Abstract

Severe lost circulation frequently occurs in deep and ultra-deep wells under high-temperature/high-pressure (HPHT) conditions and in fracture-cavity composite loss channels. Conventional lost-circulation materials (LCMs) often fail because of premature loss of mobility, insufficient residence in loss paths, and irreversible failure after solidification. Cement-based sealing systems, owing to their ability to plug large leakage channels and their cost-effectiveness, have become the mainstream solution. To improve their performance under extreme downhole conditions, recent studies have focused on base-cement design, reinforcement phases, and property regulation strategies-including the use of granular/fibrous/nanoscale additives for bridging reinforcement, rheology and thickening control to enhance injectability and residence, and chemical/functional modifiers to improve compactness and durability of the hardened matrix. Significant progress has been achieved in terms of HPHT resistance, densification design, regulation of rheological properties and thickening behavior, and self-healing/responsive sealing functions. However, most existing studies still focus on improving individual properties and lack a cross-scale, holistic design and unified mechanistic perspective for fracture-cavity coupled flow and long-term sealing stability. Distinct from previous reviews that mainly catalogue material types or discuss single-performance optimization, this review is framed by fracture-cavity composite loss channels and long-term sealing requirements under HPHT conditions, systematically synthesizes the material design strategies, reinforcement mechanisms and applicability boundaries of cement-based plugging systems, builds cross-scale linkages among these aspects, and proposes future research directions toward sustainable plugging design.

1. Introduction

As shallow conventional oil and gas resources become increasingly depleted and global energy demand continues to climb, deep (>4500 m) and ultra-deep (>6000 m) reservoirs have emerged as critical successor targets for ensuring energy security and advancing the low-carbon transition [1]. However, the development of these reservoirs typically encounters extreme conditions, including elevated temperatures, high pressures, intense geological stresses, and highly complex tectonic and lithological settings [2]. Bottomhole temperatures in deep wells often exceed 150 °C, while formation pressure coefficients frequently surpass 1.5. Furthermore, fractures, dissolution pores, and fault zones within carbonate, igneous, and metamorphic formations often form interconnected three-dimensional flow networks. These features result in frequent wellbore leakage, prolonged drilling cycles, and significantly increased operational costs [3].

Wellbore losses can be classified according to their severity into permeable, fractured, karstic, and total losses of circulation. Fractured and karstic losses are typically categorized as severe lost-circulation events, characterized by high loss rates, substantial fluid consumption, and low sealing success [4]. For instance, in the Ordovician carbonate formations of the Shunbei region within the Tarim Basin, cavernous voids can reach several thousand cubic meters, with circulation losses per well reaching 1000–3000 m3 [5]. Similarly, OMV reported severe lost circulation in the Sawan field in Pakistan, where highly permeable zones and naturally or induced fractured formations in the SML interval caused mud losses of about 3000 bbl per well and more than 20,000 bbl in the Sawan-3 well despite 8 days of conventional LCM treatments [6]. Severe lost-circulation pathways span a wide range of scales-from micrometers to meters-and display complex fracture-karst connectivity, making it challenging for conventional plugging materials to maintain stability [7]. Meanwhile, elevated temperatures accelerate the degradation of material strength, whereas high pressure differentials induce secondary extrusion and structural failure of the plugging body, rendering conventional plugging systems incapable of ensuring long-term sealing effectiveness [8].

Among the various technical approaches currently used to control severe lost circulation—such as mechanical isolation tools, granular/fibrous LCM pills and chemical gel plugging systems—cement-based composite sealing systems have become the predominant solution in deep wells because of their superior pumpability, high post-curing load-bearing capacity, and durable interfacial bonding performance [9]. This system has evolved from a single-phase volumetric filling approach to a multi-component synergistic mechanism involving particles, fibers, and cement. Specifically, optimally graded particles bridge the pore throats, fibers form a three-dimensional support network, and the cement slurry subsequently fills the residual voids and hydrates to form a high-strength sealing structure [10,11,12]. This three-stage synergistic mechanism—comprising particle bridging, fiber reinforcement, and cement consolidation—effectively mitigates chaotic slurry loss, thereby enhancing the structural integrity and erosion resistance of the sealing layer.

High-temperature and high-pressure conditions in deep wells strongly affect the hydration process, microstructural evolution and mechanical integrity of cement-based systems; elevated temperatures can alter hydration products and accelerate strength degradation, while large pressure differentials may extrude or erode the grout before solidification [13]. To mitigate these effects, most studies converge on three main strategies: optimizing hydration and matrix densification with supplementary and nano-scale materials, constructing load-bearing skeletons with fibers and rigid fillers, and employing functional admixtures (e.g., setting regulators, expansive and self-healing components) to stabilize sealing layers under HPHT and long-term fluid erosion [14,15,16,17]. Together, these approaches address complementary failure modes and improve the robustness of cement-based sealing systems in deep, complex operating environments.

Overall, for severe lost circulation scenarios in deep wells, cement-based composite plugging systems have achieved significant progress in enhancing high-temperature resistance, optimizing densification design, improving fiber reinforcement, regulating nanoscale structures, introducing functional modifications, and increasing resistance to pressure-bearing erosion. They have demonstrated excellent sealing stability under conditions exceeding 200 °C and 50 MPa. However, most existing studies primarily focus on optimizing isolated performance parameters, while lacking a systematic, cross-scale, and cross-mechanism design framework that addresses composite fracture-karst channel structures, coupled thermo-pressure environments, and long-term service performance. Therefore, this study provides a systematic review of the current progress in cement-based composite plugging systems, summarizes the underlying performance enhancement mechanisms and applicability limits, and identifies the key scientific and engineering challenges. The objective is to provide structured insights and strategic guidance for future material development and engineering practice.

2. Characteristics of Severe Lost Circulation Under HPHT Conditions and Challenges in Plugging Technology

2.1. Characteristics of Severe Lost Circulation and Plugging Mechanism

Under deep drilling conditions, severe lost circulation refers to an uncontrolled event in which drilling fluid continuously invades the formation at an extremely high rate, ultimately causing a complete loss of circulation pressure. The classification based on leakage rate is presented in Table 1, including Minor (Q < 5 m3/h), Moderate (5 < Q ≤ 15 m3/h), Severe (15 < Q < 30 m3/h), and Loss-of-Circulation Type (Q > 30 m3/h), which is further categorized as Severe Lost Circulation [18,19]. Taking the Xuanhan-Kaijiang block as an example, Wang Weibin et al. reported that severe well losses exhibit typical features, including long leakage intervals, multiple loss zones, high loss rates, and large loss volumes [20]. In carbonate fracture-cavity reservoirs, the multi-level interconnectivity of fractures and cavities results in more than 50% of oil wells being exposed to severe leakage risks [21]. As exploration and development extend into deeper formations, regions such as Bohai Bay and the Tarim Basin have experienced a significant rise in well-loss frequency, particularly in fracture-prone formations like faulted and buried mountain fracture zones. These incidents are characterized by high variability in loss rates and considerable challenges in effective sealing [22].

Table 1.

Classification of mud loss according to its severity [19].

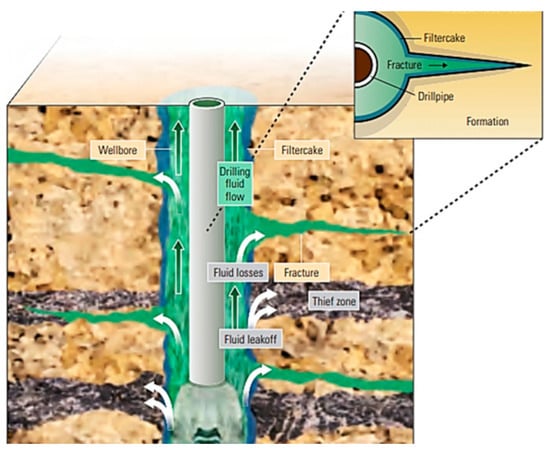

Based on formation characteristics, well losses are generally classified into six categories: (1) high-permeability losses; (2) karst-cavity losses; (3) horizontal natural-fracture losses; (4) horizontal induced-fracture losses; (5) vertical natural-fracture losses; and (6) vertical induced-fracture losses. Studies have shown that large karst cavities and highly conductive fractures serve as the main pathways for severe lost circulation (Figure 1) [23]. Among these types, highly permeable zones and large karst cavities pose the most severe challenges for cement-based sealing systems. Fracture propagation driven by pressure differentials is a common trigger: when interlayer pressure differences exceed approximately 20 MPa, drilling fluids may induce further fracture growth, with apertures potentially reaching the size of a drill bit. Liu F. et al. reported that in the foreland belt of the Tarim Basin, high-pressure salt-bearing layers and low-pressure clastic rock layers are extensively distributed within overlapping structural zones. Significant deviations in geological interface identification can readily induce non-return-type wellbore loss events [24].

Figure 1.

Fluid flowing into different lost-circulation conduits, where severe channels cause total loss of drilling fluid returns [23].

In summary, severe wellbore losses typically exhibit distinguishing characteristics such as large loss volume, high loss rate, substantial depth of loss zone, and strong connectivity of loss channels. Conventional lost circulation control systems often struggle to form stable sealing structures; thus, high-performance materials and specialized techniques are required to achieve effective containment.

2.2. Effects of High-Temperature and High-Pressure Environments on the Mechanism of Cement-Based Leak Sealing Systems

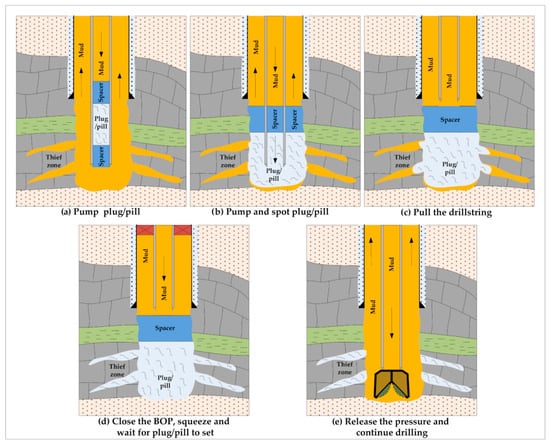

The fundamental sealing mechanism of cement-based composite plugging systems is governed by the injection, retention, and solidification of sealing slurry within formation fractures or cavities. Figure 2 illustrates a typical operational workflow, in which the sealing slurry or isolation fluid is pumped down the wellbore through the drill string and delivered to the vicinity of the loss zone. During the spotting process, the slurry is retained within the loss zone. Subsequently, the drill string is withdrawn and the blowout preventer is closed, forcing the slurry into the fracture-karst channels by displacement to ensure effective filling and sealing. Once the slurry has cured at the target location, pressure is released and normal drilling operations resume [25]. This process consists of four principal stages: pumping, spotting, squeezing, and curing. This approach represents the most widely adopted cement-based plugging strategy for deep-well leak remediation [26].

Figure 2.

Workflow procedure of spotting and squeezing cement-based plugs or polymer-based pills [25].

Building upon the operational principles of cement-based plugging systems, their performance under deep HPHT conditions presents additional technical challenges. The coupled effects of high temperature and high pressure deteriorate the mechanical and rheological properties of cement, thereby compromising the reliability and long-term durability of plugging operations [27]. Firstly, elevated temperatures markedly accelerate cement hydration reactions. According to the Arrhenius relationship, cement hydration rates roughly double for every 10 °C increase, so a 3–4 h setting time at ambient conditions can shrink to only tens of minutes at 150–200 °C [28]. Such rapid setting sharply reduces slurry fluidity, limits penetration, and produces thin, weakly bonded sealing layers that are prone to debonding and fluid migration during subsequent operations [29]. Rapid precipitation of hydration products coats the cement particles, leading to a rapid loss of fluidity. In addition to reducing setting time, elevated temperatures also significantly deteriorate the rheological behavior and fluid loss control of cement slurry. Experimental results show that as temperature increases from 25 °C to 150 °C, plastic viscosity may increase by 30–80%, dynamic shear stress by 50–120%, and overall pumpability deteriorates markedly [30,31,32].

More critically, conventional functional additives exhibit severe performance degradation under elevated temperatures: lignosulfonate retarders lose effectiveness above 120 °C, cellulose ether loss reducers hydrolyze above 130 °C, starch-based additives thermally decompose near 150 °C, polyacrylamide experiences chain scission above 180 °C, and several synthetic water reducers show markedly reduced dispersibility above 140 °C [33]. Such additive failures not only prevent the slurry from meeting performance specifications but also produce degradation byproducts that interfere with hydration reactions and alter the system pH, thereby further impairing cementitious performance. Under HPHT conditions, materials are simultaneously subjected to mechanical scouring, structural fracturing, and chemical erosion. The combined influence of these factors renders the sealing layer highly susceptible to instability and prone to the re-initiation of seepage channels [34].

3. Mechanism for Optimizing Cement-Based Leak-Sealing Systems

The sealing process of a leak-stopping cement slurry can be divided into three distinct stages: the pumping stage, the sealing stage, and the filling/curing stage [35]. Corresponding system optimization should likewise focus on these three stages. During the pumping stage, the emphasis is placed on regulating rheological properties and controlling the thickening time to ensure that the slurry remains pumpable under high-temperature conditions and can be effectively delivered to the leakage zone. In the sealing stage, particle bridging and fiber entanglement capabilities should be enhanced to facilitate rapid retention and achieve an initial seal at the entrance of the leakage channel. During the filling and curing stage, controlling the evolution of hydration products, promoting microstructural densification, and strengthening interfacial bonding are essential for forming a durable sealing barrier with high mechanical strength and erosion resistance.

3.1. Cement-Based Materials

3.1.1. Ultrafine Cement

During the sealing process of complex leakage layers, the fluidity of cement systems not only governs their capacity to penetrate narrow fractures but also affects their permeation and filling efficiency within micropore throats. Ultrafine cement, characterized by micron-scale particle sizes and markedly increased specific surface area, combines high reactivity with superior filling performance. It has emerged as a critical technological strategy for enhancing the “flow-filling-compaction” performance of cement-based sealing systems.

Existing studies indicate that ultrafine cement can effectively optimize pore structures and improve mechanical properties. Kunlei Zhu found that in ultrafine tailings cementation systems, ultrafine cement reduces total porosity and macropore volume distribution, thereby enhancing material compactness and compressive strength. Simultaneously, the presence of thickened water films increases the expansion diameter and improves flowability by reducing interparticle friction and facilitating smoother particle migration [36]. Shi et al. further demonstrated that ultrafine cement markedly accelerates early hydration, achieving a 24-h compressive strength of 55.94 MPa in a system with particle sizes of approximately 6.8 μm—roughly double that of conventional cement [37]. Zhang et al.’s findings also indicate that increasing ultrafine cement content simultaneously improves compressive and tensile strength while markedly reducing fractal dimension and porosity, thereby demonstrating concurrent optimization of material density and load-bearing capacity [38].

Beyond direct strengthening effects, ultrafine cement also exhibits synergistic mechanisms in composite systems [39]. Meng prepared green cementitious materials using ultrafine Portland cement blended with high-volume solid waste, finding that their mechanical properties significantly outperformed traditional blended cements. Energy consumption and carbon emissions were only 47.3% and 40.9% of ordinary cement, respectively, attributed to its ability to increase particle packing density and promote secondary hydration of mineral admixtures, forming a dense structure [40]. Li et al. also noted that reducing particle size enhances packing, reduces free water voids, and increases cohesion and internal friction angle between solid particles, thereby significantly improving early-stage shear resistance [41].

It is important to emphasize that ultrafine cement exhibits a high specific surface area and rapid hydration characteristics, which can readily lead to viscosity increases or even shear thickening under low water-to-cement ratio conditions. Existing studies indicate that ultrafine cement can markedly mitigate shear thickening under low water content conditions, although this effect diminishes under high water content conditions [42]. Therefore, both its performance benefits and potential rheological instabilities should be simultaneously considered in system design.

Ultrafine cement markedly improves microcrack accessibility and early sealing performance through “micro-filling densification—rapid hydration—structural compaction” and enhanced crack penetration. Nevertheless, its use is constrained by high cost, rapid fluid loss, and the risk of premature setting.

3.1.2. Geopolymer Cement

During drilling and workover operations in acidic gas reservoirs (containing CO2/H2S), fluid loss and packer failures frequently occur. Conventional Portland cement systems experience chemical reactions in this environment, including carbonation, Ca(OH)2 dissolution, and CO2 salt precipitation, which result in pore reconnection, degradation of interfacial cementation, and CO2 migration instability, rendering them unsuitable for long-term sealing applications [43]. In contrast, geopolymer-based slurries utilize a three-dimensional Si–O–Al network structure with minimal calcium content and negligible carbonatable Ca(OH)2, providing inherent resistance to degradation in acidic gas environments [44].

Existing studies have established a consistent evidence base. Ridha and Yerikania conducted HCl/HF acid immersion tests and observed that the compressive strength of geopolymers decreased by only 1.76%, markedly lower than the 28% reduction in Portland cement, indicating negligible decalcification or dissolution damage to their structure [45]. Nasvi monitored permeability under sub- and supercritical CO2 conditions, revealing no changes in pore connectivity or structural degradation after prolonged high-pressure CO2 exposure [46]. Barlet-Gouedard’s microanalysis of materials subjected to 15 days of high-temperature, high-pressure CO2 exposure similarly detected no typical failure signs, such as delamination, crack propagation, interfacial disruption, or formation of crystallization products [47].

From an engineering perspective, geopolymer slurries typically exhibit low yield stress and non-Newtonian rheological behavior, facilitating penetration into microfractures and pore throats for deep-seated sealing. Their viscosity decreases with rising temperature, aligning with the high-temperature conditions typical of acidic reservoirs and potentially reducing pumping pressure and flow resistance [48]. Moreover, multiple studies indicate that geopolymer strength positively correlates with temperature, optimally within the 122–194 °F range [49]. This trend of performance enhancement under thermochemical coupling contrasts with the degradation observed in conventional silicate systems under identical conditions, highlighting the superior suitability of geopolymers for the temperature-pressure environments of acid gas reservoirs.

In acid gas reservoir plugging applications, geopolymer systems offer multiple advantages, including resistance to acidic corrosion, resistance to CO2 degradation, enhanced high-temperature stability, superior pumpability, and durable long-term sealing performance. These characteristics position geopolymers as a high-potential alternative when conventional Portland cement systems fail to meet the demands of such challenging operational conditions.

3.1.3. Special High-Temperature Cement System

In addition to geopolymers, certain specialized high-temperature cement systems demonstrate exceptional thermal resistance and structural stability under HPHT wellbore conditions. These systems employ distinct hydration pathways and tailored product compositions to effectively mitigate the performance degradation observed in ordinary Portland cement at elevated temperatures, providing more versatile material options for addressing severe lost circulation in deep wellbore environments.

- (1)

- Calcium Sulfoaluminate, CSA

CSA primarily comprises calcium sulfoaluminate anhydrous (, 40–70%), dicalcium silicate (β-C2S), and tetracalcium aluminate ferrite (C4AF), exhibiting high hydration activity at 180–220 °C. As shown in Equation (1), at elevated temperatures, rapidly reacts with gypsum to form abundant acicular aluminate hydrates (AFt), resulting in a dense, interwoven skeletal structure. This reaction induces approximately 8–10% volumetric expansion, effectively compensating for high-temperature shrinkage and interfacial stress mismatches. Consequently, the sealing layer exhibits enhanced compactness and interfacial stability.

To improve high-temperature performance, incorporating 10–15% silica fume and 5–10% kaolinite often promotes the formation of stable C–A–S–H gel, extending the material’s upper temperature limit to approximately 220 °C. Additional admixtures can further optimize high-temperature performance. Guoxin Li reported that the LC-AS admixture promotes AFt formation and accelerates belite hydration, thereby enhancing CSA workability and early strength development across various temperatures [50]. Konrad A. Sodol observed that CSA paste undergoes localized re-sintering above 600 °C during isothermal treatment from 23 to 800 °C, yet retains residual load-bearing capacity, with compressive strength of approximately 8 MPa at 800 °C [51].

Notably, calcium aluminate in CSA systems undergoes reversible phase transitions above approximately 150 °C, as shown in Table 2, accompanied by both endothermic and exothermic processes. This behavior endows CSA with potential applications in thermal energy storage and has been proposed for utilization in thermal cycling energy storage systems [52].

Table 2.

Calcium Sulfo-Aluminate (CSA) Phase Decomposition [52].

- (2)

- Phosphate Cement

Phosphate cement is an acid-base reaction curing system, in which the setting process originates from the neutralization reaction between metal oxides (e.g., MgO, Al2O3, ZnO) and phosphoric acid or phosphates. For example, typical magnesium phosphate cement (MPC) is formed through the reaction of MgO with KH2PO4 to produce MgKPO4·6H2O, with a reaction rate constant of 0.15–0.25 min−1 at 25 °C, which is significantly higher than that of Portland cement (0.001–0.005 min−1). This enables rapid retention and solidification within high-velocity leakage channels, effectively minimizing grout loss.

The phosphate cement system shows excellent thermal stability, with its P–O/Al–O framework remaining intact up to about 400–600 °C. In ultra-high-temperature carbonate reservoirs (>250 °C), aluminum phosphate cement can maintain or even increase strength through AlPO4 crystallization and matrix densification, and Shiqun Li et al. reported that phosphoaluminate cement still retains ~60 MPa compressive strength after high-temperature transformation from an initial 24 h strength of ~16 MPa without admixtures [53].

Regarding its high-temperature behavior, Li Yue found through thermal exposure experiments conducted at 130–1000 °C that MPC exhibits a significant strength decline above 130 °C, although the rate of decline slows at higher temperatures. The addition of fly ash and sand reduces residual strength [54]. E. Qoku’s study of four phosphate systems (KH2PO4, Mg(H2PO4)2, Al(H2PO4)3, Ca(H2PO4)2) demonstrated that materials exposed to 1000 °C could recover their long-range crystal structure and form a stable KMgPO4 phase [55]. To enhance high-temperature stability, Xiaojian Gao found that incorporating 10% wollastonite improves the strength retention of MAPC and MKPC after exposure to 200–1000 °C without altering primary hydration products, demonstrating wollastonite as an effective heat-resistant reinforcement [56].

In summary, phosphate cement demonstrates significant advantages in HPHT wellbore failure scenarios where conventional cement fails, due to its rapid setting, high-temperature stability, and high compressive strength. It is emerging as a promising alternative for high-temperature plugging systems, offering substantial potential for deep and ultra-deep well applications.

- (3)

- Magnesia cement (MgO–SiO2 system)

Magnesia cement systems maintain the integrity of sealing structures under cyclic temperature fluctuations owing to their low thermal expansion and excellent thermal shock resistance. These systems produce magnesium silicate hydrate gel (M–S–H, MgxSiγOx+2γ·nH2O) via the reaction of MgO and SiO2 in aqueous solution. Its layered structure, analogous to montmorillonite, provides the system with excellent flexibility and adaptive deformation capacity. Under typical geothermal well conditions (production period approximately 180 °C, shutdown period approximately 60 °C), magnesium cement demonstrates high durability, retaining 85–90% of its compressive strength while permeability increases by less than 20% [57]. This thermal cycling stability partly arises from the system’s self-healing ability, in which unreacted MgO repairs microcracks during subsequent hydration.

To further enhance the stability of magnesium-based systems under high-temperature and high-humidity conditions, various material modification strategies have been investigated. Bin Li enhanced the high-temperature and water-resistant properties of MOSC (magnesium oxysulfate cement) by incorporating silica fume (SF). Results indicated that the addition of SF increased MOSC’s residual strength across the 200–800 °C range. Notably, under prolonged exposure at 400 °C, silica fume further promoted the conversion of MgO into M–S–H gel, thereby enhancing compressive stability after high-temperature treatment [58]. For the magnesium phosphate system, Yuqi Yang examined the strength retention of MKPC mortar after 3-h isothermal exposure at 400, 600, and 800 °C and analyzed the combined effects of fly ash and silica fume. Results indicate that MKPC mortar achieves optimal high-temperature mechanical retention at an M:P ratio of 2:1 with 5% fly ash and 15% silica fume admixtures, confirming the effectiveness of mineral additives in enhancing the high-temperature stability of phosphate-magnesium systems [59].

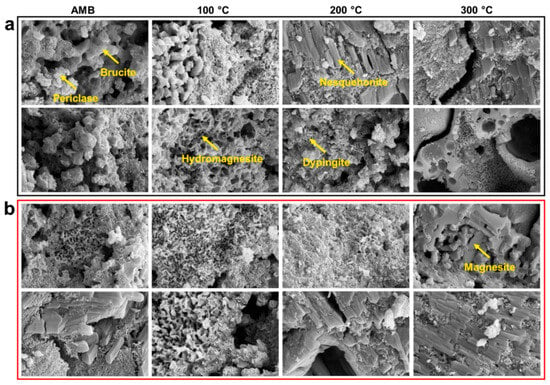

Additionally, reactive magnesium oxide cement (RMC) reacts with CO2 to form stable carbonate products, demonstrating both carbon sequestration potential and a tendency for strength gain during high-temperature cycling. Abdullah Khalil’s research shows that RMC achieves increased compressive strength after multiple thermal cycles up to 300 °C under both natural curing and accelerated carbonation conditions (Figure 3), highlighting the structural stability and reinforcing effect of carbonation products in high-temperature environments [60]. Moreover, recent advances in understanding the interfacial dynamics of magnesium–CO2 interactions have provided new insights into the long-term sealing performance of magnesia-based systems under subsurface CO2 conditions. For example, Li et al. reported that magnesium ions could significantly accelerate CO2 hydrate nucleation and growth by coupling with hydrophobic amino acids, thereby enhancing the kinetics and stability of CO2 fixation in aqueous systems [61]. These findings offer valuable implications for elucidating the interfacial reaction mechanisms of RMC during CO2 mineralization and its potential for durable carbon storage.

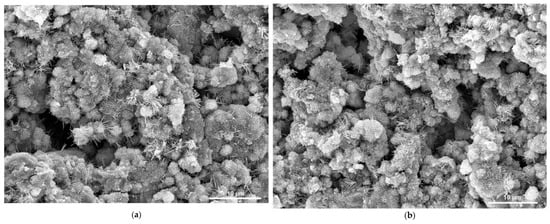

Figure 3.

SEM images of (a) RMC-A and (b) RMC-C samples after ambient and cyclic curing at 100, 200, and 300 °C. Each micrograph is 10 μm wide [60].

In summary, the magnesia cement system holds significant application potential for high-temperature wellbore leakage and cyclic thermal loading scenarios owing to its thermal cycling stability, self-healing ability, and high-temperature performance, which can be further enhanced through the use of admixtures.

Overall, specialty cement systems with differentiated chemistries—such as CSA-, phosphate-, and MgO-based cements—provide targeted material strategies for HPHT lost-circulation control, owing to their tailored hydration pathways and performance advantages. CSA cements rely on expansion compensation to achieve volumetric stability and are suitable for conditions requiring mitigation of high-temperature shrinkage. Phosphate cements (MPC/MKPC) offer rapid setting and early strength, making them attractive for high-loss-rate emergency plugging [62]. MgO-based cements exhibit excellent thermal-cycling stability and therefore support long-term well integrity.

However, the field applicability of these systems is not determined solely by their intrinsic performance; rather, it is jointly constrained by chemical compatibility with oilwell additives and durability under aggressive downhole chemistries. Existing studies demonstrate that CSA hydration is highly sensitive to superplasticizer-retarder interactions. Mondal et al. [63] highlighted the need to jointly optimize superplasticizer and retarder dosage with gypsum content and AFt formation kinetics; Govin et al. [64] reported strong nonlinear interactions between PCE and various retarders; Golaszewska et al. [65] identified a formulation-dependent “compatibility window”; and Boul et al. [66] showed that, above 150 °C, multiple retarders may exhibit synergistic or antagonistic effects and interact with other additives to alter thickening behavior. Phosphate cements, although more durable than OPC in high-salinity or chloride-rich environments, show formulation-dependent compatibility with PCE, whose dosage must be controlled because excessive retardation may compromise the rapid-setting characteristic. Molecular-scale analyses by Y. Li et al. [67] further elucidated ion-cement interactions and interfacial stability mechanisms in NaCl solutions. MgO-based systems exhibit even higher sensitivity to additive chemistry, brine composition, and pH; as summarized by Walling and Provis, the stability of their hydration products is strongly governed by solution chemistry and solid–liquid interfacial reactions. Therefore, while specialty cement systems offer promising pathways for deep fracture-cavity lost-circulation control, their advantages must be assessed together with additive compatibility envelopes and chemical-environment durability to ensure reliable sealing performance under HPHT conditions.

3.2. Selection of Cement-Based Performance Enhancers for Leak Sealing

Under severe lost circulation conditions in deep HPHT wells, relying solely on the hydration and consolidation of the cement matrix is insufficient to form a long-term stable sealing structure. Functional reinforcement materials must be incorporated to provide multiple enhancements, including erosion resistance, resistance to pressure differentials, crack resistance, and improved compaction. Current reinforcement strategies primarily target three directions: fiber reinforcement, nano-modified materials, and other structural or interfacial functional additives.

3.2.1. Fiber Materials

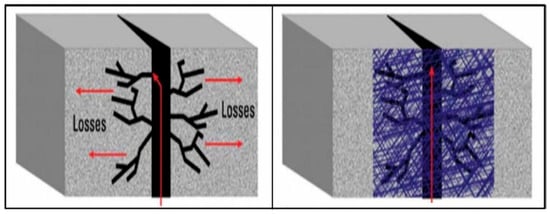

Fiber reinforcement strategies represent a crucial approach for enhancing crack resistance, erosion resistance, and compressive strength in cement-based leak sealing systems. Fibers can form hierarchical three-dimensional reinforcement networks at leak entry points and throughout the cured matrix. Through a “bridging-tensioning-energy dissipation” mechanism, fibers distribute stress and retard crack propagation, thereby enhancing the structural integrity and service life of the sealing layer (Figure 4) [68].

Figure 4.

Fiber mechanism on creating the mesh network to control the loss of circulation [68].

Previous studies indicate that various fiber types provide substantial reinforcement effects under HPHT conditions. Hao Han et al. reported that incorporating 0.05–0.1 wt% basalt fiber (BF) increased flexural strength by approximately 60% at 200 °C, attributed to multiple energy dissipation mechanisms, including fiber bridging, pull-out, and crack deflection [69]. To address retention and load-bearing requirements under high-temperature sealing conditions, Salaheldin Elkatatny observed that adding 0.75 wt% polypropylene fiber (PPF) significantly reduced setting time from 317 to 78 min, while increasing compressive and tensile strength by approximately 18%. This enhancement was primarily attributed to PPF promoting early hydration and stabilizing the C–S–H structure.

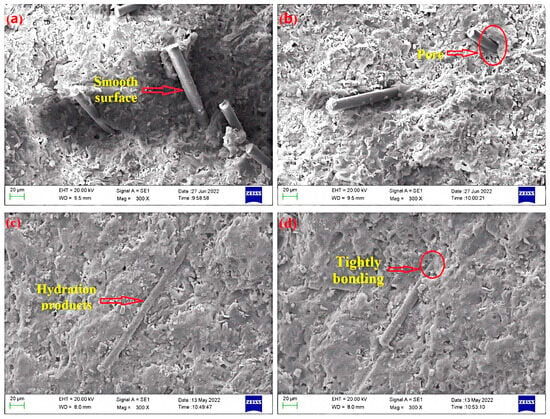

Considering the coupled rheological and mechanical behavior under downhole conditions, Haiyang Hao et al. further demonstrated that blending chopped carbon fibers with basalt fibers not only enhances tensile and flexural strength and reduces brittleness, but also has no significant adverse effect on slurry rheology, thereby facilitating pumping and retention [70]. Under HPHT conditions, Elkatatny et al. systematically examined the regulatory effect of polypropylene fiber (PPF) on G-grade cement performance [68]. Results indicated that a 0.75 wt% PPF content reduced thickening time from 317 to 78 min without significantly affecting system density, free water content, or key rheological properties. Furthermore, to improve interfacial bonding between inorganic fibers and the cement matrix, B. Zhang markedly enhanced interfacial anchoring by grafting graphene oxide onto basalt fiber surfaces. This strategy increased compressive strength by 21–27% and substantially improved toughness (Figure 5) [71], demonstrating that interfacial regulation is crucial for realizing the full potential of fiber reinforcement.

Figure 5.

Shows the microstructure of basalt fibers in cement: (a,b) are untreated basalt fiber cement stones; (c,d) are Go-modified basalt fiber cement stones [71].

In summary, fiber reinforcement not only enhances the crack resistance and energy dissipation capacity of cement-based systems but also exhibits excellent compatibility with retention control, erosion resistance, and high-temperature stability requirements. However, effective application still depends on overcoming challenges in fiber dispersion and mixing. Overall, fiber reinforcement represents a vital strategy for adapting to complex deep wellbore leakage scenarios.

3.2.2. Nanomaterials

Nanomaterials, owing to their high specific surface area, elevated surface energy, and heterogeneous nucleation effects, can modulate hydration kinetics and refine the pore structure of cement systems at the microscale, thereby improving strength, density, and long-term durability. J. Vignesh observed that the synergistic interaction between nanomaterials and cement not only enhances early-stage hydration behavior but also markedly improves resistance to sulfate attack, chloride ion penetration, carbonation, acid corrosion, and freeze-thaw cycles [72]. Hongyan Zeng’s combined theoretical and experimental results demonstrate that graphene oxide (GO) with high aspect ratios can significantly reduce permeability. At a dosage of 0.06 wt%, increasing the aspect ratio tenfold results in an 80% reduction in permeability [73].

Regarding nano-composite systems, R. Patil implemented a composite formulation consisting of 0.5–1% nano-SiO2, 1–3% nano-Al2O3, and ~0.1% carbon nanotubes (CNTs). The resulting system displayed a stable density range of 1830–1920 kg/m3, with no observable water separation. Early strength of ≥3.5 MPa was attained within 7–14 h, and compressive strength reached 50 MPa at 28 days. SEM analysis revealed substantial pore filling and enhanced microstructural densification (Figure 6) [74]. Michael B. Baragwiha et al. investigated the effects of nano-SiO2, γ-Al2O3, α-Al2O3, and TiO2 on G-grade cement at 30 °C. They reported that following PCE dispersion, nano-SiO2 and γ-Al2O3 enhanced rheological properties and reduced the induction period, thereby accelerating early hydration, whereas α-Al2O3 and TiO2 slightly hindered flowability but still facilitated nucleation and hydration [75].

Figure 6.

(a). Sample microstructure of “conventional” cement slurry (with no addition of n-SiO2). Magnification 1000×. (b). Sample microstructure of “conventional” cement slurry (with no addition of n-SiO2). Magnification 1000× [74].

Under high-temperature conditions, Anna Piktowska demonstrated that nano-SiO2 substantially improves cement paste strength, with the magnitude of enhancement depending on both dosage and particle size source. All three modified systems incorporating nano-SiO2 from distinct sources exhibited notable compressive strength improvements. Among them, Type 3 demonstrated the highest compressive strength, ranging from 132% to 149% of the control group, accompanied by the fewest cracks and minimal variability. A 1 wt% dosage produced the greatest average increase (approximately 124%) without adversely affecting rheological properties.

In summary, the incorporation of nanomaterials markedly optimizes the microstructure and overall performance of cement-based systems. Nanomaterials reduce permeability, enhance both early-age and long-term strength, and improve adaptability under extreme conditions, including high temperatures, chemical corrosion, and cyclic mechanical loading. These effects confer considerable application potential in deep well cementing and high-risk lost circulation plugging scenarios.

3.2.3. Mineral Materials

In contrast to nanomaterials, which primarily modulate micro-scale hydration kinetics and pore structure, mineral additives (e.g., silica fume, fly ash, kaolinite, slag, pozzolan) predominantly contribute to macro-scale performance and long-term durability. Their principal contributions encompass: engaging in pozzolanic reactions to improve late-age strength and matrix densification; acting as fillers to optimize particle size distribution, thereby mitigating water loss and permeability; enhancing high-temperature and thermal shock resistance via phase transformations or synergistic reactions; and modulating system pH and interfacial chemistry to bolster the stability of sealing structures under erosive and cyclic loading conditions.

Extensive studies have confirmed that mineral additives significantly enhance the macro-scale performance and long-term lifecycle behavior of cementitious systems from multiple perspectives. In the ternary silicate-silica fume-calcined illite system developed by Laura Dembovska, silica fume displays markedly higher pozzolanic reactivity and Ca(OH)2 consumption compared to calcined illite, thereby promoting secondary gel formation and improving late-age strength. J. Setina utilized micron- and nano-scale SiO2 along with biomass ash as pozzolanic components. Pore distribution and chemical erosion analyses revealed that these additives substantially reduced the number of critical permeable pores within the 1–103 μm range. Furthermore, the system preserved high structural integrity following 1–6 months of immersion in sulfate solutions, demonstrating outstanding chemical durability (Figure 7) [76].

Figure 7.

Microphotography of concrete (a), concrete with wood ashes (b); micro/nanosilica (c) after sulfate solution attack simulation in H2SO4 for 200 days in 10 mm depth. Magnification 40× [76].

With respect to structural evolution, G. Golewski monitored microstructural developments in fly ash systems over 0.5 to 28 days using SEM. The results indicate that primary hydration reactions predominated during days 0–3, pozzolanic reaction products emerged on fly ash surfaces between days 7 and 14, and from days 14 to 28, the initially disordered pores were gradually filled by newly formed gel, resulting in a more homogeneous and substantially densified microstructure. This progression facilitated a synergistic improvement in long-term strength and structural stability [77]. This gradual structural remodeling suggests that mineral admixtures not only impart early-stage regulatory effects but also provide ongoing “self-reinforcement” and “self-compaction” throughout the later service period.

4. Performance Regulation Mechanism of Leak-Sealing Cement Grout

4.1. Density Regulation

Unlike granular bridging systems, which rely on high-density materials such as barite for pressure balancing, cement-based plugging systems typically have a bulk density ≥ 2.2 g/cm3, inherently encompassing most formation fracture pressure windows [78]. Consequently, current research has shifted focus from “density enhancement” toward density reduction strategies for underpressurized and fluid-loss-sensitive formations.

The most direct approach to reducing density is increasing the water-to-cement ratio. However, merely increasing water content compromises rheological stability, leading to risks of solid settling, uncontrolled filtrate loss, and premature bridging. As a result, engineering practice often employs a synergistic “water addition plus lightweight solid phase” strategy to reduce density while preserving structural stability [79]. Materials including bentonite, diatomaceous earth, and sodium metasilicate enhance water retention while providing structural support. Compared with water-based lightweight components, hollow glass microspheres achieve greater density reduction at lower water additions and exhibit higher and more rapidly developing early strength, thereby facilitating shorter setting times. However, they carry a risk of localized fracturing under deep well high-pressure conditions, potentially leading to density rebound.

In lightweight solid-phase systems, pozzolanic by-products and hollow particles are the most commonly employed strategies. Fly ash (ρ ≈ 2.1 g/cm3) can produce slurries with densities of 1.6–1.8 g/cm3; expanded perlite (ρ ≈ 2.4 g/cm3, internally porous) achieves densities of 1.1–1.2 g/cm3; and hollow glass microspheres (ρ ≈ 0.4–0.6 g/cm3) can further reduce density to 1.0–1.2 g/cm3. Similar lightweight materials include hollow ceramic beads and urea-formaldehyde resin beads (ρ ≈ 0.5–0.7 g/cm3) [80]. Collectively termed cement slurry densifiers, these additives have become standard components in low-pressure reservoirs and severe loss cementing applications. Jiaping Yue’s composite system, incorporating artificial microspheres, foam glass beads, microsilica, fly ash, and slag, can regulate slurry density to 1.4–1.7 g/cm3 while maintaining high stability and flowability, making it suitable for cementing shallow, loose offshore formations [81].

It is important to note that high-density systems remain essential under extreme HPHT conditions. Al-Bagoury et al. demonstrated that employing micronized ilmenite as a weighting agent not only mitigates settlement, free water, and gas entrainment issues but also optimizes cement slurry rheology and reduces pumping pressure [82]. Ahmed et al. highlighted the crucial role of hematite and microcrystalline cellulose in balancing high density with structural integrity [83].

4.2. Thickening Time Control

Thickening performance is a critical factor determining the success of deep-well cementing and leak-sealing operations. The thickening time (to 70 Bc) defines the pumpable window of the cement slurry. Under HPHT conditions, elevated temperatures accelerate hydration reactions, while high pressure further shortens thickening time by promoting ion migration and crystal nucleation. Premature thickening may lead to stuck pipes, increased pumping resistance, or slurry failure before fracture entry, whereas delayed thickening prolongs operational waiting times, raises loss risks, and increases operational costs. Therefore, thickening time must be precisely controlled within the specified operational window.

Previous studies on thickening control strategies indicate that they are primarily divided into chemical and physical approaches. Chemical approaches focus on retarders, which act through mechanisms such as adsorption passivation, Ca2+ chelation, and inhibition of C–S–H nucleation. Physical approaches involve optimizing operational and system parameters (e.g., staged pumping, wellbore circulation cooling, pressure management) [84], or indirectly extending the pumpable window by adjusting the water-cement ratio and solid-phase volume fraction to maintain slurry fluidity until reaching the target zone [85].

Previous studies have highlighted the functional differences and applicability limits of various retarding mechanisms. Huajie Liu reported that biopolymer systems, exemplified by chitosan, can extend thickening time through Ca2+ chelation, but may cause initial viscosity fluctuations and even accelerate thickening under high dosages or elevated temperatures. Low-molecular-weight chitosan exhibits stronger retarding effects by significantly prolonging the induction period [86]. Samuel S.’s temperature-pressure coupling model further demonstrates that elevated temperature and pressure significantly narrow the setting time window in specific systems, confirming the strong influence of HPHT conditions on setting behavior [87].

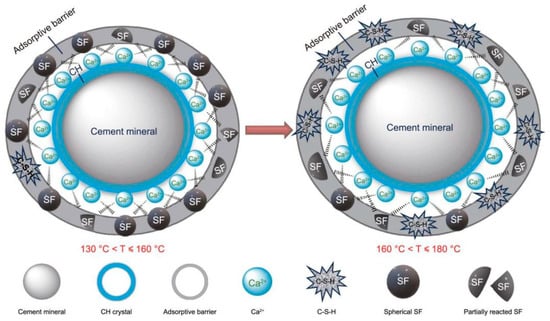

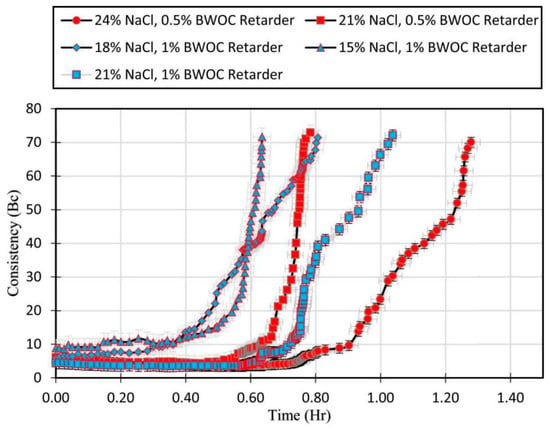

Regarding the effect of mineral admixtures on thickening behavior, Hang Zhang identified a “thickening time reversal” phenomenon in the silica fume-cement system within the 130–180 °C range. As the temperature increases to 130–160 °C, silica fume adsorbs onto newly formed CH crystal surfaces, forming an adsorption barrier that inhibits further hydration and prolongs thickening (Figure 8) [88]; When the temperature further rises to 170–180 °C, the enhanced pozzolanic activity of silica fume promotes C–S–H phase formation, thereby accelerating setting and illustrating a temperature-dependent bidirectional effect. In contrast, Hasan Maroof reported that increasing the salt content significantly prolongs setting time but still fails to satisfy the cementing operability window (Figure 9) [89], indicating that while inorganic salts provide reinforcement, they are not sufficient on their own.

Figure 8.

Schematic diagram of the disappearance of “temperature-based TTR” and the occurrence of “dosage-based TTR” above 160 °C [88].

Figure 9.

Consistency graphs of 150 PCF cement slurries with salt contents ranging from 15 % to 24 % [89].

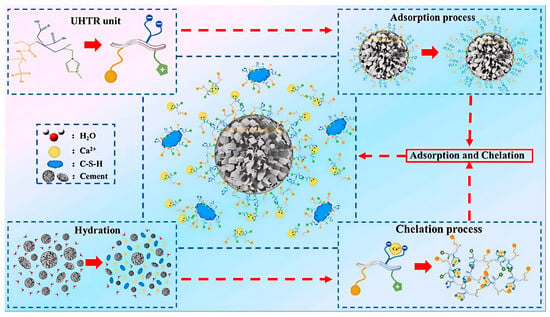

To surpass the upper temperature limitations of conventional retarders, Qian Feng developed ultra-high-temperature retarders (UHTR) by incorporating sulfonic acid, imidazole, and carboxylic acid functional groups. These retarders maintain a thickening stability window exceeding 200 min at 220–240 °C while retaining high-temperature compressive strength, significantly outperforming conventional organic retarders (Figure 10) [90]. Furthermore, existing studies highlight a high-temperature failure bottleneck in conventional systems: lignosulfonate requires modification to maintain retarding effects at 90 °C [91]; among most inorganic retarders, only borates remain effective at 90 °C [91]; AM-AMPS copolymers, in contrast, exhibit retarding decay due to high-temperature polymer chain degradation. Collectively, these findings demonstrate that high-temperature failure constitutes the primary limitation of existing thickening control strategies, representing a critical unresolved challenge for optimizing high-temperature plugging and cementing operations [92].

Figure 10.

Schematic diagram of the action mechanism of UHTR [90].

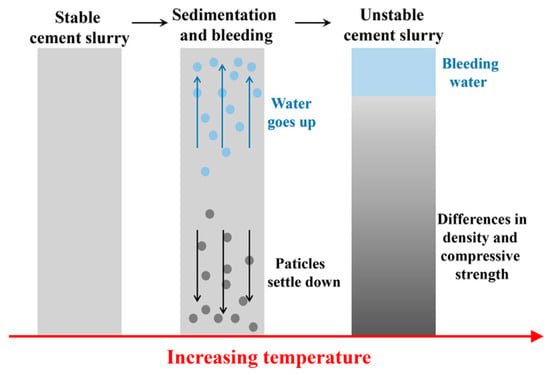

4.3. Fluidity of Cement Paste

In deep HPHT well cementing and plugging operations, the slurry must retain pumpability and filling capacity until reaching the target formation, avoiding premature flow loss or sedimentation instability. Consequently, rheological control constitutes the primary constraint in system design (Figure 11). Elevated temperatures significantly influence bleeding, density, and rheological behavior. Meng Wang’s coupled bleeding-rheology experiments on slurries with W/C ratios of 0.6–2.0 at 20–90 °C revealed that: the total bleeding rate increases with higher water-to-cement ratios and decreases approximately linearly with rising temperature; the rate of density change decreases with increasing temperature but rises with higher W/C ratios. Ultimately, density variation is primarily governed by the W/C ratio, indicating that elevated temperatures mainly affect the rate of water loss rather than the structural limits [93].

Figure 11.

Sketch for the settlement stability of cement slurry [93].

In addition to temperature effects, the composition of the system also strongly influences rheological behavior. Niu et al. reported that raising the activation temperature of coal gangue led CGCM slurry to display shear thinning at low shear rates and slight shear thickening at high shear rates, overall aligning with the modified Bingham model [94]. Deryaev demonstrated that the high-efficiency water-reducing agent Glenium-51 can increase flowability by 25–92% while maintaining pumpability at a W/C ratio of 0.30, rendering it suitable for high-density systems [95]. The thermally thickening polymer (TV-1/HTP class) developed by Chen et al. shows increased viscosity with rising temperatures (20–150 °C), counteracting sedimentation caused by “thermal thinning” [96]. At 155 °C, it can limit the density difference between the upper and lower layers of high-density slurry to within 0.03 g·cm−3.

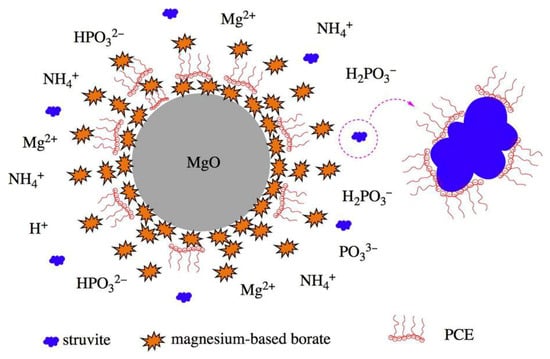

Beyond conventional PCE, rheological control in specialized cement systems has also attracted attention. Hongbo Tan observed that although PCE does not disperse effectively in MPC, it can improve 30-min flow retention by delaying struvite nucleation (Figure 12) [97]; Yan He reported that silane-modified PCE exhibits stronger adsorption control, enhancing initial flowability but with reduced retention [98]; Zhang et al. indicated that competitive adsorption between CA retarders and naphthalene/aminosulfonate-based water-reducing agents reduces initial flowability, highlighting the significant coupling effects between admixtures [99].

Figure 12.

Schematic Diagram of the Hydration Model for Magnesium Phosphate Cement and polycarboxylate superplasticizer [97].

Additionally, the morphological characteristics of mineral additives and the coupling interactions between admixtures and hydration reactions can significantly affect slurry flow behavior. Ma et al. observed that, following grinding, fly ash particles transform from near-spherical to irregular polyhedral shapes, thereby weakening the “ball-bearing effect”. This change increases particle friction and bridging probability, thereby substantially reducing flowability [100]. Uchikawa’s study indicates that the adsorption behavior of admixtures on cement particle surfaces not only governs their dispersion and viscosity-reducing effectiveness but can also inversely affect viscosity development by modifying early hydration kinetics [101]. For example, when retarders compete with water-reducing agents for adsorption, or when their effects interact with the formation of hydration products, nonlinear behaviors—such as “initial flow improvement followed by subsequent loss of flow” or “flow retention accompanied by premature thickening”—may arise.

Owing to the yield stress threshold inherent in cement paste, its flow behavior is typically characterized using viscoplastic models, describing the shear stress-shear rate relationship or steady-state rheological curves, as presented in Table 3 [102].

Table 3.

Viscoplastic models used for describing steady flow curve of cement pastes [102].

Drawing on common patterns identified in prior studies, rheological control in deep well cementing is summarized by three key insights: (1) Temperature and water-to-cement ratio primarily govern bleeding and density evolution, exerting a preeminent influence on plugging structure stability. (2) The effects of admixtures depend on their synergistic or competitive interactions within the “adsorption–hydration” dual-layer mechanism, rather than solely on dispersion. (3) Under HPHT conditions, the control objective shifts from enhancing initial flowability to managing rheological evolution over time, ensuring compatibility and controllability throughout transport, retention, and solidification processes.

5. Method for Controlling the Retention Behavior of Cement Grout in Leakage Channels

In deep fracture-karst leakage pathways, if cement slurry continues to penetrate deeper zones without adequate retention, a stable sealing structure cannot form—this directly leads to leakage failure. Therefore, achieving effective slurry retention prior to solidification becomes a central design constraint in leakage sealing systems, steering the development of cement formulations toward tailored solutions. Existing studies (Table 4) indicate that slurry retention within leakage pathways primarily depends on two mechanisms: (1) Particles or flake-like materials can form bridging plugs at fracture entrances, constricting the pathway and thereby increasing the likelihood of slurry retention. (2) Thixotropic or super-thixotropic effects induce rapid thickening and spontaneous settlement of the slurry once shear ceases [103]. Although both mechanisms enhance slurry filling and solidification in the loss pathway to achieve effective plugging, their controlling principles differ—one relies on geometric flow-path restriction, whereas the other depends on rheological behavior regulation. Consequently, each mechanism exhibits distinct dominant applicability in different types of fracture-cavity loss channels.

Table 4.

Retention Behavior Control Agents for Cement-Based Leak-Stopping Grout [103].

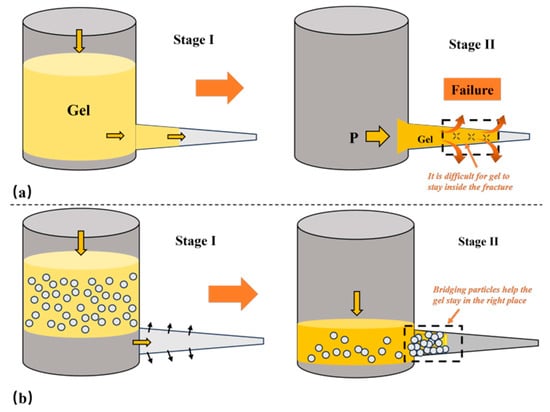

5.1. Control of Cement Slurry Retention Performance Based on the Bridging Effect

The bridging effect represents a key mechanism for improving the retention capacity of cement slurry. This mechanism involves the introduction of granular or flake-like materials into the slurry, which preferentially accumulate at crack entrances or pore throats to form a structural framework. This process reduces seepage pathways, decreases slurry flow velocity, and provides a supportive interface for subsequent solidification [104]. Commonly used bridging materials include calcium carbonate, ceramic aggregates, quartz sand, rubber particles, and walnut shells. During slurry flow, these materials preferentially accumulate in constricted sections due to geometric constraints and shear forces, forming an initial bridging plug layer. This accumulation prevents further slurry penetration into deeper zones and markedly enhances retention efficiency [105]. Fuhao Bao also observed in his study of gel and bridging plugging materials that the retention and blocking mechanisms within loss channels correspond to the sealing phase of cement-based systems (Figure 13) [106].

Figure 13.

Bridging effect as a key mechanism for retaining curable fluids in leakage channels: (a) conventional gel plugging mechanism; (b) gel-bridging coupled plugging mechanism [106].

Research shows that the degree of particle size-channel width matching (Table 5) [107] is the critical factor governing bridging success. Implementing multiscale grading—such as a synergistic D90-D50-D10 design—can markedly improve bridging success rates by concentrating retention zones and forming a denser plugging structure [108]. Additionally, incorporating fibers (e.g., basalt fibers, polypropylene fibers) establishes a three-dimensional reinforcement network within the particle skeleton. Fiber entanglement enhances structural stability and inhibits additional slurry leakage [109].

Table 5.

The LCM designs [107].

Under HPHT conditions, bridging structures must additionally demonstrate thermal stability and resistance to high pressure. To achieve this, researchers utilize high-temperature-resistant mineral particles or thermally resilient polymeric reinforcement phases. This approach allows the bridging layer to preserve its structural integrity at 200–250 °C while increasing interfacial friction with channel walls, thereby enhancing plug stability [118]. Su Xiaoming developed and validated a class of rigid particles with high-temperature resistance, acid solubility, and stiffness for cement plugging systems in high-temperature well sections [119]. Concurrently, Lei Pu employed CFD-DEM coupled simulations to elucidate particle deposition kinetics at fracture entrances and the evolution of plugging structures, providing a theoretical basis for matching and proportioning bridging materials across varying fracture scales [120].

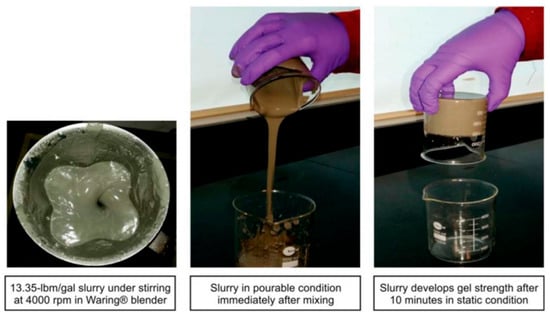

5.2. Control of Cement Slurry Retention Properties Based on Flow Behavior Regulation

Thixotropic cement, characterized by the reversible structural evolution of “shear-induced breakdown followed by static reconstruction”, is regarded as an effective strategy to improve retention performance when granular plugging materials alone are insufficient to form a bridging plug. The primary mechanism involves thixotropic agents inducing the self-assembly of the slurry into a weak three-dimensional gel network under static conditions. This structure quickly fractures under shear to maintain pumpability and then rapidly reconstitutes once shear stress ceases upon entering the loss channel, thereby significantly enhancing retention and plugging efficiency. As shown in Figure 14, Guo et al. developed a highly thixotropic system for high-temperature natural gas well conditions by incorporating xanthan gum in combination with konjac gum and KCl modification. Its salt bridges and adsorption effects facilitate the rapid reconstruction of the colloidal network after static rest, displaying the characteristic “post-rest thickening-shear-reflow” behavior [121].

Figure 14.

The schematic illustration of the thixotropic interaction between xanthan gum and cement particles. Xanthan gum chains electrostatically bridge cement particles to form a weak network at rest, while these connections are easily broken under external shear and can rebuild once the load is removed [121].

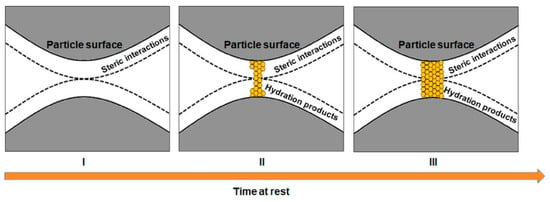

From a mechanistic standpoint, thixotropy is not a singular colloidal phenomenon but rather the combined outcome of “colloidal network restructuring, early hydration, and microstructure assembly”. Dengwu Jiao categorized its structural evolution into three stages: formation of the colloidal flow network, rigid flow development via C–S–H/AFt bridging, and the rigidification stage resulting from particle connection reinforcement (Figure 15) [122]. Wallevik’s microstructural model further demonstrates that thixotropy fundamentally originates from the “competition between gelation rate and dispersion rate”, offering a theoretical framework for numerical modeling of the thixotropic process [123].

Figure 15.

Schematic diagram of structural build-up of cementitious suspensions with superplasticizer. The physicochemical process can be divided into three stages: (I) colloidal network percolation; (II) rigid network percolation; and (III) rigidification [122].

At the application level, Rahul Jadhav’s thixotropic plugging system (10–15 ppg, rated for temperatures up to 250 °F) demonstrates reversible gelation and high early strength (Figure 16), enabling direct pumping through the BHA to mitigate medium- to high-flow rate losses [124]. Pan et al. synergistically combined thickeners with bridging agents to create a 2:1 composite plugging system capable of sealing 3–5 mm fractures and withstanding pressures above 14 MPa, thereby achieving a combined plugging mode of “thixotropic retention plus bridging plug pressure support”. Thixotropic strategies have also been applied to nanomaterial-based systems [125]. Li et al. utilized LDH/MMT composite nanoclay to develop a double-layer structure that enhances static reconstruction capability [126]; Subsequent research by Qiuchao Li and Quanji further confirmed that both nanoclay and nano-slag facilitate floc reconstruction, thereby increasing thixotropic strength and expanding the hysteresis loop area [127,128].

Figure 16.

Thixotropic cement slurry [124].

5.3. Analysis of the Applicability of Different Cement-Based Plugging Systems in Fracture-Karst Composite Lost Circulation Channels

The preceding chapters have respectively discussed the flow-limiting mechanism based on the bridging effect (Section 5.1) and the rheological control mechanism based on thixotropy (Section 5.2), which control the retention conditions of the slurry from two dimensions: geometric structure narrowing the flow channels and fluid viscosity recovery. In engineering practice, different types of leakage channels require distinct plugging systems, necessitating the alignment of plugging mechanisms with fracture-type, cavern-type, and their composite leakage characteristics to delineate the applicability scope from the material mechanism perspective.

As shown in Table 6, the applicability of different cement-based plugging systems in fracture-cavern composite leakage channels exhibits significant variations. Bridging-based systems are primarily suitable for fracture-dominated leakage, achieving efficient sealing through bridging and filling; thixotropic and gel-enhanced systems perform better in caverns or irregular cavities, forming high-viscosity dense bodies without structural support; self-healing and responsive systems are suitable for long-term sealing of micro-fractures or varying fractures, while large-scale cavern leakage typically requires high-solids slurries or filling-type plugging bodies. By aligning plugging systems with specific geological structures, the material selection can be more targeted, enhancing the engineering reliability of deep well leakage management.

Table 6.

Applicability Summary of Different Cement-Based Plugging Systems in Fracture-Cavern Composite Leakage Channels.

6. Intelligent Leak-Plugging Grout System

Once traditional leak-sealing materials cure, their sealing state becomes fixed. Thereafter, under high-velocity fluid erosion, thermal stress induced by elevated temperatures, or crack reopening, the sealing structure often fails irreversibly, requiring repeated sealing operations-a classic example of passive sealing. In contrast, intelligent cement sealing systems exhibit active responsiveness, initiating self-healing or reinforcement reactions in response to thermal-pressure fluctuations or gas/liquid intrusion. This facilitates a transition from “single-use sealing” to “long-term stable sealing”. It should be noted, however, that the intelligent systems discussed in this section are primarily intended for post-plugging microcrack remediation, micro-annulus sealing, and interface stabilization, rather than for high-rate, large-aperture primary loss control. These materials function as an extension and complement to conventional plugging systems by sustaining long-term well integrity.

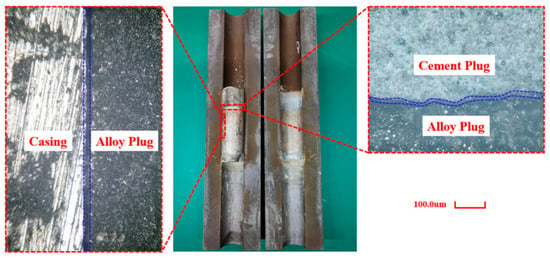

Leveraging chemical triggering mechanisms, Engelke developed a CO2-activated self-healing cementing system. By incorporating expandable reactive components within the silicate matrix, the material undergoes volumetric recovery and fracture closure upon CO2 exposure [129]. Zha designed a “cement-low-melting-point alloy-cement” composite plug, demonstrating its reversible resealing capability under thermal cycling and CO2 infiltration (Figure 17) [130]. Jia Li developed a high-temperature resin-based sealing material combining self-healing and biodegradable properties, achieving rapid repair at 180 °C [131]. Cavanagh proposed a sealing system activated exclusively during hydrocarbon fluid leaks, capable of reinitiating sealing upon subsequent damage [132].

Figure 17.

Optical microscopy of the casing/combined plug interface [130].

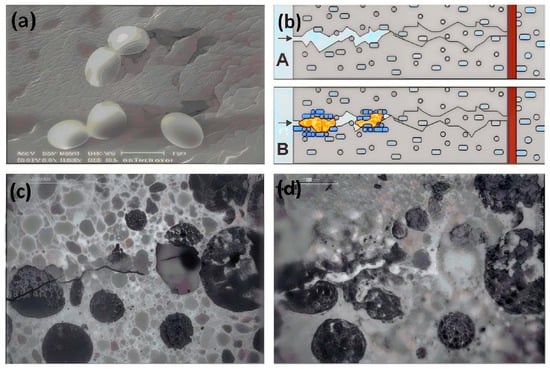

By harnessing biologically driven mechanisms, Jonkers achieved in situ crack healing via CaCO3 deposition by embedding delay-activated bacterial spores along with nutrients into the cement matrix (Figure 18) [133]; Kjøller observed self-healing behavior in composite cement-rock systems subjected to alternating CO2-brine flow conditions, which was subsequently confirmed through CT and SEM analyses [134].

Figure 18.

(a) SEM image of bacterial spores. (b) Schematic of the self-healing process in bacterial concrete. As the water enters a micro-crack, the embedded bacterial spores are activated (A). The active bacteria then seal the cracks with the production of limestone (B). (c) Before and (d) after pictures of the surface of a slab of self-healing concrete [133].

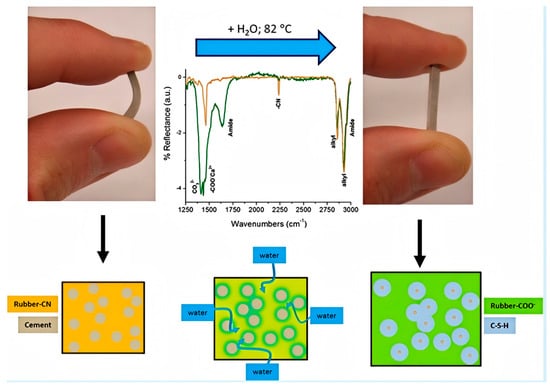

Within the domain of reversible mechanical and chemical response systems, Musso developed a rubber-cement reactive composite that exhibits reversible modulus variations, allowing dynamic adjustment of mechanical properties during wet-dry cycles (Figure 19) [135]. Similarly, Al-Yami achieved enhanced crack resistance and self-healing under thermal-pressure cycling by reducing the cement’s Young’s modulus and incorporating an expansion-active phase.

Figure 19.

Comparison of HNBR-cement (D50 ≤ 5 μm) stiffness before (left) and after (right) water exposure [135].

Collectively, these studies advance leak-sealing materials from single-cure static plugs toward reactivatable adaptive plugs, providing novel material strategies to maintain wellbore integrity under HPHT conditions, cyclic loading, and CO2/H2 exposure.

7. Conclusions and Perspectives

Under deep HPHT conditions, severe lost circulation causes traditional plugging materials to lose flowability prematurely, fail to achieve adequate retention, and undergo irreversible re-failure, thereby hindering the formation of a durable seal. Existing research indicates that the coupled effects of the temperature-pressure environment, water-to-binder ratio, and admixtures at the “adsorption-hydration” interface collectively govern slurry pumping, penetration, and solidification. Concurrently, plugging strategies are evolving from single-use passive sealing toward responsive, re-sealable, active approaches, and material systems are advancing along three main pathways: (1) enhancing plug density and durability via additive reinforcement; (2) regulating the “delivery-retention” process through time-window control of flowability and setting; and (3) achieving stimulus-driven resealing via CO2 exposure, self-healing, expansion, or phase-change mechanisms.

For deep and ultra-deep formations, however, several key scientific gaps remain: (1) the absence of a unified understanding of HPHT-controlled “adsorption-hydration-transport” behavior in severe loss channels; (2) limited design principles for truly responsive, re-sealable cement-based systems adapted to fracture-cavity composite leakage paths; and (3) the lack of a cross-scale framework linking material formulation and microstructural evolution with field-scale failure modes such as extrusion, erosion, and channel reopening. This review contributes to closing these gaps by synthesizing HPHT interfacial mechanisms that control slurry delivery and early failure, organizing current material developments within a process-oriented “delivery-retention-resealing” perspective, and proposing a cross-scale design concept that integrates materials, mechanisms, and operational processes to support effective and durable sealing in deep and ultra-deep wellbores.

Author Contributions

Conceptualization, B.M. and K.Z.; methodology, B.M.; software, C.Z.; validation, K.Z. and Y.W.; formal analysis, B.F.; investigation, Q.S.; resources, Q.S.; data curation, B.F. and P.X.; writing—original draft preparation, L.P.; writing—review and editing, Q.F.; visualization, Q.L.; supervision, Y.W.; project administration, P.X.; funding acquisition, P.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the CNPC Chuanqing Drilling Engineering Company Limited Science and Technology Project “Development of a 200 °C-Resistant Cement-Based Plugging System for Deep-Well Lost Circulation Control” (CQ2024B-4-Z2-3); PetroChina Company Limited Science and Technology Project “Integrated Research and Field Testing of Safe and Efficient Drilling and Completion Technologies for Deep Formations in Western Sichuan” (2024ZS49).

Data Availability Statement

Data availability is not applicable to this article as no new data were created or analyzed in this study.

Acknowledgments

We would like to thank the Bakken Laboratory of YANGTZE University for their support.

Conflicts of Interest

Authors Biao Ma, Kun Zheng, Chengjin Zhan, Bin Feng, and Qing Shi were employed by Downhole Service Company of CNPC Chuanqing Drilling Engineering Company Limited. Authors Qiang Fu and Qiang Lin were employed by CNPC Chuanqing Drilling Engineering Company Limited. Author Yuechun Wang was employed by Engineering Technology Research Institute, PetroChina Southwest Oil & Gasfield Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The companies had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Lei, Q.; Xu, Y.; Yang, Z.; Cai, B.; Wang, X.; Zhou, L.; Liu, H.; Xu, M.; Wang, L.; Li, S. Progress and Development Directions of Stimulation Techniques for Ultra-Deep Oil and Gas Reservoirs. Pet. Explor. Dev. 2021, 48, 221–231. [Google Scholar] [CrossRef]

- Wang, H.; Huang, H.; Bi, W.; Ji, G.; Zhou, B.; Zhuo, L. Deep and Ultra-Deep Oil and Gas Well Drilling Technologies: Progress and Prospect. Nat. Gas Ind. B 2022, 9, 141–157. [Google Scholar] [CrossRef]

- He, D.; Jia, C.; Zhao, W.; Xu, F.; Luo, X.; Liu, W.; Tang, Y.; Gao, S.; Zheng, X.; Li, D.; et al. Research Progress and Key Issues of Ultra-Deep Oil and Gas Exploration in China. Pet. Explor. Dev. 2023, 50, 1333–1344. [Google Scholar] [CrossRef]

- Chen, D.; He, B.; Wang, Y.; Han, C.; Wang, Y.; Xu, Y. Prediction of Leakage Pressure during a Drilling Process Based on SSA-LSTM. Processes 2023, 11, 2608. [Google Scholar] [CrossRef]

- Li, J.; Chen, M.; Fang, Z.; Lu, Y.; Zhao, C.; Zhang, Z. Study of the Wellbore Instability Mechanisms in Deep Ordovician Carbonate Rock in the Tarim Basin. In Proceedings of the International Conference on Information Technology in Geo-Engineering, Golden, CO, USA, 5–8 August 2024; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Priening, P.; Ali, M.; Jaffery, M.; Salazar, J.; Jain, B. Advanced Engineered Fiber Technology-A Novel Solution to Cure Lost Circulation During Drilling: Pakistan Case History. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Jakarta, Indonesia, 25–27 August 2008; SPE: Lagos, Nigeria, 2008. [Google Scholar] [CrossRef]

- Jiang, Q.; Xu, P.; Xu, J.; Hou, M.; Liu, Q.; Dai, B. Preparation and evaluation of composite hydrogel for reducing the leakage rate of lost circulation. Polymers 2023, 15, 4218. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.; SHI, Y.; Zhou, F.; Liu, X.; Yang, X.; Yang, X. High efficiency reservoir stimulation based on temporary plugging and diverting for deep reservoirs. Pet. Explor. Dev. 2018, 45, 948–954. [Google Scholar] [CrossRef]

- Li, C.; Bai, J.; Jiang, Y.; Xiao, H.; Wang, W.; Xu, F. Investigating the seepage control and plugging capabilities of polyurethane-cement composites: A comprehensive study on material properties. Constr. Build. Mater. 2024, 416, 135191. [Google Scholar] [CrossRef]

- Li, S.; Mei, J.; Niu, Y.; Li, H.; Xie, A.; Yin, S.; Dai, J. Mechanical properties of cement matrix composites reinforced with polyoxymethylene fibers of different lengths. J. Mater. Civ. Eng. 2024, 36, 04023636. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, E.; Ma, S.; Zhang, D. Study on Grouting Performance Optimization of Polymer Composite Materials Applied to Water Plugging and Reinforcement in Mines. Materials 2024, 17, 4245. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.; Wei, B.; Habiyakare, E.; Bin, B.; Wang, L.; Peng, C.; Ji, W.; Cao, H.; Yang, H. Rheological and mechanical properties of bentonite–cement paste reinforced with basalt fibers. Materials 2023, 16, 3226. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.; Wei, H.G.; Muchiri, N.D.; Li, F.L.; Zhang, J.R.; Xu, Z.X. Degradation of chemical and mechanical properties of cements with different formulations in CO2-containing HTHP downhole environment. Pet. Sci. 2023, 20, 1119–1128. [Google Scholar] [CrossRef]

- Zeng, H.; Jin, M.; Li, W.; Gao, C.; Ma, Y.; Guan, Q.; Li, B.; Liu, J. Assessing the durability performance of high belite cement incorporating fly ash under long-term temperature variations. Cem. Concr. Compos. 2024, 152, 105643. [Google Scholar] [CrossRef]

- Zhao, Z.; Ni, X.; Cao, Y.; Shi, Y. Application of fractal theory to predict the coal permeability of multi-scale pores and fractures. Energy Rep. 2021, 7, 10–18. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Yu, Z.M.; Feng, Y.C.; Xin, J.B.; Li, Y.P. Study on Axial Stress Variation of Casing in Cementing Process. Int. J. Multiphysics 2024, 18, 498. [Google Scholar]

- Song, X.; Yu, M.; Niu, H.; Li, Y.; Chen, C.; Zhou, C.; Liu, L.; Wu, G. Poly (methyl dihydroxybenzoate) modified waterborne polyurethane sizing coatings with chemical and hydrogen-bonded complex cross-linking structures for improving the surface wettability and mechanical properties of carbon fiber. Prog. Org. Coat. 2024, 187, 108112. [Google Scholar] [CrossRef]

- Sun, J.; Bai, Y.; Cheng, R.; Lyu, K.; Liu, F.; Feng, J.; Lei, S.; Zhang, J.; Hao, H. Research Progress and Prospects on Formation Plugging Technology for Fractured Malignant Well Leaks. Pet. Explor. Dev. 2021, 48, 630–638. [Google Scholar] [CrossRef]

- An, J.; Li, J.; Huang, H.; Liu, G.; Yang, H.; Zhang, G.; Li, W. Mud loss behavior in fractured formation with high temperature and pressure. Energy Rep. 2023, 9, 2638–2652. [Google Scholar] [CrossRef]

- Wang, W.; Ma, T.; Deng, T. Characteristics and Geological Factors of Severe Well Leaks in the Xuanhan-Kaixiang Area, Eastern Sichuan. Nat. Gas Ind. 2005, 25, 90–92. [Google Scholar]

- Song, B. Research on Consolidation-Type Plugging Technology for Leakage Sections in Fractured-Cavity Wells. Master’s Thesis, Xi’an Petroleum University, Xi’an, China, 2024. [Google Scholar]

- Zhang, S. Study on Leakage Mechanisms in Multi-Scale Fractured Formations and Formulation of Plugging Solutions. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2023. [Google Scholar]

- Jaf, P.T.; Razzaq, A.A.; Ali, J.A. The state-of-the-art review on the lost circulation phenomenon, its mechanisms, and the application of nano and natural LCM in the water-based drilling fluid. Arab. J. Geosci. 2023, 16, 32. [Google Scholar] [CrossRef]

- Liu, F. Severe Lost Circulation Subsea Capping Technology in the Salt-Based Formation of the Tarim Foothills. Xinjiang Pet. Nat. Gas 2024, 20, 1–7. [Google Scholar]

- Gaurina-Međimurec, N.; Pašić, B.; Mijić, P.; Medved, I. Drilling fluid and cement slurry design for naturally fractured reservoirs. Appl. Sci. 2021, 11, 767. [Google Scholar] [CrossRef]

- Leng, G.Y.; Yan, W.; Ye, H.M.; Yao, E.D.; Duan, J.B.; Xu, Z.X.; Li, K.P.; Zhang, J.R.; Li, Z. Evaluation of the injection and plugging ability of a novel epoxy resin in cement cracks. Pet. Sci. 2024, 21, 1211–1220. [Google Scholar] [CrossRef]

- Syed, H. Best practices in designing HP/HT cement-plug systems. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008; SPE: Lagos, Nigeria, 2008. [Google Scholar] [CrossRef]

- Le Saout, G.; Lécolier, E.; Rivereau, A.; Zanni, H. Chemical structure of cement aged at normal and elevated temperatures and pressures: Part I. Class G oilwell cement. Cem. Concr. Res. 2006, 36, 71–78. [Google Scholar] [CrossRef]

- Omosebi, O.; Maheshwari, H.; Ahmed, R.; Shah, S.; Osisanya, S.; Santra, A.; Saasen, A. Investigating temperature effect on degradation of well cement in HPHT carbonic acid environment. J. Nat. Gas Sci. Eng. 2015, 26, 1344–1362. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Q.; Zhang, L.; Tong, H.; Hu, Y.; Yang, Z.; Li, Z. Investigations on basic properties and water plugging ability of ordinary cement grout under high temperatures. Constr. Build. Mater. 2025, 461, 139873. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, H.; Xu, P.; Zhang, X.; Wang, H.; Hu, M.; Guo, J. Effect of Ultra-High Temperature Degradation on the Physical Properties and Chemical Structure of an AMPS-Based Copolymer Oil-Well Cement Additive PADIM in Aqueous Solution. Polymers 2025, 17, 591. [Google Scholar] [CrossRef] [PubMed]

- Feng, Q.; Wang, C.; Yue, W.; Wang, C.; Song, T. Mechanism of rigid functional groups on the temperature resistance of fluid loss additives for well cementing. React. Funct. Polym. 2025, 214, 106314. [Google Scholar] [CrossRef]

- Moradi, S.T.; Nikolaev, N.I. Considerations of well cementing materials in high-pressure, high-temperature conditions. Int. J. Eng. Trans. C Asp. 2016, 29, 1214–1218. [Google Scholar]

- Wang, S.; Wu, L.; Jiang, G.; Jian, L.; Zhang, T.; Chen, S.; Chen, L. A high temperature composite cement for geothermal application. J. Pet. Sci. Eng. 2020, 195, 107909. [Google Scholar] [CrossRef]