Abstract

Shale oil reservoirs in the Daanzhai section of central Sichuan are mainly developed in the Daer subsection, with a rich resource base and great exploration and development potential. However, the shale oil reservoir is characterized by shale and limestone interactions, poor physical properties, undeveloped fractures, and large differences in the fracture pressure of interactive reservoirs. Therefore, it is necessary to use temporary plugging and diverting fracturing technology to improve the complexity of fractures in reservoir reconstruction. To this end, an experimental device was innovatively established that takes into account the morphology of fractures and the permeability of reservoirs, and it can evaluate the temporary blocks and turns within third-level fractures in a reservoir. It can simulate third-level turning fractures under conditions involving 3–15 mm crack openings and different roughness values. Using this device and method, the combination and particle-size optimization experiments involving the temporary plugging agents used in the field were carried out, and the field tests were carried out in Well Long’an 1 and Well Ren’an 1 in the Sichuan Basin. The test results show that the pressure response after temporary plugging is obvious, which can significantly improve microseismic event points and increase the reservoir’s reconstruction volume. Compared with Well Nanchong 2H, the length in kilometers of the SRV after tackling key problems increases from 3918 × 104 m3 to 4578 × 104 m3, an increase of 17%. The average crack length increased from 265 m to 321 m, an increase of 21%, achieving a significant breakthrough in the “oil production gap”.

1. Introduction

The shale oil and gas revolution has extended the life cycle of the world oil industry, boosted the growth of global oil and gas reserves and production, and affected the strategic energy plans of countries [1,2,3]. According to a previous resource evaluation of the shale oil reservoir in the Daanzhai section of the Sichuan Basin, the oil-generating capacity of the Daanzhai section is 12.6–18.8 billion tons, but the gap between resources and production is too large [4]. A large amount of work was carried out in the early stages of research on reservoir permeability and oil displacement experiments and compressibility experiments, and a certain understanding has been achieved [5,6]. However, the Daanzhai shale oil reservoir in central Sichuan has high clay mineral content and undeveloped natural fractures, which pose certain challenges to the formation of complex fracture networks.

In recent years, given the demand for fracturing and the progress of temporary plugging agent technology, it has been widely used in the Southwest Oil and Gas Field, the Xinjiang Oilfield, the Shengli Oil Field, the Daqing Oil Field, the Tarim Oilfield, and other oil and gas fields, with an annual operation rate of more than 400 wells, which has achieved certain results [7,8,9,10,11]. Temporary plugging materials are expensive and have significant performance differences, but currently, there are no available technical standards for fracturing temporary plugging materials in foreign countries. There are no standards available for extraction, and the standards of oilfield enterprises/production enterprises are mainly used in the domestic and foreign markets (a total of three domestic oilfield enterprise standards and five production enterprise standards have been collected via research). The main problem with these eight evaluation methods is a lack of evaluation methods for the dynamic pressure-bearing capacity of temporary plugging agents. The selection of temporary plugging agent types, particle sizes, and concentration optimization still lacks effective evaluation equipment and methods, which restricts the application of temporary plugging technology. Therefore, it is necessary to carry out research on device development and method evaluations regarding dynamic plugging performance evaluations for the temporary plugging agents used for fracturing and to conduct systematic and standardized evaluations of the performance of temporary plugging agents to provide technical support for the optimization of temporary plugging and fracturing construction parameters for shale oil reservoirs in the Sichuan Basin.

2. Current Status of Evaluation Technology for Temporary Plugging Agents

2.1. Research Progress in Experimental Equipment

During temporary plugging and fracturing construction, a certain concentration of temporary plugging agent is required to effectively seal the formation. If the concentration of the temporary plugging agent is too low, the plugging rate will not be high enough to meet the construction requirements. If the concentration of the temporary plugging agent is too high, although it will be able to effectively seal the formation, it may lead to difficulties in injection and poor plugging effects. There are various types of temporary plugging agents at home and abroad, mainly divided into large particles (1–5 mm), small particles (1 mm), powder (60–100 mesh), and a fibrous series of biodegradable temporary plugging and turning materials. The evaluation methods and means are diverse [12,13].

The main equipment used in China is core flow equipment, which fills the end face of the core with a temporary plugging agent and injects testing fluid with a certain displacement value. During the testing process, the changes in core permeability and pressure difference are evaluated to determine the ability of the temporary plug to turn while plugging. The experimental results obtained with this method differ greatly from the actual situation on site and can only be used to evaluate the performance of some temporary plugging materials. Relevant researchers have conducted research on indoor experimental devices and methods. Gomaa, A.M. [14] used a self-developed bridging device to study the permeability of the sealing layer. Xu, H.L. [15] studied the effect of the temporary plugging agent’s concentration on the sealing pressure in fractures using a diversion device. Zhang, R. et al. [16,17,18] used a true triaxial hydraulic fracturing physical model device to study the effects of stress difference, material dosage, and the completion method on fracture propagation patterns and morphology after temporary plugging shale fractures using materials such as fibers, fiber and particle combinations, and water-soluble temporary plugging agents. Overall, the research has mainly adopted a static approach, which differs significantly from the actual situation and cannot simulate steering, which restricts the optimization of construction parameters to temporarily block steering within the joint.

2.2. Research Progress in Experimental Evaluation Methods

Through the comparison in Table 1, it can be seen that the standards of oilfield enterprises and production enterprises have established basic performance indicators and evaluation methods for temporary plugging agents, such as appearance, particle size, density, and dissolution time. However, the solubility index of temporary plugging agents is relatively low, and the effective bearing strength testing method is mainly based on the static method. There is no evaluation method for dynamic bearing capacity, and the applicability of the evaluation results is poor.

Table 1.

Evaluation standards for temporary blocking agents for domestic enterprises.

3. Research on the Evaluation Device and Method for Temporary Plugging Agent and Diversion Fracturing

3.1. Development of Temporary Plugging Agent and Fracturing Evaluation Device for Temporary Plugging

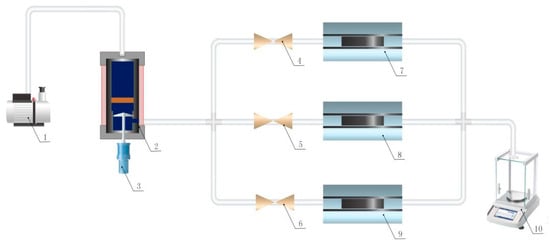

Taking into account the morphology of fractures and the permeability of reservoirs, a three-level temporary plugging and turning evaluation device has been developed, which can simulate three-level turning fractures under conditions of 3–15 mm crack opening and different roughness. The different pressure levels of the bursting discs are set between each level of fracture to achieve turning simulation under 5–30 MPa, achieving integrated simulation functions such as temporary plugging agent migration, plugging holes, turning, etc., in the wellbore (Figure 1). The simulation flow device for temporary plugging and turning of the crack mainly consists of a pumping system, a liquid storage tank, a simulation system for temporary plugging and turning within the crack, and a data acquisition system.

Figure 1.

Flow chart of simulation flow device for temporary crack blocking and turning. Description: 1—High-pressure pump; 2—Sealed tank; 3—Three-leaf stirring plate; 4—Pneumatic safety valve ①; 5—Pneumatic safety valve ②; 6—Pneumatic safety valve ③; 7—Core gripper ① (with a rough surface flat plate gripper inside); 8—Core gripper ② (with a rough surface flat plate gripper inside); 9—Core gripper ③ (with a rough surface flat plate gripper inside); 10—Metrological balance.

The pumping system consists of a liquid supply system, a high-pressure injection pump, a sealed mixing metal tank, and a high-pressure pipeline. The pressure resistance of the high-pressure injection pump shall not be less than 35 MPa, and the pump displacement shall meet 500 mL/min. The sealed stirring metal tank consists of a heating sleeve, a stainless steel-sealed container, a piston, a stirrer, etc. The pump injection outlet is located on the bottom side of the container. The mixer is designed at the bottom of the sealed container, with a three-blade shape and a rotational speed of up to 3000 rpm. The stainless steel-sealed container is a cylindrical body with a volume of 5 L and is equipped with an insulation heating sleeve on the periphery, which can meet the heating capacity within the temperature range of 0~150 °C.

The simulation system for temporary blockage and turning in the seam consists of a core gripper, a rough surface flat plate gripper, a rough surface simulation component, a pneumatic safety valve, and a balance. The core gripper is designed to be cylindrical and made of stainless steel, consisting of an inner and outer cylinder. The outer cylinder is fixed to the bracket and has an insulation sleeve on the outside. The inner cylinder is designed into two semicircles, connected with screws, with grooves on both half-designed sides, and sealed with sealing rings. The middle of the inner cylinder is a rectangular cavity for placing coarse seam boards or rock slabs.

The core component of this device is a rough surface flat plate holder, which can simulate the real rough surface characteristics of cracks under reservoir temperature and pressure. The specific manufacturing method and process are as follows:

- Formation of rough fracture surface: Rock cores with very similar mineral and geomechanical characteristics are selected, and artificial fracturing is used to perform tension damage on the cores to obtain randomly generated shale rough surfaces in order to further obtain the morphology parameters of the rough fracture surface of shale oil reservoirs in the Sichuan Basin.

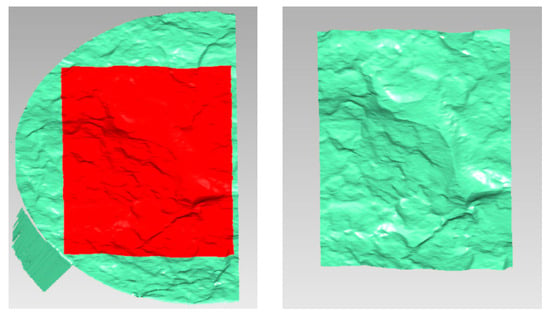

- Numerical simulation of the rough surface of cracks: Using a 3D laser scanner to scan the cut surface of the rock core, due to the design of a rectangular joint plate with temporary blockage inside the joint and fewer point cloud data, the efficiency of interpolation calculation will be improved. Therefore, we need to simplify the scanning model surface. The rectangular tool is directly used to select the middle position of the original model, and the excess data are deleted before saving. The Kriging interpolation method is used to regularize the original rough rock plate data, with the regularized data grid set to 0.1 mm × 0.1 mm. After normalization, the data retained the original sampling data features completely, meeting the subsequent analysis requirements (Figure 2).

Figure 2. Scanning of rough surface of shale fractures.

Figure 2. Scanning of rough surface of shale fractures. - The fracture surface in the formation is uneven, and there are many description methods to describe the overall distribution characteristics of fracture roughness. The fractal dimension method is mainly used to describe the characteristics of rough fracture surfaces. Due to the complexity and irregularity of rough walls, ordinary mathematical functions cannot accurately describe the complex state of rough walls. The fractal theory can precisely solve this problem. The continuous random superposition method and midpoint displacement method are used to establish the required self-similar fractal surface, which is a stationary random process:

The variance increment is given in the following equation:

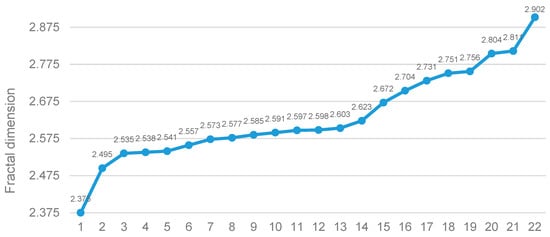

It can be seen in Figure 3. According to the statistics, the fractal dimension value of the rough fracture surface of shale is between 2.375 and 2.902, and the undulation degree of the rough surface is quite different. The average fractal dimension value of the rough surface is 2.6108, and the median is 2.5975. After comprehensive consideration, it is considered that the fractal dimension value 2.6 can represent the roughness characteristics of the fracture surface of the shale reservoir in this area.

Figure 3.

Statistics of fractal dimension of rough surface.

- 4.

- Based on the fractal dimension of the fracture, according to the fracture shape and requirements of different fracture widths, 3D-printing technology is used to obtain rough fracture plates with different fracture widths, which are installed in the rough surface plate holder to simulate the plugging turning ability of temporary plugging agent in real fractures to optimize the type of temporary plugging agent and optimize the concentration and ratio of temporary plugging agent.

3.2. Evaluation Method for Temporary Plugging Agent and Diversion Fracturing Experiment

Based on the self-developed temporary plugging and turning fracturing experimental device, corresponding experimental evaluation methods have been developed as follows:

- Set experimental parameters (including temporary plugging agent concentration, experimental temperature, displacement, and seam width), and monitor the system pressure, temporary plugging agent injection amount, and temporary plugging agent outflow at the end of the crack in real-time via a computer.

- Add clean water to the sealed stirring metal tank, and heat the sealed stirring metal tank and rough surface plate holder to the set experimental temperature.

- Select the type and particle size of the temporary plugging agent, add the temporary plugging agent to the sealed stirring metal tank in proportion, tighten the sealing cap, set the speed, and mix the temporary plugging agent with clean water evenly to prepare a temporary plugging agent solution with the set concentration.

- Turn on the high-pressure pump, pump clean water, and allow the fluid to fill the entire pipeline until there are no more bubbles in the pipeline. Connect the injection pipeline to the top of the sealed mixing metal tank to push the piston.

- Pump clean water according to the set flow rate, record the system pressure, temporary plugging agent injection amount, and temporary plugging agent outflow at the end of the crack. During the pumping process, if no blockage is formed within 30 min, the experiment will be stopped.

- At the end of the experiment, stop the experiment, remove the seam board, and observe the distribution of temporary blocking agents in the seam.

- Process experimental data, measure the pressure-bearing capacity of temporary plugging agents, and analyze the plugging effect of temporary plugging agents.

4. Research on Particle-Size Optimization of Temporary Plugging Agent Combination

4.1. Temporary Plugging Agent Filling Crack Sealing Theory

The method for optimizing the particle size of temporary plugging agents should be based on the particle stacking efficiency. In terms of particle size, the actual particle systems in contact are mostly continuous distribution systems, so it is necessary to establish corresponding mathematical models to describe the stacking characteristics of continuous distribution particle systems. At present, the most commonly used particle-size distribution model Gaudin–Schuhmann model:

In the formula,

y—the particle-size fraction content smaller than the particle size d;

d—any particle size;

dL—maximum particle size in the particle system;

n—model parameters.

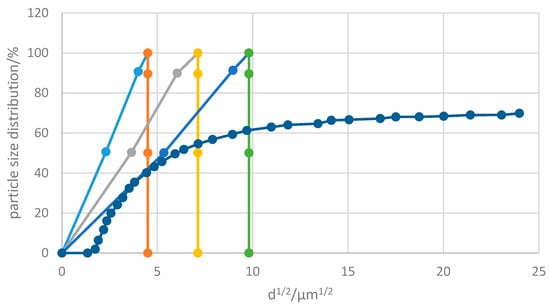

In general, the relationship curve between the particle size of the temporary plugging agent and the cumulative volume fraction of particles presents an “S” shape on a semi-logarithmic coordinate. This curve only indicates the particle-size distribution range and cannot indicate the filling efficiency of particles. Kaeufer proposed the “ideal filling theory” of temporary plugging agent particles, also called d1/2 theory: it is assumed that the temporary plugging particles in the drilling fluid obey the Gaudin–Schuhmann particle-size distribution model, and it is concluded via physical experiments and computer simulation that when the model parameter n = 0.5, there is the highest stacking efficiency, that is, when the cumulative volume fraction of temporary plugging agent particles is proportional to the square root (d1/2) of particle size, the ideal filling of particles can be achieved. According to this theory, if there is a linear relationship between the cumulative volume fraction of temporary plugging agent particles and d1/2 in the Cartesian coordinate system, it indicates that the temporary plugging agent meets the necessary conditions for ideal filling.

By optimizing and combining two or more temporary plugging agents with different particle-size distributions in a certain proportion, the cumulative distribution curve of particle size can basically coincide with the baseline, that is, an ideal temporary plugging scheme can be obtained. The values of d50 = 3/10 seam width and d90 = 5/6 seam width are set. On the coordinate graph of the cumulative volume of temporary plugging agent particles and the square root of particle size (d1/2), the line connecting the origin, d501/2, and d901/2 is used as the baseline. If the cumulative distribution curve of the particle size of the optimized temporary plugging agent is closer to the baseline and on the right side of the baseline, the higher the particle stacking efficiency and the better the temporary plugging effect.

4.2. Matching Relationship between Particle-Size Composition and Crack Width of Temporary Plugging Agent

The sealing efficiency is closely related to the size and accumulation of various particles, and accurately measuring the particle-size distribution of temporarily blocked particles is a necessary means of effective sealing. In recent years, the use of laser particle-size analyzers has become increasingly widespread because laser measurement of powder particle size has the characteristics of fast speed, good reproducibility, and high accuracy. The laser particle-size tester can test the particle-size distribution of temporary plugging agents under normal temperature, high temperature, and high-pressure conditions and identify the particle-size distribution properties of a specific temporary plugging agent. For powder temporary blocking agents, a laser particle-size analyzer is used for particle-size measurement, and for particle temporary blocking agents, sieve analysis is mainly used for measurement.

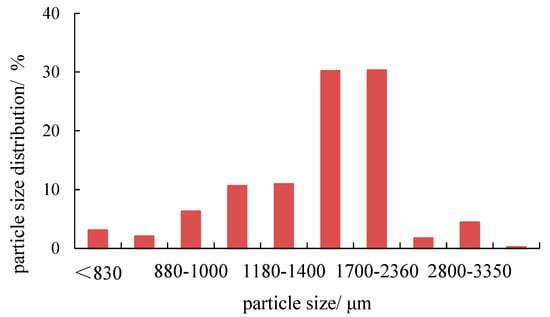

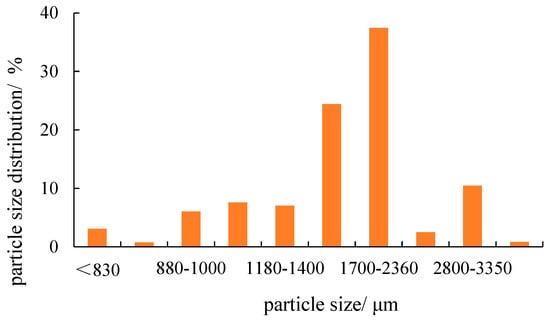

It can be seen in Figure 4 and Figure 5.The temporary plugging agents A and B are selected for the experiment on site, and the particle size of the temporary plugging agent is measured before the experiment.

Figure 4.

Particle-size composition test results of temporary plugging agent A.

Figure 5.

Particle-size composition test results of temporary plugging agent B.

It can be seen in Figure 6. The relationship curve between the cumulative volume fraction of temporary plugging agent particles and the square root of particle size (d1/2), baseline, and crack width curve is plotted on the same graph. By adjusting different crack widths, a single temporary plugging agent cannot effectively seal. The mixture of temporary plugging agent A and temporary plugging agent B at a ratio of 7:3 can effectively seal 100% μm cracks, and temporary plugging agent A+temporary plugging agent B should be mixed at a ratio of 5:5 to 180 μm for cracks to be effectively sealed, and after adding temporary plugging agent particles, the matching crack width increases.

Figure 6.

Square root relationship between cumulative volume and particle size of temporary plugging agent A+temporary plugging agent B (7:3). Different colors represent temporary plugging agents with different particle sizes. These lines represent the volume fraction of temporary plugging agent particles and the square root of particle size (d1/2).

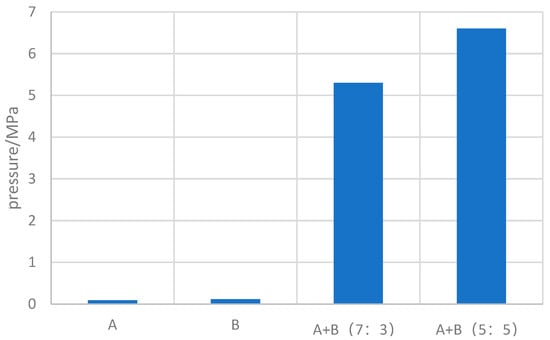

4.3. Temporary Plugging Agent Combination and Dynamic Temporary Plugging Experimental Results

The experiment uses a seam plate with a seam end width of 3 mm and a seam end width of 0.1 mm and uses temporary plugging agent A, temporary plugging agent B, temporary plugging agent A+temporary plugging agent B (7:3), temporary plugging agent A+temporary plugging agent B (5:5) to conduct temporary plugging and diverting plugging experiments on shale oil reservoirs. In Figure 7, after the powder temporary plugging agent D and particle temporary plugging agent B are mixed at a ratio of 7:3, the cumulative particle-size distribution curve of the compound temporary plugging agent is relatively close to the baseline, the particle accumulation efficiency is high, and the plugging permeability is high, which can effectively plug 100 μm fractures, and the mixture of 5:5 can effectively plug 180 μm fractures. With the increase in the amount of temporary plugging agent B, the plugging pressure increases.

Figure 7.

Particle-size combination and sealing effect of temporary plugging agent.

5. Application in Shale Oil Reservoirs

5.1. Characteristics of Shale Oil Reservoirs in Sichuan Basin

The physical properties of shale oil reservoirs in the Sichuan Basin are poor [19,20,21]. The natural fractures in Long’an 1 well are underdeveloped, while 14 natural fractures and 1 small fault are commonly developed in Ren’an 1, indicating the interaction between shale and limestone. The mineral components are mainly quartz, calcite, and clay minerals, with a high content of clay minerals, which is not conducive to the formation of a network of cracks. The average clay mineral content of the three wells in the Daanzhai section is 41%, which is equivalent to the clay mineral content of the shale oil reservoir in the Lianggaoshan Formation in central Sichuan. The average content of illite in clay minerals is 60.5%, the average content of chlorite is 34.9%, and the ratio of illite to montmorillonite is 4.4%. There are few expansive minerals that are suitable for large-scale hydraulic fracturing.

Through experimental research on the shale oil well reservoirs in the Daanzhai section as seen in Table 2, it was found that the average Young’s modulus of shale is 2~2.9 × 104 MPa, average Young’s modulus of limestone 3.6~4.7 × 104 MPa, the fracture pressure of limestone is 79~107 MPa, which is 9–10 MPa higher than the fracture pressure of adjacent deep shale, which is not conducive to the longitudinal expansion of fractures. Therefore, it is necessary to carry out temporary plugging and turning to fracturing technology to improve the complexity of reservoir reconstruction fractures.

Table 2.

Rock mechanics and crustal stress characteristics of shale oil reservoir.

5.2. Process Optimization to Improve the Complexity of Cracks

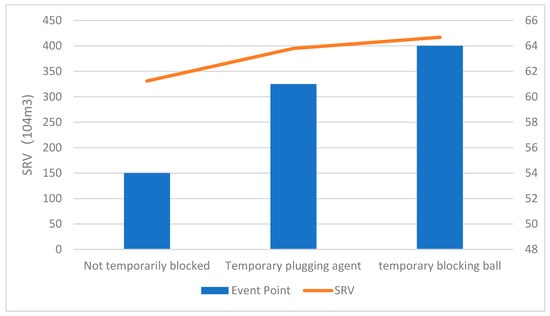

In response to the low development level of natural fractures in reservoirs and the difficulty in vertically expanding fractures caused by reservoir interactions, both Long’an 1 and Ren’an 1 wells have conducted experiments on temporary plugging and turning to fracturing technology. As seen in Figure 8,the results show that from the perspective of adjusting the fracture extension morphology, the pressure response of the temporary plugging material is significant (temporary plugging ball 2–3 MPa, temporary plugging agent 0.7–1.5 MPa), which can improve the situation where microseismic event points mainly respond on one side of the wellbore. From the perspective of increasing the volume of crack propagation, adopting temporary blocking measures can effectively increase the monitoring event points and renovation volume.

Figure 8.

Comparison of SRV before and after temporary blockage.

5.3. Application Effect

The field test effect is shown in Table 3, compared with Nanchong 2H Well, the SRV of km after tackling the key problem is 3918 × 104 m3, which increased to 5456 × 104 m3 by 39%. The average seam length increased by 21% from 265 m to 321 m. The test oil production increased from “see oil flower” to nearly 2 tons/day, making a major breakthrough in “oil export”.

Table 3.

Field test effect.

6. Conclusions

- The shale oil reservoir in the Sichuan Basin is characterized via the interaction of shale and limestone, poor physical properties, and undeveloped fractures. The fracture pressure difference between shale and limestone is 9~10 MPa, which is not conducive to the longitudinal expansion of fractures. Therefore, it is necessary to carry out temporary blocking and diversion fracturing technology to improve the complexity of fractures in reservoir reconstruction.

- Taking into account the morphology of fractures and the permeability of reservoirs, a three-level temporary plugging and turning evaluation device has been developed, which can simulate three-level turning fractures under conditions of 3–15 mm crack opening and different roughness. The different pressure levels of bursting discs are set between each level of fracture to achieve turning simulation under 5–30 MPa, achieving integrated simulation functions such as temporary plugging agent migration, plugging holes, turning, etc., in the wellbore.

- On the basis of the theory of temporary plugging agent filling crack sealing, a matching relationship between the particle-size composition of the temporary plugging agent and crack width was established, and technical countermeasures were proposed for the combination and particle-size optimization of the temporary plugging agent.

- The results of the on-site application show that the proposed temporary plugging and fracturing technology measures have significantly increased the volume of reservoir transformation, and the test oil production has increased from “oil splashes” to nearly 2 tons/day, achieving a significant breakthrough in “oil production”.

Author Contributions

Methodology, Data curation, Writing—original draft, Writing—review & editing L.W., Data curation J.Y., Data curation J.P., Methodology, Data curation, H.H., Applications, Y.W., Applications, Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Scientific Research Project of PetroChina Southwest Oil and Gas Field Company “Study on the interaction mechanism between Shale Oil Reservoir and fracturing fluid in Da ‘anzhai-Member of Central Sichuan” (No. 20210302-06). All the research funding supports are greatly appreciated.

Data Availability Statement

The data is sourced from both experimental and on-site data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Caineng, Z. Shale oil and gas revolution and its impact. Acta Pet. Sin. 2020, 41, 1–12. [Google Scholar]

- Caineng, Z.; Zhi, Y.; Sha, S. “Exploring petroleum inside source kitchen”: Shale oil and gas in Sichuan Basin. Sci. China Earth Sci. 2020, 50, 903–920. [Google Scholar]

- Zhi, Y.; Caineng, Z. Exploring petroleum inside source kitchen: Connotation and prospects of source rock oil and gas. Pet. Explor. Dev. 2019, 46, 173–184. [Google Scholar]

- Wang, L.; Yang, J.; Peng, J.; Jing, X.; Han, H.; Zhang, X. Nuclear Magnetic-Seepage Joint Measurement Experimental Technology and Field Application of Shale Oil Reservoir. Chem. Technol. Fuels Oils 2023, 59, 343–350. [Google Scholar] [CrossRef]

- Wang, L.; Yang, J.; Peng, J.; Chen, G.; Han, H.; Zhang, X. Experimental Evaluation on Compressibility of Shale Oil Reservoir in Da’anzhai Section in Central Sichuan Area. Drill. Prod. Technol. 2023, 46, 163–168. [Google Scholar]

- Yang, J.; Yang, B.; Wang, L.; Peng, J.L.; Feng, Y.H.; Tang, Y. Invasion depths of fracturing fluid imbibition displacement in matrix pores of Da’an Zhai shale oil reservoirs in central Sichuan Basin. Pet. Geol. Recovery Effic. 2023, 30, 1–8. [Google Scholar]

- Hu, S.; Zhao, W.; Hou, L. Development potential and technical countermeasures of terrestrial shale oil in China. Pet. Explor. Dev. 2020, 47, 819–828. [Google Scholar] [CrossRef]

- Zhou, F.; Yuan, L.; Liu, X.; Wang, B.; Li, M.; Li, B. Advances and key techniques of temporary plugging and diverting fracturing. Pet. Sci. Bull. 2022, 7, 365–381. [Google Scholar]

- Scanlan, W.P.; Pierskalla, K.J.; Sobernheim, D.W.; Boehringer, R. Novel Diversion Case Studies for Improved Near-Wellbore Connection between Wellbore and Hydraulic Fracture. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. URTEC-2881395-MS. [Google Scholar]

- Zhang, J.; Cramer, D.D.; Mcewen, J.; White, M.; Bjornen, K. Use of far-field diverters to mitigate parent- and infillwell-fracture interactions in shale formations. SPE Prod. Oper. 2020, 35, 272–291. [Google Scholar]

- Zheng, Y.C.; Zhao, Z.H.; Zeng, B.; Song, Y.; Guo, X.W.; Li, J.F. Exploration and practice on combination of high-density completion and high-intensity sand fracturing in shale gas horizontal well of Changning Block in southern Sichuan Basin. Drill. Prod. Technol. 2021, 44, 43–48. [Google Scholar]

- Lu, Z. Progress and prospect study on temporary plugging agent for diverting fracturing. Sci. Technol. Eng. 2020, 20, 12691–12701. [Google Scholar]

- Xiao, P. Research of temporary plugging agent for temporary plugging diverting fracturing. Petrochem. Ind. Appl. 2019, 38, 1–5. [Google Scholar]

- Gomaa, A.M.; Nino-Penaloza, A.; Castillo, D.; McCartney, E.; Mayor, J. Experimental Investigation of Particulate Diverter Used to Enhance Fracture Complexity. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 24–26 February 2016; p. 178983. [Google Scholar]

- Xu, H.; Ma, Y.; Jiang, H.; Wang, J.; Fan, L.; Guo, P. Experimental study on particle-based temporary plugging material selection and diversion law of shale gas reservoirs in WY area, Sichuan, China. Processes 2022, 10, 1720. [Google Scholar] [CrossRef]

- Li, M.; Zhou, F.; Liu, J.; Yuan, L.; Huang, G.; Wang, B. Quantitative investigation of multi-fracture morphology during TPDF through true tri-axial fracturing experiments and CT scanning. Pet. Sci. 2022, 19, 1700–1717. [Google Scholar]

- Li, M.; Zhou, F.; Sun, Z.; Dong, E.; Zhuang, X.; Yuan, L.; Wang, B. Experimental study on plugging performance and diverted fracture geometry during different temporary plugging and diverting fracturing in Jimusar shale. J. Pet. Sci. Eng. 2022, 215, 110580. [Google Scholar] [CrossRef]

- Zhang, R.; Hou, B.; Tan, P.; Muhadasi, Y.; Fu, W.; Dong, X.; Chen, M. Hydraulic fracture propagation behavior and diversion characteristic in shale formation by temporary plugging fracturing. J. Pet. Sci. Eng. 2020, 190, 107063. [Google Scholar]

- Pang, Z.; Tao, S. Multi-scale differential enrichment and main controlling factors of tight oil in the Jurassic Da’an Zhai section of Sichuan Basin, China. Nat. Gas Geosci. 2019, 30, 1301–1311. [Google Scholar]

- Huang, D.; Guang, Y.; Zhi, Y. New understanding and development potential of tight oil exploration and developent in Sichan Basin. Nat. Gas Geosci. 2019, 30, 1212–1221. [Google Scholar]

- He, W.; Bai, X.; Meng, Q. Geological characteristics and major discoveries of continental shale oil accumulation in Sichuan Basin. J. Pet. 2022, 43, 885–898. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).