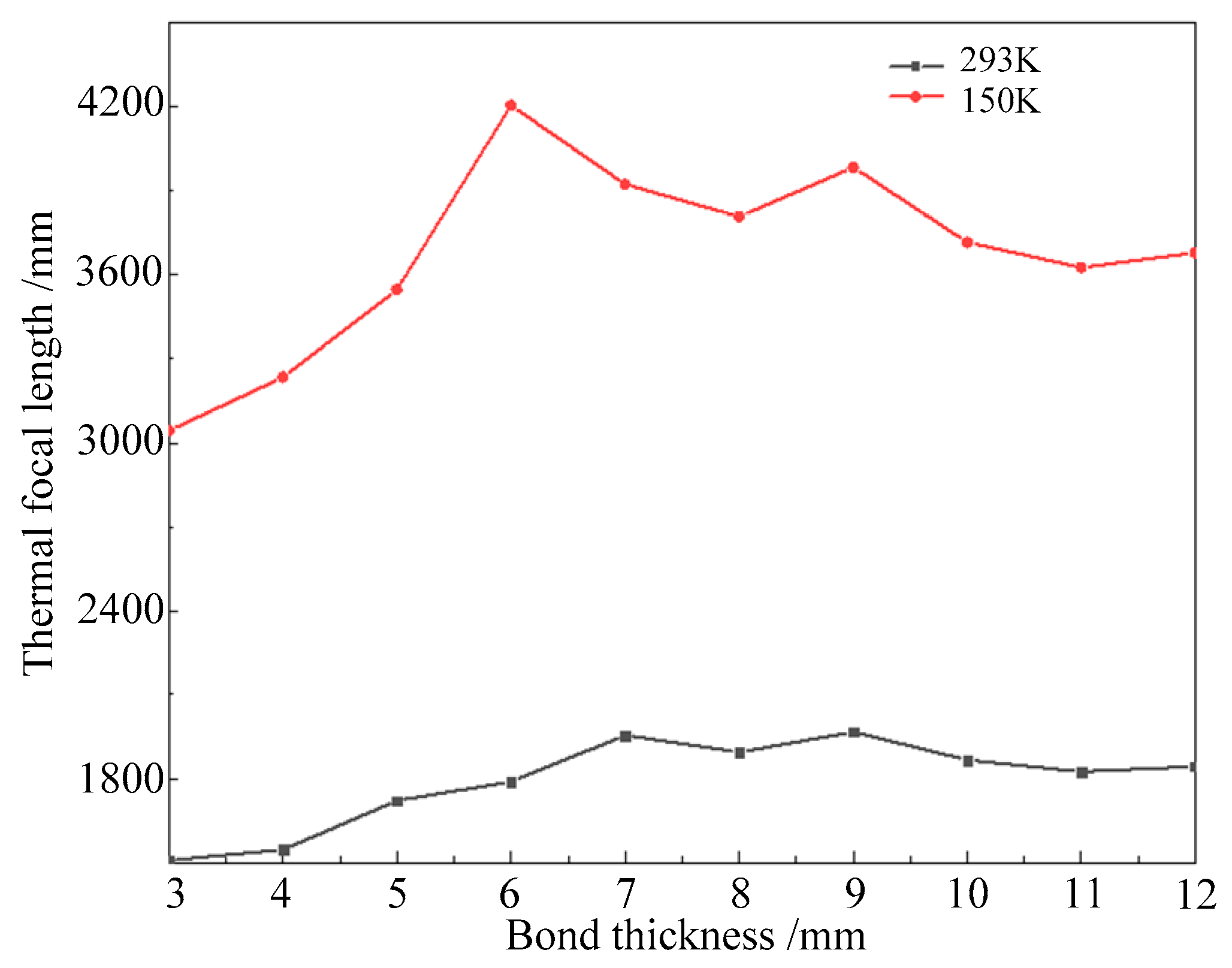

4.2. Thermal Lens

4.3. Crystal Optimization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shang, P.; Bai, L.; Wang, S.; Cai, D.; Li, B. Research Progress on Thermal Effect of LD Pumped Solid State Laser. Opt. Laser Technol. 2023, 157, 108640. [Google Scholar] [CrossRef]

- Liu, S.; Xie, W.; Wang, Q.; Liu, Y.; Hu, N. Thermal Performance of a Central-Jetting Microchannel Heat Sink Designed for a High-Power Laser Crystal. Int. J. Heat Mass Transf. 2022, 185, 122409. [Google Scholar] [CrossRef]

- Bayramian, A.; Armstrong, J.; Beer, G.; Campbell, R.; Chai, B.; Cross, R.; Erlandson, A.; Fei, Y.; Freitas, B.; Kent, R.; et al. High-Average-Power Femto-Petawatt Laser Pumped by the Mercury Laser Facility. J. Opt. Soc. Am. B 2008, 25, B57–B61. [Google Scholar] [CrossRef]

- Gonçalvès-Novo, T.; Albach, D.; Vincent, B.; Arzakantsyan, M.; Chanteloup, J.-C. 14 J/2 Hz Yb3+: YAG Diode Pumped Solid State Laser Chain. Opt. Express 2013, 21, 855–866. [Google Scholar] [CrossRef] [PubMed]

- Yasuhara, R.; Kawashima, T.; Sekine, T.; Kurita, T.; Ikegawa, T.; Matsumoto, O.; Miyamoto, M.; Kan, H.; Yoshida, H.; Kawanaka, J. 213 W Average Power of 2.4 GW Pulsed Thermally Controlled Nd: Glass Zigzag Slab Laser with a Stimulated Brillouin Scattering Mirror. Opt. Lett. 2008, 33, 1711–1713. [Google Scholar] [CrossRef] [PubMed]

- Shibib, K.S.; Abdulrazzaqand, M.J.; Bader, J.K. Analysis of Thermal Effect in Thin Disk Laser: A Review. J. Phys. Conf. Ser. 2021, 1999, 012073. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, Y.; Yan, W.; Li, Y.; Cai, X.; Chen Xiong, W.Z.; Li, P. Multi-Stage Tm-Doped Fiber and Double-Pass Ho-Doped Solid-State Hybrid Amplifier with High Energy and High Efficiency. Opt. Laser Technol. 2025, 183, 112341. [Google Scholar] [CrossRef]

- Herkommer, C.; Krötz, P.; Jung, R.; Klingebiel, S.; Wandt, C.; Bessing, R.; Walch, P.; Produit, T.; Michel, K.; Bauer, D.; et al. Ultrafast Thin-Disk Multipass Amplifier with 720 mJ Operating at Kilohertz Repetition Rate for Applications in Atmospheric Research. Opt. Express 2020, 28, 30164–30173. [Google Scholar] [CrossRef] [PubMed]

- Tian, B.; Yu, J.; Zhang, B. Theoretical Study on Beam Quality and Thermal Stability in Solid-State Zigzag Tube Laser Amplifier. Opt. Eng. 2020, 59, 076104. [Google Scholar] [CrossRef]

- Wang, C.; Khurgin, J.B.; Yu, H. 450 W Pulsed Laser System with M2 < 1.2 Based on a 969-Nm Laser Diode End-Pumped Yb:YAG Rod Amplifier. Opt. Lett. 2023, 48, 5751–5754. [Google Scholar] [CrossRef] [PubMed]

- Zeyen, M.; Affolter, L.; Abdou Ahmed, M.; Graf, T.; Kara, O.; Kirch, K.; Marszalek, M.; Nez, F.; Ouf, A.; Pohl, R.; et al. Compact 20-Pass Thin-Disk Multipass Amplifier Stable against Thermal Lensing Effects and Delivering 330 mJ Pulses with M2 < 1.17. Opt. Express 2024, 32, 1218–1230. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Liu, X.; Gao, Y.; Ou, Z.; Javed, F.; He, X.; Lu, H.; Chen, J.; Chen, Y.; Ouyang, D.; et al. Thin-Disk Multi-Pass Amplifier for Kilowatt-Class Ultrafast Lasers. High Power Laser Sci. Eng. 2024, 12, e56. [Google Scholar] [CrossRef]

- Brauch, U.; Röcker, C.; Graf, T.; Abdou Ahmed, M. High-Power, High-Brightness Solid-State Laser Architectures and Their Characteristics. Appl. Phys. B 2022, 128, 58. [Google Scholar] [CrossRef]

- Zhou, H.; Lee, J.; Kang, M.; Kim, H.; Lee, H.; In, J.B. All Laser-Based Fabrication of Microchannel Heat Sink. Mater. Des. 2022, 221, 110968. [Google Scholar] [CrossRef]

- Long, Q.; Wang, Q.; Mao, Y.; Gu, J.; Wang, L.; He, Y. Thermal Performance of a Laser-Diode End-Pumped Nd:YVO4 Slab Crystal Cooled by a Pair of Microchannel Heat Sinks. Int. J. Therm. Sci. 2023, 194, 108547. [Google Scholar] [CrossRef]

- Shen, Y.-T.; Pan, Y.-H.; Chen, H.; Cheng, W.-L. Experimental Study of Embedded Manifold Staggered Pin-Fin Microchannel Heat Sink. Int. J. Heat Mass Transf. 2024, 226, 125488. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Li, P.; Lu, Z.; Ma, F.; Ma, Y.; Zhou, J.; Chen, W. Simulation and Optimization of Heat Dissipation in Slab Laser Amplifier Based on Microchannel Heat Sink. Chin. J. Lasers 2023, 50, 0701002. [Google Scholar] [CrossRef]

- Cassada, N.; Anderson, C.; Kubicek, L.; Hobby, D.; Frye, C.; Baxamusa, S.; Kotovsky, J.; Jackson, K.; Ladner, I.; Bandhauer, T. SiC Microchannel Heat Sinks for High Heat Flux Dissipation of 1 kW/cm2. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 655–665. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, J.; Yang, Z.; Liu, J.; Li, L.; Shi, X.; Huang, W.; Wang, J.; Chen, W. A High Energy Nanosecond Cryogenic Cooled Yb:YAG Active-Mirror Amplifier System. High Power Laser Sci. Eng. 2014, 2, 03000e18. [Google Scholar] [CrossRef][Green Version]

- Wu, N.; Sun, M.; Guo, H.; Xie, Z.; Du, S. Subcooled Flow Boiling in Diamond/Cu Microchannel Heat Sinks for near-Junction Chip Cooling. Case Stud. Therm. Eng. 2025, 69, 105981. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Thermal conductivity, k, W/(m·K) | 8.2@293 K 15.5@150 K |

| Thermal expansion coefficient, α/K | 7.7 × 10−6@293 K 2.0 × 10−6@150 K |

| Specific heat capacity, c, J/(kg·K) | 590@293 K 300@150 K |

| Poisson ratio, ν | 0.3 |

| Thermally induced refractive index coefficient, dn/dT/K | 7.3 × 10−6/K |

| Thermogenesis efficiency, η | 0.1 |

| Young’s modulus, E, kg/cm2 | 3.17 × 104@293 K 3.27 × 104@150 K |

| The size of Yb:YAG, mm | Φ20 × 3 |

| Parameter | Value |

|---|---|

| Wavelength of pump light, nm | 940 |

| Size of pump light, mm | 3 × 3.62 |

| Intensity distribution of pump light | flat-top |

| Wavelength of seed laser, nm | 1030 |

| Size of seed laser, mm | 3 × 3 |

| Intensity distribution of seed laser | flat-top |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, X.; Zhang, H.; Shang, J.; Bai, H.; Lu, C.; Guo, Y. Analysis of Thermal Effects in Yb:YAG Laser Amplifiers with Active-Mirror Structure. Photonics 2025, 12, 1123. https://doi.org/10.3390/photonics12111123

Cheng X, Zhang H, Shang J, Bai H, Lu C, Guo Y. Analysis of Thermal Effects in Yb:YAG Laser Amplifiers with Active-Mirror Structure. Photonics. 2025; 12(11):1123. https://doi.org/10.3390/photonics12111123

Chicago/Turabian StyleCheng, Xiaojin, Hanguo Zhang, Jianhua Shang, Hui Bai, Chenhui Lu, and Yunpeng Guo. 2025. "Analysis of Thermal Effects in Yb:YAG Laser Amplifiers with Active-Mirror Structure" Photonics 12, no. 11: 1123. https://doi.org/10.3390/photonics12111123

APA StyleCheng, X., Zhang, H., Shang, J., Bai, H., Lu, C., & Guo, Y. (2025). Analysis of Thermal Effects in Yb:YAG Laser Amplifiers with Active-Mirror Structure. Photonics, 12(11), 1123. https://doi.org/10.3390/photonics12111123