Performance Simulation of Permeable Concrete Materials Combined with Nanotechnology in Rainwater Management

Abstract

1. Introduction

2. Related Work

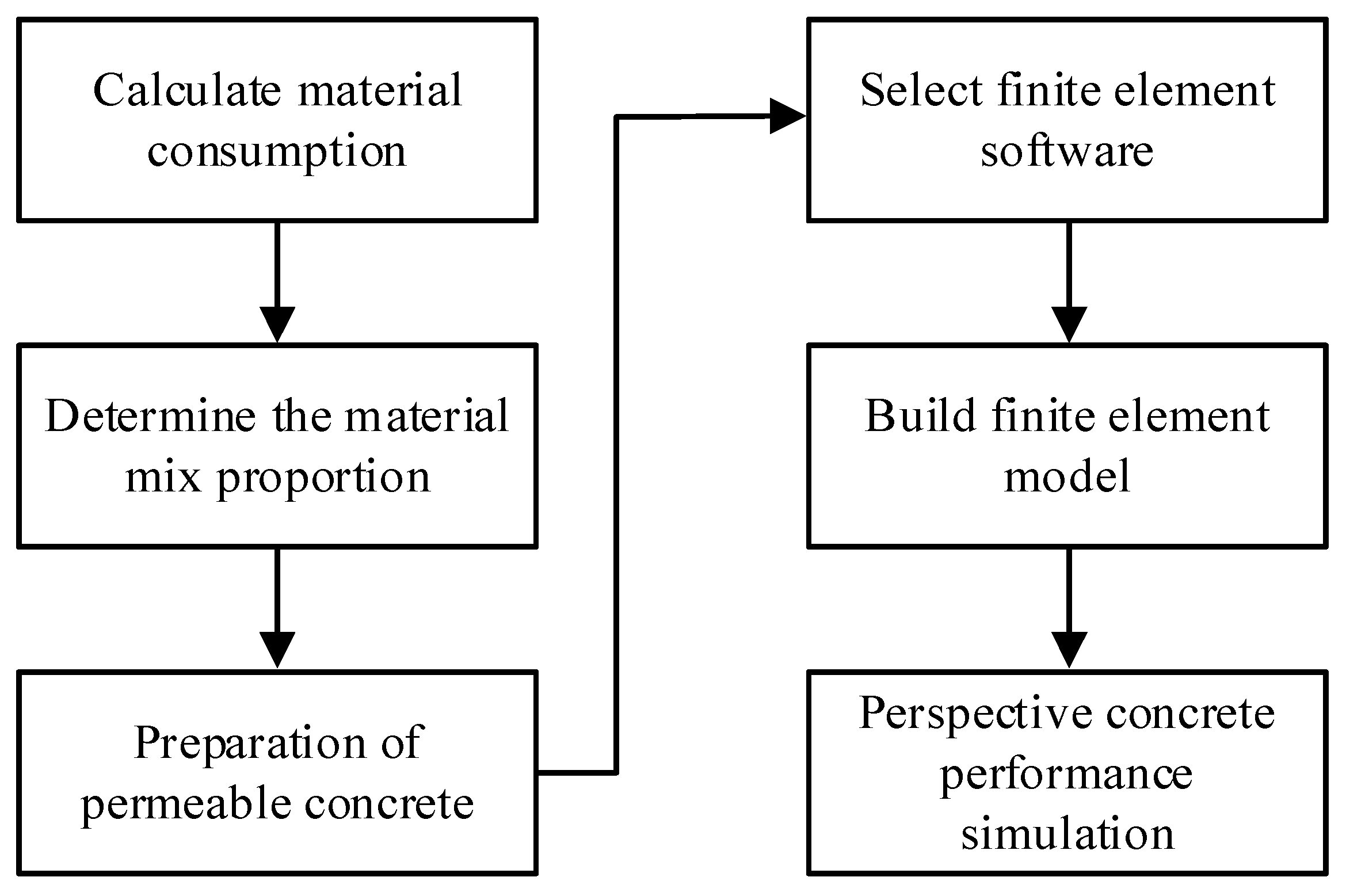

3. Preparation and Evaluation Method for Permeable Concrete Combined with Nano-Materials

3.1. Experimental Preparation and Preparation Method

3.2. Finite Element Model of Pervious Concrete Based on Nanomaterials

4. Performance Test of Permeable Concrete Incorporating Nanomaterials

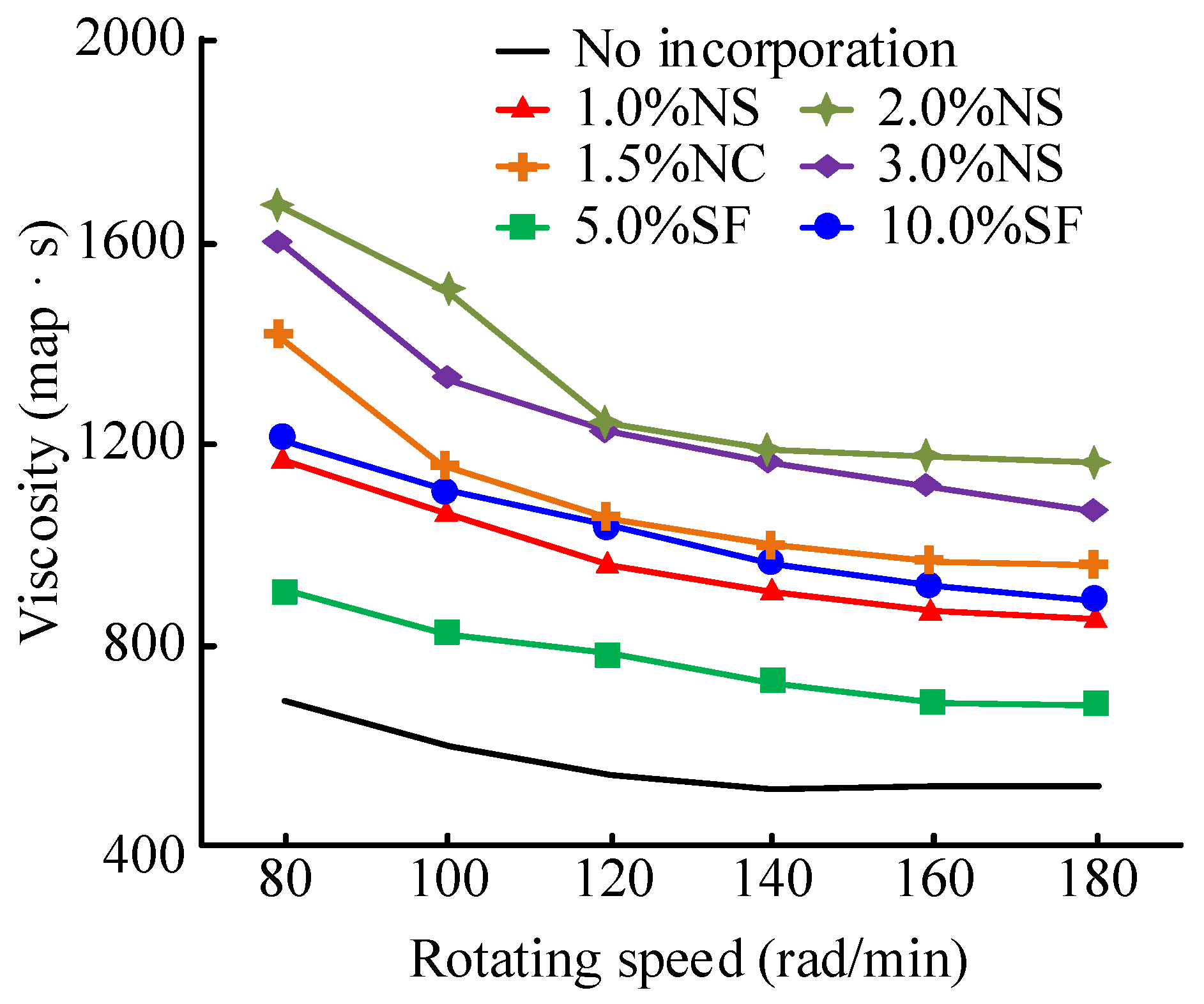

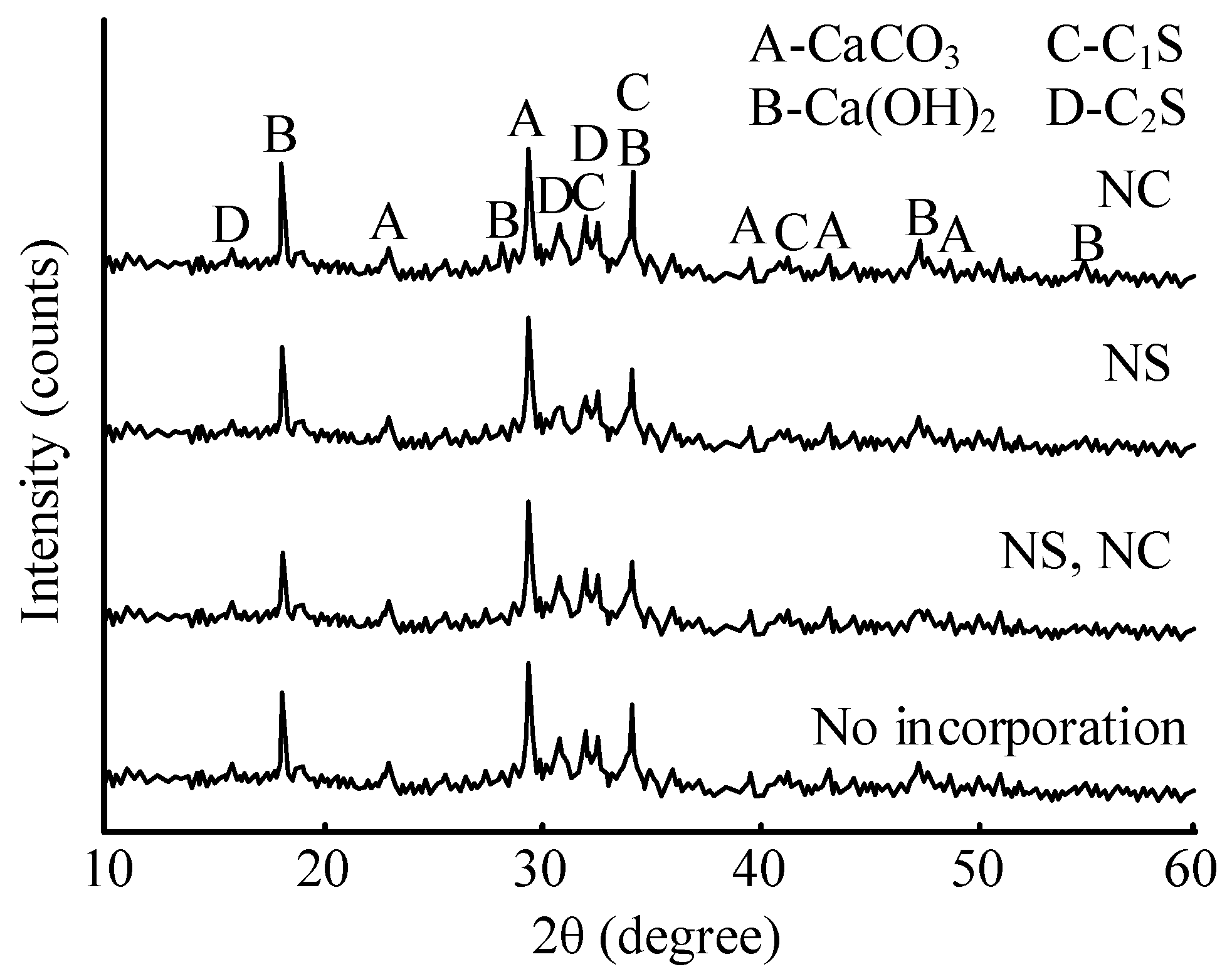

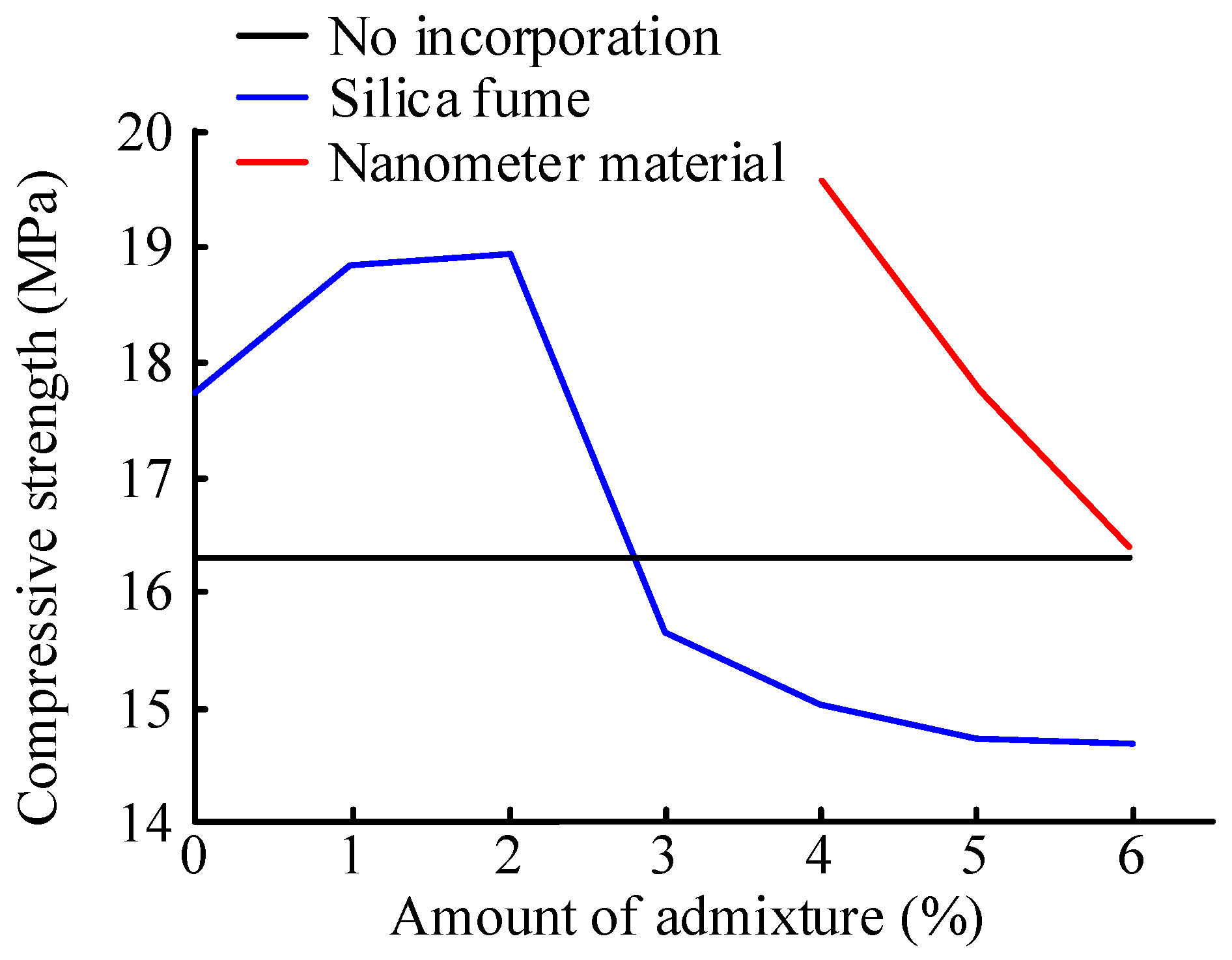

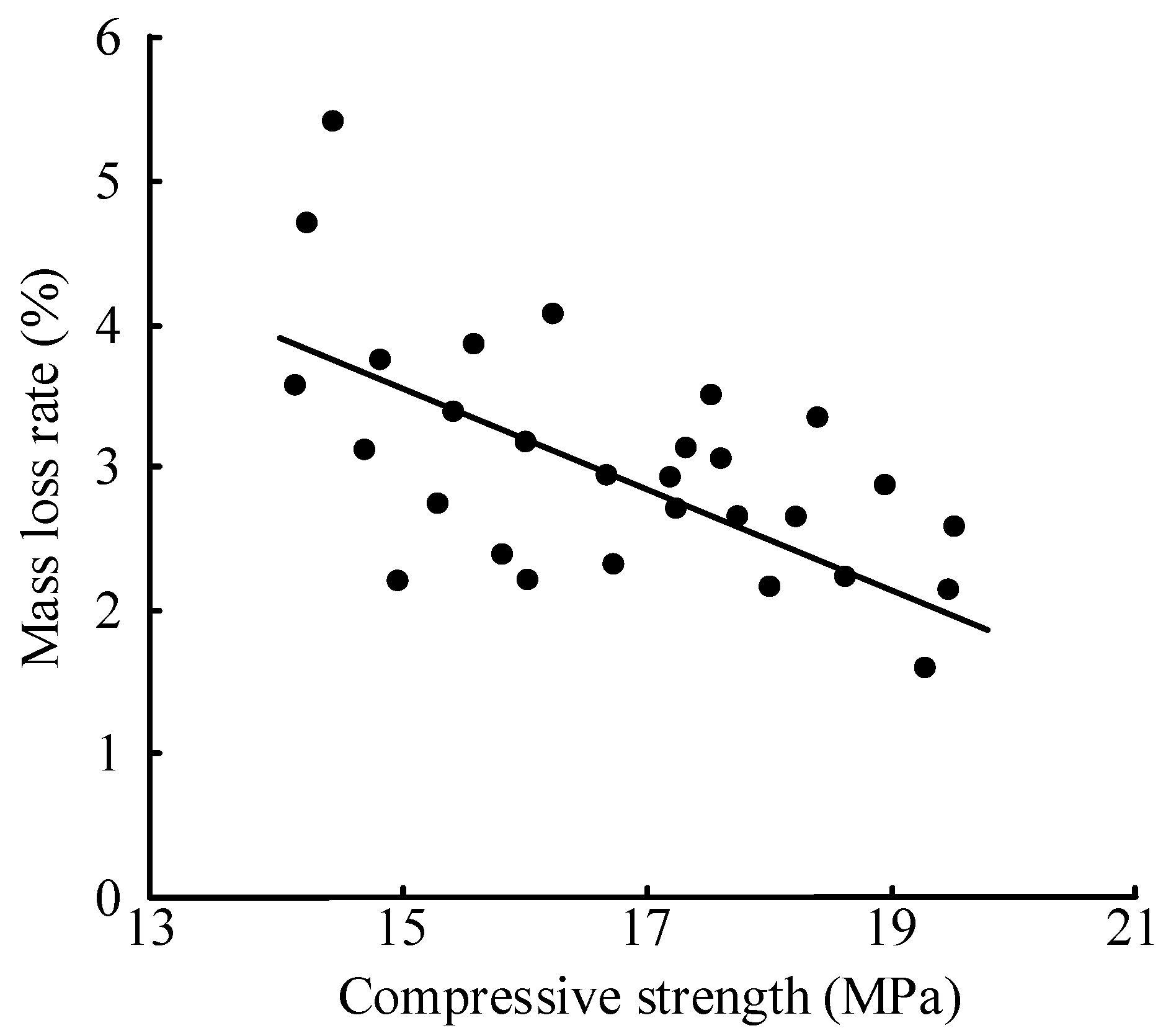

4.1. Comprehensive Performance Analysis of Pervious Concrete

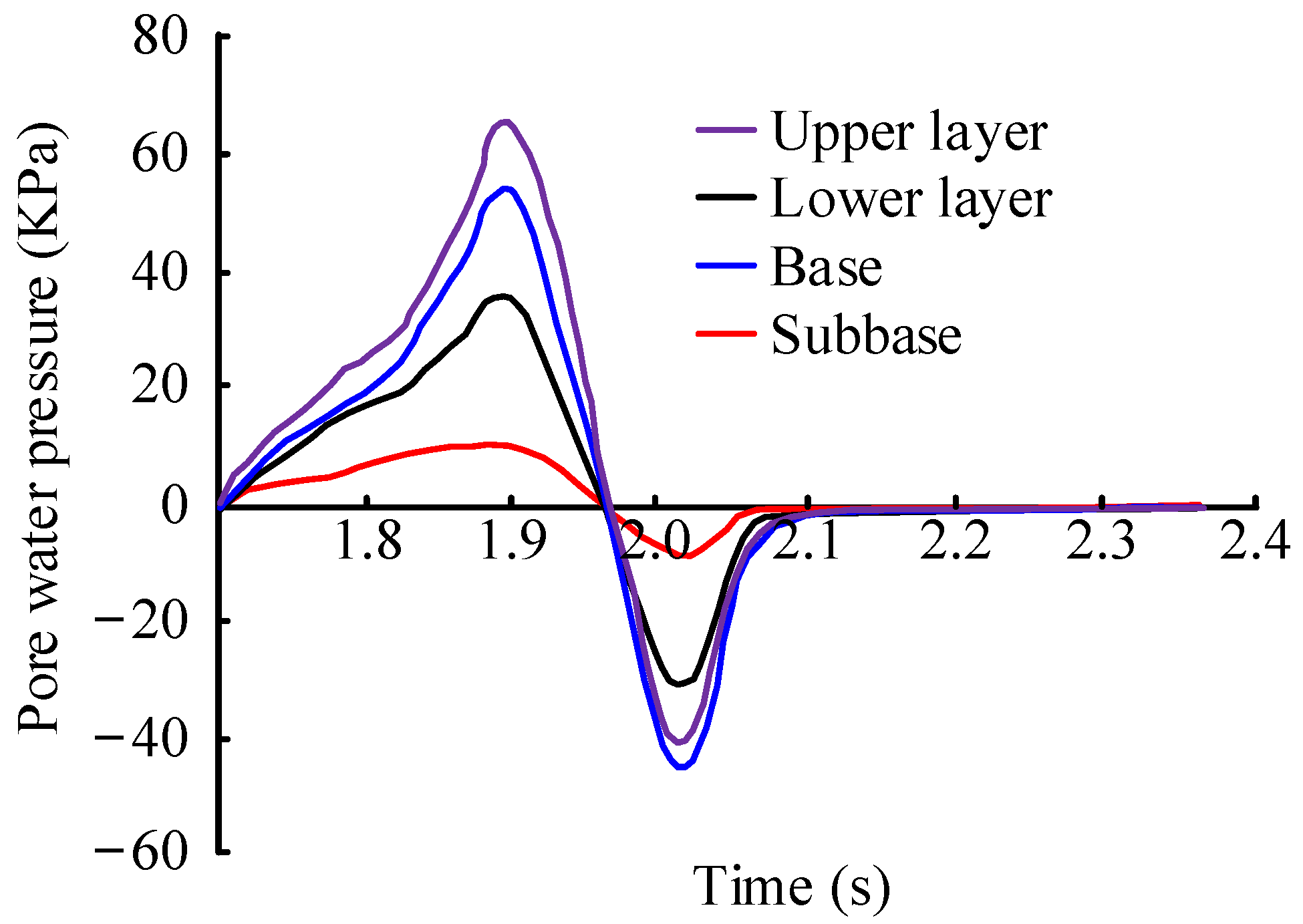

4.2. Finite Element Analysis of Permeable Concrete Mixed with Nanomaterials

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mehta, K.; Sharma, N.K. Management of storm water using pervious concrete interlocking tiles in chandigarh. Civ. Eng. 2021, 12, 401–412. [Google Scholar]

- Hu, C.; Tian, L.; Li, J.; Wang, K.; Chen, N. An observation capability information association model for multisensor observation integration management: A flood observation use case in the Yangtze River Basin. IEEE Sens. J. 2019, 19, 11510–11525. [Google Scholar] [CrossRef]

- Su, D.; Zhang, Q.H.; Ngo, H.H.; Dzakpasu, M.; Guo, W.S.; Wang, X.C. Development of a water cycle management approach to Sponge City construction in Xi’an, China. Sci. Total Environ. 2019, 68, 490–496. [Google Scholar] [CrossRef] [PubMed]

- Bouzid, C.; Salil, G.; Gregory, S.; Howard, M. Evaluation of coarse- and fine-graded superpave mixtures under accelerated pavement testing. Transp. Res. Rec. 2018, 1974, 120–127. [Google Scholar]

- Ortega, V.R.; Lizarraga, M.L.; Coronel, O.C.; Lope, L.L.D.; Alfredo, B.A.C.; Vazquez, R.G.A. Effect of photocatalytic Fe2O3 nanoparticles on urban runoff pollutant removal by permeable concrete. J. Environ. Manag. 2019, 242, 487–495. [Google Scholar] [CrossRef]

- Marvin, J.T.; Scott, J.; Seters, T.V.; Bowers, R.; Drake, J.A. Winter Maintenance of Permeable Interlocking Concrete Pavement: Evaluating Opportunities to Reduce Road Salt Pollution and Improve Winter Safety. Transp. Res. Rec. 2021, 2675, 174–186. [Google Scholar] [CrossRef]

- Mostafa, R.; Michael, B. Long-term effects of three types of permeable pavements on nutrient infiltrate concentrations. Sci. Total Environ. 2019, 670, 893–901. [Google Scholar]

- Cai, J.; Song, C.; Zhou, B.; Tian, Y.; Li, R.; Zhang, J.; Pei, J. Investigation on high-viscosity asphalt binder for permeable asphalt concrete with waste materials. J. Clean. Prod. 2019, 228, 40–51. [Google Scholar] [CrossRef]

- Yuan, X.L.; Tang, Y.Z.; Li, Y.; Wang, Q.S.; Zuo, J.; Song, Z.L. Environmental and economic impacts assessment of concrete pavement brick and permeable brick production process—A case study in China. J. Clean. Prod. 2018, 171, 198–208. [Google Scholar] [CrossRef]

- Braswell, A.S.; Winston, R.J.; Hunt, W.F. Hydrologic and water quality performance of permeable pavement with internal water storage over a clay soil in Durham, North Carolina. J. Environ. Manag. 2018, 224, 277–287. [Google Scholar] [CrossRef]

- Ding, Z.; Sigdel, K.; Yang, L.; Liu, Y.; Xie, H. Nanotechnology-based drug delivery systems for enhanced diagnosis and therapy of oral cancer. J. Mater. Chem. B Mater. Biol. Med. 2020, 8, 8781–8793. [Google Scholar] [CrossRef] [PubMed]

- Abdollahiyan, P.; Oroojalian, F.; Hejazi, M.; de la Guardia, M.; Mokhtarzadeh, A. Nanotechnology, and scaffold implantation for the effective repair of injured organs: An overview on hard tissue engineering-ScienceDirect. J. Control. Release 2021, 333, 391–417. [Google Scholar] [CrossRef] [PubMed]

- Arezki, Y.; Su, R.; Heikkinen, V.; Posta, P.; Nouira, H. Traceable reference full metrology chain for innovative aspheric and freeform optical surfaces accurate at the nanometer level. Sensors 2021, 21, 1103. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.C.; Kim, S.G.; Nam, K.B.; Yeo, J.H.; Kim, T.S.; Kim, M.J.; Yoo, J.B. A way to improve the uniformity of nanometer-thickness graphite film synthesized on polycrystalline Ni substrate: From large grain to small grain. Carbon 2019, 144, 410–416. [Google Scholar] [CrossRef]

- Mei, M.; Han, Z.; Liu, P.; Fang, F.; Wang, K. Silica encapsulation of metal perovskite nanocrystals in a photoluminescence type display application. Nanotechnology 2019, 30, 395702–395709. [Google Scholar] [CrossRef] [PubMed]

- Nizina, T.A.; Balykov, A.S.; Korovkin, D.I.; Volodin, V.V. Physical and mechanical properties of modified fine-grained fibre-reinforced concretes containing carbon nanostructures. Int. J. Nanotechnol. 2019, 16, 496–509. [Google Scholar] [CrossRef]

- Georgees, R.N.; Hassan, R.A.; Evans, R.P.; Jegatheesan, P. An evaluation of performance-related properties for granular pavement materials using a polyacrylamide additive. Int. J. Pavement Eng. 2018, 19, 153–163. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Rosas-Casarez, C.A.; Arredondo-Rea, S.P.; Gómez-Soberón, J.M.; Corral-Higuera, R. SEM Image Analysis in Permeable Recycled Concretes with Silica Fume. A Quantitative Comparison of Porosity and the Itz. Materials 2019, 12, 2201. [Google Scholar] [CrossRef]

- Zhang, H.; Anupam, K.; Skarpas, A.; Kasbergen, C.; Erkens, S. Simple Homogenization-Based Approach to Predict Raveling in Porous Asphalt. Transp. Res. Rec. 2020, 2674, 263–277. [Google Scholar] [CrossRef]

- Zhu, Y.L.; Wang, Y.X.; Gao, C.; Zhao, W.N.; Wang, X.B.; Wu, M.B. CoMoO 4 -N-doped carbon hybrid nanoparticles loaded on a petroleum asphalt-based porous carbon for lithium storage. New Carbon Mater. 2020, 35, 358–370. [Google Scholar] [CrossRef]

- Wu, S.; Liu, L.; Yao, G.; Zhang, J.; Tahri, O. Laboratory Investigation of an Alternative Permeability Indicator to Determine Optimal Maintenance Timing for Open-Graded Friction Course. Transp. Res. Rec. 2020, 2674, 165–177. [Google Scholar] [CrossRef]

- Zheng, P.; Ke, J.; Pan, W.; Zhan, X.; Cai, Y. Effects of Low-Impact Development on Urban Rainfall Runoff under Different Rainfall Characteristics. Pol. J. Environ. Stud. 2018, 28, 771–783. [Google Scholar]

| Experiment No | Nano-Silica | Nano-Calcium Carbonate | Silica Fume | Permeability Coefficient (cm/s) |

|---|---|---|---|---|

| 1 | 1% | / | / | 0.33 |

| 2 | 1.5% | / | / | 0.39 |

| 3 | / | 1% | / | 0.38 |

| 4 | / | 1.5% | / | 0.42 |

| 5 | / | / | 5% | 0.29 |

| 6 | / | / | 8% | 0.34 |

| 7 | / | / | 10% | 0.31 |

| 8 | 1.5% | 1.5% | 8% | 0.43 |

| Content (%) | Nano-Silica/Nano-Calcium Carbonate | Average Difference | Standard Error | Sig. | 95% CI |

|---|---|---|---|---|---|

| 1 | 2 | 0.189 | 0.283 | 0.504 | [−0.405, 0.783] |

| 3 | 1.726 | 0.283 | 0 | [1.135, 2.323] | |

| 2 | 1 | −0.189 | 0.283 | 0.504 | [−0.783, 0.405] |

| 3 | 1.529 | 0.283 | 0 | [0.929, 2.131] | |

| 3 | 1 | −1.726 | 0.283 | 0 | [−2.323, −1.135] |

| 2 | −1.529 | 0.283 | 0 | [−2.131, 0.929] |

| Material Science | Coarse Aggregate | Cement | Fly Ash | Water | Water-Reducing Agent | NC | NS |

|---|---|---|---|---|---|---|---|

| Consumption (kg/m3) | 1548.4 | 366.3 | 29.6 | 111.2 | 5.5 | 11.1 | 11.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Jin, M.; Chen, J.; Weng, Z.; Sun, M.; Wu, D.; Yan, H.; Huang, Z.; Xue, J.; Wang, F. Performance Simulation of Permeable Concrete Materials Combined with Nanotechnology in Rainwater Management. Processes 2023, 11, 768. https://doi.org/10.3390/pr11030768

Li J, Jin M, Chen J, Weng Z, Sun M, Wu D, Yan H, Huang Z, Xue J, Wang F. Performance Simulation of Permeable Concrete Materials Combined with Nanotechnology in Rainwater Management. Processes. 2023; 11(3):768. https://doi.org/10.3390/pr11030768

Chicago/Turabian StyleLi, Jianfeng, Mengmeng Jin, Junbo Chen, Zucan Weng, Miao Sun, Danhong Wu, Huihui Yan, Zhigang Huang, Jinglan Xue, and Feilan Wang. 2023. "Performance Simulation of Permeable Concrete Materials Combined with Nanotechnology in Rainwater Management" Processes 11, no. 3: 768. https://doi.org/10.3390/pr11030768

APA StyleLi, J., Jin, M., Chen, J., Weng, Z., Sun, M., Wu, D., Yan, H., Huang, Z., Xue, J., & Wang, F. (2023). Performance Simulation of Permeable Concrete Materials Combined with Nanotechnology in Rainwater Management. Processes, 11(3), 768. https://doi.org/10.3390/pr11030768