Numerical Simulation and Analysis of Performance of Switchable Film-Insulated Photovoltaic–Thermal–Passive Cooling Module for Different Design Parameters

Abstract

1. Introduction

2. Physical and Numerical Modeling

- (1)

- The boundary condition is considered static. The shape of the module’s air cushion, and the degree of fit between the flexible cover and the photovoltaic cells are primarily influenced by the internal and external pressure differences, while remaining largely insensitive to changes in sky temperature. The external pressure is equal to the ambient pressure, which is related to the ambient atmosphere. Given the good air tightness of the air cushion, the internal pressure can be considered constant. Therefore, the use of static boundary conditions yields simulation results with satisfactory accuracy.

- (2)

- The switching of the module’s operating mode is extremely rapid, typically completed within a few minutes. The impact of operational conditions, such as solar radiation and ambient temperature, are minimal. Therefore, the PVT-PC module can be regarded as operating under steady-state conditions [33].

- (3)

- There is no contact thermal resistance between all components [34].

- (4)

- The thermophysical properties of all solid materials are considered invariant with temperature [35].

- (5)

- The effects of dust accumulation and partial shading on the module surface are negligible [36].

- (6)

- All external surfaces of the module, except the top surface, are treated as adiabatic boundaries [35].

- (7)

- Solar radiation is incident perpendicularly on the top surface of the module and applied as a surface heat source [37].

- (8)

- The sky is idealized as an equivalent blackbody [38].

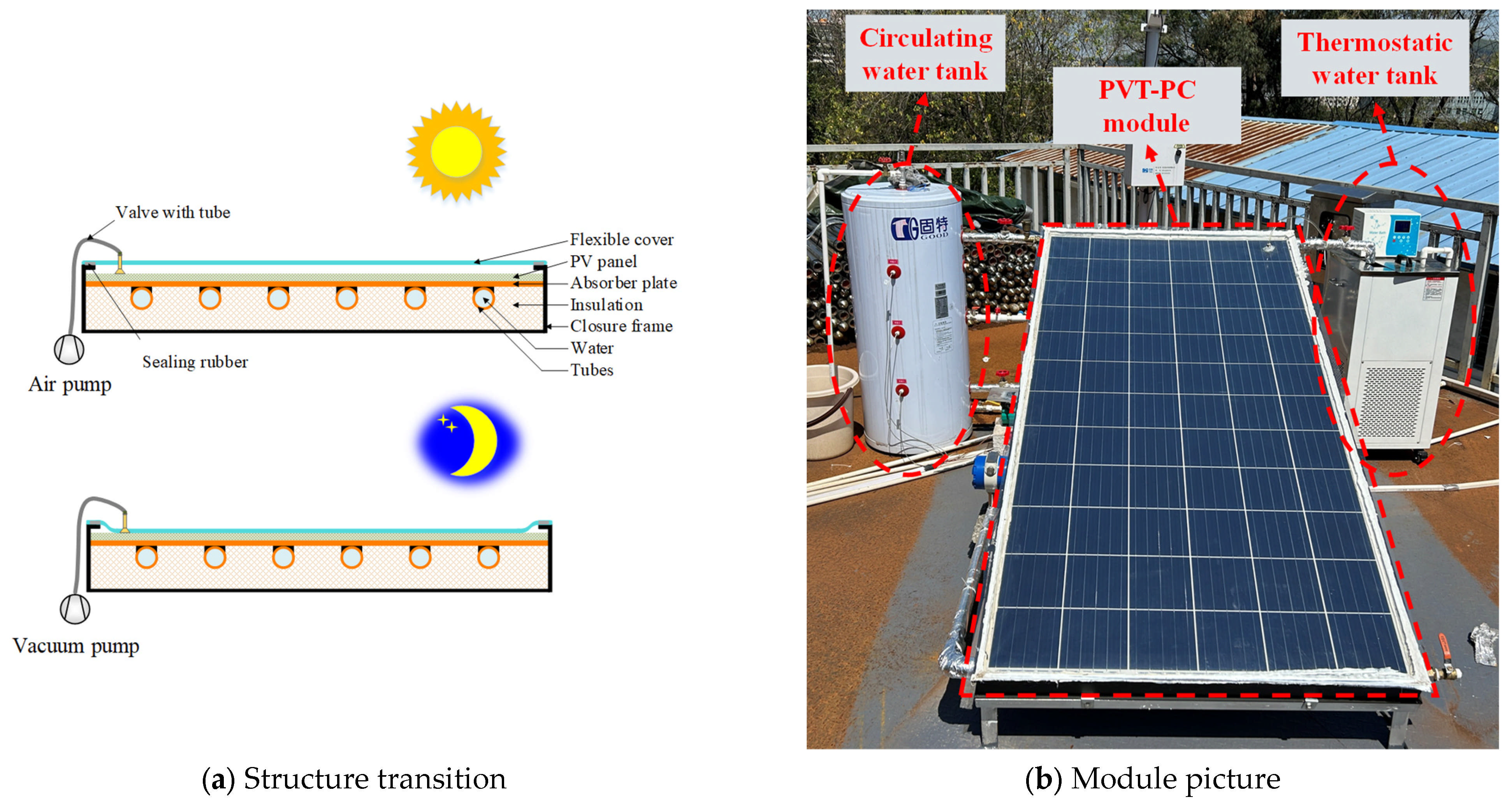

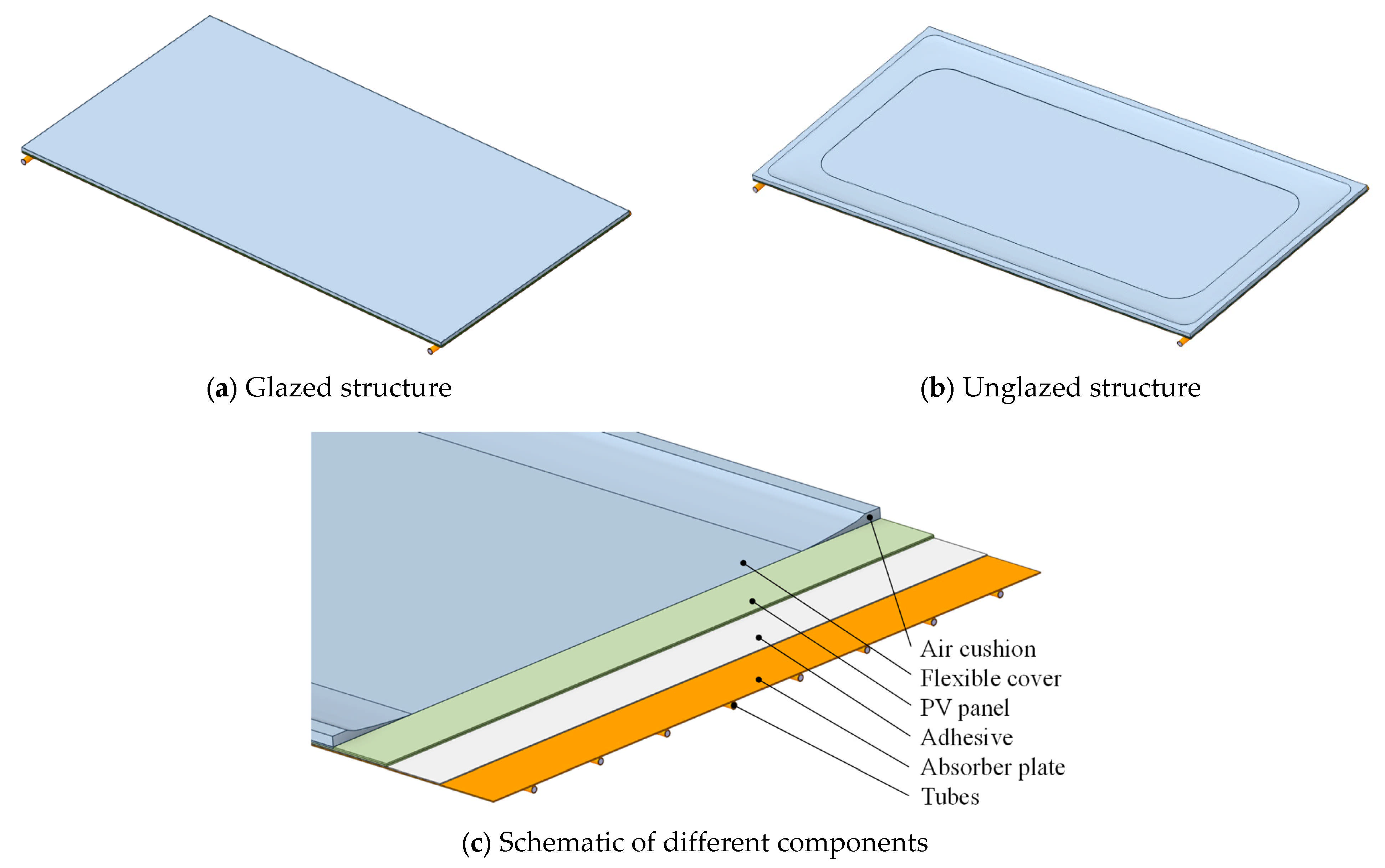

2.1. Physical Module

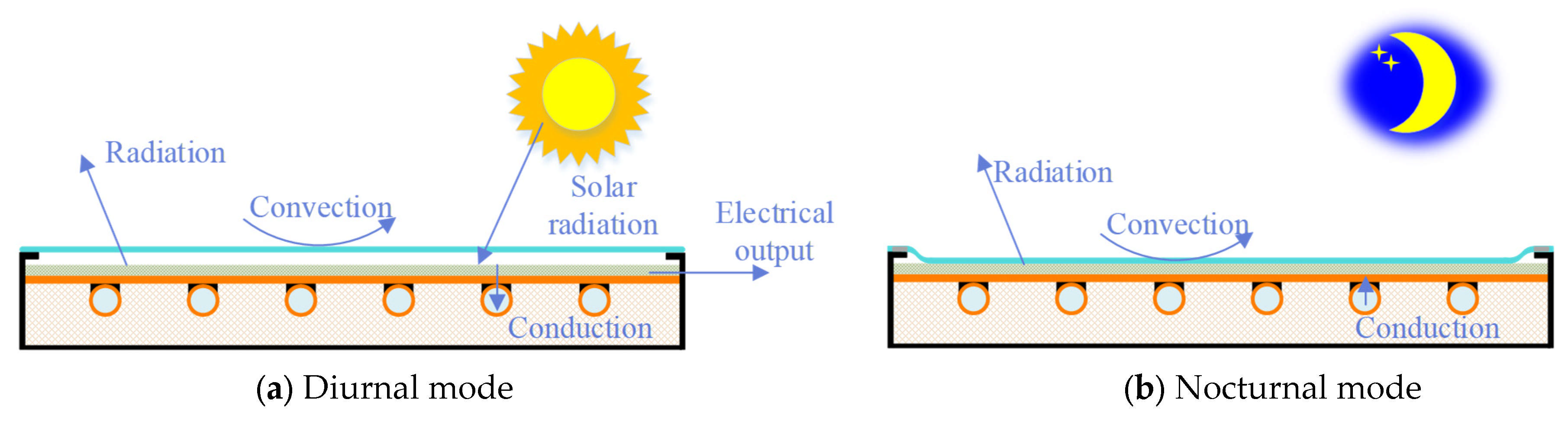

2.2. Thermal Modeling

2.2.1. Boundary Conditions

2.2.2. Performance Evaluation

2.3. Numerical Solution

2.4. Grid Independency

2.5. Validation

3. Results and Discussion

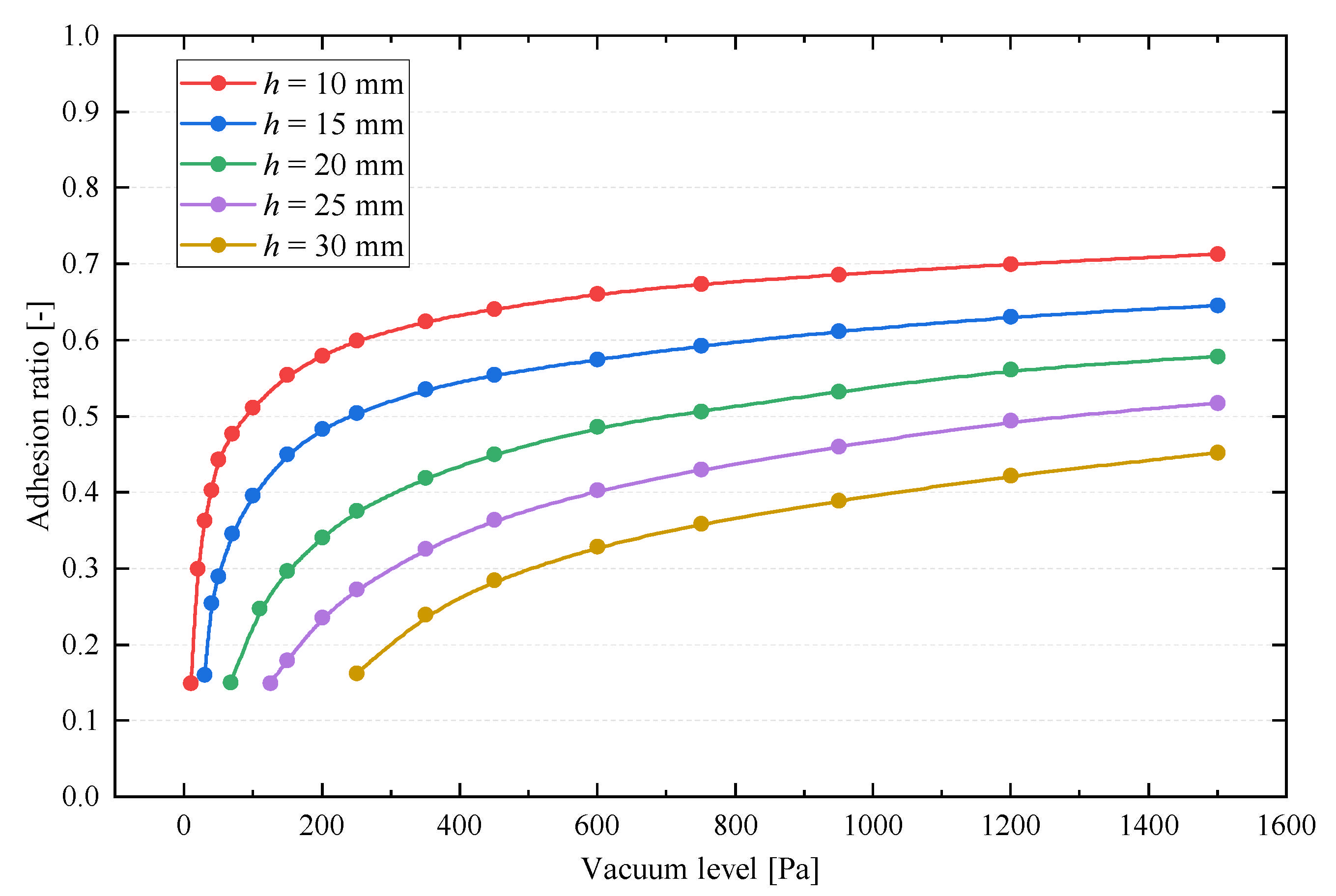

3.1. The Deformation Behavior of the Flexible Cover

3.2. Effect of Critical Design Parameters

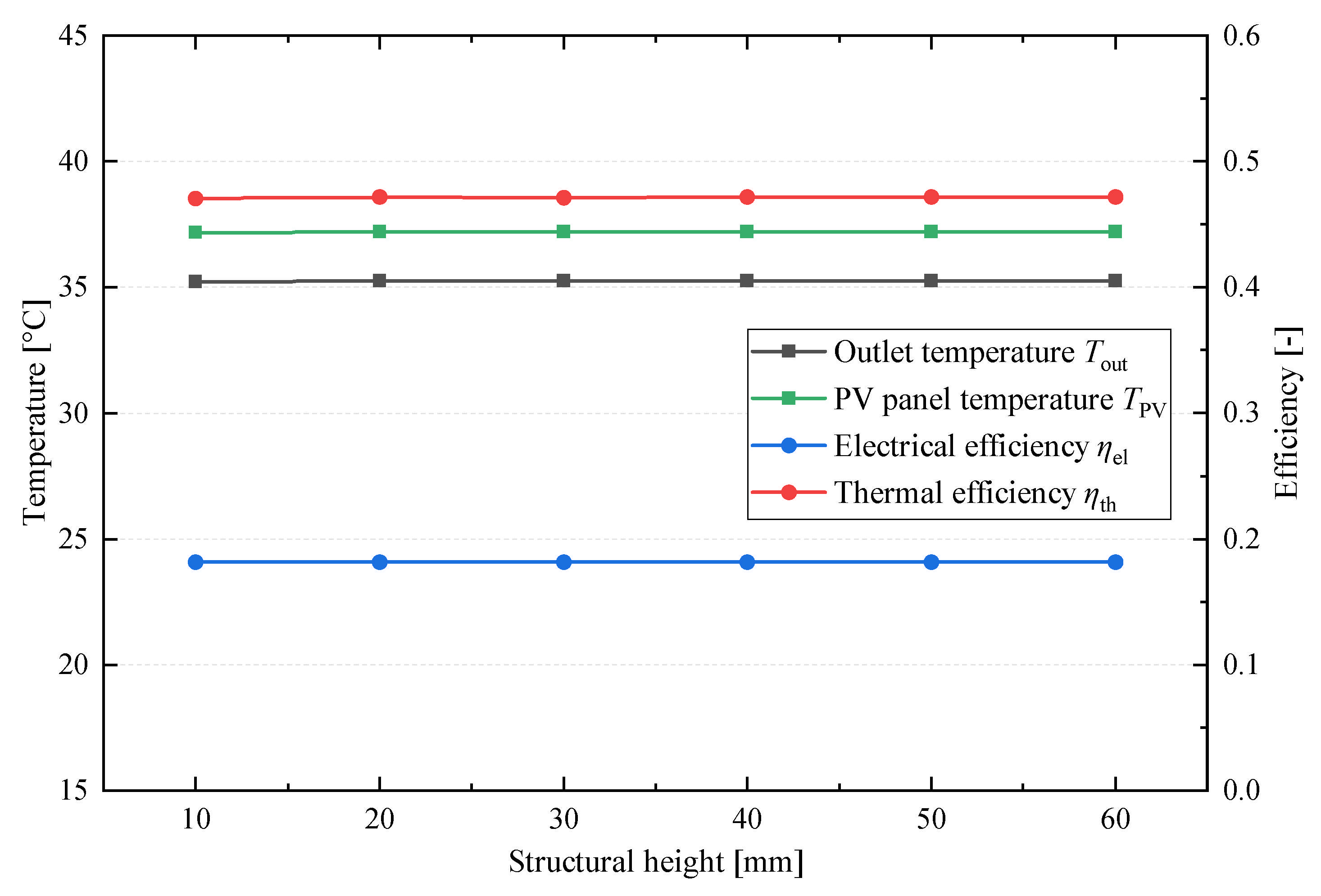

3.2.1. Effect of Structural Height on Diurnal Performance

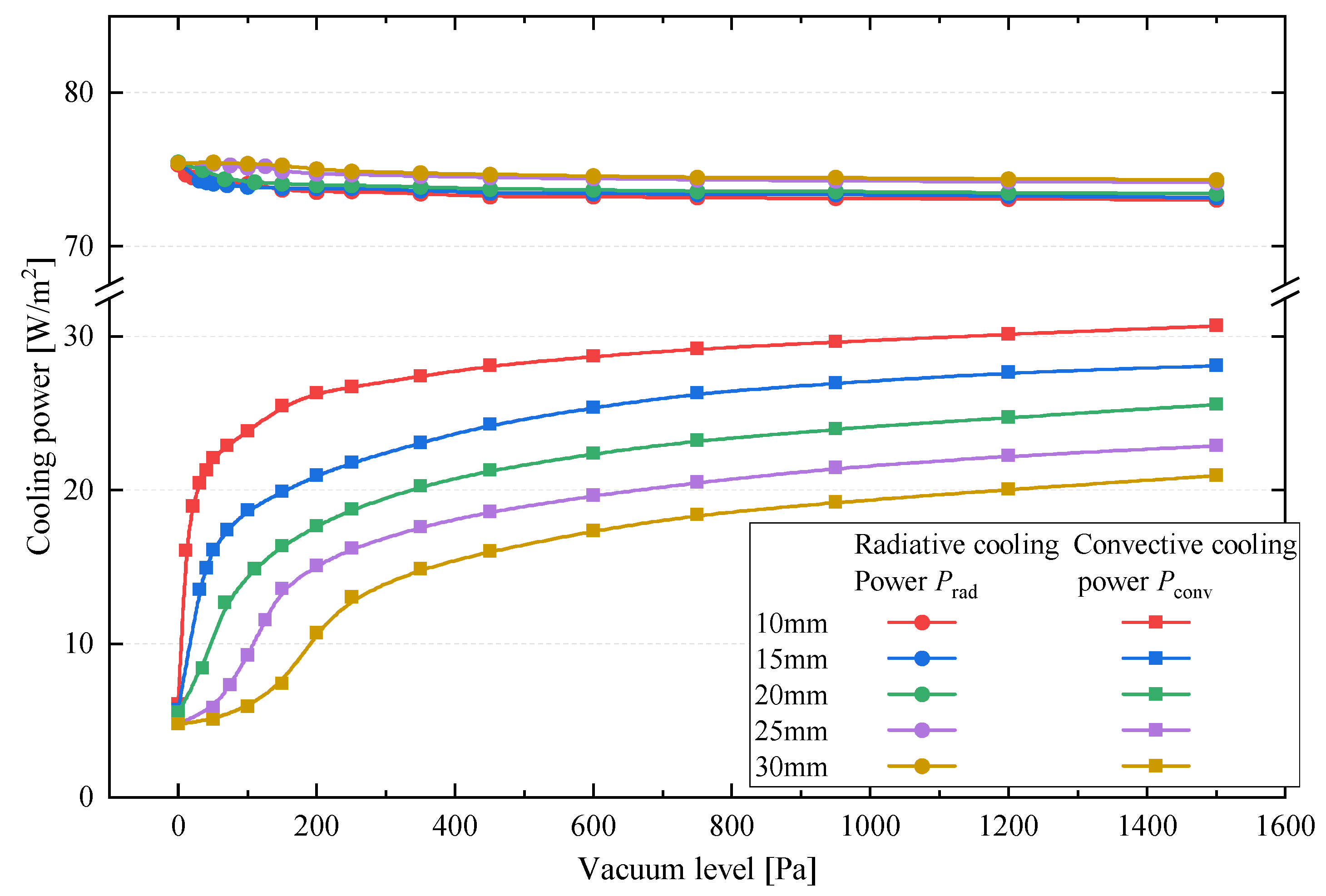

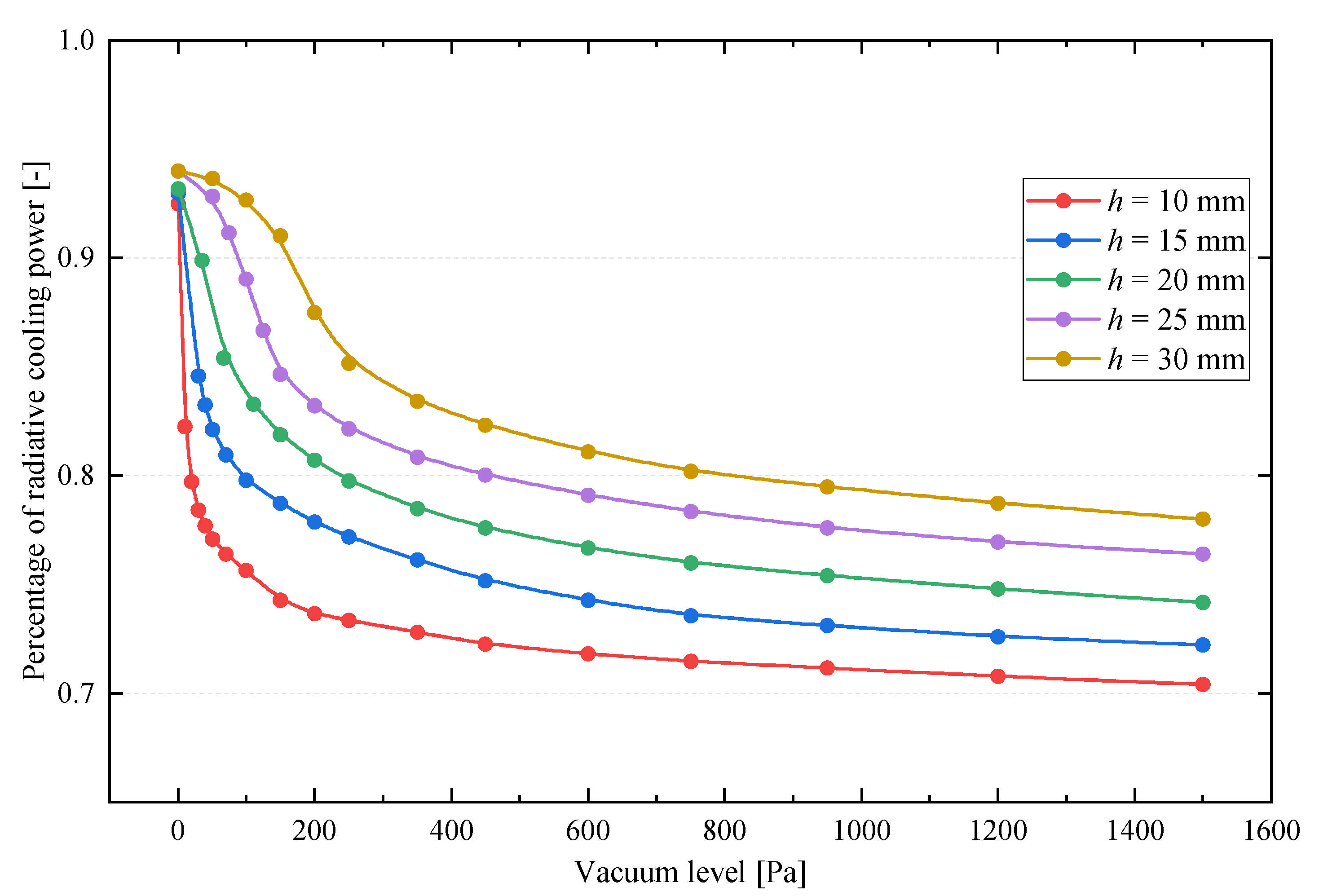

3.2.2. Effect of Structural Height and Vacuum Level on Nocturnal Performance

3.3. Effect of Critical Operating Parameters

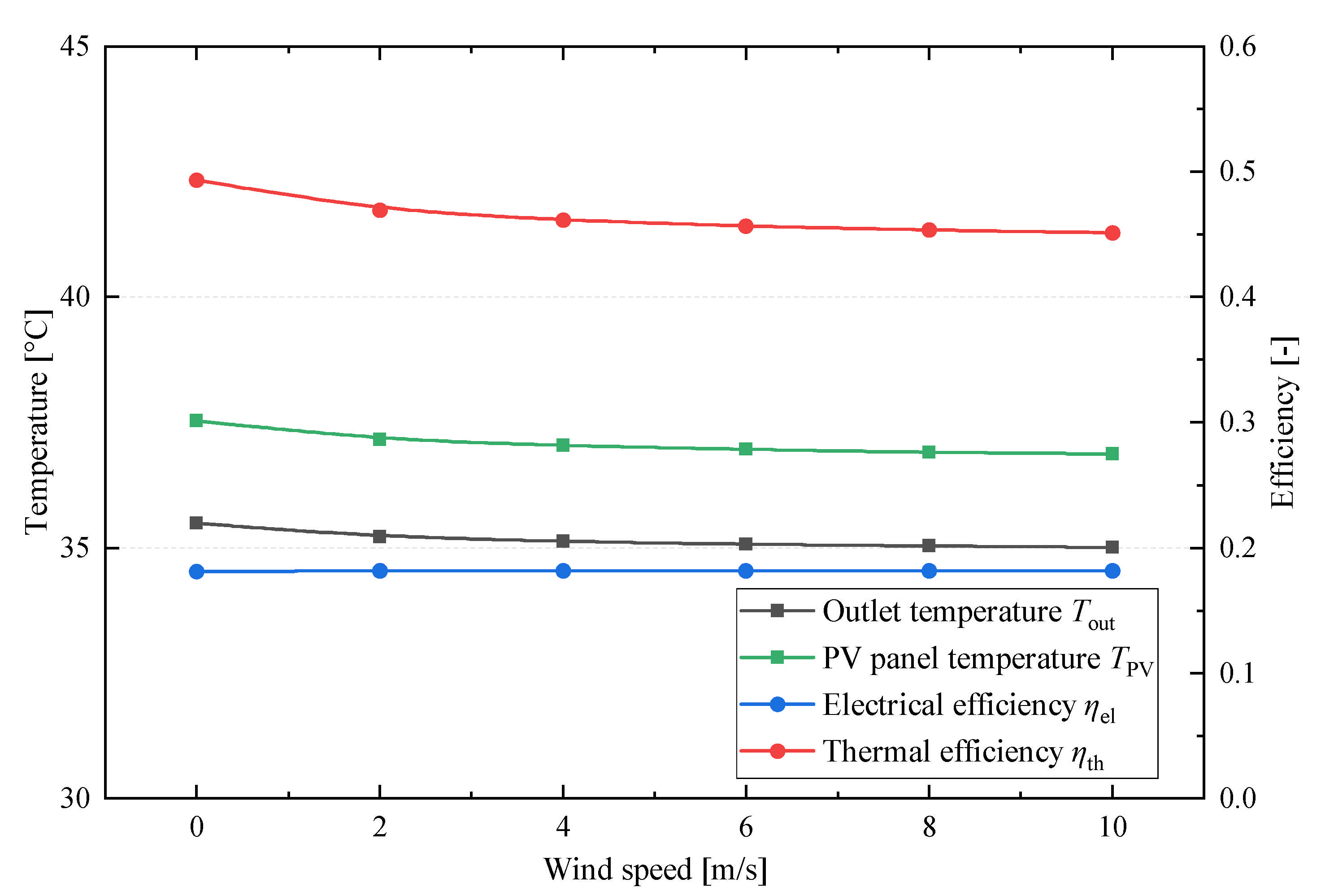

3.3.1. Effect of Wind Speed on PVT-PC Module Performance

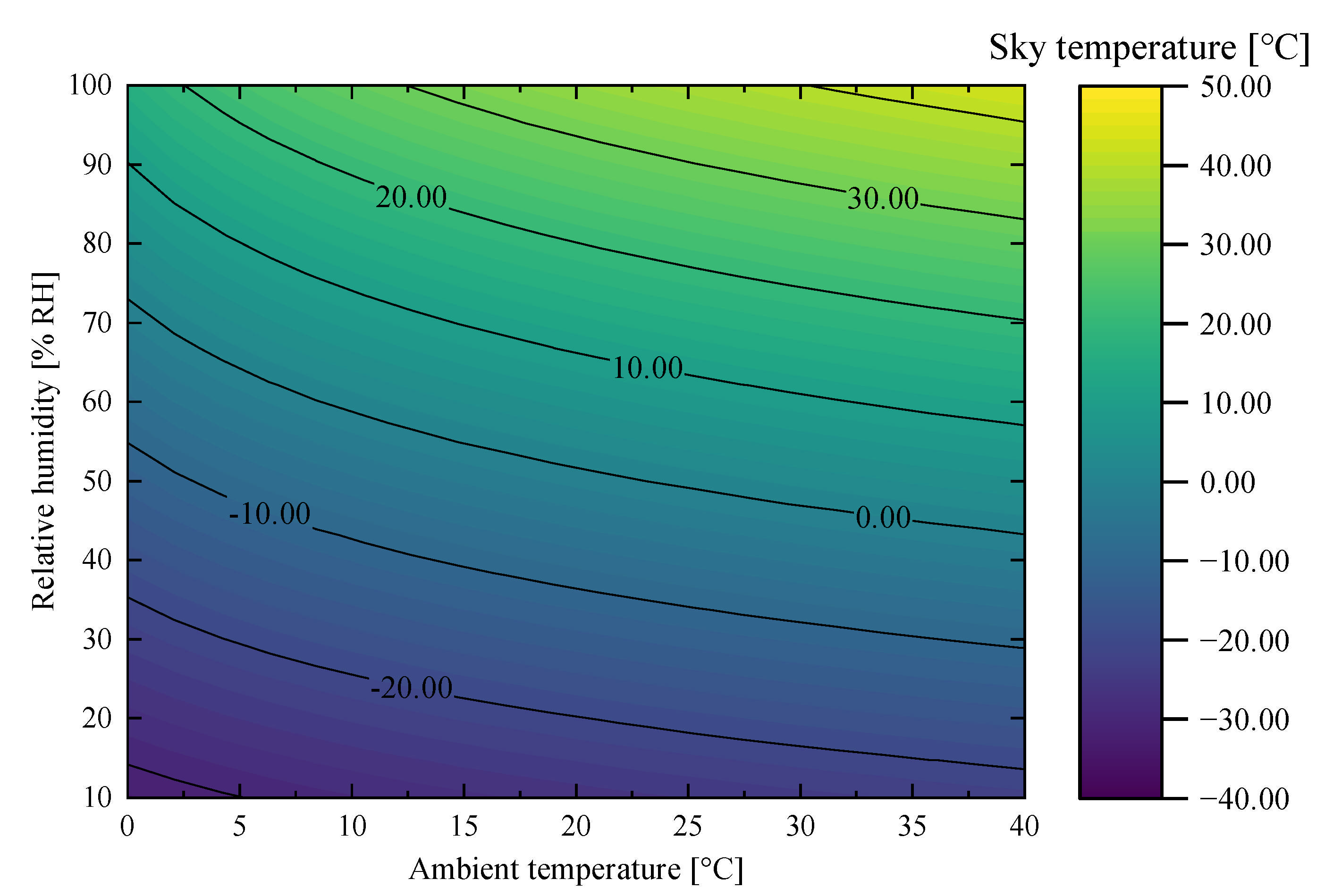

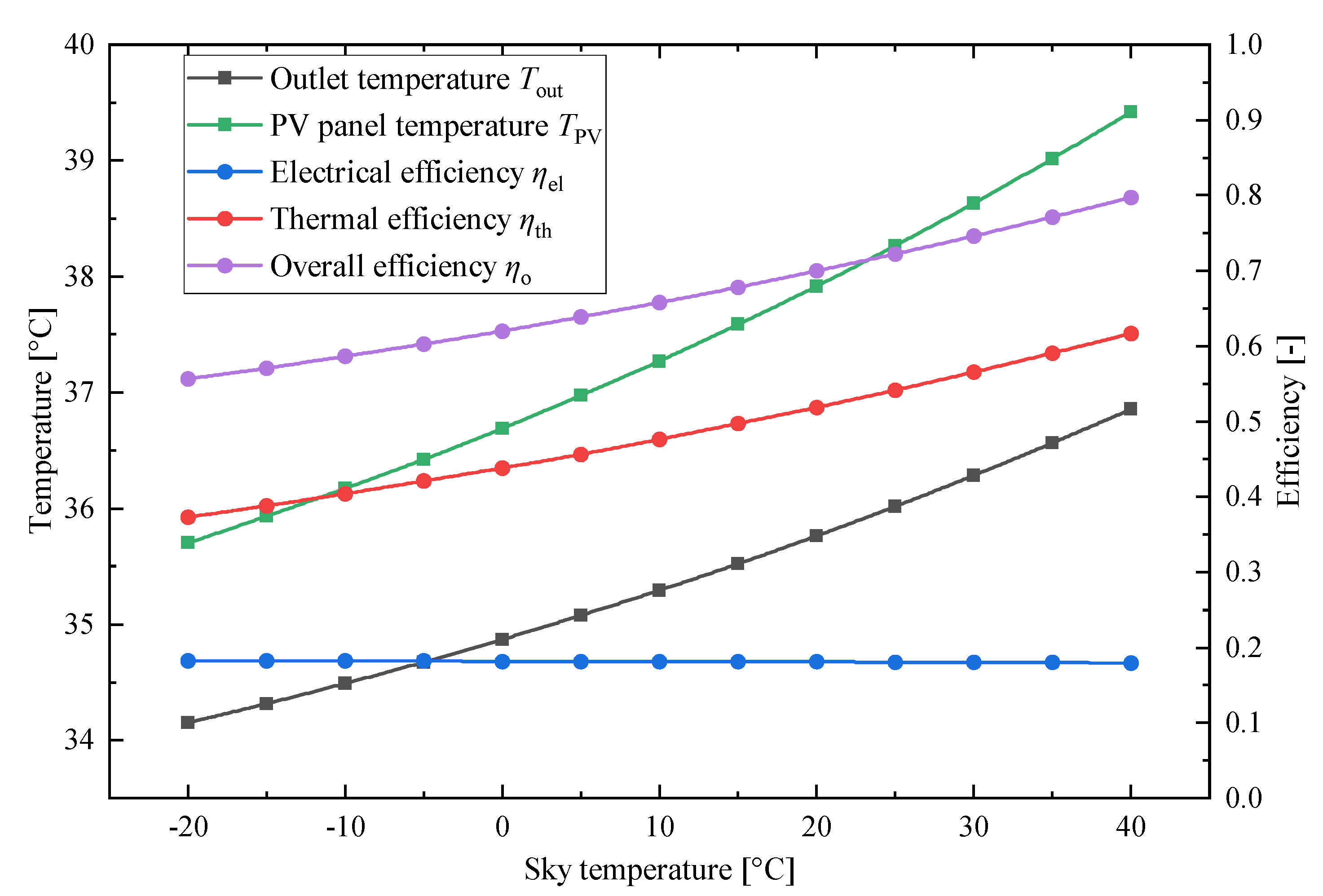

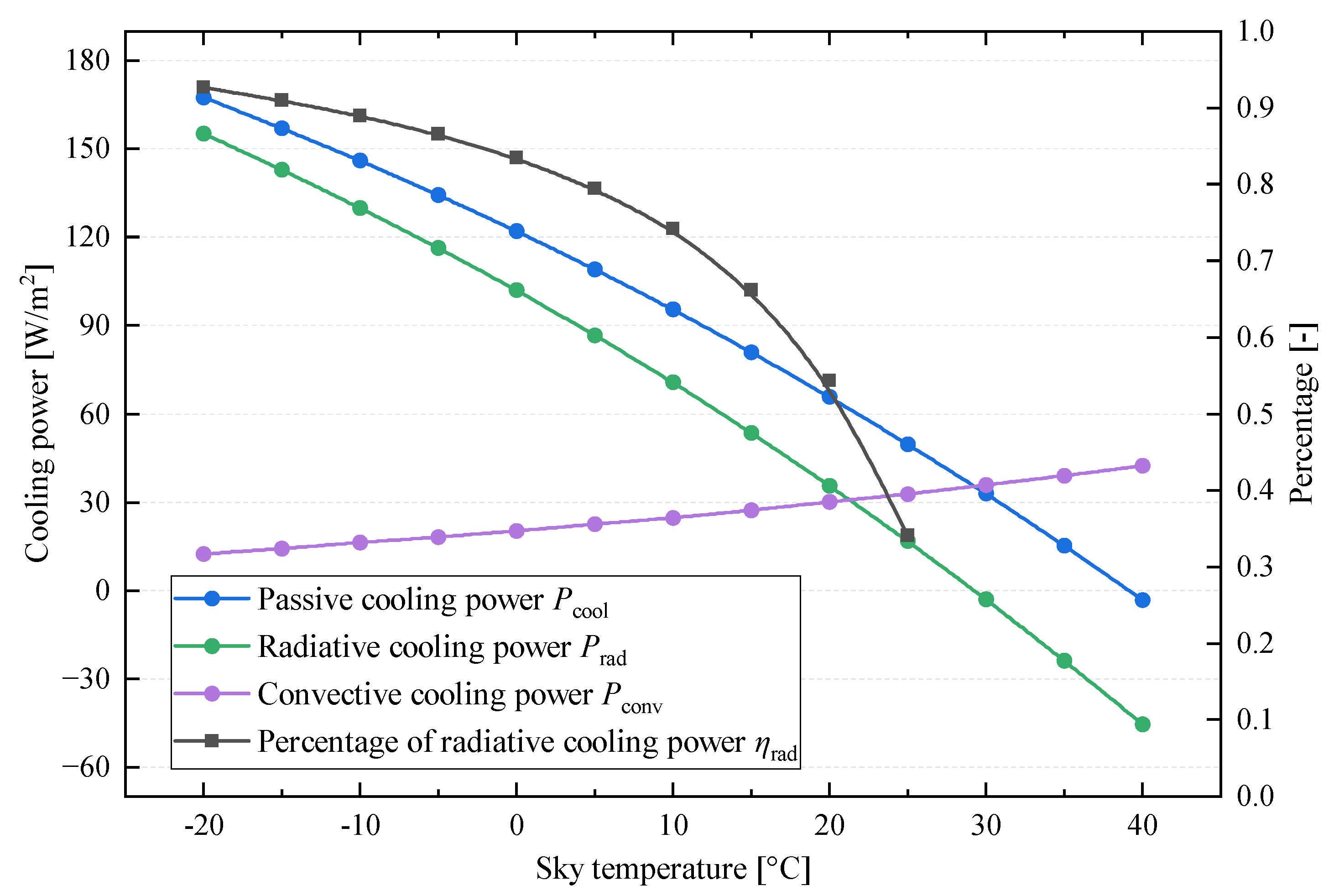

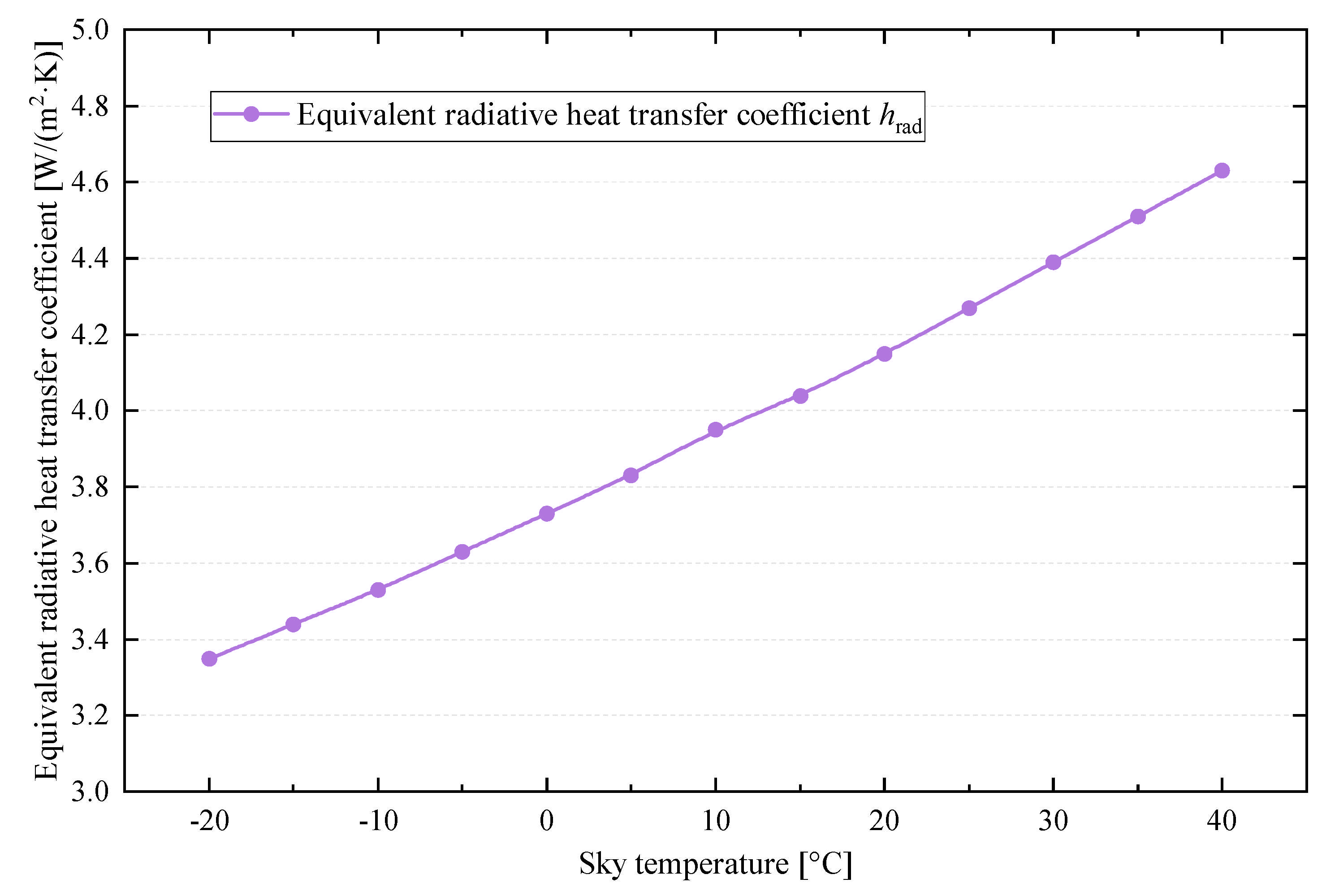

3.3.2. Effect of Sky Temperature on PVT-PC Module Performance

3.4. Economic Analysis

4. Conclusions and Future Scope

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Area, m2 | Wavelength, μm Thermal conductivity, W/(m·K) | ||

| Cooling power loss coefficient, W/m2 | Viscosity, Pa·s | ||

| Specific heat capacity, J/(kg·K) | Density, kg/m3 | ||

| Electric output power per unit volume of photovoltaic cell, W/m3 | Stefan–Boltzmann constant, W/(m2·K4) | ||

| Emissive power, W/m2 | Yield strength, MPa | ||

| Safety factor, - | Maximum stress, MPa | ||

| Heat removal factor, - | Transmissivity, - | ||

| Gravitational acceleration, m/s2 | The product of the transmissivity of the cover and the absorptivity of the absorbing surface, - | ||

| Solar irradiance, W/m2 | Packing factor, - | ||

| Average solar irradiance, W/m2 | Abbreviation and subscripts | ||

| Total incident solar energy, MJ | a | Ambient | |

| Equivalent heat transfer coefficient, W/(m2·K) Convective heat transfer coefficient, W/(m2·K) Air cushion structural height, mm | ab | Absorber plate | |

| Current, A | atm | Atmosphere | |

| Mass flow rate, kg/s | b | Blackbody | |

| Mass/Mass of water in the water tank, kg | cool | Passive cooling | |

| Cooling power, W/m2 pressure, Pa | cond | Conductive | |

| Vacuum level inside the air cushion, Pa | conv | Convective | |

| Solid domain heat source per unit volume, W/m3 | d | Dew point | |

| Temperature, K | el | Electrical | |

| Average temperature, °C | exp | Experimental | |

| Temperature difference, K | f | Fluid | |

| Temperature, °C/Time, s | gl | Glazed | |

| Recording interval of the data logger, s | in | Module inlet | |

| Velocity, m/s | o | Overall | |

| Average velocity, m/s | out | Module outlet | |

| Greek symbols | p | Panel/power plant | |

| Absorptivity, - | PV | Photovoltaic panel | |

| Temperature coefficient of photovoltaic cells, - | rad | Radiative | |

| Thickness, m | ref | Reference | |

| Emissivity, - | s | Solid | |

| Effective emissivity, - | sim | Simulated | |

| Relative humidity, %RH | sky | Sky | |

| Average relative humidity, %RH | th | Thermal | |

| Coefficient, - | ugl | Unglazed | |

| Efficiency, - Percentage, - | w | Water | |

References

- U.S. Energy Information Administration International Energy Outlook. 2023. Available online: https://www.eia.gov/outlooks/ieo/ (accessed on 3 April 2025).

- National Development and Reform Commission Mid-Term Evaluation Report on the Implementation of the Fourteenth Five-Year Plan. Available online: https://www.ndrc.gov.cn/fzggw/wld/zsj/zyhd/202312/t20231227_1362958.html (accessed on 7 March 2025).

- Herrando, M.; Wang, K.; Huang, G.; Otanicar, T.; Mousa, O.B.; Agathokleous, R.A.; Ding, Y.; Kalogirou, S.; Ekins-Daukes, N.; Taylor, R.A.; et al. A Review of Solar Hybrid Photovoltaic-Thermal (PV-T) Collectors and Systems. Prog. Energy Combust. Sci. 2023, 97, 101072. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory Champion Photovoltaic Module Efficiency Chart. Available online: https://www.nrel.gov/pv/module-efficiency (accessed on 3 April 2025).

- Wolf, M. Performance Analyses of Combined Heating and Photovoltaic Power Systems for Residences. Energy Convers. 1976, 16, 79–90. [Google Scholar] [CrossRef]

- Basalike, P.; Peng, W.; Zhang, J.; Lu, S. Numerical Analysis of Roll Bond Photovoltaic Thermal Working as a Condenser during Nighttime. Renew. Energy 2022, 181, 194–206. [Google Scholar] [CrossRef]

- Mahmood Alsalame, H.A.; Lee, J.H.; Lee, G.H. Performance Evaluation of a Photovoltaic Thermal (PVT) System Using Nanofluids. Energies 2021, 14, 301. [Google Scholar] [CrossRef]

- Poredoš, P.; Tomc, U.; Petelin, N.; Vidrih, B.; Flisar, U.; Kitanovski, A. Numerical and Experimental Investigation of the Energy and Exergy Performance of Solar Thermal, Photovoltaic and Photovoltaic-Thermal Modules Based on Roll-Bond Heat Exchangers. Energy Convers. Manag. 2020, 210, 112674. [Google Scholar] [CrossRef]

- Jurčević, M.; Nižetić, S.; Marinić-Kragić, I.; Jakić, M.; Arıcı, M. Towards Resilient Operation of Photovoltaic-Thermal Collector with Incorporated Organic Phase Change Material: Numerical and Experimental Investigation. Sustain. Energy Technol. Assess. 2023, 60, 103465. [Google Scholar] [CrossRef]

- Ali, A.; Alhussein, M.; Aurangzeb, K.; Akbar, F. The Numerical Analysis of Al2O3Cu/Water Hybrid Nanofluid Flow inside the Serpentine Absorber Channel of a PVT; the Overall Efficiency Intelligent Forecasting. Eng. Anal. Bound. Elem. 2023, 157, 82–91. [Google Scholar] [CrossRef]

- Awais, M.; Saad, M.; Ayaz, H.; Ehsan, M.M.; Bhuiyan, A.A. Computational Assessment of Nano-Particulate (Al2O3/Water) Utilization for Enhancement of Heat Transfer with Varying Straight Section Lengths in a Serpentine Tube Heat Exchanger. Therm. Sci. Eng. Prog. 2020, 20, 100521. [Google Scholar] [CrossRef]

- Kazemian, A.; Salari, A.; Ma, T.; Lu, H. Application of Hybrid Nanofluids in a Novel Combined Photovoltaic/Thermal and Solar Collector System. Sol. Energy 2022, 239, 102–116. [Google Scholar] [CrossRef]

- Guarracino, I.; Freeman, J.; Ramos, A.; Kalogirou, S.A.; Ekins-Daukes, N.J.; Markides, C.N. Systematic Testing of Hybrid PV-Thermal (PVT) Solar Collectors in Steady-State and Dynamic Outdoor Conditions. Appl. Energy 2019, 240, 1014–1030. [Google Scholar] [CrossRef]

- Zhang, L.; Chang, R.; Zhang, C.; Yu, C. Improving Thermal Performance and Energy Production of Photovoltaic Thermal Collector by Bifurcating Tree-like Cooling Channels. Therm. Sci. 2025, 21. [Google Scholar] [CrossRef]

- Kazem, H.A.; Al-Waeli, A.H.A.; Chaichan, M.T.; Al-Waeli, K.H.; Al-Aasam, A.B.; Sopian, K. Evaluation and Comparison of Different Flow Configurations PVT Systems in Oman: A Numerical and Experimental Investigation. Sol. Energy 2020, 208, 58–88. [Google Scholar] [CrossRef]

- Hissouf, M.; Feddaoui, M.; Najim, M.; Charef, A. Performance of a Photovoltaic-Thermal Solar Collector Using Two Types of Working Fluids at Different Fluid Channels Geometry. Renew. Energy 2020, 162, 1723–1734. [Google Scholar] [CrossRef]

- Deka, M.J.; Kamble, A.D.; Das, D.; Sharma, P.; Ali, S.; Kalita, P.; Bora, B.J.; Kalita, P. Enhancing the Performance of a Photovoltaic Thermal System with Phase Change Materials: Predictive Modelling and Evaluation Using Neural Networks. Renew. Energy 2024, 224, 120091. [Google Scholar] [CrossRef]

- Lari, M.O.; Sahin, A.Z. Effect of Retrofitting a Silver/Water Nanofluid-Based Photovoltaic/Thermal (PV/T) System with a PCM-Thermal Battery for Residential Applications. Renew. Energy 2018, 122, 98–107. [Google Scholar] [CrossRef]

- Ben Zohra, M.; Riad, A.; Alhamany, A. Optimizing the Conception of Hybrid PV/PCM by Optimizing the Heat Transfer at the Contact Interface and by Integrating Two Types of PCM. Results Eng. 2022, 16, 100614. [Google Scholar] [CrossRef]

- Al Arni, S.; Mahdi, J.M.; Abed, A.M.; Hammoodi, K.A.; Hasan, H.A.; Homod, R.Z.; Khedher, N.B. Novel Multi-Layer Nano-Modified PCM Configuration for Efficient Thermal Management of Photovoltaic-Thermal Systems. J. Energy Storage 2024, 103, 114352. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, Y.; Ji, J.; Wang, C. Analysis of Night Behavior and Negative Running for PVT System. Energy 2024, 301, 131555. [Google Scholar] [CrossRef]

- Zhai, Y.; Ma, Y.; David, S.N.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalable-Manufactured Randomized Glass-Polymer Hybrid Metamaterial for Daytime Radiative Cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Hu, M.; Ao, X.; Pei, G. Performance Evaluation of Daytime Radiative Cooling under Different Clear Sky Conditions. Appl. Therm. Eng. 2019, 155, 660–666. [Google Scholar] [CrossRef]

- Liang, R.; Zhou, C.; Zhang, J.; Chen, J.; Riaz, A. Characteristics Analysis of the Photovoltaic Thermal Heat Pump System on Refrigeration Mode: An Experimental Investigation. Renew. Energy 2020, 146, 2450–2461. [Google Scholar] [CrossRef]

- Chen, H.; Li, Z.; Sun, B. Performance Evaluation and Parametric Analysis of an Integrated Diurnal and Nocturnal Cooling System Driven by Photovoltaic-Thermal Collectors with Switchable Film Insulation. Energy Convers. Manag. 2022, 254, 115197. [Google Scholar] [CrossRef]

- Zhou, C.; Liang, R.; Riaz, A.; Zhang, J.; Chen, J. Experimental Investigation on the Tri-Generation Performance of Roll-Bond Photovoltaic Thermal Heat Pump System during Summer. Energy Convers. Manag. 2019, 184, 91–106. [Google Scholar] [CrossRef]

- Fu, Z.; Li, Y.; Liang, X.; Lou, S.; Qiu, Z.; Cheng, Z.; Zhu, Q. Experimental Investigation on the Enhanced Performance of a Solar PVT System Using Micro-Encapsulated PCMs. Energy 2021, 228, 120509. [Google Scholar] [CrossRef]

- Lee, J.W.; Song, M.S.; Jung, H.S.; Kang, Y.T. Development of Solar Radiation Spectrum-Controlled Emulsion Filter for a Photovoltaic-Thermal (PVT) System. Energy Convers. Manag. 2023, 287, 117087. [Google Scholar] [CrossRef]

- Kazemian, A.; Hosseinzadeh, M.; Sardarabadi, M.; Passandideh-Fard, M. Effect of Glass Cover and Working Fluid on the Performance of Photovoltaic Thermal (PVT) System: An Experimental Study. Sol. Energy 2018, 173, 1002–1010. [Google Scholar] [CrossRef]

- Hissouf, M.; Feddaoui, M.; Dayf, A. Analysis of the Exergy Performances of a Glazed and Unglazed PV/T Collector under Different Conditions. Int. J. Heat Mass Transf. 2024, 226, 125447. [Google Scholar] [CrossRef]

- Bilbao, J.I.; Sproul, A.B. Night Radiative Cooling with Unglazed Pvt-Water Collectors: Experimental Results and Estimation of Cooling Potential. In Proceedings of the Ises Solar World Congress 2015, Daegu, Republic of Korea, 8–12 November 2015; International Solar Energy Society: Freiburg im Breisgau, Germany, 2016; pp. 1–8. [Google Scholar]

- Jiao, C.; Li, Z.; Xu, Z.; Sun, B.; Ma, W.; Ooi, K.T. Development and Test of Switchable Film Insulated Photovoltaic-Thermal-Passive Cooling Module. Sol. Energy Mater. Sol. Cells 2025, 282, 113427. [Google Scholar] [CrossRef]

- Maadi, S.R.; Navegi, A.; Solomin, E.; Ahn, H.S.; Wongwises, S.; Mahian, O. Performance Improvement of a Photovoltaic-Thermal System Using a Wavy-Strip Insert with and without Nanofluid. Energy 2021, 234, 121190. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Optimization of Solar Photovoltaic System Integrated with Phase Change Material. Sol. Energy 2018, 163, 591–599. [Google Scholar] [CrossRef]

- Maadi, S.R.; Khatibi, M.; Ebrahimnia-Bajestan, E.; Wood, D. Coupled Thermal-Optical Numerical Modeling of PV/T Module—Combining CFD Approach and Two-Band Radiation DO Model. Energy Convers. Manag. 2019, 198, 111781. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Zheng, X.; Zhou, Y. A Three-Dimensional Unsteady Numerical Model on a Novel Aerogel-Based PV/T-PCM System with Dynamic Heat-Transfer Mechanism and Solar Energy Harvesting Analysis. Appl. Energy 2023, 338, 120899. [Google Scholar] [CrossRef]

- Berdahl, P.; Martin, M. Emissivity of Clear Skies. Sol. Energy 1984, 32, 663–664. [Google Scholar] [CrossRef]

- White, F.M. Fluid Mechanics, 7th ed.; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Ebrahimnia-Bajestan, E.; Moghadam, M.C.; Niazmand, H.; Daungthongsuk, W.; Wongwises, S. Experimental and Numerical Investigation of Nanofluids Heat Transfer Characteristics for Application in Solar Heat Exchangers. Int. J. Heat Mass Transf. 2016, 92, 1041–1052. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Investigation of a Nanofluid-Based Concentrating Thermal Photovoltaic with a Parabolic Reflector. Energy Convers. Manag. 2019, 180, 171–182. [Google Scholar] [CrossRef]

- Zhao, D.; Aili, A.; Zhai, Y.; Xu, S.; Tan, G.; Yin, X.; Yang, R. Radiative Sky Cooling: Fundamental Principles, Materials, and Applications. Appl. Phys. Rev. 2019, 6, 21306. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Hjortsberg, A. Radiative Cooling to Low Temperatures: General Considerations and Application to Selectively Emitting SiO Films. J. Appl. Phys. 1981, 52, 4205–4220. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive Radiative Cooling below Ambient Air Temperature under Direct Sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef]

- Shukuya, M. Exergy: Theory and Applications in the Built Environment; Springer Science + Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 1-4471-4573-9. [Google Scholar]

- Zhao, D.; Aili, A.; Zhai, Y.; Lu, J.; Kidd, D.; Tan, G.; Yin, X.; Yang, R. Subambient Cooling of Water: Toward Real-World Applications of Daytime Radiative Cooling. Joule 2019, 3, 111–123. [Google Scholar] [CrossRef]

- Chow, T.T. Performance Analysis of Photovoltaic-Thermal Collector by Explicit Dynamic Model. Sol. Energy 2003, 75, 143–152. [Google Scholar] [CrossRef]

- Yin, Y.; Chen, W.; Hu, J.; Zhao, B.; Huang, X. Photothermal-Structural-Fluid Behaviors of PV-ETFE Cushion Roof in Summer: Numerical Analysis Using Three-Dimensional Multiphysics Model. Energy Build. 2020, 228, 110448. [Google Scholar] [CrossRef]

- Hu, J.; Chen, W.; Zhao, B.; Wang, K. Uniaxial Tensile Mechanical Properties and Model Parameters Determination of Ethylene Tetrafluoroethylene (ETFE) Foils. Constr. Build. Mater. 2015, 75, 200–207. [Google Scholar] [CrossRef]

- Suhendri, S.; Hu, M.; Dan, Y.; Su, Y.; Zhao, B.; Riffat, S. Building Energy-Saving Potential of a Dual-Functional Solar Heating and Radiative Cooling System. Energy Build. 2024, 303, 113764. [Google Scholar] [CrossRef]

| Component | Description | Value |

|---|---|---|

| Flexible cover (ETFE film) | Length/width/thickness (mm) | 1986/986/0.15 |

| Density (kg/m3) | 300 | |

| Specific heat capacity [J/(kg·K)] | 1260 | |

| Thermal conductivity [W/(m·K)] | 0.23 | |

| PV panel | Thickness (mm) | 4.33 |

| Weighted average density (kg/m3) | 2133.1 | |

| Weighted average specific heat capacity [J/(kg·K)] | 935.6 | |

| Weighted average thermal conductivity [W/(m·K)] | 24.2 | |

| Adhesive layer | Thickness (mm) | 1.5 |

| Density (kg/m3) | 2500 | |

| Specific heat capacity [J/(kg·K)] | 1300 | |

| Thermal conductivity [W/(m·K)] | 1.6 | |

| Absorber plate | Thickness (mm) | 1 |

| Density (kg/m3) | 2719 | |

| Specific heat capacity [J/(kg·K)] | 871 | |

| Thermal conductivity [W/(m·K)] | 202.4 | |

| Branch tube | Spacing length/length/outer diameter/inner diameter (mm) | 120/1926/10/8 |

| Density (kg/m3) | 8978 | |

| Specific heat capacity [J/(kg·K)] | 381 | |

| Thermal conductivity [W/(m·K)] | 387.6 | |

| Header tube | Outer diameter/inner diameter (mm) | 22/20 |

| Insulation | Thickness (mm) | 50 |

| Density (kg/m3) | 45 | |

| Specific heat capacity [J/(kg·K)] | 840 | |

| Thermal conductivity [W/(m·K)] | 0.036 | |

| Air cushion | Height (mm) | 15 |

| Component | Thickness (mm) | Density (kg/m3) | Specific Heat Capacity [J/(kg·K)] | Thermal Conductivity [W/(m·K)] |

|---|---|---|---|---|

| Encapsulated | 3.0 | 3000 | 500 | 1.8 |

| Si layer | 0.23 | 2330 | 677 | 148 |

| EVA | 0.50 | 960 | 2090 | 0.35 |

| Tedlar | 0.10 | 1200 | 1250 | 0.2 |

| Property | Expression | Units |

|---|---|---|

| Viscosity [39] | Pa·s | |

| Density [40] | kg/m3 | |

| Specific heat capacity [40] | J/(kg·K) | |

| Thermal conductivity [40] | W/(m·K) |

| Grid | Cell No. | Tout (°C) |

|---|---|---|

| 1 | 546,941 | 33.581 |

| 2 | 950,348 | 33.819 |

| 3 | 1,357,652 | 34.067 |

| 4 | 2,084,912 | 34.194 |

| 5 | 2,417,695 | 34.296 |

| 8 | 2,941,397 | 34.327 |

| 9 | 3,597,616 | 34.334 |

| No. | G (W/m2) | Ta (°C) | Tin (°C) | Tout,exp (°C) | Tout,sim (°C) | RE (%) |

|---|---|---|---|---|---|---|

| 1 | 970 | 22.5 | 21.01 | 29.98 | 30.13 | 0.51 |

| 2 | 980 | 23.6 | 23.07 | 32.35 | 32.61 | 0.81 |

| 3 | 980 | 24.2 | 24.90 | 34.32 | 34.29 | 0.09 |

| 4 | 964 | 23.7 | 27.65 | 36.32 | 36.78 | 1.25 |

| 5 | 910 | 23.7 | 30.38 | 37.46 | 37.08 | 1.02 |

| 6 | 860 | 24.3 | 33.33 | 40.34 | 40.64 | 0.76 |

| 7 | 797 | 25.3 | 35.92 | 42.46 | 42.53 | 0.16 |

| 8 | 757 | 25.1 | 38.68 | 43.83 | 44.07 | 0.54 |

| No. | Ta (°C) | Tin (°C) | Tout,exp (°C) | Tout,sim (°C) | RE (%) |

|---|---|---|---|---|---|

| 1 | 31.5 | 28.57 | 28.75 | 28.63 | 0.40 |

| 2 | 31.1 | 30.79 | 30.65 | 30.56 | 0.28 |

| 3 | 30.7 | 32.56 | 32.08 | 32.05 | 0.09 |

| 4 | 30.6 | 35.32 | 34.24 | 34.45 | 0.62 |

| 5 | 30.5 | 37.67 | 36.22 | 36.22 | 0.01 |

| 6 | 30.4 | 39.93 | 38.01 | 37.84 | 0.44 |

| 7 | 30.3 | 42.18 | 40.06 | 39.85 | 0.52 |

| Structural height h (mm)/vacuum level Pv (Pa) | 10/1500 | 15/1500 | 20/1500 | 25/1500 | 30/1500 |

| (MPa) at 22 °C [49] | 17.97 | ||||

| (MPa) | 5.57 | 7.09 | 8.39 | 9.35 | 11.32 |

| (-) | 3.23 | 2.53 | 2.14 | 1.92 | 1.59 |

| Operating Conditions | Diurnal Mode | Nocturnal Mode |

|---|---|---|

| (°C) | 30 | 30 |

| (°C) | 25 | 25 |

| (%RH) | 50 | 50 |

| (°C) | 9 | 9 |

| (W/m2) | 700 | 0 |

| (m/s) | 1.5 | 1.5 |

| [kg/(s·m2)] | 0.015 | 0.015 |

| The Increased Initial Investment/(CNY∙m−2) | Electricity Price Returns/(CNY∙m−2) | Payback Period/Year |

|---|---|---|

| 450 | 52.06 | 8.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, C.; Li, Z.; Ju, T.; Xu, Z.; Xu, Z.; Sun, B. Numerical Simulation and Analysis of Performance of Switchable Film-Insulated Photovoltaic–Thermal–Passive Cooling Module for Different Design Parameters. Processes 2025, 13, 2471. https://doi.org/10.3390/pr13082471

Jiao C, Li Z, Ju T, Xu Z, Xu Z, Sun B. Numerical Simulation and Analysis of Performance of Switchable Film-Insulated Photovoltaic–Thermal–Passive Cooling Module for Different Design Parameters. Processes. 2025; 13(8):2471. https://doi.org/10.3390/pr13082471

Chicago/Turabian StyleJiao, Cong, Zeyu Li, Tiancheng Ju, Zihan Xu, Zhiqun Xu, and Bin Sun. 2025. "Numerical Simulation and Analysis of Performance of Switchable Film-Insulated Photovoltaic–Thermal–Passive Cooling Module for Different Design Parameters" Processes 13, no. 8: 2471. https://doi.org/10.3390/pr13082471

APA StyleJiao, C., Li, Z., Ju, T., Xu, Z., Xu, Z., & Sun, B. (2025). Numerical Simulation and Analysis of Performance of Switchable Film-Insulated Photovoltaic–Thermal–Passive Cooling Module for Different Design Parameters. Processes, 13(8), 2471. https://doi.org/10.3390/pr13082471