1. Introduction

Currently, the Chang 6 reservoir group is in the middle-to-late stage of oilfield development. Owing to poor reservoir physical properties and pronounced heterogeneity, oil well productivity continues to decline, accompanied by a rapid decrease in the formation recovery rate [

1,

2,

3]. It is imperative to integrate the reservoir characteristics and development status of the study area, optimize the parameters and turning angle of temporary plugging refracturing fractures based on the geological model, and establish a comprehensive refracturing technology system tailored for the Chang 6 reservoir. Building upon reservoir geology and development dynamic analysis, You et al. [

4] simulated and designed three schemes to compare changes in the seepage field under different measures. Concurrently, numerical simulation methods were employed to optimize fracture parameters, including repeated reconstruction fracture parameters for water wells and non-effective wells. The results demonstrate that the most effective displacement system can be established through water plugging diverting fracturing combined with repeated fracturing of non-effective wells. Su et al. [

5] utilized numerical simulation and production dynamic methods to investigate changes in in-situ stress and analyze production enhancement potential. They proposed a volume fracturing design concept primarily aimed at increasing fracture bandwidth, resulting in a repeated fracturing process of “whole-process multi-stage temporary plugging + volume stimulation.” This approach yields oil production increases exceeding twice that of conventional repeated fracturing effects, with notable subsequent stable production performance. Therefore, based on previous studies and using the Chang 6 reservoir block as a case study, this research thoroughly analyzes geological characteristics and development challenges [

6,

7,

8]. A refined numerical model suitable for the Chang 6 reservoir was established through Petrel geological reservoir modeling and CMG reservoir numerical simulation [

9,

10,

11]. The fracturing duration and fracture parameters, encompassing fracture length, conductivity, and fracture turning angle, are optimized to ascertain the optimal values for temporary plugging and re-fracturing operations.

2. Regional Survey

The principal productive formation within the study area is the Chang 6 oil layer group, exhibiting an average burial depth of 1600 m. The reservoir demonstrates a total thickness of 45.0 m, consisting of 14.5 m of effective thickness and 20.6 m of sandstone thickness. Comprehensive reservoir characterization indicates an average porosity of 11.85% and an average air permeability of 1.52 mD. Permeability distribution analysis reveals a distinct lognormal distribution pattern, characterized by a median value of 0.71 mD, a coefficient of variation of 0.67, and a heterogeneity coefficient of 20.5, signifying pronounced reservoir heterogeneity. Currently, the study area is in the middle-to-late stage of oilfield development, characterized by an increasing number of low-yield and low-efficiency wells with daily production rates below 1.0 tons, declining oil well productivity, and deteriorating field development efficiency. In 2014, in response to the low oil production rate and limited lateral sweep efficiency, a pilot test of small well spacing infill drilling was implemented in the low-yield central area of the reservoir. However, the initial stimulation intensity of the lateral infill wells proved inadequate, and conventional fracturing operations that merely increased treatment scale resulted in limited liquid production enhancement, significant water cut increase, and minimal oil production improvement.

3. Establishment of Repeated Fracturing Numerical Model

In order to determine the optimal value of temporary plugging re-fracturing and further improve the recovery rate, this paper selects the Chang 6 block as the research target block. This section first establishes a numerical simulation model of the target block based on the geological model of the actual block. The geological modeling software is used to establish a homogeneous model [

12,

13,

14,

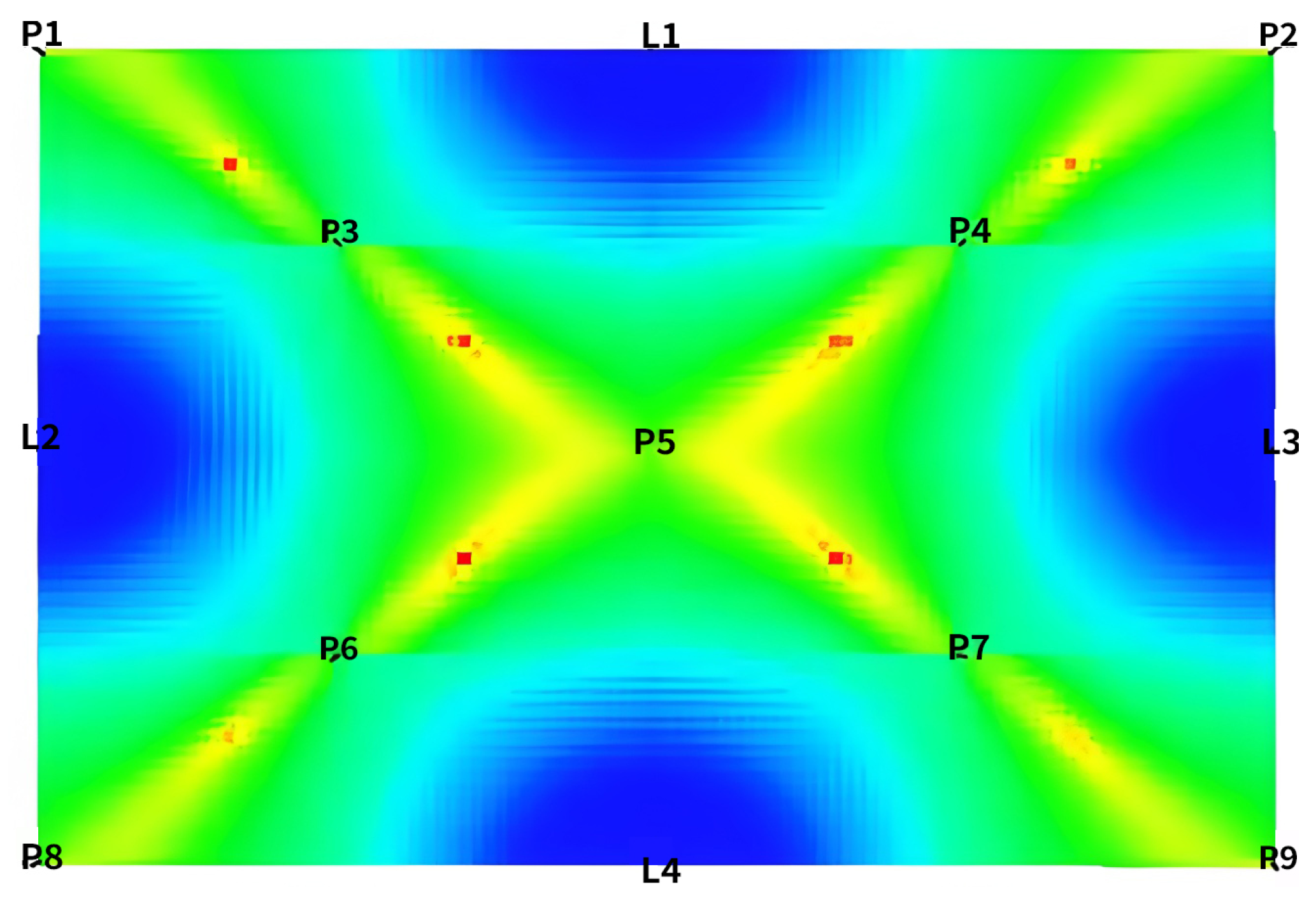

15]. As shown in the

Figure 1, the number of model grids is 104 × 56 × 15, and the grid size is 10 m × 10 m × 1 m. The local grid refinement is performed around P1~P9 wells. To a certain extent, it is equivalent to fracturing the above wells. The half-length of the fracture is 125 m and the width is 0.2 m.

4. Study on Yield Increasing Mechanism and Seepage Law

In this study, reservoir numerical simulation was carried out for the optimization design of temporary plugging and re-fracturing. By establishing a fine numerical simulation model, the seepage mechanism and yield increase law in the process of temporary plugging and re-fracturing were analyzed. The fracturing timing and fracture parameters (including fracture length, conductivity, and fracture steering angle) were optimized, and the optimal values of each parameter were determined. The stimulation effect of temporary plugging re-fracturing mainly comes from three aspects: improving fracture conductivity, increasing fracture length and changing fracture angle. Based on the stimulation mechanism of re-fracturing, the equivalent conductivity method is used to optimize the fracture parameters through reservoir numerical simulation. The stimulation mechanism and seepage law of temporary plugging re-fracturing are systematically discussed from the perspective of changing the fracture angle.

The design scheme is as follows. The initial fracture length of the basic model is 150 m, and the conductivity is 150 mD·m. Considering the time-varying conductivity of the fracture, the re-fracturing is carried out in the fourth year of production. After the re-fracturing, the conductivity is restored to 150 mD·m and the fracture is turned 45°. The edge well and the corner well are studied respectively. The specific fracture parameters are shown in

Table 1.

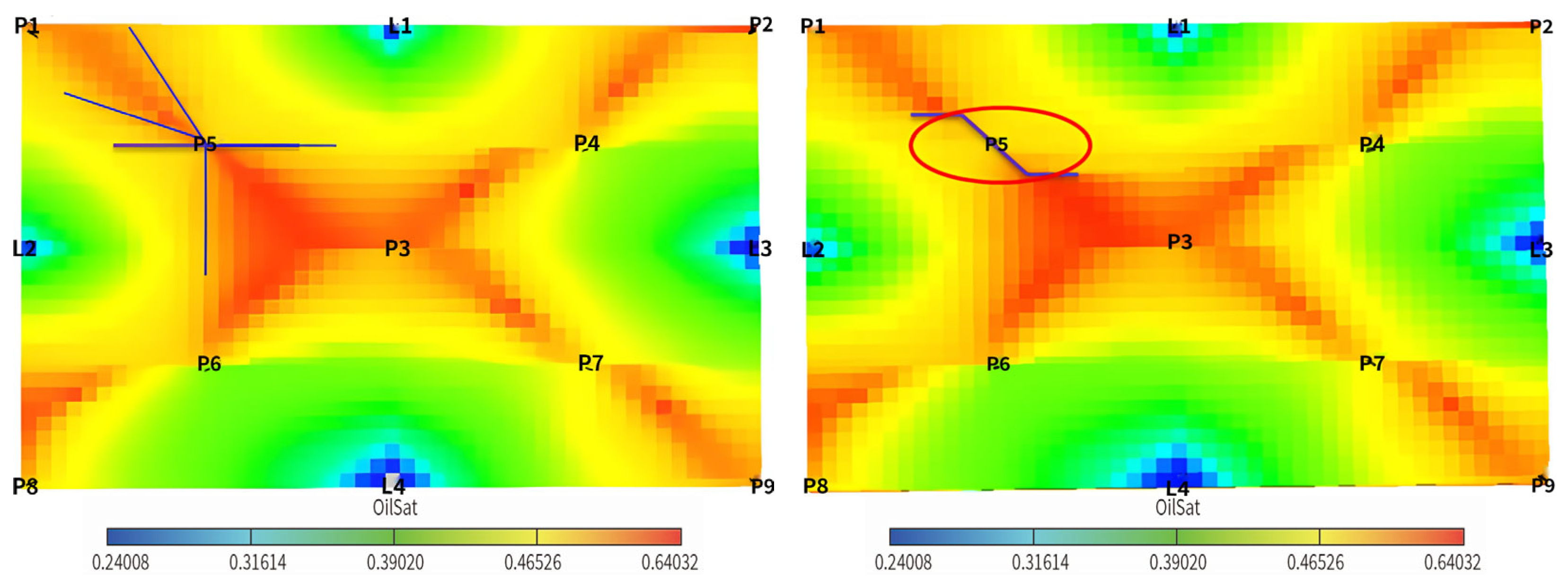

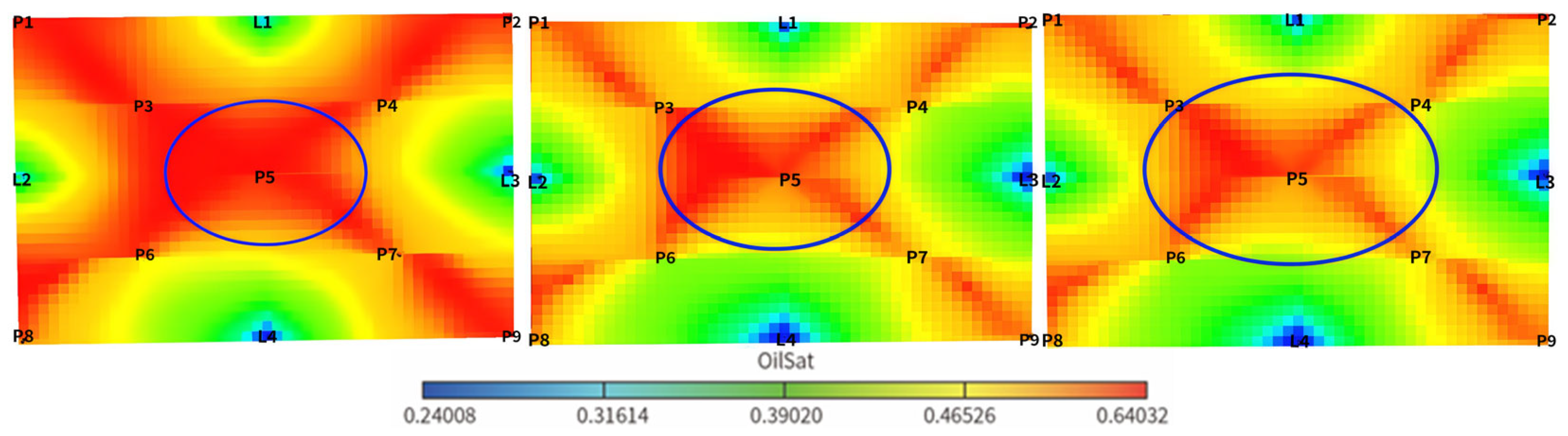

4.1. Consider the Remaining Oil

Figure 2 shows the distribution map of the remaining oil after 10 years of normal production without repeated fracturing production and the distribution map of the remaining oil after 4 years of normal production and 10 years of repeated fracturing production in the fifth year. The map shows the final oil saturation of the model production for ten years under the turning angle of −45 degrees. The example is an edge well. From the distribution map of the remaining oil, it can be seen that the remaining oil in the formation is utilized to a greater extent after the fracture turning. The new fractures of re-fracturing can crack and extend in different directions from the previous fractures. A larger range of communication old fractures do not extend to the oil and gas reservoir area to form a high-conductivity oil and gas flow channel to achieve a significant increase in production.

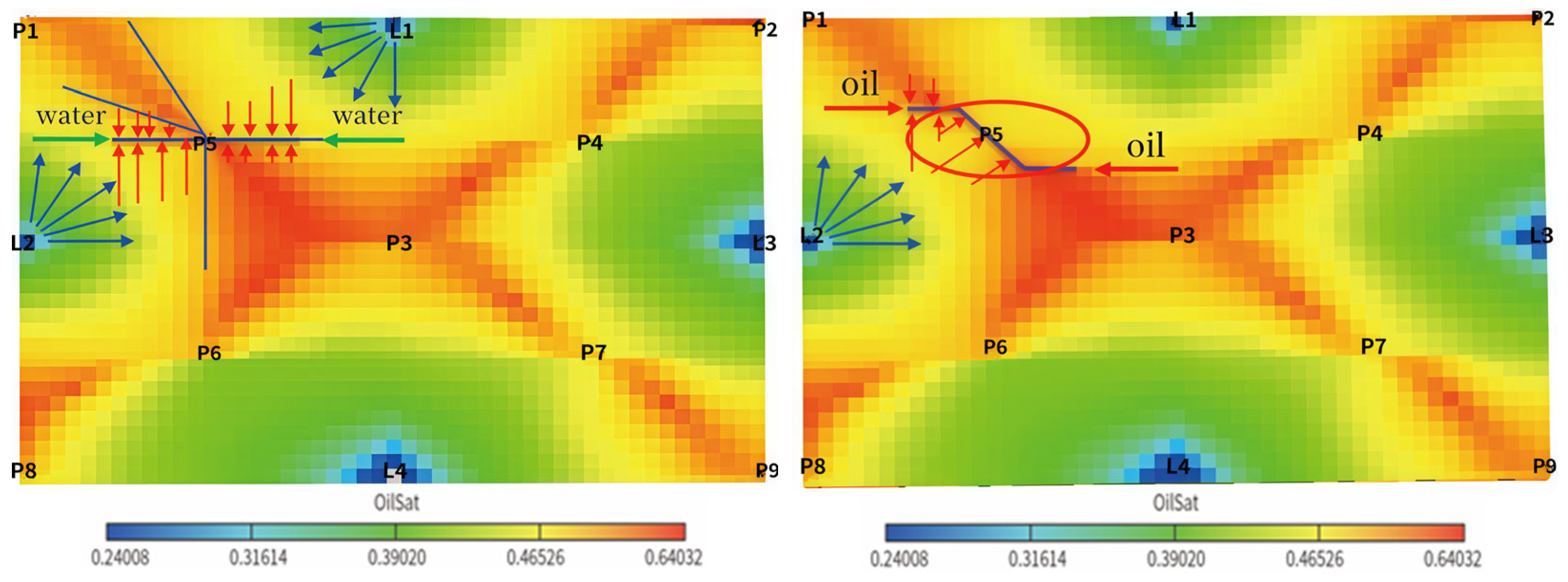

4.2. Considering the Seepage Law

Figure 3 is the distribution map of remaining oil after 10 years of normal production without repeated fracturing production and the distribution map of remaining oil from 4 years of normal production to 10 years of repeated fracturing production in the fifth year. From the perspective of oil-water seepage law, because the fracture permeability is much higher than the matrix permeability, when the low permeability layer of the old oilfield is in the high water cut period, the crude oil controlled by the fracture has been nearly all produced, and the fracture has become the main water outlet channel, but some wells still have a certain amount of remaining recoverable reserves under the existing mining conditions. After the fracture turns, the water channel is avoided, which is beneficial to control water and increase oil and give full play to the production potential of the well.

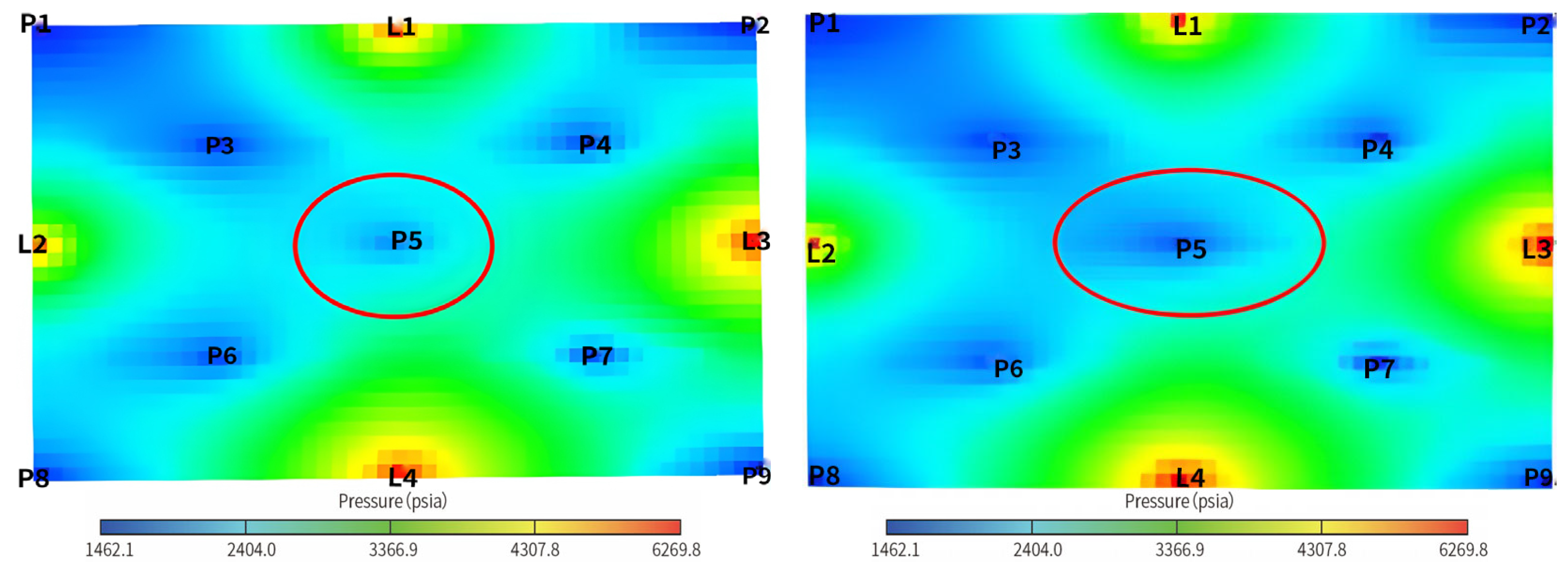

4.3. Consideration of Pressure Levels

Figure 4 shows the distribution map of remaining oil after 10 years of normal production without repeated fracturing production and the distribution map of remaining oil after 4 years of normal production and 10 years of repeated fracturing production in the fifth year. From the perspective of pressure distribution: (1) The pressure level around the re-fracturing well with fracture steering is significantly lower than that of the fracturing non-steering well, and lower than that of other production wells in the same block, which is more conducive to oil-water flow; (2) After repeated fracturing, the pressure spread range is larger, and the steering fracture effectively communicates the reservoir in the far well area, increases the drainage area, and improves the effective utilization degree. (3) The pressure propagation in the near wellbore zone is uniform, which alleviates the phenomenon of low pressure in the near wellbore caused by the long time of conventional fracturing.

5. Fracture Parameter Optimization

On the basis of the actual geological model, the parameters of the temporary plugging re-fracturing fractures are optimized. Taking P5 well (corner well) and P3 well (side well) as the research objects, considering the time-varying of the fractures, the temporary plugging re-fracturing is carried out, and the fracture parameters are optimized respectively. On the basis of the actual geological model, the parameters of the temporary plugging re-fracturing fractures are optimized. Taking P5 well (corner well) and P3 well (side well) as the research objects, considering the time-varying of the fractures, the temporary plugging re-fracturing is carried out, and the fracture parameters are optimized, respectively. The fracture conductivity of the two wells changes with time, and the selection of the time node is shown in

Table 2.

The target well was subjected to temporary plugging and re-fracturing (no water to 40%) at different water cuts. Considering the different fracture half-length (150–230 m) and fracture conductivity (100–300 mD·m) after temporary plugging and re-fracturing, three different parameters were synthesized. The orthogonal design experiment was used to study the optimal parameters under the condition of increasing fracture conductivity and extending fracture length after temporary plugging and re-fracturing. Single factor analysis can only describe its change rule from a certain aspect. Through orthogonal test design, we can understand the influence law of each parameter on development dynamics. Therefore, using the method and idea of orthogonal test design, the level selection and scheme design are carried out for fracture length, conductivity, and temporary plugging re-fracturing time. According to the above single factor analysis, the level of each parameter is selected, and the level of each factor in the corner well is shown in

Table 3.

According to the value of each factor level and the experimental scheme of the orthogonal table, the numerical simulation experiment scheme is designed, and the numerical simulation of each scheme is carried out. The model is produced by fixed bottom hole flowing pressure, and the effect of temporary plugging refracturing is analyzed from the perspective of final cumulative oil production.

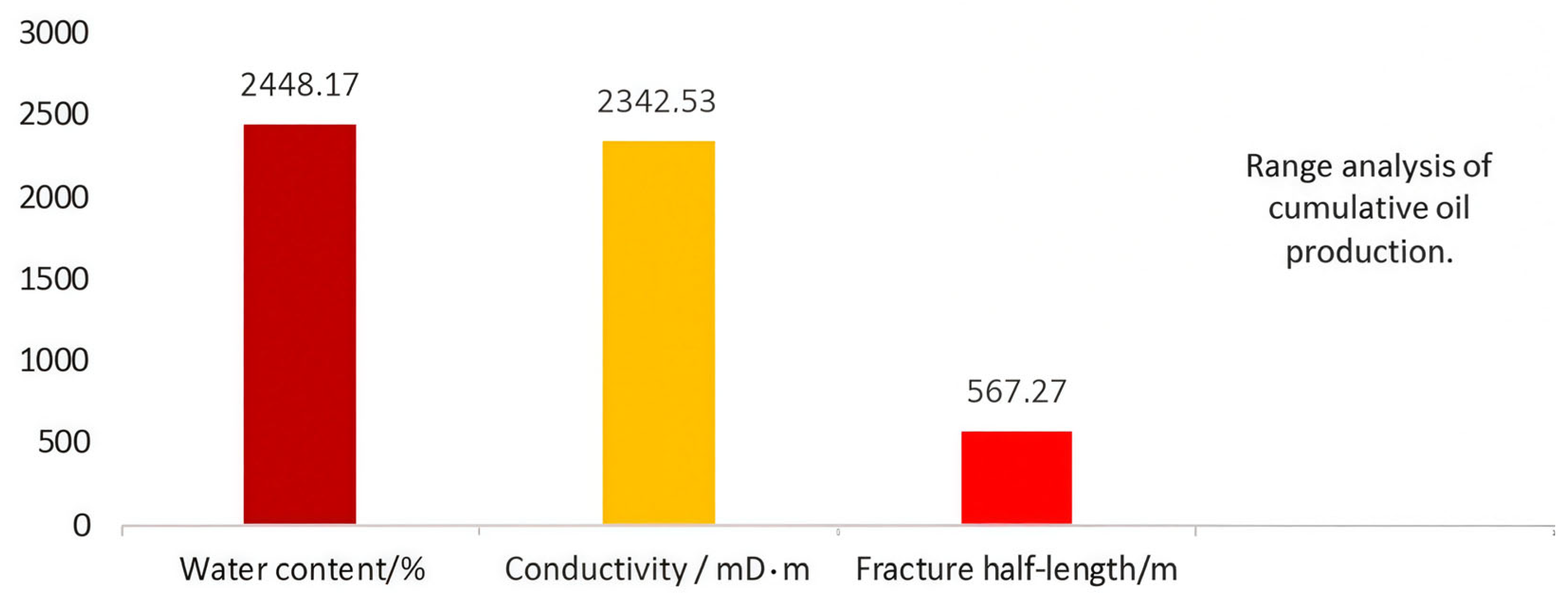

The cumulative oil production results of each scheme obtained by simulation prediction are shown in

Table 4, the sensitivity analysis results of different scheme parameters are shown in

Table 5, and the cumulative oil production range is shown in

Figure 5.

The results show that the most important factor affecting the cumulative oil production is the time of temporary plugging refracturing, followed by the fracture conductivity after temporary plugging refracturing, and the smallest is the fracture half-length after temporary plugging refracturing. In order to ensure the stable operation of the fracturing process and reduce the mutual interference between the corner well and the side well and the collusion risk of the fracture intersection, the average level analysis shows that the optimal level of each factor for the highest cumulative oil production is water content: the end of the anhydrous oil production period; half-length of crack: 190 m; fracture conductivity: 300 mD·m (30 μm2·cm).

A parallel optimization process was conducted for the side wells, with simulation predictions yielding cumulative oil production outcomes for each scenario. The findings indicate that the timing of temporary plugging and re-fracturing remains the most critical factor for cumulative oil production, succeeded by the fracture conductivity post temporary plugging and re-fracturing, while the fracture half-length after temporary plugging and re-fracturing exerts the least impact. Mean level analysis of the side wells identifies the optimal parameters for peak cumulative oil production as: water content at the end of the anhydrous oil production period; fracture half-length of 190 m; and fracture conductivity of 300 mD·m (30 μm2·cm).

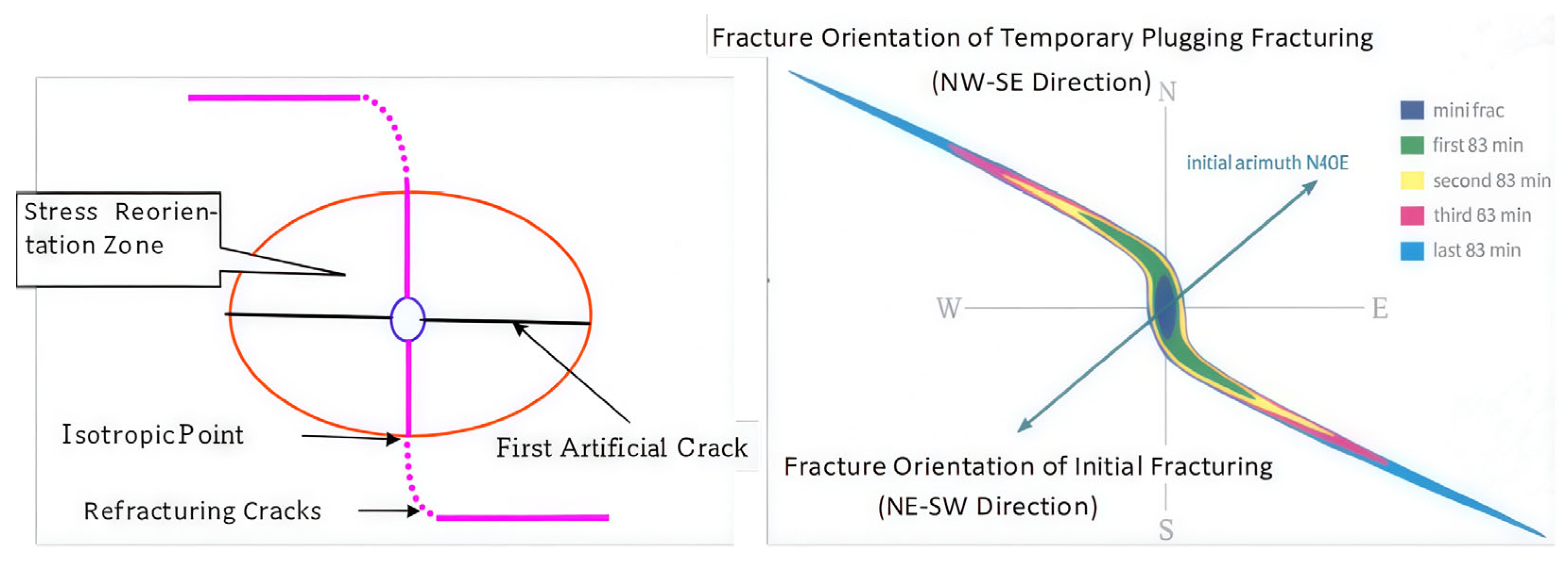

6. Turning Angle Optimization

Under specific operational conditions, temporary plugging during re-fracturing operations can modify the orientation and dip angle of hydraulic fractures through diversion mechanisms. This phenomenon primarily results from stress field alterations near pre-existing fractures due to post-initial fracturing production and proppant-filled fractures [

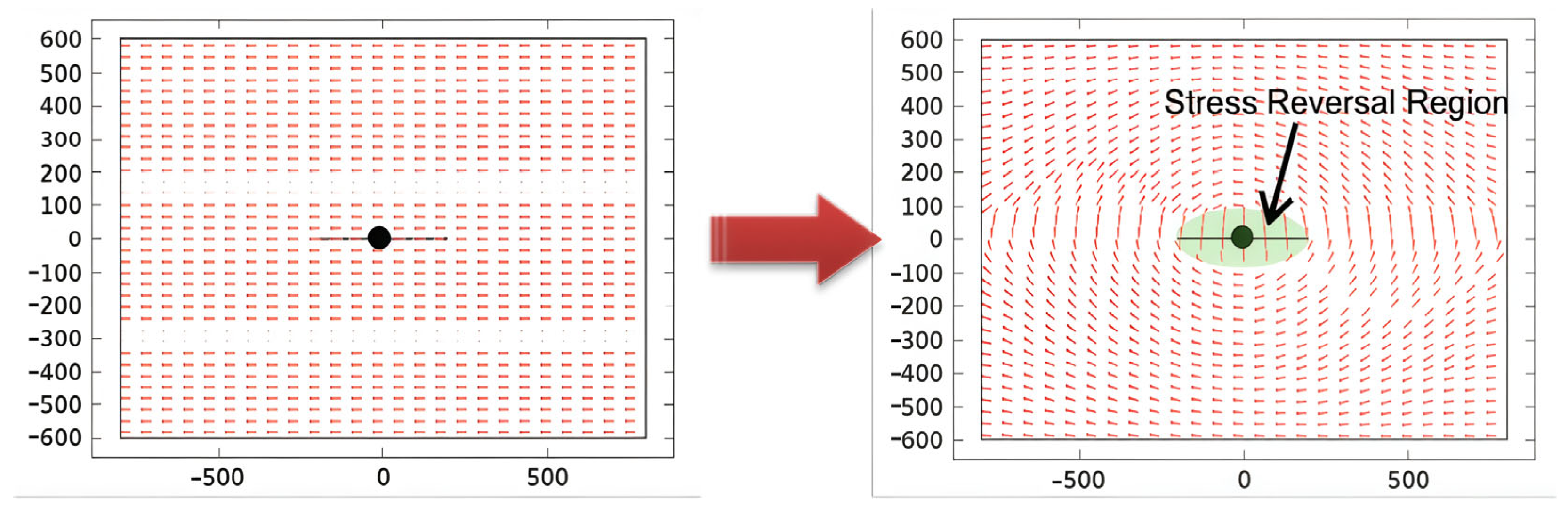

16]. Production activities in fractured wells induce pressure gradient shifts around fractures, leading to reservoir stress redistribution. Adjacent to the fracture surface, vertically oriented tensile stresses develop parallel to the fracture plane, counterbalanced by induced compressive stresses at greater distances. Initially, tensile stresses perpendicular to the fracture plane dominate over those parallel to it. When stress variations induced by pore pressure exceed the initial differential between maximum and minimum horizontal stresses, the original maximum horizontal stress direction transitions to the minimum stress orientation [

17]. Under such conditions, temporary plugging re-fracturing generates fractures oriented perpendicular to the initial fracture geometry.

The oil and gas wells continue to produce under constant bottom hole pressure, and the range affected by the induced compressive stress is further away from the fracture. Near the fracture face, induced stress differentials exhibit an initial increase followed by a decline with increasing distance. At remote locations perpendicular to the original fracture trajectory, stress differences demonstrate a characteristic pattern of initial numerical escalation followed by reduction [

18].

There are two primary factors contributing to stress steering around the fracture: mechanical effect and poroelastic effect. The mechanical stress steering is induced by the support of the fracture proppant, resulting in a greater increase in in-situ stress in the direction perpendicular to the fracture. Initially, the maximum horizontal stress is parallel to the initial fracture [

19,

20,

21]. If the stress difference on the plane is minimal, the increment of stress in the direction of the minimum principal stress exceeds that in the direction of the maximum principal stress, leading to the minimum principal stress surpassing the maximum principal stress. Consequently, the direction of the principal stress rotates 90° in the vicinity of the fracture [

22,

23]. This region is referred to as the stress steering area, and the stress change trend can be determined through simulation of fracturing production, as illustrated in

Figure 6. The stress redirection zone is depicted in

Figure 7.

6.1. Crack Turning Angle Optimization

Based on the previous optimization of temporary plugging fracturing parameters, the fracture turning angle of diagonal wells is optimized, and the fracturing time is taken as the fourth year of production. Half-length of crack: 190 m; initial pressure fracture conductivity: 300 mD·m; fracture conductivity: 300 mD·m; the decreasing law of initial pressure fracture conductivity is the same as before.

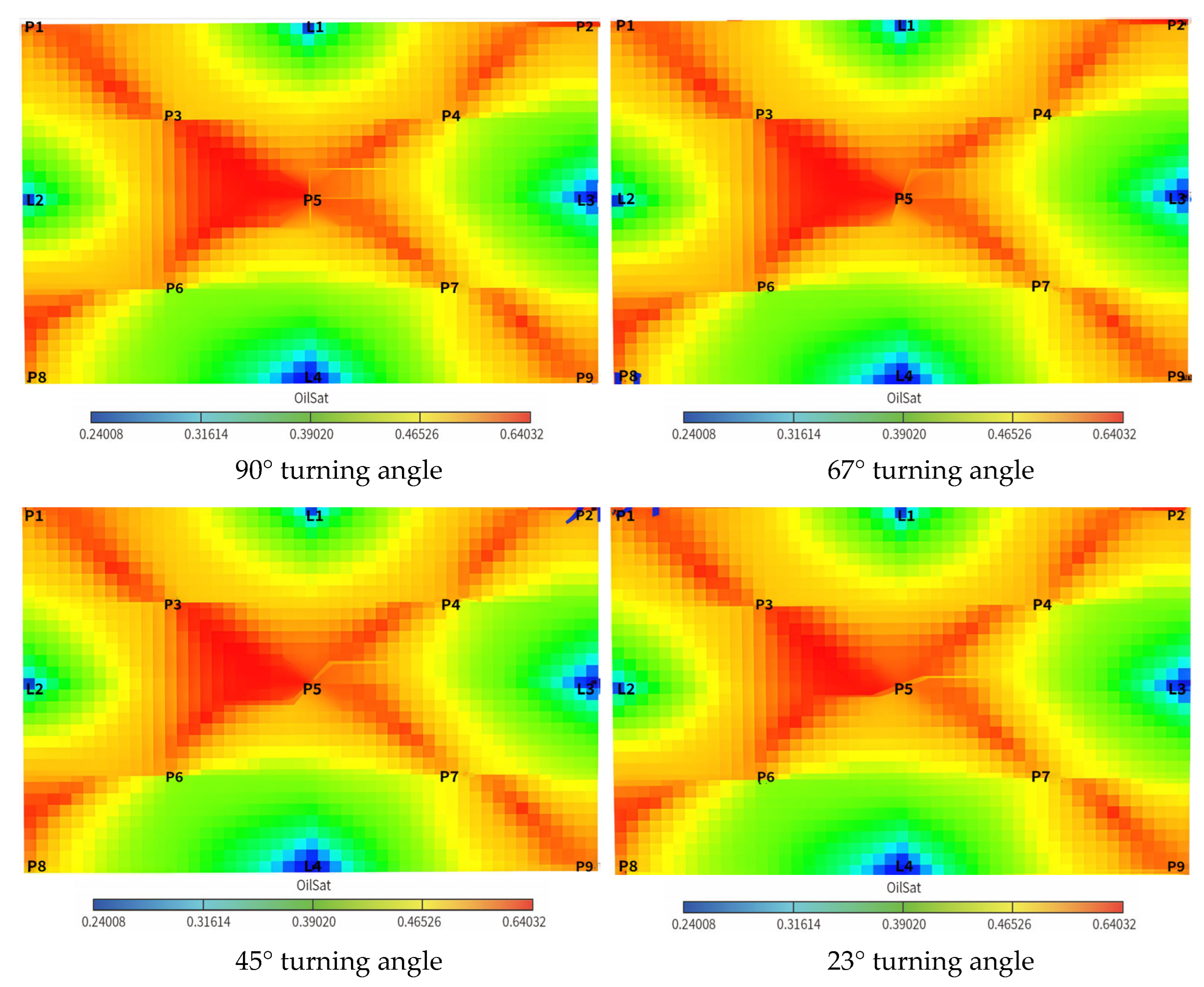

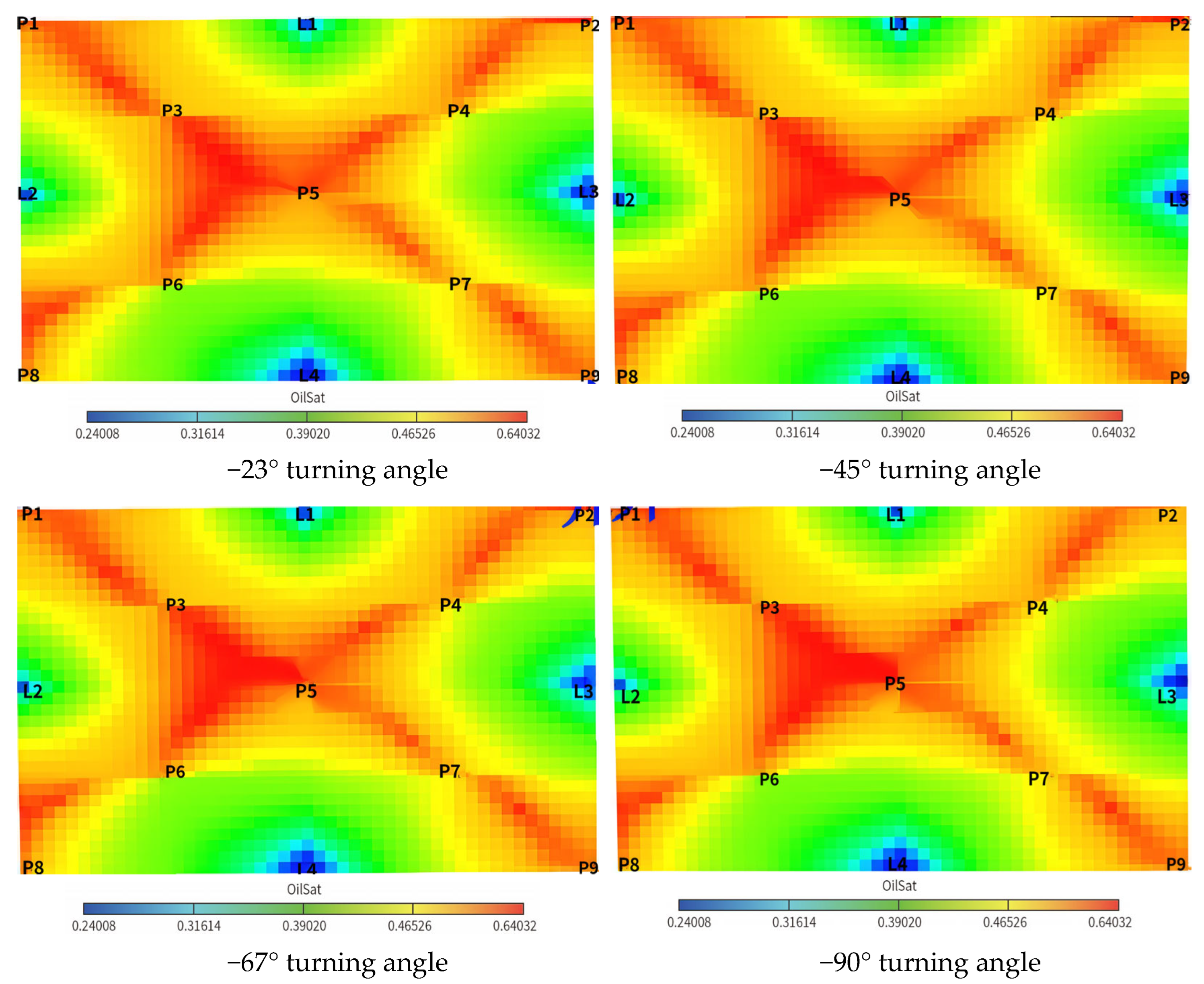

The variation law of cumulative oil in corner wells and side wells was studied, respectively. The remaining oil distribution in the fourth year of production was compared with the final oil saturation distribution without repeated fracturing for ten years and the final oil saturation distribution without fracturing, as shown in

Figure 8.

Then, the temporary plugging repeated fracturing was carried out in the fourth year, and the final oil saturation distribution map of different turning angles was shown in

Figure 9.

6.2. Analysis of Simulation Results

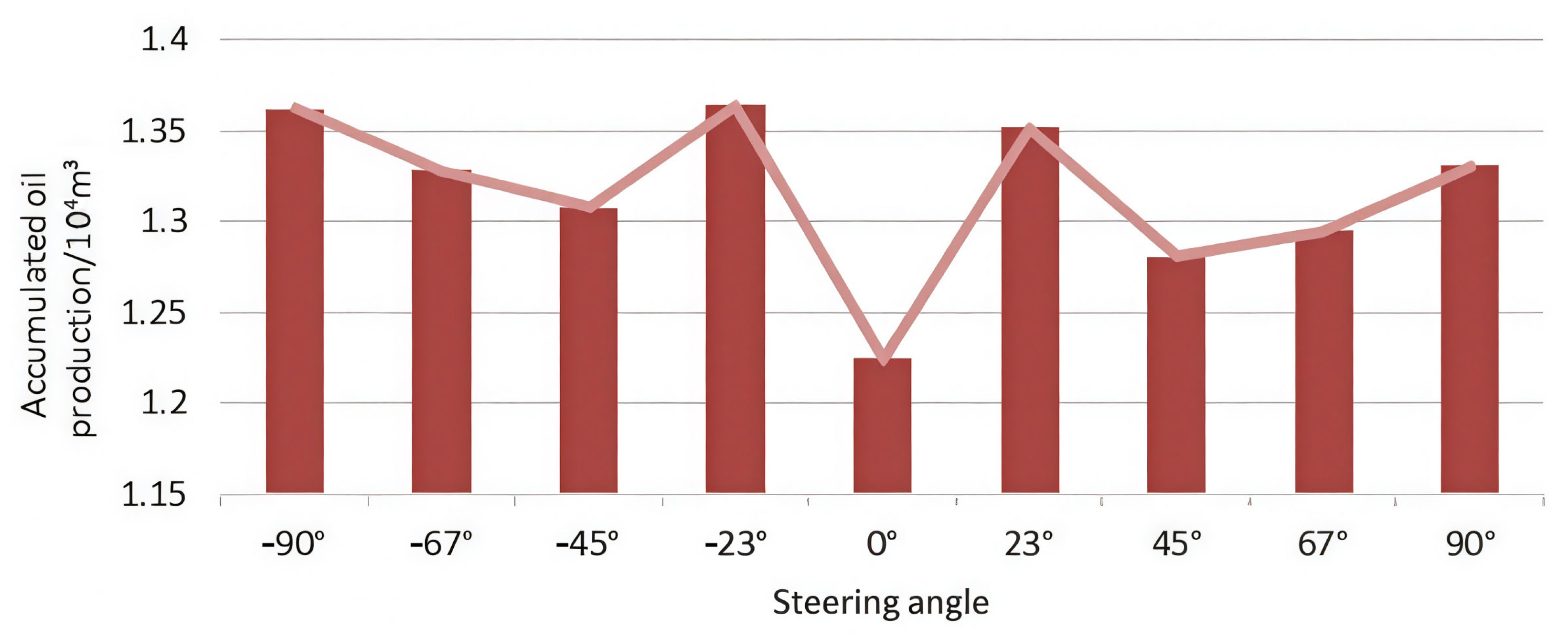

(1) From the analysis of the optimal turning angle of cumulative oil production, the cumulative oil production of oil wells under different fracture turning angles is shown in

Figure 10.

According to the distribution of the remaining oil in the corner well, the remaining oil available at different angles is different. Through the cumulative oil production of oil wells under different fracture turning angles, it can be seen that the trend of cumulative oil production effect is symmetrically distributed with 0° as the center, and the cumulative oil production is higher in the cases of −23° and −90°. It is considered that the optimal turning angle of the angle shaft is −23°.

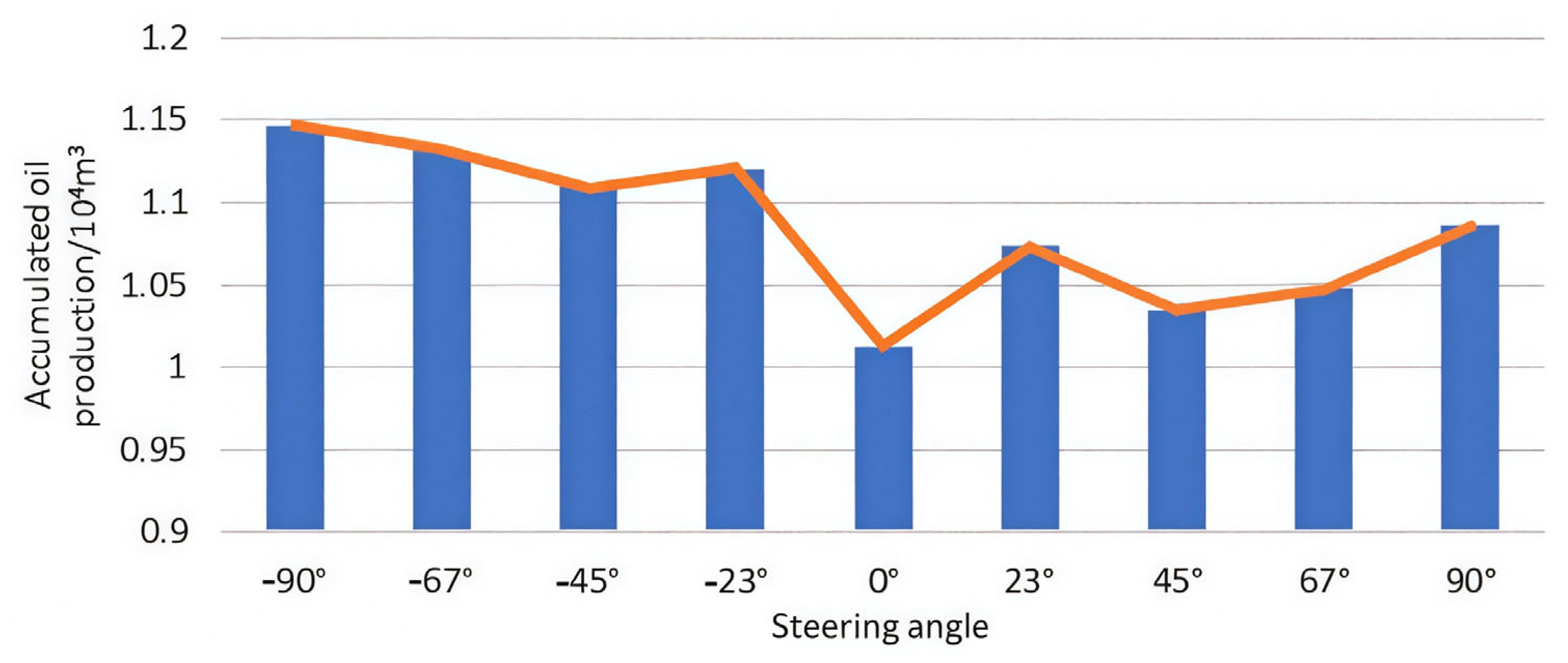

(2) From the cumulative oil production analysis of the optimal turning angle, the cumulative oil production of oil wells under different fracture turning angles is shown in

Figure 11.

According to the distribution of remaining oil in side wells, the remaining oil available at different angles is different. It can be seen from the cumulative oil production of oil wells under different fracture turning angles that the cumulative oil production effect trend is symmetrically distributed with 0° as the center, the negative angle is better than the positive angle, and the cumulative oil production is higher at −90°. It is considered that the optimal turning angle of the side well is −90°.

7. Conclusions

(1) The optimal timing for well pattern modification in corner and side wells within the anti-nine-spot configuration of high-yield zones coincides with the conclusion of the water-free oil production phase. From an economic perspective, the practical implementation of modifications is deferred until the water cut remains below 20%.

(2) The optimal fracture parameters are as follows: the half length of the fracture is 190 m, and the optimal fracture conductivity is 30 μm2·cm after the transformation. In order to ensure the stable operation of the fracturing process and reduce the mutual interference between the angle well and the side well and the collusion risk of the fracture intersection, the optimal steering angle of the angle well is 23°. The optimal steering angles of side wells at different positions are different, which are + 90° and −90°, respectively, that is, steering along the direction of remaining oil, so that the fracturing cracks pass through the remaining oil enrichment area.

(3) Regarding the anti-nine-spot well pattern in low-yield zones (characterized by reservoir parameters including oil layer thickness, porosity, and permeability at 0.8 times those of high-yield blocks), optimization follows the aforementioned procedure. While the optimized fracture parameters remain largely consistent with high-yield zones, the optimal fracture half-length increases to 230 m. Owing to inferior reservoir properties and consequently slower waterfront advancement, the optimal modification timing can be appropriately extended until the water cut reaches 20–40%.

Author Contributions

Conceptualization, Z.X. and Z.Z.; methodology, Z.X.; software, Z.Z.; validation, Y.C. and H.T.; formal analysis, Z.X.; investigation, resources, Z.X.; data curation, Y.C.; writing—original draft preparation, Z.Z.; writing—review and editing, Z.X.; visualization, supervision, Z.X.; project administration, Z.X.; funding acquisition, Z.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, Z.; Deng, X.; Li, J. Fracture Characteristics and Influencing Factors in Chang 63-Chang 71 Low-porosity and Low-permeability Reservoir of Yanchang Formation in Southeastern Ordos Basin. Sci. Technol. Eng. 2024, 24, 12025–12032. [Google Scholar]

- Xiong, Q.; Li, L.; Lan, Z.; Zhang, L. Research on the Development Law of Broadband Fracturing in Offshore Ultra-low Permeability Reservoirs. Drill. Prod. Technol. 2021, 44, 50–53. [Google Scholar]

- Da, Y.; Xue, X.; Liu, M.; Shi, P.; Qu, H.; Zhou, F. Energy Enhancement Mechanism of Energy Storage Refracturing in Ultra-low Permeability Oil Fields. Sci. Technol. Eng. 2021, 21, 14139–14146. [Google Scholar]

- You, C.; Jia, H.; Zhang, Q.; He, X.; Li, Z. Dual directional treatment technology for oil and water wells to improve single well production in fully assembled ultra-low permeability and high-water content fractured reservoirs. Oil Drill. Prod. Technol. 2024, 46, 681–694. [Google Scholar] [CrossRef]

- Su, L.; Chang, D.; Qi, Y.; Huang, T.; Li, X.; Da, Y. Research and application of volume fracturing technology for old wells in ultra-low permeability reservoirs. Drill. Prod. Technol. 2020, 43, 75–77+89+5. [Google Scholar]

- Zhou, X.; Wang, Z.; Huang, Z.; Shi, J.; Lu, T.; Zhao, X. Numerical Simulation and Application of Broadband Fracturing Parameter Optimization in Changqing Jiyuan Oilfield. Drill. Prod. Technol. 2021, 44, 47–51. [Google Scholar]

- Ling, Y.; Wang, X.; Gao, X.; Zhu, K.; Wang, R.; Wei, T.; Yin, S. Injection Production Adjustment Technology for Ultra-low Permeability Reservoirs in the Ordos Basin. Sci. Technol. Eng. 2024, 24, 11102–11110. [Google Scholar]

- Li, X.; Duan, P.; Wang, L.; Kang, B.; Li, Z. Study on Remaining Oil Distribution and Stimulation Measures of Low Permeability Bottom Water Reservoir: Taking Wellblock Y19 in Changqing Oilfield as an Example. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2022, 37, 69–75+126. [Google Scholar]

- Yuan, S.; Han, H.; Wang, H.; Luo, J.; Wang, Q.; Lei, Z.; Xi, C.; Li, J. Research progress and potential of new enhanced oil recovery methods in oilfield development. Pet. Explor. Dev. 2024, 51, 841–854. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, M. Application of facies-controlled prestack geostatistical inversion method in high quality reservoir prediction of low permeability reservoir: A case study of V Oil Formation of Es33 in Block A. Pet. Reserv. Eval. Dev. 2022, 12, 666–676. [Google Scholar] [CrossRef]

- Wu, H.; Peng, X.; Zhu, S.; Feng, N.; Zhang, S.; Ye, Z. Numerical Simulation on Polymer Flooding Recovery of Conglomerate Reservoirs:Horizontal Fractures in Arched Wells After Multi-Stage Fraturing. Xinjiang Pet. Geol. 2022, 43, 85–91. [Google Scholar]

- Guo, Y.; Qu, Q.; Cao, X.; Ji, Y.; Zou, J.; Miao, M.; Song, L.; Feng, H.; Wang, Z. Improvement of waterflooding sweeping efficiency of the well patterns in low-permeability oilreservoirs with plane heterogeneity based on injection and production optimization. Oil Drill. Prod. Technol. 2020, 42, 214–221. [Google Scholar] [CrossRef]

- Li, D.; Chen, Z.; Zou, Q.; Gong, S.; Liu, C.; Wang, T.; Lai, J.; Ge, J.; Jiang, M.; Pan, D.; et al. Fracturing technologies for Longtan Formation deep coal-rock gas in Da’an Block of western Chongqing, Sichuan Basin. Nat. Gas Ind. 2024, 44, 150–158. [Google Scholar]

- Guo, J.; Lu, C.; Ma, L. Engineering scheme optimization and field application of fracturing-flooding for low-permeability reservoirs in Shengli Oilfield. Pet. Geol. Oilfield Dev. Daqing 2024, 43, 204–214. [Google Scholar] [CrossRef]

- Cao, Y.; Shi, B.; Tian, L.; Li, F.; Cao, Y.; Dong, S.; Zhou, D. Development and application of dense multi-cluster fracturing in horizontal wells for low permeability and low pressure coal reservoir. J. China Coal Soc. 2020, 45, 3512–3521. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Liang, S.; Zhao, J.; Hu, Y.; Li, Y. Secondary propagation of hydraulic fracture in low-permeability reservoir after shut-in. Oil Drill. Prod. Technol. 2023, 45, 597–606. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, Z.; Tan, Q.; Zhang, X.; Wang, X.; Gao, B. Study on Fracture Propagation and Parameter Optimization of Fracturing Packing in Unconsolidated Sandstone Reservoirs. China Pet. Mach. 2023, 51, 67–75. [Google Scholar] [CrossRef]

- Song, L.; Wang, J.; Liu, C.; Sun, Z.; Tian, B. Multi-fractures propagation law of low permeability sand shale interbedoil reservoirs fracturing. Fault-Block Oil Gas Field 2023, 30, 25–30. [Google Scholar]

- Chen, X.; Wang, G.; Liu, P.; Du, J.; Tang, H.; Deng, Z.; Wu, Z. Diverting fracturing stimulation using a novel diverting agent: Laboratory study and field application. Geoenergy Sci. Eng. 2025, 247, 213715. [Google Scholar] [CrossRef]

- Huang, G.; Li, M.; Zhou, F.; Chu, J.; Xiong, Z. A New Numerical Simulation Method for Multi-stage in-Fracture Temporary Plugging and Diverting Fracturing: Based on the Modified Cohesive Zone Model. Rock Mech. Rock Eng. 2024, 57, 8723–8740. [Google Scholar] [CrossRef]

- Tang, C.; Xu, W.; Li, B.; Xin, H.; Zhang, X.; Tian, H.; Mou, J. Research and Successful Application of the Diverted Fracturing Technology of Spontaneously Selecting Geologic Sweet Spots in Thin Interbedded Formation in Baikouquan Field. Energies 2022, 15, 5208. [Google Scholar] [CrossRef]

- Li, M.; Liu, J.; Xia, Y. Risk Prediction of Gas Hydrate Formation in the Wellbore and Subsea Gathering System of Deep-Water Turbidite Reservoirs: Case Analysis from the South China Sea. Reserv. Sci. 2025, 1, 52–72. [Google Scholar] [CrossRef]

- Cao, L.; Lv, M.; Li, C.; Sun, Q.; Wu, M.; Xu, C.; Dou, J. Effects of Crosslinking Agents and Reservoir Conditions on the Propagation of Fractures in Coal Reservoirs During Hydraulic Fracturing. Reserv. Sci. 2025, 1, 36–51. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).