Abstract

Avoiding heat stress in cows is an important condition for animal productivity and the maintaining of animal health. For this, it is necessary to provide an optimal microclimate in cowsheds using systems of air cooling. The paper analyzes one of these systems—an air humidification–cooling system. The research was carried out in a semi-insulated box-type cowshed containing 244 places. The changes in temperature, relative humidity, and temperature humidity index (THI) were studied for the air coming from outside and for the air inside the cowshed. Considering the fact that the cows were in the cowshed most of the time (51.5%) under heat stress, the use of a cooling system is appropriate. It was established that a cooling system is capable of compensating for heat released by animals. It was determined that with an increase in air temperature the relative efficiency of a cooling system increases. An intensive constant air exchange provided using fan operation avoids an excessive growth of relative humidity in a cowshed. To reduce the consumption of electricity and water, the paper suggests regulation of both the power of the fans of the system and the water supply to the nozzles not using temperature but using THI. Theoretically, when THI is used to regulate the operation of the cooling system, the consumption of electrical energy is reduced by 17.8%, and the consumption of water is reduced by 43.2% when compared to the option when the temperature is used to regulate the operation of a cooling system.

Keywords:

cooling system; cowsheds; temperature humidity index; relative humidity; temperature; cows 1. Introduction

Avoiding heat stress in cows is an important condition for both productivity and maintaining animal health [1,2,3]. For this, it is necessary to ensure the optimal microclimate in cowsheds [4,5,6]. The main parameters that make it possible to assess the state of the microclimate in a cowshed are air temperature and relative humidity [7,8]. The temperature humidity index (THI) can be calculated using temperature and humidity [4,8,9,10], the value of which allows determination of the condition of animals in a cowshed. According to studies [11,12,13], THI values of more than 80 indicate possible severe heat stress in cows. THI values of less than 68 indicate no stress. THI values from 68 to 72 indicate slight heat stress. THI values from 72 to 80 indicate moderate heat stress. When THI values are between 72 and 80 a decrease in milk production in dairy cattle can be expected if air cooling is not applied. When THI values exceed 80, air cooling is obligatory [4,13,14] because the decrease in milk production can reach critical values and the cows’ well-being will deteriorate [1,3,15]. The researchers state that not only the temperature and the temperature and humidity indices affect the maintenance of animals, but also the duration during which the animals are exposed to stress [7]. In addition, an increased temperature in a cowshed promotes the growth of ammonia emissions into the environment [13,16].

Taking into account the fact that the cows spend most time in conditions which can cause heat stress, it is necessary to use air cooling systems [17,18]. In particular, air cooling systems based on micro-droplet spraying of water with a diameter of 2–60 μm—adiabatic humidification systems [4,16,17,18,19,20,21,22]—have become popular. For example, in a work [16] the performance of roof mounted misting fans was analyzed and the impact on heat stress in dairy cows was evaluated. It was established that the use of roof mounted misting fans in hot weather (at temperatures in the environment above 36 °C) reduces the temperature in a cowshed by 7–8 °C, and reduces THI by 10%. However, the paper does not indicate how the proposed cooling system affects the dynamics of temperature and THI at temperatures below 36 °C. In addition, the authors did not consider the influence of a cooling system on the relative humidity in a cowshed, nor did they investigate energy costs during the operation of misting fans. The paper [4] has analyzed the operation of the air humidification–cooling system in semi-insulated box-type cowsheds. As a result of research, it was found that the air temperature in a cowshed decreased by 3.17 ± 0.86 °C compared to cowsheds without a humidification–cooling system. The air humidification system creates favorable conditions for reducing the heat stress of cows—THI in a cowshed is lower than in the open air. Additionally, the authors of the paper established that the relative humidity in a cowshed is on average 16.29 ± 4.12% higher than in the open air. However, the authors did not consider the energy efficiency of the proposed system, in particular the electricity and water costs. In a study [17], the effects of water consumption on cooling efficiency and behavior of cows was carried out. It was proved that the use of nozzles with a large water flow (4.9 L/min) is not effective in comparison with nozzles with a lower water flow (3.3 L/min). Although when using both types of nozzles, an increase in milk production was observed. The authors did not analyze the influence of water consumption on the dynamics of THI changes, and did not investigate the effectiveness of the cooling system at different temperatures and humidity indices of the environment.

There are opinions that the installation of evaporative cooling systems, such as misters and sprinklers, is not recommended in environments where the relative humidity can reach more than 75% due to the increase in humidity associated with these systems [20]. In addition, the significant need for water resources for evaporative cooling systems can also be a problem [2]. In a scientific work [21], the influence of water spraying with the help of sprinklers on the temperature state of cows was investigated. The studies have proven that effective cooling is possible only with long-term water spraying.

The analysis of scientific papers shows that the majority of studies are aimed at establishing the degree of influence of cooling systems on the physiological state of animals. However, there are actually no studies on the energy efficiency of cooling systems. Additionally, there is lack of research on the effectiveness of cooling systems at different values of temperature and humidity environment.

Therefore, further research is needed to optimize the delivery of water and the consumption of electric energy. After all, the consumption of electric energy to maintain an optimal microclimate in cowsheds can reach 25–45% of all electric energy consumption [23]. The cooling control system also has an important influence on the efficiency of cooling systems [24,25]. In addition, further accumulation of data on the influence of irrigation systems (artificial fog systems, misting fans, etc.) on the microclimate of cowsheds is necessary for effective use of cooling systems.

2. Materials and Methods

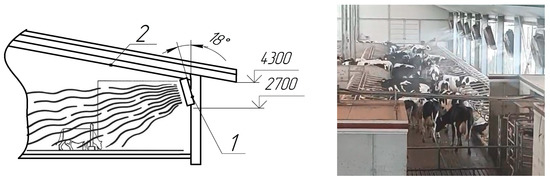

The research was carried out in semi-insulated box-type cowsheds for 244 places (Lietuva). The cowshed is equipped with an air humidification–cooling system (further on in the text of the paper, –cooling system) [14]. As many as 16 Abbifan 140-XXP-21 (Abbi-Aerotech, Hardinxveld-Giessendam, The Netherlands) [26] fans are installed in the cowshed, which increase the air circulation inside the livestock premises. The fans are turned on automatically at an air temperature of 16 °C, and their power is 25% of the nominal. As the temperature rises, the fan power increases, and at 25 °C it reaches the maximum value of 0.75 kW. The fans were installed into the side walls of the farm and were tilted at an angle of 18° (Figure 1). The productivity of one fan is 48,930 m³/h of air. Each fan is equipped with water nozzles that spray microdroplets of water with a consumption of approximately 0.8 L/min (Figure 1). Water spraying starts when the temperature reaches 16 °C; hereafter the water supply remains constant over the entire temperature range.

Figure 1.

General view of a cowshed and an air humidification–cooling system: 1—fan; 2—cowshed (the photo was taken by the authors of the paper).

The principle of operation of a cooling system is as follows: with the help of special nozzles, water is sprayed into the airstream created using the fans. Microdroplets of water evaporate in the heated air of the room, taking away heat and cooling the air, while the moisture content increases. Such a process is called the process of adiabatic cooling of moist air, the limit of which will be the temperature of a wet bulb, or relative humidity of 100% [19].

The air temperature and relative humidity were measured and recorded every hour using data loggers PeakTech P5185 (PeakTech, Ammersbek, Germany) (Figure 2) [4,27]. The temperature measurements ranged from −40 °C to 80 °C, with temperature accuracy 0.3 °C, and the humidity measurements ranged from 5% to 95%, with humidity measurement accuracy of 2%. Air velocity was measured with a wind anemometer in the Almemo 2590-9 system (Ahlborn GmbH, Hildesheim, Germany). Measurement range was 0–10 m/s, and accuracy equaled ±0.1 m/s. The air velocity in the cow zone varied from 0.94 to 1.73 m/s.

Figure 2.

Data loggers PeakTech P5185 [27] (the photo was taken by the authors of the paper).

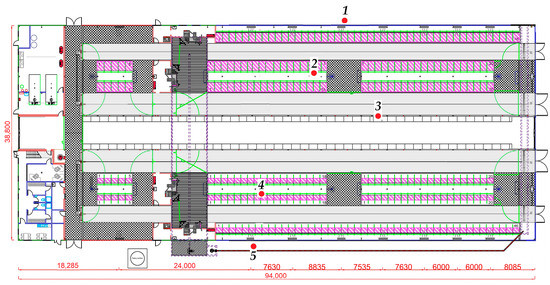

Measurements and recordings of temperature and relative humidity were performed in the warmest summer period from 18 June 2022 to 31 August 2022 (duration of measurement 1800 h). During the research the temperature and the humidity were recorded at three points of the cowshed (positions 2, 3, 4 in Figure 3). Additionally, at two points the temperature and relative humidity of the air coming from the outside were fixed (positions 1, and 5 in Figure 3). The temperature and humidity values were recorded at the beginning of an hour; in total 24 temperature and relative humidity values were recorded per day on each data logger.

Figure 3.

The scheme of placement of PeakTech P 5185 data loggers (1–5) in a cowshed.

The climate comfort was determined using the temperature and humidity indices (temperature humidity index—THI) [4,11,12,13]. THI was calculated using the equation:

where:

- Tm—average air temperature, °C;

- RHm—average relative humidity of air, %.

For the calculation of temperature humidity index of the outdoor air (THI1), the averaged values of temperature (T1) and relative humidity (RH1) from the recorders 1, and 5 were used. Additionally, for the calculations of temperature humidity index inside the cowshed (THI2), the averaged values of temperature (T2) and relative humidity (RH2) from the recorders 2, 3, and 4 were used.

Also, to evaluate the efficiency of the cooling system, the saturation coefficient of the air with moisture [28] was used, which is calculated according to a formula:

where:

- TW—thermodynamic wet-bulb temperature of entering air °C.

In order to evaluate the performance of a cooling system regarding the removal of excess moisture from a cowshed, the theoretical amount of excess moist air (V, м3/h) that must be removed from the room was calculated according to a Formula (3) [29,30,31]:

where:

- n1—the number of animals in a shed, heads (pieces);

- q1—the amount of moisture released by one head, kg/h;

- k—a coefficient of performance of a cooling system;

- n2—the number of fans equipped with nozzles;

- q2—water consumption by the nozzles of one fan, kg/h;

- ρ1—density of an incoming air kg/m3;

- d1—humidity of an incoming air, kg/kg;

- d2—humidity of the air in a cowshed, kg/kg.

3. Results and Discussion

The operation of a cooling system should improve the parameters of the microclimate in a cowshed, both at high and at moderate temperatures in a summer time period. It is important to create a stable temperature environment for animals. By controlling the heat exchange process with the help of a cooling system, the most comfortable microclimate indicators for animals can be created.

As a result of the research, 1800 values of temperature and relative humidity for the air entering the cowshed from outside were obtained. Based on the obtained values of temperature and relative humidity, THI for the air entering the cowshed was calculated (Table 1, Figure 4).

Table 1.

Values (indicators) of temperature (T1), relative humidity (RH1) and temperature humidity index (THI1) of the air entering the cowshed from outside.

Figure 4.

Dynamics of changes in temperature humidity index (THI1) in the period from 18 June 2022 to 31 August 2022 (1800 h) calculated on the basis of temperature and relative humidity of the air entering the cowshed from outside.

Temperature humidity index values greater than 80 (THI values above THImax line in Figure 4—conditions causing severe heat stress) were observed for 10 h during the measurement period (1800 h), which is 0.6% of the total number of hours.

Moderate heat stress conditions (THI values between THImax and THImed lines) were observed for 505 h (28.1%). Conditions causing mild stress (THI values between THImed and THImin lines) were observed for 410 h (22.8%). The cows stayed without heat stress for 875 h—48.5% (THI values below THImin line). Considering the fact that the cows were in conditions that could cause heat stress for 51.5% of the time, the use of a cooling system is appropriate.

Also, as a result of the research, 1800 values of temperature and relative humidity for the air inside the cowshed were received. Reference values of temperature, relative humidity, and THI are given in Table 2.

Table 2.

Maximal, minimal, and average values (indicators) of the temperature (T), relative humidity (RH), and temperature humidity index (THI) of the air.

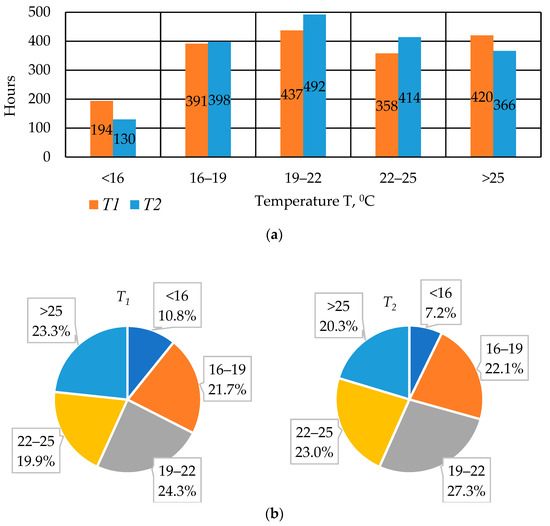

The analysis of the obtained results made it possible to analyze the operation of the cooling system. In particular, a comparison of the temperature of the air coming from outside and of the air inside the cowshed was made (Figure 5).

Figure 5.

Temperature distribution by hours (a) and by percentage (b).

The average temperature values were the same: 21.5 °C—the temperature of the air coming from outside, and 21.4 °C—the temperature of the air inside the cowshed. It should be noted that the number of hours with high temperature (more than 25 °C) inside the cowshed was 3% lower, or reduced by 54 h. In addition, the average temperature values from 19 °C to 25 °C for the air inside the shed were observed for 95 more hours than for the air coming from outside. Lower temperature values (less than 19 °C), in comparison, were observed for 57 h less.

This testifies to the ability of the cooling system to compensate for the release of the heat from animals. This conclusion was made based on the fact that the difference between the air temperature inside the cowshed and the air coming from outside is within 3.5% for all temperature ranges.

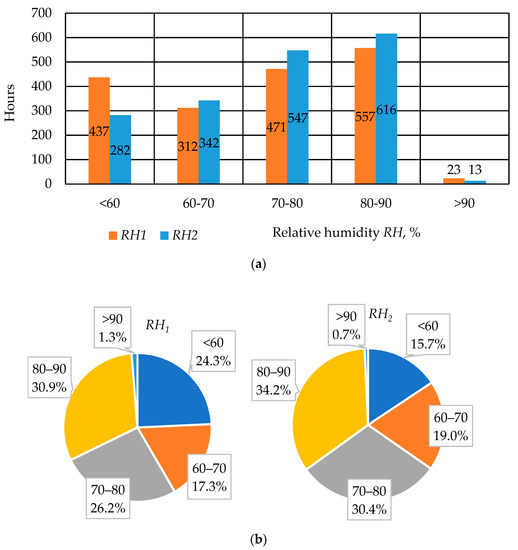

The research also compared the relative air humidity coming from outside—RH1 and the air humidity inside the cowshed—RH2 (Figure 6).

Figure 6.

Relative humidity distribution by hours (a) and by percentage (b).

The average value of relative humidity increased from 70.7% for the air coming from outside, to 73.1% for the air inside the cowshed. In addition, the relative humidity values greater than 80% increased by 2.7% inside the cowshed. The values of relative humidity less than 60%, in comparison, decreased by 8.3%. Therefore, we can conclude that the operation of a cooling system leads to an increase in relative humidity, although this growth is not significant, and for the ranges of humidity more than 60% it lies within 4.2% of hours (from 1363 h to 1518 h).

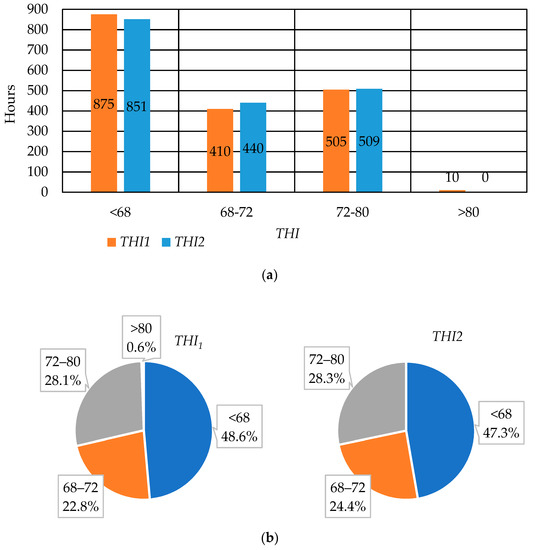

A comparison of the THI for the air coming from outside (THI1) and for the air inside the cowshed (THI2) was also made (Figure 7).

Figure 7.

THI distribution by hours (a) and by percentage (b).

The average value of THI actually did not change and was 68.2 for the air coming from outside and 68.5 for the air inside the cowshed. In particular, it should be noted that due to the operation of the cooling system, THI in the cowshed did not exceed the critical value of more than 80. Although, for the air coming from outside THI was greater than 80 for 10 h during the entire period of the study. These results allow us to make a conclusion about the ability of a cooling system to keep THI inside the cowshed at least at the level of THI for the air coming from outside. This conclusion was made based on the fact that the difference between THI for the air in the cowshed and THI for the air coming from outside is within 1.6% for all ranges of THI.

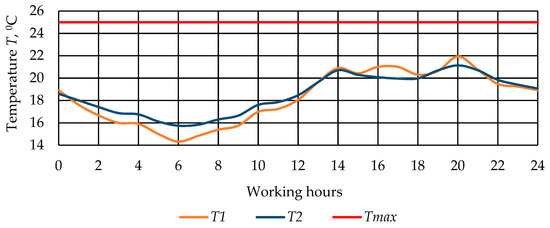

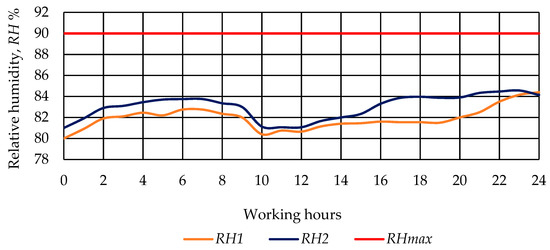

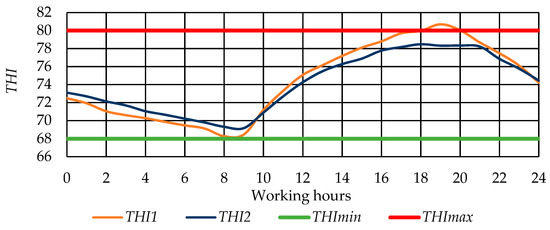

The obtained data also made it possible to perform an analysis of the efficiency of the cooling system’s performance in moderate (maximum temperature of 21.9 °C) (Figure 8, Figure 9 and Figure 10) and hot (maximum temperature of 32.2 °C) (Figure 11, Figure 12 and Figure 13) summer periods of time, limited to one day.

Figure 8.

Temperature dynamics on a moderate day (maximum temperature of 21.9 °C).

Figure 9.

Dynamics of relative humidity on a moderate day (maximum temperature of 21.9 °C).

Figure 10.

THI dynamics on a moderate day (maximum temperature of 21.9 °C).

Figure 11.

Temperature dynamics on a hot day (maximum temperature of 32.2 °C).

Figure 12.

Dynamics of relative humidity on a hot day (maximum temperature of 32.2 °C).

Figure 13.

THI dynamics on a hot day (maximum temperature of 32.2 °C).

In the temperature range up to 22 °C there is an increased relative humidity (from 80% to 85%) that does not create favorable conditions for the operation of a cooling system.

The analysis of the graphs in Figure 11, Figure 12 and Figure 13 allows us to draw conclusions about the sufficient efficiency of the cooling system, although there is no decrease in THI compared to the air coming from outside. However, cows are actually spending all the time in a cowshed with THI below 70, and the operation of the cooling system allows THI to be within acceptable limits for the absence of heat stress. Except for this, the operation of a cooling system smooths out sudden changes in temperature (16, 17, and 20 working hours) in Figure 11.

With an increase in temperature, the relative efficiency of the cooling system increased. This effect is explained by the higher intensity of the adiabatic air cooling process, i.e., in the heated air, the sprayed water absorbs heat more intensively. In addition, the relative humidity is lower at higher temperatures (for comparison, at a temperature of 32.2 °C the relative humidity is 48.2%—19th working hour in Figure 11 and Figure 12; and at a temperature of 21.0 °C the relative humidity is higher and equals 81.6%—17th working hour in Figure 8 and Figure 9), which also contributes to the intensification and duration of the cooling process [19,32,33].

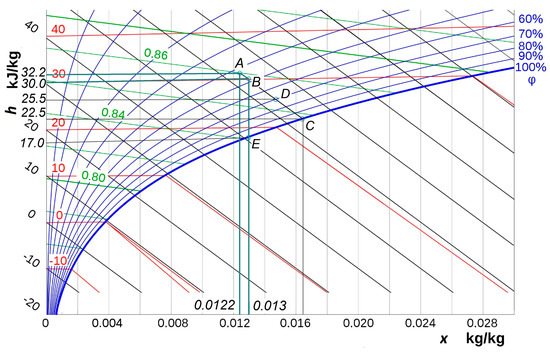

For example, for point 19 (working hours) of the graphs in Figure 11 and Figure 12 the flow of the air cooling process, due to its humidification, can be represented graphically on the Mollier h-x diagram (Figure 14). The air comes in from outside with a temperature (T1) of 32.2 °C, with a relative humidity of (RH1) 44.6%, and a moisture content of 0.0122 kg/kg (point A). Nozzles installed on fans spray water, the moisture content increases to 0.013 kg/kg, the relative humidity (RH2) increases to 48.2%, and the temperature (T2) decreases to 30.0 °C, (point B). In addition, the operation of fans at full power (0.75 kW), after raising the temperature above 25 °C, also contributes to increasing the efficiency of the cooling system as a result of a more uniform filling of the space in the cowshed with moisture and more intensive air exchange. An intensive daily air exchange, provided by the operation of fans at full power, avoids an excessive growth of relative humidity in the cowshed. However, the effect of fan power on the efficiency of a cooling system requires further thorough research.

Figure 14.

Fragment of Mollier (h-x) diagram.

To determine the coefficient of saturation of the air with moisture, the wet-bulb temperature (TW) was found using the h-x diagram for this (point C at a conditional 100% relative humidity, Figure 14), which shows TW = 22.5 °C. Next, using Formula (2), the saturation coefficient c was calculated; it equaled 0.23. Such a value of saturation coefficient indicates that the operation of the cooling system at a given temperature and relative humidity can be more effective. This can be achieved by supplying a larger amount of moisture into the cowshed with the help of nozzles. For example, when the relative humidity increases to 70%, the temperature inside the cowshed can theoretically be reduced to 25.5 °C (point D), and the value of the saturation coefficient will be 0.69. The dew point temperature under these conditions was 17.0 °C (point E), which means that when the temperature drops below 17.0 °C, excess moisture will condense in the cowshed.

At moderate temperature values in the cowshed, for example the point at 17 working hours (Figure 8 and Figure 9), the temperature (T1) and relative humidity (RH1) for the air coming from outside were 21.0 °C and 81.6%, respectively. Due to the operation of the cooling system, the temperature (T2) of the air in the cowshed decreased to 19.9 °C, and the humidity (RH2) increased to 83.9%. The coefficient c of air saturation was 0.55. The wet-bulb temperature (TW) was 19 °C. However, the operation of a cooling system in such conditions can cause moisture condensation due to air oversaturation. Therefore, it is necessary to provide the necessary air exchange to remove excess moisture from the shed. That is why it is very important to install effective ventilation systems in cowsheds. The ventilation systems must remove excess heat and moisture and prevent the formation of condensate. The ventilation systems should also provide conditions for compliance with permissible levels of concentration of harmful substances in the cowshed (ammonia acid, hydrogen sulfide, and others [34,35]. Necessary air exchange, in relation to the removal of excess moisture, mainly depends on the amount of moisture released by the animals, the number of animals in a shed, the type of shed, and the moisture content of indoor and outdoor air at corresponding temperatures [36].

According to Formula (3), the content of air with excess temperature was calculated. For the elevated temperature (T1 = 32.2 °C), the theoretical surplus of moist air was lower and equaled 94,316 m3/h. For moderate temperature values (T1 = 21.0 °C) the theoretical excess of moist air was smaller and equaled 18,637 m3/h. Considering the total theoretical performance of fans at the level of 391,444 m3/h to 782,880 m3/h, it can be concluded that the performance of cooling system fans is sufficient to remove excess moisture from the cowshed. The consumption of electrical energy for driving the cooling system fans as well as water consumption was also investigated. Regulation of power and water consumption is carried out with the help of the temperature sensors and, therefore, the power and the water flow depend on the temperature of the air in the cowshed. (Table 3).

Table 3.

Analysis of energy costs of the cooling system when regulated by using temperature.

The regulation is as follows: when the air temperature in the cowshed is 16 °C, the fans are switched on at 25% power, at temperatures from 16 °C to 19 °C—at 50% power, at temperatures from 22 °C to 25 °C—at 75% power, and at temperatures above 25 °C,—at 100% power. Accordingly, the water supply changes. It should be noted that the operation of fans at capacities lower than 75% is not effective because they do not provide cooling for the intensive flow of the adiabatic process.

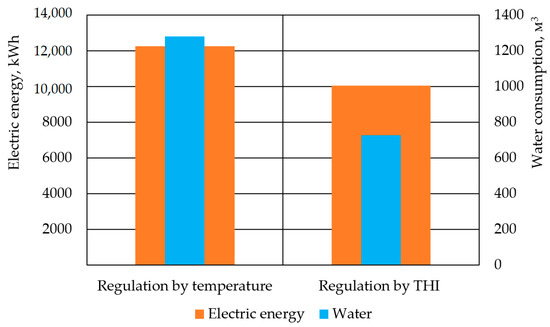

To reduce the consumption of electricity and water the authors suggest following the regulation not by using the temperature but by using THI (Table 4). With THI values lower than 68, the fans do not turn on, with THI values from 68 to 72 they work at 75% power, and with THI values greater than 72, the fans work at 100% nominal power.

Table 4.

Analysis of energy costs of the cooling system when regulated by using THI.

Theoretically, when using THI to regulate the operation of the cooling system, the consumption of the electrical energy is reduced by 17.9%, and the consumption of electricity is reduced by 43.2% (Figure 15) in comparison with the option when the temperature is used to regulate the operation of the cooling system.

Figure 15.

The consumption of electric energy and water under different methods of regulation of the cooling system operation.

With a correctly calculated and installed cooling system it is possible to achieve a decrease in air temperature in a cowshed of 4–10 °C. It should the taken into account that the efficiency of cooling directly depends on the relative humidity of the air in the shed; the higher the humidity, the less effective the air cooling will be. At a relative humidity of more than 80%, the cooling effect is reduced.

The use of THI for regulating the operation of the cooling system will reduce energy consumption but requires further practical research. It is obvious that the air humidification–cooling system creates favorable conditions for reducing the temperature stress in cows. However, it is necessary to carry out further research in order to optimize the consumption of water and electric energy, to determine the effects of the size of water drops, and the periodicity of the system operation on the effectiveness of reducing the temperature stress in cows. It is also necessary to investigate in detail the effect of the volume of water, sprayed using the nozzles, on the moisture content of the air inside the cowshed under different temperature conditions. In addition, it is necessary to continue the research on the influence of ventilation and cooling systems on the emission of harmful gases into the environment. It is necessary to investigate in detail the influence of the proposed control system (management) of the cooling system on the change in THI values, and on the condition and milk productivity of cows. The influence of the speed of the air flow from the fans on the efficiency of the cooling system also requires thorough investigation.

4. Conclusions

The research was carried out in semi-insulated box-type cowsheds for 244 places. For creating an optimal microclimate, the cowshed was equipped with an air humidification–cooling system. A temperature humidity index THI with a value greater than 80 was observed for 10 h during the measurement period (1800 h), which is 0.6% of the total number of hours. Conditions causing moderate heat stress were observed for 505 h (28.1%). Conditions causing mild heat stress were observed for 410 h (22.8%). The cows were without heat stress for 875 h (48.5%). Considering that the cows were in conditions that can cause heat stress during 51.5% of the time, the use of a cooling system is appropriate.

A comparison of the air coming from outside with the temperature of the air inside the cowshed was made. The average temperature value remained unchanged: 21.5 °C—the air temperature coming from outside, and 21.4 °C—the air temperature inside the cowshed. This testifies to the ability of the cooling system to compensate for the release of heat by animals. It should be noted that the number of hours with high temperature (more than 25 °C) inside the cowshed was 3% lower. The average value of relative humidity increased from 70.7% for the air coming from outside to 73.1% for the air inside the shed.

In addition, inside the cowshed the relative humidity values greater than 80% increased by 2.7%. Additionally, the values of relative humidity less than 60%, in comparison, decreased by 8.3%. The average value of THI actually did not change and was 68.2% for the air coming from outside, and 68.5%—for the air inside the cowshed. In particular, it should be noted that due to the operation of the cooling system, the THI in the cowshed did not exceed the critical value of more than 80. Although, for the air coming from outside the THI was greater than 80 for 10 h during the entire period of study.

As the temperature increases, the relative efficiency of the cooling system increases as well. This effect can be explained by the higher intensity of the adiabatic air cooling process, i.e., in the heated air the sprayed water absorbs heat more intensively. In addition, the operation of the fans at full power helps to increase the efficiency of the cooling system due to more uniform filling of the space in the cowshed with moisture and more intensive air exchange. Intensive constant air exchange, provided by the operation of fans at full power, avoids an excessive increase in relative humidity in a cowshed. However, the effect of fan power and the speed of the air flow on the efficiency of a cooling system requires further thorough research.

5. Recommendations and Prognosis

The regulation of fan power and water flow is carried out with the help of temperature sensors, and therefore, the power of the water flow depends on the air temperature in a cowshed. In order to reduce the consumption of electricity and water, the paper suggests regulation of the operation not using temperature but using THI.

Theoretically, when using THI to regulate the operation of the cooling system, the consumption of electrical energy is reduced by 17.8%, and the consumption of water is reduced by 43.2% in comparison with the variant when the temperature was used to regulate the cooling system operation.

Author Contributions

Conceptualization, R.B., J.Č. and S.K.; methodology, R.B. and J.Č.; validation, R.B., J.Č. and O.M.; formal analysis R.B., S.K., I.S.-B. and I.K.; project administration, S.K.; supervision, R.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Polsky, L.; von Keyserlingk, M.A.G. Invited review: Effects of heat stress on dairy cattle welfare. J. Dairy Sci. 2017, 100, 8645–8657. [Google Scholar] [CrossRef]

- Ferreira, F.; Gennari, R.; Dahl, G.; De Vries, A. Economic feasibility of cooling dry cows across the United States. J. Dairy Sci. 2016, 99, 9931–9941. [Google Scholar] [CrossRef]

- Mylostyvyi, R.; Chernenko, O. Correlations between Environmental Factors and Milk Production of Holstein Cows. Data 2019, 4, 103. [Google Scholar] [CrossRef]

- Bleizgys, R.; Naujokienė, V.; Čėsna, J. Humidification–Cooling System in Semi-Insulated Box-Type Cowsheds Prevent the Loss of Milk Productivity Due to Thermal Stress. Agronomy 2022, 12, 1131. [Google Scholar] [CrossRef]

- Aggarwal, A.; Upadhyay, R. Shelter Management for Alleviation of Heat Stress in Cows and Buffaloes. Heat Stress Anim. Product. 2013, 169–183. [Google Scholar] [CrossRef]

- Renaudeau, D.; Collin, A.; Yahav, S.; de Basilio, V.J.; Gourdine, L.; Collier, R.J. Adaptation to hot climate and strategies to alleviate heat stress in livestock production. Animal 2012, 6, 707–728. [Google Scholar] [CrossRef] [PubMed]

- Kic, P. Influence of External Thermal Conditions on Temperature–Humidity Parameters of Indoor Air in a Czech Dairy Farm during the Summer. Animals 2022, 12, 1895. [Google Scholar] [CrossRef]

- Ji, B.; Banhazi, T.; Perano, K.; Ghahramani, A.; Bowtell, L.; Wang, C.; Li, B. A review of measuring, assessing and mitigating heat stress in dairy cattle. Biosyst. Eng. 2020, 199, 4–26. [Google Scholar] [CrossRef]

- Velayudhan, S.M.; Brügemann, K.; Alam, S.; Yin, T.; Devaraj, C.; Sejian, V.; Schlecht, E.; König, S. Molecular, Physiological and Hematological Responses of Crossbred Dairy Cattle in a Tropical Savanna Climate. Biology 2023, 12, 26. [Google Scholar] [CrossRef]

- Chamberlain, A.T.; Powell, C.D.; Arcier, E.; Aldenhoven, N. The relationship between on-farm environmental conditions inside and outside cow sheds during the summer in England: Can Temperature Humidity Index be predicted from outside conditions? Anim.—Open Space 2022, 1, 100019. [Google Scholar] [CrossRef]

- Armstrong, D.V. Heat stress interaction with shade and cooling. J. Dairy Sci. 1994, 77, 2044–2050. [Google Scholar] [CrossRef]

- Zimbelman, R.B.; Collier, R.J.; Eastridge, M.L. Feeding strategies for high-producing dairy cows during periods of elevated heat and humidity. In Proceedings of the 20th Annual Tri-State Dairy Nutrition Conference, Ft. Wayne, IN, USA, 19–20 April 2011; pp. 111–125. [Google Scholar]

- Levit, H.; Pinto, S.; Amon, T.; Gershon, E.; Kleinjan-Elazary, A.; Bloch, V.; Ben Meir, Y.A.; Portnik, Y.; Jacoby, S.; Arnin, A.; et al. Dynamic cooling strategy based on individual animal response mitigated heat stress in dairy cows. Animal 2021, 15, 100093. [Google Scholar] [CrossRef]

- Broucek, J.; Novak, P.; Vokralova, J.; Soch, M.; Kisac, P.; Uhrinca, M. Effect of high temperature on milk production of cows from free-stall housing with natural ventilation. Slovak J. Anim Sci. 2009, 42, 167–173. [Google Scholar]

- Bohmanova, J.; Misztal, I.; Cole, J.B. Temperature-humidity indices as indicators of milk production losses due to heat stress. J. Dairy Sci. 2007, 90, 1947–1956. [Google Scholar] [CrossRef]

- Almuhanna, E.A.; Gamea, G.R.; Osman, O.E.; Almahdi, F.M. Performance of roof-mounted misting fans to regulate heat stress in dairy cows. J. Therm. Biol. 2021, 99, 102984. [Google Scholar] [CrossRef]

- Tresoldi, G.; Schütz, K.E.; Tucker, C.B. Cooling cows with sprinklers: Effects of soaker flow rate and timing on behavioral and physiological responses to heat load and production. J. Dairy Sci. 2019, 102, 528–538. [Google Scholar] [CrossRef]

- Lin, J.C.; Moss, B.R.; Koon, J.L.; Flood, C.A.; Smith, R.C., III; Cummins, K.A.; Coleman, D.A. Comparison of various fan, sprinkler, and mister systems in reducing heat stress in dairy cows. Appl. Eng. Agric. 1998, 14, 177–182. [Google Scholar] [CrossRef]

- Ashrae, A. Handbook of Fundamentals; American Society of Heating Refrigerating and Air Conditioning Engineers: Atlanta, GA, USA, 2013. [Google Scholar]

- Fournel, S.; Ouellet, V.; Charbonneau, É. Practices for Alleviating Heat Stress of Dairy Cows in Humid Continental Climates: A Literature Review. Animals 2017, 7, 37. [Google Scholar] [CrossRef]

- Tresoldi, G.; Schütz, K.E.; Tucker, C.B. Cooling cows with sprinklers: Spray duration affects physiological responses to heat load. J. Dairy Sci. 2018, 101, 4412–4423. [Google Scholar] [CrossRef]

- Anderson, S.D.; Bradford, B.J.; Harner, J.P.; Tucker, C.B.; Choi, C.Y.; Allen, J.D.; Hall, L.W.; Rungruang, S.; Collier, R.J.; Smith, J.F. Effects of adjustable and stationary fans with misters on core body temperature and lying behavior of lactating dairy cows in a semiarid climate. J. Dairy Sci. 2013, 96, 4738–4750. [Google Scholar] [CrossRef]

- Firfiris, V.K.; Martzopoulou, A.G.; Kotsopoulos, T.A. Passive cooling systems in livestock buildings towards energy saving: A critical review. Energy Build. 2019, 202, 109368. [Google Scholar] [CrossRef]

- Avendaño-Reyes, L.; Álvarez-Valenzuela, F.D.; Correa-Calderón, A.; Algándar-Sandoval, A.; Rodríguez-González, E.; Pérez-Velázquez, R.; Macías-Cruz, U.; Díaz-Molina, R.; Robinson, P.H.; Fadel, J.G. Comparison of three cooling management systems to reduce heat stress in lactating Holstein cows during hot and dry ambient conditions. Livest. Sci. 2010, 132, 48–52. [Google Scholar] [CrossRef]

- Drwencke, A.M.; Tresoldi, G.; Stevens, M.M.; Narayanan, V.; Carrazco, A.V.; Mitloehner, F.M.; Pistochini, T.E.; Tucker, C.B. Innovative cooling strategies: Dairy cow responses and water and energy use. J. Dairy Sci. 2020, 103, 5440–5454. [Google Scholar] [CrossRef]

- Our Dairy Farm Ventilation and Cooling Systems. Available online: https://www.abbi-aerotech.com/dairy-solutions/fans/ (accessed on 23 January 2023).

- PeakTech P5185. Available online: https://www.peaktech.de/PeakTech-P-5185-USB-Datenlogger-Lufttemperatur-und-feuchtigkeit-32000-Punkte/P-5185 (accessed on 23 January 2023).

- Howell, R.H.; Coad, W.J.; Sauer, H.J., Jr. Principles of Heating, Ventilating and Air-Conditioning, 7th ed.; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2013; ISBN 978-1-936504-57-2. [Google Scholar]

- Hellickson, M.A.; Walker, J.N. Ventilation of Agricultural Structures; American Society of Agricultural Engineers: St Joseph, MI, USA, 1983; 372p, ISBN 09-161-50569. [Google Scholar]

- Teye, F.K.; Hautala, M. Measuring Ventilation Rates in Dairy Buildings. Int. J. Vent. 2007, 6, 247–256. [Google Scholar] [CrossRef]

- Sallvik, K. CIGR Handbook of Agricultural Engineering, Volume II Animal Production & Aquacultural Engineering, PART I Livestock Housing and Environment, Chapter 2 Environment for Animals, Part 2.1 Animal Environment Requirements; American Society of Agricultural and Biological Engineers: St Joseph, MI, USA, 1999; pp. 31–41. [Google Scholar] [CrossRef]

- Mihai, V.; Rusu, L. Improving the Ventilation of Machinery Spaces with Direct Adiabatic Cooling System. Inventions 2022, 7, 78. [Google Scholar] [CrossRef]

- Jo, M.-S.; Shin, J.-H.; Kim, W.-J.; Jeong, J.-W. Energy-Saving Benefits of Adiabatic Humidification in the Air Conditioning Systems of Semiconductor Cleanrooms. Energies 2017, 10, 1774. [Google Scholar] [CrossRef]

- Bleizgys, R.; Bagdoniene, I. Control of ammonia air pollution through the management of thermal processes in cowsheds. Sci. Total Environ. 2016, 568, 990–997. [Google Scholar] [CrossRef]

- Kavolėlis, B.; Bleizgys, R.; Čėsna, J. Emission of water vapour in uninsulated cowshed. Ann. Anim. Sci. 2010, 10, 57–65. [Google Scholar]

- Samer, M.; Ammon, C.; Loebsin, C.; Fiedler, M.; Berg, W.; Sanftleben, P.; Brunsch, R. Moisture balance and tracer gas technique for ventilation rates measurement and greenhouse gases and ammonia emissions quantification in naturally ventilated buildings. Build. Environ. 2012, 50, 10–20. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).