Carbon Emission Accounting and Identifying Influencing Factors of UHV Project Based on Material List

Abstract

1. Introduction

2. UHV Carbon Emission Calculation Model

2.1. Carbon Emission Estimation Boundary of UHV Projects

2.2. Construction of the Carbon Emission Accounting Model

3. Analysis of Influencing Factors of Carbon Emissions of UHV Projects

3.1. Extraction of Influencing Factors

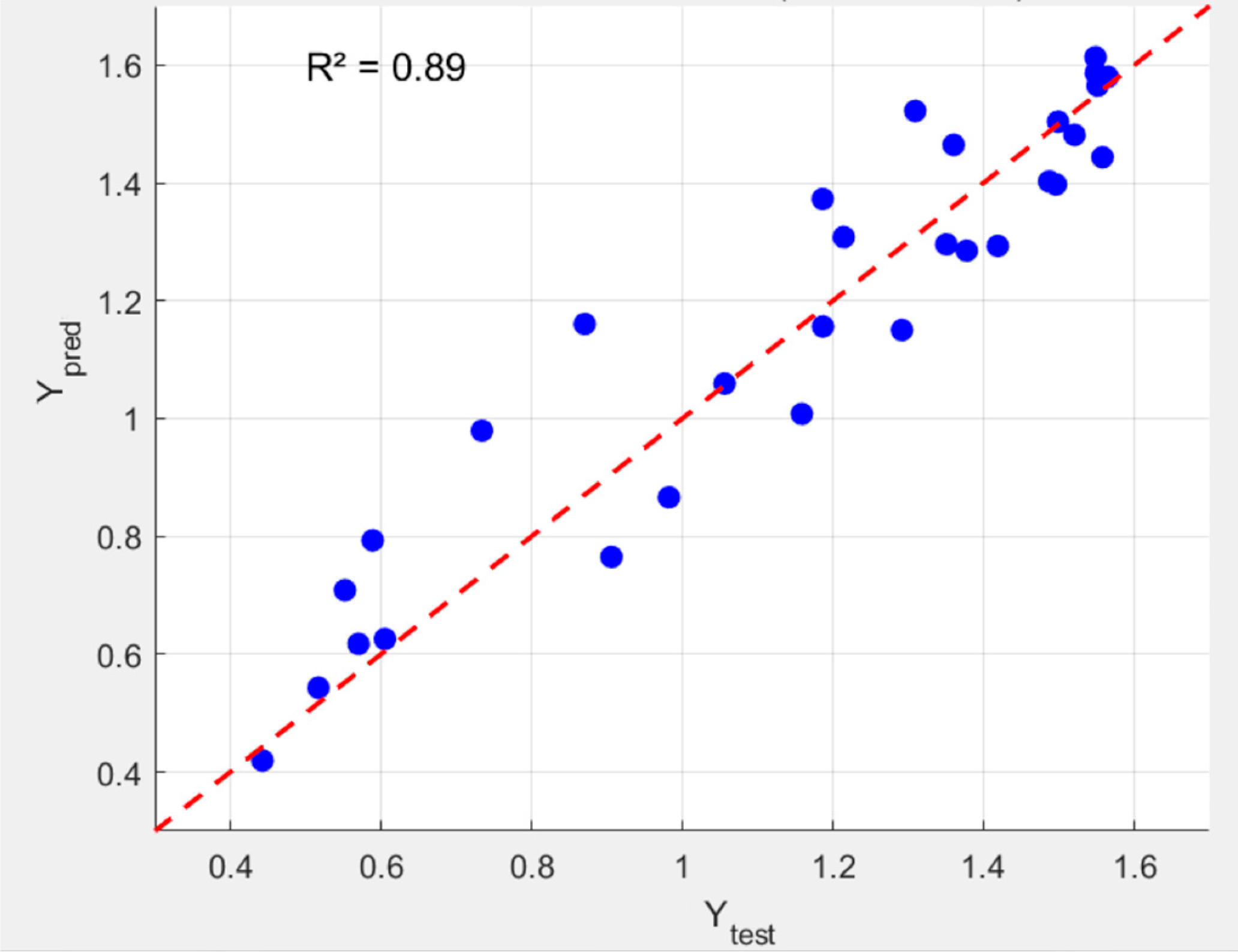

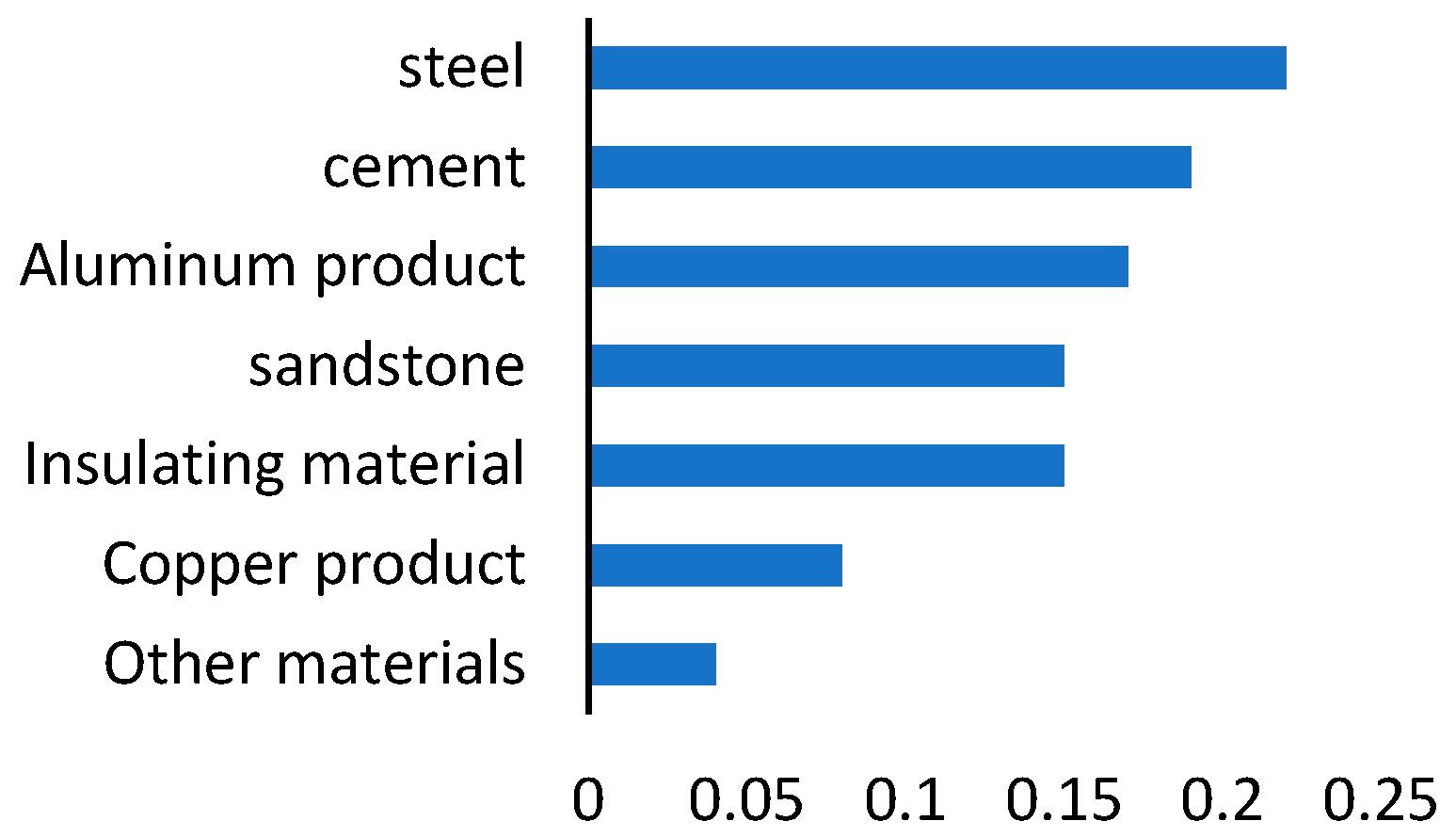

3.2. Identification of the Key Influencing Factors

3.3. Identification of Key Factors Affecting Carbon Emissions

4. Case Analysis

4.1. Project Overview and Data

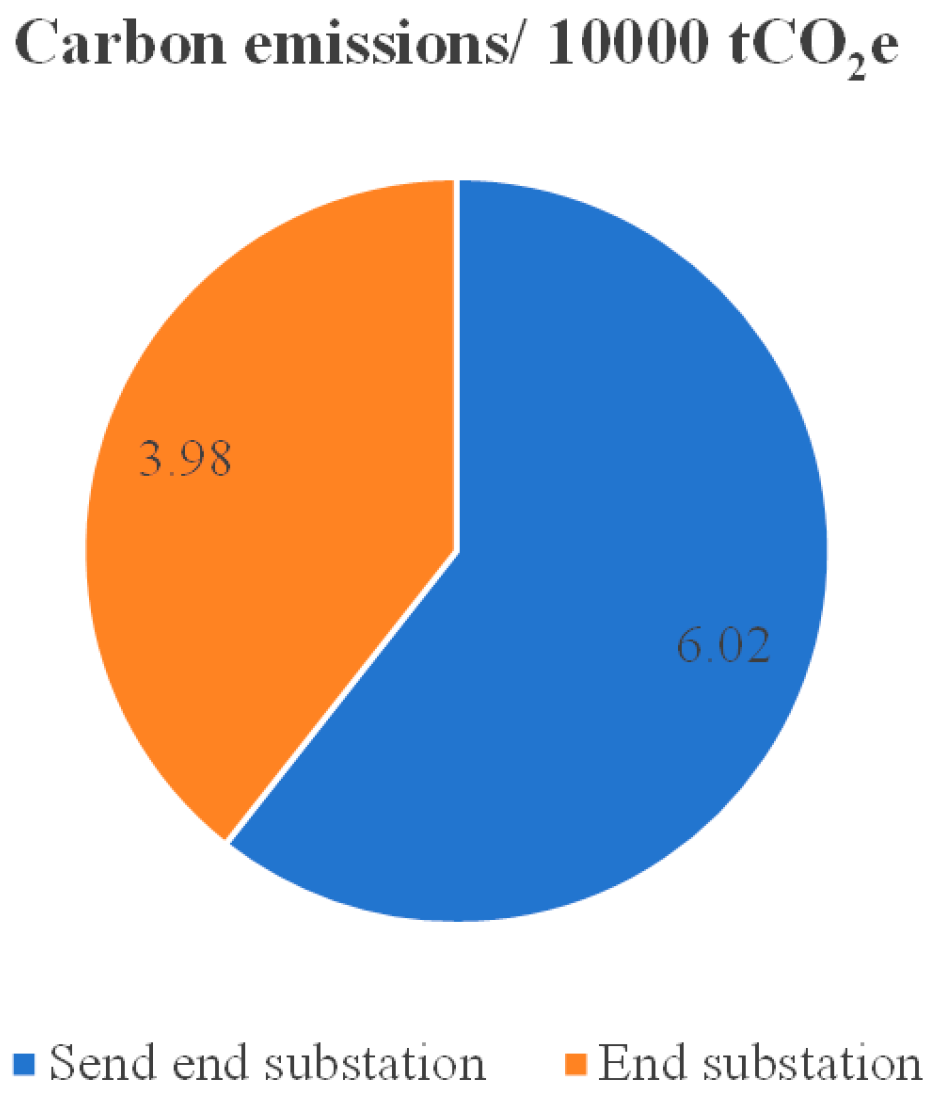

4.2. Carbon Emission Assessment Results of the UHV Project

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Wang, Z.; Zhou, S.; Lu, B.; Dai, W.; Bao, H. Optimal planning energy storage for promoting renewable power consumption in the urgent situation of UHV systems. Int. J. Electr. Power Energy Syst. 2022, 143, 108453. [Google Scholar] [CrossRef]

- Tan, X.; Lin, S.; Liu, Y.; Xie, B. Has the inter-regional transmission expansion promoted the low-carbon transition of China’s power sector. Comput. Ind. Eng. 2022, 168, 108059. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Lin, W.; Wei, W. Transregional electricity transmission and carbon emissions: Evidence from ultra-high voltage transmission projects in China. Energy Econ. 2023, 123, 106751. [Google Scholar] [CrossRef]

- Chang, H.; Ma, S.; Chiang, Y.; Lai, C. The effects of structural design alternatives on the embodied carbon emissions of steel buildings. J. Build. Eng. 2025, 99, 111603. [Google Scholar] [CrossRef]

- Greer, F.; Horvath, A. Exploring the significance of transportation emissions in upfront embodied carbon in buildings. Build. Environ. 2025, 269, 112457. [Google Scholar] [CrossRef]

- Tan, X.; Lin, S.; Xie, B. The distributional effect of inter-regional transmission grid expansion on China’s power industry. Clim. Change Econ. 2022, 13, 2240005. [Google Scholar] [CrossRef]

- Mori, M.; Gramc, J.; Hojkar, D.; Lotrič, A.; Smeacetto, F.; Fiorilli, S.; Fiore, S.; Stropniket, R. New life cycle inventories for end-of-life solid oxide cells based on novel recycling processes for critical solid oxide cell materials. Int. J. Hydrogen Energy 2024, 104, 635–650. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Qin, X. Impact of the ±1100 kV UHVDC Eurasia Interconnection Project on the Security and Stability of the German Power Grid at the Receiving End. Power Grid Technol. 2015, 39, 2094–2099. [Google Scholar]

- Zhang, Y.; Zhang, Z.; Zhang, Y. Application of UHVDC transmission technology to realize the idea of inter-subcontinental power transmission. Power Grid Technol. 2015, 39, 2069–2075. [Google Scholar]

- Chen, X.; Fu, Y.; Huang, C. Method and application of carbon emission calculation for ultra-high voltage (UHV) project construction. Resour. Sci. 2023, 45, 2291–2310. [Google Scholar] [CrossRef]

- Ulanov, V.L. The Need for the Green Economy Factors in Assessing the Development and Growth of Russian Raw Materials Companies. J. Compr. Bus. Adm. Res. 2024, 1, 19–26. [Google Scholar] [CrossRef]

- Qi, J.; Wang, Y.; Xu, P.; Hu, M.; Huhe, T.; Ling, X.; Yuan, H.; Li, J.; Chen, Y. Coupling of molten salt heating tire pyrolysis process with carbon black modification process: Technical economic evaluation and life cycle assessment. J. Clean. Prod. 2025, 486, 144454. [Google Scholar] [CrossRef]

- Wei, X.; Tan, X.; Lin, M.; Cheng, J.; Xiang, K.; Ding, S. Calculation and prediction of carbon emission factors for the national power grid from 2005 to 2035. Integr. Intell. Energy 2024, 46, 72–78. [Google Scholar]

- Feng, R.; Hu, L.; Hu, X.; Fang, X. Knowledge gaps are making it harder to formulate national climate policies. Proc. Natl. Acad. Sci. USA 2023, 120, e2218563120. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Du, G.; Xie, B. CO2 emission changes of China’s power generation system: Input- output subsystem analysis. Energy Policy 2019, 124, 1–12. [Google Scholar] [CrossRef]

- Sun, H.; Chen, Y.; Chen, S.; Zhao, Z. Promoting the “Chinese experience” of carbon neutrality—Evidence of carbon emission pilot governance in Guangdong Province based on the EIO-LCA model. Energy Strategy Rev. 2024, 53, 101393. [Google Scholar] [CrossRef]

- Canning, P.; Rehkamp, S.; Yi, J. 9—Environmental Input-Output (EIO) Models for Food Systems Research: Application and Extensions ⁎. Food Syst. Model. 2022, 1, 179–212. [Google Scholar]

- Lv, T.; Zhao, Q.; Fu, S.; Jin, G.; Zhang, X.; Hu, H.; Xu, G. Deciphering flows: Spatial correlation characteristics and factors influencing carbon emission intensity in the Yangtze River Delta. J. Clean. Prod. 2024, 483, 144290. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, G.; Zhao, Q.; Lu, Y.; Chen, J. Spatial-temporal dynamics and influencing factors of city level carbon emission of mainland China. Ecol. Indic. 2024, 167, 112672. [Google Scholar] [CrossRef]

- Fan, F.; Wang, Y.; Liu, Q. China’s carbon emissions from the electricity sector: Spatial characteristics and interregional transfer. Integr. Environ. Assess. Manag. 2022, 18, 258–273. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhang, T.; Shen, X.; Ma, X.; Hong, J. Development of life cycle assessment method. Resour. Sci. 2021, 43, 446–455. [Google Scholar] [CrossRef]

- Huang, Z.; Wen, X.; Zhu, J.; Feng, Z. Research on fault location of DC line in UHV converter station based on digital twin technology. Meas. Sens. 2024, 33, 101180. [Google Scholar] [CrossRef]

- The Construction of China’s First Ultra-High Voltage Project for Integrated Transmission of Wind, Solar, and Thermal Energy Has Been Approved. Available online: https://china.huanqiu.com/article/4C69WUXHfGW (accessed on 3 March 2025).

- Cui, P. The Establishment of a Life-Cycle Carbon Emission Factor Database for Buildings and Research. Ph.D. Thesis, Nanjing Southeast University, Nanjing, China, 2015. [Google Scholar]

- Zhu, J. Key technical challenges and innovative solutions for the construction of ultra-high voltage transmission lines across complex terrain. Constr. Mach. Technol. Manag. 2025, 38, 142–144. [Google Scholar]

- Gao, C.; Niu, J.; Wang, F. Review of carbon emission accounting methods and carbon emission factor in steel production. Contem- Porary Econ. Manag. 2021, 43, 33–38. [Google Scholar]

- Chen, J.; Chen, J.; Chen, Q.; Liu, K.; Dai, X. Nonlinear relationship model of factors influencing carbon emissions from road traffic in mountainous cities. Transp. Syst. Eng. Inf. 2024, 24, 237–245. [Google Scholar]

- Zhou, P.; Huang, H.; Ang, B.; Su, B. Input-output analysis of CO2 emissions embodied in trade: The effects of sector aggregation. Energy Econ. 2010, 32, 166–175. [Google Scholar]

- Zhang, X. Research on the Quantitative Analysis of Building Carbon Emissions and Assessment Methods for Low- Carbon Buildings and Structures. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2018. [Google Scholar]

- Huang, Y.; Liu, Y.; Xu, W.; Li, J. Life cycle carbon emissions of water reservoir and hydroelectric projects: A case study of the Quanmutang project. J. Ts-Inghua Univ. (Sci. Technol.) 2022, 62, 1366–1373. [Google Scholar]

- 2006 IPCC Guidelines for National Green Gas Inventories. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 8 June 2025).

- Standard for Building Carbon Emission Calculation. Available online: https://ndls.org.cn/standard/detail/14ff7bae82ebf95cdb72bae85a14cdbb (accessed on 8 June 2025).

- Zhang, Y.; Ren, H. Remote sensing extraction of paddy rice in Northeast China from GF-6 images by combining feature optimization and random forest. Natl. Remote Sens. Bull. 2023, 27, 2153–2164. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, T.; Shen, D. County-level spatial pattern and influencing factors evolution of carbon emission intensity in China: A random forest model analysis. China Environ. Sci. 2022, 42, 2788–2798. [Google Scholar]

- Shen, L.; Zhou, Y. Default prediction model based on optimal combination of big data variables: A case study of Chinese small enterprises. Syst. Eng.-Theory Pract. 2024, 44, 912–933. [Google Scholar]

- Sun, X. Research on Building Carbon Emission and Cost Based on Sensitivity Analysis of Carbon Reduction Technologies. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2023. [Google Scholar]

- Sun, L.; Tang, B.; Xu, P. Study on the Carbon Emission Characteristics and Carbon Reduction Potential of UHV Projects from a Life Cycle Perspective. Coal Econ. Res. 2024, 44, 43–50. [Google Scholar]

- Tang, B.; Xu, P.; Yu, F.L. Carbon Emission Accounting and Reduction Potential Assessment of Power Infrastructure—A Case Study of UHV AC Projects. Coal Econ. Res. 2024, 44, 90–99. [Google Scholar]

- Lundberg, S.; Lee, S. A unified approach to interpreting model predictions. arXiv 2017, arXiv:1705.07874. [Google Scholar]

- Long, X.; Sun, R.; Zheng, T. Liquefaction prediction model and interpretability analysis based on convolutional neural network. Geotech. Mech. 2024, 45, 2741–2753. [Google Scholar]

- Pomponi, F.; Hart, J. The greenhouse gas emissions of nuclear energy: Life cycle assessment of a European pressurised reactor. Appl. Energy 2021, 290, 116743. [Google Scholar] [CrossRef]

- Nureen, N.; Nuţă, A. Envisioning the invisible: Unleashing the interplay between green supply chain management and green human resource management: An ability-motivation-opportunity theory perspective towards environmental sustainability. J. Compr. Bus. Adm. Res. 2024, 2, 55–64. [Google Scholar] [CrossRef]

- Ding, N.; Liu, J.; Yang, J.; Yang, D. Comparative life cycle assessment of regional electricity supplies in China. Resour. Conserv. Recycl. 2017, 119, 47–59. [Google Scholar] [CrossRef]

- ISO 14064-1:2018—Greenhouse Gases. Available online: https://www.iso.org/standard/66453.html (accessed on 8 June 2025).

- Guo, J.; Kou, J. Acquirer ESG, home country policy enforcement, country distance, and cross-border mergers and acquisitions: Evidence from Chinese firms. J. Compr. Bus. Adm. Res. 2024, 2, 75–86. [Google Scholar] [CrossRef]

| Building Consumption | |||||||||

| Cement | Steel | Dinas | Iron parts | Rock wool | Coating material | ||||

| Power engineering consumption | |||||||||

| Copper products | Steel products | Aluminum alloy | Iron parts | Glass fiber-reinforced plastics | Coke | ||||

| Equipment input | |||||||||

| Electrical power unit | Building implements | ||||||||

| The construction process | |||||||||

| Material transport | Construction of construction machinery | Production process installation | Device materials | Individual work related to the site | |||||

| Other projects | |||||||||

| Land requisition immigration | Engineering management | Research experiment | Survey and design | Conservation of water and soil | Feasibility study | ||||

| Parameter | Data Sources | Scope of Application |

|---|---|---|

| EF | IPCC (2006) Guidelines [31] | Energy factors |

| ω | Building Carbon Emission Calculation Standard GB/T 51366 [32] | Materials loss rate |

| CPI | China’s annual report by the National Bureau of Statistics | Price index revised |

| Material | Carbon Emission Factors | Carbon Emission Factors | Carbon Emission Factors |

|---|---|---|---|

| Steel products | 1.9–2.3 tons of CO2/t | Iron tower, support and other structural parts | Iron-making, steelmaking, and rolling |

| Aluminum products | 8–12 tons of CO2/t | Wire and cable | High power consumption of electrolytic aluminum production |

| Copper products | 2–4 tons of CO2/t | Cable and transformer windings | Copper smelting and refining process |

| Concrete | 0.2–0.3 tons of CO2/t | Foundation and transformer substation buildings | Limestone decomposition and high-temperature calcination in cement production |

| Insulation material | Depending on the material, epoxy resin is about 5–7 tons CO2/t | Insulators and transformer insulation parts | Energy consumption and chemical reactions in the chemical production process |

| Listing Type | Project | Quantity | Project | Quantity |

|---|---|---|---|---|

| Building consumption | Steel products/t | 2372.37 | Stone/m3 | 15,902.00 |

| Sand/m3 | 14,159.94 | Stainless steel/t | 10.86 | |

| Galvanized iron/t | 1112.33 | Iron/t | 217.90 | |

| Standard brick 240 × 115 × 53/Thousand pieces | 696.43 | Portland cement 32.5/t | 1686.45 | |

| Vinyl chloride plastic/m | 4620.00 | Rock wool/t | 1.20 | |

| Fiber-reinforced silicate plate/t | 5.46 | Alufer/t | 0.36 | |

| Reinforced concrete pipe/t | 1504.40 | Each type of concrete/m3 | 91,521.15 | |

| Power engineering Consumption | Alufer/t | 40.17 | Plated copper/t | 34.68 |

| Copper product/t | 61.29 | Steel products/t | 24.63 | |

| Galvanized iron/t | 289.48 | Fire-retardant coating/t | 11.55 | |

| Fire blocking/t | 6.16 | Fire separator/m2 | 5808.00 | |

| Equipment input | Electric power equipment/ten thousand yuan | 169,373.60 | Construction equipment/ten thousand yuan | 1224.00 |

| Construction process | Construction machinery/ten thousand yuan | 1330.85 | Device material/ten thousand yuan | 1135.02 |

| Installation works/ten thousand yuan | 12,460.76 | Transportation/ten thousand yuan | 1122.00 | |

| Other expenses | Site requisition/ten thousand yuan | 17,548.41 | Project construction technical service/ten thousand yuan | 3847.72 |

| Production preparation/ten thousand yuan | 3259.20 | Project construction management/ten thousand yuan | 1923.98 |

| Listing Type | Project | Quantity | Project | Quantity |

|---|---|---|---|---|

| Building consumption | Steel products/t | 604.00 | Stone/m3 | 18,789.39 |

| Sand/m3 | 3550.98 | Iron/t | 217.54 | |

| Galvanized iron/t | 289.08 | Portland cement/t | 1231.73 | |

| Chlorinated polyethylene rubber/m3 | 185.10 | Quartz vitrified floor tiles/m2 | 926.23 | |

| Each type of concrete/m3 | 12.36 | Alufer/t | 11.41 | |

| Power engineering consumption | Alufer/t | 387.10 | Plated copper/t | 104.78 |

| Copper product/t | 21.04 | Steel products/t | 93.73 | |

| Galvanized iron/t | 26.32 | Fire-retardant coating/t | 20.37 | |

| Fire blocking/t | 83.37 | Fire separator/m2 | 5414.75 | |

| Equipment input | Electric power equipment/ten thousand yuan | 42,354.40 | Construction equipment/ten thousand yuan | 1983.97 |

| Construction process | Construction machinery/ten thousand yuan | 343.71 | Device material/ten thousand yuan | 3618.05 |

| Installation works/ten thousand yuan | 3126.19 | Transportation/ten thousand yuan | 1132.10 | |

| Other expenses | Site requisition/ten thousand yuan | 4398.10 | Project construction technical service/ten thousand yuan | 4407.28 |

| Production preparation/ten thousand yuan | 825.80 | Project construction management/ten thousand yuan | 2764.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, H.; Dan, G.; Li, P.; Wang, S.; Qie, X.; Sun, Y.; Xin, C.; Chen, T. Carbon Emission Accounting and Identifying Influencing Factors of UHV Project Based on Material List. Processes 2025, 13, 2007. https://doi.org/10.3390/pr13072007

Huo H, Dan G, Li P, Wang S, Qie X, Sun Y, Xin C, Chen T. Carbon Emission Accounting and Identifying Influencing Factors of UHV Project Based on Material List. Processes. 2025; 13(7):2007. https://doi.org/10.3390/pr13072007

Chicago/Turabian StyleHuo, Huijuan, Gang Dan, Peidong Li, Shuo Wang, Xin Qie, Yaqi Sun, Cheng Xin, and Tianqiong Chen. 2025. "Carbon Emission Accounting and Identifying Influencing Factors of UHV Project Based on Material List" Processes 13, no. 7: 2007. https://doi.org/10.3390/pr13072007

APA StyleHuo, H., Dan, G., Li, P., Wang, S., Qie, X., Sun, Y., Xin, C., & Chen, T. (2025). Carbon Emission Accounting and Identifying Influencing Factors of UHV Project Based on Material List. Processes, 13(7), 2007. https://doi.org/10.3390/pr13072007