Abstract

The spontaneous combustion disaster of coal not only causes a waste of resources but also affects the safe production of coal mines. In order to accurately detect the range and location of the spontaneous combustion source of coal, this paper studies and summarizes previous research results, and based on the principles and research and development progress of existing detection technologies such as the surface temperature measurement method, ground temperature measurement method, wellbore temperature measurement method, and infrared remote sensing detection method, it briefly reviews the application of various detection technologies in engineering practice at this stage and briefly explains the advantages and disadvantages of each application. Research shows that the existing technologies are generally limited by the interference of complex environmental conditions (such as temperature measurement deviations caused by atmospheric turbulence and the influence of rock layer structure on ground temperature conduction) and the implementation difficulties of geophysical methods in mining applications (such as the interference of stray currents in the ground by electromagnetic methods and the fast attenuation speed of waves detected by geological radar methods), resulting in the insufficient accuracy of fire source location and difficulties in identifying concealed fire sources. In response to the above bottlenecks, the ”air–ground integrated” fire source location determination technology that breaks through environmental constraints and the location determination method of a CSC fire source based on a multi-physics coupling mechanism are proposed. By significantly weakening the deficiency in obtaining parameters through a single detection method, a new direction is provided for the detection of coal spontaneous combustion fire sources in the future.

1. Introduction

China is the world’s largest energy producer and consumer, and the coal industry is related to the national economy and people’s livelihood and is an important pillar of the national economy at this stage. Taking coal as the leading energy source is an inevitable choice in the development stage of our country [1,2]. According to the bulletin of the National Bureau of Statistics and related data, in 2024, the national output of raw coal was 4.78 billion tons, an increase of 1.2% compared to the previous year. The consumption of coal rose by 1.7% compared with the previous year, accounting for 53.2% of the total energy consumption. Statistics of the output of major energy products and their growth rates in 2024 are shown in Table 1. In the first quarter of 2025, the output of raw coal above the designated amount across the country was 1.2 billion tons, increasing by 8.1% year on year. The cumulative coal exports across the country reached 1.41 million tons, increasing by 1.8% year on year [3]. Coal fire disaster is one of the five major mine disasters that affect the personal safety of underground miners, machinery and equipment, coal output and the atmospheric environment [4,5]. The coal seams mined in China are mainly prone to spontaneous combustion. With the application of deep mining, the risk of coal spontaneous combustion (CSC) is constantly increasing; most coal seam spontaneous combustion occurs in the goaf, near structural belts and in the open and cut holes of fully mechanized caving [6,7]. According to statistics, 1 billion tons of coal are burned in underground coal fires every year, accounting for 1/8 of the world’s coal consumption [8,9].

Table 1.

Production of major energy products and their growth rate in 2024.

The accurate and rapid judgment of the location of the fire source of spontaneous coal combustion is the premise of preventing and controlling coal fire disasters and plays a key role in determining the location range of underground coal fires, which is of great significance for the timely fighting of initial fires and preventing the spread of fires [10,11]. Because of the complexity of the underground environment and the concealment of the location of the spontaneous combustion of coal, the accurate detection of the location of the concealed fire source has always been a worldwide problem in coal fire disaster control. Many scholars have studied the mechanism and phenomenon of CSC, developed a variety of CSC fire source location detection technologies and applied them to field practice, providing an effective reference for the control of fire areas. However, CSC fire source location detection technology still has certain limitations, which cannot meet the realistic demand for the accurate and rapid judgment of fire source location [12]. At present, the radon measurement method is simple and widely used, but it is not suitable for deep buried coal seams because of the influence of surface atmospheric disturbance, the properties of overlying strata and the water content of strata. A temperature measurement by drilling gas can detect the temperature directly near the fire source without being restricted by the terrain, but the migration of gas in the surface rock cracks will cause deviations, resulting in low positioning accuracy [13]. The remote sensing detection method is simple and efficient and can detect large-scale fire areas, but due to low resolution and other heat sources on the surface, there are still shortcomings in the application process [14].

By analyzing the mechanism and influencing factors of CSC, the locations where CSC is prone to occur in underground coal mines are summarized. This paper summarizes the principle, application progress and existing problems of the current CSC source location detection technology and looks forward to the possible directions of the future development of this technology based on the existing research. The “air–ground integrated” fire source location determination technology, which avoids the insufficiency of a single detection method by combining multiple technologies in different spatial ranges, and the location determination method of CSC fire sources based on a multi-physics coupling mechanism, which is more suitable for deep underground fire source location detection, were proposed. This provides a reference for the refined development of coal spontaneous combustion fire source location detection technology and improves the accuracy of fire source location detection. It provides support for the precise governance of coal fire disasters at a later stage, thereby ensuring the safety of the mine and reducing casualties and economic losses.

2. Mechanism and Influencing Factors of CSC

2.1. Mechanism of Spontaneous Combustion of Coal

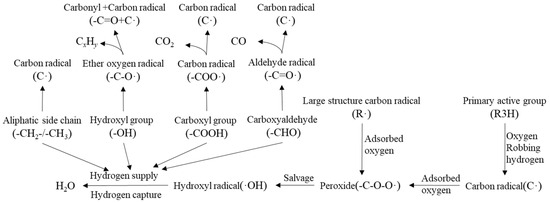

Coal is a porous solid-phase medium with a well-developed surface pore structure, which can adsorb gas molecules such as oxygen and methane and is prone to spontaneous combustion [15,16]. As early as the 17th century, scholars have put forward the pyrite causation theory, bacterial causation theory, phenol-based interaction theory and coal–oxygen complex interaction theory, through different research angles, to explain the mechanism of CSC. The widely recognized coal–oxygen complex theory holds that the interaction between coal and oxygen is the fundamental cause of CSC. The spontaneous combustion of coal is mainly caused by the coal–oxygen composite effect and the release of heat. At normal temperature, coal bodies successively combine oxygen in the air through physical adsorption and chemical adsorption, generating low-temperature oxidation, releasing a small amount of heat and producing primary oxidation products. The chemical reaction and product relationship of CSC are shown in Figure 1 [17,18]. Due to the lack of effective heat dissipation, the accumulation of heat once again promotes the oxidation of the coal body. When the temperature of the coal body exceeds the critical temperature, it accelerates the vicious cycle of oxidation–heat release–temperature rise, eventually leading to the spontaneous combustion of the coal body [19,20]. The essence of CSC is that coal comes into contact with oxygen in the air and undergoes an oxidation reaction. When the stored heat is greater than the heat dissipation, the heat continuously accumulates and reaches the ignition point of the coal, thus causing spontaneous combustion [21].

Figure 1.

Chemical reaction and product relationship of spontaneous combustion of coal.

2.2. Influencing Factors of CSC

The spontaneous combustion of coal is a complicated process of coupling physical and chemical effects, which is influenced by internal factors and the external environment. Many scholars have studied the influence of different conditions on CSC from the aspects of CSC tendency, geological occurrence conditions of coal seam, exploitation mode and ventilation conditions. The main influencing factors of CSC are as follows:

1. The metamorphic degree of coal is very important to the influence of CSC tendency [22]. In general, the higher the metamorphic degree of coal, the smaller the spontaneous combustion tendency.

2. The sulfur element contained in coal also has an impact on the oxidation process of coal. Experiments have shown that when the sulfur content is less than a certain point, a higher sulfur content can promote the reaction process of coal. When it exceeds this critical value, a large amount of sulfur-containing substances will inhibit the oxidation reaction of coal and this critical value is approximately 5% [23,24].

3. When the moisture content and specific heat capacity are high, the heat released by coal in the low-temperature oxidation stage can be absorbed and the spontaneous combustion of coal can be inhibited [25].

4. The porosity and brittleness of coal also have a significant impact on the spontaneous combustion tendency of coal. The greater the porosity of coal, the easier it is for oxygen to penetrate and adsorb the coal body, which is conducive to the spontaneous combustion of coal [26]. Coal with the same degree of metamorphism, brittle coal is prone to spontaneous combustion.

5. Compared with intact coal, coal in a broken state is more prone to spontaneous combustion. In the process of mining, the coal pillar of thick coal seams and large inclination coal seams is easy to be destroyed and difficult to retain, and air leakage will increase the spontaneous combustion tendency of coal [27].

6. The cracking of the coal wall in the goaf leads to air leakage, which also has a certain impact on the spontaneous combustion of coal. Due to mine pressure or poor sealing, sufficient oxygen enters the goaf, causing the coal to oxidize and generate heat, promoting the spontaneous combustion of coal [28].

2.3. Underground CSC Common Location

According to the actual situation of coal mine production, through the analysis of influencing factors of CSC, combined with underground coal seam exposure, geological structure, ventilation conditions, and operation methods in the mining process, underground CSC is mainly prone to occur in the following places:

1. Goaf: The goaf is an area with high incidence of coal fire disasters. After the mining of the working face, a large amount of residual coal is accumulated and caved in the goaf. If the goaf is not tightly sealed or the ventilation condition is poor, the residual coal exposed to the air for a long time is constantly oxidized, and the heat storage is greater than the heat dissipation, the spontaneous combustion of coal can easily to occur.

2. Roadway coal pillar: Under the action of mine pressure, some coal bodies break to form loose coal bodies. Inside them, a continuous network of fractures is prone to form, which further expands the contact area between the coal body and oxygen [29]. At the same time, it may also be affected by the pressure difference in underground ventilation, causing air leakage. Fresh air seeps into the coal body along the fractures, thereby accelerating the oxidation process of the coal.

3. Driving at the top of the roadway: At the top of the excavation roadway, especially the high cap area connected with the goaf, the coal seam is exposed to the air in the process of excavation, while the high volume area is connected with the goaf, the ventilation conditions are complicated, and the coal body is prone to spontaneous combustion.

4. Stop-mining line: Due to the cessation of mining work, there is usually a large amount of residual coal accumulation at the stop-mining line, and the stop-mining line is often the air leakage channel with the largest pressure difference. If the airtight is not strict, it will accelerate the oxidation of residual coal exposed to the air and spontaneous combustion.

5. Starting cut: There is usually a large section along the fully mechanized caving mining, which is easily affected by the ore pressure, resulting in cracks in the coal and rock crushing and further aggravating air leakage, which provides the necessary conditions for the oxidation of the fractured and loose coal.

6. Near the geological structure belt: Geological structure also has a certain degree of influence on spontaneous combustion of coal. Due to the complexity of geological conditions near faults, coal seams are easily squeezed by ground stress. With the leakage of surface cracks, the fractured coal seams continue to oxidize and thus increase the possibility of spontaneous combustion.

3. Research Status of CSC Source Location Detection Technology

The main research direction of coal fire detection is to accurately and quickly determine the combustion location and fire area distribution of underground CSC. When coal is burned underground, the magnetic field, electric field, light field, thermal field and concentration field in the combustion area will change. Based on the characteristics of these changes, CSC location detection technology uses relevant equipment to capture and analyze the change in physical quantity and then determine the location of the burning zone, the critical zone and the normal zone. At present, the fire source location detection methods developed based on the change in the physical quantity of the coal fire combustion region can be mainly divided into the direct exploration method, remote sensing method, geophysical exploration method and geochemical exploration method [30]. The advantages and disadvantages of each detection technology are compared in Table 2.

Table 2.

Comparative table of advantages and disadvantages of each detection technique.

3.1. Direct Detection Method

1. The ground temperature measurement method: The ground temperature measurement method is a fundamental method for detecting the location of fire sources and has a good detection effect on the location of fire sources in shallow-buried coal seams, such as some open-pit coal mines in Australia [44,45]. The heat generated by the spontaneous combustion of coal in the underground will cause abnormal surface temperature through heat conduction to the surface. Common surface temperature detection instruments mainly include a glass liquid thermometer, infrared measuring equipment and a platinum resistance ground temperature sensor, etc. According to the abnormal area of surface temperature detected by the instrument, the fire area can be delineated and the development trend of underground fire can be judged [46]. Due to the different working principles and detection methods of different measuring instruments, the observation results also have errors to a certain extent, and the surface wind flow, solar radiation and other environmental factors will also affect the observation results. Zhang et al. [47] test the land surface temperature in coal fire regions and consider the impact of slope surface and slope direction on solar uneven heating. The research results can provide substantial support for thermal mapping activity planning and the analysis of coal fire anomalies in remote sensing data and can provide initial and boundary conditions for coal fire-related numerical simulation.

2. The drilling temperature measurement method: On the surface, for the suspected high-temperature point areas, the depth and number of boreholes are determined based on geological exploration and mine design, and construction drilling is carried out. High-temperature-resistant temperature measurement instruments such as thermocouples are placed along the boreholes to directly detect the underground temperature. After the readings stabilize, the location of the high-temperature point can be judged based on the temperature changes within the detection area. In the current engineering practice, this method is mostly used to verify the high-temperature points after delineating the underground fire area in a large range [48]. Peng et al. [49] studied the current geothermal distribution characteristics through surface drilling exploration and groundwater temperature measurement in the eastern Chenghe mining area of the Weibei Coal field. Combined with the thermal conductivity test of coal and rock, the formation model of geothermal anomalies in the region was constructed to provide reference for the prevention and control of geothermal disasters.

3.2. Physical Detection Method

1. The infrared detection method: Infrared is a kind of electromagnetic wave with extremely strong thermal energy; its wavelength range is between 0.75 um and 1000 um. Any object higher than absolute zero to the surrounding infrared radiation will be captured by infrared thermal imaging technology, so as to achieve its accurate positioning and analysis. Photoelectric conversion is used to convert it into a visual temperature image, which has been widely used in civil aviation, the military industry, industrial manufacturing and firefighting fields [50]. Objects with different temperature ranges have different temperature fields, and the higher the energy of the object itself, the greater the energy radiated to the outside world, which is the theoretical basis of infrared thermal imaging technology and the physical basis of detection. Infrared detection has the characteristics of non-contact and high sensitivity and has a good effect in the application of concealed fire source detection in shallow coal seams, outcrop fire source detection and CSC prevention, but its application range is limited, and it is not suitable for deep buried fire areas. Wen et al. [51] used infrared imaging technology to quickly and intuitively detect the surface temperature of rock mass in the fire area of the main inclined shaft of a Hebei coal mine, preliminarily judge the fire situation, observe the temperature in the hole combined with the drilling temperature measurement method, judge the degree of coal combustion, and determine the treatment plan. Wang et al. [52] used infrared equipment to detect the surface temperature field of gangue mountain in Dongzhou Kiln, Datong City, and found 13 possible fire areas, which provided a basic basis for the risk assessment of the mine. Cao et al. [53] proposed an infrared recognition algorithm based on ResNet50 combined with transfer learning to effectively identify infrared fire images, aiming at the shortcomings of the low accuracy and complex information extraction process of traditional means. By comparing with the experiments of CNN, VGG16, ResNet101 and ResNet152, it is found that the accuracy of the algorithm is as high as 99.63%.

2. The resistivity detection method: The heat generated by spontaneous combustion of underground coal seams is transferred to the surface along the temperature gradient by heat conduction, and the change in temperature causes a change in resistivity between coal and rock [54,55]. Under normal circumstances, the resistance value of coal rock in the firing area is higher than that in the non-firing area. By comparing the difference in resistivity between the firing area and the non-firing area, the location of underground CSC can be judged. The resistivity detection method is easy to be disturbed by the ground stray current, so it is widely used in detecting fire sources in shallow coal seams and open-pit coal mines. Hui et al. [56] applied the transient electromagnetic method with power supply to the detection of the spontaneous combustion of coal according to the characteristics of resistivity changes in the combustion process of coal. Based on the inversion of the unstructured finite element method and L-BFGS algorithm, the effectiveness of this method in the spontaneous combustion region was verified. Shao et al. [57] used three different geophysical detection methods in the coal fire detection of Hefeng 9# in Xinjiang, China, and obtained the current density distribution curve through the inversion of resistivity data. The location of the fire source detected by this method was consistent with the verification results of the temperature measurement in the last borehole.

3. Magnetic detection: During the spontaneous combustion of the lower coal seam, various chemical reactions will occur in the rocks at the top and bottom of the coal seam, and the magnetic susceptibility of the rocks will be increased, even up to 2–3 orders of magnitude [58,59]. The magnetic differences in the fire area caused by the above changes objectively describe the characteristics of burned rock and the abnormal situation of the spontaneous combustion boundary, which can accurately delineate the coal seam fire area [60]. Zhang et al. [61] analyzed the influence of coal fire on the geomagnetic field by collecting the data of magnetic anomalies in open-pit coal mines in Ordos, explored its internal relationship, and found that a magnetic anomaly in coal mines can indicate the distribution of underground coal fire. Combined with a topographic map, magnetic anomaly map and magnetic correlation imaging methods, more accurate fire source depth can be calculated. Meng et al. [62] proposed a three-dimensional constrained magnetic vector response method based on coal seam informatization to obtain magnetic sources and then extended it to the natural regions of coalfields. Through this method, in Liaoning Province, the range and future spread trend of coalfield spontaneous combustion areas were analyzed by combining infrared remote sensing temperature data, and the accuracy of the results was verified through drilling.

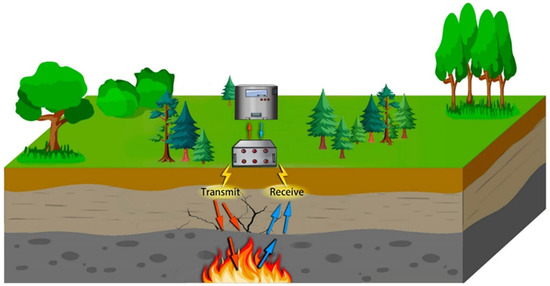

4. The geological radar detection method: Georadar can effectively detect the distribution of underground media. This technology relies on powerful pulses of electromagnetic waves emitted by transmitters to pinpoint deep rock structures. When the electromagnetic wave signal is transmitted to the underground detection target, a reflection occurs, and the receiver receives the two signals and amplifies them and displays them by the oscilloscope [63]. Geological radar detection is based on the characteristics of the electromagnetic wave source strength and propagation rate in different temperature media, and the collected reflected signal is processed, the form of underground CSC space is analyzed, and the fire area is delineated. Its working principle is shown in Figure 2. Ma et al. [64] carried out research in a Gongwusu open-pit coal mine in Wuhai City, Inner Mongolia. Based on the correlation analysis of coal seam resistivity and temperature, geological radar and conical transient electromagnetic methods were used to detect the ignition point and fire zone range of CSC and effectively identify the location of the potential natural ignition point and fire range. Gao et al. [65] proposed a deep learning-based coal fire ground-penetrating radar identification method based on the images obtained by scanning the physical model of coal fire with radar based on a deep learning algorithm. This method has the characteristics of extremely high accuracy and rapidity in identifying coal field fire areas. However, some scholars have found through a series of experiments that the intensity of electromagnetic waves will attenuate with the increase in depth. And under the condition of a certain depth, the energy of electromagnetic waves usually decreases as the water content increases [66].

Figure 2.

Working principle of geological radar detection method.

5. Mine acoustic temperature measurement technology: Acoustic temperature measurement technology is widely used in granary and other fields. Coal is a porous medium, which is similar to grain particles stored in granary. In recent years, this technology has been gradually applied by scholars in the study of underground CSC concealed fire source detection. Acoustic temperature measurement technology is a temperature measurement method based on the physical relationship between the propagation speed, the time of sound and the temperature of the propagation medium, and the propagation speed of sound in the medium is used to calculate the temperature of the medium [67]. Guo et al. [68,69] analyzed the principle of acoustic temperature measurement technology and the propagation characteristics and influencing factors of acoustic emission signals in coal and rock, combined with the research status of acoustic temperature measurement simulation methods such as the least square method, SVD algorithm and iterative method, and discussed the adaptability of acoustic temperature measurement technology in the spontaneous combustion area of loose coal in a goaf. It is expected to provide a new solution for the accurate detection of underground CSC ignition sources. Deng et al. [70] took coal samples with different degrees of metamorphism as the research object and explored the propagation characteristics and main path of sound waves in loose coal by measuring the propagation time of sound waves in three different media, nitrogen, air and carbon dioxide.

3.3. Remote Sensing Detection Method

1. Infrared remote sensing: Aerial infrared remote sensing uses an infrared sensor mounted on an aircraft to detect the surface coal field fire area in the air [71]. Sun [72] used satellite thermal infrared to delineate the coal fire target area in a large range and accurately detected the specific location and temperature of coal fires through high-resolution thermal infrared and the optical remote sensing of unmanned aerial vehicles. The study found that the satellite data resolution was low and the calculation error was large, it was only suitable for large-scale fire area delineation, it had a UAV thermal infrared detection surface resolution of up to centimeters, and it could accurately detect the specific location, range and temperature of underground coal fire. Most of the coal mines in China are mainly underground mines and some are open-pit coal mines. However, there are more open-pit coal mines in India and Australia, such as Tajdarul Hassan Syed, Li Beibei, etc. This paper reviews the current situation of coal mining and the distribution of fire areas in India and Australia, analyzes the application status of remote sensing technology in the fire areas of Indian coalfields, and affirms the role of remote sensing technology in coal fire detection [73,74]. The remote sensing method is applicable to the census of large-scale fire areas and the preliminary screening of surface high-temperature points, but it has certain limitations in the detection of deep fire sources and the precise delineation of fire sources. Liu et al. [75] used the M300RTK UAV thermal imager and Zenmusel hybrid sensor to collect the data of the southern fire area of the Baijinou coal mine, delimit the high-temperature abnormal area in a large range, combined with the method of natural potential and drilling verification, make a more refined division of the fire area of the mine, and effectively establish a fire prevention system.

2. Multi-spectral remote sensing: Multi-spectral remote sensing uses the spectral intensity information and Planck formula in multiple wavelength channels to invert the target’s true temperature and spectral emissivity, which can be used to dynamically measure the temperature and thermal properties of high-temperature or ultra-high-temperature objects, and is a promising non-contact temperature measurement method [76]. David M. Szpakowski et al. [77] reviewed the application of remote sensing technology in fire ecology, focused on the application of a multi-spectral sensor, lidar and unmanned aerial vehicle system in analyzing and monitoring fire activities, illustrated the current research status, and made prospects for the future development of this technology. Du et al. [78] analyzed ASTER thermal infrared images and ground temperature multi-spectral images collected by satellite-borne sensors in the Wuda coal field of China by using the Adaptive Gradient Threshold (SAGBT) method based on ASTER data and evaluated and verified the performance of SAGBT. Using thermal infrared images at night and images from different seasons, it was found that SAGBT’s coal fire area matched the observed fire area in the field by up to 70% to 85%, and SAGBT’s coal fire area matched the high-temperature pixels in ASTER images.

3. Hyperspectral remote sensing: Hyperspectral remote sensing technology, as an important branch of optical remote sensing technology, can obtain the image and continuous spectrum of the observed object synchronously and also realize the synchronous detection of the spatial and spectral characteristics of the detected target [79]. The early remote sensing monitoring of a mine environment is mostly used multi-spectral data analysis. Compared with other multi-spectral remote sensing methods, the hyperspectral method is more precise, so it has the advantage of being able to conduct the narrow-wave imaging of slits and provide 0-nanometer vision–near-infrared images [80,81]. Yang et al. [82] used the TASI aerial hyperspectral thermal imager and the TASI data of night aerial thermal infrared hyperspectral remote sensing to establish an air–earth regression equation by means of the emissivity normalization method and the surface temperature measurement data to invert the surface temperature, so as to obtain the range of surface temperature anomalies and provide decision support for coal fire disaster control in mining areas. Based on the existing studies of hyperspectral remote sensing in the field of fire monitoring and monitoring, Yang et al. [83] proposed and designed a fire detection model based on sparse vision transformers to promote the development of the field of fire detection.

3.4. Chemical Detection Method

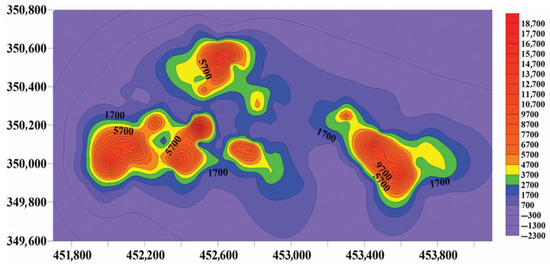

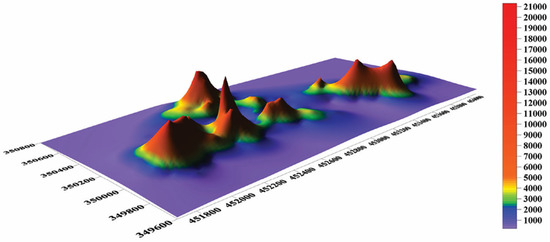

1. The radon measurement method: A radioactive radon element with strong migration ability exists widely in nature and is often used as a tracer. When a coal field fire occurs, the underground temperature and pressure increase, forming negative pressure with the surface. Radon in the ground soil, along with other gases such as water vapor and carbon monoxide produced by combustion, moves in the cracks in the top space of the CSC area along with the temperature gradient and pressure gradient and constantly precipitates to the surface, and then by embedding α detection cups in the soil to collect radon ions released from the surface and by analyzing and comparing the radon values in the detection cups, abnormal areas can be determined [84]. The radon measurement method is an effective method for exploring the location of shallow-buried coal seam fire areas at present. It has developed relatively maturely and is less affected by the environment. However, this method is easily affected by geological structures such as surface fissures during the detection of deep-buried coal seam fire areas. Usually, when combined with other methods, it can achieve good detection results. Chan et al. [85] studied the long-distance migration rule of radon during the spontaneous combustion of coal, covering a specific abandoned fire area, by using the methods of laboratory experiments and numerical simulation and obtained the mathematical relationship between the exhaled concentration of radon and the spontaneous combustion temperature of coal through nonlinear fitting. Based on the theoretical foundation of the radon measurement and magnetic detection, Hu et al. [86] proposed the detection principle of the “radon–magnetic” combined technology, successfully delineated an acquisition area of 213 square meters, and completed the treatment of the fire zone through the method of drilling and grouting. Tan et al. [87] conducted a study, and based on the infrared thermal imaging data of Mine No. 1 in the Fukang mining area, combined with an on-site inspection of the radon measurement method, the borehole temperature measurement was further verified, and the high-temperature fire source point was successfully determined by analyzing the abnormal emission point of radon concentration, providing a basis for the development of a fire extinguishing plan in the Fukang Coal Mine. Duan et al. [88] proposed a new method to increase the number of single gas sampling points and expand the single detection range in the process of radon element measurements, which improved the detection efficiency by reducing the number of measurement points, and based on the measurement results, through simulation, the radon concentration distribution map of the research area in the detection area as shown in Figure 3 and the three-dimensional diagram of the abnormal radon value as shown in Figure 4 were obtained. From the figures, the magnitude of the abnormal radon value can be clearly seen and the potential location of the underground fire source can be determined.

Figure 3.

A map of radon concentration distribution in the study area.

Figure 4.

A three-dimensional map of radon concentration distribution in the study area.

2. Binary tracer technology: SF6, CClBrF2 and other tracer gases with good thermal stability are used to detect the position change in a fire source. Dai et al. [89,90] carried out a pyrolysis experiment and model tracer experiment of SF6 and CClBrF2, mixing the reference tracer gas SF4 and the indicator tracer gas CClBrF2 at the air leak source, and sampling and analysis at the air leak sink. The results showed that the indicator tracer gas with poor thermal stability was decomposed by heat after passing through the fire source. The heat resistance of the benchmark tracer gas is high, and the location of the fire source can be determined indirectly by analyzing and comparing the concentration of the sampled gas components. The dual tracer gas detection of a fire source location has the advantages of a simple operation, less release and high chromatographic analysis accuracy. However, due to the influence of mining technology and geological conditions, the specific location and range of high-temperature points cannot be accurately determined [91,92].

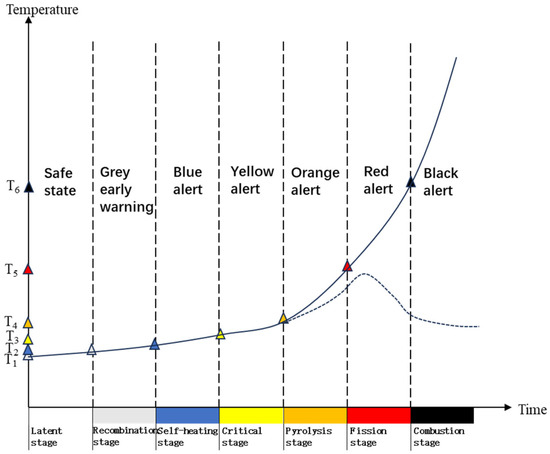

3. The gas detection method: When coal reaches a certain temperature, different concentrations and types of gases will be released, and the occurrence and release of these gases can accurately reflect the degree of oxidation and the spontaneous combustion of coal. Due to the heat production of coal oxidation and spontaneous combustion, the temperature of surrounding coal rock and air rises, and the pressure difference between the underground high-temperature site and the surface is generated, and the gas in the coal fire area migrates to the surface along this pressure gradient in the coal rock fracture [93,94]. Li et al. [95] determined the pyrolysis temperature, ignition temperature and starting temperature of different kinds of marker gases by analyzing the pyrolysis process of HQL and DY coal. Based on a comprehensive analysis of the marker gases and critical temperatures produced in various stages of CSC, the authors adopted the following methods: C2H2, C2H4, C2H4, C2H4, C2H4, C2H4, C2H4, C2H4 and C2H4, respectively. C2H6 is the evaluation basis for the classification of the CSC stage. This method divides the coal combustion process into four stages: the latent spontaneous combustion period, slow spontaneous combustion period, accelerated spontaneous combustion period and combustion period. In engineering practice, drilling experiments can be carried out at suspected high-temperature points on the surface, and the components of the collected gases can be analyzed by gas chromatography. The degree of the spontaneous combustion of coal seams is determined based on the critical concentration of CO and the type of gas, and the fire area range of the coalfield is delineated. Yue et al. [96] simulated coal seam spontaneous ignition by using a kg coal sample ignition test bench. Based on the analysis of indicator gases in the process of coal oxidation and temperature rise, and based on the original theory of dividing CSC stages, the early warning levels of CSC were further divided into seven stages, latent, composite, self-heating, critical, pyrolysis, fission and combustion, as shown in Figure 5. The prediction of the spontaneous combustion of coal is more accurate.

Figure 5.

Fine division of spontaneous combustion stage of coal seam.

4. Existing Problems and Research Prospects

4.1. Existing Problems

Due to the concealment of the underground fire source, the complexity of the environment and the limitations of the current technology, there are still the following problems in the engineering application of CSC fire source location detection technology, which are worthy of further study:

1. Complex environmental conditions and concealed fire source location: With the continuous extension of mining, the deep mining of coal has gradually become the norm. The information of underground long-distance coal fire can be reflected to the surface is more limited, and the traditional detection methods are limited in obtaining the information of underground fire suppression. Especially in deep underground goaf, the space is closed, and the application of numerous detection equipment and monitoring means is limited. As the operation area continues to extend deeper, the information of many physical parameters in a deep goaf such as the temperature field and seepage field will decay during transmission, making it difficult to obtain. The heat generated by the spontaneous combustion of coal and the indicator gas are more easily absorbed by the outside world, which will lead to a small range of scattered high-temperature points being more hidden and difficult to locate.

2. The accuracy of the existing detection means is insufficient, and the detection technology has limitations. Due to the complexity of the development of the CSC fire area and the concealment of fire source location, the existing detection methods for the CSC fire source location are insufficient in detection accuracy and cannot accurately delineate the fire area. For example, the resistivity method is susceptible to the interference of surface stray current. In infrared remote sensing, the resolution of the thermal infrared band is low, the spectrum can reflect limited information, and the location and temperature distribution of underground fire source cannot be accurately measured. The surface temperature measurement method is affected by wind flow and precipitation in the process of application in the fire area of a shallow coal seam. During the detection by the radon measurement method, the fracture of a coal seam, the properties of overlying strata in the fire area and the surface atmosphere will all affect the detection results, so it is not suitable for the location detection of the spontaneous combustion of coal with deep burial.

4.2. Research Prospect

In the field of CSC prevention and control, although the research on CSC fire source location detection technology has made progress, due to hidden fire source locations, scattered ignition points, and complex and changeable underground environments, the existing technology has different degrees of drawbacks in application practice. Conventional CSC fire source location detection methods are mainly based on detecting the change in a certain physical quantity in the process of CSC and then analyzing and determining the underground coal fire location, which is one-sided to a certain extent. Therefore, the “air–ground integrated” fire source location detection technology is proposed, and multiple methods are combined to accurately define the underground coal fire. In the application of engineering practice, multiple physical fields existing in coal fire areas change, and the change indicators of multiple physical fields can be integrated and analyzed to find out their internal correlation, and a new technology for determining the location of the CSC source can be built.

1. “Air–ground integrated” fire source location determination technology: Different CSC fire source location detection technologies have different detection advantages. The “air–ground integrated” fire source location determination technology is a technical system that combines multiple detection methods in the air and on the surface. Multiple detection methods are applied in different spatial ranges and multiple technologies are combined to make up for the shortcomings of a single detection method. It is expected to be a more accurate comprehensive technology for the detection of a shallow coal seam fire area. The principle of the technology is as follows: through the radar, infrared and other remote sensing detection devices mounted on the aircraft at the high altitude of the mining area, the target area is initially considered to comprise a large range of the coal fire area. On the surface, the radon and resistivity detection methods are used to finely detect the coal fire area and subdivide the key detection area. Combined with the existing theories, the high-temperature point is determined by the fusion analysis of various data from the upper air and the surface. Finally, the detection results are verified by the method of surface drilling to improve the accuracy and reliability of the detection results.

2. The location determination method of CSC fire sources based on a multi-physics coupling mechanism: Starting with the analysis of the mechanism of the spontaneous combustion of coal, the factors affecting the spontaneous combustion of coal are comprehensively and systematically analyzed from multiple angles, and the correlation of various physical quantities is analyzed in combination with the index gas of coal at different temperature stages and the effect changes in physical fields such as the magnetic field, electric field and thermal field in the combustion area during the spontaneous combustion process, and the multi-physical field coupling model is established. Through numerical simulation, the underground coal fire area is visually analyzed. Combined with the integrated monitoring system to monitor the underground temperature, indicator gas, sound wave, electromagnetic field and other physical quantities, through artificial intelligence big data and the in-depth mining of a number of data, one can more accurately determine the location of the fire source. Driven by the concept of interdisciplinary and multi-specialty integration, and combined with the engineering practice requirements of CSC fire source location detection, this method is expected to become a new development direction of deep underground coal fire detection.

5. Conclusions

1. Traditional detection technologies can meet the realistic demand of detecting and locating hidden fire sources in coal mines to a certain extent, but due to the limitation of actual environmental conditions, they cannot accurately identify the fire source range in coal mines. At present, the radon measurement method is widely used due to its simple operation and most developed theoretical research. In practical application, it is often combined with other methods such as infrared remote sensing detection to achieve better detection results. This also provides ideas for the proposal of the “air–ground integrated” fire source location determination technology.

2. Most fire source location detection technologies have achieved remarkable results in theoretical research and have also been applied in engineering practice. However, in engineering practice, due to the interference of unavoidable factors such as complex geological structures and surface environments, there are still certain limitations in the precise detection and delineation of fire source locations.

3. “Air–ground integrated” fire source location determination technology, through the combination of multiple technologies in different spatial ranges, can effectively make up for the deficiencies of a single detection method and will become an effective comprehensive technology for detecting fire areas in open-pit mining areas and shallow coalfields. The location determination method of CSC fire sources based on a multi-physics coupling mechanism provides a new idea for the study of underground long-distance coal fires by clarifying the laws among various physical quantities and is expected to become a new method for determining the location of deep fire sources and provide more effective support for the prevention, control and governance of coal fire disasters.

Author Contributions

Conception and review of the literature review, Y.J.; summarizing the current research status and proposing prospects, W.L. and X.C.; draft writing and submission, Y.L.; preliminary literature search and screening, X.Y. and C.Q.; analysis and organization, C.L. and J.H.; data review, L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Department of Ningxia Hui Autonomous Region, the 2025 Autonomous Region Key R&D Program, grant number 2025BEG01009 and the Natural Science Basic Research Program of Shaanxi Province, grant number 2025JC-YBMS-582. The APC was funded by the above two program.

Acknowledgments

We thank the Science and Technology Department of Ningxia Hui Autonomous Region, the 2025 Autonomous Region Key R&D Program, the Natural Science Basic Research Program of Shaanxi Province and the Shaanxi Key Laboratory of Prevention and Control of Coal Fire for providing a technical and platform support for the analyses of this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kang, H.; Xie, H.; Wang, S.; Ren, S.; Zhang, Y.; Wang, B.; Chen, P.; Jiao, X.; Zheng, D.; Ren, Y.; et al. Research on the integrated green development strategy of coal and co-existed and associated resources. Strateg. Stud. CAE 2025, 27, 172–183. [Google Scholar]

- Yuan, L. Theory and technology considerations on high-quality development of coal main energy security in China. Bull. Chin. Acad. Sci. 2023, 38, 11–22. [Google Scholar]

- National Bureau of Statistics of China. Statistical Communiqué of the People’s Republic of China on the 2024 National Economic and Social Development. Available online: https://www.stats.gov.cn/english/PressRelease/202502/t20250228_1958822.html (accessed on 28 June 2025).

- Deng, J.; Yang, C.; Ren, L.; Li, X.; Wang, C.; Bai, Z. A review on coal spontaneous combustion prediction based on machine. J. China Coal Soc. 2025. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, K.; Du, F.; Guo, H.; Li, K.; Wang, Y. Mechanical-permeability characteristics of composite coal rock under different gas pressures and damage prediction model. Phys. Fluids 2024, 36, 036615. [Google Scholar] [CrossRef]

- Li, W.; Guo, Y.; Liu, X.; Du, F.; Li, G.; Ma, Q. Failure mechanisms and reinforcement support of soft rock roadway in deep extra-thick coal seam: A case study. Eng. Fail. Anal. 2024, 165, 108745. [Google Scholar] [CrossRef]

- Ma, L.; Gao, W.; Tuo, L.; Zhang, P.; Zheng, Z.; Guo, R. Characteristics and prediction methods of coal spontaneous combustion for deep coal mining in the Ximeng mining area. Coal Geol. Explor. 2025, 53, 33–43. [Google Scholar]

- Deng, J.; Zhao, X.; Wang, C.; Ren, S.; Qu, G.; Wang, J.; Dou, L. Study on the thermodynamic characteristics of hypoxic oxidation of coal. Min. Saf. Environ. Prot. 2025, 52, 9–16. [Google Scholar]

- Liu, H.; Li, Z.; Wang, G.; Niu, H.; Tan, B. The characteristics of heat production and key structure evolution in the initial stage of coal spontaneous combustion. J. China Coal Soc. 2025, in press.

- Deng, J.; Qu, G.; Ren, S.; Wang, W.; Wang, C.; Wang, J. Research on underground coal fire source detection. J. Mine Autom. 2023, 49, 68–77. [Google Scholar]

- Guo, J.; Liu, H.; Jin, Y.; Cai, G.; Liu, Y.; Yang, P. Summary of underground hidden coal spontaneous combustion fire source detection methods and prospect of new technologies. China Saf. Sci. J. 2022, 32, 111–119. [Google Scholar]

- Kong, B.; Li, Z.; Yang, Y.; Liu, Z.; Yan, D. A review on the mechanism, risk evaluation, and prevention of coal spontaneous combustion in China. Environ. Sci. Pollut. Res. 2017, 24, 23453–23470. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Hou, X.; Luo, H.; Tian, F.; Yu, G. Development countermeasures and current situation of coal mine fire prevention & extinguishing in China. Coal Sci. Technol. 2016, 44, 1–6. [Google Scholar]

- He, J.; Zheng, B.; Li, W.; Yang, L.; Sun, H. Land surface temperature retrieval of the geothermal area in Eastern Liaoning, China, based on thermal infrared remotely sensed data of MODIS. J. Indian Soc. Remote Sens. 2018, 46, 1023–1034. [Google Scholar] [CrossRef]

- Cheng, X.; Song, J.; Wen, H.; Fan, S.; Liu, M.; Mi, W.; Yu, Z.; Liu, Y.; Li, R. Mitigation of coal spontaneous combustion and enhanced coalbed methane recovery using liquid CO2: Mechanisms, field applications, and implications for mines. J. CO2 Util. 2024, 90, 102987. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, E.; Guo, Y.; Du, F.; Ding, K. Effect of loading rate on the mechanical and seepage characteristics of gas-bearing coal–rock and its mechanical constitutive model. Phys. Fluids 2024, 36, 026606. [Google Scholar] [CrossRef]

- Chen, X.; Liu, X.; Yao, Y.; Zhao, Z. The evolution patterns of active functional groups and reaction pathways during the low-temperature oxidation process of coal. J. Min. Sci. Technol. 2024, 9, 998–1006. [Google Scholar]

- Qin, B.; Zhong, X.; Wang, D.; Xin, H.; Shi, Q. Research progress of coal spontaneous combustion process characteristics and prevention technology. Coal Sci. Technol. 2021, 49, 66–99. [Google Scholar]

- Onifade, M.; Genc, B. A review of research on spontaneous combustion of coal. Int. J. Min. Sci. Technol. 2020, 30, 303–311. [Google Scholar] [CrossRef]

- Liu, H.; Li, Z.; Yang, Y.; Miao, G.; Li, J. The temperature rise characteristics of coal during the spontaneous combustion latency. Fuel 2022, 326, 125086. [Google Scholar] [CrossRef]

- Deng, J.; Yang, N.; Wang, C.; Chen, G.; Kang, F.; Ren, L.; Cui, X.; Bai, G. Key technology of “preventing-suppressing-extinguishing” coordinated fire preventing and extinguishing for coal spontaneous combustion in goaf. Saf. Coal Mines 2022, 53, 1–8. [Google Scholar]

- Nie, B.; Yan, H.; Liu, P.; Chen, Z.; Peng, C.; Wang, X.; Yin, F.; Gong, J.; Wei, Y.; Lin, S.; et al. Experimental investigation on spontaneous combustion oxidation characteristics and stages of coal with different metamorphic degrees. Environ. Sci. Pollut. Res. 2023, 30, 8269–8279. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Zou, L.; Ren, L.; Wang, J.; Wang, W. Reactivity and spontaneous combustion characteristics of high-sulphur coal during low-temperature oxidation. Int. J. Oil Gas Coal Technol. 2019, 21, 375–389. [Google Scholar] [CrossRef]

- Zhang, Q.; Jia, X.; Wang, D. Experimental evaluation of the effect of sulfur content on the spontaneous combustion characteristics parameters of coal. Thermochim. Acta 2024, 732, 179651. [Google Scholar] [CrossRef]

- Wu, K.; Yao, Q.; Chen, Y.; Zhao, P.; Xi, C.; Zhao, Y.; Wang, Q. Dependence evaluation of factors influencing coal spontaneous ignition. Energy Sci. Eng. 2023, 11, 3738–3750. [Google Scholar] [CrossRef]

- Wang, Q.; Lu, X.; Ma, C.; Luo, Z.; Li, Q.; Deng, J.; Sheng, Y.; Peng, B. Comparative study of the kinetic characteristics of coal spontaneous combustion. J. Therm. Anal. Calorim. 2023, 148, 4463–4476. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, M.; Yang, Z.; Liu, Y.; Ding, C.; Huang, G. Effect of fault structure on the structure and oxidative spontaneous combustion characteristics of coal. J. China Coal Soc. 2023, 48, 1246–1254. [Google Scholar]

- Li, J.; Li, X.; Liu, C.; Zhang, N. Study on the air leakage characteristics of a goaf in a shallow coal seam and spontaneous combustion prevention and control strategies for residual coal. PLoS ONE 2022, 17, e0269822. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Liu, X.; Li, W.; Du, F.; Ma, J.; Qian, R.; Huo, N. Research on abutment stress distribution of roof-cutting coalface: Numerical simulation and field measurement. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 86. [Google Scholar] [CrossRef]

- Wang, T.; Wang, H.; Fang, X.; Wang, G.; Chen, Y.; Xu, Z.; Qi, Q. Research progress and visualization of underground coal fire detection methods. Environ. Sci. Pollut. Res. 2023, 30, 74671–74690. [Google Scholar] [CrossRef] [PubMed]

- Ma, F.; Sun, Z.; Sun, Z.; Wang, X.e.; Lu, R.; Gu, H.; Guo, J.; Cai, X. Temperature measurement used for 4000-m depth drilling and geothermal characteristics in Jiaodong Peninsula, China. Environ. Earth Sci. 2017, 76, 728. [Google Scholar] [CrossRef]

- Luo, B.; Hou, G.; Zhang, K.; Cheng, H. Hole-wall temperature characteristics in thick UD-CFRP drilling by different condition. Mater. Manuf. Process. 2024, 39, 563–576. [Google Scholar] [CrossRef]

- Bustos, N.; Mashhadi, M.; Lai-Yuen, S.K.; Sarkar, S.; Das, T.K. A systematic literature review on object detection using near infrared and thermal images. Neurocomputing 2023, 560, 126804. [Google Scholar] [CrossRef]

- Ducut, J.D.; Alipio, M.; Go, P.J.; Concepcion, R., II; Vicerra, R.R.; Bandala, A.; Dadios, E. A review of electrical resistivity tomography applications in underground imaging and object detection. Displays 2022, 73, 102208. [Google Scholar] [CrossRef]

- Du, B.; Liang, Y.; Tian, F. Detecting concealed fire sources in coalfield fires: An application study. Fire Saf. J. 2021, 121, 103298. [Google Scholar] [CrossRef]

- Song, J. The research and detection practice of geological radar technology. Adv. Mater. Res. 2014, 838–841, 883–888. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.L.; Loboichenko, V.; Divizinyuk, M.; Wilk-Jakubowski, G.; Shevchenko, R.; Ivanov, S.; Strelets, V. Acoustic waves and their application in modern fire detection using artificial vision systems: A review. Sensors 2025, 25, 935. [Google Scholar] [CrossRef] [PubMed]

- Cao, H.; Hu, Y.; Wang, Z.; Yang, J.; Zhou, G.; Wang, W.; Liu, Y. An infrared small moving target detection method in complex scenes based on dual-region search. Remote Sens. 2025, 17, 323. [Google Scholar] [CrossRef]

- Reinprecht, V.; Kieffer, D.S. Application of UAV photogrammetry and multispectral image analysis for identifying land use and vegetation cover succession in former mining areas. Remote Sens. 2025, 17, 405. [Google Scholar] [CrossRef]

- Ni, Z.; Wu, M.; Lu, Q.; Huo, H.; Wu, C.; Liu, R.; Wang, F.; Xu, X. A review of research on cloud detection methods for hyperspectral infrared radiances. Remote Sens. 2024, 16, 4629. [Google Scholar] [CrossRef]

- Wen, H.; Cheng, X.; Fan, S.; Xu, Y.; Ren, S.; Guo, J. A method for detecting hidden fire source in deep mine goafs based on radon measurement and its experimental verification. Appl. Geochem. 2020, 117, 104603. [Google Scholar] [CrossRef]

- Guo, Y.; He, Q.; Su, Y. Study on air leakage in high temperature area of Xinliu coal mine. Coal Technol. 2019, 38, 84–86. [Google Scholar]

- Portola, V.; Bobrovnikova, A.; Shirokolobov, G.; Paleev, D. Detection and location of places of spontaneous combustion of coal in mines due to gas anomalies on the earth’s surface. E3S Web Conf. 2020, 174, 01061. [Google Scholar] [CrossRef]

- Zhang, P.; Ni, K.; Wang, H.; Yu, H.; Liu, X.; Li, Q.; Jin, L.; Du, Y.; Li, X.; Bei, R. Research on the development of open-pit coal mines in Australia. China Coal 2023, 49, 128–136. [Google Scholar]

- Reisen, F.; Gillett, R.; Choi, J.; Fisher, G.; Torre, P. Characteristics of an open-cut coal mine fire pollution event. Atmos. Environ. 2017, 151, 140–151. [Google Scholar] [CrossRef]

- Chu, C.; Ma, S.; Zhang, S.; Gong, N. Summary of the study on land surface temperature measurement. Electron. Des. Eng. 2014, 22, 187–189, 192. [Google Scholar]

- Zhang, J.; Kuenzer, C. Thermal surface characteristics of coal fires 1 results of in-situ measurements. J. Appl. Geophys. 2007, 63, 117–134. [Google Scholar] [CrossRef]

- Wang, Y.; Si, G.; Oh, J. Coupled geomechanical CFD modelling of goaf under goaf gas drainage: Impact of goaf characteristics. In Proceedings of the 15th ISRM Congress, Salzburg, Austria, 9–14 October 2023; Austrian Society for Geomechanics: Salzburg, Austria, 2023; pp. 295–300. [Google Scholar]

- Peng, T.; Liu, K.; Chen, Y.; Wang, F.; Li, B. Main controlling factors and formation mode of geothermal anomaly in eastern chenghe mining area of Weibei coalfield. Geofluids 2022, 2022, 3209790. [Google Scholar] [CrossRef]

- Zhu, X.; Weng, Q. Infrared near-field radiation detection and super-resolution temperature mapping. J. Infrared Millim. Waves 2023, 42, 569–573. [Google Scholar]

- Wen, H.; Ma, M.; Fei, J. Mine fire disaster control based on infrared imaging technology. Coal Sci. Technol. 2010, 38, 28–30. [Google Scholar]

- Wang, H.; Tan, B.; Zhang, X. Research on the technology of detection and risk assessment of fire areas in gangue hills. Environ. Sci. Pollut. Res. 2020, 27, 38776–38787. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.H.; Shi, X.Y.; Wang, Y.D. Infrared fire image recognition algorithm based on ResNet50 and transfer learning. In Proceedings of the International Conference on Cyber Security, Artificial Intelligence, and Digital Economy, Nanjing, China, 3–5 March 2023; Loskot, P., Niu, S., Eds.; SPIE: Bellingham, WA, USA, 2023; p. 127181Q. [Google Scholar]

- Karaoulis, M.; Revil, A.; Mao, D. Localization of a coal seam fire using combined self-potential and resistivity data. Int. J. Coal Geol. 2014, 128–129, 109–118. [Google Scholar] [CrossRef]

- Shao, Z.; Wang, D.; Wang, Y.; Zhong, X.; Tang, X.; Xi, D. Electrical resistivity of coal-bearing rocks under high temperature and the detection of coal fires using electrical resistance tomography. Geophys. J. Int. 2016, 204, 1316–1331. [Google Scholar] [CrossRef]

- Hui, Z.; Liu, Y.; Yin, C.; Su, Y.; Ren, X.; Zhang, B.; Xiong, B. Detection of coal spontaneous combustion using the TEM method: A synthetic study. Pure Appl. Geophys. 2021, 178, 3987–4000. [Google Scholar] [CrossRef]

- Shao, Z.; Zhang, G.; Zhou, T.; Wei, J.; Cao, F.; Zhang, Y.; Li, H.; Sun, H.; Qing, S.; Chen, T.; et al. Locating the scope and depth of coal fires based on magnetic and electrical data. Pure Appl. Geophys. 2023, 180, 3883–3900. [Google Scholar] [CrossRef]

- Song, W.; Wang, Y.; Shao, Z. Numerical simulation of electrical resistance tomography method and magnetic method in detecting coal fires. J. China Coal Soc. 2016, 41, 899–908. [Google Scholar]

- Yu, Y.; Li, X.; Shi, L.; Liu, K.; Guo, J.; Ma, G. Research on the application of time shifting aeromagnetic method in detecting coal mine burning areas. J. Mine Autom. 2023, 49, 114–120. [Google Scholar]

- Wang, Y.; Song, Z.; Liu, F. Study on magnetic detection of fire area in underground gob in open-pit coal mine. China Coal 2020, 46, 93–99. [Google Scholar]

- Zhang, B.; Xiao, F.; Jin, W. Burnt coal field detection via magnetic exploration. Environ. Earth Sci. 2023, 82, 160. [Google Scholar] [CrossRef]

- Meng, Q.; Ma, G.; Li, L.; Li, J. An optimized detection approach to subsurface coalfield spontaneous combustion areas using airborne magnetic data. Remote Sens. 2025, 17, 1185. [Google Scholar] [CrossRef]

- Tang, Q.; Gu, Z.; Zhao, Y.; Bu, H.; Wang, Z.; Xu, G.; Fang, B. Research on Chirp modulated heat flow induced infrared thermal wave radar imaging detection technology of coal-rock combination interface. Infrared Phys. Technol. 2025, 148, 105844. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, H.; Li, W.; Xu, Y.; He, Y.; Liu, Z.; Li, P.; Huang, J. Application of integrated geophysical surveys in the identification of hidden fire sources in spontaneous combustion zones in coal seams. Coal Geol. Explor. 2023, 51, 131–137. [Google Scholar]

- Gao, R.; Zhu, H.; Liao, Q.; Qu, B.; Hu, L.; Wang, H. Detection of coal fire by deep learning using ground penetrating radar. Measurement 2022, 201, 111585. [Google Scholar] [CrossRef]

- Liu, S.; Li, Z.; Zhao, G. Attenuation characteristics of ground penetrating radar electromagnetic wave in aeration zone. Earth Sci. Inform. 2021, 14, 259–266. [Google Scholar] [CrossRef]

- Deng, J.; Wang, J.; Ren, S.; He, Q.; Wang, C.; Qu, G. Application and prospect of acoustic detection in the mining sector. Coal Geol. Explor. 2023, 51, 149–162. [Google Scholar]

- Guo, J.; Li, S.; Cai, G.; Li, R.; Jin, Y. Discussion on new technologies of hidden fire source detection and coal temperature sensing by acoustic method for goaf. J. Saf. Sci. Technol. 2021, 17, 5–11. [Google Scholar]

- Guo, J.; Wang, K.; Cai, G.; Jin, Y.; Liu, Y. Research progress of acoustic emission signal and its application prospect in coal temperature sensing field. Coal Sci. Technol. 2022, 50, 84–92. [Google Scholar]

- Deng, J.; Qu, G.; Ren, S.; Wang, C.; Wang, J.; Zhao, X.; Bai, G. Experimental study on acoustic wave propagation characteristics and main paths in loose coal. J. China Coal Soc. 2023, 48, 1238–1245. [Google Scholar]

- Biswal, S.S.; Raval, S.; Gorai, A.K. Delineation and mapping of coal mine fire using remote sensing data—A review. Int. J. Remote Sens. 2019, 40, 6499–6529. [Google Scholar] [CrossRef]

- Sun, C. Research on coal fire detection and identification in mining areas based on UAV thermal infrared remote sensing technology. China Coal. 2023, 49, 85–94. [Google Scholar]

- Syed, T.H.; Riyas, M.J.; Kuenzer, C. Remote sensing of coal fires in India: A review. Earth-Sci. Rev. 2018, 187, 338–355. [Google Scholar] [CrossRef]

- Li, B.; Gao, Z.; Wu, Z.; Li, C.; Sun, H. Overview of Australia coal industry. China Coal. 2021, 47, 77–88. [Google Scholar]

- Liu, Y.; Qi, X.; Luo, D.; Zhang, Y.; Qin, J. Detection and management of coal seam outcrop fire in China: A case study. Sci. Rep. 2024, 14, 4609. [Google Scholar] [CrossRef] [PubMed]

- Araújo, A. Multi-spectral pyrometry—A review. Meas. Sci. Technol. 2017, 28, 082002. [Google Scholar] [CrossRef]

- Szpakowski, D.M.; Jensen, J.L.R. A review of the applications of remote sensing in fire ecology. Remote Sens. 2019, 11, 2638. [Google Scholar] [CrossRef]

- Du, X.; Bernardes, S.; Cao, D.; Jordan, T.R.; Yan, Z.; Yang, G.; Li, Z. Self-adaptive gradient-based thresholding method for coal fire detection based on ASTER data—Part 2, validation and sensitivity analysis. Remote Sens. 2015, 7, 2602–2626. [Google Scholar] [CrossRef]

- Wang, J.; Li, C. Development and prospect of hyperspectral imager and its application. Chin. J. Space Sci. 2021, 41, 22–33. [Google Scholar] [CrossRef]

- Murphy, R.J.; Taylor, Z.; Schneider, S.; Nieto, J. Mapping clay minerals in an open-pit mine using hyperspectral and LiDAR data. Eur. J. Remote Sens. 2015, 48, 511–526. [Google Scholar] [CrossRef]

- Jaiswal, G.; Sharma, A.; Yadav, S.K. Critical insights into modern hyperspectral image applications through deep learning. WIREs Data Min. Knowl. Discov. 2021, 11, e1426. [Google Scholar]

- Yang, G.; Zhao, Y.; Tian, X.; Zhang, G.; Pei, C. Coalfield fire quantitative detection in Daliuta mining area based on hyperspectral thermal infrared remote sensing. Coal Eng. 2016, 48, 103–106, 109. [Google Scholar]

- Yang, L.; Feng, Y.; Wang, Y.; Wang, J. Refined fire detection and band selection method in hyperspectral remote sensing imagery based on sparse-VIT. Infrared Phys. Technol. 2024, 137, 105104. [Google Scholar] [CrossRef]

- Zhou, B.; Deng, C.; Hao, J.; An, B.; Wu, R. Experimental study on the mechanism of radon exhalation during coal spontaneous combustion in goaf. Tunn. Undergr. Space Technol. 2021, 113, 103776. [Google Scholar] [CrossRef]

- Chan, Z.; Zhou, B.; Wang, J.; Lu, Z.; Yang, Q.; Dong, Z.; Dong, K. Long-distance migration law of radon in overburden of abandoned goaf during coal spontaneous combustion. J. Environ. Radioact. 2023, 270, 107284. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Hong, H.; Dong, H.; Wu, B.; Sun, Z.; Wang, W.; Zhang, Q. Research on the application of “radon measurement-magnetic” method to detect spontaneous combustion technology in small coal mines. Coal Sci. Technol. 2025, 53, 200–210. [Google Scholar]

- Tan, B.; Zhang, F.; Zhang, Q.; Wei, H.; Shao, Z. Firefighting of subsurface coal fires with comprehensive techniques for detection and control: A case study of the Fukang coal fire in the Xinjiang region of China. Environ. Sci. Pollut. Res. 2019, 26, 29570–29584. [Google Scholar] [CrossRef] [PubMed]

- Duan, S.; Fang, L.; Shi, Q.; Qi, G.; Huang, Q.; Wang, H. Application of rapid identification technology in shallow coal seam fire detection. Combust. Sci. Technol. 2025, 197, 1535–1549. [Google Scholar] [CrossRef]

- Dai, G. Study on the technique of double tracing for probing coal spontaneous combustion source. J. Xi’an Univ. Sci. Technol. 1996, 16, 20–23, 30. [Google Scholar]

- Ye, Q.; Dai, G.; Li, P.; Tang, M.; Nie, S.; Song, X. Air leakage law of surface above shallow coal seam goaf based on dual-element tracing. Coal Eng. 2020, 52, 83–87. [Google Scholar]

- Liang, X. Position determination of coal spontaneous combustion in quanchuang mine. Shanxi Coal 2015, 35, 16–19. [Google Scholar]

- Shao, H.; Dai, G.; Zhang, G. Measuring and monitoring technology of ventilation leakage in goaf with SF6-CF2ClBr two element trace gas. Coal Sci. Technol. 1998, 26, 2–5, 58. [Google Scholar]

- Wei, D.; Du, C.; Lei, B.; Lin, Y. Prediction and prevention of spontaneous combustion of coal from goafs in workface: A case study. Case Stud. Therm. Eng. 2020, 21, 100668. [Google Scholar] [CrossRef]

- Li, J.; Sun, J.; Yang, Z.; Li, J.; Chen, L.; Zhuo, H.; Zhang, Q.; Lu, W. Different perspectives and explanations regarding the influence of pre-oxidation on the spontaneous combustion characteristics of coal. J. China Univ. Min. Technol. 2025, 54, 423–436. [Google Scholar]

- Li, Z.; Zhang, M.; Yang, Z.; Yu, J.; Liu, Y.; Wang, H. Division of coal spontaneous combustion stages and selection of indicator gases. PLoS ONE 2022, 17, e0267479. [Google Scholar] [CrossRef] [PubMed]

- Yue, N.; Jin, Y.; Sun, M.; Yang, C.; Ran, X.; Cheng, M. Multi-staged warning system for con-trolling the coal spontaneous combus-tion based on the various index gases. J. Saf. Environ. 2020, 20, 2139–2146. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).