Abstract

Pressing issues such as a growing energy demand and the need for energy diversification, emission reduction, and environmental protection serve as motivation for the utilization of biomass for production of sustainable fuels. However, use of biomass is currently limited due to its high moisture content, relatively low bulk and energy densities, and variability in shape and size, relative to fossil-based fuels such as coal. In recent years, a combination of thermochemical treatment (torrefaction) of biomass and subsequent pelletization has resulted in a renewable fuel that can potentially substitute for coal. However, production of torrefied wood pellets that satisfy fuel quality standards and other logistical requirements typically requires the use of an external binder. Here, we describe the development of a renewable binder from proteinaceous material recovered from specified risk materials (SRM), a negative-value byproduct from the rendering industry. Our binder was developed by co-reacting peptides recovered from hydrolyzed SRM with a polyamidoamine epichlorohydrin (PAE) resin, and then assessed through pelleting trials with a bench-scale continuous operating pelletizer. Torrefied wood pellets generated using peptides-PAE binder at 3% binder level satisfied ISO requirements for durability, higher heating value, and bulk density for TW2a type thermally-treated wood pellets. This proof-of-concept work demonstrates the potential of using an SRM-derived binder to improve the durability of torrefied wood pellets.

1. Introduction

In recent years, torrefaction of biomass has gained popularity for its ability to improve the fuel properties of the treated material [1,2,3,4,5,6]. In torrefaction, biomass is heated in the temperature range of 200–300 °C in the absence or very limited supply of oxygen, typically for 1 h. This pre-treatment of biomass removes volatiles and yields a thermally treated product (called torrefied biomass) that typically contains 70% of the mass, but 90% of the energy, of the original crude biomass. The conversion results in a product with an energy density that is roughly 1.3 times higher on a mass basis [1,2]. Additionally, torrefaction of biomass results in a significantly reduced moisture content, and improved grindability and hydrophobicity [1,2,3,7], which are all desirable attributes for a fuel destined for co-combustion in coal-firing power plants.

Despite the improved qualities achieved through torrefaction, the torrefied biomass has a lower volumetric energy density (typically 4–5 GJ/m3) than that of coal (18–24 GJ/m3) [4], and the process of torrefaction leads to increased dust formation, which poses difficulties for handling and transportation [1,2,4]. The combination of torrefaction and densification (i.e., by pelletization) has been reported to resolve these issues [2,3,7,8]. Torrefied wood pellets have bulk density of up to 850 kg/m3 and a net calorific value in the range of 20–24 MJ/kg, corresponding to a volumetric energy density of 14–18.5 GJ/m3 [4,7], which is comparable to that of sub-bituminous coal (16–17 GJ/m3) [7]. Consequently, torrefied wood pellets, which are also referred to as densified biocoal [1,3,4], are becoming an attractive renewable fuel for major end-use applications such as co-firing and co-gasification in coal fired powerplants [4,8,9,10].

Even though torrefied wood pellets have several attractive properties and are in many cases superior fuels compared to untreated biomass and biopellets, pelletization of torrefied biomass is more technically challenging and energy intensive compared to pelletization of raw biomass [3,11,12,13,14,15,16]. Hence, significant research interest has focused on making the pelletization process easier and/or improving the durability of pellets without compromising fuel quality. The use of external binders in the pelletization process has been shown to reduce the energy required for pelletization and/or result in more durable pellets [3,17,18,19].

Through a detailed analysis of two different process schemes on producing biocoal, Ghiasi et al. concluded that a binder is necessary for pelletization of torrefied wood with reasonable energy consumption [3]. The effect of additives/binders such as lignin, starch, saw dust, caster bean cake, peanut shell, calcium hydroxide, and sodium hydroxide on pelletization of torrefied biomass has been investigated [17,18,19,20]. However, in these studies, the binders/additives were used at much higher levels (up to 30%) than allowable by current International Organization for Standardization (ISO) guidelines (≤4%) for premium quality pellets made from thermally treated wood [21]. Additionally, the pellets made with starch had lower bulk density and durability [18]. Two recent reports have thoroughly reviewed the availability of proteinaceous feedstocks and various approaches of developing protein-based adhesives for bonding of cellulosic materials, uncovering the tremendous potential of this renewable resource for development of protein-based wood adhesives/binders [22,23]. In this perspective, proteinaceous material constitutes an attractive feedstock for the development of binders/additives for pelletization of torrefied wood.

Over the years, our group has developed a technology platform for chemical conversion of specified risk materials (SRM), a proteinaceous waste from the rendering industry, into valuable products such as adhesives [24,25,26], plastics [27], and composites [28]. Recently, we demonstrated that adhesive formulations consisting of 78% peptides and 22% polyamidoamine epichlorohydrin (PAE) resin (dry weight basis) satisfied the performance requirement of the American Standard of Testing and Materials (ASTM) as a plywood adhesive [24]. PAE resin contains azetidinium (four-membered cyclic structure consisting of a quaternary nitrogen atom) functional groups that can easily react with amine, carboxyl, and hydroxyl groups. Hence, the PAE resin acts as a co-reactant for chemical crosslinking of protein/peptides, thus imparting mechanical strength and enhancing adhesive property of protein/peptides-based adhesive formulations for bonding of cellulosic materials [24,25,29,30]. Herein, we report on the potential of an SRM protein-based binder (78% peptides and 22% PAE resin) for pelletization of torrefied wood, as well as the fuel quality of resulting pellets.

2. Materials and Methods

2.1. Materials and Chemicals

The torrefied wood used in this study was kindly supplied by Airex Energie (Laval, QC, Canada). According to the information provided by the supplier, the feed material was spruce/fir sawdust, and the torrefied material had undergone 30% weight loss on a dry mass basis. This mass loss (30%) upon oven drying is the same value that has been found to be suitable for production of good quality pellets from torrefied SPF (spruce, pine, fir) [13,17]. The SRM was supplied in dried, ground form by a local rendering industry. The received SRM sample was handled following the safe handling and disinfection protocol recommended by the Canadian Food Inspection Agency (CFIA) [31,32]. Kymene™ 557H resin purchased from Solenis (Wilmington, DE, USA) was used as a representative PAE resin. As per the supplier’s information, the PAE resins contained 12.5% solids.

The protein/peptide standards for molecular size distribution analysis of hydrolyzed SRM were purchased from Sigma Aldrich (St. Louis, MO, USA) as lyophilized powders. High purity High Performance Liquid Chromatography (HPLC) grade water, acetonitrile (99.9%), and hexane (99.9%) were purchased from Fisher Scientific (Hampton, NH, USA). The filter paper employed for vacuum filtration was Whatman no. 4 filter paper (GE Healthcare, Chicago, IL, USA), and was procured from Fisher Scientific.

2.2. Methods

2.2.1. Thermal Hydrolysis of SRM and Recovery and Characterization of Peptides

Regulations set by the Canadian Food Inspection Agency (CFIA) require segregation, removal, and disposal of SRM from slaughtered cattle [31,32]. One of the CFIA approved methods of SRM disposal is thermal hydrolysis at minimum conditions of 180 °C and 1200 kPa for 40 min per cycle [32]. In this study, thermal hydrolysis of SRM and recovery of hydrolyzed protein fragments (referred to as peptides hereafter) from the hydrolysate was achieved following our standard protocol [24,26,28,33]. A high-temperature and high-pressure stainless-steel Parr reactor vessel (5.5 L capacity, Parr 4582, Parr Instrument Company, Moline, IL, USA) equipped with Parr reactor controller (Parr 4848, Parr Instrument Company, Moline, IL, USA) was used for thermal hydrolysis of SRM. In a typical run, 1 kg of SRM was mixed with 1 kg of distilled water in the Parr reactor vessel, and then subjected to hydrolysis at 180 °C and ≥174 psi pressure for 40 min. Recovery of peptides was achieved by diluting the hydrolysate with distilled water (hydrolysate: water ratio = 1:4.5, w/v), agitating the slurry at 200 rpm in a shaker (Innova lab shaker, New Brunswick, Canada) for 10 min, and then allowing the mixture to settle for 10 min. The aqueous fraction was decanted, and then subjected to centrifugation (Avanti J-26 XP high-performance centrifuge, Beckman Coulter, Mississauga, ON, Canada) at 7000× g for 40 min. The supernatant was then subjected to vacuum filtration (Whatman no. 4 filter paper, 20–25 µM pore size) to remove any insoluble, if present. The collected filtrate was then washed with hexane (1:1 ratio) three times to remove any residual lipids and/or long-chain fatty acids. Lyophilization of the aqueous fraction afforded a tan colored proteinaceous cake representing 34 ± 2% of the feed material. Prior to hydrolysis, the SRM sample was considered as biohazardous material, and was handled by practicing the safety measures as described in previous reports [24,26,28,33].

The recovered peptides were characterized following the standard characterization methods being practiced in our lab, which comprises analyzing elemental composition, end functional groups (carboxyl and amines), and molecular size distribution by size exclusion high performance liquid chromatography (SEC-HPLC) [24,33]. An Agilent Technologies 1200 series HPLC (Agilent Technologies, Santa Clara, CA, USA) was used for SEC-HPLC analysis of peptides recovered from SRM hydrolysates. The HPLC was equipped with an autosampler and variable wavelength UV detector, and size exclusion was achieved using two size exclusion columns—Superdex™ 200 and Superdex™ Peptide (GE Healthcare Biosciences AB, Uppsala, Sweden)—connected in series, and using 5% acetonitrile in 0.15 M phosphate buffer (pH 9.0) at a flow rate of 0.5 mL/min. Solutions of HPLC standards were prepared using 0.15 M phosphate buffer (pH 9.0). The concentrations of the prepared standards were as follows: Blue dextran, 5 mg/mL; alcohol dehydrogenase, 3 mg/mL; albumin, 5 mg/mL; carbonic anhydrase, 3 mg/mL; cytochrome C, 2 mg/mL; aprotinin, 8 mg/mL; and vitamin B-12, 5 mg/mL. A standards mixture was prepared by combining 1 mL of each of the individual standards, with 5 µL of the mixture injected for each HPLC run. In order to ensure batch-to-batch reproducibility of the starting material (peptides), thermal hydrolysis as well as analysis of recovered peptides were conducted in at least three replicates.

2.2.2. Binder Formulation and Characterization

The SRM peptides-based binder was used as a wet formulation, and was prepared as described in a previous report [24]. In a typical experiment, an aqueous solution of peptides prepared by dissolving 35.0 g of peptides in 105 g water was mixed with 80.0 g PAE resin (solid content = 12.5%), and the resulting slurry was stirred for 2 h at room temperature prior to mixing with ground torrefied wood. In the prepared formulation, the ratio of peptides:PAE resin is 78:22 on a dry weight basis.

Lyophilization of the peptides-PAE wet formulation produced a tan colored powder, which was characterized by molecular size distribution and analysis of thermal properties. Molecular size distribution studies were conducted by SEC-HPLC as described in 2.2.1. TA Instruments Q100 Differential Scanning Calorimeter (DSC) and Q50 Thermogravimetric Analyzer (TA Instrument, New Castle, DE, USA) were used for Temperature Modulated Differential Scanning Calorimetry (TMDSC) studies and Thermogravimetric Analysis (TGA) of the binder, respectively. In DSC studies, temperature was modulated in the range of −50–150 °C at a heating rate of 1 °C/min. The thermogravimetric analysis was conducted up to 600 °C at a heating rate of 10 °C/min.

2.2.3. Pelletization of Torrefied Wood

Prior to pelletization trials, the torrefied wood feedstock was pre-processed, which involved grinding and sieve-screening to ≤3.18 mm (≤1/8”). The ground torrefied feedstock was moisturized to the desired level (~18.5 wt.%) in a horizontal stand mixer (Hobart N-50 mixer, Hobart Canada, Edmonton, Canada) along with addition of binders at the pre-requisite loadings. Pelletization experiments were conducted using a laboratory scale Kahl flat-die pelletizer (Kahl GmbH, Germany) equipped with a flat die press having 6.35 mm die holes and a length of 21.2 mm. The maximum die temperature noted during pelleting was in the range of 80–85 °C. The collected pellets were air dried at ambient conditions for 20–24 h, and then subjected to durability testing.

2.2.4. Analysis of Untreated Wood, Torrefied Wood, and Wood Pellets

The fuel quality of untreated wood (before torrefaction), torrefied wood, and torrefied wood pellets was evaluated through analysis of calorific value and bulk density. An isothermal oxygen bomb calorimeter consisting of four units (1241 Oxygen Bomb Calorimeter, 1710 Calorimeter Controller, 1108 Oxygen Combustion Bomb, and 1541 Water heater (Parr Instruments, Moline, IL, USA)) was employed to determine the calorific value of the torrefied wood pellets as per ASTM D5865-13. The bulk density of different materials was analyzed by evaluating the mass of a given volume of the substance following ASTM 6393. Analysis of chlorine content was performed using Instrumental Neutron Activation Analysis (SLOWPOKE Nuclear Reactor Facility, University of Alberta, Canada).

Durability index (DI) is a measure of the ability of pelletized fuels to resist degradation due to shipping and handling. The durability tests were conducted using a Continental AGRA Equipment Inc (USA) manufactured Dual Tumbler made up of dust tight boxes, with a diagonal baffle to emulate mixing as per ASAE S269.4 methodology. The tumbler simulates the amount of breakage that normally occurs between pellet formation and pellet use. In a typical test, 500 g of pre-screened pellets were tumbled for 10 min at 50 rpm in a dust tight chamber. Durability Index (%) is determined by dividing the post-tumbled weight by the pre-tumbled weight, and multiplying by 100 as shown below:

3. Results and Discussion

3.1. Characterization of Peptides

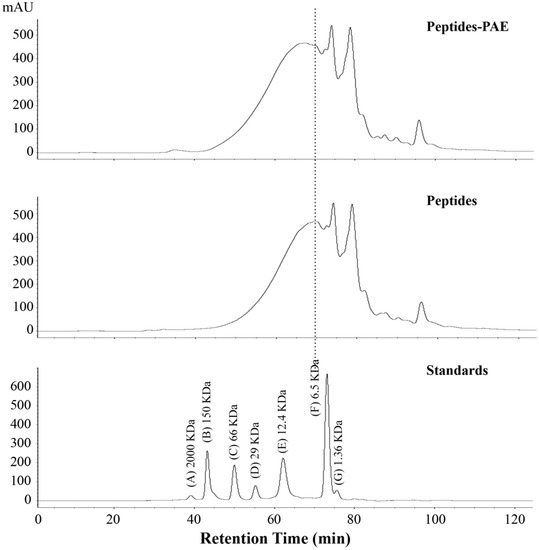

The peptides recovered from SRM hydrolysates were characterized by elemental analysis (C, H, N and S), end functional group determination (-NH2 and -COOH), and molecular size distribution analysis (by SEC-HPLC) to ensure batch-to-batch reproducibility, and also to confirm that peptides recovered in these experiments were consistent with those generated in previous studies. The elemental composition and chemical functionality (Table 1) confirmed batch to batch reproducibility and also indicated that the peptides recovered in this study were identical to the peptides recovered in previous studies [24,25,33]. The molecular size of recovered peptides ranged from as small as dipeptides to those having molecular weight of 66 KDa (referenced with albumin in SEC-HPLC). The majority of peptides have molecular weights in the range of 1.36–12.4 KDa (Figure 1), which was again consistent with our previous studies [24,25,33].

Table 1.

Elemental composition and functional group analysis of peptides recovered from hydrolyzed Specified Risk Materials (SRM).

Figure 1.

SEC-HPLC chromatograms of peptides and peptides-PAE binder formulation. The standards are (from left to right): Blue dextran (A; MW: 2000 KDa), alcohol dehydrogenase (B; 150 KDa), albumin (C; 66 KDa), carbonic anhydrase (D; 29 KDa), cytochrome C (E; 12.4 KDa), aprotinin (F; 6.5 KDa) and vitamin B-12 (G; 1.36 KDa). The molecular weight of the peptides ranged from as small as dipeptides to as large as that of albumin (66 KDa). The majority of peptides have molecular weight in the range of about 1.36–12.4 KDa. The peptides-PAE formulation had limited solubility in water; analysis of the water-soluble fraction showed a general shift towards higher molecular weight species. The dotted line was added as a visual reference.

3.2. Thermal Properties of Peptides-PAE Binder

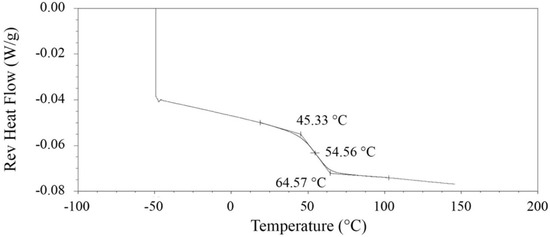

A review of available literature on pelletization of torrefied wood indicated that one of the most important requirements for obtaining good quality pellets is that the die temperature used for pelletization corresponds to that at which softening and/or melting of the binder occurs [4,7,8,13,14,15,16,17]. Hence, identifying the glass transition temperature (Tg) of the binder was essential for selecting the pelletization parameters. However, no obvious phase change behavior was observed in differential scanning calorimetry (DSC) of peptides-PAE binder, and Tg of the binder was not discernible in conventional DSC. Accordingly, temperature modulated differential scanning calorimetry (TMDSC) of the binder was conducted, and Tg of peptides-PAE binder was assessed from the plot of reversing heat flow rate as a function of temperature in standard TMDSC of the binder (Figure 2). As evident from the TMDSC plot, onset of glass transition occurred at 45.33 °C and ended at 64.57 °C, the midpoint being measured as 54.56 °C. This suggests that the glass transition (softening) of peptides-PAE binder occurs at about 55 °C, which is a very convenient temperature range for pelletization at industrial scale. Nevertheless, it should also be noted that the glass transition of wood components, which are generally much higher than the glass transition of the binder of this study, also have substantial impact on the mechanical strength/durability of pellets, and must be taken into account in pelleting experiments.

Figure 2.

Reverse heat flow rate as a function of temperature in temperature modulated differential scanning calorimetry (TMDSC) of the peptides-PAE binder. Parameters of modulation: Equilibrated at −50 °C, heating rate = 1 °C/min, modulation period = 60 s, isothermal for 3 min, amplitude of program temperature = 2 °C/min to 150 °C.

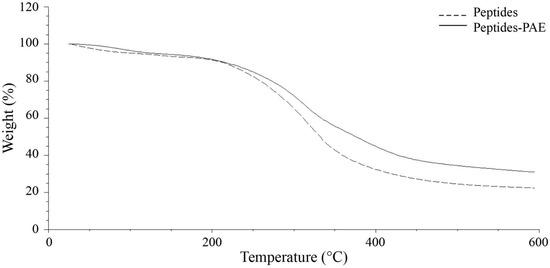

Thermogravimetric analysis was then conducted to determine the degradation temperature of the peptides-PAE binder. The typical plot of weight (%) of a sample of the binder as a function of increasing temperature indicates that the thermal degradation of the binder started at around 190 °C, before which it had undergone small weight loss in two steps (Figure 3). An initial weight loss of about 4% occurring in the temperature range up to 100 °C is attributed to the loss of unbound water (moisture). A shallow weight loss occurring from 100 °C to around 190 °C is likely due to the loss of bound (H-bonded) water and low molecular weight compounds. The TGA plot infers that the onset of thermal degradation of peptides-PAE binder occurs at around 200 °C. From the onset of thermal degradation, one step weight loss occurred up to 500 °C due to the continuous decomposition of the polymer and formation of gaseous reaction products. After the decomposition of the binder, nearly 30–32% mass remained as carbon black.

Figure 3.

Thermogravimetric analysis of peptides and the peptides-PAE formulation. Amplitude of program temperature = 10 °C/min to 600 °C.

3.3. Bulk Density and Calorific Value of Raw and Torrefied Wood Chip Feedstocks

On a wet weight basis, the bulk density of torrefied biomass is lower than that of the raw biomass (Table 2). This is attributable to the fact that torrefaction results in removal of volatiles from inside of the particles with insignificant reduction in particle size [13,14,17]. On a dry basis, however, the torrefied wood chips had higher bulk density than the raw wood chips (Table 2), which is due to the removal of moisture and volatiles in the torrefied product. After torrefaction, the high heating value was measured at 22.5 ± 0.1 MJ/Kg, compared to 19.7 ± 0.1 MJ/Kg of raw wood chips (based on analytical duplicates).

Table 2.

Bulk density and calorific value of raw wood chips and torrefied wood used in this study.

3.4. Pelletization and Analysis of Torrefied Wood Pellets

3.4.1. Pelletization of Torrefied Wood

Pellet durability is one of the most important parameters that determines the quality of torrefied wood pellets. Dense and strong pellets—characterized by high mechanical strength—have minimum breakage during handling, transportation, and storage, which translates to improved tradability of the pellets. Verhoef et al., suggested that pelletizing torrefied wood requires a proper balance of material quality (e.g., degree of torrefaction), particle size, moisture content, binder, as well as the thickness, hole size and temperature of the pelleting die [2]. For our experiments, the length and bore diameter of the pelleting die were 21.2 mm and 6.35 mm, respectively, and the torrefied wood was ground to ≤3.18 mm (≤1/8”) particle size. The optimal moisture content employed for the pelletization experiments was 18.5%, which was assessed from preliminary experiments evaluating the durability of pellets made from torrefied wood pre-conditioned with moisture content in the range of 16–30%. It should be noted that the temperature of the pelleting die was 80–85 °C, which is well above the glass transition of the peptides-PAE binder (Figure 2).

According to the International Standard for fuel specifications and classes of solid biofuels (ISO/TS 17225-8:2016), the specifications for the highest quality classes (TW1a and TW2b) of thermally-treated wood pellets require that the additives/binders should be ≤4 wt% on a dry mass basis [21]. On the other hand, specifications from International Maritime Organization (IMO) require that the additives in torrefied wood pellets cannot be more than 3% if they have to be transported through marine vessels. Hence, in our experiments, the effect of binder on the qualities of torrefied wood pellets was evaluated at a 2% and 3% binder level.

The bulk density as well as durability of pellets are important quality parameters for bulk handling, storage, and transportation of pellets as a commodity fuel [34]. Whereas the bulk density refers to the mass of a given volume of pellets, the durability index indicates the mechanical strength and resistance of pellets against breakage and dust formation when handled during storage and transportation. Both of these characteristics were examined to assess the potential of using peptides-PAE as a binder for torrefied wood pellets.

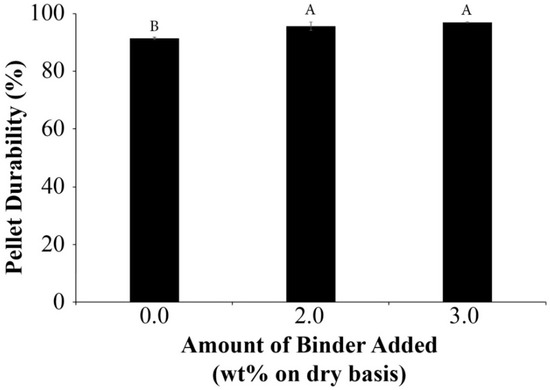

3.4.2. Pellet Durability

In the absence of a binder (control experiment), the torrefied wood pellets had an average durability of 91.4 ± 0.3% (Figure 4). The addition of peptides-PAE binder at a 2% level significantly improved the durability of pellets, resulting in an average durability of 95.6 ± 1.4%. On further increasing the binder level to 3%, the average durability of resulting pellets was found to be 96.9 ± 0.2%. The fuel specification standards of ISO/TS 17225-8 for thermally treated wood pellets of TW2a property class requires a minimum durability of 95%. Thus, it is worth mentioning that although there was no statistical difference in the average durability achieved using either 2% or 3% of the peptides-PAE binder, one of the three trials using 2% binder had a durability index of 94.0%; the other two values obtained were both 96.4%. Conversely, the lowest durability index observed using a peptides-PAE binder level of 3% was 96.8%, which was achieved in two of the three trials, with the final value obtained being 97.2%. Thus, the torrefied wood pellets generated using 3% of the peptides-PAE binder satisfied the durability requirement of ISO for TW2a class wood pellets.

Figure 4.

Effect of binder level on durability of torrefied wood pellets produced using a bench scale pelletizer. The peptides-PAE binder was generated using 22% PAE resin and 78% SRM peptides on a dry weight basis. The pre-pelletization moisture content was 18.5% and the pelleting die temperature was in the range of 66–85 °C. Triplicate experiments were conducted for pelletization experiments and pellet durability analysis, and the results are presented as average ± standard deviation. Means that do not share a letter are significantly different (Tukey HSD test, 95% confidence level).

The polar functional groups of the peptides-PAE formulation (e.g., hydroxyl, amide, amine, and carboxyl) are expected to enhance attractive intermolecular forces such as polar interactions and hydrogen-bonded connections amongst the wood particles and binder. Additionally, as the peptides-PAE formulation has demonstrated its excellent ability as a binder for wood veneers [24], it is likely that the added binder improves the adhesion forces among the torrefied wood particles and enhances the mechanical strength. Additives such as protein, starch, and lignin have been found to be effective for improving the durability of torrefied and/or biochar pellets through the enhancement of adhesive forces, formation of solid bridges and hydrogen bonded interactions, leading to an improved close-knit structure of wood polymers/particles in pellets [17,19]. It should be noted that since the feedstock was ground to fine powder before pelletization, contributions from mechanical interlocking of particles is minimal. Hence, the forces of adhesion and cohesion are likely the major players in the observed durability of pellets made with peptides-PAE binder. The added binder is expected to have appreciable forces of cohesion due to chemical crosslinking, and it enhances the forces of adhesion by introducing attractive forces such as non-covalent interactions and hydrogen bonding among the particles.

3.4.3. Bulk Density and Heating Value of Torrefied Wood Pellets

The bulk density of torrefied wood pellets produced by using peptides-PAE binder (3% binder level) were compared with that of pellets made without binder (control pellets). The torrefied wood pellets made without a binder and with 3% peptides-PAE had bulk densities of 654 ± 33 kg/m3 and 679 ± 26 kg/m3, respectively (Table 3). It should be noted that the two values are not statistically different, which indicates that the addition of our binder did not negatively impact the bulk density of the resulting torrefied wood pellets, while at the same time improving pellet durability (Figure 4). The average bulk density of the torrefied wood feedstock used in this research was 177 ± 3 kg/m3 (Table 2), which indicates that after pelletization, the bulk density was enhanced by a factor of ~3.8.

Table 3.

Comparison of bulk density and gross heating value of torrefied wood pellets (dry basis) made with or without binder.

It is also worth mentioning that the fuel specification standards of ISO/TS 17225-8 for thermally treated wood pellets of TW2a property class requires a minimum bulk density of 650 kg m−3. While there was no statistical difference with regards to the bulk densities of torrefied wood pellets obtained, the measured bulk densities for the 3 batches of pellets made without the use of a binder were 692 kg m−3, 638 kg m−3, and 632 kg m−3, indicating that 2 of the 3 batches were below the International Organization for Standardization Technical Specification (ISO/TS) 17225-8 requirement. Conversely, for the batches made with 3% peptides-PAE, a bulk density below 650 kg m−3 was not observed (673 kg m−3, 707 kg m−3, and 656 kg m−3).

The calorific values of the torrefied wood pellets generated with and without a binder were measured (Table 3). As the gross heating value reported was obtained from analytical duplicates, a conclusive comparison cannot be made between the torrefied wood pellets made with and without binder. Nevertheless, the data obtained suggest that the torrefied wood pellets made using 3% peptides-PAE binder may possess a heating value that would satisfy the ISO/TS 17225-8 fuel specification standards for TW2a property class pellets. It is also worth mentioning that for the pellets made with peptides-based binder, the final moisture content varied from 2.08 to 6.87, which is less than the 8% limit for TW2a pellets.

3.4.4. Chlorine Content

ISO/TS 17225-8 specifies that the chlorine content for thermally treated wood pellets of the fuel quality TW2a class should be ≤0.05%. Analysis of chlorine content indicated that pellets made with the peptides-PAE binder have an average chlorine content of 1200 ± 20 µg/g, which translates to 0.12%. In contrast, pellets made without a binder had an average chlorine content of only 8 ± 1 µg/g. The relatively high chlorine content of wood pellets is likely associated with the risk of corrosion due to emission of HCl gas as effluent while burning the pellets. Thus, the chlorine content of pellets made with peptides-PAE will need to be reduced.

The peptides recovered from SRM hydrolysis contain an average of 1.77 ± 0.09% inorganic chloride. Although the PAE resin is also a source of chlorine in the pellets, since the binder formulation consist of 78% peptides and 22% PAE resin, the major contribution to chlorine in the pellets is most likely from peptides. To address this concern, we examined the possibility of adding an SRM washing step to our thermal hydrolysis protocol. Briefly, 200 g of SRM were washed with Milli-Q water, after which the mass of the wet SRM was brought up to 400 g, then subjected to our standard thermal hydrolysis process. Using this methodology, the chlorine content of the resulting peptides was reduced to 0.513 ± 0.059%. In future pelletization experiments, the SRM pre-washing step will be incorporated to minimize chlorine levels.

4. Conclusions

In this research, we explored the potential of using peptides recovered from a negative-value proteinaceous waste from the meat industry as a binder for pelletization of torrefied wood. Our peptides-based binder formulation, which consisted of 78% peptides and 22% PAE resin (dry weight basis), demonstrated remarkable potential as a binder for pelletization of torrefied wood. The torrefied wood pellets obtained using our peptides-PAE binder at a 3% binder level had a net calorific value of ~21 MJ/kg, as well as a durability index and bulk density that satisfied the specifications of ISO/TS 17225-8:2016 for thermally treated wood pellets of the TW2a property class. Although the chlorine content of these pellets was higher than the ISO requirement, prewashing of the SRM prior to thermal hydrolysis was shown to dramatically reduce chlorine levels in the peptides. Future pelletization experiments will employ peptides-PAE derived from prewashed SRM. The research presented in this study provides proof-of-concept that peptides derived from SRM can be utilized for sustainable production of a binder for pelletization of torrefied wood that can potentially serve as a coal replacement.

Author Contributions

Conceptualization, B.B.A., M.C., P.C. and D.C.B.; Methodology, B.B.A., M.C., A.K., D.H., P.C., D.C.B.; Software, B.B.A., A.K.; Validation, B.B.A., M.C., A.K., D.H., P.C., D.C.B.; Formal Analysis, B.B.A., C.Z.; Investigation, B.B.A., M.C., C.Z., P.C. and D.C.B.; Resources, B.B.A., M.C., C.Z., A.K., D.H., P.C. and D.C.B.; Data Curation, B.B.A., M.C., C.Z., A.K.; Writing—Original Draft Preparation, B.B.A. and M.C.; Writing—Review & Editing, B.B.A., M.C., A.K., P.C., D.C.B.; Visualization, B.B.A. and M.C.; Supervision, M.C., P.C. and D.C.B.; Project Administration, M.C. and D.C.B.; Funding Acquisition, M.C., P.C. and D.C.B.

Funding

This research was funded by Alberta Livestock and Meat Agency (ALMA; 2012R038R), Alberta Prion Research Institute (APRI) and Alberta Agriculture and Forestry (2017A003R), and the Natural Science and Engineering Research Council of Canada (NSERC; 298352-2013).

Acknowledgments

The authors gratefully acknowledge the generous financial support received from Alberta Livestock and Meat Agency (ALMA; 2012R038R), Alberta Prion Research Institute (APRI) and Alberta Agriculture and Forestry (2017A003R), and the Natural Science and Engineering Research Council of Canada (NSERC; 298352-2013) for conducting this research. We would also like to recognize Tim Anderson (InnoTech Alberta) who passed away prior to the writing of this manuscript. Anderson was instrumental for this research and performed the pelletization trials and some of the analyses.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bergman, P.C.A.; Boersma, A.R.; Zwart, R.W.R.; Kiel, J.H.A. Torrefaction for Biomass Co-Firing in Existing Coal-Fired Power Stations; ECN-C-05-013; Energy Research Centre for the Netherlands: Petten, The Netherlands, 2005; pp. 1–71. [Google Scholar]

- Verhoeff, H.; Arnuelos, A.A.; Boersma, A.R.; Pels, J.R.; Lensselink, J.; Kiel, J.H.A.; Schukken, H. Torrefaction Technology for the Production of Solid Bioenergy Carriers from Biomass and Waste; TorTech Project Report; ECN-E-11-039; Energy Research Centre of the Netherlands (ECN): Petten, The Netherlands, 2011; pp. 1–82. [Google Scholar]

- Ghiasi, B.; Kumar, L.; Furubayashi, T.; Lim, C.J.; Bi, X.; Kim, C.S.; Sokhansanj, S. Densified Biocoal from Woodchips: Is it Better to do Torrefaction before Or After Densification? Appl. Energy 2014, 134, 133–142. [Google Scholar] [CrossRef]

- Kumar, L.; Koukoulas, A.A.; Mani, S.; Satyavolu, J. Integrating Torrefaction in the Wood Pellet Industry: A Critical Review. Energy Fuels 2017, 31, 37–54. [Google Scholar] [CrossRef]

- Rousset, P.; Macedo, L.; Commandré, J.; Moreira, A. Biomass Torrefaction under Different Oxygen Concentrations and its Effect on the Cmposition of the Solid by-Product. J. Anal. Appl. Pyrolysis 2012, 96, 86–91. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of Reed Canary Grass, Wheat Straw and Willow to Enhance Solid Fuel Qualities and Combustion Properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Bergman, P.C.A. Combined Torrefaction and Pelletization the TOP Process; ECN-C-05-073; Energy Research Centre of the Netherlands (ECN): Petten, The Netherlands, 2005; pp. 1–29. [Google Scholar]

- Thrän, D.; Witt, J.; Schaubach, K.; Kiel, J.; Carbo, M.; Maier, J.; Ndibe, C.; Koppejan, J.; Alakangas, E.; Majer, S.; et al. Moving Torrefaction Towards Market Introduction—Technical Improvements and Economic-Environmental Assessment Along the overall Torrefaction Supply Chain through the SECTOR Project. Biomass Bioenergy 2016, 89, 184–200. [Google Scholar] [CrossRef]

- Tsalidis, G.; Joshi, Y.; Korevaar, G.; de Jong, W. Life Cycle Assessment of Direct Co-firing of Torrefied and/or Pelletised Woody Biomass with Coal in the Netherlands. J. Clean. Prod. 2014, 81, 168–177. [Google Scholar] [CrossRef]

- Bergman, P.C.A.; Boersma, A.R.; Kiel, J.H.A.; Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction for Entrained-Flow Gasification of Biomass; ECN-C-05-067; Energy Research Centre of the Netherlands (ECN): Petten, The Netherlands, 2005; pp. 1–50. [Google Scholar]

- Agar, D.; Gil, J.; Sanchez, D.; Echeverria, I.; Wihersaari, M. Torrefied Versus Conventional Pellet Production—A Comparative Study on Energy and Emission Balance Based on Pilot-Plant Data and EU Sustainability Criteria. Appl. Energy 2015, 138, 621–630. [Google Scholar] [CrossRef]

- Rudolfsson, M.; Stelte, W.; Lestander, T.A. Process Optimization of Combined Biomass Torrefaction and Pelletization for Fuel Pellet Production—A Parametric Study. Appl. Energy 2015, 140, 378–384. [Google Scholar] [CrossRef]

- Peng, J.H.; Ti, H.T.; Lim, C.J.; Sokhansanj, S. Study on Density, Hardness, and Moisture Uptake of Torrefied Wood Pellets. Energy Fuels 2013, 27, 967–974. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, X.T.; Sokhansanj, S.; Lim, C.J. Torrefaction and Densification of Different Species of Softwood Residues. Fuel 2013, 111, 411–421. [Google Scholar] [CrossRef]

- Shang, L.; Nielsen, N.P.K.; Stelte, W.; Dahl, J.; Ahrenfeldt, J.; Holm, J.K.; Arnavat, M.P.; Bach, L.S.; Henriksen, U.B. Lab and Bench-Scale Pelletization of Torrefied Wood Chips—Process Optimization and Pellet Quality. Bioenergy Res. 2014, 7, 87–94. [Google Scholar] [CrossRef]

- Stelte, W.; Clemons, C.; Holm, J.K.; Sanadid, A.R.; Ahrenfeldt, J.; Shanga, L.; Henriksen, U.B. Pelletizing Properties of Torrefied Spruce. Biomass Bioenergy 2011, 35, 4690–4698. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an Effective Binder for Making Torrefied Pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- Hu, Q.; Shao, J.; Yang, H.; Yao, D.; Wang, X.; Chen, H. Effects of Binders on the Properties of Bio-Char Pellets. Appl. Energy 2015, 157, 508–516. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Jiang, L.; Huang, B.; Xiao, Z.; Chen, X.; Wang, H.; et al. Complementary Effects of Torrefaction and Co-Pelletization: Energy Consumption and Characteristics of Pellets. Bioresour. Technol. 2015, 185, 254–262. [Google Scholar] [CrossRef] [PubMed]

- Bai, X.; Wang, G.; Gong, C.; Yu, Y.; Liu, W.; Wang, D. Co-Pelletizing Characteristics of Torrefied Wheat Straw with Peanut Shell. Bioresour. Technol. 2017, 233, 373–381. [Google Scholar] [CrossRef]

- ISO. Solid Biofuels—Fuel Specifications and Classes—Part 8: Graded Thermally Treated and Densified Biomass Fuels; ISO/TS 17225-8:2016(E); ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Adhikari, B.B.; Appadu, P.; Chae, M.; Bressler, D.C. Protein-based wood adhesives: Current trends of preparation and application. In Bio-Based Wood Adhesives: Preparation, Characterization, and Testing, 1st ed.; He, Z., Ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 1–56. [Google Scholar]

- Adhikari, B.B.; Chae, M.; Bressler, D.C. Utilization of Slaughterhouse Waste in Value-Added Applications: Recent Advances in the Development of Wood Adhesives Polymers. Polymers 2018, 10, 176. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, B.B.; Appadu, P.; Kislitsin, V.; Chae, M.; Choi, P.; Bressler, D.C. Enhancing the Adhesive Strength of a Plywood Adhesive Developed from Hydrolyzed Specified Risk Materials. Polymers 2016, 8, 285. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, B.B.; Kislitsin, V.; Appadu, P.; Chae, M.; Choi, P.; Bressler, D.C. Development of Hydrolysed Protein-Based Plywood Adhesive from Slaughterhouse Waste: Effect of Chemical Modification of Hydrolysed Protein on Moisture Resistance of Formulated Adhesives. RSC Adv. 2018, 8, 2996–3008. [Google Scholar] [CrossRef]

- Mekonnen, T.H.; Mussone, P.G.; Choi, P.; Bressler, D.C. Adhesives from Waste Protein Biomass for Oriented Strand Board Composites: Development and Performance. Macromol. Mater. Eng. 2014, 299, 1003–1012. [Google Scholar] [CrossRef]

- Mekonnen, T.; Mussone, P.; El-Thaher, N.; Choi, P.Y.K.; Bressler, D.C. Thermosetting Proteinaceous Plastics from Hydrolyzed Specified Risk Materials. Macromol. Mater. Eng. 2013, 298, 1294–1303. [Google Scholar] [CrossRef]

- Mekonnen, T.; Mussone, P.; Alemaskin, K.; Sopkow, L.; Wolodko, J.; Choi, P.; Bressler, D. Biocomposites from Hydrolyzed Waste Proteinaceous Biomass: Mechanical, Thermal and Moisture Absorption Performances. J. Mater. Chem. A 2013, 1, 13186–13196. [Google Scholar] [CrossRef]

- Zhong, Z.; Sun, X.S.; Wang, D. Isoelectric pH of Polyamide–Epichlorohydrin Modified Soy Protein Improved Water Resistance and Adhesion Properties. J. Appl. Polym. Sci. 2007, 103, 2261–2270. [Google Scholar] [CrossRef]

- Li, K.; Peshkova, S.; Geng, X. Investigation of Soy Protein-Kymene® Adhesive Systems for Wood Composites. J. Am. Oil Chem. Soc. 2004, 81, 487–491. [Google Scholar] [CrossRef]

- CFIA. Enhanced Animal Health Protection from BSE—Specified Risk Materials (SRM). SRM. Available online: http://www.inspection.gc.ca/animals/terrestrial-animals/diseases/reportable/bse/srm/eng/1299870250278/1334278201780 (accessed on 24 October 2018).

- CFIA. Annex D: Specified Risk Materials. Food, 2016. Available online: http://www. inspection.gc.ca/food/meat-and-poultry-products/manual-of-procedures/chapter-17/annex-d/eng/1369768468665/1369768518427 (accessed on 24 October 2018).

- Mekonnen, T.H.; Mussone, P.G.; Stashko, N.; Choi, P.Y.; Bressler, D.C. Recovery and Characterization of Proteinacious Material Recovered from Thermal and Alkaline Hydrolyzed Specified Risk Materials. Process Biochem. 2013, 48, 885–892. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A Review of Biomass Densification Systems to Develop Uniform Feedstock Commodities for Bioenergy Application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).