Abstract

A novel sample preparation method based on the use of the Arrow solid-phase microextraction device was used to extract and preconcentrate volatile organic compounds (VOCs) from milk samples prior to their determination by gas chromatography–mass spectrometry (GC-MS). The experimental parameters of the solid-phase microextraction (SPME) Arrow method were evaluated in terms of fiber type, sample volume, extraction temperature, extraction time, stirring rate and salt addition. Under the optimum extraction conditions, the SPME Arrow was compared with conventional SPME fibers to evaluate the effectiveness of the SPME Arrow method. Evaluation of the conventional SPME procedure was also performed under optimized conditions, for appropriate method comparison. Due to the larger sorption phase volume of SPME Arrow, a higher sensitivity and reproducibility were observed for the determined chromatographic peaks in comparison with conventional SPME fibers. The use of Carbon wide range (WR) SPME Arrow/polydimethylsiloxane (CAR/PDMS) SPME Arrow fibers leads to a compound-dependent improvement of a factor of 4–5x over the classical SPME setup. Moreover, the relative standard deviation (RSD) of the total volatiles for a conventional SPME procedure was 12.5%, while for SPME Arrow it was 6.2%. Finally, the novel method was successfully employed for the analysis of commercially available milk samples. The findings of this study indicate that SPME Arrow can be effectively used for the determination of volatile organic compounds in complex food matrixes.

1. Introduction

Volatile organic compounds (VOCs) count among the most important compounds in foods, since they determine the sensory characteristics of the food, which are closely related to the acceptance or preference of particular food varieties []. The determination of VOCs in foods is of high importance in order to understand their origins, to evaluate the aroma profile differences among similar foods and to ensure food safety and quality. However, due to the presence of a plethora of VOCs in largely varying concentrations, the determination of the volatile profile in complex food matrices is considered difficult. Additionally, individual VOCs may have very high odor activities and thus may contribute to the characteristic flavor of a given food even at very low concentrations [].

Multiple solvent extraction or headspace (HS) analysis methods have been employed for the determination of VOCs in milk and dairy products. Typical examples of solvent extraction techniques include conventional solvent extraction, vacuum distillation, simultaneous distillation extraction (SDE/Likens–Nickerson extraction) and solvent-assisted flavor evaporation (SAFE), while purge-and-trap extraction and solid-phase microextraction (SPME) are the most commonly used headspace analysis methods [].

Until now, various research methods regarding the identification of VOCs in milk samples have employed SPME for the sample preparation of the liquid sample in order to evaluate its volatile profile [], to study the milk off-flavors [] and to study the light-induced lipid oxidation products in milk []. Among the identified milk volatiles are low molecular weight aldehydes (e.g., pentanal, hexanal, heptanal), ketones (e.g., 2-heptanone, 2-nonanone), terpenes (e.g., α-pinene), carboxyl acids (e.g., butanoic acid, hexanoic acid, octanoic acid) and sulfur-containing compounds (e.g., dimethyl sulfide, dimethyl sulfone) [].

SPME was initially introduced by the research group of Janusz Pawliszyn in 1990 []. In this approach, the analytes are directly extracted and preconcentrated to the outer surface of a coated fused-silica fiber. Due to the appropriate choice of fiber coating material, the selectivity of the extraction can be tuned to reduce matrix interference. After the preconcentration step, the analytes can be desorbed by the addition of organic solvent or by direct thermal desorption into the injection port of a gas chromatograph []. SPME exhibits many advantages such as full process automation, avoidance of organic solvent consumption and application for in situ, in-field and in vivo sampling. However, SPME is characterized by low fiber mechanical robustness and easy fiber breakage, as well as small sorption phase volume which limits its sensitivity for analytes with low sample/fiber partitioning coefficient [].

Stir bar sorptive extraction (SBSE) was introduced in 1999 from Baltussen et al. [] for the analysis of volatile and semivolatile micropollutants from aqueous samples. In this approach, a coated stir bar is inserted in the headspace or immersed directly into a liquid sample for the adsorption of the analytes. Subsequently, the bar is washed to remove nonvolatile components and the target analytes are finally desorbed either by the addition of a solvent or thermally. Compared to conventional SPME, SBSE provides a significantly larger extraction phase volume but loses the advantage of full automation and, moreover, requires a dedicated device for the thermal desorption of the stir bars [].

Recently, a novel SPME-related extraction device, named Prep And Load (PAL solution) SPME Arrow, was proposed as alternative extraction method that combines the advantages of conventional SPME fiber and SBSE, while remediating the main inherent drawbacks of these approaches. SPME Arrow employs a robust stainless steel backbone, which carries a screw connection to the sampler, the sorption phase, as well as an arrow-shaped tip to provide conservative penetration of septa []. Until now, SPME Arrow has been employed for the determination of VOCs in a wide variety of environmental and food stuffs including waste water and atmospheric air samples [], brown rice vinegar [], Korean salt–fermented fish sauce [] and soy sauce [].

The aim of this research was the development and optimization of a reliable analytical SPME Arrow method for the extraction and preconcentration of volatile components of milk samples prior to their determination by gas chromatography–mass spectrometry (GC-MS). Moreover, comparison of the SPME Arrow with the conventional SPME approach for VOC analysis in milk samples took place to evaluate the effectiveness of the novel extraction technique.

2. Materials and Methods

2.1. Materials and Chemicals

The Arrow SPME fibers, namely polydimethylsiloxane (PDMS) (phase thickness 100 μm), carbon wide range (WR) SPME Arrow/PDMS (CAR/PDMS) (phase thickness 120 μm) and divinylbenzene/PDMS (DVB/PDMS) (phase thickness 120 μm) were obtained from Restek Corporation (Bellefonte, PA, USA), while conventional PDMS (phase thickness 100 μm), CAR/PDMS (phase thickness 75 µm) and DVB/PDMS (phase thickness 65 µm) fibers were acquired from Supelco (Bellefonte, PA, USA). Methyl isobutyl ketone (98.5%), used as internal standard (IS), was supplied by Sigma-Aldrich (St. Louis, MO, USA). Milk samples were purchased from a local market in Vienna, Austria. Finally, for the headspace extraction and a heating magnetic stirrer (RCT basic, IKA Labortechnik, Staufen, Germany) was employed.

2.2. Conventional SPME Procedure

The conventional SPME procedure was performed with a CAR/PDMS fiber (phase thickness 75 μm), attached onto an SPME fiber holder from Supelco (Bellefonte, PA, USA). Prior to extraction, the SPME fibers were preconditioned in the injector port of the gas chromatograph according to the manufacturer’s instructions. For the conventional SPME procedure, glass vials (20 mL) closed with a polytetrafluoroethylene (PTFE) coated silicone rubber septum were used. Under the optimum conditions, an aliquot of 3 mL milk samples was placed into the glass vial and equilibration of the milk samples took place at 50 °C. Extraction of the volatiles was performed within 60 min under magnetic stirring at 1000 rpm without addition of salt.

2.3. SPME Arrow Procedure

The SPME Arrow procedure was performed with a CAR/PDMS Arrow with a 1.1 mm outer diameter and 120 μm phase thickness, attached onto a Restek PAL SPME Manual Injection Kit (Restek Corporation, Bellefonte, PA, USA). Prior to extraction, the Arrows were preconditioned in the injector port of the gas chromatograph according to the manufacturer’s instructions. For the SPME Arrow procedure, glass vials (20 mL) closed with polytetrafluoroethylene (PTFE) coated silicone rubber septum were used. Under the optimum conditions, an aliquot of 5 mL of milk samples was placed into the glass vial and 50 μL of internal standard solution was added to the vial to obtain a final IS concentration of 25 μg L−1. Equilibration of the milk samples took place at 50 °C and extraction was achieved in 60 min under magnetic stirring at 1000 rpm without addition of salt. Triplicate analysis of each sample was performed.

2.4. Gas Chromatography–Mass Spectrometry

The determination of analytes took place using a GC-2010 Shimadzu gas chromatograph (Shimadzu, Kyoto, Japan) equipped with a split/splitless inlet and mass spectrometry detector (MS). Helium (99.999%) was used as the carrier gas at a constant linear gas flow rate of 1.0 mL min−1. The ion source and interface temperatures were 200 and 250 °C, respectively. An Agilent (Santa Clara; CA, USA) J & W Ultra 2 column (50 m × 0.20 mm internal diameter, 0.33 μm) was used as stationary phase. The oven temperature program was as such: initial temperature 35 °C (held for 5 min), ramp to 150 °C at a rate of 5 °C min−1, and ramp to 320 °C at a rate of 15 °C min−1. The total analysis time was 39.3 min. The desorption of VOCs took place in the GC injection port at 230 °C for 1 min in splitless mode and the fiber was kept in the injection port for 9 min more for cleaning. The mass analyzer was set on scan mode and the recorded ions were m/z: 35 to m/z: 350. Finally, identification of analytes was performed with NIST/EPA/NIH (National Institute of Standards and Technology/Environmental Protection Agency/National Institutes of Health) Mass spectral library (NIST 08) and the calculation of the retention index of the analytes.

3. Results and Discussion

3.1. Evaluation of the SPME Arrow Procedure

The main factors affecting the extraction of VOCs from milk samples were evaluated. The well-established one-factor-at-a-time approach was followed for optimizing adsorption and desorption conditions. Regarding the extraction step, the effects of fiber type (100 μm PDMS, 120 μm CAR/PDMS, or 120 μm DVB/PDMS SPME Arrow fibers), sample volume (1–10 mL), extraction temperature (25–60 °C), extraction time (5–80 min), salt addition (0–20% w/w of NaCl), and stirring rate (0–1000 rpm) were investigated. Regarding the thermal desorption step, the desorption time (1–5 min) and desorption temperature (220–300 °C) were investigated. The evaluation of the experimental parameters was performed in terms of the normalized peak areas of 2-heptanone, α-pinene and dodecane, due to their abundance, as well as the total volatiles in milk samples. Since the reproducibility of the measurements was satisfactory, each experiment was performed with one repetition.

3.1.1. Selection of SPME Arrow Fiber

The selection of the appropriate fiber coating material is crucial in the development of an SPME method. In this study, three different SPME Arrow fibers (100 μm PDMS, 120 μm CAR/PDMS, or 120 μm DVB/PDMS SPME Arrow fibers) were evaluated for the extraction of volatile compounds from milk samples. The suitability of a particular fiber coating for a specific analyte is related to the polarity of the extraction phase and the overall selectivity toward the analyte over other matrix components []. The initial experiments were performed with 3 mL of sample, 30 min extraction time, 40 °C extraction time, 500 rpm stirring rate and no salt addition. Due to the different polarities of the coatings, various volatile compound patterns were observed. Among the examined Arrow fibers, the CAR/PDMS fiber provided a higher extraction efficiency for the volatile compounds. Therefore, this coating was chosen for further experiments. This observation agrees with other studies regarding the determination of VOCs in complex food matrices. The CAR/PDMS Arrow SPME fibers have recently also been used for the extraction of VOCs from brown rice vinegar [] and Korean salt–fermented fish sauce [].

3.1.2. Selection of Sample Volume

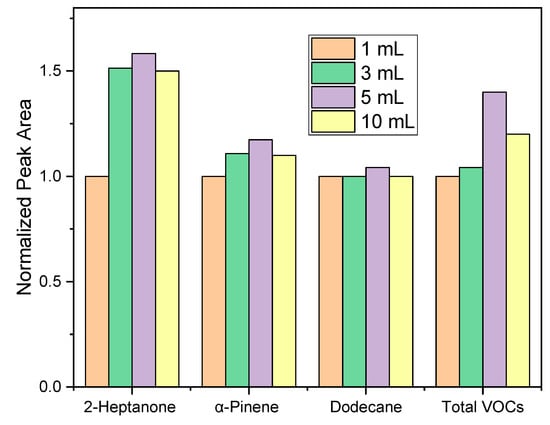

For the SPME Arrow extraction procedure, different sample volumes (i.e., 1, 3, 5 and 10 mL) were tested in 20 mL vials. Under conditions of exhaustive extraction which are applicable to small sample volumes, large fiber coating volumes and/or very large sample/coating partitioning coefficients, the amount of analytes extracted is proportional to the quantity and number of the adsorbed analytes, which are proportional to sample volume, resulting in higher analyte extraction with higher sample volume until a certain point. However, if the sample volume exceeds that point, fiber saturation can be observed. In this case, an increase in sample volume can have negative effects for quantitation, as the region of direct proportionality of analyte concentration and response is left. In this experiment, the extraction of the examined analytes, as well as the extraction of total volatiles, was enhanced by increasing the sample volume from 1 to 5 mL. However, a further increase from 5 to 10 mL had negative effect on the extraction []. Therefore, the optimum sample volume of milk for the SPME Arrow procedure was set as 5 mL. Figure 1 shows the effect of sample volume in the SPME Arrow extraction procedure.

Figure 1.

Evaluation of the sample volume for solid-phase microextraction (SPME) Arrow.

3.1.3. Selection of Extraction Temperature

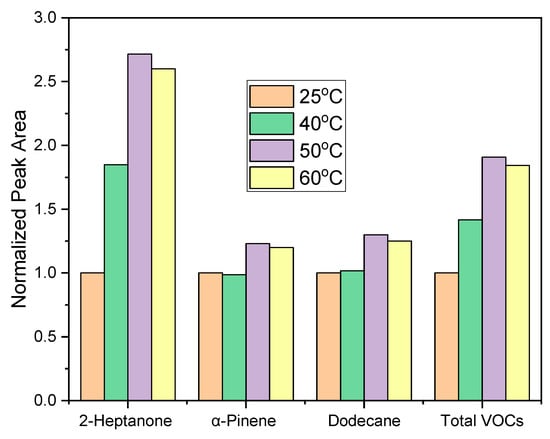

The effect of the extraction temperature in the SPME Arrow extraction procedure was performed by heating the sample at different temperatures (i.e., 25, 40, 50 and 60 °C). An increase in extraction temperature is known to release more volatiles to the headspace and enhance the overall extraction procedure. However, at high temperature, adverse effects which prevent the extraction can also take place (e.g., decrease in partition coefficients) []. For the SPME Arrow method, the extraction was assisted by increasing the extraction temperature value from 25 to 50 °C; however, further temperature increase did not result in higher extraction efficiency. Therefore, 50 °C was selected as the optimum extraction temperature for the SPME Arrow extraction procedure. Figure 2 shows the effect of extraction temperature in the SPME Arrow extraction procedure.

Figure 2.

Evaluation of the extraction temperature for SPME Arrow.

3.1.4. Selection of Extraction Time

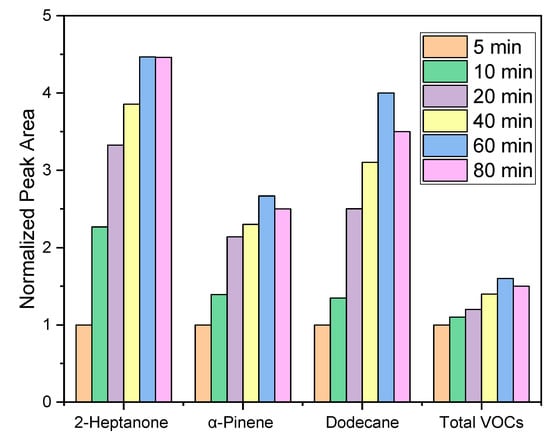

The evaluation of extraction time is a critical step for the SPME Arrow method. Therefore, different extraction time spans were investigated (i.e., 5, 10, 20, 40, 60 and 80 min). Since SPME is an equilibrium technique, the equilibrium time has to be reached in order to extract the maximum amount of analyte at various extraction times. As it can be observed, for the SPME Arrow method, equilibrium is reached at 60 min, and the use of longer extraction times even appears to decrease the response again. As a result, an extraction time span of 60 min was chosen. Figure 3 shows the effect of extraction time in the SPME Arrow extraction procedure.

Figure 3.

Evaluation of the extraction time for SPME Arrow.

3.1.5. Selection of Stirring Rate

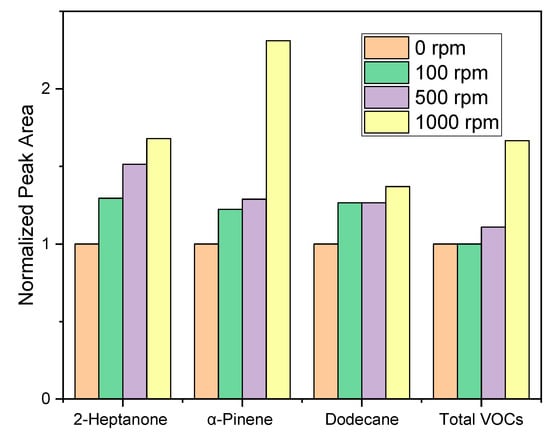

Different stirring rates (i.e., 100, 500, 1000 rpm, as well as no stirring) were evaluated for the extraction of volatile components of milk samples. It was observed that enhancement of stirring rate from 0 to 1000 rpm increased the peak intensity for the examined volatile analytes, as well as for the total volatile extraction. Due to the assisted volatilization of analytes, stirring leads to more effective and faster adsorption of analytes into the fiber []. However, further increase in stirring rate was not possible, due to the dimensions of the glass vial and the selected sample volume, in terms of avoiding fiber damage due to fast stirring. Therefore, a stirring rate of 1000 rpm was chosen to obtain higher signals. Figure 4 shows the effect of stirring rate in the SPME Arrow extraction procedure which can be achieved.

Figure 4.

Evaluation of the stirring rate for SPME Arrow.

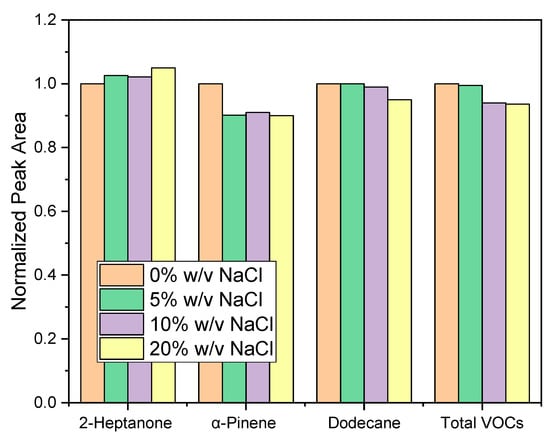

3.1.6. Selection of Salt Addition

The effect of salt addition in the SPME Arrow extraction procedure was also studied. Addition of sodium chloride was tested to check its effect on the HS-SPME procedure. The salting-out method is widely used in SPME methods, since it is known to enhance the distribution constant between the analytes and the fiber by minimizing the interaction of the analytes with water and by helping the analytes to go to the headspace []. For this purpose, different quantities (i.e., 0, 5, 10 and 20% w/w) of sodium chloride were added to the sample. Figure 5 shows the effect of addition of sodium chloride in the extraction procedure. As can be seen, no significant benefit from salt addition was observed. Although salt addition has often been observed to enhance extraction efficiency, this is not the case for volatiles analyzed in milk. This is believed to be related to milk being an emulsion rather than a homogenous solution. The volatile compounds are mainly enriched in the lipid phase of the milk while the salt dissolves in the aqueous phase, thus not affecting the response of the volatiles. For purely aqueous solutions, the addition of salt could cause an increase in the viscocity of the aqueous sample solution which might reduce the mass transfer of the analytes to the headspace and result in a reduction in the extraction efficiency []. As a result, further experiments were carried out with no salt addition.

Figure 5.

Evaluation of the salt addition for SPME Arrow.

3.1.7. Selection of Desorption Temperature and Desorption Time

In order to have complete desorption of the analytes from the fiber and avoid any carry-over effects, desorption temperature and desorption time should be evaluated. The recommended operating temperature for 120 μm CAR/PDMS Arrow fibers is 220–300 °C. Therefore, different temperature values at this range (i.e., 230, 250, 270 and 300 °C) were investigated. It was found that 230 °C was sufficient to thermally desorb the analytes. Similarly, different time spans (i.e., 1, 3 and 5 min) were investigated. It was found that 1 min was sufficient to desorb the analytes; however, the fiber was left in the injection port of the GC instrument for a total time of 10 min for cleaning, according to the manufacturer’s instructions.

3.2. Evaluation of the Conventional SPME Procedure

For the accurate comparison of the SPME Arrow technique with the conventional SPME technique, the main factors affecting the latter technique were also evaluated. Regarding the extraction step, the effects of fiber type (PDMS fiber 100 μm, CAR/PDMS 75 µm, DVB/PDMS 65 µm) sample volume (1–10 mL), extraction time (5–80 min), extraction temperature (25–60 °C), salt addition (0–20% w/w of NaCl), and stirring rate (0–1000 rpm) were investigated. Regarding the thermal desorption step, desorption time (1–5 min) and desorption temperature (220–300 °C) were investigated. The results for sample volume, extraction temperature, extraction time, salt addition and stirring rate evaluation are shown in Figures S1–S5 (Supplementary Materials).

For fiber selection, although similar chromatograms were obtained for CAR/PDMS 75 µm, DVB/PDMS 65 µm, the CAR/PDMS 75 µm fiber was finally chosen since its use provide direct comparison of the sorptive phase of SPME Arrow technique with the conventional SPME technique. Regarding extraction time and temperature, equilibrium was reached after 60 min at 50 °C, similarly with the SPME Arrow method. Moreover, salt addition was not found to assist the SPME process and, therefore, no salt addition was chosen. The optimum stirring rate was found to be 1000 rpm. This finding is also similar to the SPME Arrow method; however, the conventional SPME method was influenced more by this factor since the peak areas for the examined analytes and total VOCs became 1.3–5 times higher than without stirring, while for SPME Arrow method the peak areas for the examined analytes and total VOCs became 1.3–1.7 times higher than without stirring. Finally, for the conventional SPME method, the optimum sample volume was found to be 3 mL, instead of 5 mL which was optimum for the SPME Arrow method. This can be attributed to the lower amount of extraction phase of conventional SPME fibers that lead to fiber saturation with higher sample volume. Regarding the desorption conditions, also in the case of conventional CAR/PDMS SPME fiber, efficient analyte desorption was observed at 230 °C and 1 min was sufficient to desorb them, and the fiber remained for a total time of 5 min for cleaning.

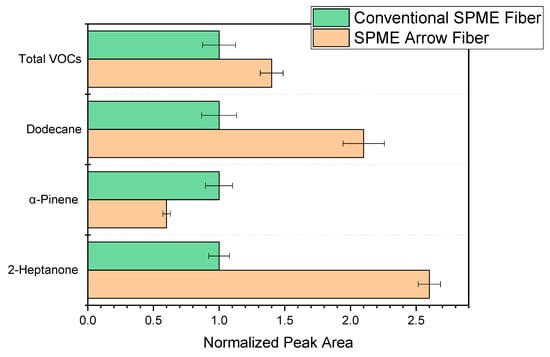

3.3. Evaluation of Sensitivity and Reproducibility for SPME Arrow and Conventional SPME Procedures

In order to compare the sensitivity of the two examined sample preparation techniques, comparison of SPME Arrow and Conventional SPME procedures took place with regard to cumulative VOC areas. For this purpose, five replicate analyses of the same milk sample took place under optimized sample preparation conditions and the average peak areas for 2-heptanone, α-pinene and dodecane, as well as the total volatiles in milk samples were calculated. It is known that the higher the cumulative area, the higher the fiber sensitivity toward the same number of accumulated analytes []. Figure 6 shows the results for sensitivity comparison obtained for the two different methods. As can be observed, higher average peak areas were observed for 2-heptanone, dodecane and total volatiles with the use of CAR/PDMS SPME Arrow fiber, while only for α-pinene was the average peak area higher with the use of conventional CAR/PDMS SPME fiber. With the use of CAR/PDMS SPME Arrow fibers a 1.4-fold increase in the peak areas for total volatiles was observed, while for 2-heptanone and dodecane the increase was 2.6- and 2.1-fold, respectively. A two-way t-test assuming unequal variances was employed (p < 0.05) in order to test the significance of the observed differences. It was found in all four cases that the differences were statistically significant. The results were similar to those obtained by Barreira et al. [] that reported an up to 2-fold increase with SPME Arrow fiber in the determination of biogenic volatile organic compounds in the atmosphere compared to conventional SPME fiber. As it can be concluded, higher sensitivity in terms of average peak areas of total VOCs can be achieved when using CAR/PDMS SPME Arrow fibers.

Figure 6.

Sensitivity comparison for Carbon wide range (WR) SPME Arrow/polydimethylsiloxane (CAR/PDMS) SPME Arrow fiber and conventional CAR/PDMS SPME fiber.

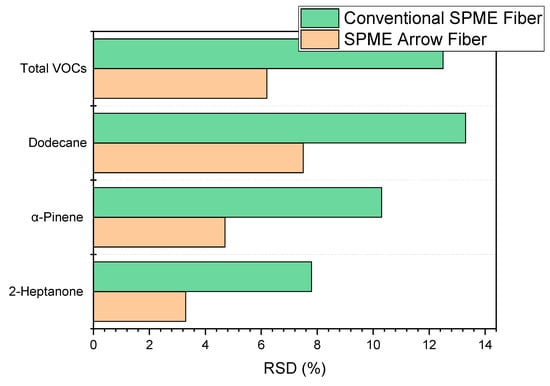

Moreover, in order to compare the reproducibility of the two examined sample preparation techniques, a comparison of SPME Arrow and conventional SPME procedures was conducted on the basis of average relative standard deviation (RSD) values for the peak areas. For this purpose, five replicate analyses of the same milk sample were conducted under optimized sample preparation conditions []. Figure 7 shows the results for reproducibility comparison obtained for the two different methods. Subsequently, the RSD values for 2-heptanone, α-pinene and dodecane, as well as the total volatiles in milk samples were calculated. It was found that the RSD of the total volatiles for conventional SPME procedure was 12.5%, while for SPME Arrow was 6.2%. For 2-heptanone, the RSD of the replicate analysis with conventional SPME procedure was 7.8%, while for SPME Arrow it was 3.3%. For α-pinene, the RSD of the replicate analysis with a conventional SPME procedure was 10.3%, while for SPME Arrow it was 4.7%. For dodecane, the RSD of the replicate analysis with a conventional SPME procedure was 13.3%, while for SPME Arrow it was 7.5%. It can be concluded that the use of SPME Arrow CAR/PDMS fiber provides more reproducible results compared to the use of conventional CAR/PDMS SPME fibers.

Figure 7.

Reproducibility comparison for CAR/PDMS SPME Arrow fiber and conventional CAR/PDMS SPME fiber.

3.4. Application of SPME Arrow Method for the Analysis of Milk Samples

The developed SPME Arrow method was employed for the analysis of thermally treated milk samples obtained from the local market in Vienna, Austria. The results are shown in Table 1. Each sample was analyzed in triplicate. As it can be observed, a wide variety of ketones, aldehydes, alkanes, alkanes, carboxylic acids and terpenes were detected in the milk samples. The content of each compound was semiquantified and their relative concentrations were determined based on the concentration of the internal standard. The major compounds were acetone, 2-butanone, 2-pentanone, 2-heptanone and 2-nonane. Hexanal, heptanal and nonanal were the major aldehydes that were detected in the milk samples. Most of these compounds have also been previously detected in milk samples []. The significant presence of alkanes in the milk samples can be attributed to the thermal treatment that the milk was subjected to in order to extend its shelf-life. The presence of these compounds may increase in high temperatures by hemolytic cleavage of carbon-carbon bonds along the fatty acid chain []. Furthermore, terpenes that were detected in milk samples were α-pinene, o-Cymene, 3-carene and α-humulene. Terpenes have been also previously detected in dairy products [,]. Finally, compounds such as styrene can be attributed to potential migration of the packaging [].

Table 1.

Results from milk samples analysis with SPME Arrow.

4. Conclusions

In this study, we developed a sensitive and reproducible method for determining VOCs in milk samples based on the use of the headspace SPME Arrow technique. The experimental conditions affecting the extraction efficiency were optimized and it was found that the best results were obtained with the CAR/PDMS SPME–Arrow fiber and 5 mL of sample after equilibrating for 60 min at 50 °C, under stirring at 1000 rpm without any salt addition. After extraction, the VOCs were thermally desorbed in the modified GC injection port, followed by their determination in a GC-MS system. The SPME Arrow method was finally compared to the conventional SPME process that was also optimized in order to make an accurate comparison. It was found that the CAR/PDMS SPME–Arrow fiber extract VOCs from milk samples had higher sensitivity and better reproducibility than the conventional CAR/PDMS SPME fiber. Considering that detection limits are proportional to the signal intensity and inversely proportional to the standard deviation of the measurement, an overall improvement of a factor of 4–5x can be observed over the classical SPME setup. Note, though, that this enhancement is compound-dependent. The only limitation of this technique is the requirement of a modified injector weldment and cap due to the larger diameter of the SPME Arrow which are not required for conventional SPME. Among the benefits of SPME Arrow is the larger extraction phase compared to SPME, the possibility of automation, the ease in handling, the increased ruggedness and the reduced sample preparation time in comparison with the classic solid-phase extraction and liquid–liquid extraction techniques, as well as its solvent free nature. In conclusion, SPME–Arrow is a powerful extraction technique for the analysis of VOCs in milk samples.

Supplementary Materials

The following are available online at https://www.mdpi.com/2297-8739/7/4/75/s1, Figure S1: Evaluation of the sample volume for conventional SPME method, Figure S2: Evaluation of the extraction temperature for conventional SPME method, Figure S3: Evaluation of the extraction time for conventional SPME method, Figure S4: Evaluation of the stirring rate for conventional SPME method, Figure S5: Evaluation of the salt addition for conventional SPME method.

Author Contributions

Conceptualization, E.R.; methodology, N.M., E.R. and G.A.Z.; experimental work, N.M.; writing—original draft preparation, N.M.; writing—review and editing, E.R. and G.A.Z.; supervision, E.R. and G.A.Z.; project administration, E.R. All authors have read and agreed to the published version of the manuscript.

Funding

The research work was supported by the Hellenic Foundation for Research and Innovation (HFRI) under the HFRI Fellowship grant (Fellowship Number: 138). Support of this work through a grant from the Restek Academic Support Programme (RASP) is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cheng, H. Volatile flavor compounds in yogurt: A review. Crit. Rev. Food Sci. Nutr. 2010, 50, 938–950. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-Y.; Kim, W.S.; Lee, Y.-Y.; Choi, Y.-S.; Choi, H.; Jang, H.W. Solid-phase microextraction Arrow for the volatile organic compounds in soy sauce. J. Sep. Sci. 2019, 42, 2942–2948. [Google Scholar] [CrossRef] [PubMed]

- Tunick, M.H. Analyzing volatile compounds in dairy products. J. Sci. Food Agric. 2014, 94, 1701–1705. [Google Scholar] [CrossRef] [PubMed]

- Tunick, M.; Iandola, S.; Van Hekken, D. Comparison of SPME Methods for Determining Volatile Compounds in Milk, Cheese, and Whey Powder. Foods 2013, 2, 534–543. [Google Scholar] [CrossRef] [PubMed]

- Marsili, R.T. SPME-MS-MVA as an electronic nose for the study of off-flavors in milk. J. Agric. Food Chem. 1999, 47, 648–654. [Google Scholar] [CrossRef] [PubMed]

- Marsili, R.T. Comparison of solid-phase microextraction and dynamic headspace methods for the gas chromatographic-mass spectrometric analysis of light-induced lipid oxidation products in milk. J. Chromatogr. Sci. 1999, 37, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Arthur, C.L.; Pawliszyn, J. Solid Phase Microextraction with Thermal Desorption Using Fused Silica Optical Fibers. Anal. Chem. 1990, 62, 2145–2148. [Google Scholar] [CrossRef]

- Manousi, N.; Zachariadis, G.A. Determination of volatile compounds in nut-based milk alternative beverages by HS-SPME prior to GC-MS analysis. Molecules 2019, 24, 3091. [Google Scholar] [CrossRef] [PubMed]

- Kremser, A.; Jochmann, M.A.; Schmidt, T.C. PAL SPME Arrow-Evaluation of a novel solid-phase microextraction device for freely dissolved PAHs in water. Anal. Bioanal. Chem. 2016, 408, 943–952. [Google Scholar] [CrossRef] [PubMed]

- Baltussen, E.; Sandra, P.; David, F.; Cramers, C. Stir bar sorptive extraction (SBSE), a novel extraction technique for aqueous samples: Theory and principles. J. Microcolumn. Sep. 1999, 11, 737–747. [Google Scholar] [CrossRef]

- Nazyropoulou, C.; Samanidou, V. Stir bar sorptive extraction applied to the analysis of biological fluids. Bioanalysis 2015, 7, 2241–2250. [Google Scholar] [CrossRef] [PubMed]

- Helin, A.; Rönkkö, T.; Parshintsev, J.; Hartonen, K.; Schilling, B.; Läubli, T.; Riekkola, M.-L. Solid phase microextraction Arrow for the sampling of volatile amines in wastewater and atmosphere. J. Chromatogr. A 2015, 1426, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Nam, T.G.; Lee, J.Y.; Kim, B.K.; Song, N.-E.; Jang, H.W. Analyzing volatiles in brown rice vinegar by headspace solid-phase microextraction (SPME)–Arrow: Optimizing the extraction conditions and comparisons with conventional SPME. Int. J. Food Prop. 2019, 22, 1195–1204. [Google Scholar] [CrossRef]

- Song, N.E.; Lee, J.Y.; Lee, Y.Y.; Park, J.D.; Jang, H.W. Comparison of headspace–SPME and SPME-Arrow–GC–MS methods for the determination of volatile compounds in Korean salt–fermented fish sauce. Appl. Biol. Chem. 2019, 62, 16. [Google Scholar] [CrossRef]

- Achouri, A.; Boye, J.I.; Zamani, Y. Identification of volatile compounds in soymilk using solid-phase microextraction-gas chromatography. Food Chem. 2006, 99, 759–766. [Google Scholar] [CrossRef]

- Demyttenaere, J.C.R.; Dagher, C.; Sandra, P.; Kallithraka, S.; Verhe, R.; De Kimpe, N. Flavour analysis of Greek white wine by solid-phase microextraction-capillary gas chromatography-mass spectrometry. J. Chromatogr. A 2003, 985, 233–246. [Google Scholar] [CrossRef]

- Safari, M.; Yamini, Y.; Mani-Varnosfaderani, A.; Asiabi, H. Synthesis of Fe3O4@PPy–MWCNT nanocomposite and its application for extraction of ultra-trace amounts of PAHs from various samples. J. Iran. Chem. Soc. 2017, 14, 623–634. [Google Scholar] [CrossRef]

- Barreira, L.M.F.; Duporté, G.; Rönkkö, T.; Parshintsev, J.; Hartonen, K.; Hyrsky, L.; Heikkinen, E.; Jussila, M.; Kulmala, M.; Riekkola, M.-L. Field measurements of biogenic volatile organic compounds in the atmosphere using solid-phase microextraction Arrow. Atmos. Meas. Tech. 2018, 11, 881–893. [Google Scholar] [CrossRef]

- Iranmanesh, M.; Ezzatpanah, H.; Akbari-Adergani, B.; Torshizi, M.A.K. SPME/GC-MS characterization of volatile compounds of iranian traditional dried kashk. Int. J. Food Prop. 2018, 21, 1067–1079. [Google Scholar] [CrossRef]

- Amirshaghaghi, Z.; Emam Djomeh, Z.; Oromiehie, A. Studies of Migration of Styrene Monomer from Polystyrene Packaging into the Food Simulant. Iran. J. Chem. Eng. 2011, 8, 43–49. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).