Abstract

The retrofitting of legacy systems enables upgrades that extend the lifespan of outdated equipment, improve efficiency, and reduce environmental impacts. This manuscript builds on existing approaches to retrofitting legacy systems using Industry 4.0 technologies. Therefore, it explores how the proposed modernization envisions the transition from Industry 4.0 to Industry 5.0, which emphasizes human-centric approaches, sustainability, and resilience. Tools such as RAMI 4.0 (a reference architecture model for Industry 4.0), Lean Six Sigma (a methodology for process improvement), and Big Data analytics are highlighted throughout the text as essential for optimizing processes and ensuring alignment with global challenges, including resource efficiency and environmental sustainability. This work addresses both conceptual and technical aspects of system modernization. It provides a comprehensive framework for retrofitting systems and integrating advanced technologies such as digital twins. These efforts ensure that industries are prepared for the evolving demands of Industry 4.0 and beyond.

1. Introduction

Advanced technology and Industry 4.0 use modern technologies, including IoT [], Big Data [,], cloud computing [], cyber–physical systems [], augmented reality and virtual reality []. These technologies are integrated into industrial processes to create “smart factories” or “intelligent manufacturing”. Integration is essential for industrial flexibility, efficiency and productivity. To accomplish this, sensors are used to collect, classify and process data and facilitate connectivity in addition to automation between equipment and processes [].

The Fourth Industrial Revolution (Industry 4.0) is defined by the integration of physical and digital systems using modern technologies. To remain competitive in continuously changing markets, firms must modernize their processes to improve productivity, flexibility and sustainability [].

Industrial modernization enables the creation of smart factories, where sensors and automation optimize operations in real time, reduce costs and minimize environmental impacts. Retrofitting refers to ways to bring old machines and processes up to date and plays a key role in this process by extending the lifespan of outdated systems and adapting them to modern challenges. An innovative example is the application of the Hartmann–Sprenger effect for natural gas pressure regulation, which eliminates the need for external heating by using the gas flow’s energy to generate heat, significantly improving energy efficiency [].

In structural retrofitting, carbon fiber-reinforced polymers (CFRPs) have emerged as a transformative solution for steel structures. CFRPs offer a high strength-to-weight ratio, corrosion resistance and ease of installation, making them a superior alternative to traditional steel plates []. Studies have shown that CFRP retrofitting enhances the flexural capacity and fatigue life of steel components while also addressing challenges like corrosion and residual stress from welding. Additionally, advancements in adhesives and surface preparation techniques have further optimized the bond strength and durability of CFRP–steel interfaces.

Another impactful approach to retrofitting is the use of Building Information Modeling (BIM) for administrative buildings. Research demonstrates that strategies such as replacing outdated systems, switching fluorescent lights to LEDs and adding thermal insulation can reduce energy consumption []. These examples highlight how retrofitting, whether through advanced materials like CFRPs or digital tools like BIM, is essential for aligning modernization efforts with sustainability and competitiveness in a dynamic industrial landscape.

Retrofitting outdated equipment and systems is a cost-effective and efficient approach to modernizing infrastructure. By integrating energy-efficient components and IoT sensors, it reduces operational costs, improves performance through real-time monitoring, and extends the lifecycle of legacy systems []. Thus, retrofitting old systems reduces costs, improves safety and energy efficiency and meets current legislation and performance criteria. This approach extends legacy system lifecycles and modernizes them for Industry 4.0 [].

As with any method, retrofitting can be hard and expensive. Software code rewrites, equipment layout reorganizations and comprehensive testing and validation are common to assure upgrades meet current and future requirements. Upgrading a production line may need process redesign to include new technologies without disruption [].

Successful retrofitting requires choosing the right technology and methodologies for the system being updated. Cost-effective solutions that prioritize integration, communication and compatibility are essential. Retrofitting may include installing smart sensors for real-time monitoring, PLCs for control systems or cloud-based data platforms for system visibility and decision-making. A scalable and economical solution that simplifies complicated technology integration and meets company goals is the goal. This method helps organizations modernize their systems quickly and prepare for Industry 4.0 and beyond.

The term ‘and beyond’ refers to the transition from Industry 4.0 to Industry 5.0. To assist in this transition, there is the Global Industry Classification Standard (GICS), which provides an organized framework for categorizing industries based on their economic activities. This framework helps align the scope and limitations of Industry 4.0 enabling technologies with the specific needs of different sectors.

Industry 5.0 emphasizes human-centric approaches, sustainability and resilience by fostering collaboration between humans and machines, prioritizing environmental sustainability and designing systems that adapt to changing conditions. GICS can guide the prioritization of sectors where human–machine collaboration and environmental considerations are critical, such as healthcare, renewable energy, and education.

In this context, statistical tools like Lean Six Sigma can be used to optimize processes during the industry’s transition. For example, DMAIC (Define, Measure, Analyze, Improve, Control) can be applied to identify inefficiencies in legacy systems and measure the impact of retrofitting; Process Capability Analysis ensures that updated systems meet quality standards; and Big Data analysis involves statistical methods that can be used to analyze large volumes of data generated by IoT sensors, identifying patterns, predicting failures and optimizing operations.

The transition from Industry 4.0 to Industry 5.0 marks a shift from purely technological advancements to a focus on human-centric approaches, sustainability and resilience. This evolution prioritizes well-being, environmental considerations and the integration of advanced technologies like digital twins. In this context, Industry 5.0 redefines its pillars by prioritizing human well-being and environmental approaches. For this integration, analyses such as financial and statistical, among others, can be included to ensure a transition aligned with global challenges, which involve environmental issues and resource efficiency.

This manuscript will address conceptual issues and technical applications using the proposed system modernization through retrofitting, ensuring that the system is modern enough to accommodate applications such as digital twins and other technologies related to Industry 4.0.

2. Brownfield Systems and Technologies

The purpose of this discussion is to explore key principles and collect the most relevant information on retrofitting and Industry 4.0 technologies. The goal is to gain an overview of the content of this work and identify the areas that are directly related, with a focus on how the incorporation of new technologies can transform legacy systems into components of a modern industrial environment []. As a result, adjusting or replacing analog components with digital ones not only modernizes machinery and equipment but also improves productivity, safety and product and service quality, resulting in higher customer satisfaction.

Industry 4.0 is based on Internet of Things (IoT) technology, which requires devices and equipment to be internet-connected in order to collect and share real-time data []. Because IoT devices, such as sensors and actuators, are constantly collecting data, this connectivity is critical for process automation and optimization. Furthermore, it is necessary for remote monitoring and control of industrial operations.

The phrase “cyber–physical systems (CPSs)” refers to the integration of computing and communication technologies with physical systems such as infrastructure and equipment. These systems are the foundation of Industry 4.0, enabling complex interaction between computational systems and the physical world []. CPSs facilitate the construction of integrated and efficient solutions since their advanced architectures and communication protocols ensure interoperability between several devices and platforms.

The integration of IoT and CPSs transforms the industry, enabling more automation, efficiency and flexibility in manufacturing processes. Real-time data analysis allows for predictive maintenance, cost reduction and better productivity. Furthermore, the use of these technologies allows for constant improvements in industrial processes and greater adaptability to changing demands.

Large and complex datasets that cannot be handled or stored with conventional techniques such as relational databases [] are referred to as “Big Data”. In cyber–physical systems (CPSs), including energy system monitoring, transportation network traffic management and industrial process control, Big Data seems to have great promise. Examining this information can provide important new ideas and trends that support strategic decision-making and optimization.

Edge computing is data storage and processing performed near the sensors or devices gathering the data. The data does not have to be transferred to a centralized data center or the cloud [], so this saves latency and network traffic. Faster and more effective responses made possible by proximity to the collecting site are essential for uses requiring real-time processing.

Artificial intelligence (AI) is a collection of technologies and methods enabling computers to perform tasks typically requiring human intellect, including language, perception, learning and reasoning, by means of which they would otherwise be executed. Among the study fields depending on artificial intelligence [] are machine learning, natural language processing, computer vision, robotics, reasoning and planning. These qualities help automated systems to grow over time, streamline operations and handle challenging tasks in ways that are comparable to human thought and hence optimizing processes.

In the integration of artificial intelligence (AI) and machine learning (ML), there are significant challenges, such as data quality, scalability and compatibility with legacy systems. Some approaches propose condition monitoring using machine learning, evaluating available methods for different purposes. For example, for classification, Artificial Neural Networks (ANNs), Support Vector Machines (SVMs) and Convolutional Neural Networks (CNNs) stand out; for clustering, methods such as K-means, Fuzzy C-means, and Dynamic Bayesian Networks are used; for regression, Recurrent Neural Networks (RNNs) and Support Vector Regression (SVR) are prominent; and for learning, techniques like Random Forest, Boosting, and Stacking are widely applied [].

AI-based predictive maintenance systems use sensor data and advanced analytics to predict equipment failures and estimate Remaining Useful Life (RUL). This prevents unexpected breakdowns, reduces maintenance costs, and improves system reliability. Techniques such as deep learning (e.g., LSTMs and CNNs) and statistical models (e.g., Hidden Markov Models) are widely used to detect anomalies and predict failures [].

AI, when combined with technologies like digital twins and machine learning-powered visual inspection systems, can identify defects earlier in the production process, reducing waste and improving the final quality of products.

Inherited from a former corporation or antiquated technology still in use by a company or organization, a legacy system consists of hardware and software []. It can be challenging to include new trends and technology in these systems, and they can be complicated, difficult to run and update and demanding.

In general, the process of brownfield includes the improvement of legacy systems, which are normally, obsolete hardware and software that have been handed down from previous technologies within modern industrial settings. By retrofitting, advanced technologies are implemented and the process can be transformed into elements of Industry 4.0. This, in turn, improves productivity, safety and product quality. Edge computing, Big Data analytics and AI are employed in this transformation to improve the pace of data processing, inform decision-making and improve operational efficiency. Finally, brownfield retrofitting enables existing systems to satisfy the demands of the modern industrial sector, thereby enhancing efficiency, adaptability and customer satisfaction, all while adhering to Industry 4.0 standards.

3. Retrofitting Frameworks

In general, the study illustrates a retrofitting method. Some discuss challenges and opportunities in transitioning from Industry 4.0 to Industry 5.0 []. Brownfield development, a key aspect of retrofitting, focuses on upgrading legacy systems to meet Industry 4.0 and 5.0 standards. This approach is cost-effective compared to building new smart factories, as it integrates IoT and advanced technologies into existing equipment, enabling digital communication and improving operational efficiency. Industry 4.0 begins by adding sensors and IoT to “brownfield settings” or industrial operations. These facilities have outdated and used equipment that must be digitalized to satisfy standards. Another approach, smart retrofitting, was stressed as being very important for changing the manufacturing equipment so that new technologies can be added without having to completely rebuild the system. The term “smart retrofitting” refers to ways to bring old machines and processes up to date.

In this context, modern industry values solutions that focus on people, which makes upgrading more difficult. The piece covers a lot of ground when it comes to the technological issues and tools needed for brownfield development. It focuses on making Industry 4.0 improve and getting ready for Industry 5.0. The suggested strategy for retrofitting aims to turn workplaces into smart places quickly, cheaply and with little work while also offering useful solutions for management. For Industry 5.0, future study will focus on brownfield development, with a focus on how to incorporate human-centered goals into systems that have already been built.

Numerous studies examine the shift from Industry 4.0 to Industry 5.0, emphasizing networked production systems and human-centered methods []. Many archaic tools cannot communicate digitally, making it difficult to collaborate. Retrofitting systems is cheaper than building new smart factories. Connecting and digitizing things, analyzing digitization and addressing practical and administrative demands are part of this process.

Another study examines real-time data collection and processing for production factors, ensuring proper workshop–machine collaboration []. A production control system for industrial workshops leverages the Internet of Things to automate and optimize operations through interconnected devices and real-time data exchange. System-design block diagrams and multi-objective optimization are included. This strategy optimizes delivery times, machine loads and efficiency. The study also discusses ordering things and advises improving machine skills and collaborative efficiency.

By connecting sensors, devices and software to track and enhance production processes, the IoT alters manufacturing. Smart factories [], predictive maintenance, asset tracking and energy efficiency are achievable with this adjustment. Industrial Internet of Things (IIoT) lets smart devices communicate and collect data remotely, improving industry.

A way is given for finding and fixing issues in project design that stop temperature drops from happening []. The study uses a dynamic thermal hydraulic simulator with multi-objective optimization to pick changes that work well and lower operating temperatures. The method was tested on a real-life DHN operation case with 60 customers and 260 pipes. It led to a big drop in the maximum working temperature and suggested a number of retrofitting changes that would be best, giving us a Pareto front approximation.

The method employs a non-linear, dynamic simulator combined with a multi-objective optimization framework. This approach identifies retrofitting targets, such as exchangers, pumps and pipes, to enhance system performance []. Lowering the supply temperature not only cuts down on greenhouse gas emissions, but it also makes it easier to use natural energy sources, which make the energy system more environmentally friendly.

Adding IoT devices to antique water meters is intriguing. A deep learning-based digit identification method is used to interpret meter register images after taking them []. Pictures are converted into digital data and transferred to the cloud for real-time analysis. Water usage data is more accurate and dependable. The study focuses on faculty and staff housing and student dorms. Data refinement can reveal trends in water use, helping one understand how Integrated Water Systems distribute water. The results suggest that an IoT-based architecture may develop to support more applications. The strategy provides precise information about water management needs to help individuals make decisions and promote long-term water management practices, according to the study. This strategy worked effectively in a busy school, suggesting it could be applied in other circumstances to improve water resource management.

A comprehensive strategy aids in developing and implementing efficient retrofitting strategies for houses and businesses []. The framework includes data collection, life cycle cost calculation, building simulation and Analytic Hierarchy Process (AHP) multi-criteria decision-making. A case study demonstrates how the framework was applied to create a retrofitting plan that saves 30% of annual energy expenses and has a payback period of 2.2 years.

Using mathematical programming, models and AHP to look into energy use and cost-effectiveness leads to the creation of a structured plan. The method makes the most of performance and energy use so that buildings use less energy overall. The case study says that the framework can help people make decisions about upgrading that meet their needs and foster environmentally friendly building.

Retrofitting is necessary for industrial system upgrades from 4.0 to 5.0. Retrofitting old equipment with IoT, AI and other advanced technologies is cost-effective, sustainable and human-centered []. Multi-objective optimization, dynamic simulation and decision-making frameworks reduce integration complexity and scalability obstacles. Future research should improve human–machine collaboration, brownfield development and IoT and AI to produce smarter, more sustainable industrial systems [].

The works utilized as the foundation for this research on the presentation of an approach to design and implement a refit procedure to attain the context of Industry 4.0 still remain relevant. First, [] presented a retrofitting approach for Industry 4.0 upgrade legacy systems. The fundamental contribution of the work is a detailed guide for retrofitting—that is, replacing outdated equipment with more advanced technologies to enhance system performance while using current devices to lower expenses. The aim is to modernize outdated systems methodically and systematically to satisfy Industry 4.0 criteria, including automation, connectivity and process optimization. retrofitting uses key I4.0 technologies to gather and process physical system data for a virtual model. This interaction between the virtual model and the real system lets one continuously monitor and assess the performance of the changed system versus objectives.

The second [] is a continuation; it shows the retrofit process in a more ordered and methodical manner and comprises steps including obtaining needs from the legacy system, assessing its features and constraints, defining update objectives and choosing suitable technologies for implementation. This detailed guide seeks to guarantee effective execution of updates in line with contemporary technological requirements. Moreover, the upgraded system’s performance is assessed using both qualitative and quantitative approaches, therefore guaranteeing the accomplishment of the set goals. Based on the RAMI (Reference Architectural Model for Industry 4.0) model, another important issue underlined is the consideration of the technological maturity level to guarantee that the revised system conforms with the criteria of smart factories. By means of identification of devices, dependencies, interactions, difficulties and constraints during the legacy system analysis, one is able to carefully choose the technologies to be used. Defining the devices and techniques that will be subject to change, performing tests to confirm proper operation and making appropriate changes as needed also constitute part of the retrofit.

The RAMI architecture, also known as RAMI 4.0 (Reference Architecture Model for Industry 4.0), is a widely used reference model designed to assist companies in implementing Industry 4.0. This model provides a systematic framework for developing flexible and efficient production systems based on advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), advanced automation, and other innovations []. RAMI 4.0 is based on the SGAM model (Smart Grid Architecture Model) and was designed to meet the main requirements of Industry 4.0, such as vertical and horizontal integration, engineering integration and the product lifecycle. It organizes these perspectives into a three-dimensional structure that combines functional layers, production hierarchies, and the product lifecycle, enabling a comprehensive and structured view of the technologies and processes involved.

Motivation

The proposed research project is justified by the urgent need to enhance the factory’s technological maturity index, which serves as a mechanism to evaluate an organization’s readiness and capabilities in implementing Industry 4.0 technologies and concepts. This necessity is supported by findings from the recent PIMM 4.0 study, which identified critical gaps in key dimensions such as automation, human resources, and interoperability. By addressing these gaps, the project aims to define strategic actions that align with the company’s overarching goal of achieving technological modernization and competitiveness [,]. The study provides a structured approach to systematically improve the factory’s maturity index, ensuring readiness for Industry 4.0 adoption while laying the groundwork for future projects that align with the principles of Industry 5.0.

The findings of this study show a low maturity index in key critical dimensions and sub-dimensions, emphasizing the importance of taking strategic and focused activities to progress toward Industry 4.0. Being themselves.

1. Products and Services: In the dimension of products and services, the study revealed a maturity index of only 2.34 for customization and 2.90 for digital values, indicating the factory’s limited ability to respond to customers’ personalized needs and incorporate digital technologies into its products. This low score illustrates the importance of using sophisticated technologies that enable mass customization and the introduction of digital features into products, both of which are crucial for increasing competitiveness and matching modern consumer expectations.

2. Manufacturing and Operations: The maturity indices, derived from the PIMM 4.0 framework, highlight critical gaps in areas such as automation (2.09) and M2M communication (1.66), which fall below industry benchmarks of 3.5 for advanced manufacturing systems. This not only reduces efficiency and productivity but also stops the firm from achieving higher levels of operational innovation and manufacturing quality. The research will concentrate on the creation and implementation of technical solutions that increase automation and communication among devices and platforms. As a result, it is required to do research on the current manufacturing process and identify prospective automation enhancements that match such standards, with the goal of developing a retrofit method for electric meter manufacturing.

3. Strategy: In terms of strategy, the maturity index was also poor, with HR training scoring only 1.48, indicating a considerable gap in the skills and knowledge required for Industry 4.0. This finding emphasizes the crucial need of creating training and development programs centered on technology and innovation in order to appropriately prepare staff for changing demands and promote a culture of constant learning and adaptability. As a result, research should be conducted to identify technologies and tools connected to production process automation and Industry 4.0 in order to train personnel involved and mitigate risks related to low adoption of an innovation-driven culture.

4. Logistics: The logistics maturity index was found to be insufficient, with the variable “visibility” scoring only 1.78, indicating concerns with transparency and integration in the supply chain. The study will look into how to implement IoT technology and advanced automated inventory management systems to significantly increase logistical efficiency.

5. Interoperability: Interoperability is another crucial aspect, with a score of 2.12 indicating a lack of integration and effective communication between systems. The research will look for potential technologies, tools, standards and protocols that promote interoperability, which is critical for genuine digital transformation.

These indices underscore the need for strategic and planned research that links the PIMM4.0 model study’s indices. Data from the indices is analyzed to define systems-level initiatives, automation and interoperability between sectors like logistics and manufacturing, which require Big Data, production estimation models, AI-assisted decision-making support, industrial Internet of Things and a mindset change program.

Retrofitting, a systematic approach and process modernization are justified to improve PIMM 4.0’s technical maturity index by detecting substantial gaps in the study’s categories. The strategy can improve M2M connectivity, automation and Industry 4.0 technologies like IoT sensors and cyber–physical systems in PIMM 4.0. This strategy is critical for Manufacturing and Operations, which have low control and automation and M2M indices (2.09 and 1.66). Retrofitting the manufacturing line with connected devices can boost efficiency, minimize waste and collect real-time data for predictive analysis and AI-assisted decision-making. Retrofitting maximizes asset use and reduces technological maturity investment, making it cost-effective.

Modernizing the organization efficiently, methodically and in line with its strategic goals requires discipline. An established process will help identify requirements in each dimension, set targets and implement steps to attain maturity indices in PIMM 4.0. Products and services have low customization (2.34) and digital values (2.90), indicating, for example, the need for product digitalization and mass customization. A structured process can be used to pick flexible production methods, digital platforms and data analysis tools to ensure an effective transformation that meets modern customer expectations.

Achieving manufacturing technical maturity and compliance with Industry 4.0 standards requires a thorough modernization of processes. The PIMM 4.0 framework highlights critical gaps, such as strategic shortcomings in human resource training (index 1.48) and system interoperability (index 2.12), necessitating a comprehensive redesign. To address these challenges and enhance technological maturity, a combination of retrofitting, a structured methodology and process modernization is essential. A well-organized retrofitting approach enables the optimization of efficiency and strategy while upgrading legacy equipment to meet modern standards. By adopting these approaches, manufacturers can position themselves as competitive, connected and forward-thinking players in industry.

4. Retrofitting Proposal

The use of retrofitting in industrial processes or systems has the ability to significantly improve the overall operation related to the system. In this study, an approach that is based on the methodology provided in previous works [,,] is applied. This methodology is designed to retrofit legacy systems. The methodology provides a structured framework for updating obsolete software and hardware, serving as the foundation for the development of a retrofitting model tailored to the study’s objectives. Its purpose is to serve as the basis for meeting the requirements of this study.

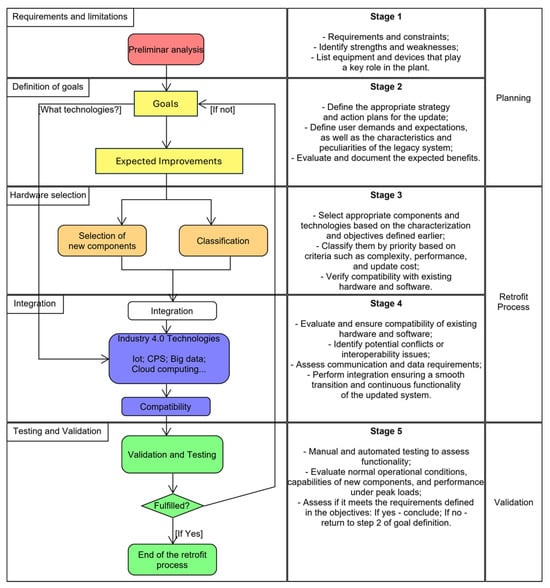

The process integrates information systems and new technologies to ensure a seamless transition to Industry 4.0 requirements. This is accomplished in order to facilitate a smooth transition. Figure 1 outlines the steps for retrofitting legacy systems, emphasizing objectives such as improving output, reducing costs, enhancing quality and ensuring safety.

Figure 1.

Steps to apply the retrofitting proposal.

Previous research [] emphasizes integrating modern technology into legacy systems to improve performance and adaptability and meet Industry 4.0 objectives. By virtualizing the physical system, digital twin architecture offers real-time process monitoring, modeling and optimization. The emphasis is on the updated system as a basis for the creation of the supervisory system, which will be explored in detail below.

Retrofitting legacy systems enhances efficiency, flexibility, safety and adaptability, aligning industrial processes with modern technological demands and Industry 4.0 standards []. By virtualizing the physical system, the digital twin architecture enables real-time process monitoring, modeling and optimization. The emphasis is on the updated system as a basis for the creation of the supervisory system, which will be explored in further detail in the next sections.

Step 1—A detailed examination of the current legacy system (case study) was required to enable appropriate retrofitting of obsolete systems. This demands a careful examination of its benefits, problems, requirements and limitations. Thus, by carefully studying these variables, we were able to make decisions regarding which components to upgrade and the best upgrading process. This initial stage was critical since it laid the groundwork for the rest of the process. It starts with a thorough understanding of the facility, plant and environment that houses the legacy system, which was documented with operational flowcharts, schematics, diagrams and other relevant documentation.

A thorough analysis of the current legacy system (case study) was necessary to ensure effective retrofitting of outdated systems. This needs a detailed assessment of its benefits, challenges, requirements and limitations.

- Objective: Carefully analyze these aspects to make informed choices about which components to upgrade and the ideal upgrade method.

- Documentation: Begin with a deep understanding of the facility, plant and environment containing the legacy system, documented with operational flowcharts, schematics, diagrams and other pertinent documentation.

Step 2—Setting initial goals, such as increasing efficiency, reducing costs and expanding flexibility, was critical for developing an efficient and effective legacy system upgrading approach. This step focuses on setting goals while taking into account user needs and the features of the previous system. Evaluating expected benefits, risks and consequences was also critical. These objectives provide a framework for assessment and decision-making, supporting compliance with quality and standards needs. A thorough evaluation of the system’s needs, advantages, risks and constraints is required for a successful upgrade.

Identifying initial goals, such as increasing efficiency, reducing costs and enhancing flexibility, was essential to establish an efficient and effective legacy system upgrade strategy.

- Focus: Identifying goals, taking into account user demands and the characteristics of the old system.

- Evaluation: Assess projected benefits, risks and repercussions. These goals serve as a framework for review and decision-making, ensuring compliance with quality standards and requirements.

- Outcome: A successful upgrade includes a comprehensive assessment of the system’s requirements, benefits, risks and limitations.

Step 3—Selecting appropriate technologies and components based on previous steps and goals includes selecting and prioritizing technologies or components to be updated based on factors such as installation complexity, upgrade cost and performance impact. To continue satisfying operational needs, the actions implemented during this stage of the retrofitting process must be coordinated. This alignment resulted in two immediate benefits: compatibility with existing hardware and software, which eliminates integration issues, and future-proofing the system by picking expandable technologies, ensuring the system’s applicability over time.

Selecting the right technologies and parts based on the previous steps and goals means picking and ranking technologies or parts that need to be upgraded based on things like how hard they are to install, how much they cost to upgrade and how they affect performance.

- Measures taken during this phase of the retrofitting process must be in sync to continue meeting operational needs.

- Compatibility with existing hardware and software to avoid integration challenges.

- Future-proofing the system by selecting technologies that can expand, ensuring the system’s applicability over time.

Step 4—entails determining the compatibility of new components with the legacy system prior to integration, taking into account communication compatibility, interoperability concerns and conflict detection. Thorough integration testing assures correct operation and eliminates critical issues required to sustain system functionality. Furthermore, careful planning, rigorous testing and post-integration monitoring were required to ensure a smooth transition and continuing functionality throughout the complicated process of integrating a new method into legacy systems.

Analyzing the compatibility of new components with the legacy system before integration, considering communication compatibility, interoperability issues and conflict detection. After outlining the retrofitting process, it is essential to consider its applications across various sectors and the limitations that may arise during implementation.

Step 5—Extensive testing and validation were required to identify the risks and implications associated with new components and technologies, as well as to ensure their appropriate operation. Automated and manual tests were used to evaluate the processes. Automated tests effectively mimic usage scenarios, whereas human testers carefully examine functionality. During this phase, tests were carried out to assess the performance of new components under both average and high workloads, as well as their integration with the existing system and standard operational settings. If any errors occurred during testing, they were corrected before the final execution. This method is required to ensure that planned goals are met and that modifications to the old system are done correctly.

During compatibility testing, a legacy system was updated to enable, for instance, real-time monitoring. Integration tests ensured seamless communication between the new sensors and the existing control system. Extensive testing and validations were necessary to determine the risks and impacts related to new components and technologies and to ensure their proper functioning.

- Testing Types: Both automated and manual tests were conducted to evaluate the processes. Automated tests effectively replicate usage scenarios, but human tests thoroughly test functionality.

- Performance Evaluation: Tests were conducted to evaluate the performance of new components under average and high workloads, integration with the existing system and standard operational configurations.

- Corrections: If inaccuracies occurred during testing, they were fixed before final execution.

- Approach: It is essential to ensure that planned goals are achieved and that changes to the old system are properly implemented.

Retrofitting a legacy system entails several steps: conducting an in-depth analysis to understand its merits, issues, requirements and limitations; setting targets to increase efficiency, effectiveness and flexibility; selecting appropriate technologies and components based on goals, complexity, cost and performance impact; running integration tests to ensure compatibility with the legacy system; and performing comprehensive tests and validations to evaluate the risks.

In terms of the scope and limitations of the industrial sector, the Table 1 highlights the applications and limitations of the methodology within the context of Industry 4.0, considering different sectors, production scales and technological levels. In terms of applications, the methodology is broadly applicable to sectors such as manufacturing, food and beverage, construction and logistics, with specific adaptations to meet the needs of each area. For instance, in the iron and steel industry, the focus may be on integrating IoT sensors for real-time monitoring and predictive maintenance, while in the food and beverage sector, the priority might be automating quality control processes and ensuring compliance with food safety standards.

Table 1.

Limitations of the approach.

Applicability also varies across economic sectors: it is limited in the primary sector due to low automation potential; high in the secondary sector, where production processes benefit from connectivity and automation; and moderate in the tertiary sector, particularly in logistics and supply chain management.

On the other hand, the methodology presents limitations when IoT infrastructure is insufficient, and legacy systems are too outdated or incompatible, which can hinder the implementation of the proposed methodology in specific cases. Scalability and interoperability issues may also arise in diverse or geographically dispersed operations, requiring customized solutions to ensure the efficient integration of new technologies.

5. Case of Use

The production line integrates automation and human expertise to ensure the efficient production of high-quality items. The state machine in Figure 2 depicts the interconnected processes and decision-making procedures, demonstrating a continuous flow from assembly to packing with strong quality assurance systems in place.

Figure 2.

Enhanced generic process flow.

The production line consists of three main phases: assembly, component insertion and packing. During assembly, robotic arms and conveyors ensure precision and flexibility, enabling the creation of diverse product designs. In the component insertion phase, automated systems place parts like electronic chips with high accuracy, supported by sensors and video systems for quality control. Finally, the packing phase prepares products for delivery, using automated tools to wrap, box and label items efficiently while conducting final quality checks. The steps are detailed below.

The assembly phase is the initial stage in which a variety of components are combined to establish the base of the product. Precision and collaboration are essential during this phase, as it establishes the base for subsequent operations. Robotic arms and conveyors are frequently used in automation at this stage to manage components with exceptional precision, thereby reducing human error and enhancing manufacturing speed. Advanced assembly technology provides increased manufacturing flexibility, allowing for the creation of numerous product designs and variations with minimal reconfiguration.

Component Insertion Phase: This step comes after assembly and involves adding certain parts to a building that has already been put together. This step is very important for supporting the practical parts that the product needs to work. Automated methods are used to carefully put parts in their right places, like electronic chips or mechanical parts. This automation makes things more consistent and accurate, which reduces the chance of mistakes and increase the general reliability of the product. At this stage, sensors and video systems are used to make sure that the parts are in the right place and facing the right way. This makes quality control better.

Packing Phase: The last step in the production line is packing, which gets the finished product ready to be delivered to customers. At this stage, the products are packed up to keep them safe during transport. Automated packing tools can quickly and easily wrap, box and label goods, making sure consistency while cutting down on labor costs. In this step, the product may also go through extra quality checks to make sure it meets all the requirements before it is delivered to customers.

Decision-Making and Quality Assurance: These three steps are connected by an important decision-making process that is based on quality assurance. This step is very important for making sure that only good items can be delivered to customers. At different steps of the production process, automated quality checks like stress tests and visual inspections are used. By finding and fixing problems early during the process, these checks help keep customers from receiving failed products. People are often involved in this stage of decision-making because they have the skills and experience to deal with complicated quality problems that technology alone might not be able to handle.

Integration of Advanced Technologies: the production line integrates complex technology defined in processes 1 and 2. These technologies include unique modules created to fit individual client wants and preferences, resulting in tailored solutions that increase product value. The integration of these innovative systems enables a high degree of flexibility and adaptability, allowing the manufacturing line to efficiently handle a wide range of goods while maintaining high quality and performance standards.

Finishing procedures, including product quality testing and storage, comprise the third manufacturing line process. This step is important since it includes the fundamental retrofit plan to improve the process. This retrofit aims to integrate innovative capabilities that allow for detailed product review to ensure clients receive only high-quality items. Cameras (computer vision) and digital image processing can improve quality checking. These technologies provide detailed visual assessments, revealing problems that would otherwise be invisible.

Automation and advanced quality control tools, such as cameras and digital image processing, enhance efficiency and reliability in the production line. These technologies reduce the risk of defective products reaching the market, aligning with Industry 4.0’s goals of data exchange and process integration.

Retrofitting current systems with these characteristics improves quality assurance and simplifies complex inspections. Keeping only high-quality products ready for shipment improves product quality and storage. The process reduces waste, rework and recalls, saving money. High quality at this important step helps the production line meet customer expectations and brand reputation.

Finally, aligning with the principles of Industry 5.0, the production process not only seeks efficiency and automation but also values human-centered approaches and sustainability. The integration of technologies in the context of Industry 4.0 and 5.0 enables product customization, while sustainable practices and collaboration between operators and intelligent systems foster a more resilient and adaptable production environment to meet current and future demands.

Analysis

The study uncovers substantial gaps in how mature key parts are inside firms, requiring concerted strategic initiatives to satisfy Industry 4.0 objectives. Personalization and digital values have low maturity ratings in products and services, scoring 2.34 and 2.90, respectively. New mass customization and digital interaction technologies are needed to fix these issues.

Table 2 shows that control and automation have a maturity score (2.09 in the Manufacturing and Operations area) and machine-to-machine (M2M) communication has an even lower score (1.66). Because of this, strong technological solutions are needed to make automation and connection a lot better. The main goal should be to bring old manufacturing methods up to date, especially those used to make electric meters, so they meet current standards. Also, there is a big talent gap in the strategy dimension, where the HR training number is only 1.48. This shows how important it is to have thorough training programs that focus on technology and innovation skills. These programs should prepare the workforce for future needs and encourage a mindset of always learning and being able to adapt.

Table 2.

Analysis of Industry 4.0 maturity and strategic actions.

Logistics has a poor visibility score (1.78), indicating supply chain clarity and integration issues. IoT and automated inventory systems should be employed to improve transportation efficiency to address these concerns. The Interoperability maturity score is 2.12, indicating poor system integration and communication. To avoid these issues, employ the correct technology, tools and standards to make system communication easier. Research and development (R&D) helps link, automate, train people, integrate data, keep IT safe and align the company’s goals with Industry 4.0. These are necessary for a smooth digital shift.

The RAMI 4.0 framework provides a structured approach to integrating digital technologies into manufacturing processes, enabling seamless communication between systems and optimizing operations at all levels.

The PIMM 4.0 study assesses a factory’s Industry 4.0 readiness. It outlines long-term steps to align with RAMI 4.0-related Industry 4.0 standards. RAMI 4.0 plans the integration of digital technology into company operations, resulting in a total transformation. Table 3 shows the mapping which indicates stages onto RAMI 4.0 allows manufacturers to slowly introduce digital technology. Technical maturity, operational efficiency and competitiveness will improve.

Table 3.

Alignment of strategic steps with RAMI 4.0 framework.

RAMI 4.0’s comprehensive architecture for Industry 4.0 transformation includes lifespan and value stream mapping, hierarchy layers and levels for system compatibility and data flow. Manufacturers can gradually integrate digital technology into their operations by following this approach, improving technical maturity, operational efficiency and Industry 4.0 competitiveness.

Table 4 shows PIMM 4.0’s assessment of the factory’s technological maturity. It finds quantitative and qualitative concerns across several operational parameters and suggests strategic ways to align with Industry 4.0 requirements. The table seeks to highlight crucial areas that need technology breakthroughs and strategic actions by evaluating these elements. This systematic approach helps the plant understand its current capabilities and plan future enhancements, keeping it competitive in the ever-changing industrial landscape.

Table 4.

Analysis of Technical Maturity and Strategic Actions.

Table 5 effectively describes the factory’s present technical maturity and identifies crucial areas for development as it transitions to Industry 4.0. The recommended strategic measures, which address both quantitative and qualitative difficulties, aim to improve the factory’s competitiveness, operational efficiency and overall digital transformation. This dual approach offers a holistic strategy that uses both numerical data and qualitative insights to drive meaningful change, preparing the factory for success in today’s industrial context.

Table 5.

Comparative analysis of factory state before and after implementation.

The comparative evaluation of the factory’s situation before and after implementing the recommended steps sheds light on the expected improvements across multiple dimensions, as specified in the PIMM 4.0 research. This analysis also takes into account alignment with the RAMI 4.0 framework, which provides a methodical way to incorporate digital technology into industrial processes.

These approaches aim to boost the factory’s technological maturity to RAMI 4.0 levels. Automation and integration improvements boost efficiency, productivity and savings. Customisation and digital integration will give the factory a competitive edge by increasing product possibilities and customer satisfaction. As employees master new technology, their inventiveness and flexibility will increase. Logistics responsiveness, bottleneck reduction and supply chain management will improve with supply chain optimization. These steps will help the facility become more integrated, automated and competitive in line with Industry 4.0 and RAMI 4.0.

With the adoption of frameworks such as RAMI 4.0 and the incorporation of Industry 5.0 principles, strategic analysis begins to consider not only technological maturity but also factors such as sustainability, employee well-being and organizational resilience. These dimensions broaden the scope of the transformation proposed in this work, making it more comprehensive and aligned with the contemporary challenges faced by industry.

6. Results

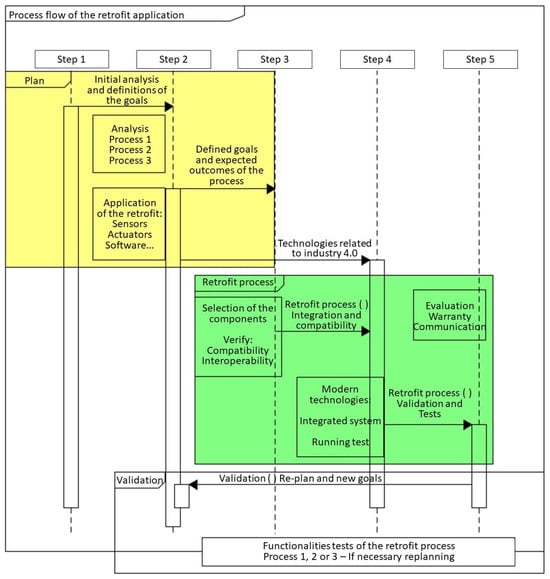

The approach included planning, retrofitting and validation. The first stage is gathering system requirements. This includes planning to achieve goals. The process begins with problem characterization, followed by data collection, analysis and interpretation. To better comprehend the activities, Figure 3 shows consecutive views of the production line.

Figure 3.

Process flow.

- Planning

- Begins with collecting system requirements.

- Involves creating a strategy to achieve defined objectives.

- Includes problem characterization, data collection and analysis and interpretation of results.

- Retrofit

- Focuses on updating existing systems with new technologies: IoT Sensors and Big Data Analytics. The process includes

- –

- Early Fault Detection: Helps in identifying issues before they escalate.

- –

- Predictive Maintenance: Scheduling maintenance activities based on data insights to prevent unexpected breakdowns.

- –

- Optimization: Enhancing the production process based on data analysis.

- Validation

- Ensures that all stages have been executed correctly.

- Includes testing new components and processes to detect and correct problems before they impact production.

- Continuous evaluation and adjustments are required to maintain effective and efficient operations.

The approach adopted follows the principles of frameworks such as RAMI 4.0, promoting vertical and horizontal integration of systems, interoperability and lifecycle management of products. This ensures that the improvements implemented are in compliance with international standards for industrial digitalization. Thus, to meet Industry 4.0 criteria, retrofitting methodically transforms outdated systems into modern ones. This improves operational performance and introduces sophisticated technology like IoT sensors, Big Data and cloud computing. The approach begins with a thorough study of legacy systems to discover inefficiencies and improvement opportunities. Installation of improvements to established procedures, processes and components follows. These enhancements enable real-time monitoring of system quality, compliance and operations, increasing productivity and optimizing procedures.

Internet of Things sensors dominated the retrofit’s third stage. These sensors monitor real-time performance and identify product batch component defects. This happened in procedure (3), the third step of the operation. This helps discover problems earlier, provides predictive maintenance support and boosts production efficiency. Industrial camera-connected IoT sensors collected data. The integration of Big Data analytics required data gathering. After filtering and saving, the data was processed and transferred to the cloud.

Retrofitting included preventative maintenance. For instance, predictive maintenance was implemented by integrating IoT sensors into the production line, allowing real-time monitoring of equipment and reducing unexpected downtime. These tactics included regular sensor and camera calibration, product standard updates and nonconformity references. These methods guarantee the accuracy and dependability of the customized system. The updates, which mostly succeeded, implemented a comprehensive quality management system. This framework allowed process 3’s essential components to be identified, measured, supervised and improved. This meets technical requirements and consumer satisfaction. Standardizing manufacturing procedures and ensuring quality accomplishes this.

However, adapting step 3 presented many complications. This persisted throughout the process. One of the main challenges of retrofitting is the compatibility of new technologies with legacy systems. This often requires significant workflow adjustments, which can disrupt production. Additionally, monitoring and maintaining modified machinery demands rigorous testing and continuous evaluation to ensure proper functionality.

For these difficulties, all new components and methods were rigorously tested to assure proper performance. These tests were essential to find and fix production issues before they affected production. Depending on the severity of the problem, technique improvements or major adjustments were performed. IoT and Big Data analytics enabled real-time monitoring, problem detection and pattern and insight discovery to improve process performance. These technologies improved process performance, making them very useful.

The new strategy will likely focus on these concerns and retrofitting methods. Modern threat detection technologies, encryption protocols and AI-powered security analytics will be applied to protect retrofitted systems from cyberattacks, ensuring data integrity and secure communication across connected devices. Networked industrial environments may require entire cybersecurity frameworks, which the project will investigate. Modified systems can withstand evolving threats because of this.

Consequently, in addition to gains in efficiency and automation, the results achieved through retrofitting also lay the groundwork for a future transition to Industry 5.0. The integration of all the aforementioned technologies not only enables smarter processes but also paves the way for human-centered approaches, mass customization and sustainability. The involvement of operators in the validation and adjustment of systems, combined with the use of current tools, contributes to a more collaborative, resilient and adaptable production environment that meets contemporary social and environmental demands.

While the current retrofitting approach has demonstrated significant improvements in operational efficiency, future research will focus on addressing remaining challenges and exploring new applications in other industrial domains. The device and system interoperability and standardized communication protocols will be prioritized.

Retrofitting will be broadened to encompass other applications to study new industrial uses outside manufacturing. In logistics, IoT technologies can enhance supply chain visibility by providing real-time data on inventory levels and transportation routes. In smart product development, CPSs can enable mass customization by streamlining design and production processes. In intelligent product development, CPSs can simplify mass customization and speed up product launch. These further examples will demonstrate the retrofitting process’s versatility and scalability, proving its utility in a range of industrial domains.

7. Conclusions

Retrofitting enhances the functionality of outdated systems, aligning them with Industry 4.0 standards. By integrating advanced technologies such as IoT, CPSs, Big Data, and cloud computing, it improves operational efficiency, enables real-time monitoring, and optimizes processes. These technologies address the gaps identified in the PIMM 4.0 study, particularly in automation, machine-to-machine (M2M) connectivity, and system interoperability. In addition to the previously mentioned benefits, retrofitting is a sustainable approach that extends the useful life of equipment, reduces the need to discard machines and minimizes the consumption of natural resources and carbon emissions. By reusing mechanical structures and updating only electronic and control components, retrofitting significantly contributes to reducing environmental impact and promoting the circular economy in industry—contexts that are explored by Industry 5.0.

Future research will improve system security infrastructures with threat detection, encryption and AI-driven analytics. Modified systems will be resilient to evolving cyberattacks with these data integrity, availability and confidentiality measures. Cybersecurity frameworks will combat linked industrial settings’ inherent issues and protect all system layers.

Future research should focus on developing modular system architectures that allow seamless integration of new technologies, improving scalability and flexibility. The transition to Industry 5.0 highlights the importance of human-centered approaches, human–machine collaboration and mass customization. Retrofitting, by integrating digital technologies and empowering operators with smart tools, paves the way for more resilient and adaptable production environments that are oriented toward employee well-being and sustainability.

To further enhance interoperability among diverse systems, it is essential to prioritize the adoption of standardized communication protocols. Addressing compatibility challenges in future retrofitting initiatives can be achieved by designing modular system architectures, which facilitate the seamless integration of emerging technologies. Moreover, implementing upgrades in well-planned phases helps minimize disruptions to ongoing operations during the transition.

Retrofitting will be used in other industrial domains and use cases outside manufacturing systems. It will be studied in logistics, supply chain management and smart product development. New applications will demonstrate retrofitting’s versatility and ability to spur innovation across sectors.

Future retrofitting research will consider the human component in addition to technical advances. PIMM 4.0 found substantial gaps in human resource training, with a poor maturity index of 1.48. To overcome this, future research will build training programs and tools to teach staff how to operate and maintain retrofitted systems. These initiatives will promote creativity and adaptation to prepare the workforce for Industry 4.0.

Therefore, retrofitting not only modernizes legacy systems to meet the requirements of Industry 4.0, but also paves the way for a more sustainable, connected, secure and human-centered industry, aligned with the challenges and opportunities of Industry 5.0.

Author Contributions

Conceptualization, R.L.P.M.; Methodology, R.S.M.; Software, L.E.S.e.S.; Validation, R.S.M., R.L.P.M. and L.E.S.e.S.; Formal analysis, V.F.d.L.J.; Investigation, R.S.M. and R.G.G.S.; Resources, L.G.S.S.; Data curation, L.E.S.e.S. and R.G.G.S.; Writing—original draft, R.S.M.; Writing—review & editing, R.L.P.M., L.E.S.e.S., R.G.G.S., L.G.S.S. and V.F.d.L.J.; Visualization, L.G.S.S.; Supervision, R.L.P.M. and V.F.d.L.J.; Project administration, R.G.G.S. and L.G.S.S.; Funding acquisition, R.G.G.S. and L.G.S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially supported by NANSEN. The authors thank the financial support from FAPEAM, CAPES, CNPQ, and Institute EVOLUÇÃO.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

Authors Renato G. G. Silva, Luis G. S. Santos were employed by the company NANSEN. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The company in affiliation and funding had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| RAMI 4.0 | Reference Architecture Model for Industry 4.0 |

| CFRP | Carbon Fiber-Reinforced Polymer (in structural retrofitting) |

| BIM | Building Information Modeling |

| GICS | Global Industry Classification Standard |

| DMAIC | Define, Measure, Analyze, Improve, Control |

| IoT | Internet of Things |

| CPS | Cyber–Physical Systems |

| AI | Artificial Intelligence |

| ML | Machine Learning |

| ANN | Artificial Neural Network |

| SVM | Support Vector Machine |

| CNN | Convolutional Neural Network |

| RNN | Recurrent Neural Network |

| SVR | Support Vector Regression |

| RUL | Remaining Useful Life |

| IIoT | Industrial Internet of Things |

| AHP | Analytic Hierarchy Process |

| SGAM | Smart Grid Architecture Model |

| PIMM 4.0 | Manaus Maturity Industrial Pole |

| M2M | Machine to Machine |

| R&D | Research and Development |

References

- Turner, C.J.; Oyekan, J.; Stergioulas, L.; Griffin, D. Utilizing Industry 4.0 on the Construction Site: Challenges and Opportunities. IEEE Trans. Ind. Inform. 2021, 17, 746–756. [Google Scholar] [CrossRef]

- Khayyam, H.; Jamali, A.; Bab-Hadiashar, A.; Esch, T.; Ramakrishna, S.; Jalili, M.; Naebe, M. A Novel Hybrid Machine Learning Algorithm for Limited and Big Data Modeling With Application in Industry 4.0. IEEE Access 2020, 8, 111381–111393. [Google Scholar] [CrossRef]

- Jagatheesaperumal, S.K.; Rahouti, M.; Ahmad, K.; Al-Fuqaha, A.; Guizani, M. The Duo of Artificial Intelligence and Big Data for Industry 4.0: Applications, Techniques, Challenges, and Future Research Directions. IEEE Internet Things J. 2022, 9, 12861–12885. [Google Scholar] [CrossRef]

- Rikalovic, A.; Suzic, N.; Bajic, B.; Piuri, V. Industry 4.0 Implementation Challenges and Opportunities: A Technological Perspective. IEEE Syst. J. 2022, 16, 2797–2810. [Google Scholar] [CrossRef]

- Sinha, D.; Roy, R. Reviewing Cyber-Physical System as a Part of Smart Factory in Industry 4.0. IEEE Eng. Manag. Rev. 2020, 48, 103–117. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented Reality: Focusing on Photonics in Industry 4.0. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 9100111. [Google Scholar] [CrossRef]

- Withanaarachchi, A.; Silva, A.M.H. Key Technologies And Critical Success Factors Of Industry 4.0 For The Sri Lankan Apparel Manufacturing Sector: A Systematic Literature Review. In Proceedings of the 2023 3rd International Conference on Advanced Research in Computing (ICARC), Belihuloya, Sri Lanka, 23–24 February 2023; pp. 286–291. [Google Scholar] [CrossRef]

- Mourinho, F.A.; Assis, T.M.L. A new approach to retrofit plans for distributed energy resources to mitigate adverse impacts on bulk power systems stability. IEEE Lat. Am. Trans. 2022, 20, 669–676. [Google Scholar] [CrossRef]

- Belousov, A.; Lushpeev, V.; Sokolov, A.; Sultanbekov, R.; Tyan, Y.; Ovchinnikov, E.; Shvets, A.; Bushuev, V.; Islamov, S. Experimental Research of the Possibility of Applying the Hartmann–Sprenger Effect to Regulate the Pressure of Natural Gas in Non-Stationary Conditions. Processes 2025, 13, 1189. [Google Scholar] [CrossRef]

- Delzendeh Moghadam, M.; Fathi, A.; Chaallal, O. Retrofitting of Steel Structures with CFRP: Literature Review and Research Needs. Appl. Sci. 2024, 14, 5958. [Google Scholar] [CrossRef]

- Danial, C.E.; Mahmoud, A.H.A.; Tawfik, M.Y. Methodology for retrofitting energy in existing office buildings using building information modelling programs. Ain Shams Eng. J. 2023, 14, 102175. [Google Scholar] [CrossRef]

- Evans, G.; Park, G.; Jandial, P.; Walker, M.; Glass, G.; Krieg, M. Retrofit of a Legacy Seaglider for Smart Sensing Capabilities. In Proceedings of the OCEANS 2024-Halifax, Halifax, NS, Canada, 23–26 September 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Keles, O.K.; Hakyemez, I.; Bagriyanik, M.; Kalenderli, O. A Study on Power System Retrofit for Cessna-172S Aircraft by Using Hydrogen Fuel Cell and Battery Hybrid. IEEE Access 2025, 13, 6089–6101. [Google Scholar] [CrossRef]

- Mendonça, R.D.S.; De Carvalho, M.M.; Machado, G.S.; Da Silva, C.S.M.; De Medeiros, R.L.P.; De Lucena, V.F. Development of a Novel Methodology to Retrofit Legacy Systems in the Context of Industry 4.0. IEEE Access 2023, 11, 123223–123235. [Google Scholar] [CrossRef]

- Sverko, M.; Grbac, T.G.; Mikuc, M. SCADA Systems With Focus on Continuous Manufacturing and Steel Industry: A Survey on Architectures, Standards, Challenges and Industry 5.0. IEEE Access 2022, 10, 109395–109430. [Google Scholar] [CrossRef]

- Eldrandaly, K.A.; Abdel-Basset, M.; Shawky, L.A. Internet of Spatial Things: A New Reference Model With Insight Analysis. IEEE Access 2019, 7, 19653–19669. [Google Scholar] [CrossRef]

- Hahanov, V.; Mishchenko, O.; Soklakova, T.; Abdullayev, V.; Chumachenko, S.; Litvinova, E. Cyber-Social Computing. In Green IT Engineering: Social, Business and Industrial Applications; Springer: Berlin/Heidelberg, Germany, 2019; pp. 489–515. [Google Scholar] [CrossRef]

- Atat, R.; Liu, L.; Wu, J.; Li, G.; Ye, C.; Yang, Y. Big Data Meet Cyber-Physical Systems: A Panoramic Survey. IEEE Access 2018, 6, 73603–73636. [Google Scholar] [CrossRef]

- Bajic, B.; Suzic, N.; Simeunovic, N.; Moraca, S.; Rikalovic, A. Real-time data analytics edge computing application for industry 4.0: The Mahalanobis-Taguchi approach. Int. J. Ind. Eng. Manag. 2020, 11, 145–156. [Google Scholar] [CrossRef]

- Ong, Y.S.; Gupta, A. AIR5: Five Pillars of Artificial Intelligence Research. IEEE Trans. Emerg. Top. Comput. Intell. 2019, 3, 411–415. [Google Scholar] [CrossRef]

- Surucu, O.; Gadsden, S.A.; Yawney, J. Condition Monitoring using Machine Learning: A Review of Theory, Applications, and Recent Advances. Expert Syst. Appl. 2023, 221, 119738. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Zhang, J.; Kline, D.; Fang, L.; Melhem, R.; Jones, A.K. RETROFIT: Fault-Aware Wear Leveling. IEEE Comput. Archit. Lett. 2018, 17, 167–170. [Google Scholar] [CrossRef]

- Ruppert, T.; Darányi, A.; Medvegy, T.; Csereklei, D.; Abonyi, J. Demonstration Laboratory of Industry 4.0 Retrofitting and Operator 4.0 Solutions: Education towards Industry 5.0. Sensors 2022, 23, 283. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.A.; Ruppert, T.; Eigner, G.; Abonyi, J. Retrofitting-Based Development of Brownfield Industry 4.0 and Industry 5.0 Solutions. IEEE Access 2022, 10, 64348–64374. [Google Scholar] [CrossRef]

- Wang, N.; Li, X.; Nie, H. Digital production control of manufacturing workshop based on internet of things. Int. J. Simul. Model. 2021, 20, 606–617. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Internet of things for smart factories in industry 4.0, a review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Merlet, Y.; Baviere, R.; Vasset, N. Optimal retrofit of district heating network to lower temperature levels. Energy 2023, 282, 8386. [Google Scholar] [CrossRef]

- Zimmerman, N.; Kyprianidis, K.; Lindberg, C.F. Achieving Lower District Heating Network Temperatures Using Feed-Forward MPC. Materials 2019, 12, 2465. [Google Scholar] [CrossRef]

- Lall, A.K.; Terala, A.; Goyal, A.; Chaudhari, S.; Rajan, K.; Chouhan, S.S. Behavioural Analysis of Water Consumption Using IoT-Based Smart Retrofit Meter. IEEE Access 2024, 12, 113597–113607. [Google Scholar] [CrossRef]

- Mejjaouli, S. Toward ZEB: A Mathematical Programing-, Simulation-, and AHP-Based Comprehensive Framework for Building Retrofitting. Appl. Sci. 2022, 12, 2241. [Google Scholar] [CrossRef]

- García, J.I.; Cano, R.E.; Contreras, J.D. Digital retrofit: A first step toward the adoption of Industry 4.0 to the manufacturing systems of small and medium-sized enterprises. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1156–1169. [Google Scholar] [CrossRef]

- Niemeyer, C.L.; Gehrke, I.; Müller, K.; Küsters, D.; Gries, T. Getting Small Medium Enterprises started on Industry 4.0 using retrofitting solutions. Procedia Manuf. 2020, 45, 208–214. [Google Scholar] [CrossRef]

- Mendonca, R.S.; da Silva, M.; Ayres, F.A.C.; Bessa, I.V.; Medeiros, R.L.P.; Lucena, V.F. Development of a Novel Retrofit Framework Considering Industry 4.0 Concepts: A Case Study of a Modular Production System. Processes 2025, 13, 136. [Google Scholar] [CrossRef]

- Baptista, L.F.; Barata, J. Piloting Industry 4.0 in SMEs with RAMI 4.0: An enterprise architecture approach. Procedia Comput. Sci. 2021, 192, 2826–2835. [Google Scholar] [CrossRef]

- Santiago, S.B.; Silva, J.R. Strategic Roadmap for Digital Transformation Based on Measuring Industry 4.0 Maturity and Readiness. In Proceedings of the Innovative Intelligent Industrial Production and Logistics, 4th International Conference, IN4PL 2023, Rome, Italy, 15–17 November 2023; Springer: Cham, Switzerland, 2023; pp. 336–347. [Google Scholar] [CrossRef]

- Benotmane, M.; Elhari, K.; Kabbaj, A. A review & analysis of current IoT maturity & readiness models and novel proposal. Sci. Afr. 2023, 21, e01748. [Google Scholar] [CrossRef]

- Mendonça, R.S.; Lins, S.O.; Bessa, I.; Ayres, F., Jr.; Medeiros, R.; Lucena Jr, V.F. Digital Twin Applications: A Survey of Recent Advances and Challenges. Processes 2022, 10, 744. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).