South Africa is burdened with 30 million waste tyres that are either landfilled or illegally dumped in open fields [

1]. The generation rates are escalating at a rate of approximately 200,000 tonnes, equating to a million waste tyres annually [

2]. In the 2016/2017 financial year, The Department of Environmental Affairs (DEA) reported that 31% of waste tyres have been diverted from landfills to be repurposed in reuse, recycling, and material or energy recovery industries [

1]. In addition, through the Recycling and Economic Development Initiative of South Africa (REDISA), approximately 170,000 tonnes of waste tyres were recycled in 2016 [

3]. In 2013, approximately 16,037 waste tyres were channeled to recycling, recovery, and reuse initiatives. Subsequently, in 2014 and 2015, the recorded figures of waste tyres allocated to recycling, energy recovery and reuse initiatives were 31,448 and 71,806, respectively [

3], showing a significant increase over the years. South Africa is successfully directing waste tyres to different markets of which 25% of waste tyres are reused, 23% are designated for cutting and shredding to be used for spongy mats or playground material, 18% are converted to oil and carbon black through pyrolysis for various applications, and 16% are incinerated for energy recovery in cement or brick manufacturing kilns [

3]. The remainder, which is about 18% of waste tyres, are redirected to landfills; this is still very high, and it gives more evidence to the case for repurposing more waste tyres. The characteristics of tyres, waste tyre pyrolysis, the associated primary and valuable secondary products, and the waste tyre management challenges have been comprehensively discussed by several authors in the literature. Muzenda [

4] comprehensively detailed the various thermochemical processes such as pyrolysis, gasification, and liquefaction that waste tyres can undergo. The literature was utilised to formulate a detailed understanding of the different thermochemical technologies. Rodriguez [

5], Islam [

6], and Williams [

7] discussed the waste tyre pyrolysis process in great detail as well as the different forms of products that the process can yield. Furthermore, Parthasarathy et al. [

8] investigated the effect of process conditions on the product yield of waste tyre pyrolysis. Laresgoiti et al. [

9] critically analysed the gases obtained in tyre pyrolysis; Cunliffe and Williams [

10] as well as Islam et al. [

11] assessed the composition of oils resulting from the pyrolysis of tyres, and Shah et al. [

12] examined waste tyre-derived carbon black and its use as an adsorbent. The referenced literature has assisted the authors with the understanding of waste tyre pyrolysis chemistry, final product quantity, and quality as well as possible markets and applications. This paper aims to assess the economic viability of operating a waste tyre batch pyrolysis plant as well as the potential of producing high-value primary and secondary final products. This can significantly contribute towards addressing South Africa’s waste tyre challenges, energy, and material recovery, thus contributing to socioeconomic development. In addition, this study taps into the current socioeconomic ills currently experienced in South Africa, such as unemployment and the lack of successful small medium and micro enterprises (SMMEs) [

13]. The results of this study can also be adopted by developing countries such as Thailand, Nigeria, and Brazil, who also face the same waste tyre problem as South Africa. In 2012, Thailand reported the energy recovery of waste tyres in the form of pyrolysis to be at 30.23% [

14]. Similarly, Nigeria and Brazil are assessing the socioeconomic benefits to be derived from waste tyre management. Waste tyre pyrolysis is yet to be fully explored in these countries [

15,

16].

1.1. Waste Tyre Pyrolysis Product Compositions, Characteristics, and Application

The waste tyre pyrolysis process yields a gaseous fraction of mainly non-condensable gases, an oily fraction mainly composed of organic substances, and a solid fraction that comprises of mainly carbon, metal, and other inert material. The composition of the primary pyrolysis products is influenced by process operating parameters such as the feed size, temperature and pressure, residence time, heating rate, and reactor configuration, as well as the presence of catalytic medium [

17]. Reactor design has been reported as one of the significant factors that affects product output, gas and oil characteristics, and process parameters [

18]. The most generally used designs are fixed-bed, rotary/screw kiln, stirred tank, vacuum and fluidised-bed reactor types [

18]. Fixed-bed reactors are commonly utilised for slow pyrolysis in batch systems with oil yield ranging from 35% to 50%, while fluidised bed reactors are commonly employed in the fast pyrolysis process and require small particle sizes, with oil yields ranging from 65% to 70% [

18]. A rotary kiln reactor is slightly inclined (1°–10°) to progress the waste material forward; the added advantages are that the processing speed of turning, the extent of filling, and particle dimensions can be optimised to improve product yield [

19]. Stirred tank reactors are designed for processing whole tyres, resulting in a considerable energy saving on size reduction costs [

20]. The vacuum pyrolysis reactor is designed to accommodate larger tyre particles at low pressure and minimum temperature [

21].

The approximate yield of gas from waste tyre pyrolysis is about 10–30% by weight and has a heating value of around 30–40 MJ/Nm

3 [

22]. Pyrolytic gas is commonly used as a source of fuel and can be adequate to provide the energy required to run a small-scale pyrolysis plant. The gas has high concentrations of methane (CH

4, 44.50 vol %) and ethane (C

2H

4, 4.4 vol %), akin to natural gas (84.6 vol % CH

4 and 6.4 vol % C

2H

4). However, the large quantities of carbon monoxide (2.41 vol %) hinders its blending with natural gas (0 vol % CO) [

23]. The tyre-derived oil (40–50%) is composed mainly of alkylated benzenes, naphthalenes, phenanthrenes, n-alkanes from C

11 to C

24, and alkenes from C

8 to C

15, with small quantities of nitrogen (N

2), sulphur (S), and oxygenated compounds [

23]. The liquid fraction contains valuable chemicals such as aromatics, d-limonene, and BTX (benzene, toluene, xylenes). BTX compounds play a critical role in the production of chemicals, dyes, plastics, and synthetic fibres; their markets are projected to upsurge at a compound annual growth rate of 5.9% from 2019 to 2027 [

24]. Additionally, tyre-derived oil has the potential to be used as automotive fuel after the removal of metal and metalloid contaminants such as zinc, aluminium, iron, titanium, sodium, lead, nickel, and traces of arsenic, chromium, and cobalt [

23]. Pyrolytic oil has a high calorific value of about 44 MJ/kg as compared to waste tyres, 33 MJ/kg [

23]; wood, 12.4 MJ/kg; coal, 30.2 MJ/kg; and it is close to that of diesel oil, which is 45.5 MJ/kg [

25]. Pyrolytic char is a valuable energy source and contributes 30–35% of the product mix with a heating value close to 30.5 MJ/kg [

12]. Its heating value is higher than that of South African lignite coals (16.7 MJ/kg) and compares well with petroleum coke (34.9 MJ/kg) [

26]. Thus, the char can substitute coal as a source of energy in briquettes and industrial boilers, or it can be co-fired together with coal. Carbon black has the potential to be used as an adsorbent in the removal of heavy metals from industrial and municipal wastewater and as a precursor for activated carbon generation [

27]. Furthermore, carbon black can be used as a filler and pigment for making printing inks, tyres, etc. [

28]. The commercial viability of steel wire derived from the pyrolytic process which constitutes 10–15 wt % of product mix depends on its cleanliness, quantity, and packaging. Steel with less than 10% of rubber contamination is considered commercially viable [

29].

These overwhelming advantages have motivated the authors to undertake this study with the aim of determining the business model for waste tyre pyrolysis in South Africa.

1.2. Waste Tyre Pyrolysis in South Africa

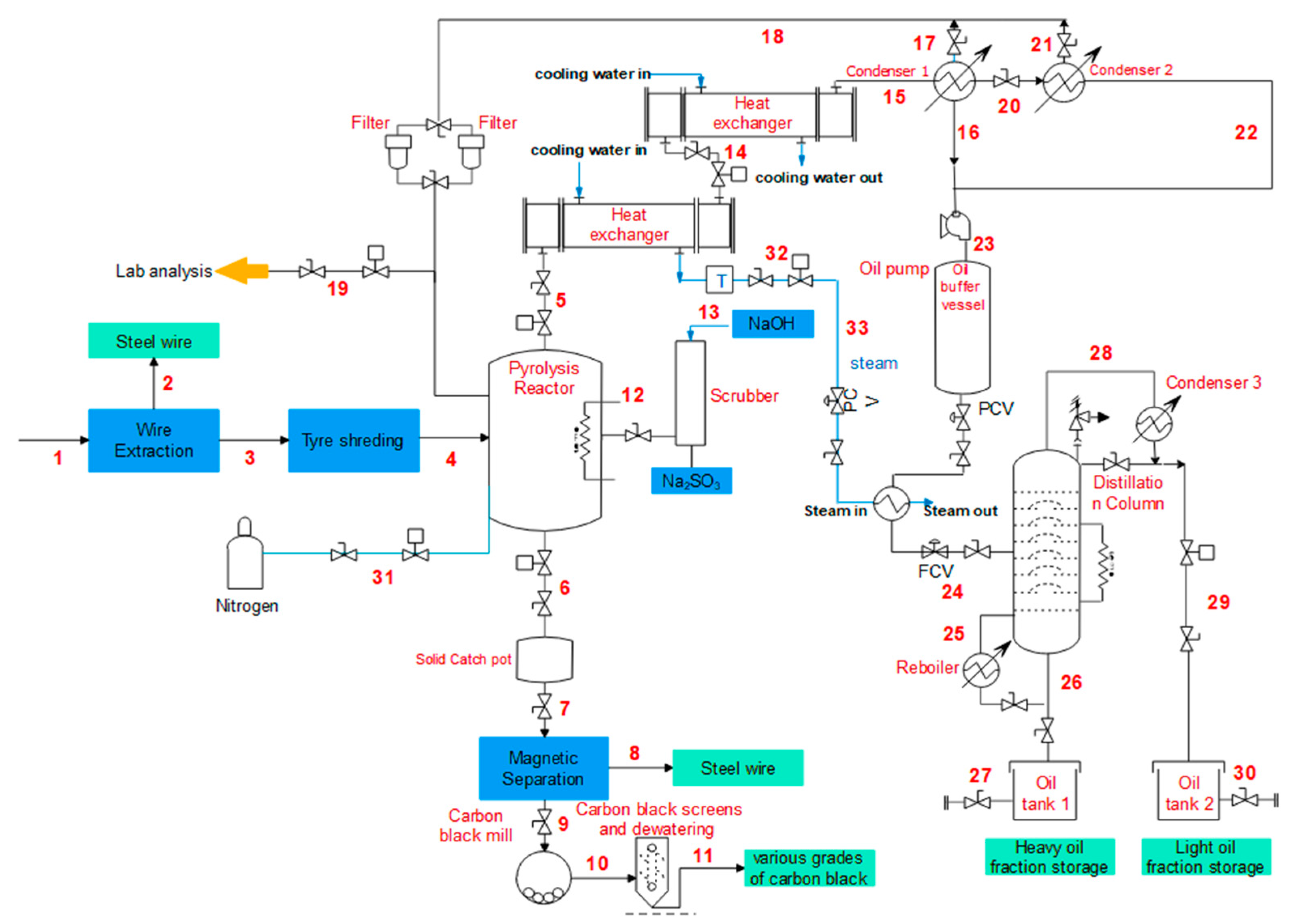

The waste tyre pyrolysis process is not a new concept in South Africa; however, it has not been fully explored to yield any significant successes. Several attempts have been made to operate profitable plants that adhere to environmental laws. Such attempts include the Pretoria-based pyrolysis plant (Innovative Recycling Pty Ltd.), which used to process 25 tonnes of waste tyres daily. The company capitalised on the opportunity of using excess waste tyres by erecting a waste rubber and plastic conversion to fuel plant. The facility ceased operations because it failed to adhere to environmental regulations and laws. In late 2018, another waste tyre pyrolysis facility, Milvinetix in Rosslyn Pretoria was shut down. This plant operated intermittently from March 2012 and processed 10 tonnes per day of the waste tyre employing a batch operation. It produced 40 wt % pyrolysis oil, 30–35 wt % carbon black, 15 wt % steel cords, and 10 wt % uncondensed gases [

30]. The oil was sold as crude for industrial applications, such as a source of fuel for kilns and furnaces [

30]. In recent years, more pyrolysis businesses have been established that produce a variety of end products. The IRR Manufacturing facility processes waste tyres, waste wood, and waste polyolefin plastics in a 1000 kg/hour pyrolysis plant in Rosslyn, Pretoria, to produce pyrolytic gas, oil, and carbon black [

31]. Recor-Waste to Energy Solutions is a South-Gauteng-based pyrolysis plant that converts a variety of wastes such as municipal solids, agricultural, medical, abattoir, and sawdust, converting them to energy. Additionally, waste tyres are converted to energy, oil, and char, while plastic and waste oils are processed to yield a variety of diesel grades [

32]. Lastly, Trident Fuels Pty Ltd., located in Germiston, Gauteng, processes waste tyres to produce crumb rubber and carbon black [

33].

The pyrolysis oil specifications and properties of the Milvinetix oil were benchmarked against local and international oil standards before application. As a result, an oil sample obtained from Milvinetix was analysed against international standards. Moreover, an additional sample of crude pyrolytic oil was obtained from Pace Oil, which is an oil refinery company that purifies crude oils obtained from different sources. Oil specifications for both Milvinetix and Pace oil are presented in

Table 1. A comparison between the different oils shows that the pyrolysis characteristics conform to the American Society for Testing and Material International (ASTM) standards [

34] for density and viscosity. However, both oils exhibit a low flash point requiring specific storage measures to meet insurance and fire prevention requirements. As a result, additives and blending would be required to increase the flashpoint and reduce the water content [

35]. The two oils were observed as containing excess contaminants, although there was minute metallic contamination. Furthermore, both oils are out of specification regarding the octane index and micro carbon residue, thus limiting their application. The Milvinetix oil is not further treated due to the economics of the business model not being sound when purified [

31,

36]; thus, it is sold in its crude form.

Carbon black obtained from Milvinetix showed a high calorific value, making it possible for fuel applications, as shown in

Table 2. However, it does not conform to the ASTM standards [

37] for ash and volatile matter content, meaning the char cannot be considered for industrial use in its virgin form after pyrolysis. The fixed carbon content is about 60%, which is an indication that the char will require a longer combustion time. Consequently, further chemical or physical purification of the carbon black is required to improve its marketing and standardisation potential. Activation agents such as ZnCl

2, KOH, and H

3PO

4 are frequently used to chemically treat the carbon black; also, traditional gases such as steam/H

2O, CO

2 and air/O

2 are employed during physical activation [

27].