Abstract

The oil sands industry employs different technologies at pilot and commercial demonstration scales in order to improve the dewatering rate of fluid fine tailings. Of these technologies, centrifugation has advanced to the commercial scale and is playing a major role in the fluid fine tailings management strategy. However, centrifuge technology on its own may not develop the required strength to ensure fine tailings can be incorporated into dry landform reclamation, which requires water contents close to their plastic limit. Hence, it is paramount to combine more than one technology to maximize post-depositional dewatering. Management of the tailings deposit to promote seasonal weathering (freeze–thaw, evaporation and self-weight consolidation) can promote further dewatering. Properly assessing the contributions of the seasonal weathering components is vital to optimizing this strategy. Using the geotechnical properties of centrifuged tailings, the effects of seasonal weathering on tailings were modeled under two different freezing temperature gradients. A coupled analysis combining FSConsol and Unsatcon was used to simulate the deposition scenario similar to the laboratory. The modeling results were found to match the laboratory response reasonably well, indicating the coupled approach proposed in this manuscript is valid and helps to predict the seasonal weathering effects on dewatering.

1. Introduction

Alberta, Canada is considered to be the fourth-largest proven reserve of crude bitumen in the world [1]. Most of Alberta’s oil is unconventional as it is trapped within oil sands and, hence, traditional drilling and pumping methods using the natural pressure differential cannot be employed here [2]. Instead, advanced extraction techniques such as oil sands mining and in-situ development are needed to extract the heavier oil/bitumen. With a combined estimated reserve of 1.8 trillion barrels of in-place reserves of in-situ crude bitumen, the Athabasca, cold Lake and Peace River deposits form a massive resource in Alberta. Of these regions, the Athabasca oil sand deposit (situated in northeastern Alberta in the Fort McMurray area) is the largest and only one to be shallow enough to allow for surface mining [3]. The extraction of bitumen from oil sands in a surface mining operation is a water-based process that generates large volumes of byproducts known as tailings. In general, tailings are a warm suspension of sand, fines (clays and silts), residual bitumen and process-affected water [4]. These are temporarily stored aboveground in dams referred to as tailings ponds, where the mixtures of coarse streams (primarily sand) form settled sand beaches near the deposition outlet and an aqueous slurry of fines and residual bitumen accumulates in the center of these ponds termed as thin fine tailings (TFT) [4,5]. When allowed to settle under quiescent conditions (self-weight consolidation under no further loading), TFT forms a material with a solids content (mass of solids divided by the total mass of tailings including bitumen) of around 30-40% by mass referred to as mature fine tailings (MFT) [6]. Dewatering of fluid fine tailings (the collective term for TFT and MFT) to recycle the released water and reduce the environmental footprint is very slow as these materials are highly dispersed, resistant to consolidation and can remain in a soft, fluid state for decades, thus creating a unique fundamental management problem for the oil sands industry [7]. Consequently, the inventory of tailings being stored in the ponds, covering a total area of 259 km2, has been steadily increasing over time, and at present, the total volume of fluid fine tailings (FFT) stored in the pond already exceeds 1302 million m3 [7,8]. In order to meet regulatory and closure requirements, FFT is needed to be dewatered so that these large volumes of FFT can be accommodated in the development of an environmentally acceptable reclamation plan.

In order to dewater and facilitate the reclamation efforts of the surface-mined FFT, different chemical, mechanical and environmental processes have been employed that could have the potential for effective tailings management in the oil sands industry [5]. One of these technologies, centrifugation, is currently being used by Syncrude and Canadian Natural Upgrading Ltd. (CNUL) as a key process technology to accelerate dewatering [6,7]. Centrifugation employs dredging FFT from the tailings pond and treating it with flocculant and/without coagulant prior to feeding to the centrifuge where solids are separated from the water via a centrifugal force [5]. The endproduct of centrifugation is known as centrifuged tailings. However, the achieved solids content from this technology is typically 50–55% [5], which is not sufficient (strength less than 1 kPa, as documented in [5,9]) to develop a trafficable surface (atleast 25 kPa for mobile equipment trafficability, as documented in [5]). Additionally, the oil sands industry is currently more focused on creating deep deposits (typically > 10–20 meters deep) to eliminate the large footprints typically required for thin-layered deposits [5,10]. However, deep deposits of these centrifuged tailings undergo settlement for centuries due to the extremely slow settlement times resulting from decreasing permeability as the deposit densifies [10].

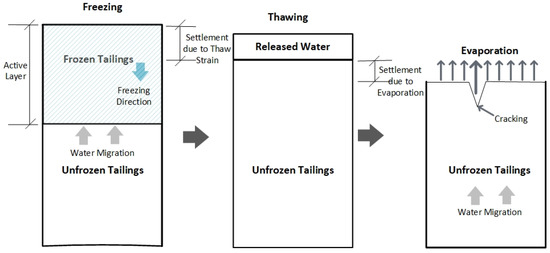

Since environmental dewatering processes (freeze–thaw dewatering, evaporation, desiccation) are economical and cost-efficient, a combination of these processes can be considered as additional dewatering technologies contributing to creating a reclaimable deposit. Figure 1 shows a simplified diagram of the environmental processes contributing to dewatering from the tailings.

Figure 1.

Simplified diagram of the seasonal weathering cycles.

The freezing process results in the formation of a three-dimensional reticulate ice network surrounding blocks of over-consolidated tailings. Upon thawing, dewatering occurs due to these structural changes within the frozen tailings, which in turn facilitates water removal from the underlying thawed tailings as ice melts [11]. Hence, tailings undergoing freeze–thaw dewatering develop thaw strain (ε) (the change in height prior to and after thawing divided by the total frozen height) that further allows for subsequent post-thaw consolidation through self-weight consolidation, thereby causing an increase in effective stress [11]. Consequently, the solids content increases and the void ratio decreases as the tailings material consolidates at a faster rate under self-weight [12]. When evaporation/drying is incorporated with freeze–thaw dewatering, the thawed tailings further dewater under the desiccation process, which is the process of drying and cracking [4]. As a result, further dewatering and higher undrained shear strength at the surface can be achieved, enabling reclamation and closure. Among all the environmental processes, the natural process of freeze–thaw dewatering has shown promise as a method to dewater, strengthen and reclaim FFT (as investigated by [11,12,13,14]). However, much of these works were focused on using thin-layered freeze–thaw dewatering but not so much on deep deposits. Hence, there is a need to develop a fundamental understanding of the effects of these environmental processes on the dewatering performances of deep-deposit tailings.

The objective of the research reported in this paper was to evaluate numerical approaches in order to simulate the dewatering of centrifuged tailings subjected to seasonal weathering under a controlled laboratory testing program. A coupled analysis methodology was developed here to validate two sequences of laboratory testing under two different freezing temperature gradients.

2. Tailings Material and Characterization

The centrifuged tailings samples studied in this research were received at the University of Alberta Laboratory in a 200L barrel from Syncrude Canada Ltd. The samples were homogenized thoroughly with a mixer and the mineralogy and geotechnical properties were determined upon delivery (Table 1).

Table 1.

Geotechnical properties of the centrifuged tailings.

The initial water content (mass of water divided by the mass of dry solids including bitumen) of the sample was found to be 89% by mass, corresponding to a solids content of 53% by mass. The properties of the as-received centrifuged tailings show a fine-grained tailings material with a higher amount of clay content, high plasticity along with moderate water adsorption onto the clays. These values are influenced by the combined effects of the geologic origin, clay mineralogy, water chemistry and bitumen content [15].

3. Laboratory Setup

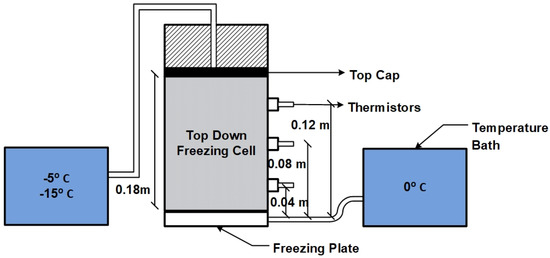

Figure 2 shows the schematic diagram of the laboratory freeze–thaw test setup. These small-scale freezing tests were carried out in cylindrical freezing cells (0.1 m dia × 0.22 m height) within a walk-in freezer where the samples were frozen from top-down (one dimensional) under two different temperature gradients of 0.083 and 0.028 °C/mm. These two temperature gradients were applied to the freezing cells through two temperature baths where the top boundary temperatures were set at −15 (to achieve 0.083 °C/mm) and −5 °C (to achieve 0.028 °C/mm) and the bottom boundary temperature was set at 0 °C in order to replicate the average temperature of Fort McMurray. The installation of the insulation wrap and the thermoelectric cooling plate were all applied in order to ensure one-dimensional freezing and to represent the freezing process that occurs in nature.

Figure 2.

Schematic diagram of the freeze–thaw test setup (after [9,16]).

For the drying–wetting cycles, the drying tests were carried out in the freezing cells at room temperature (~20 °C) under which the weight loss due to evaporation was recorded daily along with the subsequent shear strength measurements. The volume of water that evaporated during each drying cycle was poured back into the cells to simulate the rainfall/wetting event.

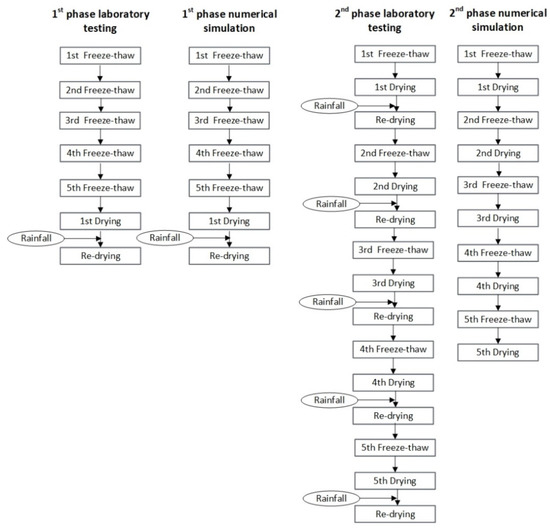

Laboratory investigations were carried out in two phases: First-phase testing that is associated with five consecutive freeze–thaw cycles followed by a single cycle of drying–wetting–re-drying after wetting; and second-phase testing includes five alternate freeze–thaw and drying–wetting cycles to better represent the natural seasonal cycles. For both phases, each of the freeze–thaw cycles took seven days to complete, whereas the drying–wetting cycles varied. For the first phase of testing, the centrifuged tailings samples were subjected to a month-long (dried to a target actual evaporation/potential evaporation (AE/PE) ratio of 0.7 for each test) drying cycle followed by a single wetting event to simulate the rainfall. After the wetting event, another drying cycle was continued for around twenty days. Further, the second phase of testing included five drying–wetting cycles and hence, each of the drying cycles was run for a shorter duration (seven days) prior to a single wetting event. After the wetting event, the re-drying cycle was continued for another seven days. The detailed procedures of the first-phase and second-phase testing were documented in [9,16].

4. Coupled Modeling

4.1. Modeling Analysis Development

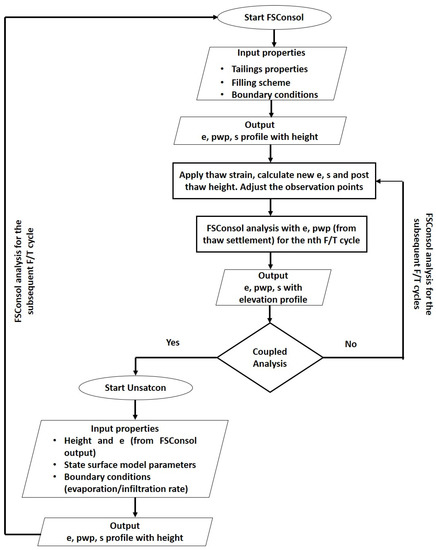

A one-dimensional coupled modeling approach was developed to simulate the effects of multiple freeze–thaw and drying–wetting cycles in the laboratory. The modeling exercises were conducted to simulate the laboratory results (water content) of centrifuged tailings samples subjected to seasonal weathering (multiple freeze–thaw consolidation and drying–wetting cycles) under two different temperature gradients (0.083 and 0.028 °C/mm), as mentioned in the above section. In this study, a coupled modeling analysis was conducted in two steps. First, the freeze–thaw analysis was coupled with the FSConsol model to incorporate the freeze–thaw process into consolidation modeling. Next, the coupled FSConsol model was coupled with the UNSATCON model to further incorporate the evaporation/drying cycles followed by the freeze–thaw cycles. FSConsol is a commercially available one-dimensional consolidation program that incorporates the large strain consolidation theory from Gibson et al. [17], whereas the UNSATCON program developed by Qi and Simms (documented in [18]) is a research code that simulates the tailings dewatering process induced by self-weight consolidation and evaporation while considering the stress/desiccation history and hydraulic hysteresis. Since none of these models incorporates the freeze–thaw consolidation directly, the change in water content due to thaw strain was calculated externally in an Excel sheet and applied to the active layer (the top layer of the ground that experiences above (thawing) and below 0 °C (freezing) during the year, also known as the frost depth (shown in Figure 1)) of the deposit (for the laboratory test, the active layer was equal to the total thickness of each of the samples) in FSConsol to account for the freeze–thaw consolidation.

Figure 3 shows the flowchart diagram of the coupling analysis. FSConsol was first run where the initial (height and void ratio) and boundary conditions similar to the laboratory were applied. A hydrostatic condition was assumed for the very first run. The boundary conditions at the top were specified as a constant water cap thickness of zero so that all the fluid will be drained off the top as the tailings consolidate. Similarly, the bottom boundary condition was specified as impermeable so that no fluid can exit through the bottom of the cell to simulate the laboratory condition. For numerical modeling of the oil sands tailings, the large strain consolidation theory is generally adopted [4] that requires one to input the compressibility (void ratio, e and effective stress) and saturated hydraulic conductivity (Ksat—void ratio) properties in FSConsol to be obtained from a large strain consolidation test. Using the large strain consolidation apparatus, the material properties of each of the samples were determined. After the consolidation analysis, the output results such as the void ratio (e), pore water pressure (pwp) and solids content (s) at different pre-sets depths were recorded. Next, solids contents were converted to the bulk density using the mass–volume relationship, and the thaw strain was applied to the analysis. The relationship between the thaw strain and bulk density for the centrifuged tailings samples under temperature gradients of 0.083 and 0.028 °C/mm is represented below using Equations (1) and (2), respectively:

where ε represents the thaw strain (unitless) and ρ represents the bulk density in gm/cm3. The above two equations were obtained by fitting the laboratory testing data from the ε–ρ relationship. The constants of these equations are dependent on the boundary conditions and hence will be changed based on the available thaw strain data for the particular deposit. Based on the thaw strain, the void ratio and solids content profile from the initial FSConsol run were adjusted. The total height and the heights of all the observation points were adjusted accordingly due to the thaw settlements. Consequently, the input for the next FSConsol run allows for incorporating the freeze–thaw consolidation process (denoted as the F/T cycle to represent freeze–thaw cycles in the diagram). This was accomplished by changing the initial conditions to reflect the thawed void ratio (based on thaw strain) and pore water pressures (from the previous run) to be applied at the adjusted preset depths in the profile. All these steps prior to the coupling with UNSATCON were repeated during consecutive multiple freeze–thaw cycles (for example, the first-phase testing simulation where FSConsol incorporating the thaw strain analysis needs to be repeated for subsequent freeze–thaw cycles).

ε = 0.0684 − 0.079 lnρ,

ε = 0.1887 − 0.276 lnρ,

Figure 3.

Flowchart diagram of coupling analysis.

Whenever a drying cycle was introduced, the coupled analysis was run by switching from FSConsol to the UNSATCON model (for example, the second-phase testing simulation where alternating analyses were required in each cycle). Hence, the output results (void ratio, elevation) from FSConsol were applied as an initial condition for the UNSATCON model. For modeling the unsaturated soil behaviour, the constitutive model (based on the state surface modeling approach) was selected, in which the void ratio and water content were expressed as the functions of the net normal and matric suction in the 3D space [19]. The parameters of this state surface model for the present study were obtained from the test conducted by Hurtado [20] on similar centrifuged tailings. The evaporation rate (in mm/day) was applied as a top boundary condition obtained from the laboratory tests, whereas no water flux through the bottom was allowed.

For the numerical modeling, a sequence similar to the laboratory was followed. Figure 4 shows the sequences of laboratory and modeling simulation of the first- and second-phase testing. However, due to the complexity of the coupling analysis in the second-phase testing (five alternate freeze–thaw and drying–wetting cycles), re-drying after the wetting event was not simulated in the numerical model.

Figure 4.

First- and second-phase laboratory testing and numerical simulation sequences.

4.2. Numerical Model Parameters

Table 1, Table 2 and Table 3 show the nessesary boundary conditions, intial conditions and summary of material and model parameters for the FSConsol and UNSATCON models, respectively. The initial thickness of each of the samples was 0.18 m, similar to the laboratory testing.

Table 2.

Boundary conditions and summary of parameters for the FSConsol models.

Table 3.

Boundary conditions and summary of parameters for the UNSATCON model.

To achieve numerical stability of the FSConsol model, a time step of 5 h was specified. The spatial discretization of this one-dimensional model was a total of 100 nodes, as per the recommendations provided by the manual of FSConsol. The sensitivity analysis was run with different timesteps including an hour and ten hours, and no significant change was observed.

Please note that the state surface model was developed by Qi [19], who solved a set of constitutive relationships incorporating volume change and water retention behaviour of unsaturated soils using finite difference techniques. All these in-depth formulations and algorithms were not studied in this paper. Only the parameters applied to similar centrifuged tailings were inputted in the models and these tests were performed by Hurtado [20].

5. Modeling Results

5.1. Numerical Simulation of First-Phase Testing

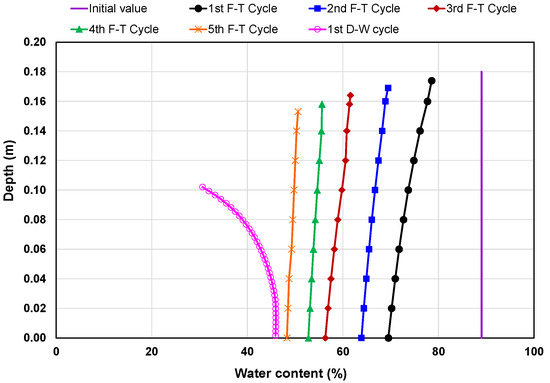

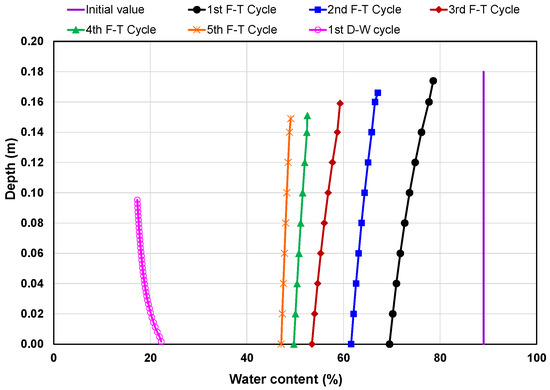

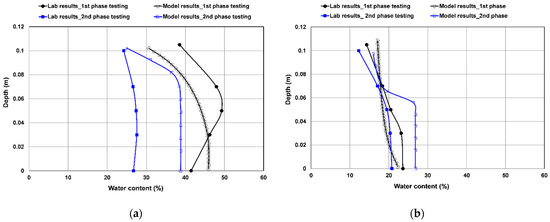

The first-phase numerical modeling of laboratory testing was run for five consecutive freeze–thaw cycles under two freezing temperature gradients of 0.083 and 0.028 °C/mm followed by a single drying–wetting cycle. Two separate scenarios were modeled here using coupling analysis incorporating the material properties, volume change relationships and the laboratory testing sequences reported above. The model-predicted water contents along with the change in elevation after each cycle (denoted as F/T cycle for each freeze–thaw cycle and D-W cycle for the drying–wetting cycle in the figures) are displayed in Figure 5 and Figure 6. Both figures show that the water contents were consistently decreasing with the freeze–thaw cycles, and by the fifth cycle, nearly half of the water had been lost (44 and 46% reduction in water content for the temperature gradients of 0.083 and 0.028 °C/mm, respectively). When drying/evaporation was incorporated in the numerical simulation, both these samples further dewatered to two-fold lower water content (Figure 5) for the higher-gradient sample and five-fold lower water content (Figure 6) for the lower-gradient sample, as compared to the initial value.

Figure 5.

Water content profile simulation of centrifuged tailings at a temperature gradient of 0.083 °C/mm.

Figure 6.

Water content profile simulation of centrifuged tailings at a temperature gradient of 0.028 °C/mm.

The centrifuged tailings samples at freezing temperature gradients of 0.083 and 0.028 °C/mm resulted in water contents of 48 and 47% at the surface, respectively, after five consecutive freeze–thaw cycles (the initial water content was 89%). Although the reduction in water contents for both the samples did not differ significantly from each other during the freeze–thaw analysis, the drying analysis from the UNSATCON model resulted in higher dewatering on the lower gradient (0.028 °C/mm) sample compared to the sample subjected to higher gradient. The lower gradient sample (as shown in Figure 6) experienced an average water content of 19% throughout the sample with the lowest one observed at the surface (17%). Conversely, the sample subjected to a higher freezing temperature gradient of 0.083 °C/mm resulted in an average water content of 42% (shown in Figure 5), with the lowest being observed at the surface was 31%. The final surface elevations for the higher- and lower-gradient samples were found to be 0.102 (43% reduction in thickness compared to the initial value) and 0.095 m (47% reduction in thickness compared to the initial value), respectively, at the end of the model run.

5.2. Numerical Simulation of Second-Phase Testing

The second-phase numerical simulations of the laboratory testing were run for five alternate freeze–thaw and drying–wetting cycles where each freeze–thaw cycle was followed by a drying–wetting–re-drying cycle, and this sequence was repeated five times per sample to represent five seasonal years in the field. The wetting event per cycle was introduced as a single event in the laboratory to simulate the rainfall where the volume of water that evaporated during atmospheric drying/evaporation for that particular cycle was poured back into the cell. As a result, the tailings surface was re-wetted, thereby allowing an increase in water content similar to the pre-drying phase. Upon wetting, the samples went through another drying cycle (with a similar time duration to the pre-wetting drying cycle) to investigate the tailings dewatering behaviour prior to and after the wetting event. The laboratory results suggest that the gain in solids content (or reduction in water content) achieved during the first seven days of the drying period was entirely depreciated by introducing the wetting event (the same amount of water was poured back into the cell that was evaporated) [9]. When the samples were re-dried for another seven days (at the end of fourteen days), upon wetting, an increase in solids content was observed similar to the pre-wetting cycle (within a difference in values of 0–1.4% by mass prior to and post-wetting drying). However, it was the last two cycles (fourth and fifth cycles) where the wetting event did not have any significant impact on increasing the water content of the tailings (particularly significant for the lower-gradient sample) because of the possible higher suction, thereby resulting in a further decrease in water content after fourteen days [9]. Nevertheless, incorporating all these components using an alternating simulation from FSConsol and UNSATCON in every cycle was very complex and, hence, the simulation was simplified by excluding the wetting and re-drying cycles.

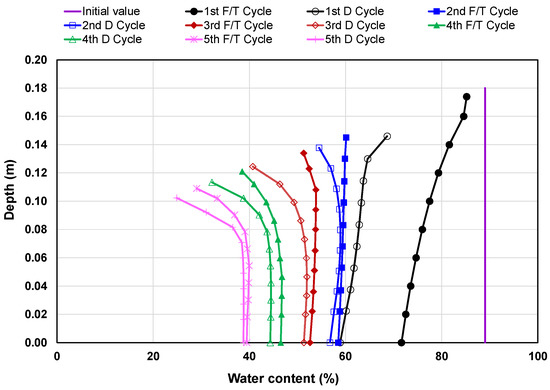

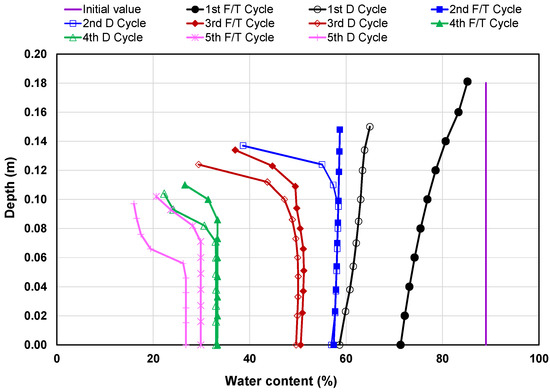

Figure 7 and Figure 8 show the model-predicted water content profiles for the two samples after each cycle (freeze–thaw and drying cycles were shown separately and denoted as F/T cycle for each freeze–thaw cycle and D cycle for drying cycle in the figures). The initial water content and elevation were found to be 89% and 0.18 m, respectively. The coupling analysis to simulate the second phase of testing shows that the centrifuged tailings samples subjected to temperature gradients of 0.083 and 0.028 °C/mm responded quite differently to seasonal weathering. After five alternate freeze–thaw and drying cycles, the samples with higher (0.083 °C/mm) and lower temperature gradients (0.028 °C/mm) were dewatered to nearly four-fold (surficial water content value was 25%, as shown in Figure 7) and six-fold (surficial water content value was 16%, as shown in Figure 8) lower water contents, respectively, at the surface when compared to the initial water content value. Both the samples dewatered similarly for the first two seasonal cycles (the first freeze–thaw–drying and second freeze–thaw cycles). It was during the second drying cycle that dewatering between the two samples started to differ. Evaporation from the lower temperature gradient sample reduced the water content by 29% at the surface compared to the other sample at the end of the second cycle. At the end of the third, fourth and fifth cycles, the sample subjected to a temperature gradient of 0.028 °C/mm resulted in a 28, 31 and 36% reduction in water contents at the surface, respectively, compared to the sample under a higher freezing temperature gradient (0.083 °C/mm). Both the higher- and lower-temperature-gradient samples dewatered considerably after five seasonal cycles with final elevations of 0.102 (43% reduction in thickness from the initial value) and 0.097 m (46% reduction in thickness from its initial value), respectively. The bottom few hundredths of a meter of the sample were not affected much by the seasonal weathering model run.

Figure 7.

Water content profile simulation of centrifuged tailings at a temperature gradient of 0.083 °C/mm.

Figure 8.

Water content profile simulation of centrifuged tailings at a temperature gradient of 0.028 °C/mm.

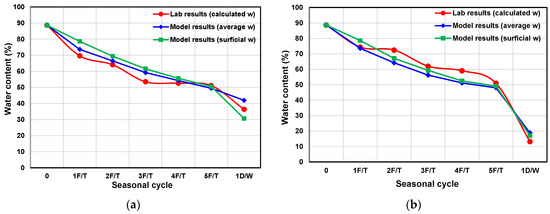

5.3. Comparison between the Model and Laboratory Results

Figure 9 and Figure 10 illustrate the cumulative decrease in water content for the two centrifuged tailings samples under the temperature gradients of 0.083 and 0.028 °C/mm, respectively, after each seasonal cycle, where Figure 9 compares the first-phase laboratory testing and modeling results and Figure 10 compares the second-phase testing results between laboratory computation and model prediction. The water content obtained from the laboratory after each seasonal cycle was calculated on the basis of the thaw strain during freeze–thaw cycles and the changes in weight loss/gain during drying–wetting cycles. Hence, the water content per cycle obtained from the laboratory represents the average water content throughout the depth. In terms of numerical modeling, both the average and surface values were reported on the graph as the deposit surface is expected to dewater the most, given it is the most susceptible to the effects of seasonal weathering.

Figure 9.

First-phase testing comparisons: Water content values per seasonal cycle for the centrifuged tailings samples under a temperature gradient of (a) 0.083 °C/mm and (b) 0.028 °C/mm.

Figure 10.

Second-phase testing comparisons: Water content values per seasonal cycle for the centrifuged tailings samples under a temperature gradient of (a) 0.083 °C/mm and (b) 0.028 °C/mm.

As evident in Figure 9, the differences between the model prediction and the laboratory computational results were marginal. However, the model overpredicted water content values compared to the laboratory results for the higher-temperature-gradient sample (Figure 9a), while it showed the reversed pattern for the lower-temperature-gradient sample (Figure 9b). The second-phase testing, as shown in Figure 10, shows a different trend. The laboratory results for both samples corroborated well with the model-predicted water contents at the surface.

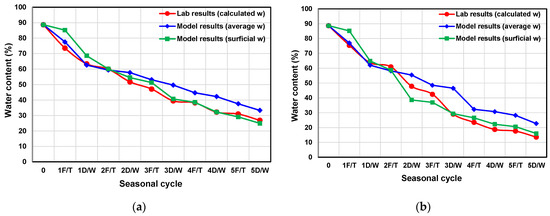

Figure 11 shows the comparisons between the final (at the end of the tests) laboratory-measured and model-predicted water content profiles for the two centrifuged tailings samples subjected to temperature gradients of 0.083 and 0.028 °C/mm, respectively.

Figure 11.

Laboratory versus. model water content profiles of centrifuged tailings at the end of the test under a temperature gradient of (a) 0.083 °C/mm and (b) 0.028 °C/mm.

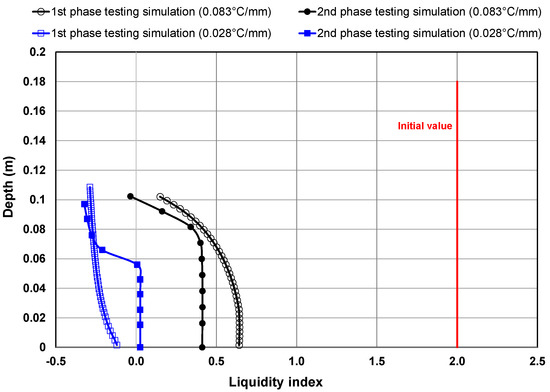

As shown in Figure 11a, first-phase testing results indicate that the simulation for the higher-temperature-gradient sample overall underpredicted water content values by 3%, as the average water content values along the depth were found to be 42 and 45%, respectively, from the modeling prediction and the laboratory measurement. Likewise, the lowest water content, observed at the surface, was found to be 31 and 39%, respectively, from the modeling and laboratory results (about an 8% underprediction of water content compared to the laboratory value). Conversely, the laboratory and model-predicted water content profiles correlated quite well for the lower gradient sample (Figure 11b). The model overall underpredicted water content values by about 1% throughout the depth and overpredicted this value by about 3% at the surface compared to the laboratory measurement. The model predicted an average water content of 19% throughout the depth with the lowest water content of 17% observed at the surface, whereas the laboratory-measured average value was found to be 20% along with the lowest water content of 14% observed at the surface. All these values from the lower-gradient sample suggest a stiff/solid consistency for the tailings, provided these values passed through the plastic limit of 26% (Figure 12).

Figure 12.

Liquidity index profiles of centrifuged tailings from coupled analysis.

As mentioned above, the numerical model to simulate the second-phase testing excluded the wetting event and re-drying cycle after wetting. Hence, the model predictions were expected to achieve higher water contents compared to the laboratory results. However, the laboratory results suggest that the water content reduction/solids content gain just prior to wetting (at the end of the seven-day drying cycle prior to the wetting event) and the post-wetting drying phase (at the end of another seven-day drying cycle post-wetting) was invariable for the higher-temperature-gradient sample (0.083 °C/mm) and, therefore, this sample is not supposed to be impacted much because of these wetting and re-drying event exclusions. It was the lower-gradient sample where the water content reduction/solids content gain prior to and after the wetting event was not similar at the higher cycles (fourth and fifth cycles). This is due to the higher suction values that prevented rainfall possibly causing any impact on the increasing water content upon wetting [9]. However, the modeling results that simulated the second-phase testing (as shown in Figure 11) suggest that the model overall overpredicted water content values by about 10 and 5% for the higher (Figure 11a) and lower (Figure 11b) temperature-gradient samples, respectively, as compared to the laboratory results. In contrast to that, the surficial water content values were comparable, given that the model overpredicted water content by almost 1 and 4% for the higher (0.083 °C/mm) and lower (0.028 °C/mm) temperature-gradient samples, respectively. The surface elevation of the higher-temperature-gradient sample was reduced to nearly half of its initial thickness (43 and 44% reduction of its initial thickness from the modeling simulation and laboratory results, respectively) at the end of the tests. Likewise, the surface elevation of the lower-gradient-temperature sample was reduced to 46 and 44% of the initial thickness from the numerical modeling and laboratory results, respectively.

Figure 12 shows the liquidity index profiles of the coupled analysis models. Similar to the first-phase testing, the second-phase testing also suggests that the surface of the lower-gradient sample was able to pass through the plastic limit. On the contrary, the higher-gradient sample was in a relatively softer consistency in the first-phase testing (could not reach the plastic limit), while the sample surface just reached the plastic limit in the second phase of testing. Overall, coupling analyses were able to predict the laboratory results reasonably well for the centrifuged tailings sample subjected to the lower temperature gradient (0.028 °C/mm) compared to the higher gradient (0.083 °C/mm).

6. Discussion

Both the laboratory results and the numerical model suggest that the centrifuged tailings samples subjected to seasonal weathering (multiple freeze–thaw and drying cycles) have the potential for improved dewatering compared to the as-received centrifuged tailings. Figure 5 and Figure 6 show how multiple freeze–thaw cycles at two different freezing temperature gradients contributed to dewatering prior to drying/evaporation. The freeze–thaw process is known to alter the structure of the tailings/soil materials by redistributing moisture inside the tailings/soil particles that, in turn, improves dewatering upon thaw [11]. Consequently, higher dewatering/volume change can be expected during the very first freeze–thaw cycle followed by a gradual decrease in subsequent cycles due to the gradual decrease in available water/moisture inside the tailings materials [21,22]. Both of these two figures may look similar until the drying/wetting cycle is introduced. Fine-grained tailings subjected to freezing likely generate high suction/negative pore water pressure at the freezing front, thereby causing water migration upwards to the front (as shown in Figure 1) and a subsequent reduction in water content and shrinkage crack development in the tailings. The extent of these cracks is predominantly dependent on the temperature gradient, the number of freeze–thaw cycles and the physio-chemical interactions among the tailings particles and solutes [11,12,23]. Apart from the earlier findings (carried out by [12,23,24]), the visual observation from the laboratory testing also suggests that the lower freezing temperature gradient results in higher shrinkage and cracks, contributing to higher evaporation and solids content. Hence, the shrinkage and cracks developed during freeze–thaw cycles facilitated different evaporation rates for the centrifuged tailings under two different gradients, which contributed to the significantly different water content profiles in the drying–wetting cycle (as shown in Figure 5 and Figure 6).

Figure 7 and Figure 8 show how seasonal weathering in nature can contribute to dewatering of the centrifuged tailings deposit. At the start of the simulation, the tailings are first consolidated at the bottom. With subsequent cycles, the upward water flux due to consolidation becomes less than the applied evaporation at the surface and, hence, desiccation occurs. As a result, the tailings surface first becomes unsaturated after being exposed to the atmosphere, thereby reducing the water content considerably more than the bottom part. However, the void ratio profile (void ratio vs. elevation) from the previous freeze–thaw cycle cannot be specified within a single-layer deposit in the UNSATCON model and hence, an average void ratio was applied that can affect the drying cycle outputs. As shown in Figure 7 and Figure 8, the water content profiles at the bottom few hundredths of a meter remain almost constant, which can be attributed to the input parameter specified as an average value (void ratio from the previous cycle).

The coupled analysis, as shown in Figure 9, correlates well with the first-phase laboratory testing results of the centrifuged tailings samples under temperature gradients of 0.083 and 0.028 °C/mm. The subsequent cycle has a lower impact on the volume changes due to the freeze–thaw cycles, thereby causing lower dewatering from the sample. Hence, the differences in water content values between the laboratory results and modeling predictions (both average and surficial water content values) are expected to be marginal. However, the results from the drying model, which has a significant impact on dewatering, corroborates well with the laboratory results and validates the efficacy of the coupled analysis model.

Similar to Figure 9, Figure 10 compares the second-phase laboratory testing with the modeling results of the centrifuged tailings under two different temperature gradients (0.083 and 0.028 °C/mm). In contrast to the Figure 9, the model-predicted water contents at the surface correlated well with the laboratory computation for both gradient scenarios of the investigated centrifuged tailings. The model-predicted average water content values deviated to an extent (up to 18% differences) from the laboratory-computed average values, and this can be attributed to the limitation of the drying (the UNSATCON model) model, where the input parameter (void ratio) has to be specified as an average value instead of a void ratio profile (varying with depth). The exclusion of wetting and re-drying after wetting events may also have an impact on the variations. However, given the fact that both the samples deviated in their average water content values compared to the laboratory results but correlated well in terms of surficial water content, the limitation of the drying model most likely predominantly contributed to these deviations.

Figure 11 shows the final water content profiles subjected to first- and second-phase testing for the two investigated centrifuged tailings under temperature gradients of 0.083 and 0.028 °C/mm, respectively. The laboratory results shown on the graph represent the oven-measured water content values at the end of the tests. Figure 11a shows that the higher-gradient centrifuged tailings sample predicted an overall lower water content profile than the laboratory measurement for the first-phase testing while the opposite trend was observed in the second-phase testing. The higher water content profile predicted in the model for the second-phase testing can be attributed to the preclusion of the wetting event and the re-drying cycle in the model. In addition to that, the limitation of the UNSATCON model to incorporate the void ratio/water content profile from the previous cycle results in the overall differences between the laboratory results and modeling prediction. However, the water content profiles developed to predict the laboratory testing (as shown in Figure 11b) supported the laboratory results considerably for the lower-gradient tailings sample. Although the drying model could predict the profile for the top few hundredths of a meter of the sample reasonably well following the evaporative flux incorporated in the top boundary, the lower part of the sample could not be predicted quite as well due to the limitation of defining input parameters. Figure 12 shows the change in consistency of tailings samples prior to and after seasonal weathering to illustrate the efficacy of these processes that can be applied in the field deposit.

Overall, this study presented the coupling of three components (incorporating the freeze–thaw process into the FSConsol, consolidation from FSConsol and atmospheric drying from UNSATCON) to develop a coupled model. Model-predicted dewatering behavior correlated well with the laboratory results that validated this coupling approach. However, the coupling analysis has a few limitations, such as:the incapability of running under a single program that can incorporate all the seasonal weathering processes (freeze–thaw, consolidation, desiccation, etc.) and the limitations of defining input parameters in the UNSATCON model, such as being unable (1) to define a void ratio profile (varying with depth) instead of an average void ratio per cycle; (2) to define data directly from the SWCC curve and compressibility curves instead of fitting data into a state surface model; and (3) to input separate files for the evaporation and infiltration under the same cycle. The numerical software available in the industry is yet to develop a program that can simulate the freeze–thaw, consolidation and desiccation of tailings under different boundary conditions and deposition scenarios. Switching between different modeling platforms to address all these seasonal weathering components is cumbersome and time-consuming. Neverthless, the coupled analysis, in some ways, is able to validate the laboratory analysis based on which field behaviour can be predicted. It may not predict the long-term field behaviour given the complexity related to combining the multiple models for each cycle (each cycle is required to go through the flowchart each time as shown in Figure 1, which implies the flowchart needs to be repeated 100 times for a prediction of 100 years). However, these analyses can provide insight into predicting dewatering behavior of the future field deposits.

7. Conclusions

The coupling modeling methodology presented in this study was able to develop an approach that was validated by comparing it with the laboratory test results of centrifuged tailings under similar boundary conditions. This coupling methodology can assist in tailings management by predicting the short-term behaviour of the dewatering performance of the tailings deposits subjected to the natural seasonal weathering (freeze–thaw, consolidation and desiccation). Within limited scope, this coupled analysis demonstrated that freeze–thaw cycles can be considered as a part of the tailings management in regions where weather permits this. The freeze–thaw process may appear to achieve lower dewatering enhancement compared to atmospheric drying, but the shrinkage and/or cracks developed during the freeze–thaw cycles facilitate greater evaporation and desiccation during the subsequent drying cycle, thereby contributing to higher dewatering overall. The model also confirms the previous research and the present laboratory findings that suggest that a lower temperature gradient results in higher solid content/lower water content in post-thawed tailings. When the drying/evaporative component was incorporated, atmospheric drying was shown to significantly (half an order of magnitude lower) reduce the water content as compared to the multiple freeze–thaw cycles only. With the combined effects of alternate freeze–thaw and drying–wetting cycles, the tailings could even achieve a water content exceeding the plastic limit (as evident in the lower-temperature-gradient sample), enabling reclamation and closure. While time consuming, this approach can provide insights into predicting the dewatering behaviour of future field deposits so that it can be used for planning purposes.

Author Contributions

Conceptualization, U.S.R.; methodology, A.A. and U.S.R.; software, U.S.R.; validation, U.S.R. and N.B.; formal analysis, U.S.R.; investigation, U.S.R.; resources, U.S.R. and N.B.; data curation, U.S.R.; writing—original draft preparation, U.S.R.; writing—review and editing, U.S.R., N.B. and A.A.; visualization, U.S.R.; supervision, N.B.; project administration, N.B.; funding acquisition, N.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science and Engineering Research Council of Canada (NSERC), Canada’s Oil Sands Innovation Alliance (COSIA) and Alberta Innovates-Energy and Environment Solutions.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada (NSERC), Canada’s Oil Sands Innovation Alliance (COSIA) and Alberta Innovates—Energy and Environment Solutions for their financial support. The authors would also like to thank Louis Kabwe for providing the large strain consolidation parameters.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, but have reviewed the results and approved to publish.

References

- Government of Alberta. Oil Sands: Facts and Stats. 2021. Available online: https://www.alberta.ca/oil-sands-facts-and-statistics.aspx (accessed on 1 October 2021).

- Cossey, H.L.; Batycky, A.E.; Kaminsky, H.; Ulrich, A.C. Geotechnical Stability of Oil Sands Tailings in Mine Closure Landforms. Minerals 2021, 11, 830. [Google Scholar] [CrossRef]

- Alberta Energy Regulator (AER). Alberta’s Energy Reserves 2015 & Supply/Demand Outlook 2016–2025 (ST98-2016); Alberta Energy Regulator: Calgary, AB, Canada, 2016. [Google Scholar]

- Jeeravipoolvarn, S. Geotechnical Behavior of In-Line Thickened Oil Sands Tailings. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2010. [Google Scholar]

- Oil Sands Tailings Consortium (OSTC) and Canada’s Oil Sands Innovation Alliance (COSIA). Technical Guide for Fluid Fine Tailings Management; OSTC and COSIA: Calgary, AB, Canada, 2012; Available online: https://www.cosia.ca/uploads/documents/id7/TechGuideFluidTailingsMgmt_Aug2012.pdf (accessed on 31 July 2021).

- Spence, J.; Bara, B.; Lorentz, J.; Mikula, R. Development of the Centrifuge Process for Fluid Fine Tailings Treatment at Syncrude Canada Ltd. In Proceedings of the World Heavy Oil Congress 2015, Edmonton, AB, Canada, 24–26 March 2015. [Google Scholar]

- Alberta Energy Regulator. State of Fluid Tailings Management for Mineable Oil Sands, 2019; Alberta Energy Regulator: Calgary, AB, Canada, 2020; Available online: https://static.aer.ca/prd/2020-09/2019-State-Fluid-Tailings-Management-Mineable-OilSands.pdf (accessed on 31 July 2021).

- Government of Alberta. Oil Sands Information Portal. Available online: http://osip.alberta.ca/map/ (accessed on 1 October 2021).

- Rima, U.S.; Beier, N. Effects of seasonal weathering on dewatering and strength of an oil sands tailings deposit. Can. Geotech. J. 2021, in press. [Google Scholar] [CrossRef]

- Hyndman, A.; Sawatsky, L.; McKenna, G.; Vandenberg, J. Fluid Fine Tailings Processes: Disposal, Capping, and Closure Alternatives. In Proceedings of the 6th International Oil Sands Tailings Conference, Edmonton, AB, Canada, 9–12 December 2018; pp. 9–12. [Google Scholar]

- Proskin, S.; Sego, D.; Alostaz, M. Oil Sands MFT Properties and Freeze-Thaw Effects. J. Cold Reg. Eng. ASCE 2012, 26, 29–54. [Google Scholar] [CrossRef]

- Proskin, S.A. A Geotechnical Investigation of Freeze-Thaw Dewatering of Oil Sands Fine Tailings. Ph.D. Thesis, Department of Civil and Environmental Engineering, University of Alberta, Edmonton, AB, Canada, 1998. [Google Scholar]

- Dawson, R.F.; Sego, D.C. Design Concepts for Thin Layered Freeze-Thaw Dewatering Systems. In Proceedings of the 46th Canadian Geotechnical Conference, Saskatoon, SK, Canada, 27–29 September 1993; pp. 283–288. [Google Scholar]

- Johnson, R.L.; Pork, P.; Allen, E.A.D.; James, W.H.; Koverny, L. Oil Sands Sludge Dewatering by Freeze-Thaw and Evaporation; Report-RRTAC 93-8; Syncrude Canada and Alberta Conservation and Reclamation Council: Vegreville, AB, Canada, 1993; Available online: https://doi.org/10.7939/R33R0PT5T (accessed on 1 October 2021).

- Scott, J.D.; Dusseault, M.B.; Carrier, W.D. Behaviour of the clay/bitumen/water sludge system from oil sands extraction plants. Appl. Clay Sci. 1985, 1, 207–218. [Google Scholar] [CrossRef]

- Rima, U.S.; Beier, N. Effects of Multiple Freeze-Thaw Cycles on Oil Sands Tailings Behaviour. Cold Reg. Sci. Technol. 2021, 192, 103404. [Google Scholar] [CrossRef]

- Gibson, R.; England, G.; Hussey, M. The theory of one-dimensional consolidation of saturated clays. Geotechnique 1967, 17, 261–273. [Google Scholar] [CrossRef]

- Qi, S.; Simms, P.; Vanapalli, S. Piecewise-linear formulation of coupled large-strain consolidation and unsaturated flow. I: Model development and implementation. J. Geotech. Geoenvironmental Eng. 2017, 143, 04017018. [Google Scholar] [CrossRef]

- Qi, S. Numerical Investigation for Slope Stability of Expansive Soils and Large Strain Consolidation of Soft Soils. Ph.D. Thesis, University of Ottawa, Ottawa, ON, Canada, 2017. [Google Scholar]

- Hurtado, O. Desiccation and Consolidation in Centrifuge Cake Oil Sands Tailings. Master’s Thesis, Carleton University, Ottawa, ON, Canada, 2018. [Google Scholar]

- Eigenbrod, K.D. Effects of cyclic freezing and thawing on volume changes and permeabilities of soft fine-grained soils. Can. Geotech. J. 1996, 33, 529–537. [Google Scholar] [CrossRef]

- Andersland, O.B.; Ladanyi, B. Frozen Ground Engineering, 2nd ed.; American Society of Civil Engineers & John Wiley & Sons Inc.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Pham, N.H.; Sego, D.C. Modeling Dewatering of Oil Sands Mature Fine Tailings using Freeze Thaw. In Proceedings of the International Oil Sands Tailings Conference, Lake Louise, AB, Canada, 7–10 December 2014. [Google Scholar]

- Sego, D.C.; Dawson, R.F. Influence of Freeze-Thaw on Behaviour of Oil Sand Fine Tails; Alberta Oil Sands Technology and Research Authority: Edmonton, AB, Canada, 1992; p. 77. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).