Abstract

Based on the engineering conditions of the 1303 working face in Zhaoxian Coal Mine, this study investigates the characteristics of mine pressure behavior and the stress-relief mechanism of advanced presplit blasting in a working face with a thick and hard roof in an extra-thick coal seam. Through a combination of numerical simulations and field experiments, the effects of advanced presplit blasting on stress distribution, roadway stability, and microseismic activity are analyzed. Corresponding mitigation measures and optimization strategies are proposed. The results indicate that the primary cause of deformation in the gob-side roadway is the superposition of lateral abutment pressure from the goaf and the front abutment pressure of the advancing working face. Advanced presplit blasting effectively reduces the magnitude of front abutment stress, inhibits its transmission, decreases the hanging area of the goaf roof, and alleviates vertical stress on the roadway side adjacent to the goaf. Furthermore, both the daily average and peak microseismic energy levels decrease as the working face approaches the advanced blasting zone. The implementation of advanced presplit blasting technology in working faces with thick and hard roofs within extra-thick coal seams significantly mitigates rockburst hazards, enhances roadway stability, and improves overall mining safety.

1. Introduction

The frequent occurrence of rockbursts in coal mines poses significant safety risks, while current monitoring and early-warning technologies remain inadequate. The underlying mechanisms of multi-field coupling-induced disasters under deep high-stress environments are still not fully understood. Moreover, traditional pressure-relief technologies demonstrate limited effectiveness in zones with high impact risk, and the reliability of intelligent prevention and control equipment requires urgent improvement.

With the progressive depletion of shallow coal resources, mining activities have extended to greater depths and intensities. High geostress, thick coal seams, and roadway excavation have collectively contributed to the increasing incidence of rockburst events [1,2,3,4,5,6]. In the “10.20” Longdan Coal Mine accident in 2018, high in situ stress was identified as a primary cause. The “6.9” Longjiapu Coal Mine incident in 2019 involved mining depths of 854.4–978.4 m and significant stress concentration due to the presence of the F13 fault. The “8.2” Tangshan Mine accident occurred in a peninsula-shaped coal pillar region influenced by the Fv fault and adjacent goafs, where superimposed tectonic and mining-induced stresses triggered failure. The “2.22” Longyan Coal Mine accident in 2020 further underscored the hazards of deep mining. In 2021, the “10.7” incident at Lushan No. 2 Mine and the “10.11” event at Hujiahe Coal Mine were linked to inadequate monitoring of borehole cuttings and failure to address collapsed pressure-relief holes. Most recently, on “11.28” in 2023, a severe rockburst occurred at Longshuangyang Coal Mine in Heilongjiang Province. Collectively, these accidents resulted in 59 fatalities and over 100 injuries [7,8,9,10].

With China’s coal development strategy shifting, rockburst disasters are no longer confined to the old mining areas in the east; deep mines in the western region are now increasingly being affected [11]. Consequently, rockburst has become the most severe dynamic disaster threatening coal mine safety in China [12]. According to statistics, there are 146 rockburst-prone coal mines nationwide, and 95% of related accidents over the past decade have occurred in roadways. Thus, roadway control in these mines is critical for safe production [13,14,15,16]. From a safety perspective, presplit blasting control technology has proven effective in reducing the environmental impact of blasting. It minimizes overbreak and underbreak, allowing the final excavation profile to more closely match the design, thereby reducing the risk of collapse. As a major dynamic hazard in deep coal mining, rockburst prevention has seen significant advances in mechanism understanding, monitoring, and control technologies, both domestically and internationally, although challenges remain [17,18,19,20]. Early theories emphasized coal and rock mass strength, stiffness, and elastic strain energy release [21,22,23,24]. Chinese researchers further developed the “three-factor” theory—based on the impact tendency of coal and rock, stress environment, and structural conditions—and the concept of dynamic−static load superposition, which deepened insights into impact initiation mechanisms and energy evolution processes [25,26]. While international efforts focus on regional stress regulation (e.g., protective seam mining), China has established a comprehensive prevention and control framework combining regional and localized measures. These include coal seam water injection, roof hydraulic fracturing, large-diameter pressure-relief drilling, and the development of intelligent support systems (e.g., constant-resistance bolts) [27,28,29]. In recent years, presplit blasting technology has evolved from traditional approaches to more efficient and intelligent systems. Whole-layer presplitting of high-level key strata has been shown to significantly reduce elastic energy accumulation and microseismic activity by weakening thick and hard roof structures [30,31]. For example, at Danjiacun Coal Mine, deep-hole pre-splitting effectively relieved stress concentration and reduced impact risk through optimized drilling layout. Ground-level segmented fracturing technology further overcomes underground construction limitations and enables large-scale roof weakening.

At Zhaoxian Coal Mine’s 1303 working face, a structurally intact thick sandstone roof is present. Its periodic rupture and collapse generate intense dynamic loads and cause stress concentration in front of the working face. Therefore, investigating the spatial structural evolution and fracture mechanisms of the thick sandstone roof is of great significance. Implementing presplit blasting control measures for such hard roofs can effectively attenuate energy release and enhance mining safety during retreat operations.

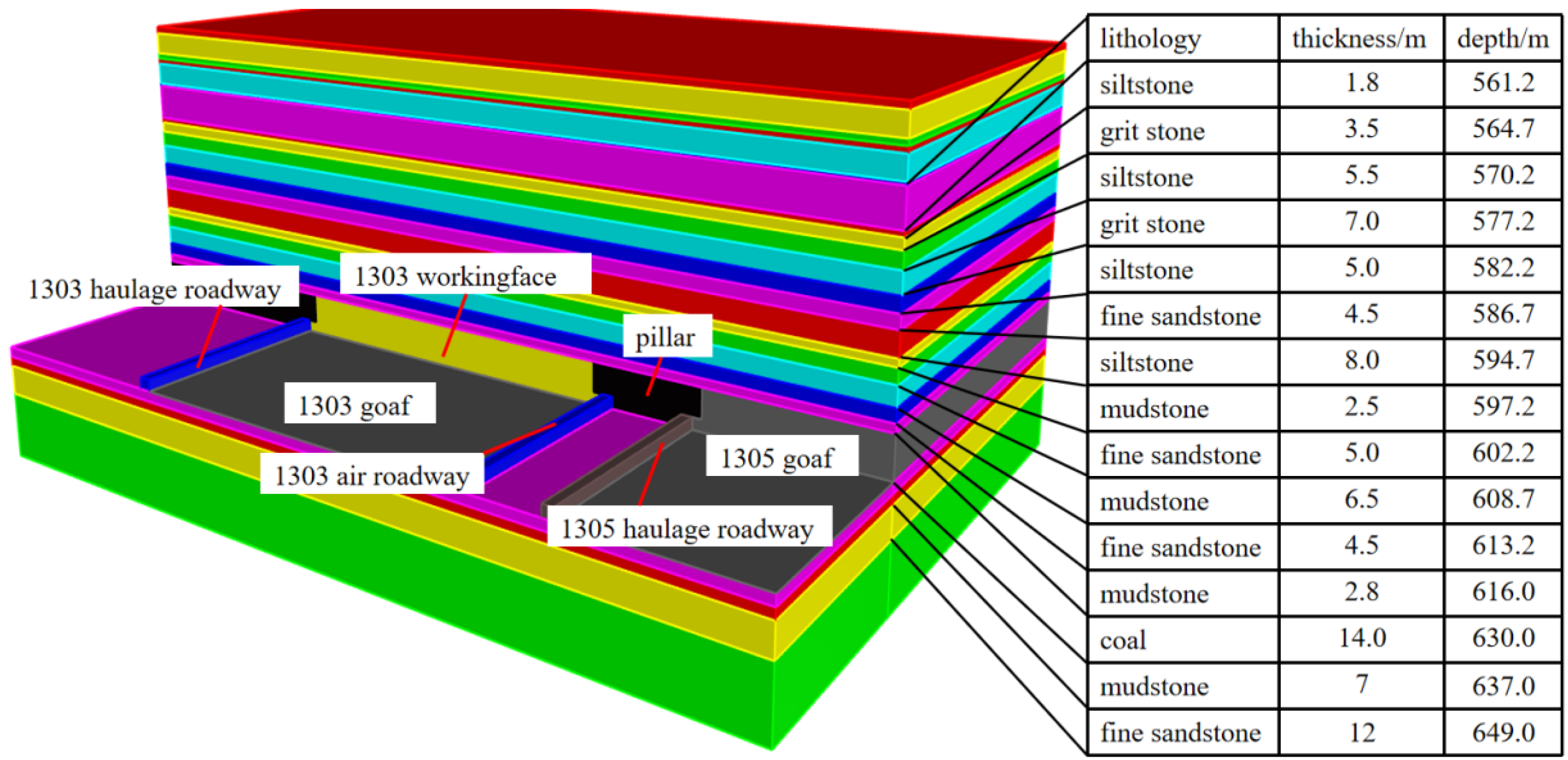

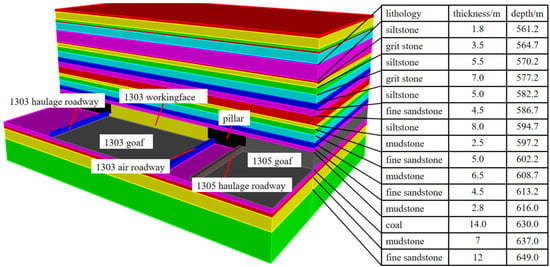

2. Geological Conditions

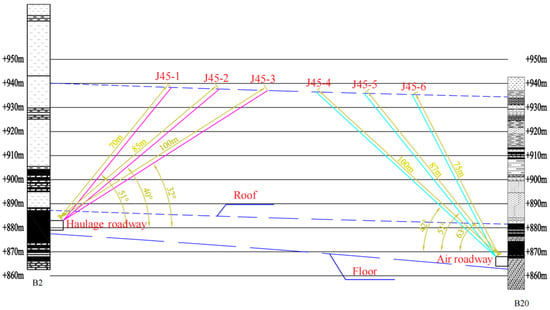

The 1303 working face of Zhaoxian Coal Mine is located on the east wing of the first mining district, adjacent to the 1305 working face. The mineable strike length is 755 m, with an inclined width of 180 m and a burial depth ranging from 556 m to 658 m. The average coal seam thickness is approximately 14 m. The layout of the working face is illustrated in Figure 1. The immediate roof above the coal seam consists of fine-grained and coarse-grained sandstone with a total thickness of approximately 20 m, while the immediate floor comprises siltstone and fine sandstone with a thickness of around 12.0 m. The presence of thick and hard roof and floor strata significantly increases the likelihood of impact ground pressure events. The adjacent 1305 working face has already been mined, with a mining height of 9.9 m. During its six-month extraction period, a total of 438 microseismic events with energy releases exceeding 104 J were recorded, indicating a high rockburst hazard. Based on the comprehensive index method, the impact risk index of the 1303 working face is calculated to be 0.52, classifying it as a medium-impact hazard zone.

Figure 1.

Layout of the 1303 working face in Zhaoxian Coal Mine.

To mitigate the problems of high peak abutment pressure and extensive influence range ahead of the 1303 working face—both of which result in severe roadway deformation—a presplit blasting scheme was implemented. This approach involved conducting presplit blasting of the roof strata along the adjacent parallel working face to weaken the overlying structure in advance.

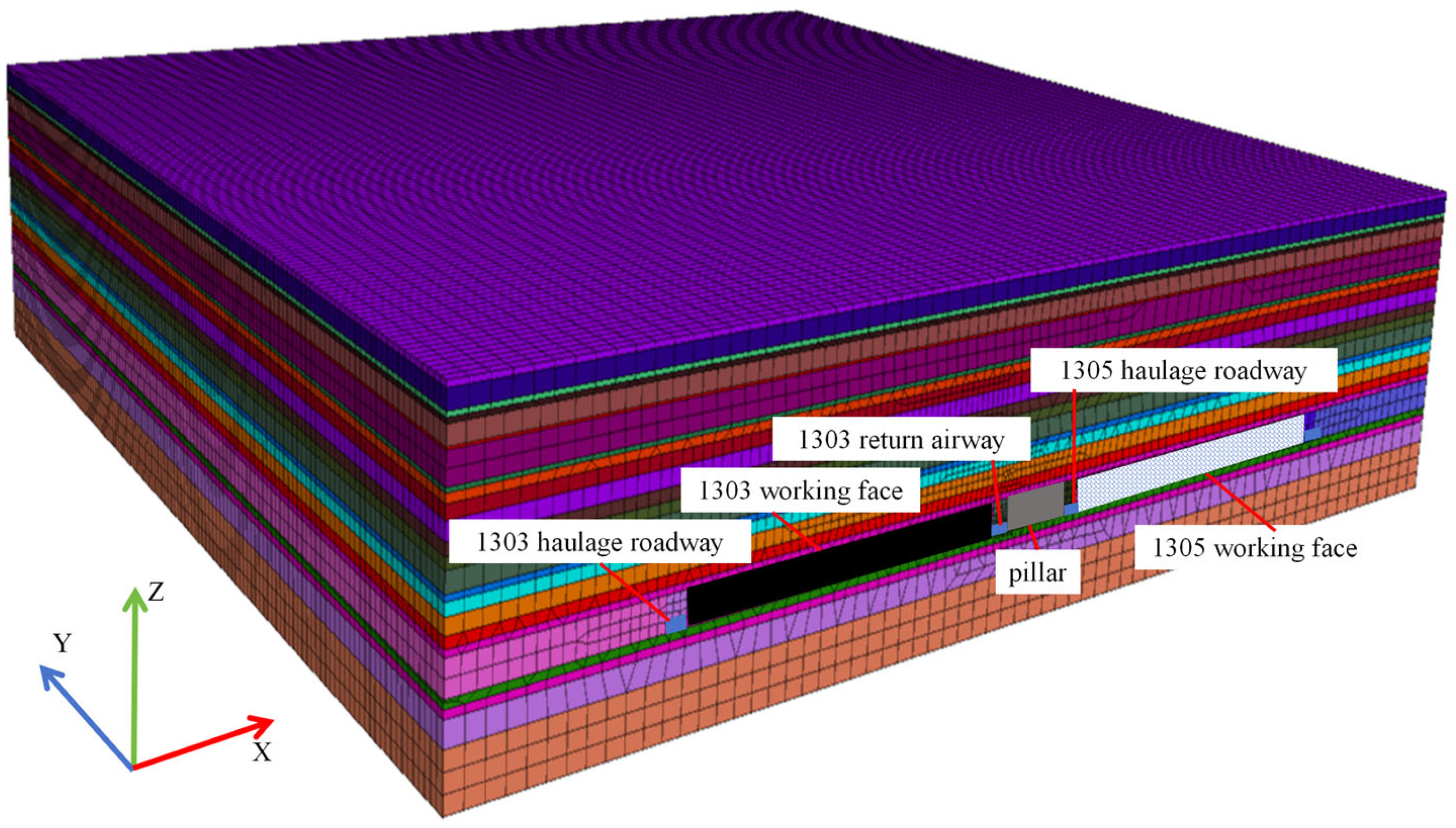

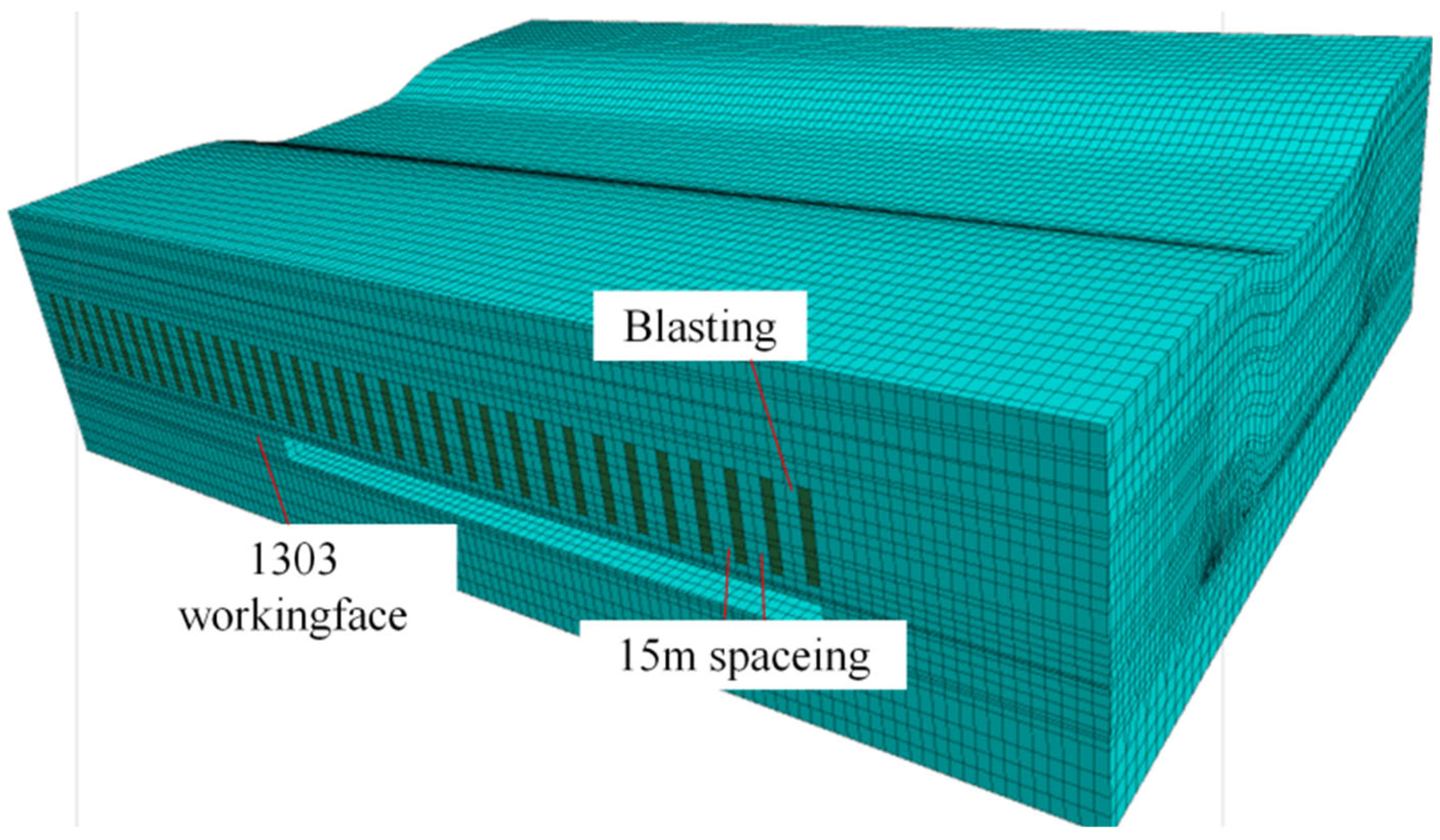

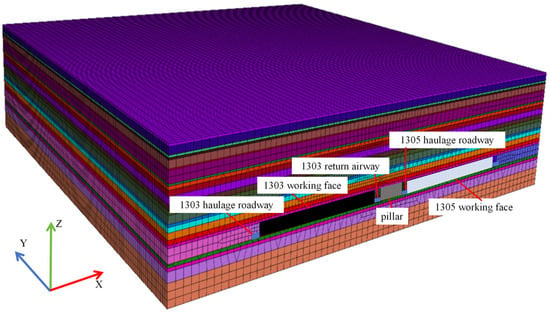

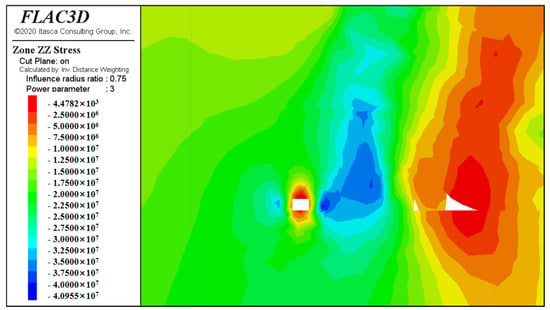

3. Numerical Simulation of Rock Transport in Thick Hard Roof Overburden of an Extra-Thick Coal Seam

FLAC3D 3.0 numerical simulation software was employed to investigate the effects of dense deep-hole presplit blasting on the working face and return airway under different borehole spacing conditions. The parameter weakening method was used to simulate blasting-induced damage in the roof strata. The numerical model, as shown in Figure 2, has dimensions of 600 m in length, 617 m in width, and 145.7 m in height. Both the 1303 and 1305 working faces are 180 m in length, separated by a 35 m wide coal pillar. To simulate the overlying rock mass, 100 m boundary zones were set on both sides of the model, including a 90 m thick rock layer above the coal seam. A compensating load of 13.59 MPa was applied at the top of the model to represent the weight of the overburden. Based on in situ stress measurements, the lateral pressure coefficient at Zhaoxian Coal Mine ranges from 1.16 to 1.71. Accordingly, the lateral pressure coefficient in the numerical model was set to 1.3. The spacing L between groups of blasting boreholes is closely related to the step length of periodic weighting and the level of impact hazard. If the spacing is too large, the pressure-relief effect becomes insufficient; if too small, the workload associated with drilling and blasting becomes excessive, negatively affecting operational efficiency and economic performance. Generally, the group spacing ranges from 10 to 20 m, with the lower bound (10 m) applied in zones with strong impact hazard, and the upper bound (20 m) used in zones with moderate or low hazard. It is recommended to align the presplit blasting area with the position of periodic weighting to maximize effectiveness. Therefore, this study simulates the effects of presplit blasting on the mining response under three different borehole spacing conditions: 10 m, 15 m, and 20 m. The three-dimensional numerical model used for the simulations is illustrated in Figure 2.

Figure 2.

Numerical simulation model.

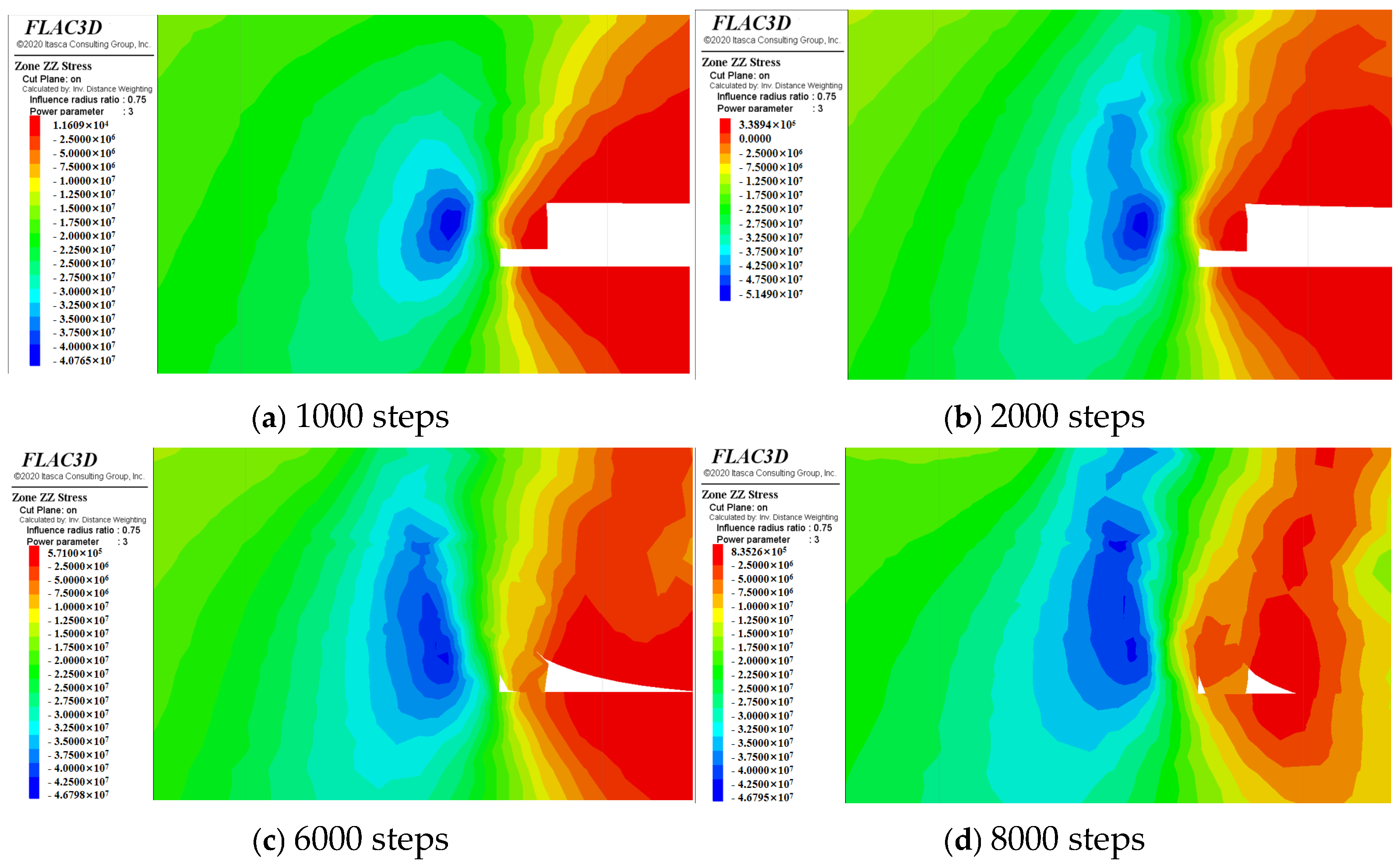

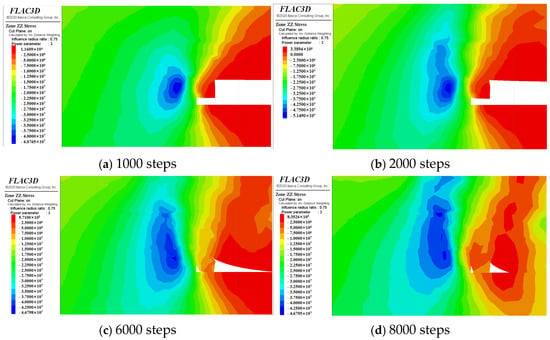

3.1. Stress Distribution and Overburden Movement Pattern in the Extraction Zone of the 1305 Working Face

To investigate the overburden migration pattern and movement state in a fully released working face, a “null model” was employed to simulate the stress redistribution after mining. The movement state of the overburden was assessed by evaluating the magnitude of the unbalanced force. As can be seen from Figure 3, the 1305 working face exhibits a symmetrical stress-deformation pattern after mining. Significant vertical stress reduction (a 40–60% decrease) and the development of tensile stress (in the range of 0.5–1.5 MPa) occur in the roof and floor strata within the gob area, confirming theoretical predictions of tensile failure at cavity boundaries. At computational step 1000, a vertical stress peak of 40.77 MPa appears 11.31 m above the coal wall beyond the panel edge, yielding a stress concentration factor of 2.58. This indicates that, during face retreat, load transfer occurs from the unsupported overburden to the adjacent coal mass. By step 2000, distinct roof deflection (8–12 mm of subsidence) is observed in the gob, and the lateral abutment pressure peaks at 51.49 MPa (concentration factor of 3.26) at a distance of 11.37 m from the face. These results verify the progressive migration of stress from the caved roof to the solid coal ribs as mining advances. At computational step 6000, the end of the working face not located beneath the top coal section makes contact with the gob. Subsequently, the roof in the caved zone subsides and contacts the underlying gangue. The peak lateral abutment pressure occurs 11.457 m from the working face, reaching 46.80 MPa with a stress concentration coefficient of 2.97. This demonstrates that after roof–gangue contact, the caved zone acquires partial bearing capacity, allowing the overburden load to be shared between the collapsed zone and the coal wall, thereby reducing the vertical pressure on the coal wall. At step 8000, the stress characteristics remain stable: the peak lateral abutment pressure is still located 11.457 m from the face, with a consistent peak stress of 46.80 MPa and concentration coefficient of 2.97.

Figure 3.

Lateral abutment pressure distribution in the 1305 working face.

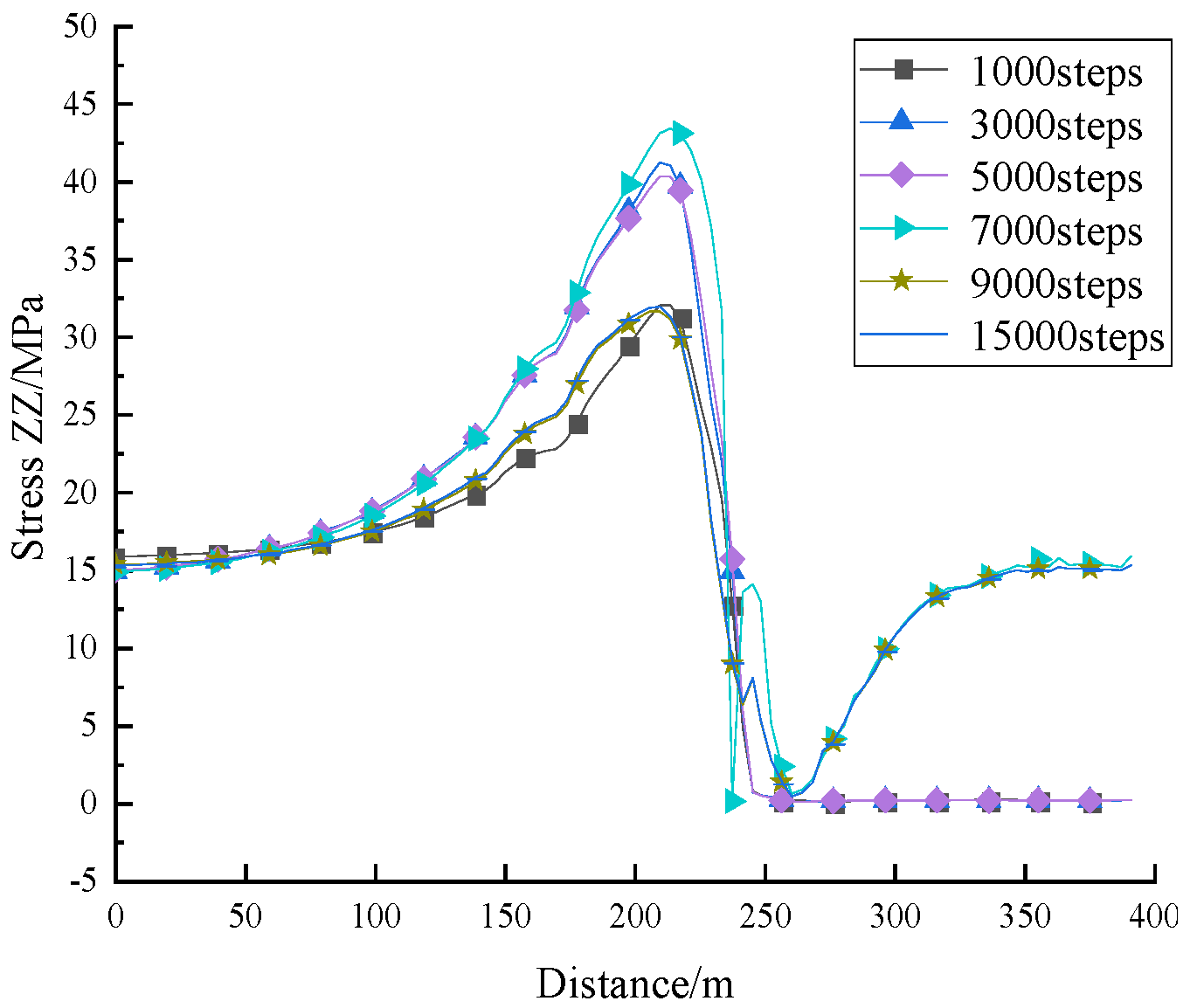

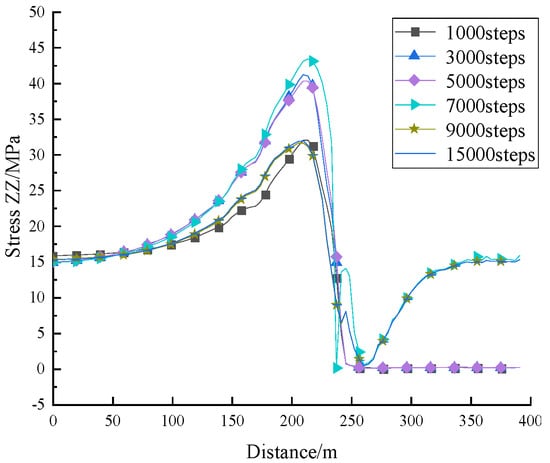

Figure 4 presents the vertical stress distribution in the floor strata. The stress evolution in the floor strata closely follows the overall stress distribution pattern of the extraction zone. At step 1000, the peak vertical stress in the coal wall floor reaches 31.83 MPa, located 15.89 m from the coal wall, while the vertical stress in the gob area is essentially zero. From step 2000 to 5000, vertical stress changes in the floor remain minimal, and the gob area continues to exhibit negligible vertical stress. At step 6000, the peak vertical stress increases to 40.57 MPa, occurring 15.08 m from the coal wall, and a maximum vertical stress of 4.01 MPa appears in the central gob area. By step 7000, the peak vertical stress further increases to 43.42 MPa, located 13.58 m from the coal wall, while the maximum vertical stress in the gob center reaches 15.3 MPa. This rise in stress is attributed to the instability caused by lateral slip and failure of the fractured roof, which leads to increased stress concentration in the coal wall region. When the computation step exceeds 8000, the vertical stress in the floor gradually decreases and tends toward stabilization. The final peak vertical stress is 31.41 MPa, located 17.32 m from the coal wall. Meanwhile, the vertical stress in the gob approaches the original in situ stress level, showing no significant variation, which indicates that the stress field in the extraction zone has reached a state of equilibrium.

Figure 4.

Vertical stress distribution in the floor strata.

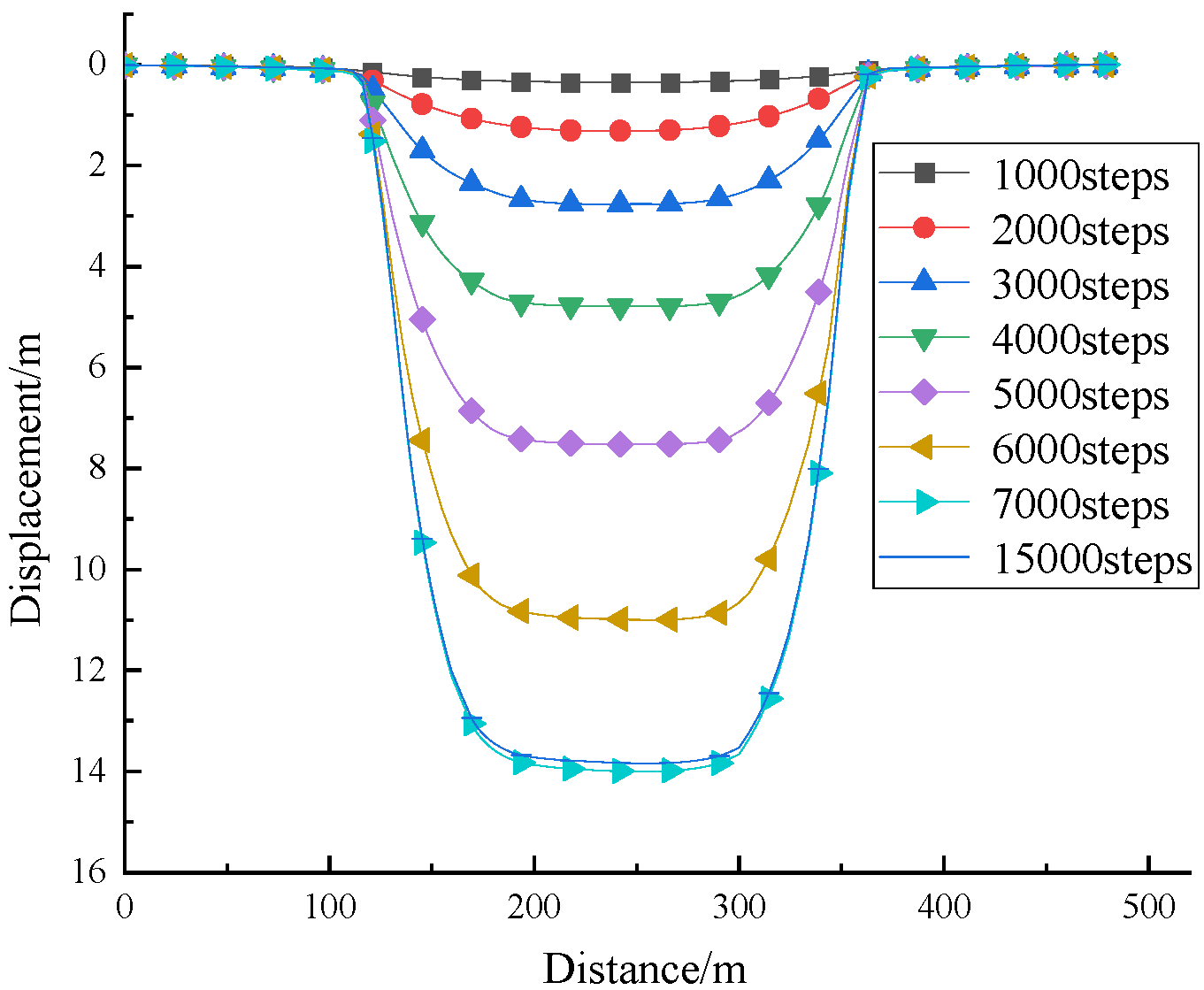

Figure 5 shows the displacement distribution of the roof strata. As illustrated in Figure 5, the roof subsidence increases progressively with the number of computational steps. The greatest subsidence occurs at the center of the gob area, while roof displacement in the solid coal rib decreases with increasing distance from the goaf. At the end of the simulation, the roof subsidence at the edge of the gob reaches 50.73 cm, whereas the subsidence is only 1.11 cm at a distance of 100 m from the coal wall. This demonstrates that the bending and sagging of the roof have a significant impact on the lateral coal and rock mass adjacent to the gob. The roof above the coal body near the gob exhibits large curvature and subsidence, resulting in strong disturbance to the surrounding rock mass. When the simulation reaches step 7000, the cumulative roof subsidence becomes approximately equal to the thickness of the coal seam. At the same time, the vertical stress at the center of the floor approaches the original in situ stress, indicating that the gob area is in a compacted and mechanically stable state.

Figure 5.

Displacement distribution of the roof strata.

After the completion of mining in the 1305 working face, a numerical simulation was conducted to evaluate the excavation of the gob-side entry along the 1303 return airway. To analyze the displacement distribution following roadway excavation and subsequent mining, the displacement field was reset to zero once mechanical equilibrium was achieved in the 1305 model. Figure 6 presents the vertical stress distribution after the excavation of the 1303 return airway. As shown in Figure 6, vertical stress concentration zones appear on both ribs of the roadway. On the solid coal side (left rib), the peak vertical stress reaches 35.16 MPa, with a stress concentration factor of 2.05, located 4.39 m from the roadway rib. Due to the superposition of lateral abutment pressure from the previously mined-out 1305 panel and the support stress induced by roadway excavation, the gob-side coal pillar rib exhibits the highest stress concentration. The peak vertical stress in this zone is 40.27 MPa, with a concentration factor of 2.56, occurring at a distance of 4.75 m from the roadway rib. Following excavation, the roof subsides by 8.89 cm, and the floor heaves by 2.76 cm. The horizontal displacements of the left and right ribs are 7.12 cm and 8.17 cm, respectively. Influenced by the high stress on the gob side, the right rib exhibits greater displacement than the left. However, due to the relatively large width of the coal pillar, the excavation has a limited impact on overburden movement, resulting in relatively minor deformation of the surrounding rock mass.

Figure 6.

Vertical stress distribution in the 1303 return airway after gob-side entry excavation.

3.2. Numerical Simulation Study on Advanced Presplit Blasting

To investigate the influence of advanced presplit blasting on the front abutment pressure and the movement behavior of overlying strata, a numerical simulation was conducted using the element strength weakening method under different blasting spacing conditions. Based on the caving zone height estimation, when the bulking coefficient is set to 1.3, the calculated height of the caving zone for a 14 m thick extra-thick coal seam reaches 46.4 m. The corresponding key stratum is KS4 coarse sandstone. Accordingly, the vertical location of the advanced presplit blasting was designed within the range of 45 m to 55 m above the coal seam to target the high-level key strata. Figure 7 shows the numerical model configured with a 15 m blasting borehole spacing.

Figure 7.

Numerical model configured with a 15 m blasting borehole spacing.

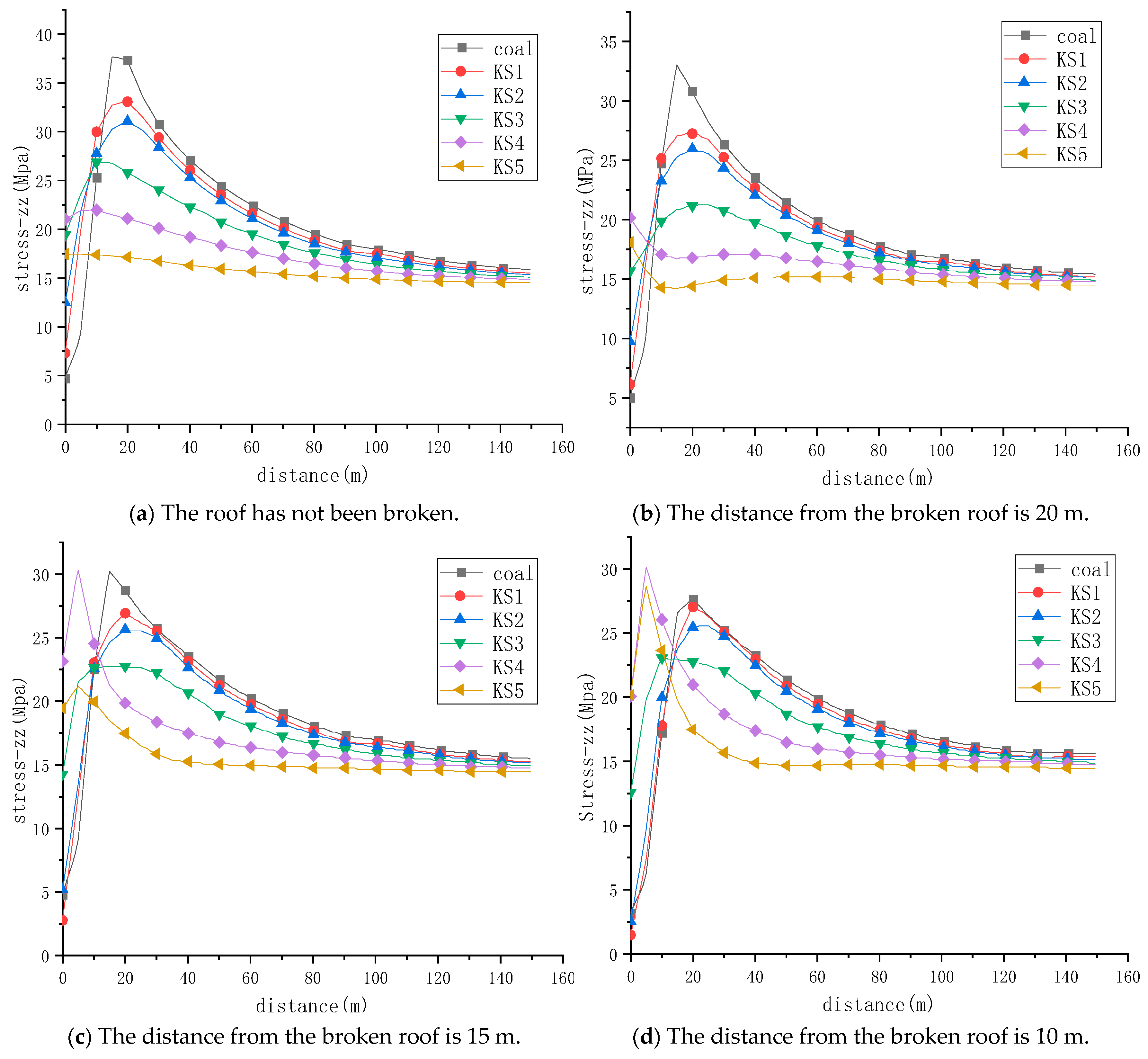

3.2.1. Influence of Blasthole Spacing on Advanced Abutment Pressure in Front of the Working Face

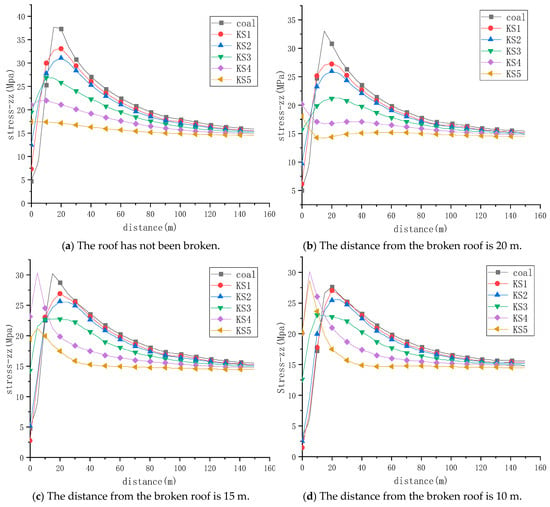

Figure 8 presents the vertical stress distribution in the overlying strata ahead of the working face after a 200 m retreat distance. Figure 8 indicates the following:

Figure 8.

Vertical stress distribution in the overlying strata ahead of the working face after a 200 m retreat distance.

- When the working face advanced 200 m, the peak vertical stress in the coal seam ahead of the face was 37.62 MPa under the intact roof condition, and 32.97 MPa, 30.19 MPa, and 29.43 MPa for roof break-off distances of 20 m, 15 m, and 10 m, respectively. Advanced presplit blasting effectively fractured the continuity of the hard overlying strata ahead of the face, thereby altering the transmission mechanism of the advanced abutment pressure and reducing the stress concentration in front of the working face. Compared to the intact roof condition, the peak advanced abutment stress reduced by 4.65 MPa, 7.52 MPa, and 7.19 MPa for roof break-off distances of 20 m, 15 m, and 10 m, corresponding to reductions of 12.36%, 17.78%, and 21.77%, respectively. When comparing between break-off distances, the peak stress under the 15 m condition was 2.78 MPa lower than that under 20 m, while the peak stress under the 10 m condition was only 0.33 MPa lower than that under 15 m. Although a 10 m break-off distance resulted in a slight additional stress reduction, the improvement was marginal, and the significantly increased number of boreholes required would impose a heavier drilling workload, negatively affecting production efficiency and economic performance.

- Advanced presplit blasting reduced the vertical stress in the lower key strata (KS1, KS2, and KS3) ahead of the working face. When the working face had advanced 200 m under intact roof conditions, the peak vertical stresses in the KS1, KS2, and KS3 layers were 33.02 MPa, 31.00 MPa, and 26.81 MPa, respectively. With a roof break-off distance of 20 m, these values decreased to 27.24 MPa, 25.88 MPa, and 21.11 MPa, representing reductions of 5.78 MPa, 5.12 MPa, and 5.70 MPa, respectively. The decrease in stress within the lower key strata significantly reduced the elastic energy stored in the surrounding coal and rock mass, which was favorable for mitigating rockburst hazards.

- In contrast, advanced presplit blasting resulted in an increase in vertical stress in the higher key strata (KS4 and KS5). At a 200 m retreat distance under intact roof conditions, the peak vertical stresses in KS4 and KS5 were 21.88 MPa and 17.34 MPa, respectively. Under a roof break-off distance of 15 m, the peak stresses increased to 30.33 MPa and 21.10 MPa, corresponding to stress increases of 8.45 MPa and 3.76 MPa. At break-off distances of 15 m and 10 m, the peak stress locations in KS4 and KS5 were concentrated directly above the working face. The magnitude of vertical stress increase in the high-level key strata grew as the break-off distance increased. Dense blasting caused full fracturing of the target key strata, enhancing roof caving effectiveness in the gob area and transferring the overburden load behind the goaf to the upper strata.

- Presplit blasting effectively weakened the transmission of advanced abutment pressure and reduced its influence range. At a location 100 m ahead of the working face, the peak vertical stress in the central coal seam was 17.89 MPa under the intact roof condition, and 16.68 MPa, 16.66 MPa, and 16.65 MPa under break-off distances of 20 m, 15 m, and 10 m, respectively. Compared to the original in situ stress, the stress increases were 2.14 MPa, 0.93 MPa, 0.91 MPa, and 0.90 MPa, respectively. These represent reductions in vertical stress increment of 56.54%, 57.48%, and 57.94% after roof break-off, confirming that presplit blasting significantly limits stress propagation ahead of the face.

- The reduced influence range of the advanced abutment pressure helped alleviate mining-induced stress disturbance on the adjacent gob-side roadway. Additionally, during the final retreat stage of the working face, this technique reduced the mining-induced stress impact on the main roadway, providing theoretical and technical support for coal pillar design and roadway deformation control in long-term mine layout planning.

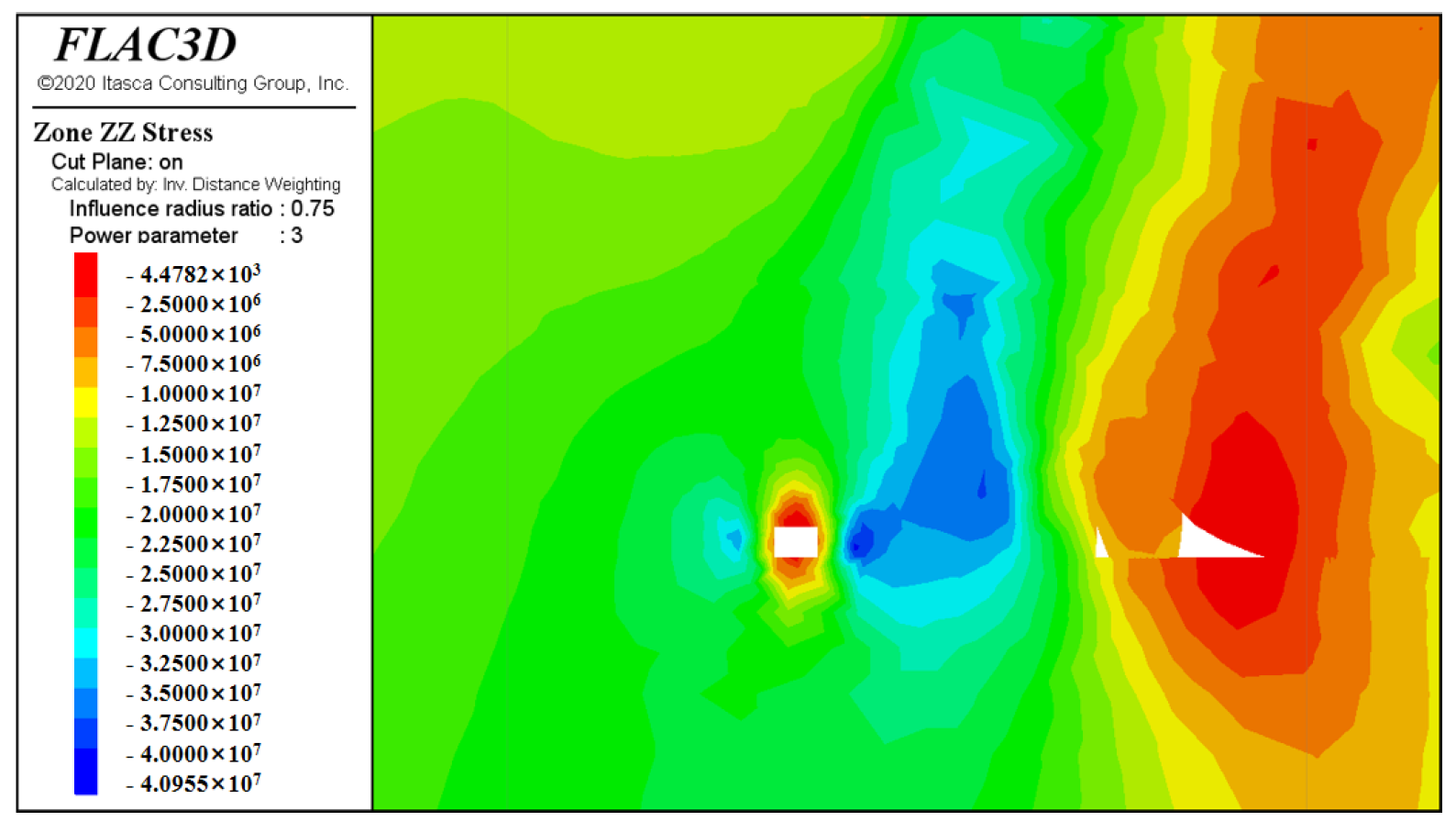

3.2.2. Vertical Stress Distribution in the Overlying Strata Behind the Working Face Under Different Presplit Blasting Conditions

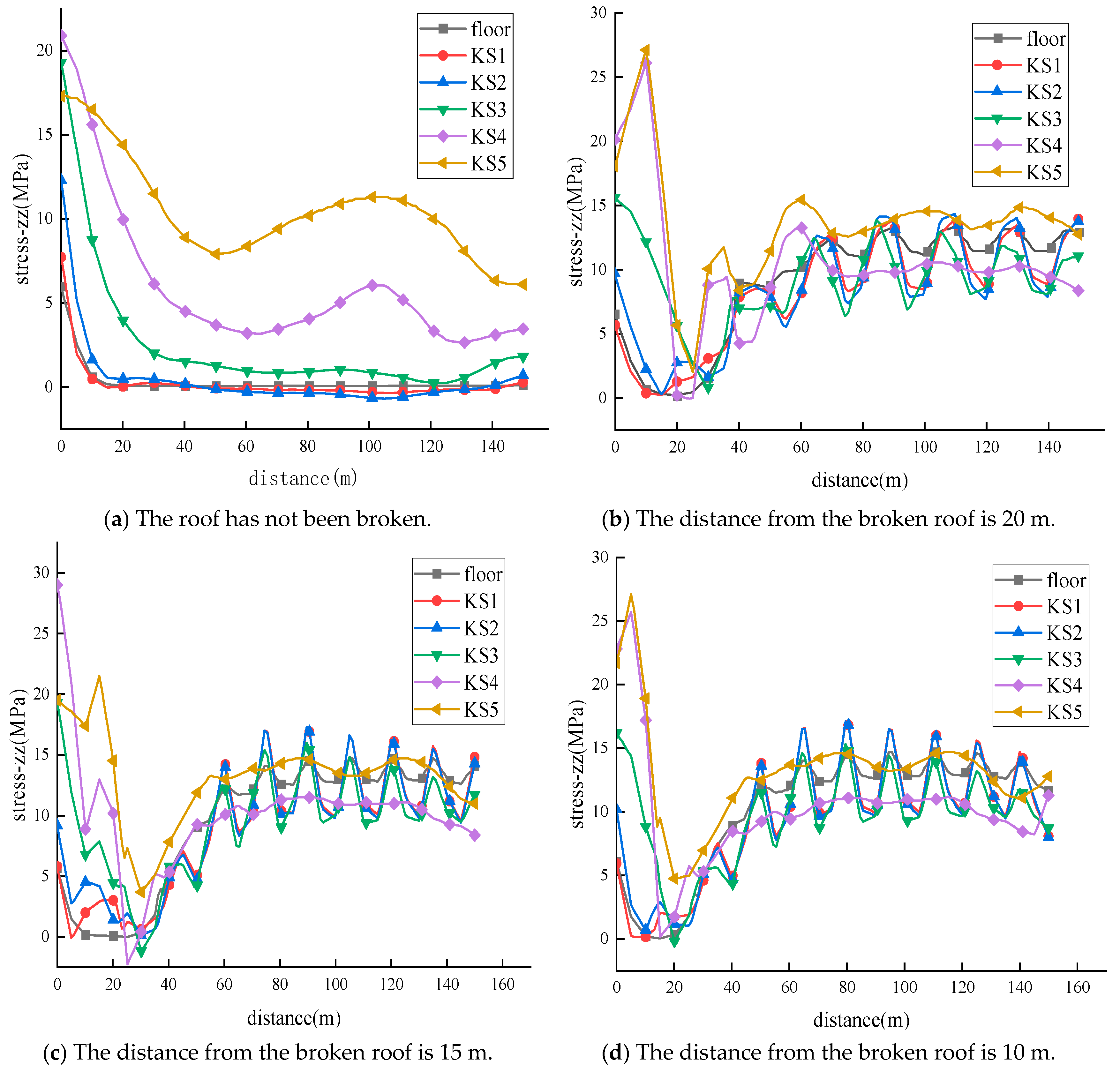

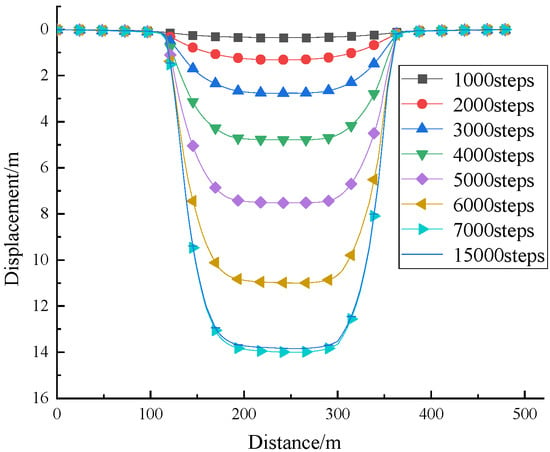

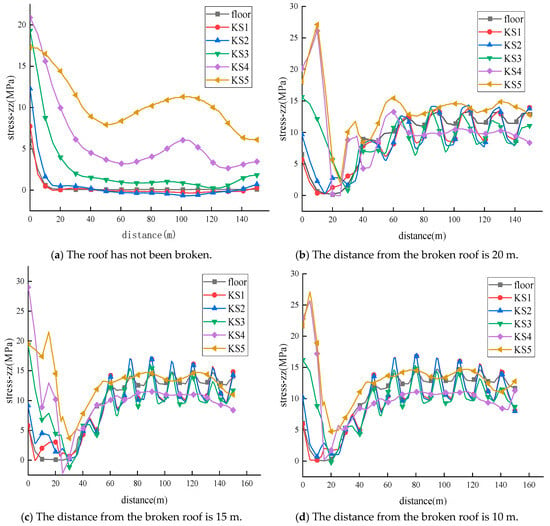

To investigate the vertical stress distribution in the overlying strata behind the goaf under varying presplit blasting parameters, stress monitoring lines were arranged in key strata KS1, KS2, KS3, KS4, and KS5 along the centerline of the working face in the direction of the goaf. The vertical stress evolution in these strata was recorded after the working face had advanced 200 m. Figure 9 illustrates the vertical stress distributions in the key strata under different roof cutting conditions. From Figure 9, we can observe the following:

Figure 9.

Vertical stress distributions in the key strata under different roof cutting conditions.

- Under the intact roof condition, at 0 m behind the working face, the KS4 stratum exhibited the maximum vertical stress, with a peak of 20.98 MPa, while the floor strata experienced the lowest stress, peaking at 5.98 MPa. As the distance behind the working face increased, the vertical stress within the overburden strata in the goaf decreased. Tensile stress appeared in KS1 and KS2 strata, with a maximum tensile stress of 0.68 MPa observed in KS2. Beyond a certain distance behind the face, the vertical stresses in the floor, KS1, and KS2 strata all fell below 2.5 MPa. A general trend of increasing vertical stress with stratigraphic elevation was evident within the goaf. The lack of timely roof caving under intact conditions caused the self-weight of the overburden and overlying strata to be transferred to the working face and the rear coal wall, resulting in elevated vertical stress both in front of the face and in the gob-side roadway. This stress concentration was unfavorable for rockburst prevention.

- After presplit blasting, the vertical stress in the high-level key strata KS4 and KS5 significantly increased at 0 m behind the working face. Peak stress concentrations were observed near the face within the goaf in these layers. When the roof cutting distance was 20 m, the vertical stress peaks for KS4 and KS5 were 26.11 MPa and 27.01 MPa, respectively. For a 15 m cutting distance, the peaks were 29.04 MPa and 21.49 MPa, and for 10 m, they were 25.69 MPa and 27.13 MPa, respectively. Presplit blasting destroyed the continuity of the targeted strata, promoted fracturing in middle- and lower-level layers behind the goaf, and caused the overburden load to be transferred upward to higher strata. Consequently, vertical stress increased in KS4 and KS5 near the working face.

- Following presplit blasting, vertical stress increased in the strata behind the goaf. To minimize the influence of localized peak stresses near the blasting zone, the average vertical stress was statistically analyzed over a range of 30–130 m behind the goaf. For the KS1 stratum, the average vertical stresses under conditions of no roof cutting, and cutting distances of 20 m, 15 m, and 10 m, were 0.13 MPa (tensile), 9.61 MPa, 10.31 MPa, and 11.36 MPa, respectively. Presplit blasting promoted full collapse of the overlying strata, leading to gangue compaction and enhanced bearing capacity. The stress within the gangue increased as the roof cutting distance decreased.

- Similarly, the vertical stress in high-level strata behind the goaf increased after presplit blasting. For the KS5 stratum, the average vertical stresses in the 30–130 m range behind the face were 9.82 MPa (no cutting), 12.59 MPa (20 m), 12.57 MPa (15 m), and 13.18 MPa (10 m). Presplit blasting accelerated the roof collapse, allowing most of the overburden load within the goaf to be borne by the compacted gangue, thereby reducing the abutment pressure acting on the coal wall in front of the face and at the edge of the goaf. Reducing the stress level in the surrounding rock contributed to improved rockburst resistance in both the working face and the advanced roadway.

- Presplit blasting weakened the structural continuity and bearing capacity of the targeted strata. At certain distances behind the working face, the vertical stresses in the floor, KS1, KS2, and KS3 strata exhibited a multi-peak distribution, with peaks and troughs corresponding to the positions of the blasting boreholes. The blasting process generated a crushed zone, fracture zone, and elastic vibration zone, with the crushed and fractured zones having limited load-bearing capacity. After the roof collapsed fully in the goaf, the intact rock strata between presplit surfaces bore most of the overburden load, forming a fractured layered-bearing structure.

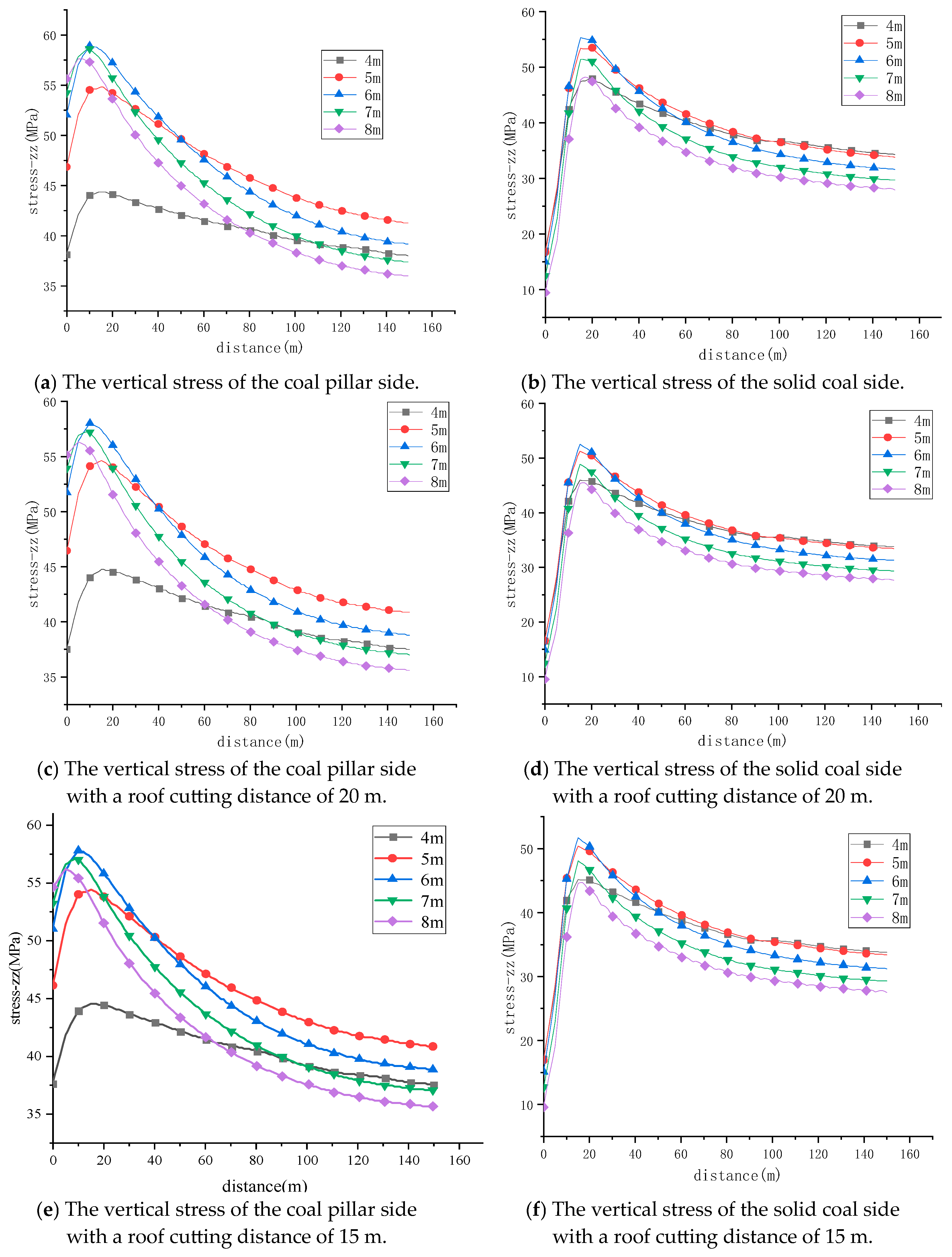

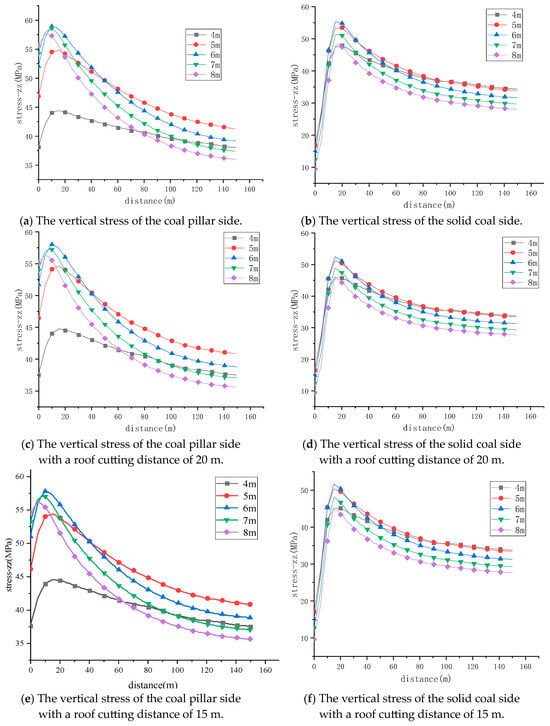

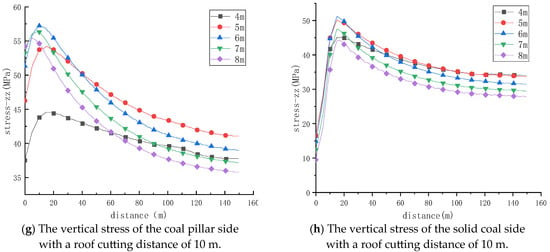

3.2.3. Vertical Stress Distribution in Roadways Under Different Presplit Blasting Conditions

To investigate the influence of advanced presplit blasting on the gob-side roadway, vertical stress-measuring lines were arranged at the center of both ribs. Due to the asymmetrical distribution of vertical stress on the two sides of the roadway adjacent to the goaf, stress monitoring points were set 4 m, 5 m, 6 m, 7 m, and 8 m deep into the coal mass from the centerline of each rib. This setup was used to study the vertical stress distribution characteristics of the roadway ribs under different presplit blasting parameters. The vertical stress results for both ribs are shown in Figure 10.

Figure 10.

Vertical stress distribution on both ribs of the roadway.

From Figure 10, we can draw the following conclusions:

- Due to the influence of the lateral abutment pressure from the 1305 goaf and the advanced abutment pressure generated by the retreat of the 1303 working face, the vertical stress distribution on both ribs of the 1303 return airway exhibited varying trends at different face advance distances. The superposition of mining-induced stress from the 1303 working face and the lateral support pressure from the goaf resulted in a sharp increase in vertical stress on the coal pillar rib of the gob-side roadway. Under high-stress conditions, the shallow surrounding rock on the gob-side experienced severe failure, and the peak stress shifted deeper into the coal pillar.

- Under intact roof conditions, when the advance distance was 0–4.03 m, the peak advanced abutment pressure in the coal pillar was located 8 m from the coal wall; at 4.03–9.06 m, the peak was located 7 m from the wall; at 9.06–52.3 m, the peak shifted to 6 m; and when the advance distance exceeded 52.3 m, the peak stabilized at 5 m. Meanwhile, the vertical stress distribution on the two ribs of the roadway was asymmetrical. On the solid coal rib side, under intact roof conditions, the peak advanced abutment pressure occurred 4 m from the coal wall at a 0–2 m face advance; at 2–10 m, it moved to 5 m; at 10–32 m, it was located 6 m away; at 32–96 m, it returned to 5 m; and when the advance distance exceeded 96 m, the peak position shifted back to 4 m.

- Roof-cutting blasting can effectively reduce the peak vertical stress in the coal pillar. When the advance distance was 10.1 m, the peak stress on the coal pillar rib was 58.90 MPa under intact roof conditions. With roof break-off distances of 20 m, 15 m, and 10 m, the corresponding peak stresses were 57.98 MPa, 57.80 MPa, and 55.26 MPa, respectively. Compared with the intact roof case, the stress reductions were 0.92 MPa, 1.10 MPa, and 3.64 MPa. As the roof cutting spacing decreased, the peak stress in the coal pillar also decreased; however, the rate of reduction gradually diminished with further densification of the blasting pattern.

- Roof-cutting blasting also mitigated the impact of mining-induced stress on the solid coal rib. The peak vertical stress in the solid coal rib was 55.27 MPa under intact roof conditions, and 52.52 MPa, 51.69 MPa, and 54.21 MPa under roof break-off distances of 20 m, 15 m, and 10 m, respectively. The stress reductions in these cases were 2.75 MPa, 3.58 MPa, and 1.06 MPa. These results indicate that roof-cutting blasting can effectively reduce the transmission of mining-induced stress and alleviate stress concentration in the solid coal mass ahead of the working face.

- In addition, roof-cutting blasting reduced the influence range of the advanced abutment pressure. Taking the vertical stress at a point 5 m inside the coal pillar rib as an example, and with a 50 m advance distance of the working face, the measured vertical stress values were 49.56 MPa under intact roof conditions and 48.60 MPa, 48.58 MPa, and 48.51 MPa under roof break-off distances of 20 m, 15 m, and 10 m, respectively. The pre-mining in situ stress at this location was 40.46 MPa, resulting in vertical stress increments caused by mining of 9.10 MPa, 8.14 MPa, and 8.12 MPa under different blasting conditions. Roof-cutting blasting significantly reduced both the intensity and spatial extent of advanced abutment pressure, which was beneficial for maintaining roadway stability. However, as the roof break-off spacing continued to decrease, the vertical stress in the coal pillar rib declined at a slower rate.

4. Field-Scale Industrial Test

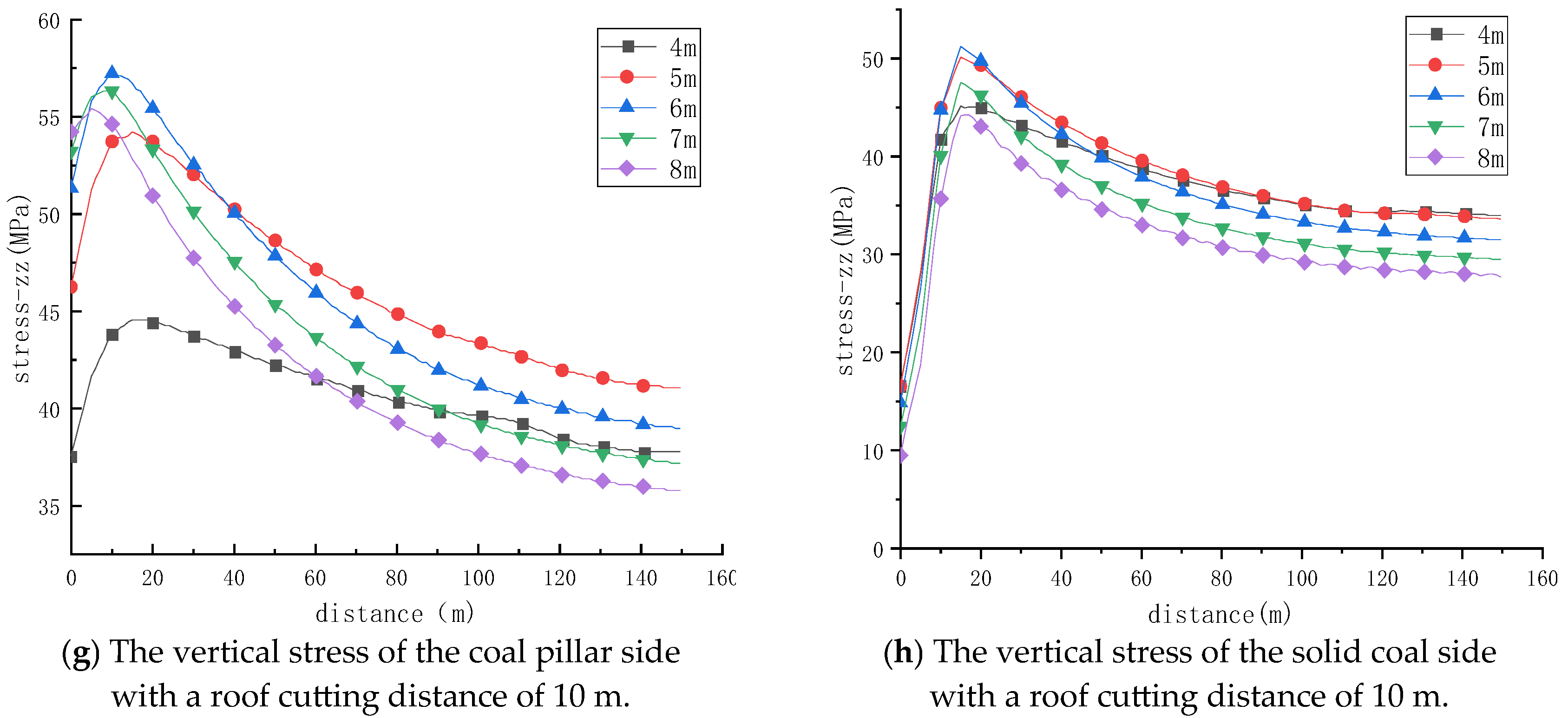

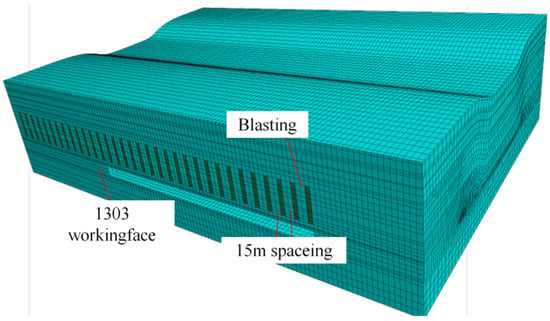

4.1. Implementation Plan for Advanced Presplit Blasting in the 1303 Working Face

The flexural strain energy of the roof is proportional to the fifth power of its cantilever length. Therefore, thick and hard roof strata are less prone to caving and tend to form longer suspended sections. When the cantilever length reaches its critical limit, the accumulated energy may suddenly be released, generating strong dynamic loads. When these loads act on coal bodies already under high stress, the risk of rockburst is significantly increased. To mitigate this hazard, a presplit blasting scheme is planned for the target stratum to artificially create fractures and weaken the manifestation of strong mine pressure in the 1303 working face. Based on the calculated height of the overburden caving zone, the designed blasting height for the roof is 57.5–67 m, which effectively targets thick, hard strata within the fracture zone of the overlying rock. The actual blasting height may be adjusted according to the lithology of the roof above the coal seam. The length of advanced deep-hole blasting is determined by the length of the working face and the dip angle of the coal seam. For working faces shorter than 120 m, single-directional drilling is adopted, and the horizontal distance from the bottom of the borehole to the main entry should not be less than 20 m. For working faces longer than 120 m, bi-directional drilling from both entries is recommended, and the horizontal distance from each borehole bottom to the respective entry should exceed 10 m. A schematic diagram of the drilling layout is shown in Figure 11. In the 1303 working face, three parallel blast holes are arranged per group in both the main and return entries. The borehole diameter is 94 mm, and the spacing between holes within a group is less than 2 m. The explosive used is φ63×1000 mm plastic-cased permitted water gel explosive, and the advance distance of the working face at the time of blasting is no less than 200 m. Specific charge quantities and stemming lengths are listed in Table 1.

Figure 11.

Comprehensive sectional diagram of roof presplit blasting boreholes in the main and return entries of the 1303 working face.

Table 1.

Drilling parameters for bi-directional blasting boreholes in the main and return entries of the 1303 working face.

During construction, the parameters of the roof presplit boreholes should be optimized based on the actual roof conditions on site to ensure the effectiveness of the presplit blasting. If the lithology at the drilling location is relatively fractured and more than two re-drilling attempts fail to achieve borehole formation, further drilling operations may be discontinued.

A reasonable cycle spacing for deep-hole presplit blasting should be shorter than the periodic weighting step of the medium-to-high-level key strata that the working face support system can bear. This ensures that the hard roof strata at medium and high positions can be fractured in a controlled manner according to the planned cycle spacing. The optimal blasting cycle spacing depends on the lithological characteristics, thickness, and degree of fracture development in the roof strata. It should be comprehensively determined based on the rock mechanical properties, sandstone thickness, roof weighting behavior, and microseismic monitoring data. Considering the geological and mechanical characteristics of the adjacent 1305 working face, the fracture step length calculations for the 1303 working face, and the results of numerical simulations, the preliminary blasting cycle spacing is determined to be 12–17 m. Construction shall start approximately 50 m away from the cross-cut of the working face, and the spacing may be further optimized in the later stage according to the observed periodic weighting intervals.

4.2. Microseismic Data Analysis of the 1303 Working Face

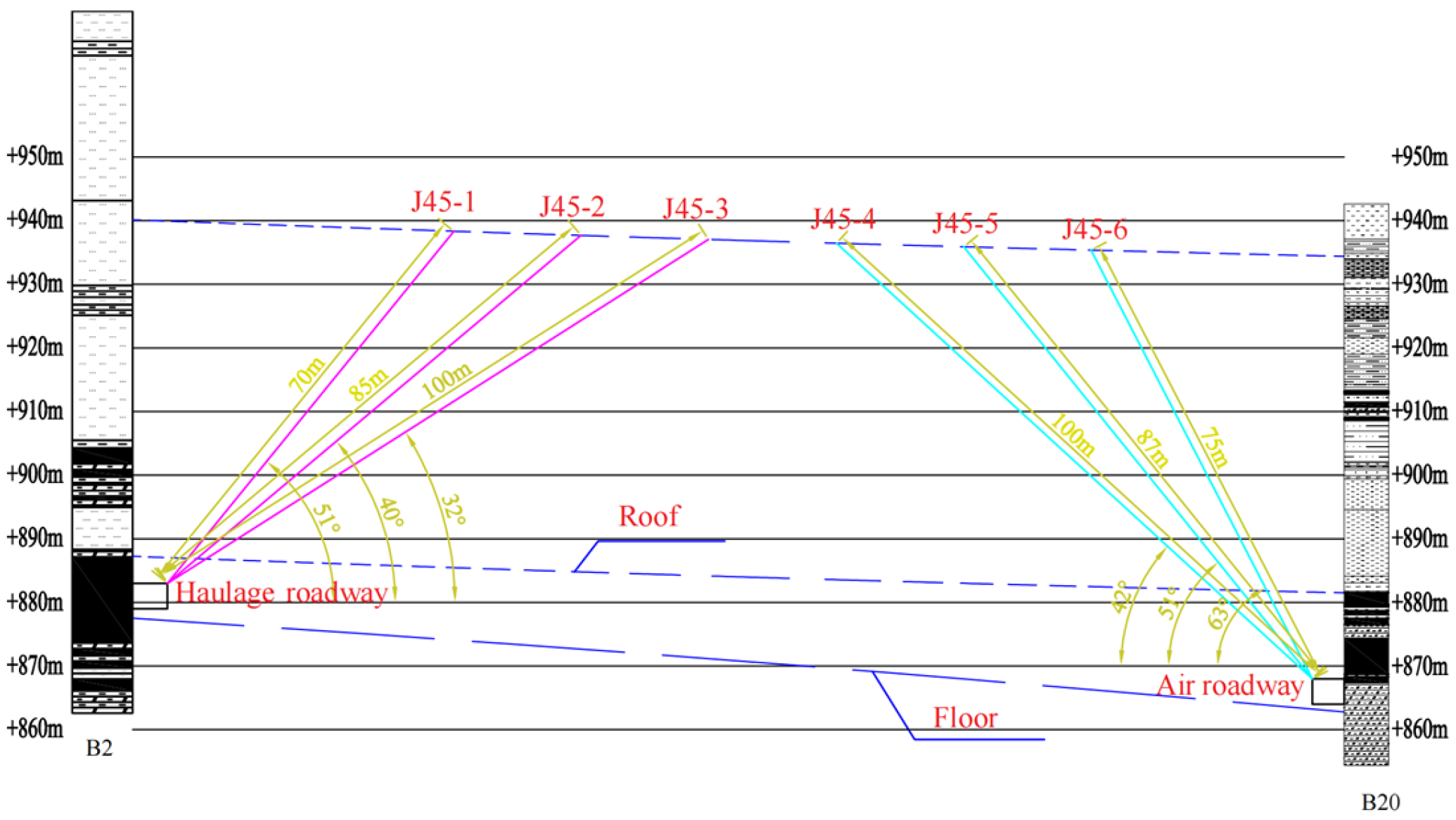

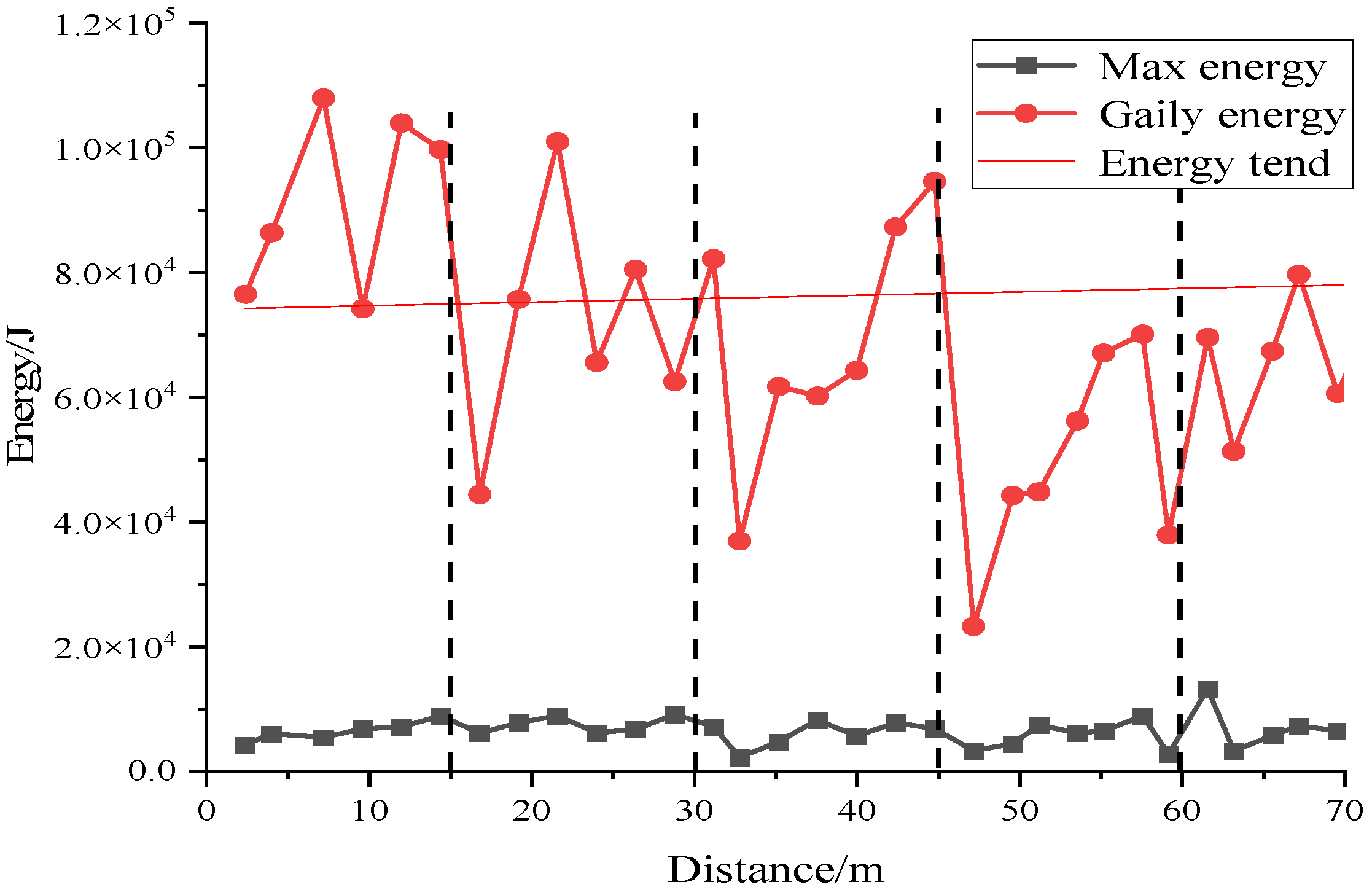

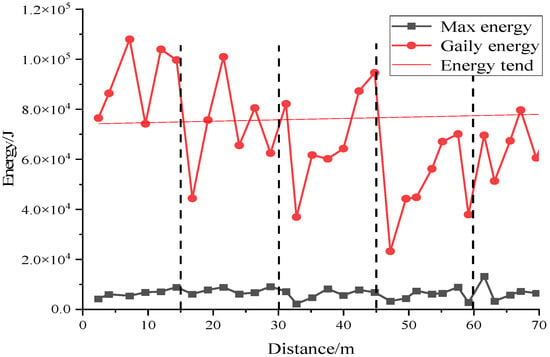

Microseismic data from the 1303 working face in March 2023 were statistically analyzed. During this period, the working face advanced 67.2 m. The daily microseismic event data corresponding to different face advance distances are shown in Figure 12.

Figure 12.

Microseismic energy statistics of the 1303 working face in March 2023.

The following findings are shown in Figure 12:

- After advanced deep-hole presplit blasting, the maximum microseismic energy in the 1303 working face during March appeared on March 27, when the monthly face advance reached 61.6 m, with a peak energy of 1.32×104 J. The maximum daily average energy was observed on March 3, when the advance was 7.2 m, reaching 1.08×105 J. Throughout the entire mining process, the highest recorded seismic hazard level was classified as weak rockburst risk.

- As the working face passed through the vicinity of the presplit blasting zone, both the peak and average daily microseismic energies decreased significantly. When the working face advanced to the first presplit blasting section, the maximum energy dropped from 8.83×10³ J to 6.08×10³ J, representing a 31% reduction. Meanwhile, the daily average energy decreased from 9.97×10⁴ J to 4.44×10⁴ J, a 55% reduction.

- Linear fitting of the daily average energy data revealed a gradual increasing trend as the working face advanced. In March, the face advanced from 260.4 m to 330 m from the initial cut, indicating the approach to the second square-cutting stage, during which mine pressure manifestations became more pronounced.

A comparison of microseismic monitoring results between the 1303 and 1305 working faces—under equal advancing days and advance lengths—is provided in Table 2 and Table 3. From the comparison based on the same mining days, the daily advance rate and daily average yield of the 1303 working face are slightly lower than those of the 1305 working face, whereas the average mining height is higher in the 1303 working face. After the implementation of advanced presplit blasting, the energy and frequency of microseismic events in the 1303 working face were significantly lower than those in the 1305 working face. Based on a comparison of microseismic events under similar advance distances, the total frequency of microseismic events in the 1303 working face was slightly higher than that in the 1305 working face when advancing the same distance. However, 33.8% of microseismic events in the 1305 working face exceeded 103 J, compared to 26.0% in the 1303 working face. Moreover, 2.8% of microseismic events in the 1305 working face exceeded 104 J, while the 1303 working face recorded only three 104 J microseismic events, a 99.2% reduction compared to the 1305 working face. The daily average frequency of microseismic events was also relatively lower in the 1303 working face, with a 43.8% reduction in events exceeding 103 J. In conclusion, after the implementation of presplit blasting, the stress concentration in the working face was significantly improved, and the daily average energy of microseismic events decreased by 72.3%. During the mining of the 1303 working face, no rockbursts were observed on site. Microseismic monitoring showed no signs of rockburst hazards, while monitoring of the advanced roadway, including machine and ventilation entries, indicated no early warnings. The geoacoustic monitoring also showed no signs of risk, indicating an overall absence of rockburst hazards, which effectively ensured production safety.

Table 2.

Comparison of microseismic events under equal advancing days.

Table 3.

Comparison of microseismic events under equal advancing lengths.

5. Conclusions

- This numerical simulation study reveals that the main factor driving the deformation of the open roadway in a full-mechanized caving face of an extremely thick coal seam with a thick hard roof is the superposition of the lateral support pressure from the goaf and the advanced abutment pressure from the working face.

- Mining operations at the working face significantly reduce both near-field peak energy and daily maximum energy around the presplit blasting zone. When advancing to the first presplit blasting line, energy monitoring data show a decrease in maximum instantaneous energy from 8.83×103 J to 6.08×103 J (a 31% reduction), and a drop in daily cumulative energy from 9.97×104 J to 4.44×104 J (a 55% reduction).

- After presplit blasting, the vertical stress in the high-position rock strata behind the goaf increases. The average vertical stresses of the KS5 rock stratum within the range of 30−130 m behind the goaf, under different roof cutting conditions, are 9.82 MPa (no roof cutting), 12.59 MPa (20 m roof cutting), 12.57 MPa (15 m), and 13.18 MPa (10 m).

- Field tests demonstrate that both the average daily microseismic energy and maximum microseismic energy decrease as the mining advances to the presplit blasting location.

Author Contributions

Conceptualization, Shouguo Wang and Kai Zhang; methodology, Yingming Li and Bin Qiao; software, Shaoze Liu and Shunjie Huang; validation, Junpeng An and Kai Zhang; data curation, Kai Zhang and Shunjie Huang; writing—original draft preparation, Kai Zhang; writing—review and editing, Shouguo Wang. All authors have read and agreed to the published version of the manuscript.

Funding

The study was funded by the Major project of Natural Science Research Project of Anhui Educational Committee: Research on full-length anchoring mechanism and bearing effect of bolt-grouting integration in high-stress soft rock roadway (2024AH040067). The key research and development plan of Anhui Province: Research on the large deformation mechanism of surrounding rock of soft rock roadway with high ground stress and the key technology of flexible bolt-anchor-grouting integrated support (2022m07020007). National Natural Science Foundation of China General Project: Research on stress transfer mechanism and intelligent identification method of stress distribution at anchorage interface of full-length anchorage bolt (52174102).

Data Availability Statement

Data to support the findings of this study are available from the first author upon request.

Acknowledgments

The authors of this paper would like to express their gratitude for the major project of natural science research project of the Anhui educational committee (2024AH040067), the key research and development plan of Anhui province (2022m07020007), and the national natural science foundation of China general project (52174102).

Conflicts of Interest

Authors Shouguo Wang, Bin Qiao, Shaoze Liu and Junpeng An were employed by China Coal Group Shanxi Co., Ltd. Also, authors Bin Qiao, Shaoze Liu and Junpeng An were employed by China Coal Chejiazhuang (Xingxian) Coal Industry Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relation-ships that could be construed as a potential conflict of interest.

References

- Pan, Y.; Xiao, Y.; Luo, H.; Wang, G.; Shi, T. Safety Research of Rockburst Mines. J. China Coal Soc. 2023, 48, 1846–1860. [Google Scholar]

- Dou, L.; Bai, J.; Li, X.; He, H. Research on Prevention and Control Technology of Rockburst Disaster Based on the Principle of Dynamic and Static Load Superposition. Coal Sci. Technol. 2018, 46, 1–8. [Google Scholar]

- Lu, C.P.; Liu, G.J.; Liu, Y.; Zhang, N.; Xue, J.H.; Zhang, L. Microseismic multi-parameter characteristics of rockburst hazard induced by hard roof fall and high stress concentration. Int. J. Rock Mech. Min. Sci. 2015, 76, 18–32. [Google Scholar] [CrossRef]

- Qi, Q.; Li, Y.; Zhao, S.; Zhang, N.; Zheng, W.; Li, H.; Li, H. 70 Years of Rockburst Development in China’s Coal Mines: Establishment and Reflection on the Theory and Technology System. Coal Sci. Technol. 2019, 47, 1–40. [Google Scholar]

- Chen, J.; Liu, Z.; Zhao, Y.; Yang, S.; Zhou, Z. Generalized Weighted Mahalanobis Distance Improved VIKOR Model for Rockburst Classification Evaluation. Mathematics 2024, 12, 181. [Google Scholar] [CrossRef]

- Laitsos, V.; Vontzos, G.; Paraschoudis, P.; Tsampasis, E.; Bargiotas, D.; Tsoukalas, L.H. The State of the Art Electricity Load and Price Forecasting for the Modern Wholesale Electricity Market. Energies 2024, 17, 5797. [Google Scholar] [CrossRef]

- Wang, Y.; He, M. Numerical Investigation on Effect of Inclination and Position of Structural Planes on Rockbursts Triggered by Blasting Disturbance in Deep-Buried Tunnels. Rock Mech. Rock Eng. 2025, 58, 2739–2761. [Google Scholar] [CrossRef]

- Sun, J.H.; Wang, W.J.; Xie, L.K. Short-term rockburst prediction model based on microseismic monitoring and probability optimization naive Bayes. Rock Soil Mech. 2024, 45, 1884–1894. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, W.; Yuan, L.; Zheng, T.; Liang, Z.; Wang, X. A review of tunnel rockburst prediction methods based on static and dynamic indicators. Nat. Hazards 2024, 120, 10465–10512. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.; Tan, Y.; Wang, R.; Xie, W.; Wang, E.; Liu, X.; Shang, J. Experimental Study of Loading System Stiffness Effects on Mechanical Characteristics and Kinetic Energy Calculation of Coal Specimens. Rock Mech. Rock Eng. 2024, 57, 9941–9957. [Google Scholar] [CrossRef]

- Wu, Y.; Fu, K.; Ren, Y.; Ma, L.; Liu, J.; Ge, T.; Ren, J.; Chiu, A.C. Mechanical Characteristics of Methane Hydrate-Bearing Clayey Silt Containing Carbonate Sand and the Modified Duncan–Chang Model. Energy Fuels 2025, 39, 1919–1937. [Google Scholar] [CrossRef]

- Bai, J.; Zhao, Y.; Shi, X.; Feng, G.; Wang, S.; Hou, B.; Mi, J.; Ma, J.; Li, J. Deformation and Failure Behaviour of Coal-Backfilling Composite Structure Under Double Shearing. Rock Mech. Rock Eng. 2024, 57, 9079–9096. [Google Scholar] [CrossRef]

- Qiu, Y.; Wu, J.; Yang, Z.; Ma, Y.; Niu, S.; Chen, S.; Feng, Z.; Song, G. Experimental research on deformation response of hot dry rock (HDR) geothermal reservoir during hydraulic modification at 300 °C and depth 2500m. Energy 2024, 312, 133610. [Google Scholar] [CrossRef]

- Xu, W.; Qu, X.; Yan, L.; Ning, Y. Experimental Study on Mechanical Properties and Permeability Characteristics of Calcareous Mudstone under Different Confining Pressures. Materials 2024, 17, 2731. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Q.; Yao, S.; Yang, K.; Ma, H.; Ni, J.; Zhong, B.; Liu, Y.; Wang, J.; Fan, T. Achieving atomically flat copper surface: Formation of mono-atomic steps and associated strain energy mechanisms. Acta Mater. 2024, 263, 119414. [Google Scholar] [CrossRef]

- Jing, C.; Zhicheng, H.; Wulin, L.; Dingding, Z.; Jianfeng, Y.; Chenyang, M.; Gang, H.; Mingyue, W. The Application of Distributed Fiber-Optic Sensing Technology in Monitoring the Loose Zone in the Floor of Stoping Roadway. Rock Mech. Rock Eng. 2025, 58, 723–744. [Google Scholar] [CrossRef]

- Fan, D.; Liu, X.; Tan, Y.; Li, X.; Yang, S. Energy mechanism of bolt supporting effect to fissured rock under static and dynamic loads in deep coal mines. Int. J. Min. Sci. Technol. 2024, 34, 371–384. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Wang, T.; Shi, X.; Cui, P. Development and validation of a remotely triggered pressureand gas-preserved coring tool for deep coal mines in drilling fluid environments. Adv. Geo-Energy Res. 2024, 14, 147–160. [Google Scholar] [CrossRef]

- Chaolin, Z.; Peizhong, W.; Mingliang, Q.L. Energy Evolution and Coal Crushing Mechanisms Involved in CoalandGas Outburst. Nat. Resour. Res. 2024, 33, 455–470. [Google Scholar]

- Chen, L.; Guo, J.; Yang, X. Research progress and engineering practice of rockburst disaster prevention and control in deep mining of metal mines. Min. Metall. 2024, 33. [Google Scholar]

- Feng, L.; Zhang, Q.; Liu, G. Influence mechanism of mining speed on energy release in a mine roof and elastic coal system. Int. J. Oil Gas Coal Technol. 2024, 36, 23. [Google Scholar] [CrossRef]

- Jiao, Y.; Zuo, Y.; Wen, Z.; Chen, Q.; Zheng, L.; Lin, J.; Chen, B.; Rong, P.; Jin, K.; Du, S.; et al. Crack-tip propagation laws and energy evolution of fractured sandstone. Eng. Fail. Anal. 2024, 166, 108832. [Google Scholar] [CrossRef]

- Kukhtinskii, A. Estimation of parameters for 3D geomechanical modeling from triaxial test results. Energy Geosci. 2025, 6, 100354. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, R.; Hou, S.; Zhu, L.; Pang, Z.; Zhuang, W. Investigation of energy evolution process of rock mass during deep tunnel excavation based on elasto-viscoplastic damage model and time-dependent energy indices. Acta Geotech. 2025, 20, 1549–1570. [Google Scholar] [CrossRef]

- Huang, G.; Li, H.; Dai, F.; Zhang, X.; Gao, W. Study of the influence of coal column width on the stress-fracture-displacement evolution law in sequential coal seam mining. Sci. Rep. 2025, 15, 10474. [Google Scholar] [CrossRef]

- Yin, S.; Wang, E.; Li, Z.; Zang, Z.; Liu, X.; Zhang, C.; Ding, X.; Aihemaiti, A. Multifractal and b-value nonlinear time-varying characteristics of acoustic emission for coal with different impact tendency. Measurement 2025, 248, 116896. [Google Scholar] [CrossRef]

- Lei, W.; Chai, J.; Liu, J.; Cao, Y.; Yuchi, X.; Zhang, D.; Zheng, C.; Du, X.; Gong, Y. Research on stress release and pressure relief mechanism of underlying coal and rock under protective layer mining. Sci. Rep. 2025, 15, 5583. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Wen, M.; Zhang, Y. Influence of Hydraulic Fracturing and Stress Unloading on Fracture Propagation in Deep Seam Excavation. Geotech. Geol. Eng. 2025, 43, 1–22. [Google Scholar] [CrossRef]

- Yan, Z. Quantitative Identification of Emission Sources and Emission Dynamics of Pressure-Relieved Methane Under Variable Mining Intensities. Processes 2025, 13, 704. [Google Scholar] [CrossRef]

- Yu, Q.; Zhao, Y.; Zhao, X.; Liu, S.; Cong, Y.; Li, H.; Zhu, H.; Jiang, T.; Cao, J.; Zhang, S. Initiation Pressure and Fracture Path of Near-Field Symmetric Pre-cut Hydraulic Fracturing. Rock Mech. Rock Eng. 2025, 58, 1003–1020. [Google Scholar] [CrossRef]

- Hao, Q.; Cao, A.; Zhao, W.; Yang, Y.; Xue, C.; Hao, Q. Application of Long-Distance Drilling and Blasting Technology to Prevent Rock Bursts in High-Level Roofs. Appl. Sci. 2025, 15, 2076–3417. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).