Abstract

The micro, small, and medium enterprises (MSMEs) sector plays a very crucial role in the economic and social development of Peru. Unfortunately, the tough access to the use of technologies is one of the weaknesses of this type of enterprises, which implies a low technological intensity production, according to the new technological trends. This study analyzes the factors that are affecting the implementation of Industry 4.0 technologies in Peruvian micro, small, and medium enterprises. According to the findings from the semi-structured interviews, it has identified four factors that respond to the main question of this research—lack of advanced technology, lack of financial investment, poor management vision, and lack of skilled workers. Data from 49 enterprises from the manufacturing sector were used for the assessment. The surveys conducted on business managers were evaluated using a multi-criterion decision-making method by the analytic hierarchy process. The findings of the study generate some recommendations that could be beneficial for the sectors involved with micro, small, and medium enterprises in Peru.

1. Introduction

Manufacturing is a production business and its primary objective is to convert raw material into quality goods that have a value in the market place and as a result, generated profit. Factors such as system efficiency, product quality and reliability, productivity and lower cost, and efficient and effective management techniques contributing to increasing that profit [1].

The manufacturing industry is key to the country’s development and economy. Since many years ago, this industry has been experiencing many changes to improve efficiency in order to produce products with higher quality and become more competitive in the market [1].

In the past few years, new emerging technologies such as cloud computing, cyber-physical systems [2], wireless sensor networks [3], big data [4], or mobile Internet have been introduced into the manufacturing environment [5]. The fusion of manufacturing with these new technologies is enabling a game-changing transformation in terms of manufacturing models and approaches [6], leading to a new concept called Industry 4.0.

The term “Industry 4.0” was first used in 2011 as part of the German government initiative establishing it as a critical strategy for industrial production [7].

Industry 4.0 fuses production system technologies with smart production processes to prepare enterprises for the next technological era that is transforming business models and production value chains [8].

The number of academic investigations focuses on the application of Industry 4.0 on large enterprises is higher [9,10] in comparison with micro, small, and medium enterprises (MSMEs). It is important to know how MSMEs will implement Industry 4.0 and how it will impact them because in many cases MSMEs play the role of suppliers to large size enterprises and vice versa [11]. The performance of MSMEs affects the response of their bigger supply chain partners and their requirements influence the positioning of MSMEs in the technological developments derived from Industry 4.0 [11]. Different methods that improve the performance already exist, for example, just-in-time, whose aim is to synchronize flows via production lines [12]. Although the effectiveness has been proven in different cases [13], this approach seems challenging to apply in small and medium enterprises (SMEs) because of their lack of leadership and proficiency [14,15]. Another case is the adoption of Material Requirement Planning (MRP) [16] and Material Requirement Planning II (MRPII) [17], driven by the development of computer tools such as Enteprise Resource Planning (ERP) [18], was boarded differently in SMEs than in large companies [19] because SMEs level of digitalization is lower than their large counterparts [11].

Understanding the perspective of SMEs on how achievable it is for them to adopt Industry 4.0 helps to create a more comprehensive picture [11] of how they can affront this new industrial revolution.

Research studies conducted in Germany show that SMEs waver to make use of Industry 4.0 applications because of the different challenges these technologies involve for the enterprises [20].

In India, the most critical challenge for the Industry is to raise the manufacturing value chain in a way to cover the gap in critical technologies [21].

In the case of New Zealand, the lack of enough experience and a shortage of available resources is one of the major challenges for SMEs to implement Industry 4.0 applications [22].

To understand the Peruvian scenario, 49 manufacturing MSMEs business managers were surveyed. The goal of the present study was to identify the factors that are challenging the implementation of industry 4.0 technologies in Peruvian MSMEs. In order to achieve that, the analytic hierarchy process method was applied. The results obtained show that the there is a factor that affects the most in the implementation of Industry 4.0 technologies and is the lack financial of investment, followed by lack of advanced technology, lack of management vision, and lack of skilled workers. This method will guide public and private institutions that support small and medium enterprises to overcome the barriers that now are affecting the implementation of Industry 4.0 technologies in Peru. Finally, this study gives a new insight into the challenges and necessity of support for manufacturing enterprises in this new manufacturing era.

The paper is organized with the following structure. Section 2 provides a review of the literature related to the concept of MSMEs in Peru and criterions that involve the implementations of new technologies in small enterprises. Section 3 presents the research method and its applications used in this study, followed by Section 4 which describes the results. The paper ends with our discussion and conclusions.

2. Literature Review

2.1. MSMEs Sector in Peru

The micro and small enterprises (MSEs) is a sector that emerges as a socio-economic phenomenon that has been transformed over the last years by the economies of most countries worldwide, mainly from developing countries, as a response to many unmet needs by low-income sectors of the population.

Micro-enterprises are considering a powerful tool to battle poorness and to empower households that are struggling economically [23]. This sector of enterprises plays an important role providing support for large-sized enterprises [24].

In case of Peru, the regulation define a micro enterprise is a business with annual sales less tha or equal to 525,000 PEN, small enterprise is a business with sales more than 525,000 PEN and less than 5,950,000 PEN, and medium enterprise is a business with 1 to 100 employees and annual sales more than 5,950,000 PEN and less than 8,050,000 PEN [25].

MSMEs Peru, face many obstacles in its development such as problems of access to markets, technological barriers, and difficulties in obtaining credit facilities from the financial sector [26]. In Peru, 96.5% of the existing enterprises belong to the MSMEs sector, according to the Peruvian Trade Society (ComexPerú, Sociedad de Comercio Exterior Del Perú).

According to the Tax Identification Number of 2016, which is the source of the National Superintendency of Tax Administration (SUNAT), in Peru were a total of 1,737,743 formal enterprises and 99.5% of them were micro or small companies (1,728,777 companies) [27].

One of the most favorable points of these small businesses is that if they grow in size, the economy of the country will be affected and as a consequence, the levels of poverty will decrease. However, the real situation is that in some cases their productivity and performance remain low for several years. Whereas their low performance can be assigned to the adverse circumstances affecting them, past researchers have found problems within firms, especially related to management (poor management practices), finance (cost of finance or access to finance,) and lack of decision making [28].

2.2. The Concept of Industry 4.0

Industry 4.0 is derived from the concept “Industrie 4.0” initiative started by the German government for ensuring the future competitiveness of the German manufacturing industry [7]. The concept describes the expectations of the government and the industry heading towards the fourth ndustrial revolution [7]. This revolution is intended to be supported via high-grade digitization as well as the interconnection of industrial value creation, leading to smart industrial value creation [29].

The new available technologies such as big data, collaborative robots, or augmented reality, among others, are released just to improve the enterprises value creation architecture, representing a bunch of opportunities [30], which involves increasing the efficiency and improving performance (reducing time, costs or failures, offering employee training, etc.). These opportunities could be the best way to capture the attention of traditional manufacturing companies to adopt Industry 4.0 technologies without addressing high risks [31].

The new industrial revolution offers different opportunities for the industry, including real-time data access, development of new skills, and achieving sustainable goals, among others.

The concept of real-time data between any process steps is another opportunity that Industry 4.0 offers to the enterprises, removing one of the most difficult challenges of prior support systems—the lack of up-to-date information [32].

Paravizo et al. [33] introduced three categories of skills needed in the era of Industry 4.0, and they are: (1) technical, which could involve the installation of IT devices, or operate automatic Ggided vehicles, just to cite some example; (2) transformational skill involves more the proposition and realization of changes; and (3) social, this one involves interaction between members, for example teamwork, knowledge transfer and acquisition, among other [34].

Industry 4.0 appear to be a new ally in achieving sustainable manufacturing, which is one of the key aspects to achieving sustainable development in the contemporary era, new industrial organization paradigms with an intrinsic focus on resource efficiency and increased “corporate social responsibility” [33]. Facilitated by Industry 4.0, the reduction of waste, energy and resource consumption, as well as improved working conditions, can be achieved [35].

Industry 4.0 introduces new chances that may disrupt the traditional manufacturing approach of planning, control [14], and management.

2.3. How Industry 4.0 Affects the SMEs Sector?

Moeuf et al. [14] present a study that addresses the recent switches to the production planning and control actions in SMEs related to Industry 4.0. The study exhibited that in the case of technologies, the least expensive and least revolutionary such us cloud computing or simulation are the most utilized in SMEs while those that represent profound business transformations such as big data [4] or cyber-physical systems [2] are not considered by SMEs.

Müller et al. [11] explains that it is indispensable for SMEs managers to understand the different ways for tackling Industry 4.0. The study shows diverse possibilities to innovate the business models of manufacturing SMEs according to the demand of Industry 4.0, encouraging managers to explore further scenarios for their business.

Ganzarain et al. [36] present a step-by-step process model to lead and train enterprises to identify new diversification opportunities within Industry 4.0. The study conducted on a representative sample of SMEs in the Basque Country found that just a few SMEs use any Industry 4.0 methodology, but they also present a real need for guided support in developing a company-specific Industry 4.0 vision and specific project planning.

Müller et al. [29] suggest the following strategies for SMEs in a way to achieve the implementation of Industry 4.0: adaptation programs especially oriented for SMEs, implement intelligent assistance systems for supporting employees designing workplace, and address the skills shortages.

2.4. Criterions to Consider in the Implementation of Industry 4.0 Technologies

Premkumar and Roberts [37] present a study that identifies three criterions that influence the embrace of new technologies in small enterprises located in rural areas: innovation, organization, and environment.

Innovation is an idea or practice recognized for new adopters [37]. It is also considered as a key element for entrepreneurial success [38]. The main motivation for enterprises to adopt new technologies is the expected benefits they would generate to the company. Nonetheless, before organizations assume the benefits they must first be conscious of their need for the innovation and how that can be applied to succeed the actual performance or exploit new opportunities [37].

Minterzberg (1972) defined the organizational structure as the framework of the relations on jobs, systems, operating process, people, and groups making efforts to achieve the goals. M. Mehrpour et al. [39] indicates that organizational structure can be influenced by strategy, environment, goals, organization size, and technology. These variables are key and content-based and indicate the entire organization and its position between the organizations. Also, they define an organizational structure in three principles. First, it identifies formal relations and report them, which will help to determine the number of levels in the hierarchy and it defines the span of the control of managers. Second, it identifies the position of people as working in a group in a unit and it divides the units in the entire organization. And the third one includes the design of systems by which all units are coordinated and effective relationships in the organization is guaranteed [39].

MSMEs need flexible organizational structures because the interconnection between businesses is growing very fast, and business areas that at the moment are separated without any relation will become interconnect with each other [40].

In terms of the environment aspect, the external environment plays an essential role in the embrace of new technologies [37]. In the macro environment, it could be distinguished by the following variables: social (social conflicts, transport, and communication), economic (incentives, national/regional investment climate) [30], industry competition (markets for technologies or technical support) and the political framework (regional plans and programs, legislative framework). It is constituted by the strategic areas of the environments, conditioning the objectives and the innovative strategies.

When considering industry competition, in order to increase competitive pressure on global markets, businesses need to approach customer-individual demands in the less time possible [41]. Especially MSMEs present a lack of developing strategies to perform new solutions. The heads of MSMEs must try to understand how new technologies can make their products smarter and which new business models might arise from that. There is a variety of possible business model features that can be offered to the customer, considering Industry 4.0 technologies as key. It is found that these benefits are foremost intended by manufacturing enterprises in contrast to service enterprises. Smart products can increase the proportion of value added from product sales to downstream services [40,42].

Government and private organizations can take action so that Industry 4.0 technologies can be adapted and implemented in the manufacturing and service industry [43]. The authorities should start to promote Industry 4.0 technologies, actions such as: making businesses familiar with the concept of emerging technologies, offering support for implementation (through national programs) and sensibilization about this topics, application-oriented research, or offering consultation services could help improve the relationship between MSMEs and Industry 4.0 [40].

3. Research Method

3.1. Research Design and Empirical Setting

The case studies are suggested in exploratory research because they can provide very important data and allow the investigation of the different contemporaneous managerial challenges [44]. Due to the present research employs an exploratory research design, a multiple case study approach was found to be appropriate.

Based on research work on how emerging technologies are impacting SMEs [11,14], the present paper uses a multiple case study research design in order to identify the criterions that are affecting the implementation of Industry 4.0 in Peruvian MSMEs. Two targets were followed throughout the research: (1) to assess the Peruvian MSMEs current approach towards Industry 4.0 and (2) illustrate the scenario of criterions and factors affecting the implementation of Industry 4.0 in Peruvian MSMEs. On top of this, the research elaborates on future actions and implementation strategies.

3.2. Study Area and Data Collection

The nature of this study is qualitative [45], and that may raise issues concerning the generalizability of the results. To discard any concern, enterprises from Lima, the capital of Peru, were selected prior to the survey; around 2 months were spent to identify the potential enterprises that could support this research, factors such as company size and industry sector were critical for the selection of the companies. In total, 70 enterprises were identified and surveyed subsequently (with the questionnaire presented in Appendix A). Out of those, just 49 enterprises were considered suitable for the study. The managers from those 49 enterprises also provided their opinion to prepare the pairwise comparison of the alternatives and the criterions. Table 1 shows the breakdown.

Table 1.

Classification of the enterprises surveyed.

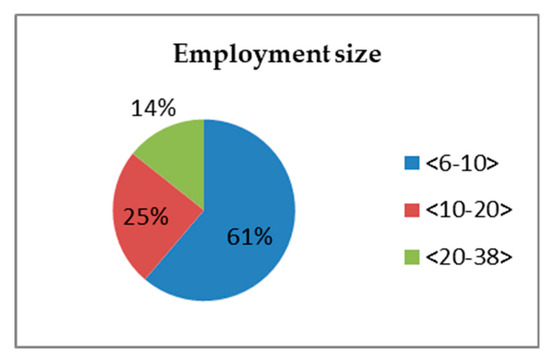

Respondent employment sizes range from 6 to 38 employees. Sixty-one percent were micro-enterprises with 6 to 10 employees, another 25% were small enterprises that had 10–20 employees, and the remaining 14% represented medium-size with more than 20 but less than or equal to 38 employees, as shown in Figure 1. All of the respondents were single-establishment firms headquartered in Peru.

Figure 1.

Classification of enterprises per number of employees.

3.3. Method of Analysis

Some problems are very complicated and they cannot be measured or analyzed by a single criterion since there can hardly be found a feature integrating all essential properties. To solve these type of problems the multi-criterion quantitative evaluation methods are applied [46].

The analytic hierarchy process (AHP) method, proposed by Saaty [47], is a multi-criterion decision-making tool. This method involves structuring criterion into a hierarchical structure in order to assess a problem [47].

In the following lines, the solution process of the AHP method has been explained in 8 steps.

Step 1. Identification of the decision problem. The first step consists of clearly defining the problem to be solved and as a consequence defining the goal to achieve or expected to achieve after the method will be implemented.

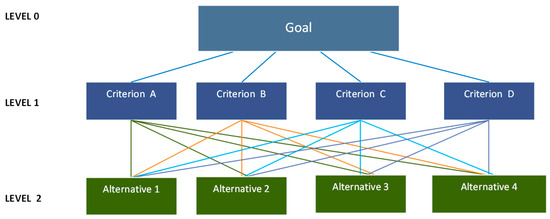

Step 2. Construction of the hierarchical structure. This structure is defined with the goal (problem to be solved) at the top of the diagram, followed by the criterion or factors affecting the problem. In case the hierarchy has possible alternatives the levels of the structure can continue been defined, as is shown in Figure 2. This step is very important because structuring the problem in this way will make possible understand the final decision, the criterion to be analyzed and the alternatives to be evaluated [48].

Figure 2.

Example of a hierarchy structure.

Step 3. Calculation of the weight (priority) of each criterion. This step starts with the development of pairwise comparison matrices between the criterion and alternatives, with the main purpose of determining the importance weights by binary comparisons; the pairwise comparison involves one-on-one comparisons between each of the factors and derives the relative weight for the criterion [48].

The 9-points scale created by Saaty [49] (Table 2) is used to measure the relative weight of each criterion and is assigned for the pairwise comparison. After deriving the weights of each criterion it is necessary to review the consistency of judgments.

Table 2.

Scale for pairwise comparison, adopted from Saaty [49].

Cells in comparison matrices use a value from the numeric scale shown in Table 2, to show the relative preference in each of the compared pairs [43]. For example, if we consider that factor A is extremely more important than the factor B, the A–B comparison cell will contain the value 9, and this implies that B–A has the reciprocal value 1/9, as is presented in the following example (Table 3).

Table 3.

Example of how to complete the pairwise comparison matrix.

After the pairwise comparison matrix has been developed, the next step is the creation of normalized matrices. First, the sum of each column is calculated as shown the Table 4.

Table 4.

Example of completed pairwise comparison matrix.

Then, the normalized matrix is obtained by dividing each column value by the respective column sum, as shown in the example presented in Table 5. After obtained the normalized matrix; the priority of each criterion (weight vector, column W of Table 4) is obtained by simply calculating per each row the average value.

Table 5.

The normalized matrix of the example presented in Table 3.

Step 4. Evaluating the consistency ratios of the comparison matrices. First, we start, multiplying the pairwise matrix by the weight vector (C × W = WS) obtaining a new vector called weight sum (WS), as is shown in the Equation (1).

In a way to calculate the values of the WS vector, first we need to multiply each value in the column of the comparison matrix by each value of the weight vector, then the result of each multiplication has to be added and that will be the weight sum value, as is shown in Equation (2).

After this process has been completed, we need to divide each value of the weighted sum vector (WS) by the corresponding weight of each criterion, in a way to obtain λ vector, represented in Equation (3).

With λ vector calculated is easy to calculate λmax, which is the average of the values of λ vector, as shown in Equation (4):

With the value of λmax calculated, the consistency index (CI) is obtained as follow:

After calculating the CI value, the random index (RI) needs to be obtained. This value is tabulated for different matrix sizes [49]. The RI values for different matrix sizes are shown in Table 6.

Table 6.

Values of Random Index

Finally, the “consistency ratio (CR)” is obtained, defined as:

A CR of less than 0.1 indicates that the application is consistent. If this value is exceeded, the judgments should be reviewed again.

Step 5. Calculation of the weight (priority) of each alternative with respect to the criterion. This step is defined by deriving the relative priorities of the alternatives with respect to each criterion. For this purpose, a pairwise comparison of all the alternatives, with respect to each criterion, need to develop, and after that the consistency ratio needs to be calculated per matrix developed (following the step number 4, presented in the above lines) in a way to evaluate the accuracy of the matrix.

Step 6. Synthesis of the model. This step consists of aggregate the relative weights of the criterion and alternatives to produce a vector of composite weights for each alternative [48].

Step 7. Final decision. After obtaining the composite weight, the alternatives should be ranked in order to decide which one is more important.

3.4. Applications of the AHP Method

The AHP method can be applied to different kind of problems from different sectors and is considered one of the most useful methods where teams of people are working on complex problems that involve human perceptions and judgments, whose resolutions have long-term repercussions [50]. The method has obtained extensive results in problems involving priority identification, planning, resource assignment, or selection between multiple alternatives [50]. Decision makers can make concrete and abstract assessments on alternatives/criterion/sub-criterion. The application of this tool can be seen in the following sectors: Baffoe et al. [51] in the social sector, prioritizing livelihood activities to achieve sustainable rural development interventions; in the energy sector, Ghimire et al. [52] identifying the barriers to renewable energy development; Moraes [53] applied AHP in project portfolio management; and Liberatore and Nydick [54] in the medical and healthcare sector.

4. Results

Large-sized enterprises produce in high volumes; constant optimization is a standing factor of process management. In the case of medium, small, or micro enterprises the production is in low volume and as a consequence, the number of manual activities is in higher proportion. In comparison with SMEs, large companies will realize much higher efficiency gains from the use of Industry 4.0 technologies because of their level of production [40]. The integration of communication and information technology into production, create concepts like the smart product and smart machine and enterprises that include these concepts in the business performance have begun to activate their power in today’s competitive environment [55]. In this study, we examined the difficulties that MSMEs are facing in the application of Industry 4.0 technologies and with the support of the AHP method the most relevant factor will be determined. The application of AHP for this research is described the following steps:

Step 1. Identification of the decision problem. This research planned to identify the specific obstacle that is affecting Peruvian MSMEs in the implementation of Industry 4.0 technologies.

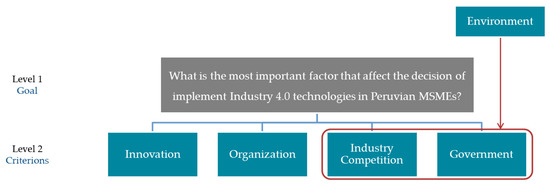

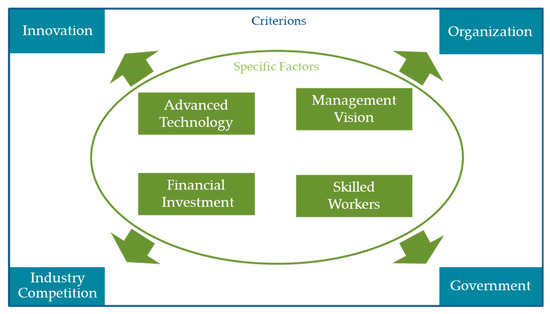

Step 2. Construction of the hierarchical structure. Although there is a presence of Industry 4.0 in Peruvian enterprises, its level of the establishment have not yet a very representative position; furthermore, it is considered that, in terms of digital transformation, only 1% of the massive consumption enterprises could be considered to belong to category 4.0 [56]. The criterions influencing are based in two sources—literature and authors perspective. In the case of literature, the study presented by Premkumar and Roberts [37] and Ali Sevinç et al. [55] was used to support the criterions. From the author’s perspective, the criterion environment was divided into two—industry competition and government. As a consequence, in this study, industry innovation, organization, industry competition, and government were defined as the four criterions constituting the second level of the hierarchy by the criterions as is shown in Figure 3.

Figure 3.

Level 1 and 2 of the hierarchy structure.

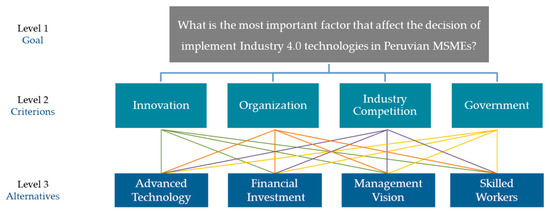

The AHP method structures the problem as a hierarchy. After defining the goal to be achieved and the criterion to be used, the next step is to define the factors to be evaluated. The factors were based on Schröder’s [40] study, related to the challenges of industry 4.0 for SMEs and the findings from the 26 semi-structured interviews conducted with MSMEs experts.

Figure 4 present the hierarchy proposed for this study. The first level is the goal; in this case, what is the most important factor that affects the decision to implement Industry 4.0 technologies in Peruvian SMEs? The second level is constituted by the criterions, and in this case, are represented by organization, industry competition, and government support. The third level presents the available alternatives, which means the factors that will help to answer the initial goal. According to the findings from the semi-structured interviews conducted with relevant stakeholders, four factors, including lack of advanced technology, lack of financial investment, poor management vision, and skilled workers, were selected as key factors for the assessment.

Figure 4.

Research’s hierarchy structure.

In Figure 5, the criterions and the factors involved are presented in a diagram by taking into account the answers obtained in the survey presented in Appendix A. The lack of advanced technology factor is the tough access to the use of technologies, which implies a low technological intensity production, according to the new technological trends. The experts have opined that the lack of technological device markets still create barriers for the Peruvian manufacturing business managers to think regarding industry 4.0.

Figure 5.

Criterion factors relationship diagram.

In terms of the lack of financial investment, finance is a major restriction facing SMEs and it can have a remarkable impact on their performance [38]. Different costs are involved in the implementation of new technologies or systems that need to be integrated with the company for these processes cost such as the cost of maintenance and technical support to ensure the continuity of new technologies integrated into enterprises or the cost of training when the new technologies are integrated into the enterprises. The installation of new technologies to gain the benefits of Industry 4.0 are consider very expensive; therefore, the companies do not like to apply them in the factory sector, which is another challenge for the application of Industry 4.0 [43].

The poor management vision involves the support for new technologies and the adoption of innovations. With the support of top management, various studies can be done, and sufficient resources can be allocated for the adoption of new technologies.

Skilled workers are the key to make every global scenario different and to achieve that is necessary to demand a better education and development new skills [21]. A qualified workforce is very important for the development and implementation of Industry 4.0. The high demand for skilled workers and a lack of know-how is one of the biggest impediments to achieve the implementation of Industry 4.0 [40]. Enterprises will need qualified managers for complex global supply chains and very qualified employees. Also, to support ongoing efforts to upgrade pedagogy and course content, policy makers (which involves that compromise from the government) must work with educational institutions and industry and to ensure that youth workforce develops new skill sets [21]. The insertion of new educational trends, such as: customizing learning based on each student’s capabilities; learning at diverse times and places (virtual classes); using new learning devices, tools, and resources; execution of project-based and problem-based learning approaches; remote laboratories for teaching engineering; using collaborative and experimental learning; involving students in the curriculum design; and promoting mentorship programs is important for the development of skilled workers [57].

Step 3. Calculation of the priority (weight) of the criterion. After the hierarchical structure was established, the paired comparison matrices were developed with the results obtained from the 49 MSMEs managers opinion. Table 7 shows the first comparison matrix established between the main criteria.

Table 7.

Pairwise comparison between criterions.

After the pairwise comparison matrix was obtained, the next step was the calculation of the normalized matrix, as is presented in Table 8. Then, the priority of each criterion (column Weight vector in Table 8) is obtained by merely calculating the average value per each row.

Table 8.

Normalized matrix.

Once the priority of each criterion was calculated, it was necessary to review if they are consistent in order to continue with the method.

Step 4. Calculation and analysis of the consistency ratio of criterion. The CR was calculated by multiplying the pair-wise matrix by the weights vector (Equation (1)); as a result of that two vectors were obtained—weight sum (Equation (2)) and λ vector (Equation (3)), as is shown in Table 9.

Table 9.

Calculation of weight sum (WS) and λ vector.

Then λmax, which is the average of the λ vector, is calculated as follows:

After obtaining λmax, the consistency index (CI) is calculated, as follows:

Finally, the consistency ratio (CR) is calculated, as Equation (5) indicates:

Since this value of 0.062 and is less than 0.10, it is assumed that the comparison matrix between criterion is consistent so is possible to continue with the decision-making process.

From Table 8, it could be seen that organization and government support are the two major reasons that influence MSMEs to consider the implementation of Industry 4.0. These are represented by relative weights of 0.632 and 0.219, respectively. These two criterions were strongly expressed by manufacturing managers surveyed. This can be assigned to the fact that they know the real condition of the manufacturing sector in the country. It is important to mention that the results are consistent with the findings presented by Gutarra et al. [58], who indicated that “An articulated and systemic regulatory framework that promotes technological development and innovation” is a variable that will support the future development of the Peruvian technological MSMEs.

Step 5. Calculation of the weight (priority) of each ʺalternativeʺ with respect to the criterion, and creation of comparison matrices of alternatives with respect of each criterion and the respective consistency ratio. This step consists of identifying and deriving the relative weight of the alternatives with respect to each criterion. In other words, what are the priorities of the alternatives with respect to innovation, organization, industry competition, and government support, respectively? For this purpose, a pairwise comparison of all the alternatives with respect to each criterion was developed and followed based on the response of the 49 MSMEs business managers surveyed.

Comparison Question I: With respect to the innovation criterion, which alternative is preferable: Lack of advanced technology, lack of financial investment, lack of management vision, or lack of skilled workers? The results of this first question are presented in Table 10, followed by its normalized matrix presented in Table 11.

Table 10.

Pairwise comparison of alternatives versus the Innovation criterion.

Table 11.

Normalized matrix of alternatives versus the Innovation criterion.

Comparison Question II: With respect to the organization criterion, which alternative is preferable: Lack of advanced technology, lack of financial investment, lack of management vision, or lack of skilled workers? The results of this second question are presented in Table 12, followed by its normalized matrix presented in Table 13.

Table 12.

Pairwise comparison of alternatives versus the Organization criterion.

Table 13.

Normalized matrix of alternatives versus the Organization criterion.

Comparison Question III: With respect to industry competition criterion, which alternative is preferable: Lack of Technology, lack of financial investment, lack of management vision, or lack of government Support? The results of this third question are presented in Table 14, followed by its normalized matrix presented in Table 15.

Table 14.

Pairwise comparison of alternatives versus the Industry Competition criterion.

Table 15.

The normalized matrix of alternatives versus the Industry Competition criterion.

Comparison Question IV: With respect to government support criterion, which alternative is preferable: Lack of Technology, lack of financial investment, lack of management vision, or lack of government support? The results of this fourth question are presented in Table 16, followed by its normalized matrix presented in Table 17.

Table 16.

Pairwise comparison of alternatives versus the Government Support criterion.

Table 17.

Normalized matrix of alternatives versus the Government Support criterion.

Step 6. This step consisted of calculating the final priority for each alternative; in other words, priorities that take into account only the weight of alternatives for each criterion but also consider the point that each criterion has a different weight. Table 18 shows the synthesis of Table 8, Table 11, Table 13, Table 15 and Table 17.

Table 18.

Calculation of alternatives with respect to the criterions.

Step 7. Finally, after obtaining the weight of the alternatives respect to the criterion we can rank them in order of importance as is shown in Table 19.

Table 19.

Ranking of the main challenges to Industry 4.0 implementation in SMEs in Peru.

Considering the importance of the organization as the most relevant criterion (0.632), financial investment (0.491) is the factor that affects the most in the implementation of Industry 4.0 in manufacturing MSMEs in Peru.

5. Discussion and Conclusions

The present research aimed to identify the factors that are affecting the implementation of Industry 4.0 in Peruvian MSMEs. The analysis of the criterions and alternatives were done by the AHP method. The AHP method was chosen for two reasons: (1) the identified problem involved more than one criterion and finding the solution required a multi-criterion decision-making method and (2) the method helped to determine the level of importance of the involved factors.

Table 8 presents the resulted pairwise comparison of the criterion in perspective of the overall goal of the assessment. From this table, it could be seen that organization and government support are the two major reasons that influence enterprises’ decision to consider the option of Industry 4.0 technologies. These are represented by relative weights of 0.632 and 0.219, respectively. These two factors were strongly express by the business managers during the interviews. This can be attributed to the fact that they face the reality of the sector. Although important, the weight (0.092) of innovation implies that the factor does not have meaningful influence in affecting managers’ decision in the implementation of Industry 4.0 technologies. Meanwhile, from the result, it is likely that industry competition is not a major factor that managers consider because was with the least weight (0.057).

From Table 19, the lack of financial investment (0.491) is the factor that most interfere with the implementation of Industry 4.0 in Peruvian MSMEs. This is followed by a lack of advanced technology (0.225), poor management vision (0.173), and, finally, lack of skilled workers (0.111), in that order. The fact that Industry 4.0 technologies are not implemented in Peruvian MSMEs is supported by the organization criterion and, specifically, for the lack of financial investment factor. The high cost of investment and the long time of the return of the investment are factors that stop firms from being convinced. The factor for the development of MSMEs is the capacity to access finance. There is a very notorious difference between a large enterprise (LE) and an MSMEs when applying for bank loans because while the LEs have the chance to explore the potential of capital markets, the MSMEs only have limited financing possibilities as compared to large companies [59,60]. Understanding the benefits of Industry 4.0 technologies will make it easier for business managers to make positive decisions [55]. This study provides a transparent and consistent method of deciding the best factor that is likely to affect the decision of MSMEs in the implementation of Industry 4.0.

The literature review included in the present study explain the relationship between SMEs and Industry 4.0 [11,14,29,36], and most of the authors try to respond the answer: How can we help or make less challenging the adoption of Industry 4.0 solutions by SMEs? Even though each author point of view differs from each other, all conclude that part of the step is to let SMEs decide to consider the big step showing them the effectiveness of the technologies, that will be one the ways to attract the attention of traditional manufacturing.

The present study contributes to this literature by identifying four specific factors involved in the decision of MSMEs to give the big step from traditional manufacturing to Industry 4.0, and they are: Lack of advanced technology, lack of financial investment, lack of management vision, and lack of skilled workers. According to the findings, it has been identified that Peruvian manufacturing MSMEs need to work in strategies that will help to improve these four factors and give an opportunity to implement Industry 4.0 technologies. However, it would not be difficult for the country if it concentrated on technological integration and infrastructure development.

In this respect, it is highly recommended to the Peruvian government that they increase the support for the integration of Industry 4.0 technologies. Otherwise, the country will not be a part of the new industrial revolution, which could accelerate its present economic progress and would contribute to building a stronger economy in South America. A good example to cite is Thailand, where the government presented as the second point in their Agenda 3, a strategy called ʺthe transformation of traditional SMEs into “Smart SMEs” “Thailand 4.0” [61], in which the objective is to increase the profit and contribution of SMEs. Basically, the government plans to expand SMEs through financial support for those enterprises that have business potential and management skills but lack financial liquidity.

This study is one of the first studies that analyzes the challenges of MSMEs in Peru; it presents the factors that are challenging the adoption processes and their reasons were approached analytically, but also has some limitations. First, we only include the data obtained from 49 enterprises, hence it cannot be generalized. Future research could increase the number of enterprises surveyed so a stronger generalization could be produced. Therefore, by systematically following all the scientific procedures, applying the AHP technique, it is further argued, could be one of the effective ways to find the best option that could help to solve a problem [48], but it is important to consider that the results obtained are based on the evaluations received from the business managers. The AHP methodology just defines which alternative is the most consistent based in the criteria and level of importance that we give them [62]. Considering the mentioned limits of the study, future researches may be made in order to improve the study.

Author Contributions

Conceptualization, C.-J.H and E.D.T.C.; Data curation, E.D.T.C.; Formal analysis, C.-J.H and E.D.T.C.; Investigation, E.D.T.C.; Methodology, C.-J.H, E.D.T.C. and Y.-H.H.; Project administration, E.D.T.C. and C.-J.H.; Resources, Y.-H.H.; Supervision C.-J.H; Validation, C.-J.H and Y.-H.H; Visualization, E.D.T.C.; Writing—original draft, E.D.T.C.; Writing—review & editing, C.-J.H. and Y.-H.H.

Funding

This research received no external funding.

Acknowledgments

The authors would like to express their great appreciation to the National Kaohsiung University of Science and Technology, Taiwan for their support in this paper.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Survey A1 for Experts (Important Factor that Challenges the Implementation of Industry 4.0 Technologies in Peruvian Manufacturing MSMES)

This survey is conducted to develop benchmark information to help manufacturers become more competitive and improve business and technology services to industry.

All company information will be kept confidential. The enterprises’ information will not be revealed in any publication or presentation of the results of this survey.

| 1. When did you start this business? | Year |

2. Your facility’s manufacturing activity is: (Please select one)

| Textiles | Machinery (industrial, nonindustrial) | ||

| Food, beverages | Primary metals (iron, steel, nonferrous) | ||

| Apparel, leather | Fabricated metal products | ||

| Furniture (wood or metal) | Computer and electronic products, instruments | ||

| Printing, publishing | Transportation equipment | ||

| Plastics or rubber | Other (please indicate)_______________________ |

3. As manager of this business, do you have a clear the concept of Industry 4.0?

| Yes | |

| No (skip the questions 5, 6, 7 and 8) — Would you be interested in know about it? _______ | |

4. Do you consider that the lack of presence of advanced technology in the country is an obstacle in the implementation of Industry 4.0 in Peru?

| Yes | |

| No (Please skip the following questions until question 6) |

| TECHNOLOGY Facility—Industry, and Needs |

4.1. For the plant’s main product(s), please RANK the order of importance of the following factors according to: how your facility competes in the marketplace for sales? 1 = most important, 6 = least important (Please do not give the same ranking to more than one factor).

| Low price | |

| High quality | |

| Innovation/new technology | |

| Quick delivery | |

| Adapting existing product to customer needs | |

| Sustainable or green manufacturing |

4.2. Did any of the following significant changes occur to this facility in the last 2 years?

| Facility expanded due to acquisition of or merger with another business or part of it | |

| Facility downsized due to sale or closure of part of the business | |

| No major change | |

| Other major change (please describe): ____________________________________________________ |

4.3. Which of the following information technologies are currently used (or planned to be used) at your facility? (Check one option for each item)

| Currently Practiced | Plan to practice in next 4 years | No plan to practice | |

| Software for scheduling, inventory control, or purchasing (e.g., ERP) | |||

| RFID for inventory tracking | |||

| Supply chain management system | |||

| Bar code readers for data collection | |||

| Cloud-based design and manufacturing | |||

| Others |

4.4. Which of the following manufacturing production technologies are currently used (or planned to be used) at your facility? (Check one option for each item)

| Currently Practiced | Plan to practice in next 4 years | No plan to practice | |

| Sensors, vision, other real-time monitoring technology | |||

| Computer-integrated manufacturing (CIM) | |||

| 3-D, additive, printed manufacturing | |||

| Robots | |||

| Advanced materials (e.g., nano-materials, bio-materials, composites) | |||

| Others |

5. Do you consider that the lack of management vision is an obstacle in the implementation of Industry 4.0 technologies in Peru?

| Yes | |

| No (Please skip the following questions until question 6) |

| MANAGEMENT VISION Product, Process and Organizational Innovation |

5.1. During the period 2015-2017, did your facility introduce new or significantly improved: (Please check all that apply)

| Processes or manufacturing technologies | |

| Logistics, delivery, or distribution methods | |

| Support activities for processes, such as maintenance systems or operations for purchasing, accounting, or computing | |

| Higher performing materials | |

| None of the above |

5.2. During the period 2015–2017, did your facility introduce new or significant changes in: (Please check all that apply)

| Corporate strategy, plan | |

| Management systems to better use or exchange information, knowledge and skills | |

| Work organization, such as changes in management or departmental structure | |

| Relations with other firms, such as alliances, partnerships, outsourcing, or subcontracting | |

| None of the above |

5.3. During the period 2015-2017, did your facility introduce new or significant changes in: (Please check all that apply)

| Design or packaging of goods or services | |

| Sales methods or distribution channels, such as Facebook/Twitter/other social media, franchising, direct sales or distribution licenses |

6. Do you consider that financial investment is an obstacle in the implementation of Industry 4.0 technologies in Peru?

| Yes | |

| No (Please skip the following questions until question 7) |

| FINANCIAL INVESTMENT Manufacturing Production and Performance |

6.1. In the past 2 years, have your business demand the investment of a considerable amount of money to improve the technology?

| Yes | |

| No |

6.2. Please indicate the facility’s expenditures for the following innovation activities over the last 12 months, including personnel and related costs. (Please insert zero in categories with no expenditures)

| In-house R&D (including personnel costs & capital expenditures on buildings & equipment) | |

| Acquisition of external R&D | |

| Acquisition of machinery, equipment, and software (excluding R&D-related expenditures) | |

| Other development work for innovation and all other innovation-related expenditures | |

| Total (sum of above 4 categories) |

6.3. Do you know about any government program that could support financially MSMEs in technology initiatives?

| Yes | |

| No |

7. Do you consider that the lack of skilled workers is an obstacle in the implementation of Industry 4.0 technologies in Peru?

| Yes | |

| No (skip the following questions) |

| 4. SKILLED WORKERS Workforce and Training |

7.1. Please, answer for the past two years about your workforce using exact numbers or estimates, for this facility.

| 2016 | 2017 | |

| On average, how many employees worked at this location? (Include temporary workers and convert part-time and contract labor to full-time equivalents.) | Full-Time Equivalent Employees | Full-Time Equivalent Employees |

| Of your full-time equivalent employees listed above, how many are temporary workers? | Temporary Employees | Temporary Employees |

7.2. On average in 2017, what percentage of your production workers used the following at least once a day, as part of their job:

| A computer or programmable controller? | % | |

| A mobile device to monitor and control industrial equipment | % | |

| The Internet | % |

7.3. In the past 2 years, has your facility received business assistance from: (Check all that apply)

| University | |

| Technical college | |

| Other public or nonprofit business assistant source | |

| A private-sector business assistance source, such as a private consultant or vendor | |

| Another source not included in the above | |

| Facility has not received outside business assistance |

References

- Foston, A.L.; Smith, C.L.; Au, T. Fundamentals of Computer-Integrated Manufacturing; Prentice Hall: Englewood Cliffs, NJ, USA, 1991. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Qiu, M.; Xue, C.; Shao, Z.; Zhuge, Q.; Liu, M.; Sha, E.H.M. Efficent Algorithm of Energy Minimization for Heterogeneous Wireless Sensor Network. In Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2006; pp. 25–34. [Google Scholar]

- Chen, M.; Mao, S.; Liu, Y. Big Data: A Survey. Mob. Netw. Appl. 2014, 19, 171–209. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Shen, W.; Norrie, D.H. Agent-Based Systems for Intelligent Manufacturing: A State-of-the-Art Survey. Knowl. Inf. Syst. 1999, 1, 129–156. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative Industry 4.0; National Academy of Science and Engineering: Munich, Germany, 2013. [Google Scholar]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Arnold, C.; Kiel, D.; Voigt, K.-I. How the industrial internet of things changes business models in different manufacturing industries. Int. J. Innov. Manag. 2016, 20, 1640015. [Google Scholar] [CrossRef]

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The Smart Factory: Exploring Adaptive and Flexible Manufacturing Solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Taylor & Francis: London, UK, 1988. [Google Scholar]

- Krijnen, A. The Toyota way: 14 management principles from the world’s greatest manufacturer. Action Learn. Res. Pract. 2007, 4, 109–111. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Achanga, P.; Nelder, G.; Roy, R.; Shehab, E. Critical success factors for lean implementation within SMEs. J. Manuf. Technol. Manag. 2006, 17, 460–471. [Google Scholar] [CrossRef]

- Petroni, A. Critical factors of MRP implementation in small and medium-sized firms. Int. J. Oper. Prod. Manag. 2002, 22, 329–348. [Google Scholar] [CrossRef]

- McGarrie, B. Case study: Production planning and control - selection, improvement and implementation. Logist. Inf. Manag. 1998, 11, 44–52. [Google Scholar] [CrossRef]

- Guttridge, P.; Deep, A.; Burns, N.; Dani, S. Investigating factors affecting ERP selection in made-to-order SME sector. J. Manuf. Technol. Manag. 2008, 19, 430–446. [Google Scholar] [CrossRef]

- Tagliavini, M.; Sciuto, D.; Ravarini, A.; Buonanno, G.; Pigni, F.; Faverio, P. Factors affecting ERP system adoption: A comparative analysis between SMEs and large companies. J. Enterp. Inf. Manag. 2005, 18, 384–426. [Google Scholar] [CrossRef]

- Bischoff, J.; Taphorn, C.; Wolter, D.; Braun, N.; Fellbaum, M.; Goloverov, A.; Ludwig, S.; Hegmanns, T.; Prasse, C.; Henke, M.; et al. Erschließen der Potenziale der Anwendung von Industrie 4.0 im Mittelstand; Fraunhofer: Dortmund, Germany, 2015. [Google Scholar]

- Iyer, A. Moving from Industry 2.0 to Industry 4.0: A case study from India on leapfrogging in smart manufacturing. Procedia Manuf. 2018, 21, 663–670. [Google Scholar] [CrossRef]

- Hamzeh, R.; Zhong, R.; Xu, X.W. A Survey Study on Industry 4.0 for New Zealand Manufacturing. Procedia Manuf. 2018, 26, 49–57. [Google Scholar] [CrossRef]

- Al Mamun, A.; Ibrahim, M.; Yusoff, M.; Fazal, S. Entrepreneurial Leadership, Performance, and Sustainability of Micro-Enterprises in Malaysia. Sustainability 2018, 10, 1591. [Google Scholar] [CrossRef]

- Huang, X. Strategic decision making in Chinese SMEs. Chin. Manag. Stud. 2009, 3, 87–101. [Google Scholar] [CrossRef]

- (Superintendencia Nacional de Aduanas y de Administración Tributaria (SUNAT) Labour-Related Laws in Micro and Small Enterprises. Available online: http://www.sunat.gob.pe/orientacion/mypes/caracteristicas-microPequenaEmpresa.html (accessed on 24 January 2019).

- Zevallos, E.E.C. Competitiveness of Micro and Small Companies in the presence of Free Trade Agreement (NAFTA). Quipukamayoc. J. Faculty Account. Sci. UNMSM. Lima, Peru. 2010, 17, 127–132. [Google Scholar]

- PRODUCE, Minister of Production of Peru. Micro and Small Business and Internal Trade, Industrial Statistical Yearbook 2016 Studies; G.O.o.I.E.a.E., Ed.; National Library of Peru: Lima, Perú, 2017; Volume 17686. [Google Scholar]

- Bloom, N.; Mahajan, A.; McKenzie, D.; Roberts, J. Why Do Firms in Developing Countries Have Low Productivity? Am. Econ. Rev. 2010, 100, 619–623. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.-I. Sustainable Industrial Value Creation in SMEs: A Comparison between Industry 4.0 and Made in China 2025. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- Antunes, J.; Pinto, A.; Reis, P.; Henriques, C. Industry 4.0: A Challenge of Competition. Millenium 2018, 2, 89–97. [Google Scholar] [CrossRef]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Enke, J.; Glass, R.; Kreß, A.; Hambach, J.; Tisch, M.; Metternich, J. Industrie 4.0—Competencies for a modern production system: A curriculum for Learning Factories. Procedia Manuf. 2018, 23, 267–272. [Google Scholar] [CrossRef]

- Paravizo, E.; Chaim, O.C.; Braatz, D.; Muschard, B.; Rozenfeld, H. Exploring gamification to support manufacturing education on industry 4.0 as an enabler for innovation and sustainability. Procedia Manuf. 2018, 21, 438–445. [Google Scholar] [CrossRef]

- Schallock, B.; Rybski, C.; Jochem, R.; Kohl, H. Learning Factory for Industry 4.0 to provide future skills beyond technical training. Procedia Manuf. 2018, 23, 27–32. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Ganzarain, J.; Errasti, N. Three Stage Maturity Model in SME’s toward Industry 4.0. J. Ind. Eng. Manag. 2016, 9, 1119–1128. [Google Scholar] [CrossRef]

- Premkumar, G.; Roberts, M. Adoption of new information technologies in rural small businesses. Omega 1999, 27, 467–484. [Google Scholar] [CrossRef]

- Ndiaye, N.; Abdul Razak, L.; Nagayev, R.; Ng, A. Demystifying small and medium enterprises’ (SMEs) performance in emerging and developing economies. Borsa Istanb. Rev. 2018, 18, 269–281. [Google Scholar] [CrossRef]

- Ahmady, G.A.; Mehrpour, M.; Nikooravesh, A. Organizational Structure. Procedia Soc. Behav. Sci. 2016, 230, 455–462. [Google Scholar] [CrossRef]

- Schröder, C. The Challenges of Industry 4.0 for Small and Medium-Sized Enterprises; Friedrich-Ebert-Stiftung: Berlin, Germany, 2016. [Google Scholar]

- Dombrowski, U.; Wullbrandt, J.; Krenkel, P. Industrie 4.0 in production ramp-up management. Procedia Manuf. 2018, 17, 1015–1022. [Google Scholar] [CrossRef]

- Müller, M.J.; Däschle, S. Business Model Innovation of Industry 4.0 Solution Providers Towards Customer Process Innovation. Processes 2018, 6, 260. [Google Scholar] [CrossRef]

- Islam, M.; Jantan, A.; Binti Hashim, H.; Chong, C.W.; Abdullah, M.M.; Rahman, M.; Hamid, A.B. Fourth Industrial Revolution in Developing Countries: A Case on Bangladesh. J. Manag. Inf. Decis. Sci. 2018, 21, 1–9. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; Sage Publications: London, UK, 2009. [Google Scholar]

- Bryman, A.; Bell, E. Business Research Methods; Oxford University Press: Oxford, UK, 2015. [Google Scholar]

- Podvezko, V. Application of AHP Technique. J. Bus. Econ. Manag. 2009, 10, 181–189. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Mu, E.; Pereyra-Rojas, M. Understanding the Analytic Hierarchy Process. In Practical Decision Making: An Introduction to the Analytic Hierarchy Process (AHP) Using Super Decisions V2; Springer International Publishing: Cham, Switzerland, 2017; pp. 7–22. [Google Scholar]

- Saaty, T.L. How to make a decision: The analytic hierarchy process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Bhushan, N.; Rai, K. Strategic Decision Making: Applying the Analytic Hierarchy Process; Springer: London, UK, 2014. [Google Scholar]

- Baffoe, G. Exploring the utility of Analytic Hierarchy Process (AHP) in ranking livelihood activities for effective and sustainable rural development interventions in developing countries. Eval. Program Plan. 2019, 72, 197–204. [Google Scholar] [CrossRef] [PubMed]

- Ghimire, L.P.; Kim, Y. An analysis on barriers to renewable energy development in the context of Nepal using AHP. Renew. Energy 2018, 129, 446–456. [Google Scholar] [CrossRef]

- Moraes, E.; Bernanrdes, R.; Camanho, R. Project Portfolio Management Using AHP; Centro Universitário da FEI: São Paulo, Brazil, 2019. [Google Scholar]

- Liberatore, M.; Nydick, R.L. The Analytic Hierarchy Process in Medical and Health Care Decision Making: A Literature Review. Eur. J. Oper. Res. 2008, 189, 194–207. [Google Scholar] [CrossRef]

- Sevinç, A.; Gür, Ş.; Eren, T. Analysis of the Difficulties of SMEs in Industry 4.0 Applications by Analytical Hierarchy Process and Analytical Network Process. Processes 2018, 6, 264. [Google Scholar] [CrossRef]

- Mendoza, M. Peru Only Has 1% of Industries in 4.0. Available online: https://elcomercio.pe/economia/peru-1-industrias-4-0-noticia-467091 (accessed on 12 January 2019).

- Elbestawi, M.; Centea, D.; Singh, I.; Wanyama, T. SEPT Learning Factory for Industry 4.0 Education and Applied Research. Procedia Manuf. 2018, 23, 249–254. [Google Scholar] [CrossRef]

- Gutarra Romero, R.J.; Valente Mercado, A.G. The peruvian technological MSMEs to 2030. Strategies for their insertion to industrie 4.0. Nova Scientia 2018, 10. [Google Scholar] [CrossRef]

- Moreira, D.F. The Microeconomic Impact on Growth of SMEs When the Access to Finance Widens: Evidence from Internet & High-tech Industry. Procedia Soc. Behav. Sci. 2016, 220, 278–287. [Google Scholar] [CrossRef]

- Matt, D.T.; Orzes, G.; Rauch, E.; Dallasega, P. Urban production—A socially sustainable factory concept to overcome shortcomings of qualified workers in smart SMEs. Comput. Ind. Eng. 2018. [Google Scholar] [CrossRef]

- Charlie Jones, P.P. Innovative ideas: Thailand 4.0 and the fourth industrial revolution. Asian Int. J. Soc. Sci. 2017, 17, 4–35. [Google Scholar]

- Forman, E.H.; Gass, S.I. The Analytic Hierarchy Process—An Exposition. Oper. Res. 2001, 49, 469–486. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).