1. Introduction

The evaporation process, boiler, and steam turbine are the main components of the cogeneration system in the sugar industry. Diluted sugar juice becomes raw sugar and molasses in the evaporation process after a specified amount of water is removed by evaporation. Thermal energy required for water evaporation is provided by steam condensation. The boiler generates high-pressure steam that is supplied to the steam turbine for power generation. Older cogeneration systems use the back-pressure turbine, in which steam is exhausted at a lower pressure, whereas modern cogeneration systems use the extraction–condensing steam turbine, in which some steam is extracted at lower pressure, and the remaining steam is sent to the condenser. Kamate and Gangavati [

1] have shown that a cogeneration system using the extraction–condensing steam turbine is more energy efficient than a cogeneration system using the back-pressure steam turbine.

The multiple-effect evaporator is used in the evaporation process. The evaporator is designed to increase the juice concentration from approximately 15% to 70%. The removal of the remaining water content in sugar occurs in the pan stage. The multiple-effect evaporator requires a supply of saturated steam extracted from an extraction–condensing steam turbine at a specified pressure. An adverse consequence of the exposure of sugar juice to high-temperature steam and vapor in the multiple-effect evaporator is sucrose inversion loss, which converts sucrose to glucose and fructose. In order to increase the profitability of raw sugar manufacturing, the amount of required steam and sugar inversion loss should be minimized without compromising the capacity of the process. There have been several suggestions to improve the energy efficiency of the evaporation process. Urbaniec et al. [

2] have suggested that heat recovery can be improved by retrofitting the evaporation process. Ensinas et al. [

3] have used a thermo-economic procedure to reduce steam consumption by the evaporation process. An analysis by Higa et al. [

4] shows that increasing the number of effects can decrease steam consumption. Bapat et al. [

5] have shown that steam consumption can be reduced by using heat recovery devices. Sharan and Bandyopadhyay [

6] have shown that steam consumption by the entire plant can be minimized by integrating the evaporator with the background process. Mechanical vapor compression [

7] and thermal vapor compression [

8] have been suggested as methods to increase the energy efficiency of the multiple-effect evaporator. The energy efficiency of the multiple-effect evaporator can also be increased by the optimum distribution of heating surface areas [

9,

10,

11,

12]. Recently, Chantasiriwan has shown that the energy efficiency of the cogeneration system, in which the evaporation process is a component, can be increased by replacing the forward-feed evaporator with the backward-feed evaporator [

13]. Investigations of sucrose inversion loss in sugar juice evaporation process have yielded conclusions that increased time between cleanings of the evaporator results in more inversion loss [

14]; inversion loss may be reduced by replacing Robert evaporators with falling-film evaporators [

15]; and using smaller diameter and longer tubes decrease inversion loss due to shorter residence time of juice in the evaporator [

16]. In addition, Rein [

17] has suggested that decreasing the temperature profile across the effects of the evaporator can also reduce inversion loss.

Energy efficiency of the evaporation process can be improved not only by reducing the steam consumption of a given pressure, which is the subject of most of the previous investigations, but also by decreasing extracted steam pressure. There is a lower limit of extracted steam pressure because the thermal energy input required for an evaporation process is approximately equal to the product of the total heating surface area of the evaporator and the difference between the steam temperature at the evaporator inlet and the vapor temperature at the evaporator outlet. The lower limit can be decreased by increasing the total heating surface area. Furthermore, it is interesting to note that vapor is usually bled from the first effect of the multiple-effect evaporator in order to be used for heating duty in the pan stage. This requirement imposes an additional constraint on the lower limit of the extracted steam pressure. It is possible to remove this constraint by using extracted steam instead of bled vapor for this purpose. A consequence of this constraint removal is further reduction of extracted steam pressure. Reduced extracted steam pressure results in not only higher energy efficiency but also lower sucrose inversion loss due to decreased temperature profile across the effects of the evaporator [

17].

In this paper, the performance of the conventional process, in which vapor bled from the multiple-effect evaporator is used for the pan stage, is compared with that of a modified sugar juice evaporation process, which uses extracted steam instead of bled vapor for heating duty in the pan stage. Mathematical models of the conventional and modified processes are presented in

Section 2 and

Section 3. Both processes operate in cogeneration systems described in

Section 4.

Section 5 shows that, under the same conditions, differences in energy efficiency and sucrose inversion loss can be attributed to the process modification.

2. Conventional Evaporation Process

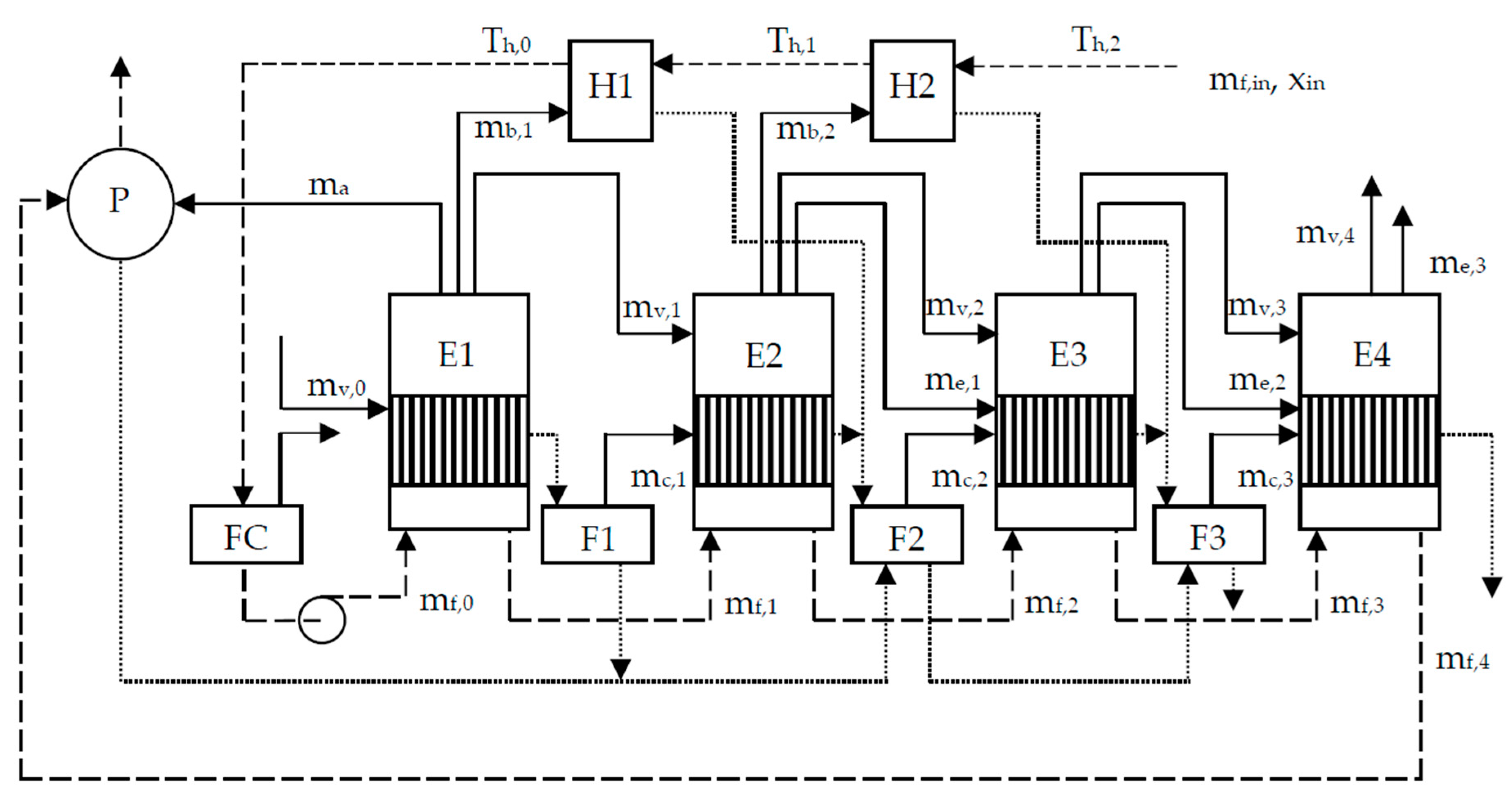

The conventional sugar juice evaporation process is shown in

Figure 1. The components of the process are 4 effects of the evaporator (E1, E2, E3, and E4), 2 heat exchangers of the juice heater (H1 and H2), the flash tanks (FC, F1, F2, and F3), and the pan stage (P). Sugar juice at the ambient temperature (

Th,2) is heated in H2 and H1 to the saturation temperature (

Th,0), which is 103 °C. This temperature corresponds to a pressure slightly larger than the atmospheric pressure (

patm). Juice pressure is decreased to

patm in FC before entering E1. Sugar juice and saturated steam or vapor flow from E1 to E4. The steam turbine (not shown in

Figure 1) supplies extracted steam at pressure

p0 to E1. Vapor from E1 is sent to P, H1, and E2. Vapor from E2 is sent to H2 and E3. Vapor from E3 is sent to E4. Vapor from E4 is sent to the condenser (not shown in

Figure 1). In effect

i, water evaporation at pressure

pi+1 is caused by vapor condensation at pressure

pi. Concentrated sugar juice from E4 is sent to P.

In order to improve the energy efficiency of the process, condensates from E1, E2, and E3 are sent, respectively, to F1, F2, and F3. F2 also receives condensates from P, F1, and H1, and F3 also receives condensates from F2 and H2. Flash tanks (F1, F2, and F3) produce vapor and condensate at a lower pressure from condensate at a higher pressure.

The model of the conventional evaporation process in

Figure 1 is similar to the model presented by Chantasiriwan [

13]. The difference between the two models is the treatment of condensate from E1. In the model presented by Chantasiriwan [

13], the condensate is sent to the boiler. In the model shown in

Figure 1, the condensate is sent to F1. It can be shown that this treatment increases the overall energy efficiency of the process.

Due to the similarity between this model and the model presented by Chantasiriwan [

13], only different equations are shown for the sake of concise presentation. The different treatment of condensate in this paper gives rise to the following energy equations:

Expressions for the other parameters are the same as those in the model presented by Chantasiriwan [

13], and an interested reader is asked to consult that reference. The heat transfer equations in this model are also slightly different from those in the model presented by Chantasiriwan [

13]. They are shown as follows.

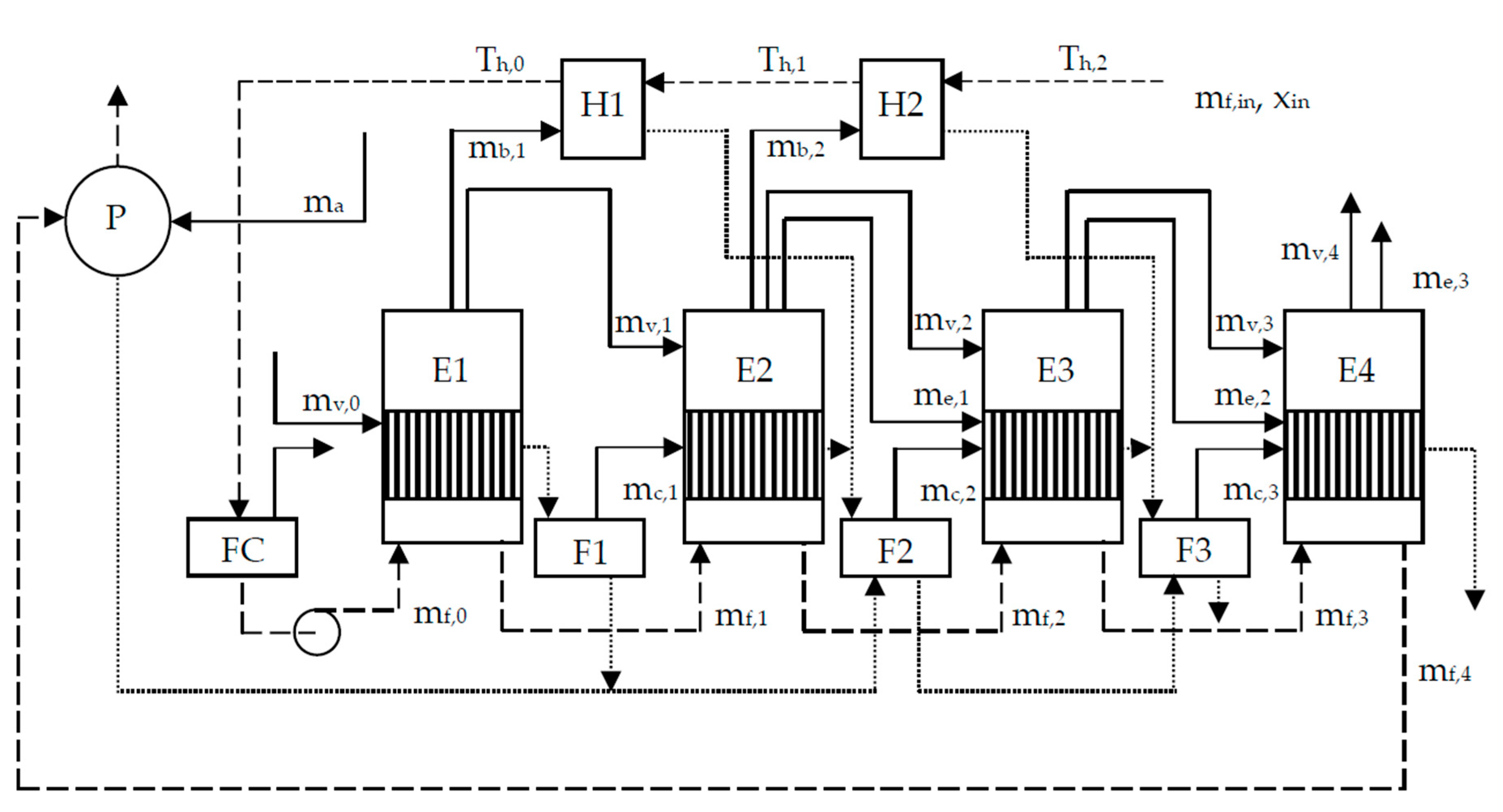

3. Modified Evaporation Process

The conventional evaporation process uses bled vapor from the first effect of the evaporator for the pan stage. A consequence of this requirement is that the extracted steam pressure (p0) must not be lower than the minimum value that corresponds to a specified juice mass flow rate. It is possible to remove this constraint by using extracted steam instead of bled vapor for the pan stage in the modified evaporation process.

The modified evaporation process is depicted in

Figure 2. It can be seen that extracted steam at pressure

pa is supplied to the pan stage. The model of this process is the same as that of the conventional process with

ma deleted from Equation (1). The mass flow rate of extracted steam required by the pan stage is

It is interesting to note that, under the same operating conditions, mf,4, x4, and p4 of the modified and conventional evaporation processes are identical. Therefore, the values of ma of both processes are the same if pa = 150 kPa.

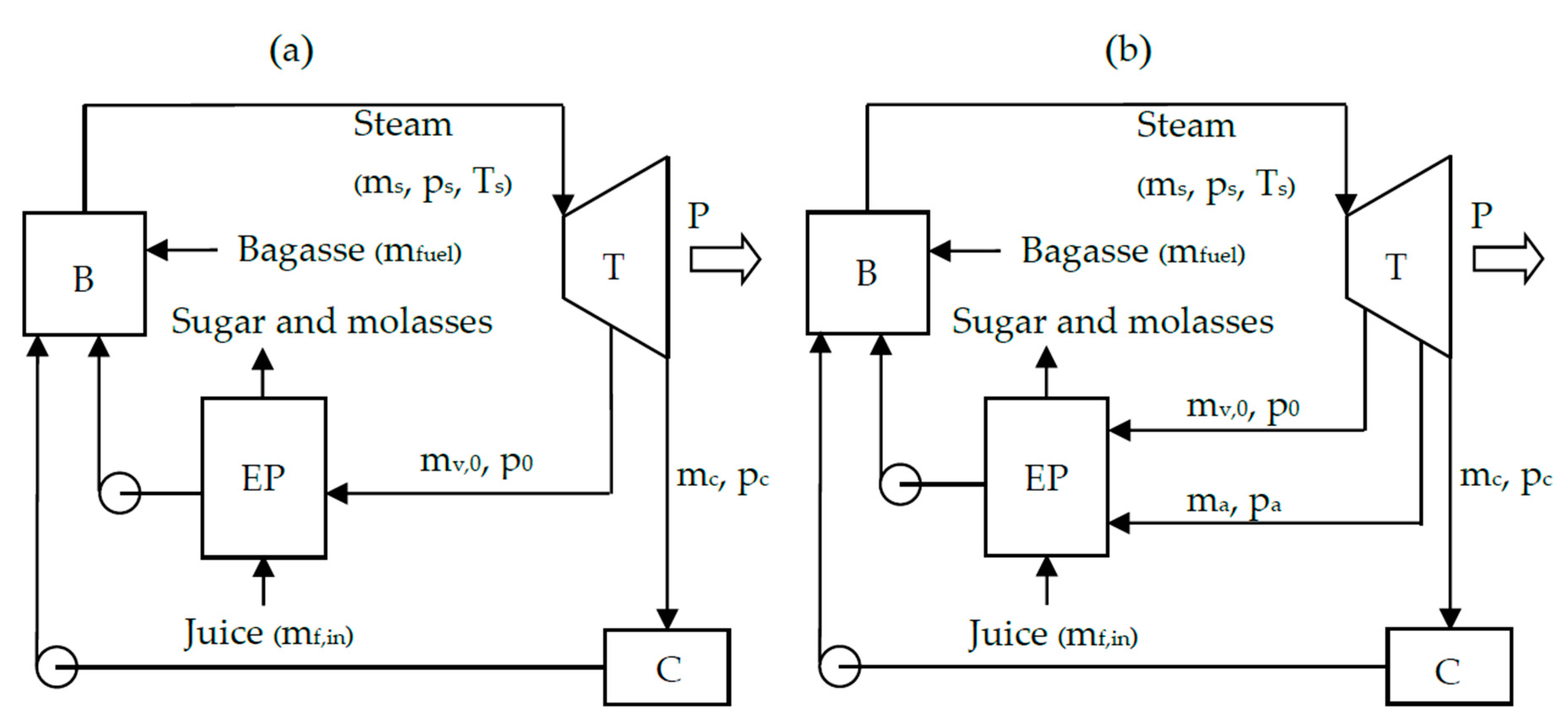

5. Results and Discussion

The parameters of both evaporation processes are xin = 15%, xout = 70%, p4 = 16 kPa, and Th,2 = 30 °C. In each process, the total surface areas of the multiple-effect evaporator and the juice heater are, respectively, 13,000 and 2500 m2. Multiple-effect evaporators in both systems are designed to process 125 kg/s (or 450 t/h) of juice. The optimum distribution of the total evaporator surface area that maximizes the steam economy at a specified extracted steam pressure (p0) may be determined for each system.

The procedure for determining the optimum distribution of the evaporator surface area in the conventional evaporation process that maximizes the steam economy (

SE) is shown in

Figure 4.

Figure 4a shows that, for the first-effect area (

A1) of 6000 m

2 and the second-effect area (

A2) of 1200 m

2, the optimum value of the third-effect area (

A3) that yields the required juice mass flow rate of 125 kg/s and the maximum steam economy (

SE) is 1233 m

2.

Figure 4b shows that, for the same value of

A1, the optimum value of

A2 that results in maximum

SE is 1251 m

2.

Figure 4c shows that, as

A1 increases,

SE decreases, and first-effect pressure (

p1) increases. By requiring that

p1 is 150 kPa, the optimum value of

A1 is found to be 4518 m

2. The corresponding value of

SE is 2.508. Therefore, the mass flow rate of extracted steam for the evaporator (

mv,0) is 41.63 kg/s.

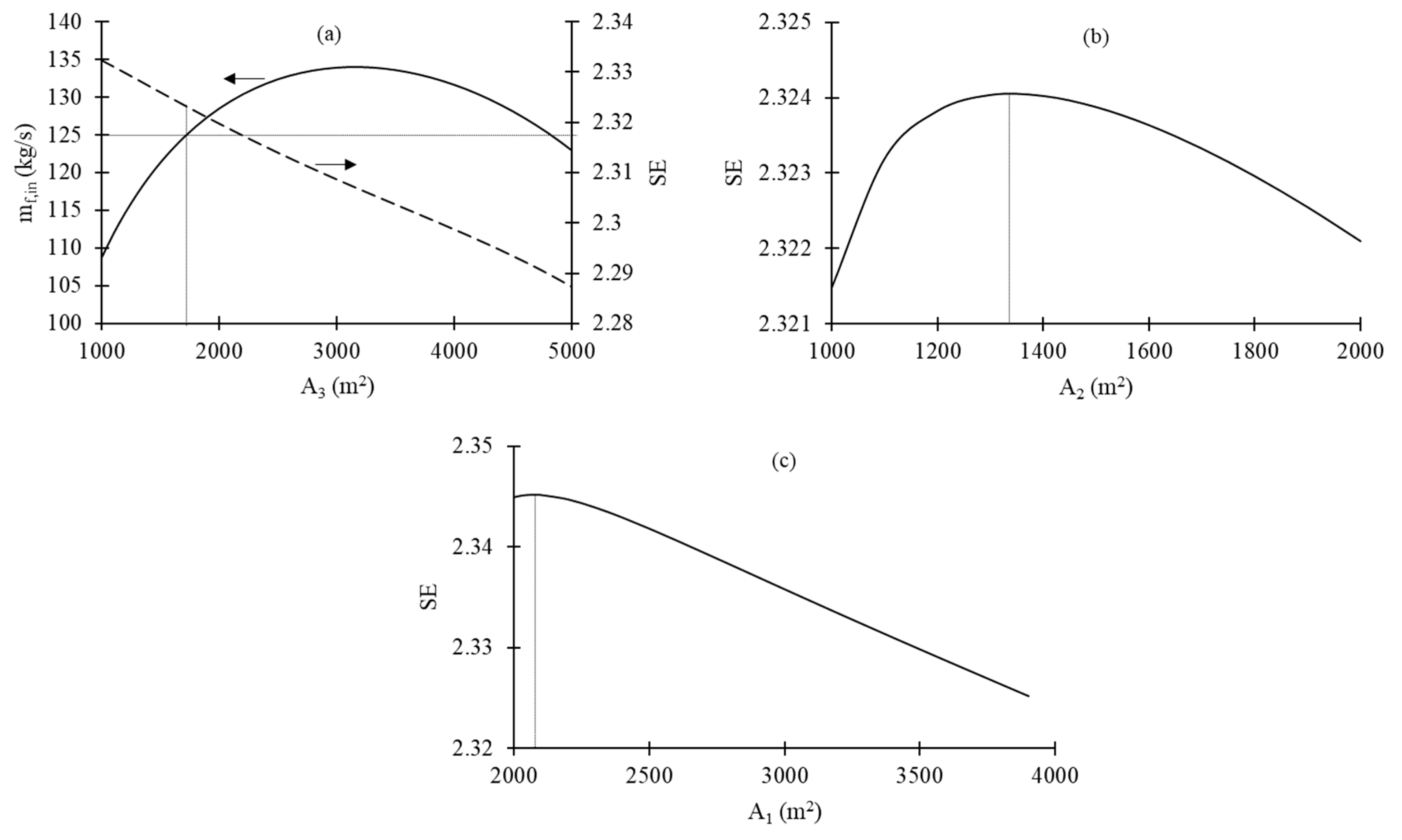

The procedure for determining the optimum distribution of evaporator surface area in the modified evaporation process that maximizes

SE is shown in

Figure 5.

Figure 5a shows that, for the first-effect area (

A1) of 4000 m

2 and the second-effect area (

A2) of 1100 m

2, the optimum value of the third-effect area (

A3) that yields the required juice mass flow rate of 125 kg/s and the maximum

SE is 1723 m

2.

Figure 5b shows that, for the same value of

A1, the optimum value of

A2 that results in the maximum

SE is 1342 m

2.

Figure 5c shows the optimum value of

A1 that results in the maximum

SE is 2074 m

2. The corresponding value of

SE is 2.345. Since the mass flow rate of juice leaving E4 (

mf,4) is 26.79 kg/s, and the mass flow rate of extracted steam for the pan stage (

ma) is 13.16 kg/s, the value of

mv,0 is found to be 31.53 kg/s.

The calculation of the turbine power output (

P) of a cogeneration system requires information about the fuel, the boiler, and the steam turbine. It is assumed that the fuel consumption rate in the boiler of each system is 21 kg/s, the higher heating value of fuel is 9000 kJ/kg, the boiler efficiency is 70%, the pressure and temperature of superheated steam generated by the boiler are 4.5 MPa and 440 °C, and the turbine efficiency is 85%.

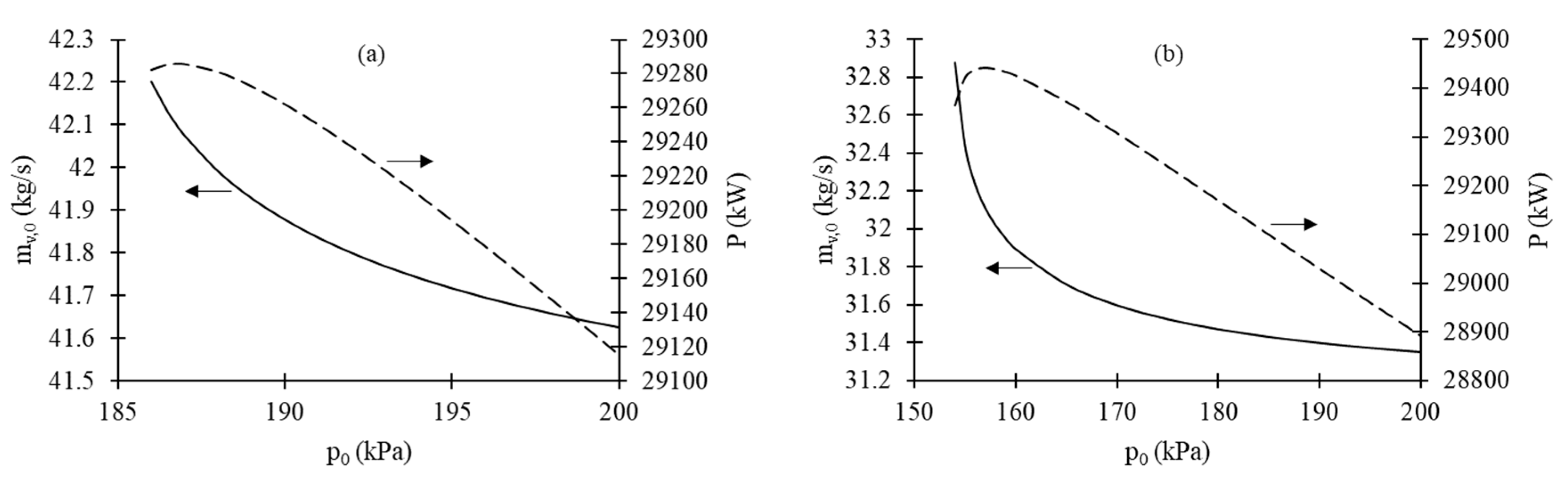

Figure 6 shows variations of

mv,0 and

P with

p0 in cogeneration systems for the conventional and modified evaporation processes that have the optimum distributions of evaporator surface areas. It can be seen that, in each system, there exists the optimum value of

p0 (

p0,opt) that results in the maximum turbine power output (

Pmax). In the cogeneration system for the optimum conventional evaporation process,

p0,opt is 186.8 kPa, and

Pmax is 29,286 kW. In the cogeneration system for the optimum modified evaporation process,

p0,opt is 157.0 kPa, and

Pmax is 29,442 kW. It is interesting to compare the cogeneration systems for the optimum modified evaporation process and a non-optimum conventional evaporation process, in which

p0 is 200 kPa. The non-optimum conventional process has the same juice processing capacity as the optimum conventional process, but it is less energy efficient. The value of

SE in this process is 2.411, and the value of

mv,0 is 43.31 kg/s. The turbine power output of the cogeneration system that uses this process is 28,789 kW, which is 2.3% lower than the turbine power output of the cogeneration system that uses the optimum modified evaporation process.

Table 1 shows simulation results of cogeneration systems for the non-optimum conventional evaporation process, the optimum conventional evaporation process, and the optimum modified evaporation process.

Table 1 shows that steam and vapor pressures in the optimum modified evaporation process are lower than those in the non-optimum and optimum conventional evaporation processes. Sucrose inversion losses in all effects of evaporators in the three processes are compared in

Table 2. It can be seen that sugar inversion loss is largest in the first effect of each process. Sucrose inversion loss in the first effect of the optimum modified evaporation process has the lowest value due to the smallest extracted steam pressure and temperature. As a consequence, the total sucrose inversion loss of the optimum modified evaporation process is 63% lower than that of the non-optimum conventional evaporation process.