Abstract

With the continuous increase in well depth and the gradual depletion of formation energy, the pump-setting depths in rod-pumped wells have increased significantly, leading to higher suspension loads at the pumping unit. The application of glass fiber-reinforced plastic (FRP) sucker rods can effectively reduce suspension loads due to their low density and high tensile strength. However, the mechanical performance of FRP rods is highly sensitive to temperature, which poses challenges for their application in deep and high-temperature wells. In FRP–steel hybrid sucker-rod string design, the influence of temperature—particularly on FRP rods—must therefore be carefully considered to prevent failures such as rod parting or coupling separation. This study systematically investigates the effects of temperature on the mechanical properties of FRP sucker rods, including elastic modulus, flexural shear strength, and tensile strength. Based on the operating characteristics of sucker-rod pumping systems and established design criteria, a temperature-aware design methodology for FRP–steel hybrid rod strings is developed and implemented in dedicated design software. The proposed approach enables rational determination of the FRP–steel partition depth under thermal constraints while satisfying mechanical safety requirements. A field case study is conducted to validate the design results, demonstrating that the software provides reliable and practical guidance for hybrid rod-string design in deep wells.

1. Introduction

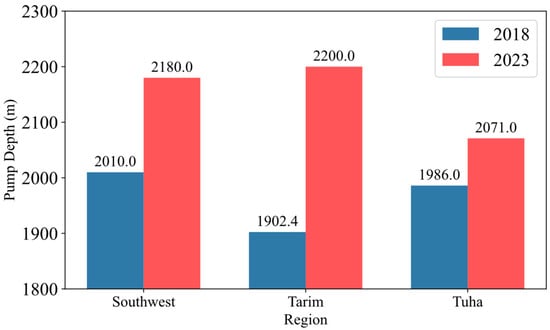

Driven by the progressive shift toward deeper drilling and the gradual depletion of natural reservoir drive in mature oilfields, pump-setting depths (PSDs) in rod-pumped wells have increased steadily in recent years. In major Chinese oilfields, this deepening trend is particularly evident. As shown in Figure 1, the average PSDs in representative regions such as Tuha, Southwest China, and the Tarim Oilfield all exhibit a clear upward shift from 2018 to 2023. Among them, the Tarim Oilfield shows the most pronounced increase, with the average PSD rising to approximately 2200 m in 2023. The continuous increase in pump-setting depth inevitably leads to higher axial loads along the sucker-rod string, which significantly elevates the risks of rod parting, coupling failure, and other operational safety incidents. Under such increasingly demanding conditions, conventional all-steel rod strings face growing challenges in terms of load-bearing capacity, energy efficiency, and long-term service reliability, thereby placing stricter requirements on rod-string material selection and engineering design methodologies for deep-well applications.

Figure 1.

Comparison of pump-setting depths in selected Chinese oilfields in 2018 and 2023, showing a consistent increase in pump-setting depth over time with the most pronounced deepening trend observed in the Tarim Oilfield.

To alleviate excessive suspension loads and improve energy efficiency in deep-well rod-pumping systems, fiber-reinforced polymer (FRP) sucker rods have been increasingly adopted in recent years. Owing to their low density, high tensile strength, and excellent corrosion resistance, FRP rods can significantly reduce the overall weight of the rod string and mitigate corrosion-related failures in aggressive downhole environments. As summarized in Table 1, the density of FRP rods is less than one-third that of steel rods, resulting in substantially lower suspension loads and improved energy efficiency. Consistent with this advantage, field applications and experimental studies have reported that FRP rod strings can reduce energy consumption by approximately 15–20% compared with steel rods [1], while maintaining satisfactory tensile performance in corrosive downhole environments. Moreover, FRP rods exhibit comparable or even higher tensile strength under moderate temperatures, which supports their application in tension-dominated sections of deep rod strings.

Table 1.

Comparison of the mechanical properties of FRP and steel sucker rods.

However, Table 1 also reveals inherent limitations of FRP rods when compared with steel counterparts. The elastic modulus and flexural strength of FRP rods are significantly lower than those of steel rods, indicating reduced resistance to bending and compressive instability. In addition, the allowable operating temperature of FRP rods is restricted to a relatively narrow range, beyond which pronounced degradation of mechanical properties may occur. These characteristics suggest that direct replacement of steel rods with full-length FRP strings may introduce mechanical and thermal risks in deep-well applications, particularly in sections subjected to high-temperature and complex loading conditions.

The contrasting mechanical and thermal characteristics summarized in Table 1 indicate that neither FRP rods nor steel rods alone can simultaneously satisfy the requirements of high load capacity, temperature tolerance, and energy efficiency in deep-well rod-pumping systems, which provides a fundamental motivation for hybrid rod-string configurations. Over the past two decades, extensive research has been conducted to investigate the mechanical behavior, failure mechanisms, and durability of composite sucker rods. Zhang Yanwen and co-workers [2,3,4] systematically studied interfacial debonding and fracture in composite rod couplings, as well as interlaminar cracking and delamination in carbon/glass hybrid rods, using full-scale numerical models based on the cohesive zone model and Johnson–Cook constitutive relations, validated by pull-out experiments. Saponja [5,6,7] developed recyclable fiber-reinforced thermoplastic sucker rods to overcome the high weight, poor corrosion resistance, and limited fatigue performance of conventional steel rods. Krechkovska and co-authors [8,9] investigated the fracture characteristics and fatigue-crack propagation of hybrid composite rods under corrosive environments, highlighting the complexity of fatigue-life prediction. Lv Xiaoxiao [10,11,12,13,14] proposed dual-scale failure-assessment frameworks combining macro- and meso-scale finite-element models to clarify multiple failure modes of carbon–glass hybrid fiber-reinforced polymer rods and their couplings under complex loading conditions. Other studies addressed recycling technologies [15,16], environmental degradation effects [17,18], defect detection using deep learning [19], service-life prediction models [20,21], and data-driven fatigue-life assessment methods [22,23]. In addition, glass-fiber sucker rods have been applied in late-stage reservoirs to enhance production and reduce energy consumption through modified API-based design approaches [24], while failure analyses of fiberglass rods have revealed the combined effects of material degradation and eccentric wear [25].

Beyond conventional glass-fiber reinforcement, recent studies have demonstrated that the incorporation of alternative or hybrid fiber systems—such as carbon fibers, basalt fibers, and aramid fibers—can introduce additive or synergistic effects on the mechanical performance of composite sucker rods. Carbon fibers are known to significantly enhance elastic modulus and fatigue resistance, while basalt and aramid fibers contribute to improved impact toughness, crack-arrest capability, and thermal stability. Through appropriate hybridization and fiber architecture design, these additive effects enable tailored combinations of stiffness, strength, and durability that cannot be achieved by single-fiber systems alone, thereby expanding the design space of composite sucker rods for demanding deep-well applications [26,27]. However, despite the increasing diversity of fiber systems and the demonstrated material-level performance enhancement, most existing studies primarily emphasize material characterization rather than their direct implications for engineering design of full-length rod strings.

Despite these significant advances, existing studies still exhibit several critical limitations when viewed from an engineering design perspective. First, most investigations focus on material-level properties or isolated failure mechanisms under laboratory conditions, whereas the coupled effects of downhole temperature, corrosion, cyclic loading, and compressive instability along the entire rod string are rarely incorporated into an integrated design framework. Consequently, a persistent gap remains between laboratory-based evaluations and actual downhole service conditions in deep and ultra-deep wells. Second, many experimental studies are limited by small sample sizes and narrow dimensional ranges, which restrict the generalizability of their conclusions across different well depths and operating regimes. Third, although valuable insights into damage mechanisms have been obtained, many studies stop short of addressing key engineering questions, such as compatibility with existing rod-pumping systems, optimization of hybrid rod-string configurations, and practical design constraints required for field-scale deployment. Moreover, limited disclosure of critical design parameters in some proprietary studies further hampers independent benchmarking and widespread application.

A particularly critical issue that has not been sufficiently addressed in existing design methodologies is the pronounced temperature sensitivity of FRP sucker rods. However, temperature is still commonly treated as a secondary or implicit factor in current rod-string design practices, rather than an explicit design constraint. While FRP rods exhibit excellent tensile performance at moderate temperatures, elevated downhole temperatures can significantly reduce their elastic modulus, shear strength, and long-term load-bearing capacity due to resin softening, interfacial degradation, and time-dependent creep. In deep wells, where high axial loads often coincide with elevated temperatures at greater depths, the indiscriminate use of full-length FRP rod strings may introduce hidden safety risks, such as excessive elongation, coupling separation, or premature rod failure. Conversely, relying solely on steel rod strings negates the potential benefits of FRP in reducing suspension loads and energy consumption.

In view of the complementary advantages and limitations of FRP and steel sucker rods, FRP–steel hybrid rod strings have emerged as a promising solution for deep-well rod-pumping systems. However, the rational design of such hybrid strings requires explicit consideration of temperature-dependent mechanical degradation of FRP rods and its implications for allowable deployment depth and load distribution along the rod string. To address this challenge, the present study proposes a temperature-aware design methodology for FRP–steel hybrid sucker-rod strings. By integrating a wellbore temperature distribution model with experimentally established temperature-dependent mechanical properties of FRP rods, the proposed approach explicitly constrains the permissible FRP section and optimizes hybrid rod-string configurations under established design criteria. The methodology is implemented in a dedicated design software module and validated through a field case study, demonstrating its practicality and engineering applicability for deep and ultra-deep rod-pumped wells.

2. Theoretical Foundation

2.1. Thermal Calculation

In deep and ultra-deep rod-pumped wells, the downhole temperature environment constitutes a fundamental boundary condition governing the mechanical behavior and long-term reliability of sucker-rod strings. As pump-setting depth increases and geothermal gradients become more pronounced, the temperature experienced by the rod string rises significantly along the wellbore. Accurate characterization of the wellbore temperature distribution is therefore a prerequisite for evaluating temperature-dependent material degradation, stress redistribution, and the applicability limits of FRP sucker rods.

To characterize the axial temperature distribution of the produced fluid along the wellbore, a one-dimensional steady-state heat-transfer model is adopted. The model is derived from the principle of energy conservation by considering the heat exchange between the fluid flowing inside the tubing and the surrounding formation. Under steady operating conditions, the energy balance over an infinitesimal wellbore segment of length (m) can be written as [28]

where (°C) is the fluid temperature at depth (m), (°C) denotes the formation temperature at the same depth, (W/°C) is the water equivalent of the produced fluid defined as the product of mass flow rate and specific heat capacity, and (W/(m·°C)) is the overall heat-transfer coefficient per unit length between the tubing fluid and the surrounding formation. The formation temperature is assumed to vary linearly with depth according to the geothermal gradient, such that

where (°C) is the original formation temperature at the reference depth, and (°C/100 m) is the geothermal gradient. Substituting Equation (2) into Equation (1) and integrating with respect to depth yields the general analytical solution

where is an integration constant determined by the boundary condition at the wellhead. For the boundary condition and , the integration constant is obtained as

Accordingly, the temperature distribution along the wellbore can be expressed in a compact form as

It should be noted that the thermal calculation presented above is based on a steady-state heat-transfer assumption, which is appropriate for long-term rod-string design. In practical operations, production fluctuations or changes in operating conditions may cause transient temperature variations; however, these effects mainly influence short-term thermal responses, while the temperature level governing material degradation and design constraints is determined by sustained operating conditions. Therefore, the steady-state temperature profile is adopted as a representative and conservative thermal envelope for FRP performance evaluation and hybrid rod-string design.

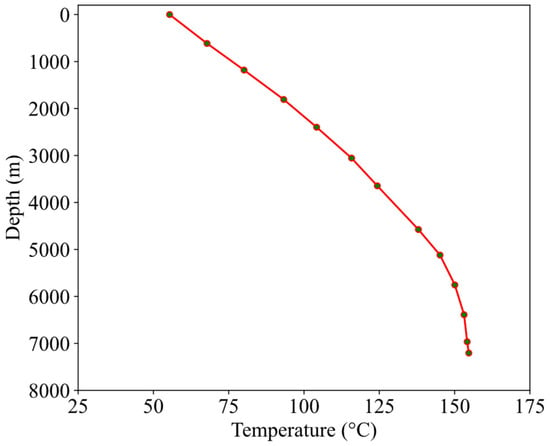

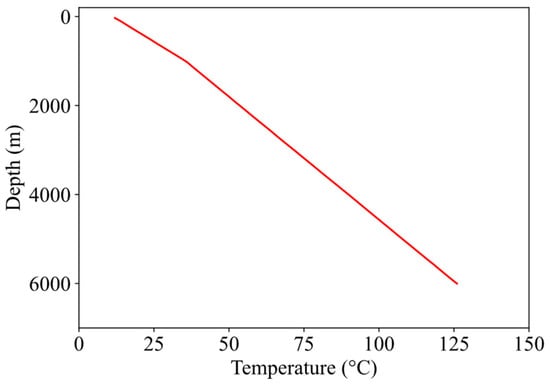

In deep and ultra-deep wells, particularly in reservoirs with high geothermal gradients exceeding 3 °C per 100 m [29], the downhole thermal environment becomes increasingly severe. Field observations reported in the literature indicate that bottomhole temperatures commonly fall within the range of 150 to 180 °C, while temperatures exceeding 200 °C have been documented in some wells [30]. The temperature depth profile of a representative well in the Tarim Oilfield shown in Figure 2 exhibits a continuous increase in fluid temperature with depth, reflecting the combined effects of geothermal heating and wellbore heat transfer.

Figure 2.

Wellbore temperature variation with depth for a representative deep well in the Tarim Oilfield, illustrating a continuous increase in downhole temperature with increasing depth under high geothermal conditions.

Sustained exposure to such high-temperature conditions leads to progressive thermal aging of sucker-rod strings and degradation of their mechanical properties. Compared with steel rods, fiber-reinforced polymer sucker rods are more sensitive to temperature because the mechanical behavior of the resin matrix and interfacial bonding deteriorates with increasing temperature. As a result, temperature becomes a governing factor in evaluating the applicability and long-term reliability of fiber-reinforced polymer rods in deep-well applications, which is discussed in detail in the following section.

2.2. Effect of Temperature on FRP Sucker Rods

In shallow wells, the downhole thermal environment is relatively mild, and temperature effects are generally not a primary concern in sucker-rod design. In contrast, deep and ultra-deep wells are characterized by higher wellbore temperatures and greater rod insertion depths, which makes temperature an important factor influencing rod string performance. As downhole temperature increases, the stress distribution within the sucker-rod string is altered, and fiber-reinforced polymer sucker rods exhibit a higher sensitivity to temperature compared with conventional steel rods.

With increasing wellbore fluid temperature, degradation of the resin matrix and bonding materials at the coupling sections of fiber-reinforced polymer sucker rods gradually occurs, leading to a reduction in mechanical strength and an increased likelihood of rod fracture or coupling separation [31]. Experimental observations indicate that when the wellbore temperature reaches approximately 115 °C, the allowable stress of fiber-reinforced polymer rods decreases by about 20 percent, while at temperatures between 130 and 140 °C, visible discoloration of the rod body is commonly observed, indicating pronounced material deterioration. These observations highlight that temperature-induced degradation is governed primarily by long-term thermal aging and creep-related mechanisms rather than short-term tensile strength alone. Consequently, although a unified upper temperature limit has not yet been formally established, existing experimental evidence and engineering practice consistently suggest that the operating temperature of fiber-reinforced polymer rods should preferably remain below 104 °C, which provides a conservative safety margin against progressive stiffness loss, interfacial degradation, and time-dependent creep under sustained downhole conditions.

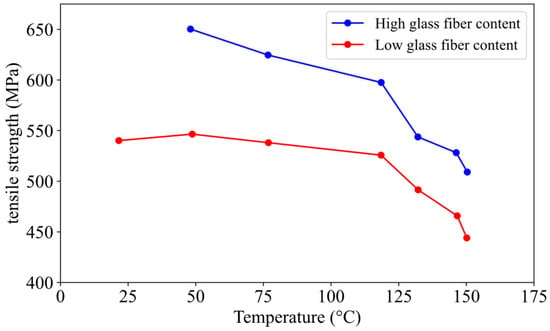

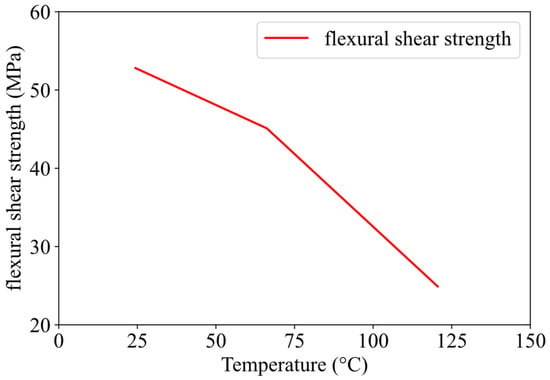

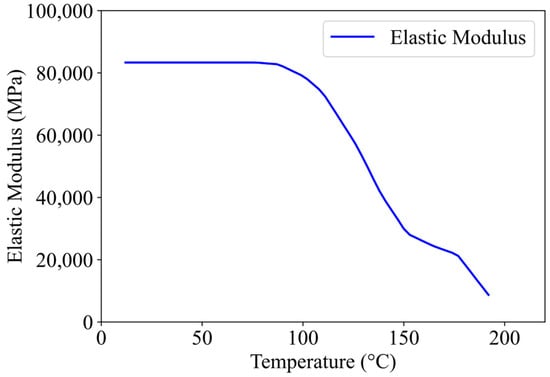

The temperature-dependent variation in tensile strength flexural shear strength and elastic modulus of fiber-reinforced polymer sucker rods is illustrated in Figure 3, Figure 4 and Figure 5. These figures are used to reflect the general influence of temperature on the mechanical behavior of fiber-reinforced polymer rods, and the data are provided by the rod manufacturer.

Figure 3.

Temperature-dependent variation in tensile strength of fiber-reinforced polymer sucker rods, showing a gradual reduction in tensile strength with increasing temperature and a lower tensile capacity for rods with reduced glass fiber content, indicating that the high tensile advantage of fiber-reinforced polymer rods is diminished under high-temperature conditions.

Figure 4.

Temperature-dependent variation in flexural shear strength of fiber-reinforced polymer sucker rods, showing a progressive decrease in shear strength with increasing temperature and indicating an increased susceptibility to fracture or coupling separation in high-temperature well environments.

Figure 5.

Variation in elastic modulus of fiber-reinforced polymer sucker rods with temperature, indicating an initially stable modulus followed by a sharp reduction beyond a critical temperature level, which reflects increased material plasticity and enhanced axial elongation of the rod string.

Figure 3 shows a progressive reduction in tensile strength with increasing temperature. As temperature rises, the tensile capacity of fiber-reinforced polymer rods decreases continuously, and rods with lower glass fiber content exhibit more pronounced strength degradation. Under high-temperature conditions, the inherent advantage of high tensile strength associated with fiber-reinforced polymer rods cannot be fully utilized. This behavior is mainly attributed to resin matrix softening and fiber–matrix interfacial degradation, which reduce the efficiency of load transfer along the rod.

Figure 4 presents the variation in flexural shear strength with temperature. As temperature increases, flexural shear strength decreases steadily, which increases the susceptibility of fiber-reinforced polymer rods to fracture or coupling separation under combined bending and shear loading. This behavior indicates that such rods are not suitable for wells with large deviation angles.

Although tensile strength and flexural shear strength correspond to different loading modes, both are governed by matrix-dominated and interface-controlled failure mechanisms in fiber-reinforced polymer rods under elevated temperatures. Therefore, their temperature-induced degradation follows similar kinetics. In this study, a unified exponential degradation model is adopted for strength-related parameters

where S(T) denotes the strength at temperature T, S0 is the corresponding reference value at the reference temperature T0, and bS is the temperature degradation coefficient. Different values of bS are used for tensile strength and flexural shear strength to reflect their respective sensitivities to temperature. The degradation coefficients are obtained by fitting the experimental trends, as shown in Figure 3 and Figure 4.

Figure 5 illustrates the change in elastic modulus with temperature. At relatively low temperatures, the elastic modulus remains nearly constant, while a sharp reduction occurs once a critical temperature level is exceeded. This decrease reflects increased material plasticity and leads to greater axial elongation of the rod string. Unlike strength parameters, the elastic modulus represents the global stiffness of the composite and is less sensitive to localized damage. Within the investigated temperature range, its temperature dependence can be reasonably approximated by a linear relationship:

where E(T) is the elastic modulus at temperature T, E0 is the elastic modulus at the reference temperature T0, and aE is the modulus degradation coefficient determined from the experimental trend shown in Figure 5. The reduction in elastic modulus leads to greater axial elongation during pumping operations, which may induce an overstroke effect at moderate temperatures. However, excessive elongation adversely affects load transfer and dynamic performance of the rod string under high-temperature conditions.

Field experience indicates that fiber-reinforced polymer sucker rods subjected to sustained high-temperature service may fail through coupling separation or rod parting at stress levels well below their ultimate tensile strength. Under such conditions, time-dependent creep deformation and interfacial degradation accumulate progressively, leading to elongation growth and loss of effective load transfer. Accordingly, a hybrid rod-string design should ensure that the maximum expected downhole temperature at the deepest pump-setting depth remains below the onset temperature associated with pronounced material property degradation. Because steel rods exhibit lower sensitivity to temperature and higher compressive capacity, it is common practice to install a steel tail section at the lower end of the fiber-reinforced polymer rod string to mitigate compressive loading and thermal effects.

3. Method

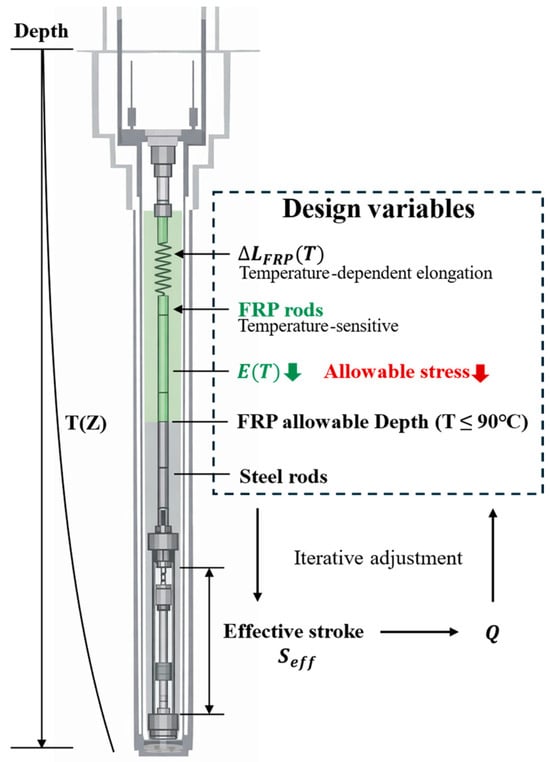

3.1. Temperature-Aware Design Framework

The design of an FRP–steel hybrid sucker-rod string is developed within a temperature-aware, closed-loop design framework, aiming to improve production performance while ensuring mechanical safety under deep-well thermal conditions. As schematically illustrated in Figure 6, the proposed framework integrates operating parameters, temperature evaluation, structural response, and performance assessment into an iterative design process.

Figure 6.

Schematic of the temperature-aware closed-loop design process for FRP–steel hybrid sucker-rod strings, integrating operating parameters, wellbore temperature prediction, temperature-dependent deformation of FRP rods, production evaluation, and mechanical constraint checking.

The hybrid rod string consists of an upper FRP section and a lower steel section. The hybrid configuration is characterized by the lengths of the FRP and steel sections, denoted as and , respectively, which satisfy

where is the total rod-string length determined by the pump-setting depth and surface completion. The proportion of FRP rods is defined as

and serves as a key design parameter controlling material allocation along the wellbore.

In addition to the hybrid-string composition, pump operating parameters—including pump diameter , stroke length , pumping speed , and pump-setting depth —are incorporated into the design framework. These parameters influence both the mechanical loading of the rod string and the thermal environment through their impact on flow conditions and energy dissipation.

The wellbore temperature distribution is evaluated using the analytical thermal model presented in the preceding section and given by Equation (5). Within this framework, the mass flow rate and heat-generation terms are implicitly governed by the selected pump parameters. As a result, variations in operating conditions lead to corresponding changes in the temperature profile along the wellbore.

The temperature profile imposes a critical constraint on the allowable placement depth of FRP rods. To avoid excessive thermal degradation, the FRP section must satisfy

where denotes the maximum allowable operating temperature of FRP rods. This constraint directly determines the feasible boundary between the FRP and steel sections within the hybrid rod string.

Under a given temperature distribution, the mechanical properties of FRP rods exhibit pronounced temperature dependence. In particular, the elastic modulus of FRP rods can be expressed as

which decreases with increasing temperature. As a result, the axial elongation of the rod string is dominated by the FRP section and can be approximated as

where , , and denote the axial load, length, and cross-sectional area of the FRP section.

The elongation of the steel section, while also present, exhibits weaker sensitivity to temperature and is implicitly accounted for through the axial load distribution along the rod string. By explicitly resolving the temperature-dependent deformation of the FRP section and implicitly treating the steel-section contribution, the framework captures the dominant thermal–mechanical coupling without introducing unnecessary model complexity.

The combined elongation effect leads to a reduction in the effective plunger stroke, which is evaluated as

where is the nominal stroke length. The reduction in effective stroke directly affects the liquid production rate, which is evaluated as

with being the volumetric efficiency and the plunger cross-sectional area. Production performance is subsequently adopted as the primary metric for guiding design adjustments.

Mechanical feasibility is ensured by evaluating the axial stress distribution along the rod string. The axial stress at depth is given by

and the maximum operating stress is defined as

For FRP rods, the allowable stress is determined using a safety factor and the temperature-dependent material strength,

where denotes the tensile strength at temperature ; both the stress constraint and the temperature constraint are checked within each design iteration.

From a design standpoint, the safety factor introduced for FRP rods is not only intended to account for uncertainty in instantaneous strength. Unlike conventional steel rods, whose safety margins are mainly governed by elastic strength limits and fatigue behavior, FRP rods exhibit additional temperature-dependent mechanisms, such as creep deformation and fiber–matrix interfacial weakening. Under sustained high-temperature and cyclic loading conditions, these mechanisms may lead to progressive performance degradation even when the instantaneous stress level remains below the nominal strength limit.

Accordingly, the safety factor adopted for FRP rods, together with stress-range and elongation constraints evaluated in the design process, is intended to provide a conservative margin that accounts for long-term reliability under thermally demanding and cyclic operating conditions. While a detailed fatigue-life assessment is not explicitly performed in this study, controlling stress amplitudes and limiting excessive deformation are employed as design-level measures to mitigate fatigue-related risks in an engineering-practical manner.

Within this framework, the hybrid rod-string design is carried out in a closed-loop manner, whereby production performance and constraint satisfaction are jointly evaluated and used to iteratively adjust the hybrid configuration and operating parameters. The overall workflow enables systematic refinement of the hybrid rod-string design while maintaining consistency among thermal evaluation, structural response, and production objectives.

3.2. Design Space and Applicability

The admissible hybrid designs are identified through a set of temperature-dependent feasibility checks that act as a practical filter on the candidate design space. Given the temperature profile from Equation (5), feasibility is evaluated in terms of the FRP placement boundary, section-wise strength utilization, and operational effectiveness. This formulation keeps the constraints concise while allowing any infeasibility to be attributed to a specific cause and rod segment, which is essential for subsequent design updates.

The first check determines the FRP termination depth by mapping the temperature profile to a structural boundary. Rather than re-stating the temperature inequality, the FRP placement is defined as the deepest location that remains within the allowable FRP operating temperature. Accordingly, the FRP termination depth is obtained as

which directly converts the thermal environment into the FRP–steel partition. To account for modeling uncertainty and operational fluctuations, a conservative margin can be applied by replacing with , ensuring that the selected boundary is robust in long-term service.

Mechanical feasibility is then assessed using section-wise utilization factors, which provide an immediate indication of whether a violation originates from the FRP segment or the steel segment. For the FRP section, the utilization factor is evaluated by comparing the local stress demand to the temperature-dependent allowable stress,

and feasibility requires . For the steel section, the corresponding utilization factor is

with . This pair of metrics avoids redundant re-definition of stress relations while preserving a clear, implementable safety check that remains consistent with the local thermal state through .

To prevent designs that are mechanically feasible yet operationally ineffective under elevated temperature, an additional feasibility requirement is imposed on displacement effectiveness. In particular, the effective stroke must remain above a minimum acceptable threshold, ; alternatively, when a minimum liquid-rate target is specified, the predicted production must satisfy . These conditions ensure that the design does not rely on nominal pump settings that are subsequently undermined by temperature-amplified compliance, leading to excessive stroke loss and poor volumetric delivery.

Finally, applicability screening is used to exclude scenarios where FRP limitations would dominate regardless of thermal feasibility. Since FRP rods are not intended to operate in compression- or bending-dominated regimes, the candidate design should ensure that the FRP interval remains predominantly tensile during operation and that well trajectory severity does not exceed the practical deployment envelope of FRP rods. In practice, these checks are implemented using load-envelope information together with basic survey indicators such as deviation angle or dogleg severity as preliminary geometric triggers. For well sections where trajectory-induced bending may become non-negligible, a simplified bending-stress verification is further introduced. Under small-deflection assumptions, the local bending stress of an FRP rod is estimated from wellbore curvature according to

where denotes the temperature-dependent elastic modulus of the FRP rod, is the rod radius, and is the local wellbore curvature derived from directional survey data. The calculated bending stress is combined with the axial tensile stress to form an equivalent stress measure and is compared against the allowable FRP stress at the corresponding temperature. This treatment provides a lightweight yet quantitative applicability gate that preserves the intended scope of the proposed temperature-aware design framework.

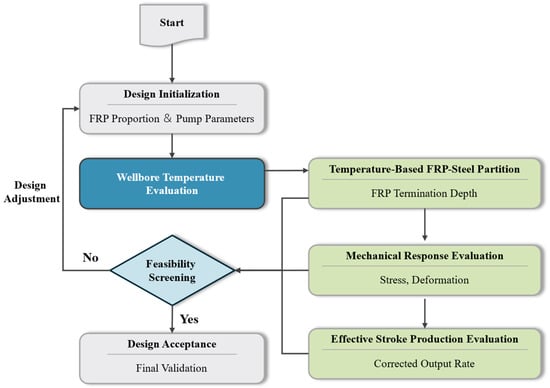

3.3. Iterative Design Procedure

Based on the temperature-aware framework and feasibility criteria established in Section 2.1 and Section 2.2, the hybrid rod-string design is implemented through an iterative process that links operating conditions, thermal response, structural configuration, and production performance. The overall workflow is summarized in Figure 7.

Figure 7.

Temperature-aware closed-loop design process for FRP–steel hybrid sucker-rod strings, highlighting thermal constraints, mechanical response, and iterative design adjustment.

The design procedure starts from an initial specification of the FRP proportion and pump operating parameters. These initial values serve only as a starting point for the subsequent evaluation. Under the given operating conditions, the wellbore temperature distribution is first evaluated, as temperature acts as the governing field variable throughout the design process. The resulting temperature profile directly determines the allowable placement depth of FRP rods and defines the FRP–steel partition within the hybrid rod string.

With the temperature-constrained configuration established, the mechanical response of the hybrid rod string is evaluated. In this step, particular attention is given to the temperature-dependent deformation of the FRP section, which dominates the axial elongation of the rod string. The corresponding elongation is then used to correct the effective plunger stroke, from which the resulting production performance is obtained.

The thermally corrected mechanical and production responses are subsequently subjected to a system-level feasibility screening, including mechanical safety of both FRP and steel sections, displacement effectiveness, and applicability conditions. If all criteria are satisfied, the current configuration is accepted as a valid hybrid rod-string design. Otherwise, the design parameters are adjusted in a targeted manner, and the wellbore temperature distribution is re-evaluated under the updated conditions, thereby forming a temperature-driven closed-loop design process.

4. Practical Case Application

A temperature-aware design methodology for FRP–steel hybrid sucker-rod strings was implemented algorithmically and embedded into the sucker-rod pumping optimization module of PetroPE. PetroPE (Petroleum Production Engineering Optimization and Decision Support System, version 2.3) is an integrated production-optimization and design platform developed by PetroChina (Beijing, China) for oil and gas engineering applications. In addition to its native design and analysis capabilities, the implementation follows a standardized interface specification, allowing the proposed methodology to be integrated into existing production-analysis and decision-support systems without modifying their core architectures. This implementation approach facilitates practical deployment of the method within established engineering workflows.

To verify the applicability and engineering feasibility of the proposed methodology under realistic operating conditions, a deep rod-pumped well from the Tarim Oilfield was selected as a field case. The well is characterized by a large pump-setting depth and elevated wellbore temperature, making it representative for evaluating temperature-related constraints on FRP rod-string design. The main operating parameters include a formation pressure of 52.3 MPa, a reservoir midpoint depth of 6093 m, a liquid production rate of 15.16 m3/d, a gas–oil ratio of 12 m3/m3, tubing and casing pressures of 0.1 MPa, a plunger diameter of 38 mm, a stroke length of 7.5 m, a pumping speed of 1.6 spm, a water cut of 49%, a dynamic fluid level of 3012 m, a pump-setting depth of 3600 m, tubing OD/ID of 73/62 mm, and a casing ID of 124 mm. The wellbore temperature distribution calculated under these conditions is shown in Figure 8.

Figure 8.

Calculated wellbore temperature distribution with depth under the given operating conditions. Representative temperatures are 71.9 °C at the dynamic fluid level (3012 m), 81.8 °C at the pump-setting depth (3600 m), and 125.7 °C near the reservoir midpoint depth (6093 m).

Under identical operating conditions and safety criteria, two rod-string design schemes were evaluated for comparison using the same software-based design platform. The design inputs include well parameters (pump-setting depth, dynamic fluid level, casing and tubing dimensions), production and operating parameters (liquid production rate, water cut, gas–oil ratio, stroke length, and pumping speed), pump specifications (plunger diameter and pump depth), and rod-string design constraints such as service factor, allowable stress–range ratio, and material selection. Temperature-related constraints are explicitly incorporated through the calculated wellbore temperature profile, which governs the allowable placement depth of FRP rods based on their permissible operating temperature. Certain engineering parameters that are not directly exposed in the graphical interface, including detailed wellbore structure and material property databases, are retrieved from the backend database of the platform and maintained by field engineers, ensuring consistency with actual field conditions.

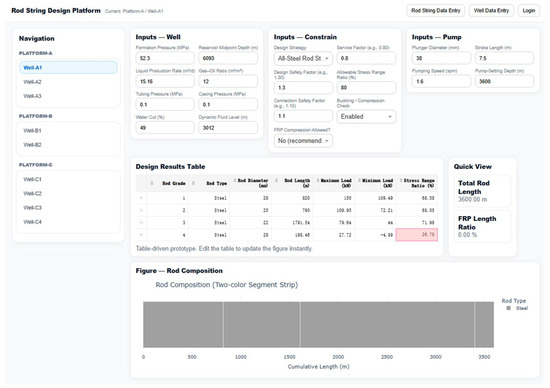

Based on this unified set of inputs and constraints, a conventional all-steel rod string was first designed using a service factor of 0.8, with the allowable stress–range ratio limited to 80% of the rated strength. The rod string was configured as a four-grade tapered steel string, with heavy-weight rod sections incorporated in the lower part to satisfy mechanical and stability requirements. The resulting rod-string configuration, load distribution, and stress-response characteristics were generated by the software and are presented in the graphical interface shown in Figure 9. The results indicate that, although the all-steel rod string satisfies the design constraints on maximum and minimum loads as well as stress–range ratios, the overall load level is relatively high, particularly in the upper rod sections, which imposes increased demands on surface pumping equipment and system energy consumption.

Figure 9.

Software-based design results of the all-steel sucker-rod string, showing rod-string configuration and corresponding load and stress distributions.

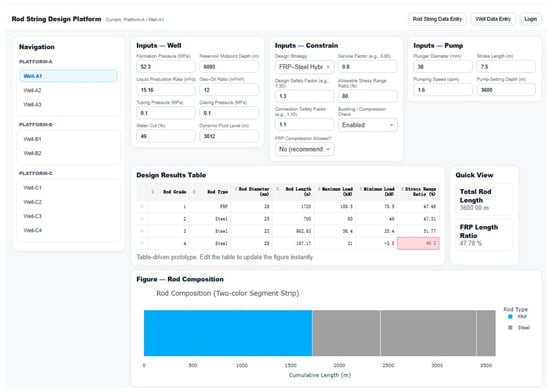

The proposed temperature-aware FRP–steel hybrid rod-string design methodology was then applied under the same conditions. In this scheme, the rod string was also configured as a four-grade tapered structure, with FRP rods placed in the uppermost section and steel rods used in the remaining lower sections, together with sinker bars as required. Importantly, the placement depth of the FRP section was not predefined but determined directly from the calculated wellbore temperature profile and the allowable operating temperature of the FRP material. The results show that the optimal termination depth of the FRP section is 1720 m, where the wellbore temperature is approximately 74 °C, well below the threshold for significant degradation of FRP mechanical properties. The corresponding hybrid rod-string configuration and load distribution are illustrated by the software interface in Figure 10.

Figure 10.

Software-based design results of the temperature-aware FRP–steel hybrid sucker-rod string, including FRP placement depth and load–stress response.

A comparison of the two design results shows that, in both the all-steel and hybrid schemes, the maximum and minimum rod-string loads, as well as the stress–range ratios, remain within allowable limits, satisfying the fundamental safety requirements. However, the FRP–steel hybrid rod string exhibits consistently lower stress–range ratios than the all-steel string, indicating more favorable cyclic loading conditions. In addition, the maximum load of the hybrid rod string is markedly lower than that of the all-steel design, which can effectively reduce the load on surface pumping equipment, lower energy consumption, and improve operational reliability in deep-well applications. These results demonstrate that, when guided by wellbore temperature constraints, the FRP–steel hybrid rod-string design achieves improved mechanical performance while maintaining engineering safety.

From an economic perspective, although the unit material cost of FRP rods is approximately three times that of steel rods, the hybrid design produces quantifiable operational cost benefits under deep-well conditions. In the present case, the maximum rod-string load of the FRP–steel hybrid configuration is reduced by approximately 25–30% compared with the all-steel design, which directly lowers the suspension load acting on the surface pumping unit. According to standard power-consumption correlations used in rod-pumped system engineering, such a reduction in suspension load typically results in a 15–20% decrease in surface motor power demand. Assuming continuous operation, this corresponds to an annual electricity saving on the order of 104–105 kWh for a single deep well, depending on pumping conditions. In addition, the stress–range ratio of the hybrid rod string is reduced by approximately 20–30%, which significantly decreases fatigue damage accumulation and is expected to extend rod-string service life and reduce workover frequency. When the combined effects of energy savings and reduced intervention costs are considered over a typical service period of several years, the additional upfront cost of FRP rods can be largely offset, rendering the FRP–steel hybrid rod string economically competitive for deep and ultra-deep rod-pumped wells.

In terms of field applicability, the field validation presented in this study is based on a single representative deep-well case and is primarily intended to demonstrate the feasibility and engineering effectiveness of the proposed temperature-aware FRP–steel hybrid rod-string design methodology. While the underlying framework is not restricted to this specific case, its applicability to highly deviated wells or more extreme high-temperature regimes has not been explicitly evaluated herein. This limitation is mainly associated with the availability of field data. Further investigations incorporating additional field cases, particularly those involving large deviation angles and higher bottomhole temperatures, will be conducted in future work to more comprehensively assess the generalizability of the proposed approach.

5. Conclusions

This study investigates the pronounced temperature sensitivity of FRP sucker rods in deep rod-pumped wells and proposes a temperature-aware design methodology for FRP–steel hybrid rod strings. By explicitly incorporating the wellbore temperature distribution into the design process, the method avoids empirical assumptions regarding FRP placement depth and establishes a physically grounded basis for rod-string configuration.

The results demonstrate that key mechanical properties of FRP rods, including elastic modulus, shear capacity, and tensile strength, degrade significantly with increasing temperature, indicating that temperature effects cannot be neglected in deep and ultra-deep wells. Accordingly, the proposed hybrid design framework treats the wellbore temperature profile as a primary constraint, clearly defining the applicable ranges and functional roles of FRP and steel rods along the string.

The methodology is implemented in an engineering design platform and validated through a field case from the Tarim Oilfield. Compared with a conventional all-steel rod string, the temperature-aware hybrid design satisfies all safety constraints while achieving lower maximum rod loads and stress–range levels, leading to improved cyclic loading conditions, reduced surface equipment demand, and lower energy consumption.

Overall, the proposed approach provides a practical and implementable engineering workflow for deep rod-pumped wells and has been verified under realistic field conditions. The results confirm its effectiveness and applicability, and the framework offers a solid basis for future extensions toward multi-objective optimization and intelligent rod-string design under more complex operating scenarios.

Author Contributions

Conceptualization, X.L. (Xin Lu) and G.H.; methodology, X.L. (Xin Lu); software, X.L. (Xin Lu) and X.L. (Xingyuan Liang); validation, X.L. (Xin Lu), Z.Z., and S.C.; formal analysis, X.L. (Xin Lu); investigation, X.L. (Xin Lu), Z.Z., and P.M.; resources, S.C. and P.M.; data curation, Z.Z. and P.M.; writing—original draft preparation, X.L. (Xin Lu); writing—review and editing, X.L. (Xin Lu), Z.X., and G.H.; visualization, X.L. (Xin Lu); supervision, Z.X. and G.H.; project administration, G.H.; funding acquisition, G.H. and X.L. (Xingyuan Liang). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science Foundation of China University of Petroleum, Beijing, grant number 2462023YJRC019. The APC was funded by the Science Foundation of China University of Petroleum, Beijing.

Data Availability Statement

The data presented in this study are available from the corresponding author upon reasonable request. Due to confidentiality agreements and field data restrictions, some datasets are not publicly available.

Conflicts of Interest

Author Zhuangzhuang Zhang was employed by the company Petro China Changqing Oilfield Company. Author Shuping Chang was employed by the company SLB. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhang, Y.-W.; Che, J.-Q.; Wang, H.-X.; Zhang, J.; Li, F.; Du, M.-C.; Wang, Y.-T. Mechanical characteristic and failure mechanism of joint with composite sucker rod. Pet. Sci. 2023, 20, 3172–3183. [Google Scholar] [CrossRef]

- Zhang, Y.; Che, J.; Zhang, H.; Li, F.; Zhang, J.; Wang, H.; Pei, D. An evaluation of the influence of mechanical strength on carbon/glass hybrid rods under various design parameters. Geoenergy Sci. Eng. 2024, 240, 212927. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Che, J.; Du, M.; Liu, Y. Numerical investigation and structural optimization of bonded joints with fiber reinforce plastic sucker rods in offshore reservoirs. J. Adhes. 2023, 99, 733–751. [Google Scholar] [CrossRef]

- Carpenter, C. Fiber-Reinforced Thermoplastic Sucker Rods Provide Artificial Lift Efficiencies. J. Pet. Technol. 2024, 76, 85–87. [Google Scholar] [CrossRef]

- Saponja, J.; Coyes, C.; Conner, M. Fiber Reinforced Thermoplastic (FRTP) Sucker Rods Providing High Strength Light Weight Low Cost and Environmentally Responsible Artificial Lift Efficiencies. OnePetro 2024. [Google Scholar] [CrossRef]

- Saponja, J.; David, S.; Pipchuk, D.; Hari, R.; Gothrup, J.; Bentsen, J.; Smith, C.; Kubacak, T. Recyclable Fiber Reinforced Thermoplastic Sucker Rods for Improving Rod Pumping. OnePetro 2024. [Google Scholar] [CrossRef]

- Krechkovska, H.; Bakun, B.; Kopey, I.; Student, O. Feature of fatigue fracture of the composite sucker rod. Procedia Struct. Integr. 2024, 59, 292–298. [Google Scholar] [CrossRef]

- Krechkovska, H.; Kopey, B.; Bakun, B.; Kopey, I. Pecularities of fatigue cracks growth in steel and composite sucker rods. Procedia Struct. Integr. 2022, 42, 1406–1413. [Google Scholar] [CrossRef]

- Lv, X.-X.; Jin, W.-R.; Zhang, X. A dual-scale failure evaluation method for Carbon-glass hybrid Fiber sucker rod and their joints under complex loads. Pet. Sci. 2025, 22, 2570–2591. [Google Scholar] [CrossRef]

- Lv, X.-X.; Wang, H.-X.; Xin, Z.; Liu, Y.-X.; Zhao, P.-C. Adaptive fault diagnosis of sucker rod pump systems based on optimal perceptron and simulation data. Pet. Sci. 2022, 19, 743–760. [Google Scholar] [CrossRef]

- Lv, X.; Feng, L.; Wang, H.; Liu, Y.; Sun, B. Quantitative diagnosis method of the sucker rod pump system based on the fault mechanism and inversion algorithm. J. Process Control 2021, 104, 40–53. [Google Scholar] [CrossRef]

- Lv, X.; Wang, H.; Zhang, X.; Liu, Y.; Jiang, D.; Wei, B. An evolutional SVM method based on incremental algorithm and simulated indicator diagrams for fault diagnosis in sucker rod pumping systems. J. Pet. Sci. Eng. 2021, 203, 108806. [Google Scholar] [CrossRef]

- Lv, X.; Wang, H.; Zhang, X.; Liu, Y.; Chen, S. An equivalent vibration model for optimization design of carbon/glass hybrid fiber sucker rod pumping system. J. Pet. Sci. Eng. 2021, 207, 109148. [Google Scholar] [CrossRef]

- Guan, W.; Guo, S.; Guo, Y.; Chen, K.; Zhao, G. Research on the recovery process and product performance of carbon fiber flexible sucker rod in microwave field. Compos. Part B Eng. 2024, 282, 111576. [Google Scholar] [CrossRef]

- Guan, W.; Han, Z.; Su, W.; Guo, S.; Guo, Y. Comprehensive study of thermal degradation behavior of carbon fiber flexible sucker rods: Product characteristics, kinetics and thermodynamics. Fuel 2023, 333, 126306. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Hong, B. Effects of rod size and fiber hybrid mode on the interface shear strength of carbon/glass fiber composite rods exposed to freezing-thawing and outdoor environments. J. Mater. Res. Technol. 2021, 14, 2812–2831. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Hua, C.; Chen, S.; Xu, G.; Lu, Y.; Du, B. Defect identification method of carbon fiber sucker rod based on GoogLeNet-based deep learning model and transfer learning. Mater. Today Commun. 2022, 33, 104228. [Google Scholar] [CrossRef]

- Li, C.; Yin, X.; Wang, Y.; Zhang, L.; Zhang, Z.; Liu, Y.; Xian, G. Mechanical property evolution and service life prediction of pultruded carbon/glass hybrid rod exposed in harsh oil-well condition. Compos. Struct. 2020, 246, 112418. [Google Scholar] [CrossRef]

- Yin, X.; Liu, Y.; Miao, Y.; Xian, G. Water Absorption, Hydrothermal Expansion, and Thermomechanical Properties of a Vinylester Resin for Fiber-Reinforced Polymer Composites Subjected to Water or Alkaline Solution Immersion. Polymers 2019, 11, 505. [Google Scholar] [CrossRef]

- Jiang, J.; Wan, X.; Li, K.; Du, J.; Liu, Y.; Jing, J.; Li, J. Research progress of sucker rod fracture detection and prediction model. Eng. Fail. Anal. 2024, 159, 108119. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, S.; Ma, W.; Ran, X.; Qu, B. Machine learning method for predicting the fatigue life of sucker rods. Eng. Fract. Mech. 2023, 282, 109161. [Google Scholar] [CrossRef]

- Zhong, X.-C.; Xie, R.-K.; Qin, S.-H.; Zhang, K.-S. A process-data-driven BP neural network model for predicting interval-valued fatigue life of metals. Eng. Fract. Mech. 2022, 276, 108918. [Google Scholar] [CrossRef]

- Zuo, Y.; Wu, X. A comparative study of four rod load reduction techniques for deep-rod pumping. J. Pet. Explor. Prod. Technol. 2018, 8, 475–483. [Google Scholar] [CrossRef]

- Song, C.; Song, W.; Li, Y.; Li, N.; Liang, M.; Zhang, H. Cause Analysis on Fracture of Fiberglass Sucker Rod. lhjywlfc 2020, 56, 70–73. [Google Scholar] [CrossRef]

- Wdowiak-Postulak, A.; Świt, G.; Dziedzic-Jagocka, I. Application of Composite Bars in Wooden, Full-Scale, Innovative Engineering Products—Experimental and Numerical Study. Materials 2024, 17, 730. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.N.; Ishak, M.R.; Taha, M.M.; Mustapha, F.; Leman, Z. Rheological and Morphological Properties of Oil Palm Fiber-Reinforced Thermoplastic Composites for Fused Deposition Modeling (FDM). Polymers 2021, 13, 3739. [Google Scholar] [CrossRef]

- Ramey, H.J., Jr. Wellbore Heat Transmission. J. Pet. Technol. 1962, 14, 427–435. [Google Scholar] [CrossRef]

- Yu, Y.; Meng, Z. Geothermal Distribution Characteristics in the Qinshui Basin and Its Significance to the Production of Coalbed Methane. ACS Omega 2021, 6, 18914–18927. [Google Scholar] [CrossRef]

- Wang, C.; Liu, H.; Yu, G.-W.; Yu, C.; Liu, X.-M.; Huang, P. Wellbore-heat-transfer-model-based optimization and control for cooling downhole drilling fluid. Pet. Sci. 2024, 21, 1955–1968. [Google Scholar] [CrossRef]

- Raman, R.; Guo, F.; Al-Saadi, S.; Zhao, X.-L.; Jones, R. Understanding Fibre-Matrix Degradation of FRP Composites for Advanced Civil Engineering Applications: An Overview. Corros. Mater. Degrad. 2018, 1, 27–41. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.