Abstract

Coalbed methane (CBM) is a vital clean energy resource, yet its extraction efficiency is often hindered by rapid production decline and low production rates in medium-shallow reservoirs. This study investigates the potential of CO2 huff-and-puff technology to enhance CBM recovery and achieve CO2 storage in low-productivity wells. A comprehensive model, constructed based on the geological conditions of the Qinshui Basin, was developed. Numerical simulations revealed that CO2 huff-and-puff significantly improves CH4 production by displacing adsorbed CH4 and maintaining reservoir pressure. Key findings indicate that higher CO2 injection volumes yield substantial increases in both peak CH4 production and cumulative production compared with conventional extraction. Optimal soaking times balance recovery efficiency and operational costs. Sensitivity analysis identified gas diffusion coefficients, initial permeability, and Langmuir volume constants as critical geological parameters influencing the performance. This study preliminarily demonstrates the feasibility of large-scale CO2 huff-and-puff for enhancing production in low-productivity CBM wells and provides theoretical insights for revitalizing China’s underperforming CBM wells while advancing carbon neutrality goals, although further experimental validation is still required.

1. Introduction

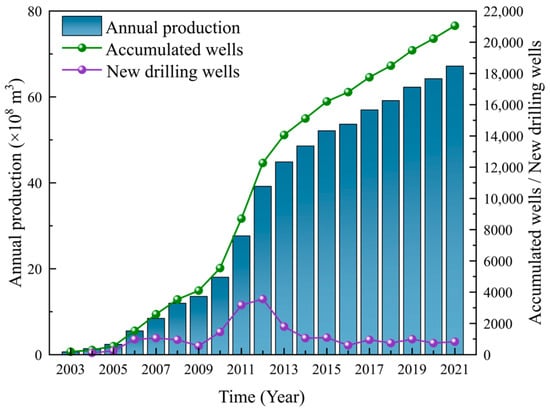

Coalbed methane (CBM), a significant clean and efficient energy source, plays a dual role in addressing energy shortages and enhancing environmental sustainability. Its large-scale development not only supplements natural gas supplies and mitigates coal mine hazards (e.g., gas outbursts) but also contributes to greenhouse gas reduction [1,2,3]. China possesses the world’s third-largest CBM reserves, with two major production bases established in the Qinshui Basin and the eastern Ordos Basin [4,5]. Distinct from other tight gas reservoirs (e.g., shale gas), medium- to shallow-depth CBM primarily exists in an adsorbed state within coal seams [6,7,8]. However, conventional extraction methods face a critical limitation: rapid production decline due to reservoir pressure depletion, coupled with slow desorption of adsorbed CBM, which hinders efficient recovery [9]. Globally, the CBM industry has experienced divergent developmental trajectories. Since 2008, the development of CBM in the United States has entered a period of decline, characterized by a continuous decrease in annual production and a drop in single-well productivity [10,11,12]. This situation highlights the urgent need for technological innovations to revitalize the CBM industry. In the Powder River Basin, approximately 8000 wells have already been shut down or abandoned [13]. In the southern part of the Cooper Basin in Australia, although coal seams exhibit relatively high permeability, their low gas content necessitates stimulation and productivity enhancement measures to achieve commercial viability [14]. In countries such as England, France, and Turkey, large-scale CBM development has not been realized, primarily due to low permeability, which results in poor well productivity [13]. China’s annual CBM production has demonstrated sustained growth since 2005. However, since 2012, this growth has markedly slowed, accompanied by a decline in newly drilled wells (as shown in Figure 1). The slowdown in production growth is primarily attributed to the prevalence of low-productivity CBM wells, resulting from multiple engineering challenges: reservoir damage during drilling and completion, improper drainage strategies, and natural pressure depletion following prolonged production. By the end of 2020, only ~60% (12,880 wells) of the 21,217 drilled nationwide were operational [15]. Analysis of 4200 CBM wells (Table 1) reveals that more than 50% are low-productivity wells across most blocks, with some regions exceeding 90%. Additionally, certain blocks exhibit average daily production as low as a few hundred cubic meters per well, highlighting severe inefficiencies. Given the ubiquitous distribution and high proportion of underperforming wells, low productivity has emerged as a critical bottleneck in China’s CBM development. Consequently, enhancing recovery in existing wells has become an urgent priority for the industry.

Figure 1.

Annual CBM production and well development statistics (accumulated and newly drilled wells) in China from 2003 to 2021 [16], Copyright 2023 Coal Geology & Exploration.

Table 1.

CBM production data for partial regions of China.

In recent years, various stimulation measures have been implemented in several regions to enhance production from low-productivity CBM wells. Reservoir stimulation has become a critical technical approach for improving CBM productivity, primarily through refracturing techniques including conventional hydraulic fracturing, acid fracturing, indirect roof fracturing, and nitrogen fracturing [25]. To address well shutdowns caused by sand or coal fines during drainage operations, a pilot project was conducted in the Zhengzhuang Block of the Qinshui Basin, where oriented sand-controlled hydra-jet fracturing was applied in two L-shaped horizontal wells. Following stimulation, these wells achieved stable daily gas production rates of 1.01 × 104 m3/d and 1.60 × 104 m3/d respectively [26]. Furthermore, to tackle the challenges of low pressure, low permeability, and low saturation, a field trial was conducted in the Pingdingshan mining area using liquid nitrogen injection-assisted fracturing technology. After the treatment, the wells achieved stable and sustained gas production, with a cumulative gas production of 6.2 × 105 m3 [27]. While these technologies have demonstrated promising results in field applications, their broader implementation requires further validation. Notably, secondary hydraulic fracturing may cause reservoir damage and environmental contamination [28], and is often ineffective for wells experiencing production declines due to natural depletion or inherently low gas content [29].

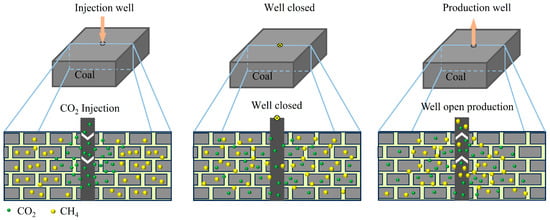

It is widely recognized that CO2-enhanced coalbed methane (CO2-ECBM) recovery is an effective method for improving CBM production [30,31,32,33,34,35]. This technology enhances CBM recovery through CO2 injection into coal seams while simultaneously enabling CO2 geological storage, thereby contributing to carbon emission reduction and supporting the “dual carbon” strategy [36,37,38]. Numerous studies on CO2-ECBM have elucidated the mechanisms underlying CH4 production enhancement, CO2 sequestration, and changes in the physical properties of coal reservoirs during the process. Li et al. [39] based on a coupled numerical model and employing the influence factor method, analyzed the effects of CO2 and CH4 on coal deformation in CO2-ECBM. Their results indicated that, in the early stage of injection, coal deformation is primarily governed by CH4 desorption, whereas in the later stage it gradually shifts to being dominated by CO2 adsorption. Wang et al. [40] using molecular dynamics simulations, investigated the CO2 injection process as well as the displacement of CH4 by CO2 after injection cessation, and revealed that the CO2–CH4 displacement rate is relatively high in the initial stage of gas injection, while isobaric diffusion effects dominate once gas pressure equilibrium is reached. Ye et al. [41] developed a classification-based model to examine the dynamic evolution of the fracture network within coal seams during CO2 injection, and found that the injection altered the original stress equilibrium of the coal seam, thereby inducing corresponding deformation and thermal expansion. As a practical application of CO2-ECBM, CO2 huff-and-puff involves direct CO2 injection into low-productivity wells to enhance CH4 output. As illustrated in Figure 2, the CO2 huff-and-puff process for enhancing CBM comprises three distinct phases: gas injection, soaking, and production. Among its operational strategies, the CO2 huff-and-puff approach is particularly suited for stimulating low-productivity CBM wells. In this process, CO2 is injected into a target well, allowed to soak and displace adsorbed CH4, and subsequently produced together with mobilized CH4. After CO2 is separated from the mixed gas produced during the third stage of CO2 huff-and-puff, it can be re-injected into the coal seam for a new huff-and-puff, which is analogous to the injection of dry gas into hydrocarbon reservoirs to enhance condensate recovery [42]. Compared with conventional displacement methods, CO2 huff-and-puff requires no auxiliary injection wells, consumes less CO2, and can be implemented using existing well infrastructure, thus lowering operational costs and cycle time. Owing to its simplicity, cost-effectiveness, and effectiveness in enhancing CH4 production while ensuring CO2 storage, this technology can serve as a practical solution for revitalizing underperforming CBM wells, especially in regions like China where numerous such wells exist. Two early-stage micro-pilot tests conducted in the Qinshui Basin in 2004 [43] and 2010 [44], injected 192.3 t and 233.6 t of CO2, respectively. Post-soak production data confirmed enhanced CH4 production upon wells reopening, demonstrating the technique’s preliminary feasibility. However, due to the limited injection volumes and small scale, the stimulation mechanisms and the scalability for commercial deployment remain insufficiently understood and require further systematic investigation. While most research on CO2 huff-and-puff has focused on shale gas, findings exhibit significant discrepancies. For instance, one numerical simulation reported a 55% CO2 storage efficiency and increased gas production after injecting ~3.8 × 104 t CO2 over 12 cycles in two years [45]. Similarly, Fathi and Akkutlu [46] observed a 30% recovery increase with over 90% CO2 storage after five years of continuous CO2 injection. Conversely, Eshkalak et al. [47] documented merely 4% recovery enhancement after five years of injection and five years of soaking, with most CO2 being re-extracted. These contradictory results may be related to variations in operational huff-and-puff strategies and reservoir-specific factors. Furthermore, the technique proves less effective in low-permeability formations or those with high CO2 Langmuir volume constant [48]. Currently, no studies have been conducted on large-scale CO2 huff-and-puff for enhancing production in low-productivity CBM wells in medium-shallow coal seams. Despite these shale gas studies, existing results are inconsistent regarding both methane recovery and CO2 storage efficiency. Critically, coal reservoirs differ fundamentally from shale in permeability, adsorption behavior, and geomechanical properties, necessitating targeted investigations. Thus, a comprehensive evaluation of CO2 huff-and-puff’s feasibility and mechanistic effects in coal seams—particularly for revitalizing low-productivity CBM wells is imperative to bridge this knowledge gap.

Figure 2.

Schematic diagram of CO2 huff-and-puff.

Numerous researchers have developed mathematical models to simulate the CO2-ECBM process, facilitating in-depth investigations of CO2 injection and CH4 extraction through numerical simulations. Typically, coal seams are conceptualized as dual-porosity system consisting of fractures and matrix blocks. Upon CO2 injection into the coal seam, multiple complex mechanisms come into play, including CO2-CH4 binary gas interactions, gas adsorption and desorption, gas-water two-phase flow within fractures, mass exchange between fractures and the matrix, and dynamic variations in porosity and permeability [49,50,51]. For instance, Liu et al. [52] incorporated these complex processes into a fully coupled model to evaluate CH4 recovery under a scenario involving one CO2 injection well and eight production wells. Similarly, Fan et al. [53] developed a numerical model to optimize the composition scheme for CO2/N2 mixed-gas displacement. Yang et al. [54] established a numerical model based on the Qinshui Basin to examine the impact of different CO2 injection rates on the CO2-ECBM process. Based on the aforementioned mechanisms, Hou et al. [55] further incorporated thermodynamic effects to investigate the influence of CO2 injection temperature and pressure on CO2-ECBM. While these models provide a relatively comprehensive description of the CO2-ECBM process, most studies have predominantly focus on CO2 displacement, with significantly less attention given to CO2 huff-and-puff technologies.

In summary, existing research on CO2 huff-and-puff for enhancing production in low-productivity CBM wells within shallow to medium-shallow coal reservoirs remains limited. The fundamental mechanisms governing gas migration during CO2 huff-and-puff operations, along with their dual effects of CH4 production enhancement and CO2 storage potential, are not yet fully understood. To address these knowledge gaps, we develop a comprehensive numerical model employed to simulate CO2 huff-and-puff applications, evaluating both its technical feasibility for enhancing recovery of low-productivity CBM wells in medium-shallow reservoirs and its associated CO2 storage potential. Finally, through extensive parametric studies, we identify and analyze the key geological parameters that significantly influence the production enhancement efficacy of CO2 huff-and-puff operations.

2. Derivation of Mathematical Model for CO2 Huff-and-Puff Technology

In the following, a set of field governing equations are defined to govern the fluid transport, gas adsorption, coal deformation and porosity-permeability evolution. Based on these equations, a corresponding numerical model is developed to investigate its feasibility for both CBM production enhancement and CO2 storage, as well as the actual enhancement effect and influencing factors. This model aims to systematically simulate the interactions between CH4 and CO2 in coal seams and can be applied to evaluate the performance of CO2 huff-n-puff operations in low-production CBM wells in medium-shallow reservoirs, with simulation results potentially informing field development strategies.

2.1. Basic Assumptions

The migration of CH4, CO2, and water within coal seams involves complex multi-physical processes, including gas adsorption/desorption, matrix swelling/shrinkage, and fluid flow/diffusion. The following model is developed based on the following assumptions [56,57,58,59,60]: (1) The coal seam is modeled as a homogeneous and isotropic dual-porosity medium, consisting of a matrix system and a fracture system. The matrix serves as the primary storage site for gas adsorption, while the fracture provides the main pathways for fluid flow; (2) The fluids in the coal seam comprise both gas and water phases, with gas solubility in the aqueous phase assumed negligible; (3) Gas flow obeys Darcy’s law, and competitive adsorption of CH4 and CO2 is described by the extended Langmuir equation; and (4) All gaseous components in the coal seam are treated as ideal gases and obey the ideal gas law.

2.2. Governing Equations of Fluid Transport

The gas in the matrix exists in two states: free gas in micropores and adsorbed gas on the micropore surfaces. The gas adsorption behavior follows the extended Langmuir adsorption equation. Therefore, the governing equation for fluid transport in coal matrix can be derived by applying the mass conservation principle, expressed as follows [61,62,63,64]:

where the subscript i denotes the gas component (i = 1 for CH4, i = 2 for CO2); ϕₘ is the porosity of the matrix; ρmgi is the free gas density of component i in the matrix, kg/m3; ρc is coal density, kg/m3; ρgsi is the standard density of gas component i, kg/m3; VLi represents the Langmuir volume constant of gas component i, m3/kg; bi is defined as the reciprocal of the Langmuir pressure constant (bi = 1/pLi, where pLi is the Langmuir pressure constant of component i, Pa); pmgi denotes the partial pressure of gas component i in the matrix pore space, Pa; and Qᵢ represents the source-sink term for gas component i, kg/(m3·s).

Based on the ideal gas law, the free gas density is given by [65]:

where ρgi is the density of the free gas component i, kg/m3; Mgi is the molar mass of gas component i, kg/mol; R is the universal gas constant, J/(mol·K); T is the temperature, K; and pgi is the partial pressure of gas component i, Pa.

The gas exchange between matrix and fractures is governed by the following mass transfer equation derived from Fick’s law [66]:

where ξ is the shape factor related to the matrix block size, m−2; Dᵢ is the diffusion coefficient of gas component i, m2/s; Sg is the gas saturation; and pfgi denotes the partial pressure of gas component i in the fractures, Pa.

By substituting Equations (2) and (3) into Equation (1), the governing equations for CH4 and CO2 transport in the coal matrix can be expressed as:

The fracture system contains a mixture of CH4, CO2, and water, resulting in gas-water two-phase flow. The mass conservation equations for the water phase and gas phase in the fracture system can be expressed as [54]:

where sg and sw represent the gas saturation and water saturation, respectively, satisfying sw + sg = 1; ϕf denotes fracture porosity; k is the permeability of the coal fracture, m2; krg and krw represent the relative permeability of gas and water, respectively; μgi and μw denote the dynamic viscosities of gas component i and water, respectively, Pa·s; ρw indicates water density in the fractures, kg/m3; and pfw are the pressures of water in the fractures, Pa; and related by pfw = pfg − pcgw, where pcgw is the gas-water capillary pressure, Pa.

2.3. Governing Equation of the Mechanical Field

Coal seams are characterized as homogeneous porous media comprising both matrix and fracture systems, with their deformation governed by multiple factors, including stress conditions, gas adsorption/desorption effects, and mechanical interactions with adjacent coal seams. Based on poroelastic theory, the stress field in coal reservoirs can be described by the following governing equation [52,67]:

where σij represents the stress tensor component, Pa; G denotes the shear modulus of coal, Pa; εij is the strain tensor component; ν is Poisson’s ratio; α is the Biot coefficient; pf is the mean pore pressure, satisfying pf = pwsw + (pfg1 + pfg2)sg, Pa; K = E/3(1 − 2ν) is bulk modulus, Pa; E is Young’s modulus, Pa; εLi denotes the maximum swelling strain of gas component i; pmg is the total matrix pore pressure, Pa; yi is the mole fraction of gas component i; and δij is the Kronecker delta.

The strain–displacement relation equations and stress equilibrium equation in coal seam can be defined as [68,69]:

where ui is the displacement component in the i-th direction, m; and Fi is the body force component in the i-th direction, N.

Substituting Equation (6) into Equation (7) yields the governing equation for the mechanical field in coal reservoirs:

2.4. Dynamic Porosity-Permeability Model for Coal Seam Fractures

Permeability and porosity are key factors influencing CO2-ECBM. During CBM extraction, the boundary conditions of the coal reservoir can be regarded as uniaxial strain conditions. Under these conditions, the fracture compressibility follows the Palmer and Mansoori [70]. By integrating the multi-component adsorption model with the Palmer-Mansoori porosity-pressure relationship, the following governing equation can be obtained:

where ϕf0 represents the initial fracture porosity; cf denotes the fracture compressibility, 1/Pa; pfg0 is the initial total gas pressure in fracture, Pa; M = E(1 − ν)/[(1 + ν)(1 − 2ν)] defines the constrained axial modulus, Pa; pmg0 indicates the initial total matrix pore pressure, Pa; and y0i corresponds to the initial mole fraction of gas component i.

Based on the cubic law [71,72], the dynamic evolution model of permeability can be expressed as:

where k0 is the initial permeability of fracture, m2.

Equations (4), (5) and (8)–(10) collectively constitute the CO2 huff-and-puff mathematical model, which can be validated by previous studies [66,73], as this work adopts a similar modeling approach to those earlier publications.

3. Numerical Simulation of CO2 Huff-and-Puff Technology

3.1. Geological Model

The Qinshui Basin, one of China’s earliest CBM development regions, holds significant commercial potential with estimated CBM reserves of 3.95 × 1012 m3 [74]. In 2019, CBM production in Qinshui Basin accounted for 71% of China’s total output [75], underscoring its pivotal role in the domestic CBM industry. The southern Qinshui Basin includes multiple blocks such as Mabi, Zhengzhuang, Panzhuang, and Fanzhuang, which primarily host medium-shallow CBM reservoirs. Prior to 2015, vertical wells and small-scale hydraulic fracturing were the primary extraction methods; however, sustained single-well production rarely exceeded 104 m3 [76]. A significant proportion of CBM wells exhibited low productivity, with an overall production capacity fulfillment rate of merely 59.4%. Notably, 56% of these wells had daily production below 500 m3 [15], indicating widespread underperformance. To address these challenges, numerical simulations of CO2 huff-and-puff ECBM recovery could provide valuable insights into optimizing extraction techniques and improving production efficiency in the Qinshui Basin.

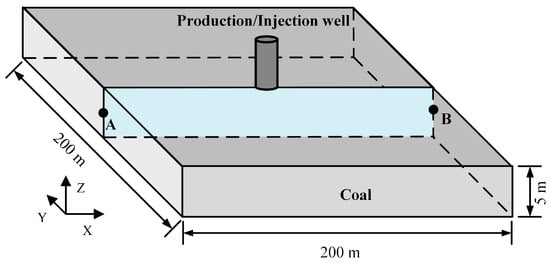

The numerical model for CO2 huff-and-puff ECBM recovery was developed based on the geological conditions of the southern Qinshui Basin in Shanxi Province. The model adopts a well spacing of 200 m, with the production/injection well positioned at the center and perforations evenly distributed along the vertical axis. The coal seam dimensions are 200 m × 200 m × 5 m, discretized into grid blocks of 4 m × 4 m × 1 m. A schematic diagram of the coal seam model is presented in Figure 3, where points A (0, 100, 2.5) and B (200, 100, 2.5) denote key monitoring locations, respectively. The top surface of the coal seam is situated at a burial depth of 500 m. Initial reservoir conditions include a permeability of 10 mD, a gas pressure of 2200 kPa, and a coal seam saturated solely with CH4. The key physical parameters used in the simulation, summarized in Table 2, were derived from field-measured data and laboratory test results.

Figure 3.

Geological model of numerical simulation.

Table 2.

Parameters used in the numerical simulation.

3.2. Simulation Schemes

The CO2 huff-and-puff ECBM recovery process is simulated in two phases:

(1) Conventional extraction phase: The initial stage involves direct CBM production without CO2 injection. When the CH4 production rate declines below 500 m3/d, the well is considered to have reached a low-production state. Production is stopped, and the well is shut in to facilitate the transition to the subsequent operational phase.

(2) CO2 huff-and-puff phase: CO2 is injected into the coal seam at a constant rate of 50 t/d. After injection, the well is shut in for a soaking period to allow gas adsorption and pressure equilibration. The well is then reopened for CBM production. Once the CH4 production rate again falls below 500 m3/d, production ceases, and the recovery and storage efficiency are calculated and summarized.

Table 3 presents the numerical simulation schemes, which evaluate varying CO2 injection volumes and soaking durations to assess CO2 huff-and-puff performance. These schemes are designed to investigate CH4 production enhancement under different CO2 huff-and-puff conditions and evaluate CO2 storage efficiency and its influencing factors. Subsequently, the impact of key geological parameters on process performance is analyzed to provide further insights.

Table 3.

Numerical simulation schemes.

To systematically evaluate the impact of geological parameters on CO2 huff-and-puff performance, we designed numerical simulation scenarios incorporating diverse combinations of key geological parameters and performed extensive simulations. The results demonstrate that three key geological factors exert the most pronounced effects on CO2 huff-and-puff performance: (1) gas diffusion coefficient, (2) initial fracture permeability, and (3) Langmuir volume constant. Based on these findings, we focused our subsequent sensitivity analysis on these three key factors. Using a baseline scheme of 2000 t CO2 injection with a 60-day soaking time, we performed sensitivity analysis by independently varying individual each of these key parameters by 20%, while maintaining constant total injection volume and soaking time. This approach allowed us to isolate and quantify the impact of each geological factor on production enhancement. Table 4 details the specific numerical simulation scenarios and corresponding parameter settings employed to analyze the influence of these key geological factors.

Table 4.

Numerical schemes for key geological parameters analysis.

4. Results and Discussion

4.1. Mechanisms of CO2 Huff-and-Puff ECBM Recovery

To gain an in-depth understanding of the intrinsic mechanisms underlying CBM enhancement during CO2 huff-and-puff operations, this section comprehensively examines simulation results through multiple perspectives. These include the spatiotemporal evolution of CH4 and CO2 distribution, temporal variations of adsorbed and free gas mole fraction, and compositional evolution in production wells. Special attention is devoted to investigating the transport behavior of CH4 and CO2, as well as competitive adsorption/desorption processes throughout the injection-soaking-production phases. The integrated analysis aims to reveal the multi-physical processes governing CO2 huff-and-puff ECBM recovery.

4.1.1. Transformation Between Adsorbed and Free Gas During CO2 Huff-and-Puff

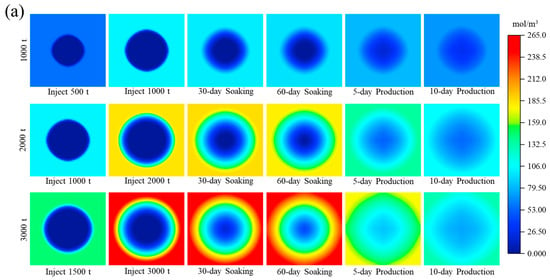

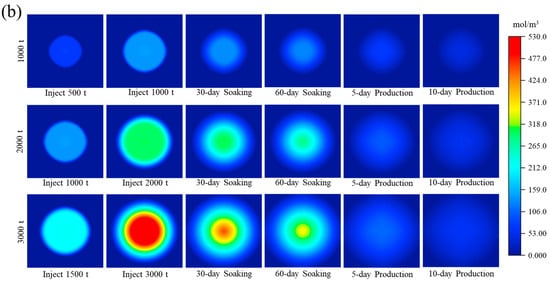

Figure 4 presents the spatiotemporal evolution of free CH4 and CO2 distribution within horizontal cross-section fracture network under varying CO2 injection volumes of 1000 t, 2000 t, and 3000 t, respectively. It reveals three distinct migration patterns during different operational phases:

Figure 4.

Spatiotemporal evolution of free gas content in the coal reservoir during the CO2 huff-and-puff process under different CO2 injection volumes: (a) CH4 and (b) CO2.

- (1)

- During the gas injection phase, the free CH4 content within fractures demonstrates progressive accumulation, with CH4 near the wellbore experiences displacement by injected CO2, migrating toward peripheral regions. Simultaneously, significant CO2 accumulation occurs near the wellbore, with the high-concentration zone expanding proportionally with injection volume.

- (2)

- During the soaking phase, free CH4 exhibits concentration gradient-driven back-migration toward the wellbore. Continuous CO2 diffusion from fractures into the coal matrix occurs, accompanied by adsorption phenomena. This dual process leads to continuous reduction in free CO2 content, diminution of the wellbore-proximal high-CO2-concentration zone, and progressive expansion of the CO2-CH4 mixing zone. Notably, the extent of the mixed zone increases significantly with higher CO2 injection volumes. This is due to the higher injection volume leading to an increase in coal seam pore pressure, resulting in an increase in concentration gradients in the coal seam, thus accelerating the diffusion and mixing of CO2 and CH4 molecules.

- (3)

- During the production phase, after reopening the well, rapid co-extraction of the mixed CH4 and CO2 occurs, causing a rapid decline in the content of both CH4 and CO2 within the fracture system. Meanwhile, CH4 located farther from the wellbore migrates toward the wellbore. Due to the relatively limited shut-in duration, some of the injected CO2 has not been fully adsorbed by the coal matrix, resulting in partial CO2 being re-extracted after reopening the well.

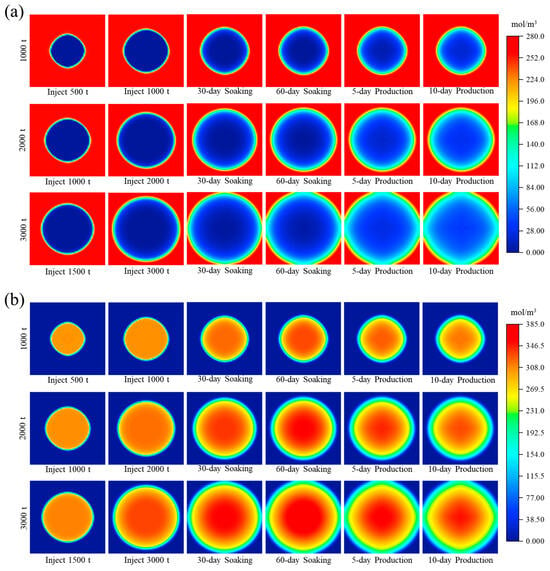

Figure 5 presents the spatiotemporal evolution of adsorbed CH4 and CO2 distribution within horizontal cross-section under varying CO2 injection volumes of 1000 t, 2000 t, and 3000 t, respectively. The analysis reveals three distinct migration patterns during different operational phases:

Figure 5.

Spatiotemporal evolution of adsorbed content in the coal reservoir during the CO2 huff-and-puff process under different CO2 injection volumes: (a) CH4 and (b) CO2.

- (1)

- During the CO2 injection phase, competitive adsorption between CO2 and CH4 induces rapid desorption of CH4 near the wellbore. Additionally, free CH4 in fractures is displaced to regions farther from the wellbore, leading to a reduction in CH4 partial pressure in the near-wellbore region. According to the Langmuir equation, this decrease in partial pressure results in a reduction of CH4 adsorption capacity.

- (2)

- During the soaking phase, CO2 adsorption continues to increase, forming a high-concentration CO2 adsorption zone near the wellbore. After 60 days of soaking, the spatial extent of this CO2-rich zone expands with higher injection volumes.

- (3)

- During the production phase, extraction of free CO2 from fractures slightly reduces adsorbed CO2 content. Meanwhile, as CH4 migrates toward the wellbore, a portion of CH4 is re-adsorbed by the coal matrix during this flow process, leading to a localized increase in CH4 adsorption near the wellbore. Overall, after CO2 huff-and-puff, the adsorbed CH4 content around the wellbore remains significantly lower than the initial state, confirming effective displacement. Moreover, substantial CO2 storage is achieved, with both the storage capacity and spatial distribution of CO2 increasing proportionally with injection volume.

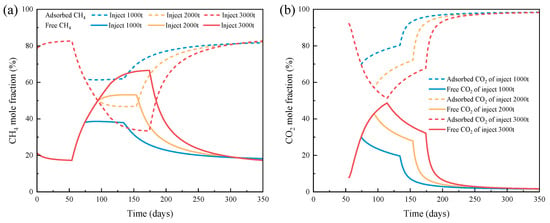

Figure 6 presents the variation of adsorbed and free gas mole fraction in coal seam during the CO2 huff-and-puff process. The process can be distinctly divided into four phases: conventional extraction, injection, soaking, and production.

Figure 6.

Variation of adsorbed and free gas mole fraction in coal seam: (a) CH4 and (b) CO2.

The conventional extraction phase demonstrates limited effectiveness in extracting adsorbed CH4 from the coal seam, as it relies exclusively on pressure depletion to recover a limited amount of free methane. Consequently, the free CH4 mole fraction shows a marginal decline while the adsorbed CH4 mole fraction increases accordingly. After the conventional extraction, the adsorbed and free CH4 molar fractions are 82.69% and 17.31%, respectively.

The initiation of CO2 injection marks a significant transition. Given the initial absence of CO2 in the coal seam, the injected CO2 rapidly diffuses through the coal matrix, achieving extensive adsorption. Following the first day of injection, the majority of the injected CO2 has been adsorbed by the coal matrix, resulting in an adsorbed CO2 mole fraction of 92.15%. As the CO2 injection rate outpaces the adsorption rate by the coal matrix, the adsorbed CO2 mole fraction continuously declines with ongoing injection. The competitive adsorption of CO2 and CH4, as well as the reduction in CH4 partial pressure induced by CO2 injection promotes substantial CH4 desorption. Consequently, the free CH4 mole fraction rises significantly. When the injection amount of CO2 reaches 2000 t, the adsorbed and free CH4 mole fraction in the coal seam become equal, each accounting for 50%. Furthermore, higher CO2 injection volumes result in greater CO2 adsorption within the coal seam, inducing more extensive desorption of adsorbed CH4. When the injection volume reaches 3000 t, the free CH4 content in the coal seam increases markedly, even surpassing the adsorbed CH4 content, reaching 66.56% after soaking.

The subsequent soaking phase shows continued but diminished displacement activity. While free CO2 persists in displacing adsorbed CH4, the rate of change for both adsorbed and free CH4 contents decreases significantly compared to the injection phase, stabilizing in later soaking periods. This temporal pattern indicates that the majority of CO2-CH4 adsorption-displacement behavior occurs during the injection phase. Notably, considerable CH4 desorption continues during early soaking, particularly under high CO2 injection volumes. During the soaking phase, continuous conversion of adsorbed CO2 to the free state occurs, leading to a progressive increase in the adsorbed CO2 mole fraction and a corresponding decrease in the free CO2 mole fraction. Moreover, higher injection volumes intensify the mutual transformation between adsorbed and free CO2 during this phase. Over the entire injection and soaking process, adsorbed CO2 consistently dominates over free CO2, demonstrating that most of the injected CO2 remains in the adsorbed state within the coal seam. Quantitative analysis reveals that by the end of soaking, adsorbed CH4 mole fraction decreases by 24.87%, 43.30%, and 59.55% for CO2 injection volumes of 1000 t, 2000 t, and 3000 t, respectively, compared to pre-injection levels. The observed CO2–CH4 adsorption-displacement ratio ranges between 1.41 and 1.49, suggesting that approximately 1.45 CO2 molecules are required to displace each CH4 molecule.

Gas extraction following well reopening is identical to conventional extraction and does not induce significant changes in the total adsorbed gas content within the coal seam. However, the total free gas content decreases rapidly due to drainage, resulting in a corresponding decline in its fraction. The adsorbed and free CH4 mole fractions become equal again at day 4 for an injection volume of 2000 t and at day 12 for an injection volume of 3000 t after reopening. Changes in the adsorbed and free CO2 mole fractions occur predominantly during the initial phase of well reopening. As drainage progresses, these fractions gradually stabilize.

Post-extraction analysis reveals that the adsorbed CH4 and CO2 mole fractions stabilize at approximately 82% and 98%, respectively. Compared to free CO2, adsorbed CO2 exhibits stable and secure attachment to the micropore surfaces of the coal matrix with minimal migration potential. These characteristics establish CO2 huff-and-puff as an effective method for both enhanced coalbed methane recovery and long-term CO2 storage.

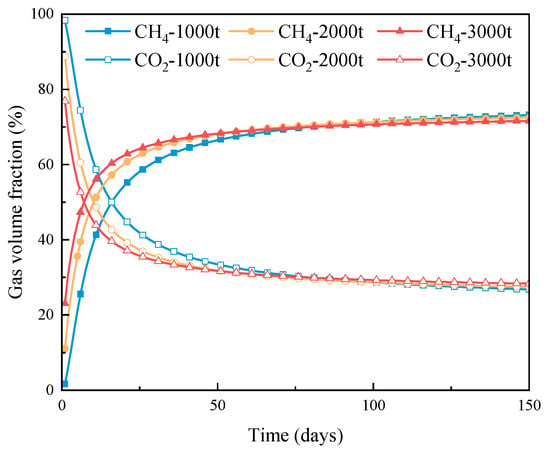

4.1.2. Evolution of Gas Volume Fraction in Production Well

Following CO2 injection and the soaking period, the production phase yields a mixture of CO2 and CH4 from the extraction well. Figure 7 illustrates the variations in the CH4 and CO2 volume fraction in production well under three CO2 injection schemes (1000 t, 2000 t, and 3000 t) with a fixed 60-day soaking time.

Figure 7.

Variation of CH4 and CO2 volume fraction in the production well after reopening.

During the initial production phase, the CO2 volume fraction is relatively high due to the accumulation of undiffused CO2 near the wellbore. On the first production day, CO2 accounts for over 75% of the produced gas across all injection volumes, peaking at 98.3% for the 1000 t case—indicating near-pure CO2 production initially.

As extraction progresses, CH4 migration toward the well gradually alters the composition. The crossover point (50% CH4/50% CO2) occurs at day 16, 10, and 7 for injection volumes of 1000 t, 2000 t, and 3000 t, respectively. Beyond this parity point, the CH4 volume fraction continues to rise but at a diminishing rate. By approximately day 80, the produced gas becomes predominantly CH4 in all cases, with CH4 volume fractions exceeding 70%, demonstrating effective recovery of the native CBM.

4.1.3. Evolution of Coal Seam Permeability

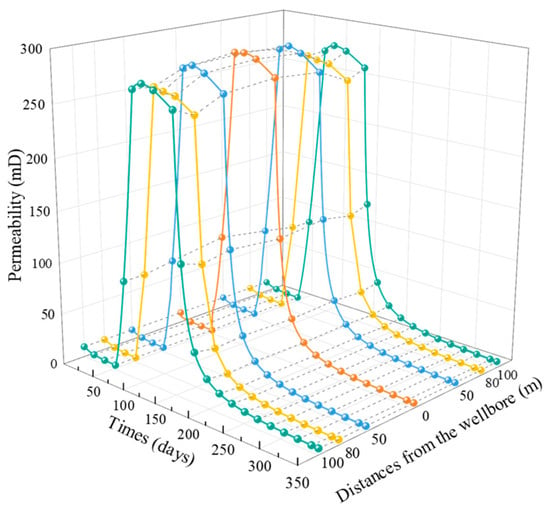

Permeability is a critical factor influencing CH4 production, with its variation governed by both effective stress and coal matrix swelling/shrinkage induced by gas adsorption/desorption. To illustrate this, we analyze the scheme involving CO2 injection volume of 2000 t followed by a 60-day soaking time. Figure 8 presents the temporal evolution of coal seam permeability at varying distances from the wellbore along cross-section A–B. The analysis reveals three patterns during different operational phases:

Figure 8.

Variation in coal seam permeability with time at distances of 0, 50, 80, and 100 m from the wellbore along cross-section A–B.

- (1)

- During the initial phase of conventional extraction, the abrupt pressure drops near the wellbore after well opening causes a rapid increase in effective stress, resulting in a sharp decline in permeability. In contrast, regions farther from the wellbore exhibit a moderate permeability increase primarily due to coal matrix shrinkage caused by CH4 desorption. As extraction progresses, the sustained reduction in coal seam gas pressure elevates effective stress, inducing compressive deformation and an overall downward permeability trend. By the end of conventional extraction, the permeability reaches a minimum of 3.42 mD.

- (2)

- During the injection phase, CO2 injection increases fracture pressure, which reduces effective stress and consequently enhances permeability. During the subsequent soaking phase, permeability initially increases before declining. This transient increase occurs because CO2 continues displacing adsorbed CH4 early in the soaking period, thereby improving flow pathways. However, as displacement weakens, ongoing CO2 diffusion and adsorption reduce free gas in fractures, lowering pore pressure and permeability. A notably permeability reduction is observed at 80 m from the wellbore during soaking. This phenomenon occurs because permeability in this region, where pore pressure remains relatively stable, is predominantly governed by matrix adsorption characteristics. Situated within the CH4–CO2 transition zone, the coal matrix exists in a mixed-gas adsorption state. According to the extended Langmuir strain model, matrix swelling under mixed-gas adsorption exceeds that under single-component adsorption. This leads to a greater pore structure contraction and thus lower permeability compared to adjacent zones under pure adsorption states.

- (3)

- Following well reopening, continuous reservoir pressure depletion leads to a sustained permeability decline, causing the production to drop rapidly after reaching its peak. By the 97th day of extraction, the coal seam permeability reverts to its initial value of 10 mD. Continued extraction further reduces the minimum permeability to 8.51 mD by the end of production—below the initial permeability level.

4.2. Effects of CO2 Injection Volume and Soaking Time on CH4 Enhancement and CO2 Storage Performance

4.2.1. Variation of CH4 Production

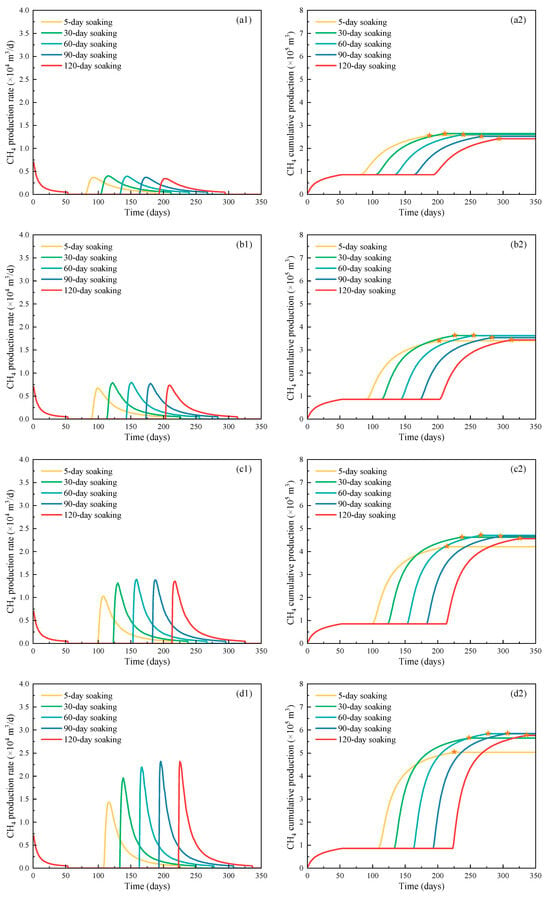

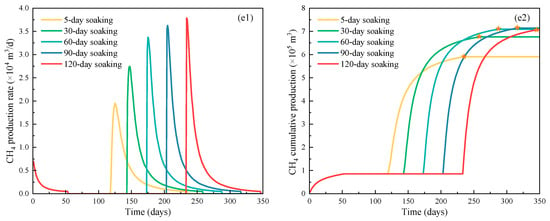

CH4 production is a key indicator for evaluating the engineering feasibility and stimulation potential of CO2 huff-and-puff technology, reflecting its practical effectiveness in ECBM recovery. Figure 9 presents the CH4 production rate and cumulative production under different CO2 injection volumes and soaking times.

Figure 9.

CH4 production rate and cumulative production under different operating schemes. ((a–e) represents CO2 injection volumes of 1000 t, 1500 t, 2000 t, 2500 t, and 3000 t, respectively, and numbers 1 and 2 represent CH4 production rate and cumulative production, respectively. The pentagram symbol represents the shut-in operation of the production well).

During the conventional extraction phase (without CO2 injection), CBM is produced directly from the coal seam. Initial production peaks rapidly at 7804.53 m3/d but declines sharply thereafter. By day 53, CH4 production rate drops to 500 m3/d, yielding a cumulative output of only 8.61 × 104 m3—a recovery of just 5.33%. This limited recovery occurs because the extracted CH4 primarily derives from free CH4 in the coal seam, while adsorbed CH4 cannot effectively replenish fractures through desorption and diffusion. Additionally, declining pore pressure increases effective stress, reducing coal permeability and further accelerating CH4 production decline. Given that most CBM exists in an adsorbed state, conventional extraction methods result in extremely low efficiency. Therefore, stimulation measures are necessary to improve production in low-productivity wells.

Following conventional extraction, CO2 is injected into the coal seam, followed by a soaking period. During this phase, the production well is converted into an injection well, and production is temporarily suspended, resulting in no CH4 output and constant cumulative production. The injected CO2 reduces the partial pressure of CH4 and competes for adsorption sites, promoting extensive CH4 desorption from the coal matrix.

Upon well reopening, CH4 production rapidly rises to a new peak, with magnitude strongly dependent on CO2 injection volumes. At 1000 t injection, peak production rate reaches 4051.43 m3/d, still below the conventional extraction peak. At 3000 t injection, peak production rises to 37,867.95 m3/d—3.85 times higher than conventional extraction, demonstrating a substantial improvement. Notably, higher CO2 injection volumes lead to earlier peak production but also faster subsequent decline rates. Additionally, at low CO2 injection volumes, peak production initially increases with soaking time before declining. In contrast, at high injection volumes, peak production improves continuously with extended soaking. Under all simulation schemes, CH4 production eventually falls below 500 m3/d by approximately 112 days of operation, prompting well shut in.

Overall, CO2 huff-and-puff significantly enhances cumulative CH4 production compared to conventional extraction under all simulation schemes. Particularly, with 3000 t injection volume and 90 days soaking, maximum cumulative CH4 production reaches 7.14 × 105 m3, 7.29 times higher than conventional extraction. When the soaking time is short, cumulative CH4 production increases with longer soaking times. This occurs because CO2 continuously displaces adsorbed CH4 while free CO2 is adsorbed, enriching CH4 in fractures. Additionally, driven by concentration gradients, free CH4 displaced by injected CO2 diffuses back toward the wellbore. Thus, extended soaking enhances post-reopening CH4 production. However, as soaking time increases, excessive soaking reduces cumulative CH4 production due to gas diffusion into micropores, depleting reservoir energy. This suggests an optimal soaking window for maximizing recovery, consistent with findings in nitrogen huff-and-puff studies [82].

Compared to soaking time, CO2 injection volume has a more pronounced impact on CH4 production. Higher injection volumes consistently yield greater cumulative CH4 production. For instance, at 60 days soaking time, increasing CO2 injection from 1000 t to 3000 t raises cumulative CH4 production from 2.60 × 105 m3 to 7.09 × 105 m3, a 172.69% increase. Larger CO2 injection volumes enhance CH4 displacement efficiency and maintain high reservoir pressure, further improving production, analogous to the principle of dry gas injection in hydrocarbon reservoirs for sustaining pressure and boosting condensate recovery [42].

In summary, CO2 huff-and-puff effectively revitalizes low-productivity CBM wells, substantially boosting both CH4 production rates and cumulative CH4 output in a short timeframe. Optimization of injection volume and soaking duration is critical to maximizing economic returns while avoiding diminishing recovery effects from excessive soaking.

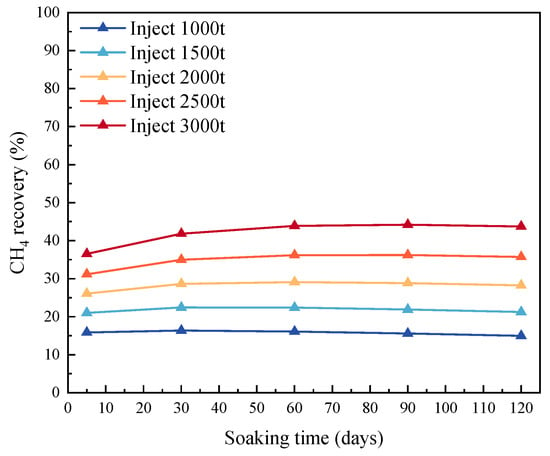

Figure 10 presents the relationship between total CH4 recovery and soaking time under different CO2 injection volumes after CO2 huff-and-puff operations. The simulation results demonstrate significantly enhanced CH4 recovery across all simulation schemes compared to conventional extraction. Specifically, with a 3000 t injection volume and 90-day soaking time, the maximum CH4 recovery reaches 44.19%. Our analysis indicates that CH4 recovery is particularly sensitive to CO2 injection volume, exhibiting a positive correlation where larger injection volumes correspond to higher recovery rates.

Figure 10.

Variation in total CH4 recovery with soaking time under different CO2 injection volumes after CO2 huff-and-puff operations.

The data show a consistent pattern where CH4 recovery initially increases, then decreases with prolonged soaking time, although the soaking duration exhibits weaker influence than injection volume. This trend becomes especially evident at lower injection quantities. For instance, at an injection volume of 1000 t, CH4 recovery remains relatively stable (15.01–16.38%) regardless of soaking times. This phenomenon suggests that at lower injection volumes, the majority of CO2–CH4 displacement occurs during the injection phase itself, rendering prolonged soaking times unnecessary for optimal recovery.

These findings highlight the importance of tailoring soaking duration to both coal seam properties and injection scale in practical applications. Such optimization can maximize production gains while maintaining operational efficiency, providing valuable guidance for field implementation of CO2 huff-and-puff techniques.

4.2.2. CO2 Storage Efficiency

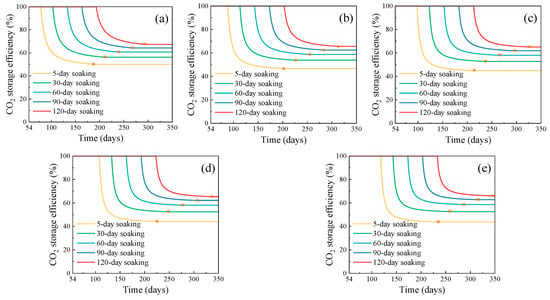

To evaluate the CO2 storage capacity of coal seams, we define CO2 storage efficiency as the ratio of stored CO2 to injected CO2. Figure 11 indicates the variation in storage efficiency during CO2 huff-and-puff operations under different injection volumes and soaking times after conventional extraction. Initially, before well reopening, the stored CO2 equals the injected amount, maintaining a 100% storage efficiency. However, when production resumes after the soaking period, partial CO2 is re-extracted, causing a rapid decline in storage efficiency. Across all simulation schemes, the storage efficiency stabilizes approximately 50 days after production restart, suggesting equilibrium in CO2 retention within the coal seam. This stabilization coincides with reservoir pressure depletion, characterized by an initial production peak followed by gradual decline. Simultaneously, wellhead gas composition transitions from CO2-dominated to CH4-rich as production continues.

Figure 11.

Variation of CO2 storage efficiency during CO2 huff-and-puff under different simulation schemes after conventional extraction. ((a–e) represent CO2 injection volumes of 1000 t, 1500 t, 2000 t, 2500 t, and 3000 t, respectively. The pentagram symbol represents the shut-in operation of the production well).

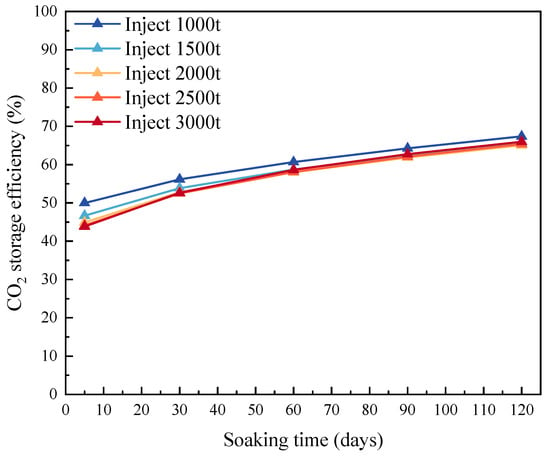

Figure 12 presents the ultimate storage efficiencies at well closure, showing significant impacts from soaking time. For 2000 t injection, increasing the soaking period from 5 to 120 days enhances storage efficiency from 44.94% to 65.09%. This represents a 44.84% increase in storage efficiency, with an additional 402.58 t of CO2 storage. Comparatively, injection volume demonstrates more modest influence, with storage efficiencies ranging narrowly between 58.02% and 60.69% for different CO2 injection volumes at a fixed 60-day soaking time.

Figure 12.

Variation of CO2 storage efficiency with soaking time after CO2 huff-and-puff under different CO2 injection volumes.

4.2.3. Displacement Efficiency

Displacement efficiency is defined as the ratio of cumulative CH4 production to injected CO2 volume, reflecting the amount of CH4 recovered per unit of CO2 injected and serving as a key indicator for evaluating CO2 huff-and-puff performance.

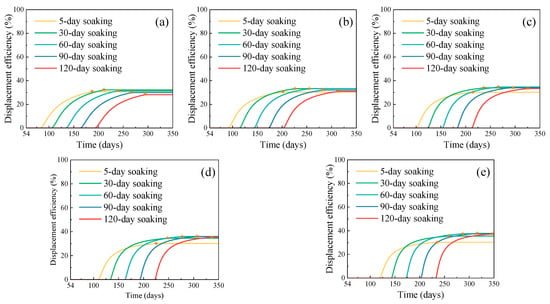

Figure 13 presents the CO2 displacement efficiency during huff-and-puff operations under different CO2 injection volumes and soaking times following conventional extraction. The variation pattern of displacement efficiency closely follows that of cumulative CH4 production. During injection and soaking phases, when no CH4 is produced, the efficiency remains at zero. Upon well reopening, efficiency increases steadily but at a declining rate as CH4 production rate declines, eventually stabilizing.

Figure 13.

Variation in displacement efficiency during CO2 huff-and-puff under different simulation schemes after conventional extraction. ((a–e) represent CO2 injection volumes of 1000 t, 1500 t, 2000 t, 2500 t, and 3000 t, respectively. The pentagram symbol represents the shut-in operation of the production well).

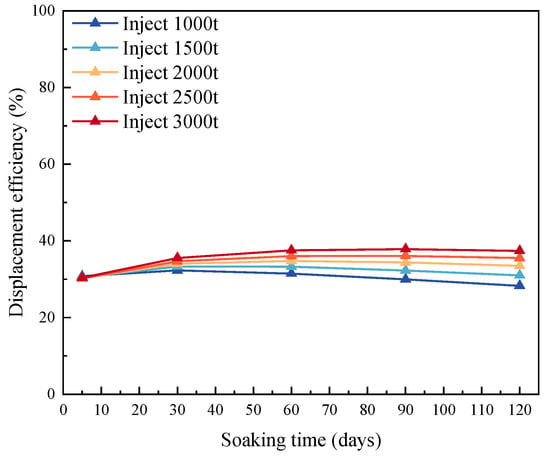

Figure 14 further presents the variation in final displacement efficiency at well closure under different simulation schemes. At constant injection volumes, the efficiency first increases but then decreases with prolonged soaking. With a 5-day soaking period, all injection volumes yield similar efficiencies around 30%. As the soaking time increases, the difference in displacement efficiency between different injection volumes becomes more pronounced. Moreover, larger CO2 injection volumes generally lead to higher displacement efficiencies.

Figure 14.

Variation in displacement efficiency with soaking time after CO2 huff-and-puff under different CO2 injection volumes.

Across all simulation schemes, the CO2 displacement efficiency ranges between 28% and 38%, demonstrating the effectiveness of huff-and-puff in enhancing CH4 recovery. Previous simulation studies on CO2 and N2 displacement in CBM recovery reveal that the displacement efficiency of CO2 under varying injection pressures ranges merely from 6.0% to 8.7%, whereas N2 achieves a significantly higher efficiency of 23–32% [66]. Notably, the CO2 huff-and-puff technique not only outperforms continuous CO2 flooding but also slightly exceeds N2 displacement efficiency, confirming its significant advantage in enhancing CH4 recovery.

4.3. Effects of Key Geological Parameters on CO2 Huff-and-Puff Performance

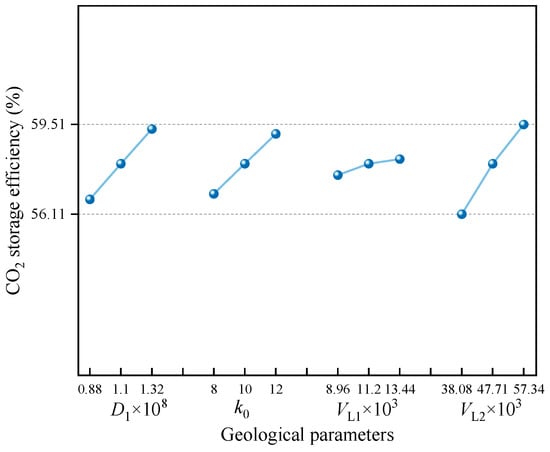

Existing studies indicate that the effectiveness of CO2 huff-and-puff technology for ECBM varies significantly across different reservoirs due to heterogeneous geological conditions. To systematically investigate the key geological parameters influencing CO2 huff-and-puff performance, we conducted extensive numerical simulations under various schemes. It was found that three key geological factors predominantly influence CO2 huff-and-puff performance: (1) gas diffusion coefficient, (2) initial fracture permeability, and (3) Langmuir volume constant.

Using a baseline scheme of 2000 t CO2 injection with a 60-day soaking time, we performed sensitivity analysis by independently varying individual parameters by 20%, while maintaining constant total injection volume and soaking time. This approach allowed us to isolate and quantify the impact of each geological factor on production enhancement.

4.3.1. Effects of Key Geological Parameters on CH4 Production

In coal seams, CH4 primarily exists in an adsorbed state within the coal matrix. For CH4 to migrate to the wellbore for extraction, it must undergo a three-stage process: (1) desorption from the coal matrix into a free state, (2) diffusion through the matrix to the fracture network, and (3) flow through the fractures to the wellbore. This process is commonly described as the “desorption–diffusion–flow” mechanism.

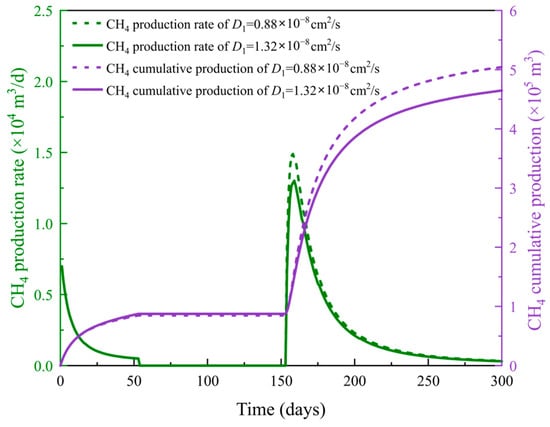

In most coal seams, desorption and diffusion are the rate-limiting steps that govern CH4 migration and ultimately determine well productivity. The diffusion coefficient, which controls the rate of gas transfer between the matrix and fractures, plays a critical role in both CO2 adsorption and CH4 desorption efficiency within the coal matrix. Figure 15 compares CH4 production rates and cumulative production for diffusion coefficients of 0.88 × 10−8 cm2/s and 1.32 × 10−8 cm2/s. The results demonstrate that reducing the CH4 diffusion coefficient leads to higher CH4 production rates and greater cumulative production. This occurs because a lower diffusion coefficient inhibits the re-adsorption of free CH4 displaced by CO2. Consequently, more free CH4 accumulates in the fractures, enhancing CH4 production when the well is reopened.

Figure 15.

Effects of different gas diffusion coefficients on CH4 production rate and cumulative production.

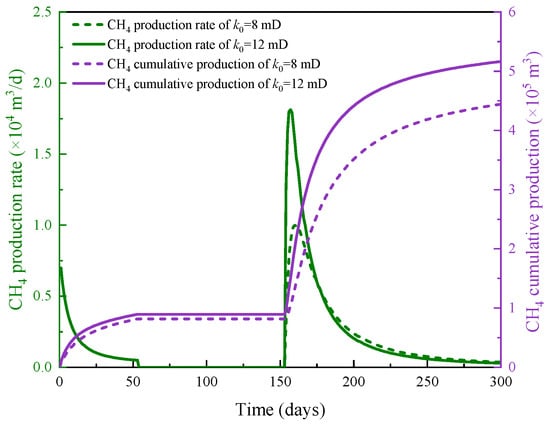

Coal seam permeability is a key parameter controlling gas flow capacity in reservoirs, directly determining gas migration velocity and ultimate production. Low permeability is a primary factor contributing to low-productivity wells, as it restricts gas flow rates. This limitation not only reduces CH4 recovery efficiency but also diminishes the effectiveness of CO2 huff-and-puff ECBM. Figure 16 compares CH4 production rates and cumulative production for initial fracture permeability of 8 mD and 12 mD. The results demonstrate the significant impact of permeability on CH4 production. At 12 mD, the peak CH4 production rate is 1.93 times that at 8 mD, accompanied by a 13.6% increase in cumulative production. These findings underscore that higher permeability substantially enhances the performance of CO2 huff-and-puff ECBM.

Figure 16.

Effects of different initial fracture permeability on CH4 production rate and cumulative production.

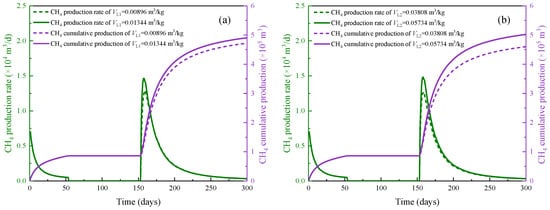

The Langmuir volume constant is a critical parameter for evaluating gas adsorption capacity in coal seams, as it directly determines gas adsorption quantity and influences the gas storage capability of the coal matrix. Figure 17 presents the CH4 production rate and cumulative production under different Langmuir volume constants for CH4 (VL1) and CO2 (VL2). The results indicate that variations in VL1 have a limited impact on cumulative CH4 production, with fluctuations remaining within 5%. However, VL1 significantly influences initial CH4 reserves in coal seams, consequently affecting recovery efficiency. In contrast, cumulative CH4 production shows a positive correlation with VL2. A higher VL2 indicates greater CO2 adsorption capacity in the coal seams, which enhances the desorption of adsorbed CH4 and consequently improves CH4 production after well reopening.

Figure 17.

Effects of different gas Langmuir volume constants on CH4 production rate and cumulative production: (a) CH4 Langmuir volume constant VL1 and (b) CO2 Langmuir volume constant VL2.

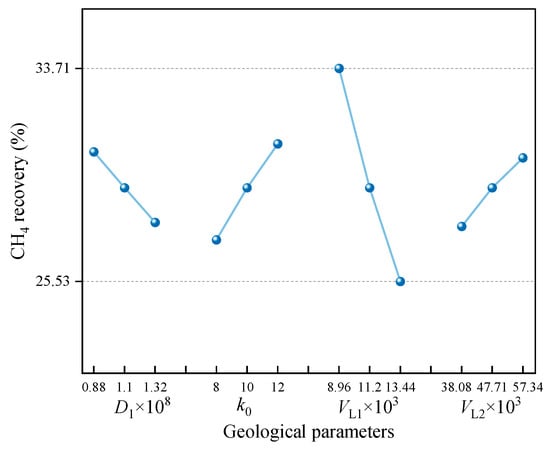

Figure 18 presents the CH4 recovery performance after CO2 huff-and-puff operations under different geological parameters. Specifically, when VL1 values are 0.00896 and 0.01344 m3/kg, the corresponding CH4 recovery is 33.71% and 25.53%, representing a 15.72% increase and 12.36% decrease, respectively, compared to the baseline scheme. This inverse relationship demonstrates that higher VL1 values lead to lower CH4 recovery, indicating that coal seams with lower initial CH4 reserves exhibit more significant production enhancement during CO2 huff-and-puff operations.

Figure 18.

Effects of different geological parameters on CH4 recovery.

Overall, the results demonstrate that the CH4 Langmuir volume constant (VL1) has the most significant influence on recovery efficiency, followed by initial fracture permeability and the diffusion coefficient, while the CO2 Langmuir volume constant (VL2) shows the least impact. Therefore, in practical CO2 huff-and-puff projects, priority should be given to characterizing VL1, permeability, and diffusion coefficient to achieve higher recovery.

4.3.2. Effects of Key Geological Parameters on CO2 Storage

Figure 19 presents CO2 storage efficiency under different geological parameters. Contrary to the trend observed for CH4 recovery, VL2 emerges as the primary controlling factor for CO2 storage, with coal seam permeability and diffusion coefficient playing secondary roles. However, the absolute variation in CO2 storage efficiency across all parameter schemes remains relatively modest, with deviations within 5% compared to the baseline scheme.

Figure 19.

Effects of different geological parameters on CO2 storage efficiency.

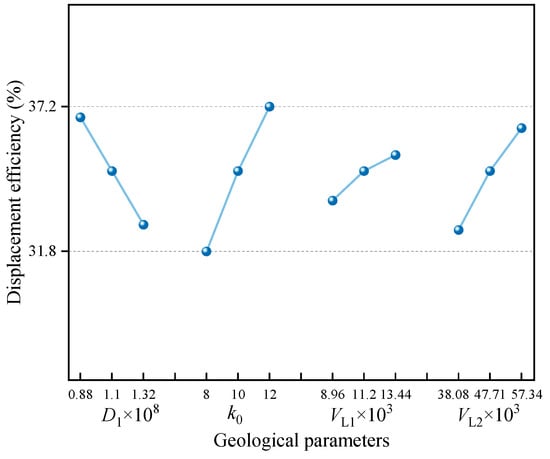

Figure 20 presents the displacement efficiency under different geological parameters. It can be observed that, compared to the CO2 storage efficiency, the displacement efficiency exhibits greater sensitivity to variations in these geological parameters. Permeability exerts the most significant influence on displacement efficiency. Specifically, at permeability values of 8 and 12 mD, the corresponding displacement efficiencies are 31.8% and 37.2%, representing a decrease of 8.62% and an increase of 6.90% relative to the baseline scheme. Consequently, CO2 huff-and-puff achieves greater CH4 displacement in high-permeability reservoirs. Consistent with the trend observed for CO2 storage efficiency, the Langmuir volume constant of CH4 has the least pronounced effect on displacement efficiency.

Figure 20.

Effects of different geological parameters on displacement efficiency.

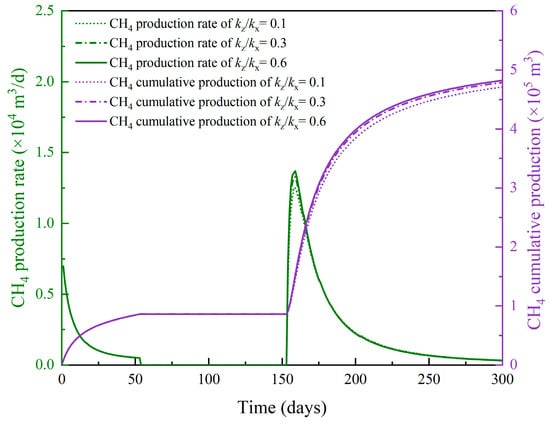

4.4. Effects of Coal Seam Anisotropy

In actual coal seams, strong heterogeneity and anisotropy often develop due to tectonic deformation and diagenetic processes, which can significantly influence the distribution and migration of gases within the reservoir. Using a baseline scheme of 2000 t CO2 injection with a 60-day soaking time, the CO2 huff-and-puff performance considering anisotropy was analyzed by maintaining a constant horizontal permeability while varying the vertical permeability of the coal seam. Figure 21 presents the CH4 production rate and cumulative production when the ratio of vertical to horizontal permeability is 0.1, 0.3 and 0.6, respectively. The results indicate that when the ratios are 0.1, 0.3 and 0.6, the peak CH4 production rates are 13,687.74 m3/d, 13,289.00 m3/d and 12,518.16 m3/d, representing reductions of 2.92%, 5.75% and 11.22% compared with isotropic conditions. Coal seam anisotropy decreases both the daily and cumulative CH4 production, and the greater the anisotropy, the more pronounced the reduction in CH4 yield. This is because the reduction in vertical permeability hinders gas flow in the vertical direction and to some extent slows the migration of CH4 toward the well.

Figure 21.

Effects of different ratios of vertical to horizontal permeability on CH4 production rate and cumulative production.

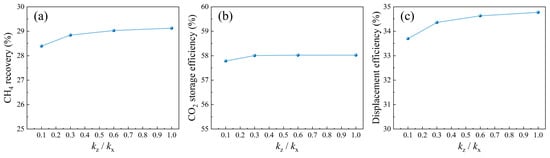

Figure 22 presents the variations in CH4 recovery, CO2 storage efficiency, and displacement efficiency with respect to the ratio of vertical to horizontal permeability. The results show that when the ratio is 0.1, the CH4 recovery, CO2 storage efficiency, and displacement efficiency are 28.39%, 57.78%, and 33.70%, respectively, which are 2.31%, 0.42%, and 3.07% lower than those under isotropic conditions. After considering anisotropy, CH4 recovery, CO2 storage efficiency, and displacement efficiency all decrease slightly, although the overall influence remains limited. This is because perforations are distributed across different coal seam layers, and gas mainly migrates horizontally through perforations at the same depth toward the wellbore. As a result, vertical gas flow between coal seams at different heights has a limited effect on the overall CH4 recovery and CO2 storage performance.

Figure 22.

Effects of different ratios of vertical to horizontal permeability: (a) CH4 recovery, (b) CO2 storage efficiency and (c) displacement efficiency.

5. Conclusions

This study investigates the theoretical principles and advantages of CO2 huff-and-puff ECBM for low-productivity wells in medium-shallow reservoirs. A comprehensive numerical model reflecting the geological conditions of the Qinshui Basin was established to assess CH4 production enhancement and CO2 storage potential in medium-shallow coal seams via CO2 huff-and-puff. Key findings include:

- CO2 huff-and-puff enhances CH4 recovery through competitive adsorption, where CO2 displaces CH4 from the coal matrix, and reservoir pressure maintenance. The process involves three phases—injection, soaking, and production, wherein soaking time critically influences CH4 desorption and CO2 storage.

- Higher CO2 injection volumes (e.g., 2000–3000 t) significantly enhance CH4 production. Soaking times of 30–90 days maximize economic returns, while excessive soaking diminishes gains due to energy depletion.

- CH4 recovery is most sensitive to the CH4 Langmuir volume constant and initial fracture permeability, whereas CO2 storage efficiency is primarily controlled by the CO2 Langmuir constant. Lower diffusion coefficients enhance CH4 retention in fractures.

- This study preliminarily demonstrates the feasibility of large-scale CO2 huff-and-puff for enhancing production in low-productivity CBM wells. However, further research under field-world conditions is essential for large-scale deployment. CO2 huff-and-puff offers a sustainable solution for CBM extraction and carbon storage, aligning with China’s “dual carbon” strategy. The integration of this technology with carbon capture, utilization, and storage (CCUS) promises a sustainable pathway for energy production and emission reduction.

- In this study, the coal seam is assumed to be a homogeneous and isotropic medium. The results presented above are based on idealized homogeneous coal properties and must be calibrated against field pilot tests before practical implementation. Key uncertainties, including the neglect of thermal effects, simplified boundary conditions, coal heterogeneity, permeability anisotropy, and the long-term security of CO2 storage, will be addressed in future research.

Author Contributions

Conceptualization, C.Y.; funding acquisition, Z.F.; investigation, C.Y.; methodology, C.Y.; project administration, Z.F.; supervision, Z.F.; validation, S.S.; visualization, H.W.; writing—original draft preparation, C.Y.; writing—review and editing, Z.F., S.S. and H.W. All authors have read and agreed to the published version of the manuscript.

Funding

This study was partly supported by the Hubei Provincial Technological Innovation Program (Grant No. 2025BCB042) and the 181 Major R&D projects of Metallurgical Corporation of China Ltd., project number (212024YH611225).

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest. The authors declare that this study received funding from the Metallurgical Corporation of China Ltd. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

References

- Bai, G.; Su, J.; Zhang, Z.; Lan, A.; Zhou, X.; Gao, F.; Zhou, J. Effect of CO2 injection on CH4 desorption rate in poor permeability coal seams: An experimental study. Energy 2022, 238, 121674. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Booth, P.; Nemcik, J. Experimental investigation of N2 injection to enhance gas drainage in CO2-rich low permeable seam. Fuel 2018, 215, 665–674. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, E.; Li, B.; Kong, X.; Xu, J.; Peng, S.; Chen, Y. Laboratory experiments of CO2-enhanced coalbed methane recovery considering CO2 sequestration in a coal seam. Energy 2023, 262, 125473. [Google Scholar] [CrossRef]

- Tu, Z.; Li, L.; Wang, F.; Zhang, Y. Review on separation of coalbed methane by hydrate method. Fuel 2024, 358, 130224. [Google Scholar] [CrossRef]

- Xu, F.; Hou, W.; Xiong, X.; Xu, B.; Wu, P.; Wang, H.; Feng, K.; Yun, J.; Li, S.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Heng, X.; Li, H.; Li, Q.; Fu, J.; Yao, C.; Ye, P.; Zhang, S.; Niu, Y. Investigation of an adsorption model of wet coal that considers coal seam gas pressure and temperature effects. ACS Omega 2025, 10, 5634–5644. [Google Scholar] [CrossRef]

- Tang, X.; Wang, Z.; Ripepi, N.; Kang, B.; Yue, G. Adsorption affinity of different types of coal: Mean isosteric heat of adsorption. Energy Fuels 2015, 29, 3609–3615. [Google Scholar] [CrossRef]

- Zhu, Q.; Du, X.; Zhang, T.; Yu, H.; Liu, X. Investigation into the variation characteristics and influencing factors of coalbed methane gas content in deep coal seams. Sci. Rep. 2024, 14, 18813. [Google Scholar] [CrossRef]

- Yin, G.; Deng, B.; Li, M.; Zhang, D.; Wang, W.; Li, W.; Shang, D. Impact of injection pressure on CO2–enhanced coalbed methane recovery considering mass transfer between coal fracture and matrix. Fuel 2017, 196, 288–297. [Google Scholar] [CrossRef]

- Gao, L.; Mastalerz, M.; Schimmelmann, A. The origin of coalbed methane. In Coal Bed Methane; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–34. [Google Scholar]

- Li, D.; Gao, X.; Liu, Z.; Zan, X.; Zheng, Z.; Jia, J.; Wu, J. Comparison and revelation of coalbed methane resources distribution characteristics and development status between China and America. Coal Sci. Technol. 2018, 46, 252–261. [Google Scholar]

- Ma, T.; Liu, J.; Fu, J.; Wu, B. Drilling and completion technologies of coalbed methane exploitation: An overview. Int. J. Coal Sci. Technol. 2022, 9, 68. [Google Scholar] [CrossRef]

- Palmer, I. Coalbed methane completions: A world view. Int. J. Coal Geol. 2010, 82, 184–195. [Google Scholar] [CrossRef]

- Salmachi, A.; Rajabi, M.; Wainman, C.; Mackie, S.; McCabe, P.; Camac, B.; Clarkson, C. History, Geology, In Situ Stress Pattern, Gas Content and Permeability of Coal Seam Gas Basins in Australia: A Review. Energies 2021, 14, 2651. [Google Scholar] [CrossRef]

- Xu, F.; Wang, B.; Zhao, X.; Yun, J.; Zhang, S.; Wang, H.; Yang, Y. Thoughts and suggestions on promoting high quality development of China’s CBM business under the goal of “double carbon”. China Pet. Explor. 2021, 26, 9–18. [Google Scholar]

- Sang, S.; Liu, S.; Han, S.; Zheng, S.; Liu, T.; Zhou, X.; Wang, R.; Wang, M. Coal methane control and its emission reduction potential in China. Coal Geol. Explor. 2023, 51, 159–175. [Google Scholar]

- YI, Y. Research on the Production Characteristics and Drainage Control of CBM Wells in the Shizhuangnan Block of Qinshui Basin. Master’s Thesis, China University of Geosciences, Beijing, China, 2020. [Google Scholar]

- Feng, Y. Analysis on the Low-yield Genesis of Coalbed Methane Stripper Wells and Key Stimulation Technologies. Master’s Thesis, Henan Polytechnic University, Jiaozuo, China, 2021. [Google Scholar]

- Wang, T. Key Factors of Low Production of Coalbed Methane Vertical Well in Fanzhuang Block and Its Secondary Fracturing Reconstruction. Master’s Thesis, China University of Mining and Technology, Beijing, China, 2020. [Google Scholar]

- Dong, K. Study on Geological Conditions Affected to Production of Coalbed Methane Well of Broken Soft Coal Reservoir. Ph.D. Thesis, China Coal Research Institute, Beijing, China, 2019. [Google Scholar]

- Zhao, L. Research on the genesis Mechanism and Development Technology of Low Temperature and Low Pressure Coalbed Methane Reservoirs in Yangquan Mining Area. Ph.D. Thesis, Henan Polytechnic University, Jiaozuo, China, 2023. [Google Scholar]

- Wang, D. The Research of Affective Facts of Production and Enrichment of CBM in Linfen Block. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2015. [Google Scholar]

- Wang, W. Analysis on effect of gas production and influence factors of CBM separate layer pressure control and multi-layer drainage in tectonic coal mining area. Coal Sci. Technol. 2019, 47, 120–124. [Google Scholar]

- Zhang, Z. Controlling Factors of Productivity Difference of Coalbed Methane Wells in Eastern Yunnan and Western Guizhou. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2022. [Google Scholar]

- Sun, H. Development status and prospect of CBM fracturing technology in China. China Offshore Oil Gas 2021, 33, 120–128. [Google Scholar]

- Huang, Z.; Li, Z.; Li, G.; Yang, R.; Mei, Y.; Niu, J.; Li, Z.; Wu, C.; Wen, H.; Cong, R. Oriented and sand control hydra-jet fracturing in coalbed methane horizontal wells and field applications. J. China Coal Soc. 2022, 47, 2687–2697. [Google Scholar]

- Zhang, W.; Si, L.; Guo, Q.; Tian, K.; Zhang, R. Study on mechanism and application of liquid nitrogen injection combined with fracturing to enhance permeability in CBM wells. Coal Sci. Technol. 2019, 47, 97–102. [Google Scholar]

- Qin, L.; Li, S.; Zhai, C.; Lin, H.; Zhao, P.; Shi, Y.; Bai, Y. Changes in the pore structure of lignite after repeated cycles of liquid nitrogen freezing as determined by nitrogen adsorption and mercury intrusion. Fuel 2020, 267, 117214. [Google Scholar] [CrossRef]

- Cao, Y.; Shi, B.; Zhou, D.; Wu, H.; Liu, T.; Tian, L.; Cao, Y.; Jia, M. Study and application of stimulation technology for low production CBM well through high pressure N2 Injection-soak. J. China Coal Soc. 2019, 44, 2556–2565. [Google Scholar]

- Lin, X.; Liu, Z.; Zhu, W.; Si, L.; Qu, B.; Liu, S.; Zhang, Y. Mechanism of matrix–fracture equilibrium time lag property inducing coal sub-matrix mass transfer behavior and its effect on the coal seepage characteristics in CO2 sequestration. Phys. Fluids 2025, 37, 016601. [Google Scholar] [CrossRef]

- Wang, Z.; Fu, X.; Pan, J.; Deng, Z. Effect of N2/CO2 injection and alternate injection on volume swelling/shrinkage strain of coal. Energy 2023, 275, 127377. [Google Scholar] [CrossRef]

- Zhou, F.; Hussain, F.; Cinar, Y. Injecting pure N2 and CO2 to coal for enhanced coalbed methane: Experimental observations and numerical simulation. Int. J. Coal Geol. 2013, 116–117, 53–62. [Google Scholar] [CrossRef]

- Fang, Z.; Yang, C.; Wang, R. Monitoring technologies for CO2 storage in coal seams and enhanced coalbed methane recovery: A review of field applications. Fuel Process. Technol. 2025, 276, 108274. [Google Scholar] [CrossRef]

- Shen, S.C.; Fang, Z.M.; Li, X.C.; Jiang, Q.; Shen, H.M.; Shi, L. Enhanced coalbed methane recovery from lignite using CO2 and N2. Energy Fuels 2025, 39, 10394–10409. [Google Scholar] [CrossRef]

- Lin, K.; Jing, T.; Wei, N.; Chen, Q.; Zhao, W.; Zhou, J.; Ali, M.; Wang, W.; Li, X. A Comprehensive Analysis of the Mutual Feedback Mechanisms between CO2 Geological Storage and Underground Coal Mining in the Ordos Basin. Energy Fuels 2025, 39, 5802–5817. [Google Scholar] [CrossRef]

- Fang, H.; Sang, S.; Wang, Z.; Guo, J.; Liu, H.; Xu, H.; Chen, R. Numerical analysis of temperature effect on CO2 storage capacity and CH4 production capacity during the CO2-ECBM process. Energy 2024, 289, 130022. [Google Scholar] [CrossRef]

- Zhang, S.; Sang, S.; Wu, J.; Zhou, X.; Zhang, B.; Yang, R.; Guo, J.; Liu, X.; Zhang, W.; Li, Y. Progress and application of key technologies for CO2 enhancing coalbed methane. J. China Coal Soc. 2022, 47, 3952–3964. [Google Scholar]

- Lin, K.; Wei, N.; Jiang, D.; Zhang, Y. Progress and perspectives in source-sink matching for CCUS: A critical review. Renew. Sustain. Energy Rev. 2026, 226, 116313. [Google Scholar] [CrossRef]

- Li, Z.; Ni, G.; Wen, Y.; Jiang, H.; Liu, Y.; Huang, Q.; Huang, W. Analysis of permeability evolution mechanism during CO2 enhanced coalbed methane recovery based on impact factor method. Fuel 2021, 304, 121389. [Google Scholar] [CrossRef]

- Wang, L.; Hu, L.; Guo, H.; Wang, Z.; Xiao, Y.; Zhang, Z. Differences in CH4 Displacement Efficiency by CO2/N2 Injection in Anthracite under Isobaric and High Pressures: Molecular Dynamics Insights. Energy Fuels 2025, 39, 1959–1970. [Google Scholar] [CrossRef]

- Ye, D.; Liu, G.; Gao, F.; Wang, X.; Wei, M.; Liu, Z.; Li, D. A novel interdisciplinary model for optimizing coalbed methane recovery and carbon dioxide sequestration: Fracture dynamics, gas mechanics, and its application. Phys. Fluids 2024, 36, 076607. [Google Scholar] [CrossRef]

- Matkivskyi, S. Optimization of gas recycling technique in development of gas-condensate fields. Min. Miner. Deposits 2023, 17, 101–107. [Google Scholar] [CrossRef]

- Wong, S.; Law, D.; Deng, X.H.; Robinson, J.; Kadatz, B.; Gunter, W.D.; Ye, J.P.; Feng, S.L.; Fan, Z.Q. Enhanced coalbed methane and CO2 storage in anthracitic coals-Micro-pilot test at South Qinshui, Shanxi, China. Int. J. Greenh. Gas Control 2007, 1, 215–222. [Google Scholar] [CrossRef]

- Liu, S.; Huang, F.; Du, R.; Chen, S.; Guan, Y.; Liu, Y.; Wang, T. Progress and typical case analysis of demonstration projects of the geological sequestration and utilization of CO2. Coal Geol. Explor. 2023, 51, 158–174. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, J.; Lee, K.S. Effects of aqueous solubility and geochemistry on CO2 injection for shale gas reservoirs. Sci. Rep. 2020, 10, 2071. [Google Scholar] [CrossRef] [PubMed]

- Fathi, E.; Akkutlu, I.Y. Multi-component gas transport and adsorption effects during CO2 injection and enhanced shale gas recovery. Int. J. Coal Geol. 2014, 123, 52–61. [Google Scholar] [CrossRef]

- Eshkalak, M.O.; Al-Shalabi, E.W.; Sanaei, A.; Aybar, U.; Sepehrnoori, K. Simulation study on the CO2-driven enhanced gas recovery with sequestration versus the re-fracturing treatment of horizontal wells in the U.S. nconventional shale reservoirs. J. Nat. Gas Sci. Eng. 2014, 21, 1015–1024. [Google Scholar] [CrossRef]

- Kim, T.H.; Cho, J.; Lee, K.S. Evaluation of CO2 injection in shale gas reservoirs with multi-component transport and geomechanical effects. Appl. Energy 2017, 190, 1195–1206. [Google Scholar] [CrossRef]

- Su, E.; Zhu, X.; Chen, X.; Su, W.; Wang, L.; Ye, X.; Wang, T. Gas transport behavior of tectonic and intact coal reservoirs during CO2-enhanced coalbed methane recovery. Phys. Fluids 2025, 37, 076652. [Google Scholar] [CrossRef]

- Fang, H.; Ye, K.; Yu, S.; Wang, Y.; Wang, Z. Determining the Starting Time of CO2 Injection and Its Implications for the CO2-ECBM Process. ACS Omega 2024, 10, 1591–1609. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Rutqvist, J.; Oldenburg, C.M.; Liu, W. Coupled thermal–hydrological–mechanical modeling of CO2-enhanced coalbed methane recovery. Int. J. Coal Geol. 2017, 179, 81–91. [Google Scholar] [CrossRef]

- Liu, X.; Sang, S.; Zhou, X.; Wang, Z. Coupled adsorption-hydro-thermo-mechanical-chemical modeling for CO2 sequestration and well production during CO2-ECBM. Energy 2023, 262, 125306. [Google Scholar] [CrossRef]

- Fan, C.; Elsworth, D.; Li, S.; Chen, Z.; Luo, M.; Song, Y.; Zhang, H. Modelling and optimization of enhanced coalbed methane recovery using CO2/N2 mixtures. Fuel 2019, 253, 1114–1129. [Google Scholar] [CrossRef]

- Yang, L.; Fan, C.-J.; Luo, M.-K.; Wen, H.-O.; Sun, H.; Zhou, L.-J.; Cheng, Z.-H.; Zhang, Z.-P. Geological parameters and gas mixture composition on enhanced coalbed methane recovery: A THM modeling approach. Pet. Sci. 2025, 22, 2078–2095. [Google Scholar] [CrossRef]

- Hou, Y.; Huang, S.; Han, J.; Liu, X.; Han, L.; Fu, C. Numerical Simulation of the Effect of Injected CO2 Temperature and Pressure on CO2-Enhanced Coalbed Methane. Appl. Sci. 2020, 10, 1385. [Google Scholar] [CrossRef]

- Fan, N.; Wang, J.; Deng, C.; Fan, Y.; Mu, Y.; Wang, T. Numerical study on enhancing coalbed methane recovery by injecting N2/CO2 mixtures and its geological significance. Energy Sci. Eng. 2019, 8, 1104–1119. [Google Scholar] [CrossRef]

- Fan, Y.P.; Deng, C.B.; Zhang, X.; Li, F.Q.; Wang, X.Y.; Qiao, L. Numerical study of CO2-enhanced coalbed methane recovery. Int. J. Greenh. Gas Control 2018, 76, 12–23. [Google Scholar] [CrossRef]

- Fang, H.-H.; Sang, S.-X.; Liu, S.-Q. Numerical simulation of enhancing coalbed methane recovery by injecting CO2 with heat injection. Pet. Sci. 2019, 16, 32–43. [Google Scholar] [CrossRef]

- Liu, S.; Fang, H.; Sang, S.; Ashutosh, T.; Wu, J.; Zhang, S.; Zhang, B. CO2 injectability and CH4 recovery of the engineering test in qinshui Basin, China based on numerical simulation. Int. J. Greenh. Gas Control 2020, 95, 102980. [Google Scholar] [CrossRef]

- Wei, X.R.; Wang, G.X.; Massarotto, P.; Golding, S.D.; Rudolph, V. Numerical simulation of multicomponent gas diffusion and flow in coals for CO2 enhanced coalbed methane recovery. Chem. Eng. Sci. 2007, 62, 4193–4203. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Nemcik, J. Simulation investigation of N2-injection enhanced gas drainage: Model development and identification of critical parameters. J. Nat. Gas Sci. Eng. 2018, 55, 30–41. [Google Scholar] [CrossRef]

- Kumar, H.; Elsworth, D.; Mathews, J.P.; Liu, J.; Pone, D. Effect of CO2 injection on heterogeneously permeable coalbed reservoirs. Fuel 2014, 135, 509–521. [Google Scholar] [CrossRef]

- Mu, Y.; Fan, Y.; Wang, J.; Fan, N. Numerical study on injection of flue gas as a heat carrier into coal reservoir to enhance CBM recovery. J. Nat. Gas Sci. Eng. 2019, 72, 103017. [Google Scholar] [CrossRef]

- Fang, H.; Sang, S.; Liu, S. The coupling mechanism of the thermal-hydraulic-mechanical fields in CH4-bearing coal and its application in the CO2-enhanced coalbed methane recovery. J. Pet. Sci. Eng. 2019, 181, 106177. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Yang, W.; Zhai, C.; Liu, T. Coal permeability evolution and gas migration under non-equilibrium state. Transp. Porous Media 2017, 118, 393–416. [Google Scholar] [CrossRef]

- Shen, S. Study on Gas Displacement of Coalbed Methane in Low-Rank Coal Seams in Jiergalangtu Area, Inner Mongolia. Ph.D. Thesis, Institute of Rock and Soil Mechanics, Chinese Academy of Sciences, Beijing, China, 2024. [Google Scholar]

- Huo, B.; Jing, X.; Fan, C.; Han, Y. Numerical investigation of flue gas injection enhanced underground coal seam gas drainage. Energy Sci. Eng. 2019, 7, 3204–3219. [Google Scholar] [CrossRef]

- Zhou, L.; Zhou, X.; Fan, C.; Bai, G.; Yang, L.; Wang, Y. Modelling of flue gas injection promoted coal seam gas extraction incorporating heat-fluid-solid interactions. Energy 2023, 268, 126664. [Google Scholar] [CrossRef]

- Zhou, L.; Zhou, X.; Fan, C.; Bai, G. Coal permeability evolution triggered by variable injection parameters during gas mixture enhanced methane recovery. Energy 2022, 252, 124065. [Google Scholar] [CrossRef]

- Palmer, I.; Mansoori, J. How permeability depends on stress and pore pressure in coalbeds: A new model. SPE Reserv. Eval. Eng. 1998, 1, 539–544. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, J.; Elsworth, D.; Miao, X.; Mao, X. Development of anisotropic permeability during coalbed methane production. J. Nat. Gas Sci. Eng. 2010, 2, 197–210. [Google Scholar] [CrossRef]

- Cui, X.; Bustin, R.M. Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bull. 2005, 89, 1181–1202. [Google Scholar] [CrossRef]

- Fang, Z.; Shen, S. Optimizing enhanced coalbed methane recovery in thick lignite formations: An integrated technical and economic evaluation. Results Eng. 2025, 27, 106733. [Google Scholar] [CrossRef]

- Fan, C.; Elsworth, D.; Li, S.; Zhou, L.; Yang, Z.; Song, Y. Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy 2019, 173, 1054–1077. [Google Scholar] [CrossRef]

- Ye, J.; Hou, S.; Zhang, S. Progress of coalbed methane exploration and development in China during the 13th Five-Year Plan period and the next exploration direction. Coal Geol. Explor. 2022, 50, 15–22. [Google Scholar]