Abstract

In the current search for products that are friendly to the environment, the intent is to reduce the use of domestic, food and industrial waste of mineral origin, thereby creating new products that are functional in industrial and agricultural processes. That is why the use of raw chicken skin fat was evaluated for the creation of a biolubricant with possible applications in the operation of heavy machinery, such as agricultural tractors. The acute toxicity of the biolubricant made from transesterified fatty acids obtained from chicken skin fat was determined experimentally, using bioassays with Eisenia fetida as a test organism, by means of the median lethal concentration (LC50) using the probit method (p < 0.05) on the filter paper at 48 h and on an artificial substrate at 14 days, resulting in an LC50 of 878.675 mg mL−1 or 0.0268 mg cm−2 and 35.2348 mg kg−1, respectively. Likewise, the physiological damage was determined by means of histology, and it could be observed that there was no damage on the Eisenia fetida cell tissue. This indicates that the biolubricant is suitable for use in agricultural machinery since, in the event of an accidental spill, it does not cause damage to the soil or the organisms that live in it, as well as to the people who handle this type of product in their daily work.

1. Introduction

Lubricants are liquid substances, generally oils, that are synthesized from a petroleum base or made synthetically, and that facilitate sliding and reduce friction between moving machine parts or mechanisms [1,2]. The lubricants currently used for agricultural machinery are mostly of mineral origin and extracted from crude oil [3]. Their use is necessary above all in those implements that are exposed to environmental factors, such as high temperatures, the presence of soil and other chemical compounds, such as pesticides, and even when in contact with water, which damages the machinery, producing greater signs of corrosion and wear. Lubrication is basic and necessary for the operation of almost all the machinery used in the world, since it serves to reduce friction in the mechanical components of the machinery [4]. Without lubrication, machines could not work efficiently, or if they work, they would only operate for a short time before failing due to overheating.

In the lubricants industry, products are constantly being improved and changed as the requirements of new machinery change and new chemical and distillation processes are discovered, in order to minimize the environmental impact of the use of anthropogenic substances. The gradual depletion of oil and the ongoing environmental crisis have raised widespread concern around the world. Therefore, measures have been taken to curb these imminent threats, including the development of green energy systems and the use of renewable resources as a potential alternative to mineral-based products [1]. Currently, the lubricating capacity of animal and vegetable oils is greater than mineral oils; however, they have the disadvantage of poor oxidation stability at high temperatures and easy decomposition, producing acid substances that attack metal surfaces [5,6].

In this sense, the lubricants industry is one of the areas of interest that is being studied to reduce the dependence on oil, the pollution that is generated and the anthropogenic impact in the environment; therefore, the use of natural oil-based lubricants, instead of petroleum-based lubricants, are known as “biolubricants”, since their use generates environmental, health and degradation benefits over mineral lubricants. It should be mentioned that many of the current biolubricants come from edible vegetable oils and alternative sources [7].

Poultry farming is one of the most important animal production areas in Mexico. The state of Chiapas is one of the main chicken producers, occupying eighth place nationwide with an average production of 492,417 tons per year [8], of which 30% is equivalent to chicken skin, that is 147,725 tons of this waste per year, resulting in a significant amount of waste that currently lacks viable alternative uses. On the contrary, it is usually improperly disposed of, which represents an increase in contamination risks [7].

Chicken skin fat has already been used for application as a biofuel and a biodiesel, complying with the essential characteristics of this type of product [5,7,9,10,11,12]. To take advantage of this raw material, methodologies were developed that allowed the physicochemical properties of chicken skin fat to be modified, which allow for maintaining its tribological properties.

To do this, the most widely used chemical modifications for biolubricants are esterification/transesterification (reorganization of acyl residues to form new triesters) and epoxidation (addition of oxygen to double bonds). Esterification and transesterification are commonly used to rearrange acyl group residues in vegetable oils to form esters with new physical properties. Epoxidation is one of the most suitable methods to improve the thermo-oxidative stability caused by the presence of double bonds in natural oils [7].

The characteristics of the biolubricant carried out by Hernandez-Cruz [13] are shown in Table 1.

Table 1.

Physicochemical characteristics of the biolubricant made from chicken skin fat.

In order to consider whether the products obtained are suitable for use as biolubricants, they have to comply with certain properties to assess the suitability of a particular application, with viscosity and biodegradability being the main ones, as shown in Table 1.

To continue with the studies of the biolubricant, toxicity tests were carried out. The Organization for Economic Cooperation and Development (OECD) Guide to Chemical Tests No. 207 [14] was used. Wei Liu [15] indicated that one of the most used and studied methodologies is bioremediation, which is the use of devices to degrade a contaminant. The final products of bioremediation are mainly water and carbon dioxide. Hydrocarbons are formed mainly by carbon and hydrogen, that is, they are compounds capable of biodegradation. Therefore, it is important to know the fate and persistence of these compounds in nature. A tolerable limit of these compounds can be calculated through toxicological tests using sensitive organisms [16]. In bioassays, a living tissue, organism or group of organisms is used as a reagent to assess the effects of any physiologically active substance. The toxic effects can include mortality, immobility, growth inhibition, behavioral deterioration and weight loss, among others. Variables such as the median lethal concentration (LC50), which is the lethal concentration for 50% of those exposed, are determined [16]. Through histological tests, it is possible to determine the tissue damage that the test organism could experience in order to be able to examine and analyze its morphological components, as well as its structure through the microscope [17,18]. Eisenia fetida was used as a test organism [16].

For this reason, the main objective of this research was to implement the methodology for the evaluation of acute toxicity of a biolubricant derived from chicken skin fat through a bioassay with the earthworm Eisenia fetida and to evaluate its physiological damage using histological techniques.

2. Materials and Methods

2.1. Raw Material

The earthworms Eisenia fetida (Savigny, 1826) were obtained from the Luanda farm, located in Ocozocoautla de Espinoza, Chiapas, Mexico (latitude 16°45′41.26″ N and longitude 93°22′32.35″ W, with a cold tropical climate and an average annual temperature of 21.2 °C).

The solid substrate used was made up of 85% peat and 15% rabbit manure that was previously dried, ground and sieved to a particle size of 0.2 and 0.5 mm, which was used for the earthworms to adapt to over 60 days at 25 °C and 60% humidity, feeding them every third day. This was carried out in order to achieve a uniform size of the worms and to ensure they had developed clitella [16].

Rabbit manure was collected from a farm located in Tuxtla Gutierrez, Mexico (latitude 16°45′11″ N and longitude 93°06′56″ W). The peat was a commercial product obtained from Promix Canadian Sphagnum from Quebec, Canada (52°00′00″ W longitude).

The biolubricant was obtained by transesterification of fatty acids from chicken skin fat at the Tuxtla Gutierrez Institute of Technology [7,13,19].

2.2. Acute Toxicity Analysis

2.2.1. Filter Paper Test

The concentrations of the biolubricant used were 0.1, 1, 10, 100 and 1000 mg of biolubricant per L of solution (mg L−1) as a first trial and later, concentrations of 50, 100, 200, 400, 600, 800 and 1000 mg of biolubricant per L of solution (mgL−1) were used. The appropriate volume of the solution with the lubricant was added to glass Petri dishes with a diameter of 8.5 cm and a contact area of 56.74 cm2 containing medium pore filter paper; as a control, the Petri dishes were used with filter paper impregnated with hexane, since it is the diluent of the biolubricant. The solvent used was allowed to evaporate for one hour in an Edutec Model DED-01CEH (United States) extraction hood and later, the filter paper was rehydrated by adding 1 mL of distilled water to each Petri dish along with a worm with a clitellum that was previously developed. They were washed with distilled water, dried with absorbent paper, left in plastic containers for 3 h to empty their gastrointestinal tract and the weight of each worm was recorded. Each treatment was carried out with 10 repetitions.

All the Petri dishes were kept in a Memmert (Schwabach, Germany) incubator at 25 °C in complete darkness for 48 h. After this time, the mortality (%) in the worm was evaluated to determine the LC50. In addition, the physical damage observed was recorded. The worms were considered dead if they showed little movement and did not respond to a defined mechanical stimulus [14].

2.2.2. Artificial Substrate Test

The artificial substrate was prepared by mixing the ingredients: 10% peat, 20% clay, 70% industrial sand and 1g of CaCO3 to adjust the pH to 7.0. The evaluated concentrations were 0 (control), 1, 5, 10, 50 and 100 mg of biolubricant per kg of substrate. The experimental units were amber glass flasks with a capacity of 1 L containing 500 g of the artificial substrate. The corresponding volume of the biolubricant solution was added to reach the desired concentration. The solution was mixed thoroughly, and the humidity was adjusted to 35%.

Ten adult worms with developed clitellum, previously washed with distiller water, dried with absorbent paper and weighed, were placed in glass jars and covered with a cotton cloth to allow air flow, adjusting the humidity to 35% each 7 days. All the flasks were subjected to 12/12 h light/dark periods at a temperature of 25–28 °C. Each concentration had four repetitions. The mortality (%) (for LC50) was evaluated at 14 days, without the addition of food [20,21].

2.3. Histology

Once the mean lethal concentration (LC50) was obtained, the histological technique on Eisenia fetida was followed to determine the damage of the biolubricant at the cellular level of the worms in the contact tests. The final LC50 result was useful for repeating the filter paper test and proceeding with histology, consulting the same standard established for the evaluation of toxicity.

The histological procedure was carried out according to Montalvo-Arenas [18], with slight modifications. Briefly, the worms were immobilized with glycerol for 15 min, then fixed with formalin for 24 h. The worms were then embedded in paraffin by dehydration in successive baths of ethyl alcohol for at least 36 h, continuing with diaphanization with xylol and ethyl alcohol for one hour and then continuing with three paraffin baths for 60 min each. Subsequently, 10 µm sections were obtained using a Bresser handheld microtome. Sections were stained with hematoxylin–eosin and observed under an Optica B-350 brand microscope using the 4×, 60× and 100× objective lenses.

2.4. Statistical Analysis

The results were evaluated by probit analysis [20,22,23,24,25] using the Statgraphics Centurion statistical program XVI. The experimental design used was completely randomized, with the worm mortality for LC50 used as the response variable.

3. Results

The results obtained show the ability of Eisenia fetida to adapt to the environment in which it develops and the null toxicity of the biolubricant towards the representative sample of the soil biota, such as the earthworm.

3.1. Filter Paper Test

The effect of the biolubricant on Eisenia fetida for the filter paper test resulted in physical damage, such as reduced movement, discoloration of the extremities and cuts and losses in some of the extremities. There was also the presence of blood and coelomic fluid on the filter paper where the worms remained for 48 h, as can be observed in Figure 1. Approximately 95% of the earthworms exposed to the biolubricant were alive at the end of the experiment.

Figure 1.

Physical state of Eisenia fetida with biolubricant (a) and without biolubricant (b).

Part of the acute toxicity evaluation included monitoring the weight of Eisenia fetida in the concentrations of the biolubricant that were used, as observed in Table 2.

Table 2.

Weight of earthworms exposed to biolubricant for 48 h for the filter paper test.

The results of the exposure of the biolubricant to Eisenia fetida through filter paper for 48 h are shown in Table 3.

Table 3.

Results of exposure of the biolubricant on filter paper.

In the control, there was no mortality, and survival exceeded 50%, but slight damage, such as cuts, fatigue, stress and weakness occurred in Eisenia fetida.

3.2. Artificial Substrate

The results of these treatments show that for the highest concentration of the treatment, which was 50 mg kg−1, Eisenia fetida was affected. In some cases, there was mortality, as observed in Table 4. In addition, the biolubricant affected the earthworm by contact through the skin, presenting symptoms such as stress without physical damage, moving slowly even when exposed to light and deterioration of the earthworms’ skin.

Table 4.

Results of the biolubricant in artificial substrate.

It was observed that the higher the concentration, the greater the mortality in the artificial substrate test and a survival constant for the lowest concentrations (0.5, 2.5 and 5 mg kg−1).

3.3. Statistic Analysis

From the toxicity tests with the biolubricant, it was possible to calculate the mean lethal concentration (LC50), that is, the concentration at which half of the exposed population of earthworms failed to survive. The LC50 was assessed by Probit statistical analysis using the Statgraphics Centurion XVI statistical program, which is a type of regression used to analyze binomial response variables. The results of each treatment are shown in Table 5, with a statistical reliability of 0.05%.

Table 5.

LC50 by probit analysis.

3.4. Histological Results

Eisenia fetida was selected because it is a species sensitive to changes in soil quality; therefore, it is considered a good indicator of environmental quality. Through the histological technique applied to Eisenia fetida [18], it was possible to demonstrate that the biolubricant derived from chicken fat was a product with little probability of being able to harm terrestrial fauna and with more friendly properties for the environment. By taking cross-sections, it was possible to appreciate through the microscope that deep wear in the Eisenia fetida tissues was not noticeable, so it was determined that the biolubricant is not toxic to the earthworms and therefore to the soil.

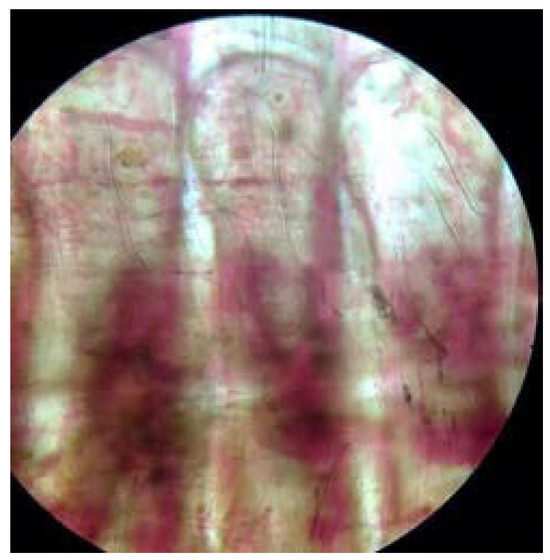

Once the LC50 results were obtained, the experiment was repeated to assess the worm histology. The results show that Eisenia fetida kept its physical appearance, without coelomic fluid spillage or stress symptoms. There were no deaths or weight loss; on the contrary, they had an increase in weight during the 48 h that the test lasted, as can be seen in Figure 2.

Figure 2.

Eisenia fetida after the filter paper test with the established LC50.

This confirmed that the concentrations applied to the filter paper test were not toxic, since all the earthworms survived after 48 h of the test. When measuring the weight of the earthworms, it was noted that their weight had increased from the initial measurements. In addition, their skin darkened drastically.

The first observation of the earthworm cell tissue was made through the microscope, before making a transverse incision for the staining process of the organism. By observing each part of the cellular tissues of the earthworm, it was noted how little wear and tear Eisenia fetida suffered when faced with this completely unknown product.

In Figure 3, the structure of the Eisenia fetida tissue is observed without the application of staining; the segmented cuts of the earthworm can be seen without apparent cell damage. The Eisenia fetida’s tissues did not present any change in their structure, thus proving with the observation of the microscope that the biolubricant exposed to Eisenia fetida did not cause damage to the structure of the earthworm. Therefore, it was determined that the biolubricant is not toxic.

Figure 3.

Eisenia fetida cell tissue without staining at 40×.

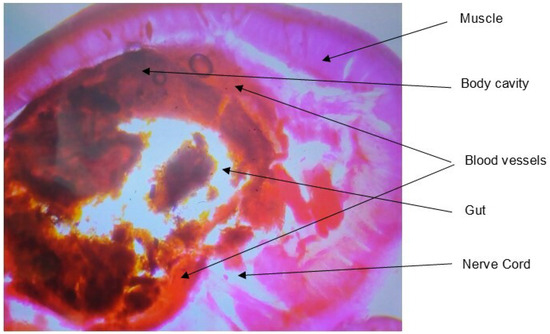

Once the coloring or staining procedure was finished, the tissues were subjected to observation through the microscope, as shown in Figure 4. It can be deduced that the biolubricant exposed to Eisenia fetida was not harmful to the environment or toxic to Eisenia fetida in the tests we carried out, compared to other authors who applied other substances that have been demonstrated to be more toxic and that damage the tissue of the earthworm [26].

Figure 4.

Cross-section of Eisenia fetida exposed to a biolubricant for 48 h; 40×.

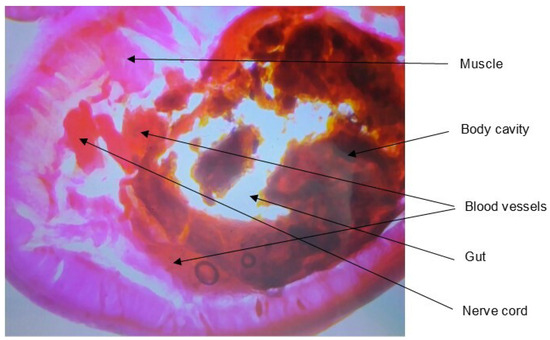

In Figure 4, a portion or cross-section of the worms is shown, in which, compared to the control of Figure 5, there is only slight swelling in the body cavity. The orange-reddish color effect is due to the absorption of the dye in the blood of the annelid.

Figure 5.

Cross-section of Eisenia fetida without biolubricant exposure; 40×.

Two different observations of the samples were made, one without staining and the other with staining. In the first observation, as the samples were not stained, it was not possible to clearly appreciate the molecular structure of the worm, unlike the observations with staining in the samples, which allowed for a better structural observation of Eisenia fetida.

4. Discussion

The Eisenia fetida worm is an annelid that easily adapts to different substrates; however, if the conditions of temperature, light and humidity are not suitable for it, it presents symptoms of stress, such as slow movements, thinning and a change in skin color.

In this study, changes in the physical characteristics of the worms, as well as changes in their weight, were evaluated. A statistically considerable decrease from the initial weight to the final weight after 48 h, in which the worm was subjected to contact with the biolubricant, was observed and is outlined in Table 2. It was also observed that there was no statistically significant difference in the initial and final weights of the earthworms in the control. Therefore, one of the reasons for the weight loss was that the earthworms did not have food, since they were in an environment completely isolated from their natural habitat; however, this external factor can affect the stress of the earthworm, but it did not affect the test because earthworms can survive 72 h without food [27].

The fact that a material is biodegradable is not directly related to its toxicity, since it depends on the formation of secondary compounds during its biodegradation. Commonly used mineral lubricants for motor vehicle use contain heavy metals. This makes them highly toxic when they biodegrade. The biolubricant analyzed by its origin does not contain metals, since it is synthesized from chicken fat that contains metal-free triglycerides. Barrios et al. [28] mentioned that worm damage can be caused by a drastic change in pH and excess of nutrients. According to the results of the toxicity test, the mortality of the individuals in the uncontaminated soil was 0% (<10%), which demonstrates that the test was valid.

The values obtained from the acute toxicity tests of the biolubricant showed that there was no mortality in the controls during 48 h, the time the test lasted. It is observed from Table 3 that from concentrations of 50, 200, 400, 600 and 800 mg mL−1, there is more than 50% mortality. In the cases of concentrations of 1000 and 100 mg mL−1, the survival rate exceeded 50% compared to the other samples.

It was expected that at the highest concentration of the biolubricant, there would be a higher percentage of mortality; however, the highest number of deaths was found at the concentration of 100 mg L−1, as can be seen in Table 4. The resistance of the earthworm to the highest concentrations could be due to them taking in the biolubricant as part of their habitat and not evading it [29].

With these data, it was established that the formulation of the lubricant by transesterification resulted in a product that does not generate toxicity at concentrations lower than 25 mg kg−1, and terrestrial fauna can have a healthy adaptability, as long as adequate concentrations are used.

Vázquez-Villegas et al. [16] indicated that growth inhibition suggests that few nutrients in the substrate were sufficient for earthworm survival and were insufficient for their growth and development.

To evaluate the mean lethal concentration (LC50), the probit analysis statistical tool was used. According to Gomez [30], probit transforms mortality expressed as a percentage into a “probability unit” that would be linearly related to a range established by its creator. With the experimental data obtained, the probit statistical analysis was performed, which delivered the estimated value of concentration for which half of the population sample did not survive.

Table 5 shows the results obtained from the LC50 of both tests that were applied to Eisenia fetida exposed to the biolubricant in order to determine how toxic the biolubricant could be when coming into contact with terrestrial fauna, as well as to observe the behavior and survival or mortality that Eisenia fetida may present.

The difference produced by the results of the experiments (filter paper test and artificial substrate test) could be due to the way in which the experimental sample came into contact with the evaluated population (Eisenia fetida). In the experiment of the filter paper test, it was in direct contact with the skin of the earthworm, and in the artificial substrate test, other means were used that avoided direct contact with the biolubricant, as it was in a homogeneous mixture with the substrate used.

On the other hand, the damage was evaluated by histological technique. Due to the anatomical samples studied with histological sections that helped to demonstrate the conditions in which the earthworm was affected, it was possible to obtain results where it was shown that chicken skin fat can be a biolubricant that is quite friendly to the environment in terms of land fauna.

In this way, the procedure was effective to evaluate that there were no internal physiological changes in Eisenia fetida at the LC50 concentration found.

5. Conclusions

The biolubricant demonstrated no inherent toxicity to Eisenia fetida. While there was observed mortality in the test, this could be attributed to external factors, like the absence of food, rather than the biolubricant itself.

The biolubricant can be used in machinery that has contact with the soil, such as agricultural machinery, since it does not present considerable damage to its fauna and therefore to its properties. Since it comes from an organic source such as chicken fat and does not represent damage or toxicity to the soil ecosystem, it is considered environmentally friendly.

Author Contributions

Conceptualization, P.T.V.-V. and M.d.C.H.-C.; formal analysis, P.T.V.-V.; funding acquisition, P.T.V.-V. and M.d.C.H.-C.; investigation, P.T.V.-V., A.L.-G., L.R.-H., M.V.-L., A.Z.-R., R.I.C.-R., R.M.-G., R.d.P.S.-R. and M.d.C.H.-C.; methodology, P.T.V.-V.; project administration, P.T.V.-V. and A.Z.-R.; resources, P.T.V.-V., M.d.C.H.-C., R.M.-G., A.L.-G. and L.R.-H.; supervision, P.T.V.-V.; visualization, P.T.V.-V., M.d.C.H.-C., A.L.-G., M.V.-L. and L.R.-H.; writing—original draft, P.T.V.-V. and M.d.C.H.-C.; writing—review and editing, A.L.-G., L.R.-H., M.V.-L., A.C.-S. and M.d.C.H.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by TECNOLOGICO NACIONAL DE MEXICO, grant project 8303.20-PD.

Data Availability Statement

Not applicable.

Acknowledgments

Special thanks to Edilvia Miguel Morales, a student from the Food Industry Engineering educational program, for carrying out her professional residency and thesis with this project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pérez, D.S.; Baizabal, F.G.; Velázquez, A.L.; Franco, R.A.; Sánchez, E.J.A.; González, L.G.; Torres, J.H. El ciclo de evolución de los lubricantes. ContactoS 2015, 97, 62–68. [Google Scholar]

- Nowak, P.; Kucharska, K.; Kaminski, M. Ecological and health effects of lubricant oils emitted into the environment. Int. J. Environ. Res. Public Health 2019, 16, 3002. [Google Scholar] [CrossRef] [PubMed]

- ACR Latinoamérica. Available online: https://www.acrlatinoamerica.com/ (accessed on 3 May 2022).

- Villafuerte-Araoz, J.C. Selection of Biolubricants According to the Function of Mechanical Components. Ph.D. Thesis, Universidad Continental, Arequipa, Peru, 2019. [Google Scholar]

- Hernández-Cruz, M.C.; Meza-Gordillo, R.; Torrestiana-Sánchez, B.; Rosales-Quintero, A.; Ventura-Canseco, L.M.C.; Castañón-González, J.H. Chicken fat and biodiesel viscosity modification with additives for the formulation of biolubricants. Fuel 2017, 198, 42–48. [Google Scholar] [CrossRef]

- Álvarez-Lomeli, N.I. Design and Production of Biolubricants in Esters from Pentaerythritol. Master’s Thesis, Universidad Autónoma de Baja California, Baja California, Mexico, 2018. [Google Scholar]

- Hernández-Cruz, M.C.; Meza-Gordillo, R.; Abud-Archila, M.; Villalobos-Maldonado, J.J.; Lagunas-Rivera, S.; Domínguez, Z. Synthesis of trimethylolpropane ester based on chicken fat as biolubricants. Rev. Mex. Ing. Química 2018, 17, 1011–1019. [Google Scholar] [CrossRef]

- SIAP. Available online: http://infosiap.siap.gob.mx/gobmx/datosAbiertos.php (accessed on 5 December 2022).

- ISO 15380:2016; Lubricants, Industrial Oils and Related Products (Class L). ISO: Geneva, Switzerland, 2016. Available online: https://www.iso.org/obp/ui/#iso:std:iso:15380:ed-3:v1:en (accessed on 16 October 2019).

- Armas, J.V.G.; Maravi, J.L.C. Biodiesel from chicken fat and its mechanical and environmental effects with an internal combustion engine. An. R. Soc. Esp. 2019, 80, 580–593. [Google Scholar]

- Shafiq, F.; Mumtaz, M.W.; Mukhtar, H.; Touqeer, T.; Raza, S.A.; Rashid, U.; Nehdi, I.A.; Choong, T.S.Y. Response Surface Methodology Approach for Optimized Biodiesel Production from Waste Chicken Fat Oil. Catalysts 2020, 10, 633. [Google Scholar] [CrossRef]

- Toala-Briones, G.; Vivas-Bautista, P.; García-Muentes, S. Physicochemical characterization of the epoxidation of biodiesel from waste chicken fat. Ing. Energ. 2022, 43, 31–39. [Google Scholar]

- Hernández-Cruz, M.C. Biotechnological Development of Biolubricants from Chicken Fat. Ph.D. Thesis, Tecnológico Nacional de México, Tuxtla Gutiérrez, Chiapas, Mexico, 2020. [Google Scholar]

- Organization for Economic Cooperation and Development (OECD). Earthworm Acute Toxicity Test; Guide to Chemical Test No. 207; OECD: Paris, France, 1984. [Google Scholar]

- Liu, W.; Zhu, L.S.; Wang, J.; Wang, J.H.; Xie, H.; Song, Y. Assessment of the genotoxicity of endosulfan in earthworm and white clover plants using the comet assay. Arch. Environ. Contam. Toxicol. 2009, 56, 742–746. [Google Scholar] [CrossRef] [PubMed]

- Vázquez-Villegas, P.T.; Meza-Gordillo, R.; Gutiérrez-Miceli, F.A.; Ruiz-Valdiviezo, V.M.; Villalobos-Maldonado, J.J.; Montes-Molina, J.A.; Fernández-Toledo, A.A.J. Determination of LC50 and EC50 of endosulfan lactone and diazinon in earthworms (Eisenia foetida). Agroproductividad 2018, 11, 105–111. [Google Scholar]

- Reddy, N.C.; Rao, J.V. Biological response of earthworm, Eisenia foetida (Savigny) to an organophosphorus pesticide, profenofos. Ecotoxicol. Environ. Saf. 2008, 71, 574–582. [Google Scholar] [CrossRef] [PubMed]

- Montalvo-Arenas, C.E. Histological Technique. Available online: https://recursoseducativos.unam.mx/ (accessed on 10 August 2019).

- Wang, Y.Y.; Wang, H.H.; Chuang, T.L.; Chen, B.H.; Lee, D.J. Biodiesel produced from catalyzed transesterification of triglycerides using ion-exchanged zeolite Beta. Energy Procedia 2014, 61, 933–936. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, Q.; Huang, D.; Zheng, X.; Shi, Y. Survival, growth, detoxifying and antioxidative responses of earthworms (Eisenia fetida) exposed to soils with industrial DDT contamination. Pestic. Biochem. Physiol. 2016, 128, 22–29. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, W.; Chen, L.; Liang, J.; Lin, K. Biological effects of decabromodiphenyl ether and Pb on earthworm (Eisenia fetida) in a soil system. Environ. Pollut. 2015, 207, 220–225. [Google Scholar] [CrossRef]

- Gupta, R.D.; Chakravorty, P.P.; Kaviraj, A. Susceptibility of epigeic earthworm Eisenia fetida to agricultural application of six insecticides. Chemosphere 2011, 84, 724–726. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, S.; Chen, L.; Wu, C.; Yu, R.; Wang, Q.; Zhao, X. Toxicity assessment of 45 pesticides to the epigeic earthworm Eisenia fetida. Chemosphere 2012, 88, 484–491. [Google Scholar] [CrossRef]

- García-Velasco, N.; Gandariasbeitia, M.; Irizar, A.; Soto, M. Uptake route and resulting toxicity of silver nanoparticles in Eisenia fetida earthworm exposed through Standard OECD Test. Ecotoxicology 2016, 25, 1543–1555. [Google Scholar] [CrossRef] [PubMed]

- Rico, A.; Sabater, C.; Castillo, M.A. Lethal and subletal effects of five pesticides used in rice farming on the earthworm Eisenia fetida. Ecotoxicol. Environ. Saf. 2016, 127, 222–229. [Google Scholar] [CrossRef] [PubMed]

- Saxena, P.N.; Gupta, S.K.; Murthy, R.C. Comparative toxicity of carbaryl, carbofuran, cypermethrin and fenvalerate in Metaphire posthuman and Eisenia fetida—A possible mechanism. Ecotoxicol. Environ. Saf. 2014, 100, 218–225. [Google Scholar] [CrossRef] [PubMed]

- Vásquez-Romero, R.; Ballesteros-Chavarro, H. Vermiculture Manual; Editorial Produmedios: Bogotá, Colombia, 2008; pp. 17–29. [Google Scholar]

- Barrios-Ziolo, L.F.; Robayo-Gómez, J.; Prieto-Cadavid, S.; Cardona-Gallo, S.A. Biorremediación de suelos contaminados con aceites usados de motor. Rev. Cintex 2015, 20, 69–96. [Google Scholar]

- Franco-Hernández, M.O.; Rodríguez-Quiroz, G. Uptake of heavy metals by the earthworm Eisenia fetida exposed to mine tailings at Mocorio, Sinaloa, México. In Proceedings of the 5 Congreso Interamericano de Residuos Sólidos, Lima, Peru, 22–24 May 2013. [Google Scholar]

- Gómez-Hernández, A.P. Evaluation of the Toxicity of Soils by Means of a Bioassay with the Earthworm Eisenia fetida. Master’s Thesis, Universidad Nacional de Colombia, Bogotá, Colombia, 2014. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).