Abstract

The aviation industry requires a series of actions that will transform its current status, aiming for sustainable operations. Aviation’s end-of-life stream is a pivotal lever for circularity, yet current dismantling and recycling practices leave significant value unrealized. Circular Economy could be considered as a transformational approach to the aviation industry and address its environmental and economic challenges, meeting sustainability principles. This study conducts a PRISMA-guided qualitative systematic review across academic and industry sources to synthesize regulations, technologies, and economics of aircraft decommissioning. It aims to quantify material recovery potential and environmental gains at the aircraft level and assess technology readiness and cost drivers for metals, polymers, and composites. Findings indicate that optimized decommissioning enables high-value part reuse and substantial material recovery (notably aluminum), with associated lifecycle greenhouse-gas avoidance at the aircraft scale. However, high costs, weak regulations, and limited recycling technologies hinder adoption. Results show that optimized dismantling and certified part-reuse pathways can recover up to 85–90% of total aircraft mass, with potential CO2-emission avoidance of 25–35 t per narrow-body aircraft compared with landfill disposal. Metal recycling technologies (TRL 8–9) already achieve high yields, whereas polymer and composite recycling remain limited (TRL 5–6) by purity and certification barriers. A comparative assessment of EU, US, and Asia–Pacific regulations identifies enforcement and infrastructure gaps hindering implementation. The study introduces an integrated CE roadmap for aviation comprising (i) standards-aligned design-for-disassembly and digital traceability, (ii) accredited MRO-to-reuse networks, and (iii) performance-based policy incentives.

1. Introduction

The aviation sector has contributed to the world’s development and economic growth, securing around 88 million jobs with 4.5 billion onboard passengers. In 2022, the industry contributed to the global Gross Domestic Product (GDP) by 3.4%, and the air transportation system recovered after two years of depression due to COVID-19 travel restrictions. In addition, a market analysis carried out by the International Air Transport Association (IATA) showed a 10.7% growth in air traffic and the airlines’ revenue from passengers, cargo, and other operations, for the period 2016–2021 [1]. However, the sector’s rapid fleet expansion—coupled with rising environmental pressures—poses challenges in managing aircraft at their end-of-life (EoL) stage. Historically, decommissioned aircraft were dismantled for scrap metal recovery, but the growing emphasis on carbon neutrality, resource efficiency, and extended producer responsibility has transformed aircraft retirement into a strategic sustainability priority. Inevitably, it should also be noted that aviation is one of the most resource-intensive industries globally, where various materials, from metals to plastics, alloys, and other composites, are used in aircraft development. Obviously, the number of materials, per type of aircraft, varies depending on the size, operations, expected performance, and usage. This raises the concern that a significant number of valuable resources and materials are being wasted when an aircraft reaches the end of its operational cycle. Namely, more than 15,000 aircraft have been retired between 1980 and 2015, with environmental and economic impacts associated with aircraft EoL treatment and materials becoming increasingly concerning [2]. Aircraft decommissioning is a process that provides an opportunity to recover residual value through part reuse and material recycling; however, challenges persist in scaling up these practices. Notably, despite advancements in aircraft decommissioning methods and practices, a significant amount of material is directed to landfills or repurposed for non-aerospace sectors [3]. Consequently, while aviation growth reflects the industry’s critical role in the global economy, it also implies intensified material demand for fleet expansion, manufacturing, and maintenance activities. The increase in aircraft production and operation consequently heightens pressures on resource availability and waste management, bringing EoL considerations to the forefront of sustainability discussions, requiring tools and frameworks to drive the change.

The circular economy (CE) framework provides an integrated approach to reducing resource depletion by promoting design for longevity, reuse, remanufacturing, and material recovery within the aviation sector [4]. CE has been successfully implemented in industries such as automotive and construction, where closed-loop manufacturing and extended product life cycles have demonstrated tangible environmental and economic benefits. These sectors provide transferable insights into how systemic resource efficiency and design-for-disassembly can reduce waste and operational costs—principles highly applicable to aviation, given its complex supply chains and material intensity. However, these two industries are used as examples to structure and support this research, given that they both are resource-intensive, with high demand for resources, and with multiple and complex operations, as the aviation industry is. However, within the aviation sector, the adoption of CE principles remains limited and fragmented. Existing studies have often focused on isolated dimensions, such as eco-design for aircraft components [5], reuse of serviceable parts [6], or regulatory and policy frameworks [7], without integrating these aspects into a unified understanding of circularity across the aircraft life cycle. A more comprehensive synthesis that connects these regulatory, technological, and economic dimensions is therefore required to translate CE principles from other industries into viable strategies for aviation sustainability.

In this context, the present study builds on lessons from established CE applications in other sectors while addressing the unique challenges of aviation—stringent safety standards, certification constraints, and complex material compositions. It aims to bridge this gap by developing an integrated framework that links regulatory instruments, technological enablers, and economic outcomes to support circular value retention in aircraft decommissioning and recycling.

It is noteworthy that CE is a model that could bring a significant solution to the continuous consumption of resources, with the current linear system exploiting around 60% of the world’s natural resources during the last 50 years [8]. Hence, a pathway to a narrow-closed loop of reuse, recycling, and energy recovery could be the option for achieving CE. Recycling materials is not always a feasible option, so defining CE as a fixed quantity of material repeatedly recycled is constraining [9]. Therefore, European countries are driven towards eco and social innovations and developing new business models demonstrating CE [10]. This paper will investigate the current practices and regulatory frameworks surrounding aircraft decommissioning, emphasizing the importance of sustainability, waste management, and material recovery for the aviation industry, considering the associated research gaps. In particular, existing literature lacks comparative evaluation of international regulations and their enforcement effectiveness; quantified metrics for environmental and economic performance (e.g., recovery efficiency, lifecycle CO2 reduction, cost per tonne of avoided emissions); and analysis of how technical aviation sectors, like maintenance, repair, and overhaul (MROs), can serve as nodes for circular value retention. By addressing these specific gaps through a structured literature synthesis and an integrated conceptual model, this study provides an empirically grounded contribution to the theoretical and practical understanding of circular aviation systems. Addressing these gaps is essential for defining evidence-based pathways toward a sustainable and resource-efficient aviation sector. This study contributes a cross-disciplinary synthesis combining regulatory analysis, technological assessment, and economic evaluation within a unified CE framework for aviation. Drawing on CE principles—closing, narrowing, and slowing resource loops—the paper develops a conceptual model that links regulatory instruments to technological enablers and economic outcomes. This framework underpins the subsequent analysis and serves as a foundation for policy and operational recommendations. Specifically, the study aims to:

- Map global regulations and standards governing aircraft EoL management and evaluate their implementation performance;

- Identify and compare technological advances in dismantling, material recovery, and component reuse;

- Quantify potential material- and emission-related benefits of circular EoL strategies;

- Formulate policy and industry recommendations for scaling circularity in aviation.

This study is therefore guided by the hypothesis that strengthening the alignment between regulatory frameworks, technological innovation, and economic incentives can significantly enhance aircraft circularity; it contributes original value by integrating these dimensions into a coherent theoretical framework grounded in circular economy principles and supported by evidence-based analysis.

2. Methods

This study employs a systematic literature review (SLR) combined with qualitative framework analysis to identify and synthesize best practices in aircraft decommissioning and recycling within the circular economy (CE) paradigm. The review protocol follows the PRISMA 2020 guidelines to ensure transparency and replicability. The methodology applied in this paper is qualitative content analysis, using the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) 2020. This framework provides a standardized protocol for conducting and transparently reporting systematic reviews. It ensures that the identification, screening, and inclusion of sources follow an explicit, replicable process that minimizes bias and enhances methodological rigor. PRISMA 2020 is widely used across disciplines, including environmental and engineering research, to improve the reliability and traceability of evidence synthesis.

In the context of this study, PRISMA 2020 serves three key purposes: (i) to structure the review process across multiple databases and document types (academic, institutional, regulatory); (ii) to enhance transparency and replicability in source selection and coding; and (iii) to strengthen the validity of the findings by ensuring consistent inclusion and exclusion criteria. Applying PRISMA thus allows the study to integrate a diverse evidence base—ranging from peer-reviewed literature to policy documents—within a systematic, quality-assured framework suitable for circular economy and aviation research.

Identifying definitions and keywords in search engines to identify relevant material in aircraft decommissioning and the CE. Even though waste management and CE are pervasive to explore and research, the use of the same terms under the aviation spectrum is infrequent. A keyword-based search strategy was used across multiple academic databases and industry reports to collect materials from organizations and research entities specializing in aviation decommissioning and waste management. A systematic literature review was conducted following PRISMA guidelines using Scopus and Web of Science databases. Some of the keywords used were CE, Decommissioning, Waste Management, Materials, Aircraft Systems, and Alloy Metals.

The selection process prioritized sources that extensively addressed the materials used in aircraft systems, including equipment, cabin interiors, airframes, landing gear, and hydraulic systems. Given the complexity of aircraft structures and the variability in material composition across different aircraft models, the collected data were categorized into clusters based on material type. The primary focus was on metals and plastics, as these represent the dominant materials in aircraft manufacturing.

2.1. Search Strategy

Relevant publications were retrieved from Scopus, Web of Science, and ScienceDirect for peer-reviewed studies, and from institutional repositories such as IATA, ICAO, AFRA, EASA, and ISO for official and regulatory documents. The selection of these databases and institutional sources was based on their comprehensive coverage, reliability, and relevance to aviation and sustainability research. Scopus and Web of Science were chosen for their extensive indexing of peer-reviewed journals across environmental engineering, materials science, and circular economy disciplines, ensuring methodological rigor and traceability. ScienceDirect was included due to its strong representation of applied engineering and aerospace technology publications. In addition to academic databases, grey literature from IATA, ICAO, EASA, and FAA was incorporated because these organizations produce authoritative, policy-relevant data and technical guidelines that are not typically indexed in academic sources but are essential for understanding regulatory and operational frameworks.

Only English-language sources were included to ensure consistency in data extraction and coding quality. Although this choice may exclude regional or non-English studies, the focus on globally recognized organizations and peer-reviewed journals mitigates this limitation by capturing the most influential and internationally cited contributions. Where possible, regional practices and regulatory developments were inferred from translated summaries or cross-referenced institutional reports.

The search string combined Boolean formats as shown in the example below:

(“aircraft” AND (“decommission*” OR “dismantl*” OR “end-of-life” OR “retirement”)) AND (“circular economy” OR “recycl*” OR “remanufactur*” OR “sustainab*”) AND (material terms: aluminium, composite, polymer, CFRP, titanium).

Additionally, some research limitations include, searches covered between January 2000–March 2025, and only English-language sources. Finally, reference lists of key papers were cross-checked to capture additional relevant studies.

2.2. Screening and Selection

The identification–screening–inclusion process followed the PRISMA framework to ensure methodological transparency. After removing duplicates, a total of 312 records were identified across databases and institutional sources. Screening occurred in three stages:

- (i)

- Title screening to exclude clearly irrelevant records (e.g., non-aviation or unrelated circular economy studies);

- (ii)

- Abstract screening to retain publications addressing aircraft, aerospace, or high-value material recovery within CE or sustainability contexts; and

- (iii)

- Full-text review to assess methodological robustness, relevance to end-of-life (EoL) management, and the presence of quantitative or regulatory insights.

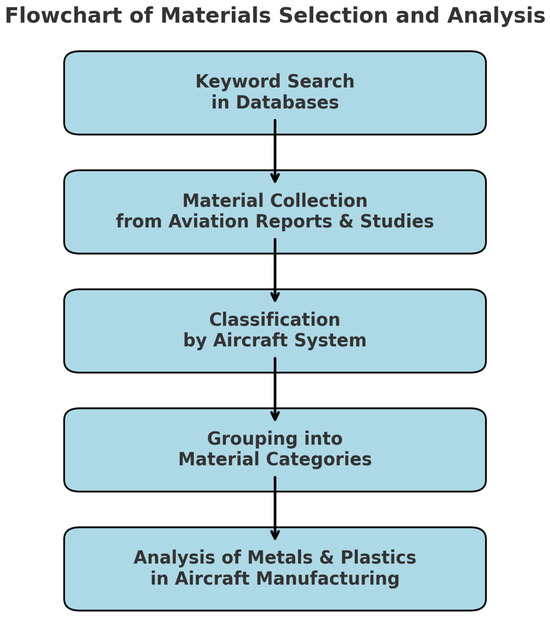

Studies were excluded if they lacked methodological transparency, quantitative data, or relevance to aviation CE applications. The final dataset comprised 102 full-text documents used for qualitative synthesis, as depicted in the PRISMA flowchart (Figure 1).

Figure 1.

Flowchart of materials selection and analysis process.

2.3. Inclusion and Exclusion Criteria

The inclusion criteria required peer-reviewed papers or institutional reports addressing aircraft EoL, circular economy frameworks, or recycling technologies with traceable methodology or quantitative indicators. The exclusion criteria concern sources from non-academic news, unverified web content, or studies lacking methodological detail.

2.4. Data Extraction and Coding

Data extraction and coding followed a structured protocol to ensure replicability. Each eligible source was entered into a standardized extraction sheet developed in Microsoft Excel, and then coded, capturing:

- –

- Publication metadata (year, region, study type);

- –

- Focus area (regulatory, technological, economic, environmental);

- –

- Reported quantitative indicators (recovery %, CO2-saving, cost/t);

- –

- Technology readiness level (TRL) and material class;

- –

- Stakeholder or policy context.

To enhance reliability, a dual-review coding process was implemented. One author conducted the primary coding, while the second independently verified a random sample of 25% of the entries. Any discrepancies were resolved through discussion until a consensus was reached. Where differences persisted, they were reviewed jointly against the PRISMA inclusion criteria. Thematic categories were then developed inductively through framework analysis, grouping findings under four domains: regulatory frameworks, CE strategies, material decommissioning, and economic implications.

2.5. Validation and Reliability

To ensure a robust and valid assessment of information. Coding reliability was ensured through cross-checking of sources and valid published information. The validation process ensured inter-coder consistency and traceability of data. Agreement rates between reviewers exceeded 90% across thematic categories, confirming reliability. The cross-verification step strengthened internal validity and reduced subjective interpretation bias in qualitative coding.

2.6. Limitations

Although the PRISMA approach enhances rigor, certain limitations persist. The restriction to English-language sources introduces potential language bias, as region-specific reports and local regulatory documents may not be represented. This limitation is partly mitigated by including international institutional data (IATA, ICAO, EASA, FAA) that consolidate information from multiple jurisdictions. Future research could benefit from incorporating multilingual searches and regional databases to enhance representativeness, particularly for Asia–Pacific and Latin American contexts. The quantitative comparability across sources may be constrained by inconsistent metrics, and proprietary industry data remains partly inaccessible. These limitations are addressed by triangulating academic and institutional evidence where possible.

To enhance clarity and replicability, Figure 1 presents a flowchart outlining the materials selection and analysis process.

3. Aircraft Decommissioning Regulations and Guidelines

As mentioned above, between 1980 and 2015, over 15,000 commercial aircraft were retired globally, and between 2010 and 2014, the number of aircraft retired annually ranged from 700 to 900, with an average retirement age of approximately 27 years. Decommissioning is a process that offers the opportunity to recover residual value from reused parts and recycled materials while mitigating environmental and safety risks [2]. Two global industry associations have produced documents describing best practices in aircraft decommissioning and recycling: the best management practices (BMP) by the Aircraft Fleet Recycling Association (AFRA) and the Best Industry Practices for Aircraft Decommissioning (BIPAD) manual by IATA. AFRA is the leading organization for the development and promotion of safe and sustainable practices for the management of the EoL aircraft components. One of the main goals and the scope of work of AFRA is the assurance of quality, safety, environmental stewardship, and collaboration among all its members. AFRA ensures that all its accredited members: meet and even exceed the industry’s standards, safety is preserved and maintained, protect the environment and reduce as much as possible, the industry’s impact on critical resources through product life cycle assessments. AFRA is the only association at the moment, offering partnerships and best practices, that can ensure aircraft disassembly, recycling, and EoL solutions to be applied across the whole aviation industry, supporting sustainability principles and the CE, among its operations [2]. Apart from the AFRA goals and having taken into great consideration that 12,000 aircraft will be retired in the next two decades, IATA’s manual BIPAD offers clear direction about all the phases of the aircraft EoL processes. The difference between the two manuals—AFRA and IATA—is that the first presents best management practices for application by specialized aircraft dismantling and recycling companies, while the latter is for aircraft owners and operators, and is therefore complementary to the AFRA manual [10].

Additionally, the International Civil Aviation Organization (ICAO) sets guidelines for aircraft dismantling activities, ensuring compliance with airworthiness standards, waste management, and recycling. This includes adhering to: ICAO Standards and Recommended Practices (SARPs); other regulatory documents from international and industry-specific organizations and various industry-specific guidelines. Disassembled aircraft parts must remain airworthy and be recertified before reuse, with their operational history properly documented and traced. Related requirements and guidance are also described in the SARPs in Annex 6 (Operation of Aircraft), and Annex 8 (Airworthiness of Aircraft) to the Chicago Convention on International Civil Aviation, as well as the Airworthiness Manual in ICAO Document 9760 [10] offering a very detailed approach regarding decommissioning. All three entities are the main ones currently supporting and giving guidance to the aviation industry as to how to move forward in the aircraft decommissioning approach and phases.

3.1. Waste Management Regulations

Waste management practices and regulations are interlinked with decommissioning. Various nations have enacted regulations and standards to manage waste and safeguard the environment and human health effectively. The EU Waste Directive (Directive 2008/98/EC) establishes a legal framework for waste treatment, recovery, and recycling, aiming at relieving pressure on resources and optimizing their use [11,12]. In 2016, the European Commission introduced Regulation (EU) 2016/1245, which provides a correlation table between customs and waste codes to aid customs officials in identifying potential waste streams, thus combating illegal waste exports from the EU [13]. When disassembling an aircraft, it’s recommended to:

- ○

- Employ a European Union Aviation Safety Agency (EASA) or a Federal Aviation Administration (FAA) Part 145 maintenance organization, depending on the aircraft registry, to remove serviceable components.

- ○

- Ensure all removed components are accompanied by appropriate documentation, including logbooks and maintenance records. All traceability standards, forms, and accompanying documents must be available.

- ○

- Store and label the removed components properly, making sure storage and environmental conditions will not affect the components and materials pertaining.

- ○

- Follow the disassembly procedures outlined in documents such as the Aircraft Fleet Recycling Association’s best management practices (AFRA BMPs) [2].

3.2. Environmental Aspects of Decommissioning and Material Use

The disassembly and dismantling phases generate several categories of hazardous waste, which require strict management to mitigate environmental risks and ensure regulatory compliance. These can be broadly categorized as air emissions, liquid waste, and solid or hazardous materials:

- Air emissions: Cutting, surface treatment, and paint-removal operations release airborne pollutants such as paint dust containing heavy metals (lead, cadmium), volatile organic compounds (VOCs), and fine particulates. Effective control requires localized exhaust ventilation and filtration systems compliant with ICAO Environmental Standards and national air-quality regulations.

- Liquid waste: Decommissioning generates contaminated wastewater and residues from hydraulic fluids, fuels, coolants, and de-icing agents (e.g., glycol-based fluids). These substances must be collected, treated, or recycled under the EU Waste Framework Directive (2008/98/EC) or equivalent national legislation to prevent soil and groundwater contamination.

- Solid and hazardous materials: Aircraft contain components with hazardous elements such as asbestos, mercury switches, nickel-cadmium batteries, and pressurized cylinders (oxygen and nitrogen). Proper segregation, labeling, and certified disposal or energy recovery are mandatory to comply with EASA and FAA hazardous material handling standards. Safe management practices—including material segregation, controlled storage, and certified disposal—are essential to avoid contamination and to recover materials where feasible [2,14].

3.3. Materials Reuse

Following proper procedures for aircraft disassembly is essential for preserving the value of its components and preventing unnecessary repairs or maintenance.

3.3.1. Reuse of Critical Assets

Halons, which are stable compounds used in fire extinguishers, have been associated with the depletion of the ozone layer. Since 1994, developed countries have banned the production and importation of newly manufactured halons under the Montreal Protocol. Due to ozone depletion and the lack of efficient substitutes, proper halon removal and recycling are necessary. Aircraft fire protection systems are vital for any aircraft operation and safety procedures. Any aircraft lacking the minimum regulatory standards of fire protection they are grounded. It is noteworthy that the aviation sector is considered one of the primary consumers of Halon 1301, yet the efforts to replace Halon 1301 in aircraft fire protection systems with other substances have been proven challenging. However, due to its severe effects on the natural environment and people, it is of paramount importance to efficiently recover and recycle halon for various aircraft components. Such approaches could bring several benefits: enhancing the aircraft fire protection systems, supporting commercial viability, and promoting environmental sustainability [2]. International frameworks such as the ICAO Standards and Recommended Practices (Annex 6 and Annex 8) and the European Regulation (EU) No. 517/2014 on fluorinated greenhouse gases mandate traceable recovery processes, certification of reclaimed halon, and proper documentation of fire-extinguishing systems. Establishing closed-loop halon recycling programs within MRO operations can therefore both minimize environmental impact and ensure continued regulatory conformity.

3.3.2. Recyclable Materials and Components

Approximately 60% of recyclable materials from aircraft consist of aluminum, with various aluminum alloys utilized. Aircraft parts predominantly comprise metal alloys and composite materials, with aluminum, titanium, and carbon fiber being the most common ones [15].

3.3.3. Material Traceability

Maintaining traceability of dismantled materials is crucial for both safety assurance and environmental accountability. Agreements between aircraft owners and dismantling organizations must clearly define data-sharing responsibilities and documentation standards. Practically, traceability is achieved through digital data logging systems that record component removal, certification, and material routing. Maintenance, repair, and overhaul (MRO) and manufacturing facilities employ unique part identification codes, barcode or RFID tagging, Enterprise Resource Planning (ERP), or blockchain-based traceability software to monitor material flows in real time. These tools follow the regulatory standards under EASA Part 145 and FAA AC 43-9C, and they could support lifecycle analysis of these components that can be reused or recycled, and which are traceable from their operational history in the respective facilities. The integration of these digital traceability mechanisms significantly enhances transparency, safety, and circular material management efficiency [16].

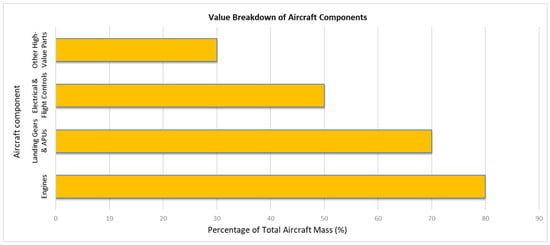

3.3.4. Value Breakdown

Moving forward with more energy-intensive production of aircraft components, engines are essential to examine. Aircraft engines represent 80% of the total residual value, heavily influencing all aircraft disassembly decisions. Landing gears, Auxiliary Power Units (APUs), electrical power systems, flight controls, and navigation systems are among the top five high-value components, constituting around 70% of the airframe’s value, excluding the aircraft engines (see Figure 2). Other valuable parts include engine control systems, environmental control systems, hydraulic systems, safety equipment, pumps, electric motors, escape slides, flap tracks, and all flight control systems from ailerons and elevators to thrust reversers and horizontal stabilizers [15]. However, the level of recycling in engines remains low, and a vast amount of the materials end up in landfills. Enabling direct recycling of aircraft engines would significantly enhance the materials’ value and could potentially reduce the need for raw materials usage [14].

Figure 2.

Value breakdown of aircraft components per total aircraft mass (%).

Regulatory frameworks are central to shaping sustainable practices in aircraft EoL management. International institutions such as the International Civil Aviation Organization (ICAO), the International Air Transport Association (IATA), and the Aircraft Fleet Recycling Association (AFRA) have issued voluntary standards and environmental guidelines promoting responsible dismantling, recycling, and reuse. Complementary regional regulations—such as the European Waste Framework Directive (2008/98/EC) and the Landfill Directive (EU 2018/850)—provide binding requirements for waste hierarchy, producer responsibility, and material recovery targets. Despite this global framework, implementation remains fragmented. The European Union (EU) maintains the most mature legal foundation, with measurable recovery and recycling targets for waste streams, including EoL vehicles and aerospace components. The United States (US) relies largely on market-driven compliance under the Federal Aviation Administration (FAA) and Environmental Protection Agency (EPA) guidelines, emphasizing voluntary adherence to AFRA’s best practices. The United Kingdom (UK) follows EU-aligned policies under its Civil Aviation Authority (CAA), while China and other Asia–Pacific countries are rapidly developing regulations to address growing fleet retirements, but still lack standardized enforcement mechanisms. While the EU demonstrates structured legal enforcement, cross-country comparison reveals substantial gaps in monitoring and transparency. Market-based systems (e.g., the US) foster innovation but lack consistent data collection, whereas emerging regions struggle with standardization and traceability. Common implementation barriers include:

- Economic constraints: high dismantling and certification costs;

- Institutional challenges: limited coordination among regulators, OEMs, and MROs;

- Infrastructure gaps: insufficient certified recycling facilities and logistics chains.

Successful practices are observed in AFRA-accredited facilities that integrate traceability and compliance reporting, and in the EASA Circular Aviation Initiative, which pilots data-driven sustainability metrics. These examples demonstrate the value of harmonized standards, data transparency, and incentive mechanisms in achieving measurable circular outcomes. To support the comparative discussion, Table 1 presents a concise cross-regional overview of aircraft EoL regulatory frameworks, their implementation mechanisms, indicative recovery outcomes, and current challenges. The comparison highlights how regulatory maturity, enforcement capacity, and market infrastructure influence the effectiveness of circularity initiatives across jurisdictions.

Table 1.

Comparative overview of regulatory frameworks for aircraft EoL management.

4. Circular Economy Strategies

CE is a manufacturing and consumption strategy that prioritizes sharing, leasing, reusing, repairing, refurbishing, and recycling materials and products to extend their lifespan [17]. This approach minimizes waste by ensuring that materials remain in circulation within the economy, often through recycling, thereby generating additional value from their ongoing use. CE also enhances environmental protection, as highlighted by reducing greenhouse gas emissions. According to the sixth assessment report by the Intergovernmental Panel on Climate Change (IPCC), human activities, such as burning fossil fuels, deforestation, and agriculture, have contributed to approximately 1.1 °C of global warming since the early 20th century [18]. In addition, CE promotes the redesign phase, reducing energy and resource consumption, given that over 80% of a product’s environmental impact is determined during its design phase [19]. Furthermore, the CE approach embraces long-lasting, durable products, enhancing their quality of life and providing long-term cost savings. It also reduces dependence on raw materials. Only in the European Union (EU), for the year 2021, there was a trade deficit of €35.5 billion, meaning that the EU imports more than it exports [20].

It is worth mentioning that the amount of waste and its management vary greatly among the EU countries [21]. Even though there has been a shift to more recycling and fewer landfilling procedures, the EU countries must continue to reduce the amount of municipal waste sent to landfills to 10% or less of the total municipal waste generated by 2035, aligning with the EU Landfill Directive [22]. Under the same perspective, and in line with the EU’s 2050 climate neutrality goal, the European Commission proposed in March 2022 the first package of measures. The purpose of that package is to speed up the transition towards a CE, as the Circular Economy Action Plan entails as well [23].

The U.S. Environmental Protection Agency (EPA) is developing strategies under the CE Strategy Series. It aims to identify the actions needed to reduce associated impacts with material use, consumption, and disposal [24]. Implementing CE principles in aviation requires interventions along the entire life cycle—design, production, operation, maintenance, and EoL. The CE framework emphasizes closing, narrowing, and slowing resource loops through design-for-disassembly, part reuse, remanufacturing, and high-value recycling.

4.1. CE Design Solution in Aviation

While aviation has adopted several approaches consistent with CE principles, the sector remains far from achieving full circularity. Embedding circularity effectively requires applying circular design principles at the earliest stage of product development—the conceptual design phase. Key priorities for circular aircraft design include extending product durability to lengthen service life and minimize replacements, and facilitating repair, disassembly, and reuse to enable maintenance, refurbishment, and material recovery. Circular design also emphasizes eco-design and recycling to reduce waste and environmental impact throughout the life cycle. The selection of materials plays a central role. Preference is given to recyclable, bio-based, and renewable materials, as well as lightweight composites that enhance efficiency while lowering environmental footprints. Efforts are also directed toward recovering materials such as aluminum, titanium, and composites from retired aircraft, contributing to resource conservation. The use of recycled materials introduces challenges related to safety and limited recycling methods. Initiatives such as urban mining at airports and aircraft boneyards—supported by regulatory and standardization bodies—aim to address these barriers and increase the use of secondary materials. Finally, circular manufacturing focuses on optimizing production processes, minimizing waste, and enabling local manufacturing through technologies like additive manufacturing (3D printing). Together, these strategies form a comprehensive framework for designing and producing more circular aircraft [14].

4.2. ISO Standards

Systemic structures like management systems and ISO standards have been used very frequently in the past decade in the aviation industry and its various operations, especially under the sustainability perspective [25]. For the respective research, the ISO 59000 group of standards for CE is evaluated as part of the CE Design solutions for Aviation. Integrating broader CE frameworks, such as those outlined in ISO 59004:2024, ISO 59010:2024, and ISO 59020:2024, can further enhance industry-wide implementation. These ISO standards provide a structured approach to defining circularity principles, business models, and measurement metrics. Aligning aviation’s circular economy efforts with these international standards could improve standardization, comparability, and the effectiveness of circular strategies within the sector. In particular:

- ISO 59004:2024; Circular Economy—Vocabulary, Principles and Guidance for Implementation. International Organization for Standardization: Geneva, Switzerland, 2024. This standard defines essential terms, establishes a vision and principles for a circular economy, and provides guidance for organizations aiming to implement circular practices [26].

- ISO 59010:2024; Circular Economy—Guidance on the Transition of Business Models and Value Networks. International Organization for Standardization: Geneva, Switzerland, 2024. ISO 59010 offers guidance for organizations transitioning their value creation models from linear to circular frameworks, emphasizing business strategies for implementing circular economy practices [27].

- ISO 59020:2024; Circular Economy—Measuring and Assessing Circularity Performance. International Organization for Standardization: Geneva, Switzerland, 2024. This standard provides requirements and guidance for organizations to measure and assess their circularity performance within defined economic systems, offering a framework for data collection and calculation using circularity indicators [28].

Incorporating these ISO standards, the aviation industry could establish a more cohesive and measurable approach to CE practices, ensuring consistency, scalability, and long-term sustainability across the sector.

4.3. Environmental and Socio-Economic Benefits of CE in Aviation

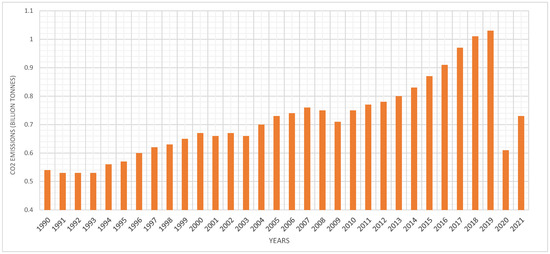

In 2019, during the aircraft operation phase (see also Table 2, global aviation operations emitted approximately 900 million- 1 billion tons of CO2, for both passenger and cargo transport [29,30]. In an aircraft’s life cycle, the operation phase holds the highest environmental impacts, such as noise, air pollution, climate change, and waste. Environmental impacts, however, stem from all life cycle stages, each one consuming energy and water while generating waste [7].

Table 2.

CO2 emissions of the aviation sector, in billion tons, per decade (Source: Our World in Data (2024) https://ourworldindata.org/global-aviation-emissions, accessed on 14 March 2025).

Figure 3 shows the CO2 emissions from the aviation sector, for the period 1985 to 2025, displaying a consistent upward trend until 2019, peaking at over 1 billion tons. The chart highlights a sharp drop in emissions between 2019 and 2021, reflecting the impact of the COVID-19 pandemic and global travel restrictions.

Figure 3.

CO2 emissions of the aviation sector in billion tons, per year from 1990 to 2021 (Source: Our World in Data (2024) https://ourworldindata.org/global-aviation-emissions, accessed on 9 September 2025).

These trends align with Table 2, which shows steady growth in aviation CO2 emissions across the decades leading up to 2019. There are several environmental, economic, and social benefits gained from implementing CE practices in the aviation industry. Recycled aluminum consumes 90% less energy than aluminum produced from raw materials. With the increased usage of more precious materials (e.g., titanium alloys) and increasing prices for energy and raw materials, recycling becomes more important from an environmental and economic perspective [31]. CE practices in aviation lead to reduced greenhouse gas (GHG) emissions emitted by the aviation industry. Current recycling practices yield substantial energy savings, equivalent to powering 10,510 households annually (840.8 million MJ/year) [6]. Reduction in CO2 emissions attributed to aircraft material recycling (61,100 tons) is comparable to the yearly CO2 output of 11,980 average vehicles [6]. Environmental benefits include waste reduction, sustainable resource use, and minimizing carbon footprint [7].

Additionally, social benefits include job creation, attitudes toward sustainability initiatives, and education on sustainability [7]. The recovery of these materials could provide benefits, such as increasing job opportunities, improving a sector’s energy efficiency, and stimulating the market for recycled products [31]. Local economic development, particularly in regions with aviation facilities or recycling infrastructures, can benefit from increased economic activity. For example, the recycling of aircraft materials, such as aluminum, composites, and titanium, from manufacturing plants can generate significant economic advantages for local communities [6]. Recycled materials not only generate revenue but also help reduce costs related to extracting new resources [31]. Despite the creation of additional costs, such as labour expenses and disposal of non-recyclable materials, the positive economic impacts often outweigh these drawbacks [6]. Community engagement is also fostered through aviation recycling initiatives, which often include educational programs, volunteer opportunities, and public outreach campaigns designed to promote sustainable practices [6].

Implementing circular-economy practices within the supply chain enables companies to improve resource efficiency, reduce environmental impacts, and create new business opportunities [32]. For example, by repurposing production residues and scraps, manufacturers can create tools and reduce raw material consumption, thereby cutting costs and reducing waste [33]. Robotic systems used for aircraft part painting have achieved a 30% reduction in paint usage, leading to fewer volatile gas emissions, lower costs, and improved environmental outcomes [34].

In a work conducted, in 2022 ([29]), a hybrid multi-criteria decision-making tool to assess the sustainability and circularity of recycled components in aviation, considering environmental, economic, and social aspects, was investigated. The findings highlight that high-quality recycled components can compete with virgin materials in terms of life-cycle costs and environmental performance, reinforcing the economic viability of CE practices in aviation. However, the study also underscores the challenges associated with the high costs of alternative fuels like hydrogen, which could impact the broader adoption of circular solutions, while emphasizing that maintaining material quality is crucial for ensuring technological and economic feasibility in the sector [29]. In another research, an economic indicator to evaluate aircraft EoL strategies was investigated, aiming to support decision-making in aircraft decommissioning by assessing the financial viability of disposal and recycling options. The financial viability of CE initiatives was assessed using simplified economic indicators from recent studies. Life-cycle cost (LCC) analyses show that design-for-disassembly and modular interiors can lower total maintenance and disposal costs by 8–12% compared with conventional designs [33]. Net-present-value (NPV) assessments for component reuse programs indicate positive returns within 2–4 years, while recycling of advanced composites remains marginally profitable due to energy intensity. When evaluated per avoided tonne of CO2, optimized decommissioning and reuse pathways achieve cost efficiencies of US$ 100–250/t CO2, competitive with typical carbon-offset benchmarks. The findings highlight that disassembling and dismantling aircraft engines yield higher economic gains than entire aircraft, while delaying the recycling process leads to financial inefficiencies. By integrating product, process, and cost properties, the study provides stakeholders with a structured approach to optimize EoL strategies, ensuring cost-effectiveness while promoting sustainable practices in aviation. However, the study underscores the need for a more refined evaluation of salvage values and cost elements to enhance accuracy and account for broader social and environmental impacts [5]. Summing up the key circular strategies for sustainable aircraft design and operation, Table 3 summarizes CE strategies across the aircraft life cycle, illustrating practical applications and quantitative indicators derived from current literature and industrial cases. The integration of quantitative and economic indicators highlights the tangible performance benefits of circular strategies in aviation. Design-for-disassembly and material substitution approaches applied in wide-body programmes such as the Airbus A350 and Boeing 787 achieve a life-cycle cost (LCC) reduction of approximately 10% and avoid 150–200 USD per tonne of CO2, primarily through weight savings and recyclability improvements. In the operation and maintenance phase, digital twin-based predictive maintenance systems (e.g., Rolls-Royce TotalCare, Lufthansa Technik AVIATAR) yield an NPV increase of about 0.5 million USD per aircraft, alongside reduced downtime. For MRO and reuse, certified component recovery achieves 40–60% of part value with a payback period under two years. These metrics demonstrate that circular practices not only enhance environmental performance but also deliver measurable economic gains, confirming the viability of circular economy strategies across the aircraft life cycle.

Nonetheless, future research should explore the economic evaluation of aircraft within a CE framework, providing a more in-depth analysis of cost-benefit mechanisms in material recovery and reuse. Legislative measures and policy incentives play a crucial role in promoting CE adoption, ensuring long-term viability and competitiveness in the sector. An approach integrating economic, technological, and regulatory dimensions is essential for a more effective and sustainable transition to circular aviation. While the current study emphasizes the broader environmental and economic benefits of CE practices in aviation, the lack of available numerical data remains a limitation that future research with industry-specific datasets could address.

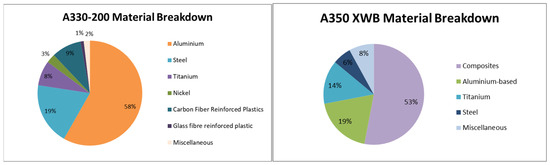

5. Decommissioning of Aircraft Metals

Metal parts are important components of modern aircraft. In a material breakdown of the A330-200 Aircraft, aluminum is the most used material and accounts for 58% of the total weight (specifically 62 tons of aluminum). This is followed by steel, accounting for 19%, and the composites, which represent around 11% of the aircraft’s total weight. On the other hand, carbon fiber reinforced plastic is the largest of composites, a trend that seems to extend to the most recent Airbus aircraft as well [35]. The Airbus A330-200 and A350 XWB were selected as representative models due to their widespread commercial use and contrasting material compositions, traditional metallic vs. composite-intensive designs, allowing comparative assessment of circularity potential. In an Airbus A350 XWB, composite materials account for 53%, aluminum-based materials 19%, titanium 14%, steel 6%, and 8% miscellaneous [36]. In Figure 4, the percentage of the material breakdown for an A330-200 aircraft and an A350 XWB aircraft is depicted.

Figure 4.

Percentage of the material breakdown for an A330-200 aircraft (left side) and an A350 XWB aircraft (right side).

Table 3.

CE strategies for sustainable aircraft design and operation.

Table 3.

CE strategies for sustainable aircraft design and operation.

| CE Stage | Strategy/Mechanism | Industrial Example | Quantitative/Economic Indicator | Reference |

|---|---|---|---|---|

| MRO & Reuse | Certified reuse of components (landing gear, avionics, interiors) | AFRA-certified MROs in Europe and U.S. | Recovery value ≈ 40–60% of part cost; payback < 2 years | [10,11] |

| Operation & Maintenance | Predictive maintenance and part life-extension via digital twins | Rolls-Royce TotalCare, Lufthansa Technik AVIATAR | Extended component life + 15%; downtime ↓ ≈ 25%; NPV↑≈ US$ 0.5 M per aircraft | [6,16] |

| Policy & Business Models | Extended producer responsibility, carbon crediting, and leasing models | EU EPR pilots; ICAO CORSIA integration | CO2 reduction potential ≈ 25–35 t per aircraft; ROI ≈ 12–15% | [23,29] |

| Recycling & Material Recovery | Mechanical shredding and metal remelting; composite pyrolysis/solvolysis | Tarmac Aerosave, ELG Carbon Fibre Ltd. | Metal recovery > 90%; composite fiber yield≈ 70%; TRL 6–9 | [14,36] |

| Design & Production | Design-for-disassembly; material substitution (biobased polymers, recycled aluminum) | Airbus A350 XWB uses 70% lightweight alloys and composites; Boeing 787 employs modular panels | Weight reduction ≈ 20%; LCC↓ ≈ 10%; cost per tCO2 avoided ≈ US$ 150–200 | [33,37] |

5.1. Aluminum Recycling

The predominant metal in aircraft at the end of their operational life is aluminum. The fuselage, the wings, the rudder, the exhaust pipes, the door and floors, the seats, the engine turbines, and the cockpit instrumentation are all made of aluminum. It can be found in landing gear components, engine components, structural components, and fasteners [34]. Recycled aluminum scrap is often used in ferroalloys or as an oxidant in electric steelmaking. If aluminum alloys could be separated during demolition, aircraft aluminum could be reused in different types of applications like manufacturing new aircraft parts; the automotive industry; vehicle manufacturing; bicycle production; construction materials (structural beams, window frames, and roofing materials); non-structural aeronautical uses, and marine applications [38]. Recycling aluminum is highly energy-efficient, requiring only about 5% of the energy needed for primary production, and significantly reducing CO2 emissions.

5.2. Steel and Titanium Recovery

Steel and titanium, which complement aluminum in aircraft structures, also offer recovery potential within circular economy practices. Steel is mainly used in landing gear and engine components, while titanium is found in beams, fasteners, and other high-performance parts. Both materials can be melted and reused in aerospace, automotive, and heavy industries, contributing to resource efficiency and emissions reduction.

5.3. Composite Challenges

Composites, including carbon fiber reinforced plastics (CFRPs), pose greater recycling challenges due to their complex structure and limited end-of-life processing options. Current technologies such as pyrolysis and solvolysis remain under development, with Technology Readiness Levels (TRL 5–6).

6. Decommissioning of Aircraft Plastics

6.1. Introduction and Environmental Impact

Retired aircraft have, on average, 800–1000 components that can be recycled. The major aircraft materials to be recycled are metal alloys (see Section 3) and composite materials. However, plastic is one of the materials in aircraft technologies, with a high share of usability. Undoubtedly, plastics are crucial in modern society’s activities, but they also have a considerable negative impact on the environment and climate. To mitigate these effects while maintaining the benefits of plastics, a transition to a more circular and sustainable plastics system is necessary [39]. The production of plastics is significantly dependent on fossil fuels, leading to a considerable increase in carbon emissions. Projections indicate that if the current growth trajectory continues, by 2050, the plastics industry could account for 20% of global oil consumption and 15% of the available carbon budget. This trend poses a significant threat to achieving the goal of limiting global warming to below 2 °C. While plastics can offer resource efficiency during their usage phase, the associated environmental and health risks, stemming from the diverse chemical substances they contain, are increasingly concerning [40].

6.2. Aircraft Plastic Applications and Hazard Issues

Under these concepts and urgency, plastic use in aircraft and waste must also be addressed. Aircraft plastic parts include panels, luggage compartments, overhead bins, seat frames, tray tables, window shades, decorative panels, ventilation ducting and seals, fuselages, rudders and landing components, insulation, and soundproofing. Materials such as expanded polystyrene (EPS) or polyurethane foam are used to provide thermal insulation and reduce noise levels inside the cabin and cockpit. Other small technical components that use plastic are wiring. Also, certain onboard safety equipment in aircraft, such as life vests and emergency oxygen masks, is made of plastic. Nonetheless, many aircraft components often pose a danger to the environment, since they may be included in the section of hazardous materials and must be handled with care at the end of aircraft service life [6].

6.3. Composites and Recycling Strategies for Circularity

Composite materials play a significant role in modern aircraft, constituting over 50% of their weight. However, there are currently no satisfactory recycling technologies for these materials, posing a challenge for the aviation industry. Despite this, manufacturers continue to favour composite materials for their mechanical properties and lightweight, contributing to the primary structures of aircraft as well as interior applications. Aircraft interior components, constructed from thermoplastic or reinforced thermoset materials, must meet stringent safety regulations while providing durability. Major manufacturers, such as Airbus and Boeing, have explored aircraft recyclability, with Airbus achieving promising results in recycling aircraft components and with Boeing utilizing recycled carbon fiber in cabin sidewalls for certain aircraft models. Efforts are ongoing to develop comprehensive and environmentally friendly recycling processes for aircraft materials to address both economic and environmental concerns [41]. Furthermore, manual dismantling could be considered as an option to improve recovered plastic material quality. However, it would increase recovery costs, particularly in countries with high labour costs. There’s a trade-off between dismantling costs and recovered material quality. Exploring more sophisticated dismantling techniques, such as automation or reverse manufacturing, could optimize the quality of recovered materials. Designing future aircraft with recycling in mind could further enhance recovery and reuse capabilities for EoL materials [38]. Circularity practices in plastic could reduce greenhouse gas emissions, waste, and consequently pollution. The aviation industry could use existing best practices that expand in various industries and adjust them to aviation operations [39].

7. Results

Aircraft decommissioning involves the systematic dismantling, segregation, and recycling of materials to maximize resource recovery while minimizing environmental impact. The metallic and polymeric components of aircraft represent over 85% of total structural mass, offering significant potential for circular material flows. Comparative data from Airbus A330-200 and A350 XWB models (Figure 4) illustrate the evolution toward lightweight alloys and composite materials. The A330’s metallic structure accounts for approximately 68% aluminum, 11% titanium, and 7% steel, whereas the A350 integrates 53% composites, 19% aluminum–lithium alloys, 14% titanium, and 7% steel. These transitions reduce operational weight and emissions but complicate EoL material recovery due to the heterogeneous composition of composites. Aluminum, commonly found in fuselage, wings, and engine turbines, is extensively recycled into aircraft parts, automotive, and construction materials. Steel and titanium, primarily used in landing gear and engine components, are repurposed in heavy industries and high-performance manufacturing. Tungsten and copper are often reused in electronic and industrial applications. Although plastic interior parts and insulation materials have some potential for repurposing, safety equipment and tires present more recycling challenges, although aircraft tires can be retreated up to 12 times. While materials such as aluminum, steel, and titanium have well-established recycling pathways, plastics, insulation, and safety equipment face difficulties due to their material composition and regulatory constraints (see Table 4 for more details).

Table 4.

Decommissioning of aircraft metals and plastic components.

This study focuses on aluminum and aircraft plastics due to their significant presence in decommissioned aircraft and their differing recycling potential. Aluminum, used in structural components, has well-established recycling pathways, while aircraft plastics, including composite materials, pose greater challenges due to their complexity and limited reuse options.

7.1. Environmental Benefits of Aluminum Recycling

Recycling aluminum has significant environmental benefits, particularly in terms of energy conservation and carbon dioxide emissions reduction. One of the key advantages is the substantial reduction in energy consumption. Recycling aluminum significantly reduces energy consumption, requiring only about 5% of the energy used in the primary production of aluminum. This process can help avoid approximately 9 tons of CO2 emissions for every ton of aluminum recycled, highlighting its substantial environmental benefits [42]. The recycling of aluminum prevents over 100 million tons of CO2 from being released into the atmosphere each year, further underscoring the impact of aluminum recycling on global carbon emissions [42]. According to the European Aluminium Association, recycling aluminum avoids the release of 61,100 tons of CO2 emissions annually, equivalent to the emissions produced by approximately 11,980 cars [37].

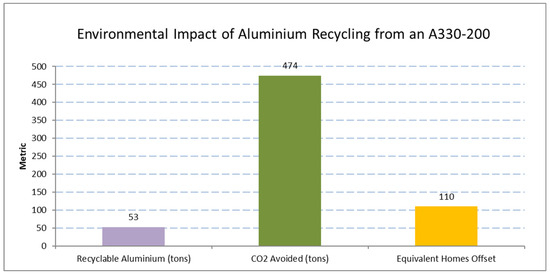

Recycling aluminum from decommissioned aircraft presents a substantial opportunity for both resource conservation and environmental impact mitigation. An Airbus A330-200 contains approximately 62 tons of aluminum [35], and with an estimated 85% recyclability rate—as evidenced by findings from the PAMELA project (see Section 7.2)—this translates to the recovery of 53 tons of aluminum per aircraft. Given that recycling aluminum avoids 9 tons of CO2 emissions per ton recycled [6], this process can prevent the release of approximately 474 tons of CO2 per aircraft.

To contextualize this environmental benefit, this reduction is equivalent to the annual emissions of 110 residential homes, provided only by one aircraft (the average CO2 emissions per US household is 4.4 tons annually [43]). These gains are depicted in Figure 5. This demonstrates the critical role that CE practices in aviation can play in significantly reducing the sector’s carbon footprint, aligning with global sustainability targets, and reinforcing the necessity of advancing aircraft recycling technologies and policies.

Figure 5.

Environmental impact of aluminum recycling scenario of an A330-200 aircraft.

7.2. Industrial Recycling Projects

The PAMELA project (Process for Advanced Management of End of Life of Aircraft) was an EU LIFE-funded project that achieved a significant breakthrough by demonstrating the potential to recycle up to 85% of airplane components, a notable improvement from the previous rate of 60%. Overall, the project reached an 85% recovery rate by weight, achieved a reuse and recycling rate of up to 70% by weight, decreased landfilled waste to below 15% (from 40–50%), and showed promising results in the recycling of metallic materials, especially aluminum, reaching energy savings of up to 90% and a reduction in the need for mining resources [37]. Also, Finnair, in partnership with recycling company Kuusakoski, dismantled and recycled a 21-year-old Airbus A319 aircraft that had reached the end of its economic life cycle. Initially, they estimated that they could reuse and recycle about 90–95% of the aircraft. The final recovery rate exceeded expectations, with only 0.8% of the aircraft ending up in disposal. Finnair’s aircraft recycling project successfully recovered 15 tons of aluminum, achieving CO2 emission savings equivalent to the annual consumption of 55 private cars. Materials from the aircraft were analysed at Kuusakoski’s accredited research center, and the aluminum recovered was likely to appear in future car models [43].

7.3. Manufacturer Initiatives and End-Use Applications

Boeing has tested the recycled carbon fiber coming from its 777 and 787 aircraft manufacturing processes. This material is being considered as a viable EoL solution by the company. A cabin sidewall constructed from these recycled materials is already installed in a 737 MAX aircraft [44]. Retreading truck and aircraft tires is a process that regularly occurs because it is economically profitable. It requires only 30% of the energy and 25% of the raw materials needed to produce new tires, which also allows for a significantly reduced amount of rubber waste [45]. Aircraft tires can be sent back to recycling facilities where they can be retreated up to 12 times for certain tires. Carcasses can be repurposed in less demanding applications such as agriculture and port-handling vehicles. Remaining rubber can also be used in non-tire products, such as sports fields and playground floors, or used as an energy source for cement factories [46]. Similarly, the automotive industry increasingly incorporates recycled aluminum, as it contributes to vehicle lightweighting, lowering fuel consumption and emissions [47]. In construction, recycled aluminum is employed for energy-efficient building materials that support green architecture and sustainable design [48]. The marine industry also utilizes recycled aluminum, taking advantage of its corrosion resistance for durable marine applications [41]. Non-structural aircraft components, such as cabin fittings, make extensive use of recycled materials without compromising safety or performance [49]. Additionally, recycled rubber from tires is commonly used in sports and recreational equipment, contributing to a reduction in waste and resource use [42].

8. Conclusions

This study provides a comprehensive synthesis of regulatory frameworks, technological advances, and economic mechanisms shaping aircraft decommissioning and recycling within a CE context. Applying a PRISMA-guided systematic review and framework analysis, the findings demonstrate that circular practices—such as design-for-disassembly, certified component reuse, and policy-based incentives—can achieve material recovery rates exceeding 90%, CO2-avoidance of 25–35 tons per aircraft, and positive net present value within three to five years. The integrated conceptual model developed in this research links regulatory instruments, technological enablers, and economic outcomes, providing a structured foundation for advancing sustainability within the aviation sector and informing evidence-based decision-making. From a practical and policy standpoint, the results indicate that transitioning to a CE in aviation is both technically feasible and economically advantageous when supported by coherent regulation, innovation, and collaboration across stakeholders. Policymakers should prioritize harmonizing international regulations, strengthening producer responsibility frameworks, and expanding incentive-based mechanisms such as tax credits and carbon accounting for circular activities. Industry stakeholders—including OEMs, MROs, and recycling facilities—should invest in design-for-disassembly, digital material traceability systems, and industrial symbiosis networks to enhance resource efficiency and material recovery. In parallel, government-supported initiatives such as grants, low-interest loans, and public–private partnerships could accelerate the establishment of certified aircraft recycling infrastructures, ensuring both economic viability and environmental performance. Nevertheless, several limitations must be acknowledged. The systematic review relied primarily on English-language and publicly accessible sources, which may have excluded region-specific insights. Quantitative comparability across studies was constrained by inconsistent reporting of environmental and economic indicators, while some cost and performance data were derived from secondary rather than primary datasets. Although these limitations were mitigated by triangulating institutional and academic sources, future research should adopt mixed methods, integrating LCA and techno-economic modeling to enhance statistical robustness and representativeness across aircraft categories and global regions. Looking forward, further research should examine the economic and environmental trade-offs of circularity through detailed case studies, industry surveys, and standardized CE performance indicators tailored to aviation. Expanding the analysis to include social aspects—such as employment creation, skill transition, and community impacts—would strengthen the sustainability framework. Moreover, emerging technologies such as robotic dismantling, composite recycling, additive manufacturing, and hydrogen-based materials warrant closer investigation to support the aviation sector’s decarbonization pathway. Overall, this study underscores that transitioning to a circular aviation economy is not only technically achievable but also economically and environmentally imperative, provided that regulatory alignment, technological innovation, and financial incentives advance in parallel.

Author Contributions

Conceptualization, D.P. and E.M.; methodology, D.P.; formal analysis, D.P.; investigation, D.P.; resources, D.P. and E.M.; data curation, D.P. and E.M.; writing—original draft preparation, D.P.; writing—review and editing, D.P. and E.M.; visualization, D.P. and E.M.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| GDP | Gross Domestic Product |

| IATA | International Air Transport Association |

| CE | Circular economy |

| EoL | End-of-life |

| BMP | Best management practices |

| AFRA | Aircraft Fleet Recycling Association |

| BIPAD | Best Industry Practices for Aircraft Decommissioning |

| ICAO | International Civil Aviation Organization |

| EU | European Union |

| EASA | European Union Aviation Safety Agency |

| FAA | Federal Aviation Administration |

| EPS | Expanded polystyrene |

| IPCC | Intergovernmental Panel on Climate Change |

| APU | Auxiliary power unit |

| PAMELA | Process for Advanced Management of End of Life of Aircraft |

References

- International Civil Aviation Organization (ICAO). The Aircraft Life-Cycle: “Reduce, Re-Use, Recycle.” ICAO Environmental Report 2016. Available online: https://www.icao.int/sites/default/files/sp-files/environmental-protection/Documents/EnvironmentalReports/2016/ENVReport2016_pg194-195.pdf (accessed on 14 March 2025).

- International Civil Aviation Organization (ICAO). 2019 Environmental Report—Aviation and Environment: Destination Green—The Next Chapter; ICAO: Montréal, QC, Canada, 2019; pp. 279–284. [Google Scholar]

- Zhao, G.; Zhai, X.; Jing, Y. Retired Aircraft Recovery: Based on Stackelberg Game Method from the Perspective of Closed-Loop Supply Chain. Sustainability 2023, 15, 1615. [Google Scholar] [CrossRef]

- Papadaki, D.; Nikolaou, D.A.; Assimakopoulos, M.N. Circular environmental impact of recycled building materials and residential renewable energy. Sustainability 2022, 14, 4039. [Google Scholar] [CrossRef]

- Zhao, X.; Verhagen, W.J.C.; Curran, R. Disposal and Recycle Economic Assessment for Aircraft and Engine End of Life Solution Evaluation. Appl. Sci. 2020, 10, 522. [Google Scholar] [CrossRef]

- Asmatulu, E.; Twomey, J.; Overcash, M. Evaluation of recycling efforts of aircraft companies in Wichita. Resour. Conserv. Recycl. 2013, 80, 36–45. [Google Scholar] [CrossRef]

- European Union Aviation Safety Agency. Assessment of the Environmental Sustainability Status in the Aviation Maintenance and Production Organisation (M&P) Domain. 2022. Available online: https://www.easa.europa.eu/en/document-library/research-reports/study-assessment-environmental-sustainability-status-aviation (accessed on 14 March 2025).

- Weetman, C. A Circular Economy Handbook for Business and Supply Chains: Repair, Remake, Redesign, Rethink; Kogan Page Publishers: London, UK, 2016. [Google Scholar]

- Jia, S.; Yin, L.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Elsayed, A.; Roetger, T.; Amy, B. Best Practices and Standards in Aircraft End-of-Life and Recycling. 2017. Available online: https://www2023.icao.int/environmental-protection/Documents/EnvironmentalReports/2019/ENVReport2019_pg279-284.pdf (accessed on 9 September 2025).

- Parlov, I.; das Neves, M.M. Regulating the Sustainable Decommissioning of Offshore Wind Turbines: Lessons from Europe? Ocean. Dev. Int. Law 2025. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Off. J. Eur. Union 2008, L312, 3–30. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32008L0098 (accessed on 14 March 2025).

- European Commission. Commission Implementing Regulation (EU). 2016/1245 of 28 July 2016 Setting out A Preliminary CORRELATION Table Between Codes of the Combined Nomenclature and Entries of Waste Listed in Annexes III, IV, and V to Regulation (EC) No 1013/2006. Off. J. Eur. Union 2016, L204, 1–17. [Google Scholar]

- Domone, J.; Bliss, P.; Copus, M.; A Circular Economy for Civil Aerospace. Atkins Realis. 2021. Available online: https://www.researchgate.net/publication/354652228_A_Circular_Economy_for_Civil_Aerospace (accessed on 14 March 2025).

- SGI Aviation. Aircraft Decommissioning Study: Final Report (May 2018). Amsterdam. 2018. Available online: https://www.sgiaviation.com/wp-content/uploads/2020/03/IATA_Aircraft_Decommissioning_Study_May-2018.pdf (accessed on 14 March 2025).

- Yang, Y.; Keivanpour, S.; Imbeau, D. Integrating X-reality and lean into end-of-life aircraft parts disassembly sequence planning: A critical review and research agenda. Int. J. Adv. Manuf. Technol. 2023, 127, 2181–2210. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. CE Terminology. In Sustainable Waste Management: What the EU Is Doing. European Parliament. Available online: https://www.europarl.europa.eu/topics/en/article/20180328STO00751/sustainable-waste-management-what-the-eu-is-doing (accessed on 14 March 2025).

- Intergovernmental Panel on Climate Change. Climate Change 2023: Synthesis Report. 2023. Available online: https://www.ipcc.ch/report/ar6/syr/ (accessed on 14 March 2025).

- European Parliament. Circular Economy: Definition, Importance and Benefits. 2015. Available online: https://www.europarl.europa.eu/topics/en/article/20151201STO05603/circular-economy-definition-importance-and-benefits (accessed on 14 March 2025).

- Eurostat. EU Trade in Goods: 2021 Overview. 2022. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/ddn-20220425-1#:~:text=In%202021%2C%20the%20value%20of,deficit%20of%20%E2%82%AC35.5%20billion (accessed on 14 March 2025).

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the circular economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- European Commission. EU Landfill Directive (Directive EU 2018/850). Available online: https://circular-cities-and-regions.ec.europa.eu/support-materials/eu-regulations-legislation/landfill-directive-directive-eu-2018850 (accessed on 14 March 2025).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Circular Economy Strategy Series. Available online: https://www.epa.gov/circulareconomy (accessed on 14 March 2025).

- Maleviti, E. Fundamentals of Sustainable Aviation; Routledge: Abingdon, UK, 2023. [Google Scholar] [CrossRef]

- ISO 59004:2024; Circular Economy—Vocabulary, Principles and Guidance for Implementation. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/84572.html (accessed on 14 March 2025).

- ISO 59010:2024; Circular Economy—Guidance on the Transition of Business Models and Value Networks. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/80649.html (accessed on 14 March 2025).

- ISO 59020:202; Circular Economy—Measuring and Assessing Circularity. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/84706.html (accessed on 14 March 2025).

- Markatos, D.N.; Pantelakis, S.G. Assessment of the impact of material selection on aviation sustainability, from a circular economy perspective. Aerospace 2022, 9, 52. [Google Scholar] [CrossRef]

- Global Aviation Emissions. Available online: https://ourworldindata.org/global-aviation-emissions (accessed on 14 March 2025).

- Scheelhaase, J.; Müller, L.; Ennen, D.; Grimme, W. Economic and environmental aspects of aircraft recycling. Transp. Res. Procedia 2022, 65, 3–12. [Google Scholar] [CrossRef]

- Hsieh, H.-H.; Yao, K.-C.; Wang, C.-H.; Chen, C.-H.; Huang, S.-H. Using a Circular Economy and Supply Chain as a Framework for Remanufactured Products in the Rubber Recycling Industry. Sustainability 2024, 16, 2824. [Google Scholar] [CrossRef]

- Rodrigues Dias, V.M.; Jugend, D.; de Camargo Fiorini, P.; do Amaral Razzino, C.; Paula Pinheiro, M.A. Possibilities for applying the circular economy in the aerospace industry: Practices, opportunities, and challenges. J. Air Transp. Manag. 2022, 102, 102227. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Lopes, J. Life-Cycle Assessment of the Airbus A330-200 Aircraft. Master’s Thesis, Universidade Técnica de Lisboa, Lisbon, Portugal, 2010. [Google Scholar]

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in the aviation sector—A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef]

- European Recycling Industries’ Confederation (EuRIC). Metal Recycling Factsheet. Available online: https://circulareconomy.europa.eu/platform/sites/default/files/euric_metal_recycling_factsheet.pdf (accessed on 14 March 2025).

- Suomalainen, E.; Celikel, A.; Vénuat, P. Aircraft Metals Recycling: Process, Challenges and Opportunities; ENVISA and Bartin Recycling Group: Milan, Italy, 2017. [Google Scholar]

- European Environment Agency. Plastics. 2023. Available online: https://www.eea.europa.eu/en/topics/in-depth/plastics?activeTab=07e50b68-8bf2-4641-ba6b-eda1afd544be (accessed on 14 March 2025).

- Athanasopoulou, E.; Power, D.M.; Flemetakis, E.; Tsironi, T. Towards the Rational Use of Plastic Packaging to Reduce Microplastic Pollution: A Mini Review. J. Mar. Sci. Eng. 2025, 13, 1245. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Pylkkö, M.; Kärki, T. Closed-loop recycling and remanufacturing of polymeric aircraft parts. J. Compos. Sci. 2023, 7, 121. [Google Scholar] [CrossRef]

- European Commission. Recycling Aluminium: A Key Component of A Circular Economy. Available online: https://circulareconomy.europa.eu (accessed on 14 March 2025).

- U.S. Environmental Protection Agency. Assumptions and References: Household Carbon Footprint Calculator. 2024. Available online: https://www.epa.gov/ghgemissions/assumptions-and-references-household-carbon-footprint-calculator (accessed on 14 March 2025).

- Bailey, J. Simple Flying. Side Panels and Laptops: How Boeing Uses Recycled Carbon Fiber. 2024. Available online: https://simpleflying.com/side-panels-and-laptops-how-boeing-uses-recycled-carbon-fiber/ (accessed on 14 March 2025).

- Goevert, D. The value of different recycling technologies for waste rubber tires in the circular economy—A review. Front. Sustain. 2024, 4, 1282805. [Google Scholar] [CrossRef]

- Goodyear. Moving Forward Towards A Sustainable Future in Aviation. 2024. Available online: https://news.goodyear.eu/moving-forward-towards-a-sustainable-future-in-aviation/ (accessed on 14 March 2025).

- Miller, S.; Soulliere, K.; Sawyer-Beaulieu, S.; Tseng, S.; Tam, E. Challenges and alternatives to plastics recycling in the automotive sector. Materials 2014, 7, 5883–5902. [Google Scholar] [CrossRef]

- Rybak-Niedziółka, K.; Starzyk, A.; Łacek, P.; Mazur, Ł.; Myszka, I.; Stefańska, A.; Kurcjusz, M.; Nowysz, A.; Langie, K. Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples. Sustainability 2023, 15, 5047. [Google Scholar] [CrossRef]

- Saevarsdottir, G.; Magnusson, T.; Kvande, H. Reducing the Carbon Footprint: Primary Production of Aluminum and Silicon with Changing Energy Systems. J. Sustain. Metall. 2021, 7, 848–857. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |