Comparison of Dry and Wet Torrefaction for Biochar Production from Olive Leaves and Olive Pomace

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

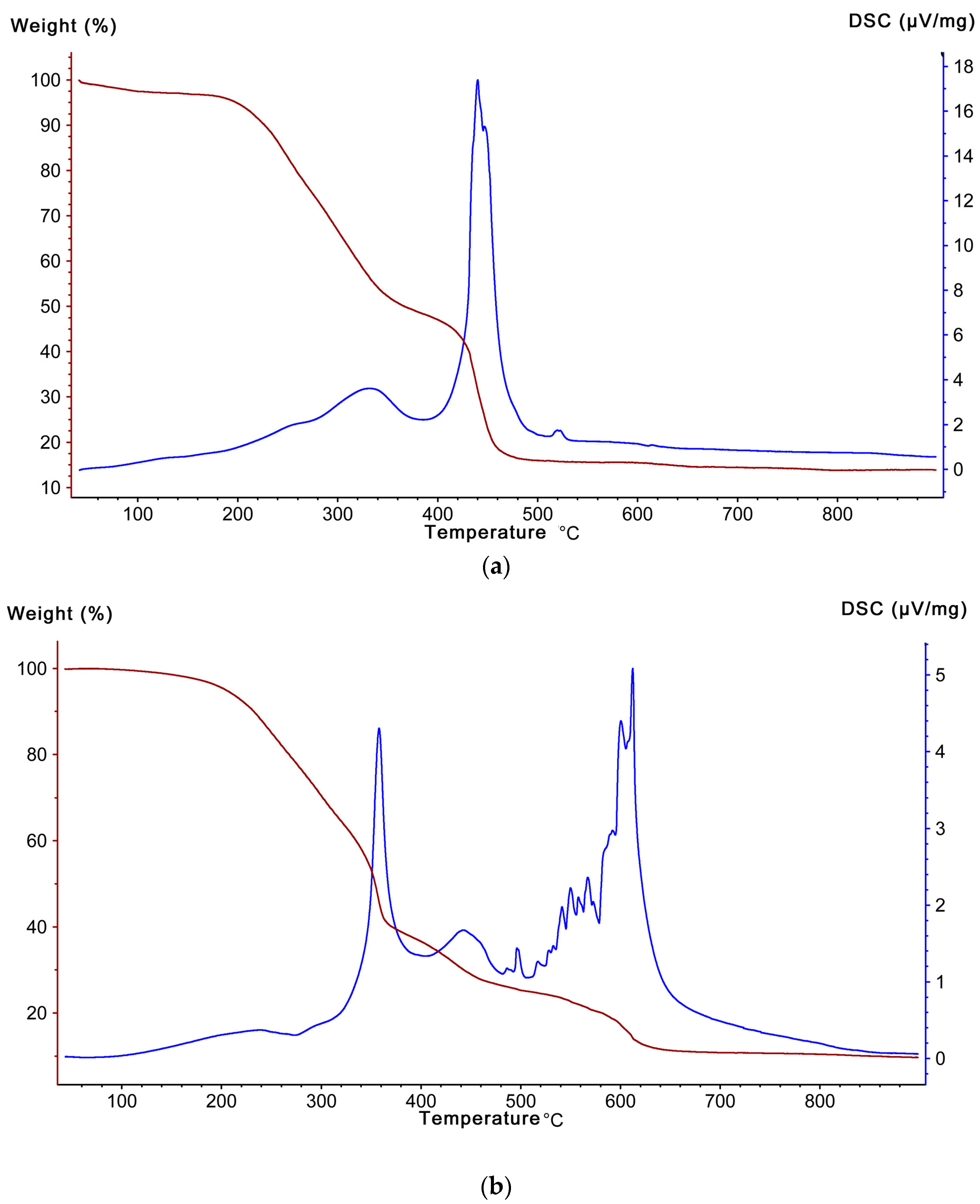

2.2. Thermogravimetric Analyses

2.3. Torrefaction Procedure

- S1—peak area of the component being determined in the analyzed sample;

- V—dilution volume of the sample;

- S2—peak area of the component being determined in the standard sample;

- m—sample weight, g;

- 1000—coefficient expressing the concentration in g/kg.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Souilem, S.; El-Abbassi, A.; Kiai, H.; Hafidi, A.; Sayadi, S.; Galanakis, C. Chapter 1—Olive oil production sector: Environmental effects and sustainability challenges. In Olive Mill Waste: Recent Advances for Sustainable Management; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–28. [Google Scholar] [CrossRef]

- Daibo, O. Moroccan Producers Face Third Straight Year of Declining Production. 2025. Available online: https://www.oliveoiltimes.com/production/moroccan-producers-face-third-straight-year-of-declining-production/136221#:~:text=According%20to%20preliminary%20estimates%20from,year%20average%20of%20141%2C600%20tons (accessed on 4 July 2025).

- Rodis, P.S.; Karathanos, V.T.; Mantzavinou, A. Partitioning of olive oil antioxidants between oil and water phases. J. Agric. Food Chem. 2002, 50, 596–601. [Google Scholar] [CrossRef]

- Morillo, J.; Antizar-Ladislao, B.; Monteoliva-Sanchez, B.; Ramos-Cormenzana, A.; Russell, N. Bioremediation and biovalorisation of olive-mill wastes. Appl. Microbiol. Biotechnol. 2009, 82, 25–39. [Google Scholar] [CrossRef]

- Volpe, R.; Messineo, A.; Millan, M.; Volpe, M.; Kandiyoti, R. Assessment of olive wastes as energy source: Pyrolysis, torrefaction and the key role of H loss in thermal breakdown. Energy 2015, 82, 119–127. [Google Scholar] [CrossRef]

- Abid, N.; Sayadi, S. Detrimental effects of olive mill wastewater on the composting process of agricultural wastes. Waste Manag. 2006, 26, 1099–1107. [Google Scholar] [CrossRef]

- Cayuela, M.L.; Millnerb, P.; Slovinc, J.; Roiga, A. Duckweed (Lemna gibba) growth inhibition bioassay for evaluating the toxicity of olive mill wastes before and during composting. Chemosphere 2007, 68, 1985–1991. [Google Scholar] [CrossRef]

- Jauhiainen, J.; Martin-Gullon, I.; Conesa, J.A.; Font, R. Emissions from pyrolysis and combustion of olive oil solid waste. J. Anal. Appl. Pyrolysis 2005, 74, 512–517. [Google Scholar] [CrossRef]

- Cliffe, K.R.; Patumsawad, S. Co-combustion of waste from olive oil production with coal in a fluidized bed. Waste Manag. 2001, 21, 49–53. [Google Scholar] [CrossRef]

- Messineo, A.; Volpe, R.; Asdrubali, F. Evaluation of net energy obtainable from combustion of stabilised olive mill by-products. Energies 2012, 5, 1384–1397. [Google Scholar] [CrossRef]

- Chen, W.-H.; Kuo, P.-C. A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Medic, D.; Darr, M.; Shah, A.; Potter, B.; Zimmerman, J. Effects of torrefaction process parameters on biomass feedstock up-grading. Fuel 2012, 91, 147–154. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.G.; Rubiera, F.; Pis, J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef]

- Bergman, P.C.A.; Boersma, A.R.; Kiel, J.H.A.; Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction for entrained-flow gas-ification of biomass. In Proceedings of the 2nd World Conference and Technology Exhibition, Rome, Italy, 10–14 May 2004; pp. 1–7. [Google Scholar]

- Prins, M.J. Thermodynamic Analysis of Biomass Gasification and Torrefaction; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2005. [Google Scholar] [CrossRef]

- Bourgeois, J.P.; Doat, J. Torrefied wood from temperate and tropical species. Advantages and prospects. Bioenergy 1984, 3, 153–159. [Google Scholar] [CrossRef]

- Bergman, P.C.A.; Boersma, A.R.; Zwart, R.W.R.; Kiel, J.H.A. Torrefaction for Biomass Cofiring in Existing Coal-Fired Power Stations ‘BIOCOAL; Petten ECN-C–05-013; ECN: Petten, The Netherlands, 2005. [Google Scholar]

- Wang, L.; Butterly, C.R.; Wang, Y.; Herath, H.; Xi, Y.G.; Xiao, X.J. Effect of crop residue biochar on soil acidity amelioration in strongly acidic tea garden soils. Soil Use Manag. 2014, 30, 119–128. [Google Scholar] [CrossRef]

- Baldi, H.D.; Foster, T.L.; Shen, X.; Feagley, S.E.; Smeins, F.E.; Hays, D.B.; Jessup, R.W. Characterization of novel torrefied biomass and biochar amendments. Agric. Sci. 2020, 11, 157–177. [Google Scholar] [CrossRef]

- An, J.Y.; Aung, A.; Hernandez, J.O.; Seo, J.M.; Han, S.H.; Park, B.B. Effects of torrefied wood chips and vermicompost on tree growth and weed biomass: Implications for the sustainable management of salt-affected reclaimed lands. Land 2022, 11, 725. [Google Scholar] [CrossRef]

- Thengane, S.K.; Kung, K.S.; Gupta, A.; Ateia, M.; Sanchez, D.L.; Mahajani, S.M.; Lim, C.J.; Sokhansanj, S.; Ghoniem, A.F. Oxidative torrefaction for cleaner utilization of biomass for soil amendment. Clean. Eng. Technol. 2020, 1, 100033. [Google Scholar] [CrossRef]

- Ogura, T.; Date, Y.; Masukujane, M.; Coetzee, T.; Akashi, K.; Kikuchi, J. Improvement of physical, chemical, and biological properties of arid sol from Botswana by the incorporation of torrefied biomass. Sci. Rep. 2016, 6, 28011. [Google Scholar] [CrossRef]

- Brachi, P.; Miccio, F.; Miccio, M.; Ruoppolo, G. Isoconversional kinetic analysis of olive pomace decomposition under torre-faction operating conditions. Fuel Process. Technol. 2015, 130, 147–154. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Ronda, A.; Zamora, M.C.; Calero, M. Torrefaction of olive tree pruning: Effect of operating conditions on solid product properties. Fuel 2017, 202, 109–117. [Google Scholar] [CrossRef]

- Barbanera, M.; Lascaro, E.; Stanzione, V.; Esposito, A.; Altieri, R.; Bufacchi, M. Characterization of pellets from mixing olive pomace and olive tree pruning. Renew. Energy 2016, 88, 185–191. [Google Scholar] [CrossRef]

- Bradley, D.; Hektor, B.; Hes, J.R.; Nikolaisen, L.; Tumuluru, J.S.; Wild, M. Possible effect of torrefaction on biomass trade. In IEA Bioenergy Task 40; IEA: Paris, France, 2016. [Google Scholar]

- Thengane, S.K.; Kung, K.S.; Gomez-Barea, A.; Ghoniem, A.F. Advances in biomass torrefaction: Parameters, models, reactors, applications, deployment, and market. Prog. Energy Combust. Sci. 2022, 93, 101040. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, B.-J.; Lin, Y.-Y.; Chu, Y.-S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.-S.; Ho, S.-H.; Culaba, A.B.; et al. Progress in biomass torrefaction: Principles, applications and challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

- Nhuchhen, D.; Basu, P.; Acharya, B. A Comprehensive Review on Biomass Torrefaction. Int. J. Renew. Energy Biofuels 2014, 2014, 506376. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansnj, S.; Hess, R.S.; Wright, C.T.; Boardman, R.D. A Review on Biomass Torrefaction Process and Product Properties for Energy Applications. Ind. Biotechnol. 2011, 7, 384–401. Available online: https://www.liebertpub.com/doi/pdfplus/10.1089/ind.2011.7.384 (accessed on 16 November 2021). [CrossRef]

- Biddy, M.J.; Scarlata, C.; Kinchin, C.A. Market Assessment of Bioproducts with Near-Term Potential. Available online: https://www.osti.gov/scitech (accessed on 8 October 2021).

- Schöppe, H.; Kleine-Möllhoff, P.; Epple, R. Energy and Material Flows and Carbon Footprint Assessment Concerning the Production of HMF and Furfural from a Cellulosic Biomass. Processes 2020, 8, 119. [Google Scholar] [CrossRef]

- Zhang, D.; Han, P.; Yang, R.; Wang, H.; Lin, W.; Zhou, W.; Yan, Z.; Qi, Z. Fuel properties and combustion behaviors of fast torrefied pinewood in a heavily loaded fixed-bed reactor by superheated steam. Bioresour. Technol. 2021, 342, 125929. [Google Scholar] [CrossRef]

- Mustaza, M.N.F.; Mizan, M.N.; Yoshida, H.; Izhar, S. Torréfaction of Mangrove Wood by Introducing Superheated Steam for Biochar Production. IOP Conf. Ser. Earth Environ. Sci. 2021, 765, 12027. [Google Scholar] [CrossRef]

- Isemin, R.; Muratova, N.; Kuzmin, S.; Klimov, D.; Kokh-Tatarenko, V.; Mikhalev, A.; Milovanov, O.; Dalibard, A.; Ibitowa, O.A.; Nowotny, M.; et al. Characteristics of Hydrochar and Liquid Products Obtained by Hydrothermal Carbonization and Wet Torrefaction of Poultry Litter in Mixture with Wood Sawdust. Processes 2021, 9, 2082. [Google Scholar] [CrossRef]

- Roy, B.; Kleine-Möllhoff, P.; Dalibard, A. Superheated Steam Torrefaction of Biomass Residues with Valorisation of Platform Chemicals—Part 1: Ecological Assessment. Sustainability 2022, 14, 1212. [Google Scholar] [CrossRef]

- Roy, B.; Kleine-Möllhoff, P.; Dalibard, A. Superheated Steam Torrefaction of Biomass Residues with Valorisation of Platform Chemicals Part—2: Economic Assessment and Commercialisation Opportunities. Sustainability 2022, 14, 2338. [Google Scholar] [CrossRef]

- EN 14775:2009; Solid Biofuels—Determination of Ash Content. Brussels, Belgium, 2015. Available online: https://standards.iteh.ai/catalog/standards/cen/6887c746-63c5-43b4-bc7d-05b2687fbd9f/en-14775-2009?srsltid=AfmBOorx9-sLrrYDqkV2_p5ESgJMmgJinwRcJvwbJnEa7H_w5lQmx_Kq (accessed on 22 May 2025).

- EN 14774-3:2009; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample. Brussels, Belgium, 2015. Available online: https://standards.iteh.ai/catalog/standards/cen/518eb6db-5f1c-4681-9355-8f93f0eeed06/en-14774-3-2009?srsltid=AfmBOoqY_JDNmpZmnaVY_wH2nswcTm64b8JO56-eysIKMDwuLr_mHygj (accessed on 22 May 2025).

- EN 15104:2011; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen—Instrumental Methods. Brussels, Belgium, 2015. Available online: https://standards.iteh.ai/catalog/standards/cen/8284c803-422b-409a-891e-5d4859ba52a5/en-15104-2011?srsltid=AfmBOooY0tWNQQi7wryedVT2mZICGzZ3ACtujwcj9lORWrcn5ppp56mE (accessed on 22 May 2025).

- EN 15148:2009; Solid Biofuels—Determination of the Content of Volatile Matter. Brussels, Belgium, 2015. Available online: https://standards.iteh.ai/catalog/standards/cen/7535bbc8-6cd4-4062-96c6-55a383dfd9a1/en-15148-2009?srsltid=AfmBOoqc6_XfqaJjr2n7XYlLusSsa279J7OsgnHIA7waWTHJnpnO6K7U (accessed on 22 May 2025).

- Lama-Muñoz, A.; Contreras, M.d.M.; Espínola, F.; Moya, M.; Romero, I.; Castro, E. Characterization of the lignocellulosic and sugars composition of different olive leaves cultivars. Food Chem. 2020, 329, 127153. [Google Scholar] [CrossRef]

- Freitas, L.; Simões, R.; Miranda, I.; Peres, F.; Ferreira-Dias, S. Optimization of Autohydrolysis of Olive Pomaces to Obtain Bioactive Oligosaccharides: The Effect of Cultivar and Fruit Ripening. Catalysts 2022, 12, 788. [Google Scholar] [CrossRef]

- Nebyvaev, A.; Klimov, D.; Ryzhenkov, A.; Brulé, M. Preliminary Results of Innovative Two-Stage Torrefaction Technology Applied for Thermochemical Treatment of Sunflower Husk. Processes 2023, 11, 2486. [Google Scholar] [CrossRef]

- Milovanov, O.; Klimov, D.; Kuzmin, S.; Grigoriev, S.; Mikhalev, A.; Isemin, R.; Brulé, M. Application of Torrefaction for Im-proved Fuel Properties of Sunflower Husks. Energies 2024, 17, 4643. [Google Scholar] [CrossRef]

- van Krevelen, D.W.; Schuyer, J. Coal Science: Aspects of Coal Constitution; Elsevier: Amsterdam, The Netherlands, 1957. [Google Scholar]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. More efficient biomass gasification via torrefaction. Energy 2006, 31, 3458–3470. [Google Scholar] [CrossRef]

- Chen, W.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Ohliger, A.; Förster, M.; Kneer, R. Torrefaction of beechwood: A parametric study including heat of reaction and grindability. Fuel 2013, 104, 607–613. [Google Scholar] [CrossRef]

- Sabil, K.M.; Aziz, M.A.; Lal, B.; Uemura, Y. Effects of torrefaction on the physiochemical properties of oil palm empty fruit bunches, mesocarp fiber and kernel shell. Biomass Bioenergy 2013, 56, 351–360. [Google Scholar] [CrossRef]

- Mohamed Abdoul-Latif, F.; Ainane, A.; Hachi, T.; Abbi, R.; Achira, M.; Abourriche, A.; Brulé, M.; Ainane, T. Materials Derived from Olive Pomace as Effective Bioadsorbents for the Process of Removing Total Phenols from Oil Mill Effluents. Molecules 2023, 28, 4310. [Google Scholar] [CrossRef]

- Mukhin, V.M.; Bogdanovich, N.I. Activated carbons from vegetable waste. J. Adv. Mater. Technol. 2022, 7, 135–148. [Google Scholar] [CrossRef]

- Memetova, A.E.; Memetov, N.R.; Zelenin, A.D. Evaluation of adsorption properties of a porous carbon material from coffee waste. Image J. Adv. Mater. Technol. 2023, 8, 207–216. [Google Scholar] [CrossRef]

- Timirgaliev, A.N.; Burakova, I.V.; Rybakova, S.O.; Ananyeva, O.A.; Yarkin, V.O.; Kuznetsova, S.T.; Kadum, A.H.K.; Burakov, A.E. Removal of organic dyes from aqueous solutions using a graphene-containing sorbent based on activated rapeseed biochar: Kinetics and isotherms. Image J. Adv. Mater. Technol. 2024, 9, 177–187. [Google Scholar] [CrossRef]

- Borrero-López, A.M.; Fierro, V.; Jeder, A.; Ouederni, A.; Masson, E.; Celzard, A. High added-value products from the hydro-thermal carbonisation of olive stones. Process Eng. Pollut. Control. Waste Minimization 2016, 24, 9859–9869. [Google Scholar] [CrossRef]

- Acharya, B.; Dutta, A.; Minaret, J. Review on comparative study of dry and wet torrefaction. Sustain. Energy Technol. Assess. 2015, 12, 26–37. [Google Scholar] [CrossRef]

| Biomass Type | Measured Parameter | Raw Biomass | Operational Conditions of Dry Torrefaction | |||

|---|---|---|---|---|---|---|

| 200 °C 80 min | 200 °C 120 min | 230 °C 60 min | 230 °C 80 min | |||

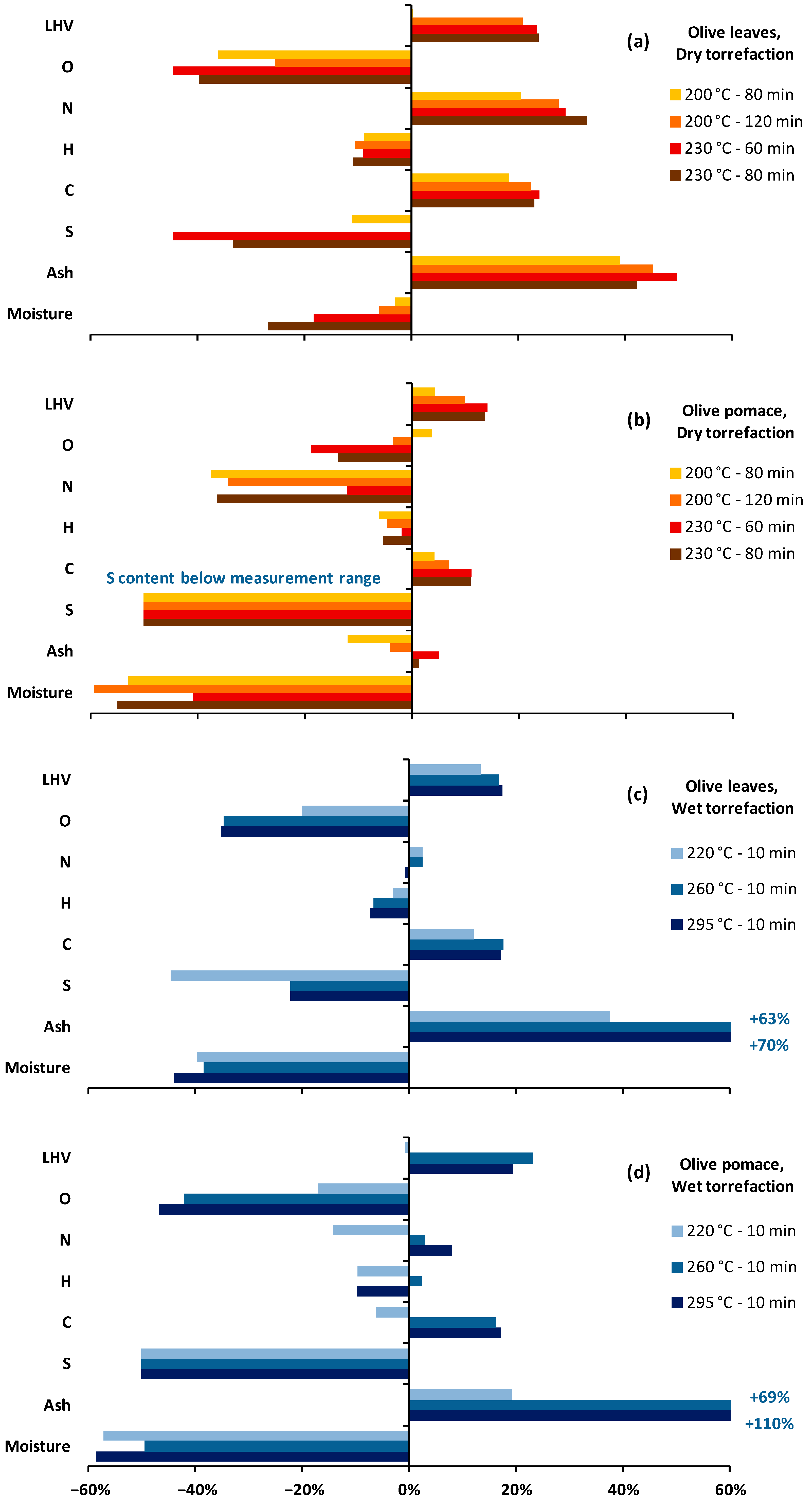

| Olive leaves | Moisture, % | 5.67 | 5.5 | 5.33 | 4.64 | 4.15 |

| Ash, % | 8.41 | 11.7 | 12.21 | 12.58 | 11.96 | |

| S, % | 0.09 | 0.08 | 0.09 | 0.05 | 0.06 | |

| C, % | 46.4 | 54.9 | 56.8 | 57.5 | 57.1 | |

| H, % | 6.23 | 5.68 | 5.57 | 5.67 | 5.55 | |

| N, % | 1.56 | 1.88 | 1.99 | 2.01 | 2.07 | |

| O, % | 31.64 | 20.26 | 23.58 | 17.55 | 19.11 | |

| LHV, MJ/kg Mass yield, % | 17.96 100 | 18.01 84.2 | 21.7 73.8 | 22.19 80.7 | 22.23 68.4 | |

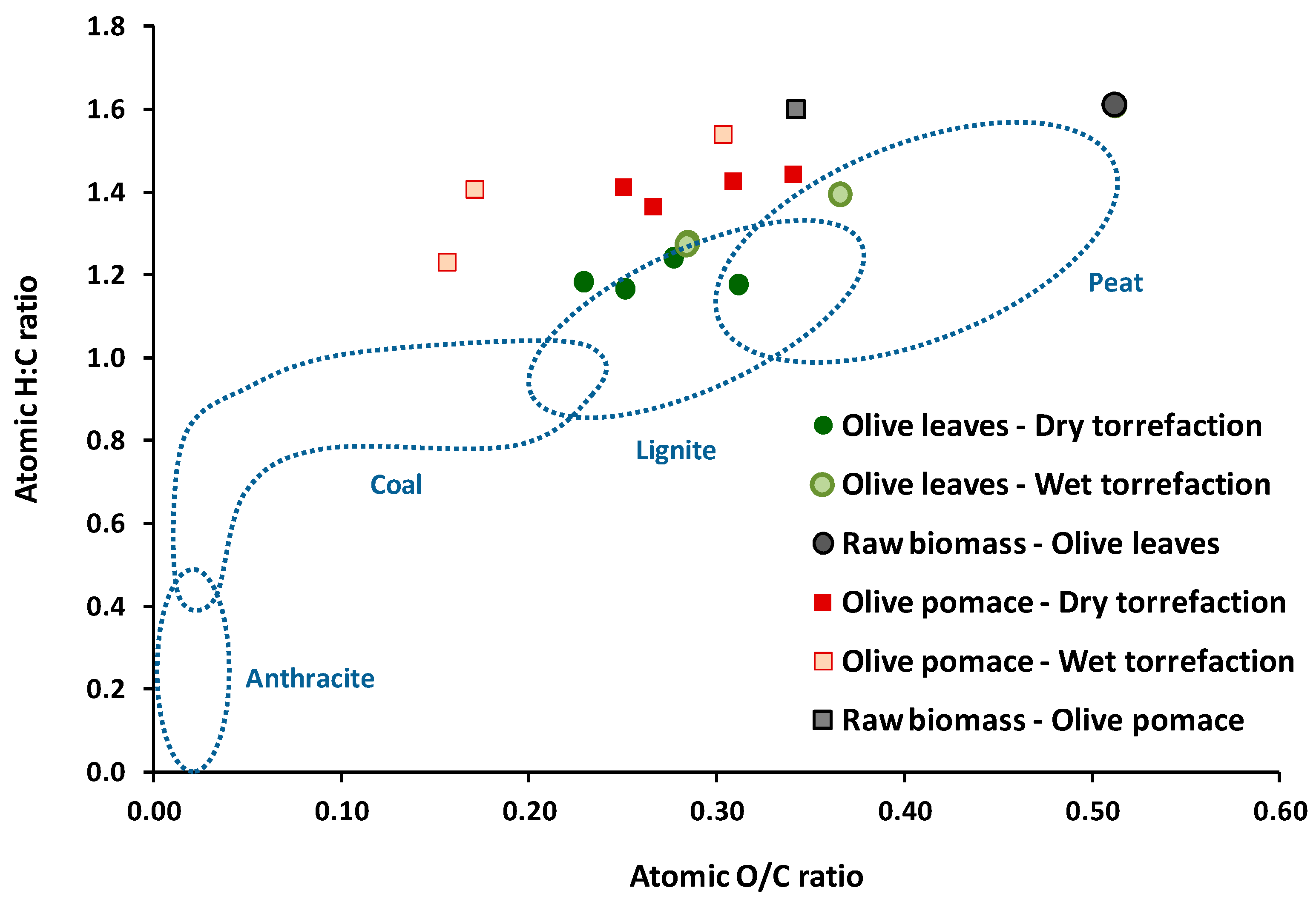

| Atomic O/C ratio | 0.51 | 0.28 | 0.31 | 0.23 | 0.25 | |

| Atomic H/C ratio | 1.61 | 1.24 | 1.18 | 1.18 | 1.17 | |

| Olive pomace | Moisture, % | 3.71 | 1.75 | 1.51 | 2.2 | 1.67 |

| Ash, % | 4.69 | 4.13 | 4.50 | 4.93 | 4.76 | |

| S, % | 0.02 | <0.01 | <0.01 | <0.01 | <0.01 | |

| C, % | 57.0 | 59.4 | 61.0 | 63.4 | 63.3 | |

| H, % | 7.60 | 7.14 | 7.25 | 7.46 | 7.20 | |

| N, % | 0.99 | 0.62 | 0.65 | 0.87 | 0.63 | |

| O, % | 25.98 | 26.95 | 25.08 | 21.13 | 22.43 | |

| LHV, MJ/kg Mass yield, % | 23.16 100 | 24.20 89.3 | 25.46 76.5 | 26.46 86.4 | 26.33 70.8 | |

| Atomic O/C ratio | 0.34 | 0.34 | 0.31 | 0.25 | 0.27 | |

| Atomic H/C ratio | 1.60 | 1.44 | 1.43 | 1.41 | 1.36 | |

| Biomass Type | Measured Parameter | Raw Biomass | Operational Conditions of Wet Torrefaction | ||

|---|---|---|---|---|---|

| 220 °C 10 min | 260 °C 10 min | 295 °C 10 min | |||

| Olive leaves | Moisture, % | 5.67 | 3.42 | 3.49 | 3.18 |

| Ash, % | 8.41 | 11.57 | 13.75 | 14.37 | |

| S, % | 0.09 | 0.05 | 0.07 | 0.07 | |

| C, % | 46.4 | 52.0 | 54.6 | 54.4 | |

| H, % | 6.23 | 6.05 | 5.82 | 5.78 | |

| N, % | 1.56 | 1.60 | 1.60 | 1.55 | |

| O, % | 31.64 | 25.31 | 20.67 | 20.55 | |

| LHV, MJ/kg Mass yield, % | 17.96 100 | 20.36 77.3 | 20.98 72.2 | 21.10 60.7 | |

| Atomic O/C ratio | 0.51 | 0.37 | 0.28 | 0.28 | |

| Atomic H/C ratio | 1.61 | 1.40 | 1.28 | 1.28 | |

| Olive pomace | Moisture, % | 3.71 | 1.59 | 1.88 | 1.54 |

| Ash, % | 4.69 | 5.59 | 7.94 | 9.86 | |

| S, % | 0.02 | <0.01 | <0.01 | <0.01 | |

| C, % | 57.0 | 53.5 | 66.3 | 66.8 | |

| H, % | 7.60 | 6.87 | 7.78 | 6.86 | |

| N, % | 0.99 | 0.85 | 1.02 | 1.07 | |

| O, % | 25.98 | 21.59 | 15.07 | 13.86 | |

| LHV, MJ/kg Mass yield, % | 23.16 100 | 23.03 75.3 | 28.51 70.2 | 27.67 58.2 | |

| Atomic O/C ratio | 0.34 | 0.30 | 0.17 | 0.16 | |

| Atomic H/C ratio | 1.60 | 1.54 | 1.41 | 1.23 | |

| Processing Conditions of Dry Torrefaction | Contents and Yield of 5-HMF and FU in Torrefaction Condensate | |||||

|---|---|---|---|---|---|---|

| Biomass Type | Processing Temperature | Processing Time | Content of 5-HMF, mg/kg | Yield of 5-HMF, % | Content of FU, mg/kg | Yield of FU, % |

| Olive leaves | 200 °C | 80 min | 284.0 | 3.3 | 341.4 | 4.58 |

| 120 min | 174.3 | 2.0 | 127.8 | 1.71 | ||

| 230 °C | 60 min | 163.1 | 1.9 | 208.8 | 2.45 | |

| 80 min | 165.3 | 1.9 | 143.6 | 1.7 | ||

| Olive pomace | 200 °C | 80 min | 1930.6 | 0.88 | 1880.3 | 0.752 |

| 120 min | 915.1 | 0.42 | 370.8 | 0.015 | ||

| 230 °C | 60 min | 1465.8 | 0.66 | 189.0 | 0.08 | |

| 80 min | 685.1 | 0.31 | 251.4 | 0.1 | ||

| Processing Conditions of Wet Torrefaction | Contents and Yield of 5-HMF and FU in Torrefaction Condensate | |||||

|---|---|---|---|---|---|---|

| Biomass Type | Processing Temperature | Processing Time | Content of 5-HMF, mg/kg | Yield of 5-HMF, % | Content of FU, mg/kg | Yield of FU, % |

| Olive leaves | 220 °C | 10 min | 48.8 | 0.06 | 43.5 | 0.58 |

| 260 °C | 10 min | 34.4 | 0.04 | 48.7 | 0.065 | |

| 295 °C | 10 min | 181.9 | 2.13 | 151.6 | 2.03 | |

| Olive pomace | 220 °C | 10 min | 11.0 | 0.005 | 26.8 | 0.01 |

| 260 °C | 10 min | 9.5 | 0.0043 | 49.3 | 0.02 | |

| 295 °C | 10 min | 8.2 | 0.0037 | 91.6 | 0.04 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Isemin, R.; Mikhalev, A.; Kuzmin, S.; Brulé, M.; Ainane, T.; Milovanov, O.; Klimov, D.; Milovanov, K. Comparison of Dry and Wet Torrefaction for Biochar Production from Olive Leaves and Olive Pomace. Processes 2025, 13, 2155. https://doi.org/10.3390/pr13072155

Isemin R, Mikhalev A, Kuzmin S, Brulé M, Ainane T, Milovanov O, Klimov D, Milovanov K. Comparison of Dry and Wet Torrefaction for Biochar Production from Olive Leaves and Olive Pomace. Processes. 2025; 13(7):2155. https://doi.org/10.3390/pr13072155

Chicago/Turabian StyleIsemin, Rafail, Alexander Mikhalev, Sergey Kuzmin, Mathieu Brulé, Tarik Ainane, Oleg Milovanov, Dmitry Klimov, and Kirill Milovanov. 2025. "Comparison of Dry and Wet Torrefaction for Biochar Production from Olive Leaves and Olive Pomace" Processes 13, no. 7: 2155. https://doi.org/10.3390/pr13072155

APA StyleIsemin, R., Mikhalev, A., Kuzmin, S., Brulé, M., Ainane, T., Milovanov, O., Klimov, D., & Milovanov, K. (2025). Comparison of Dry and Wet Torrefaction for Biochar Production from Olive Leaves and Olive Pomace. Processes, 13(7), 2155. https://doi.org/10.3390/pr13072155