Managing Engineering Change within the Paradigm of Product Lifecycle Management

Abstract

1. Introduction

2. Literature Review

2.1. Historical Development of PLM

2.2. Benefits and Impact of PLM

2.3. PLM’s Role in Change Management

2.4. General Overview of Change Management

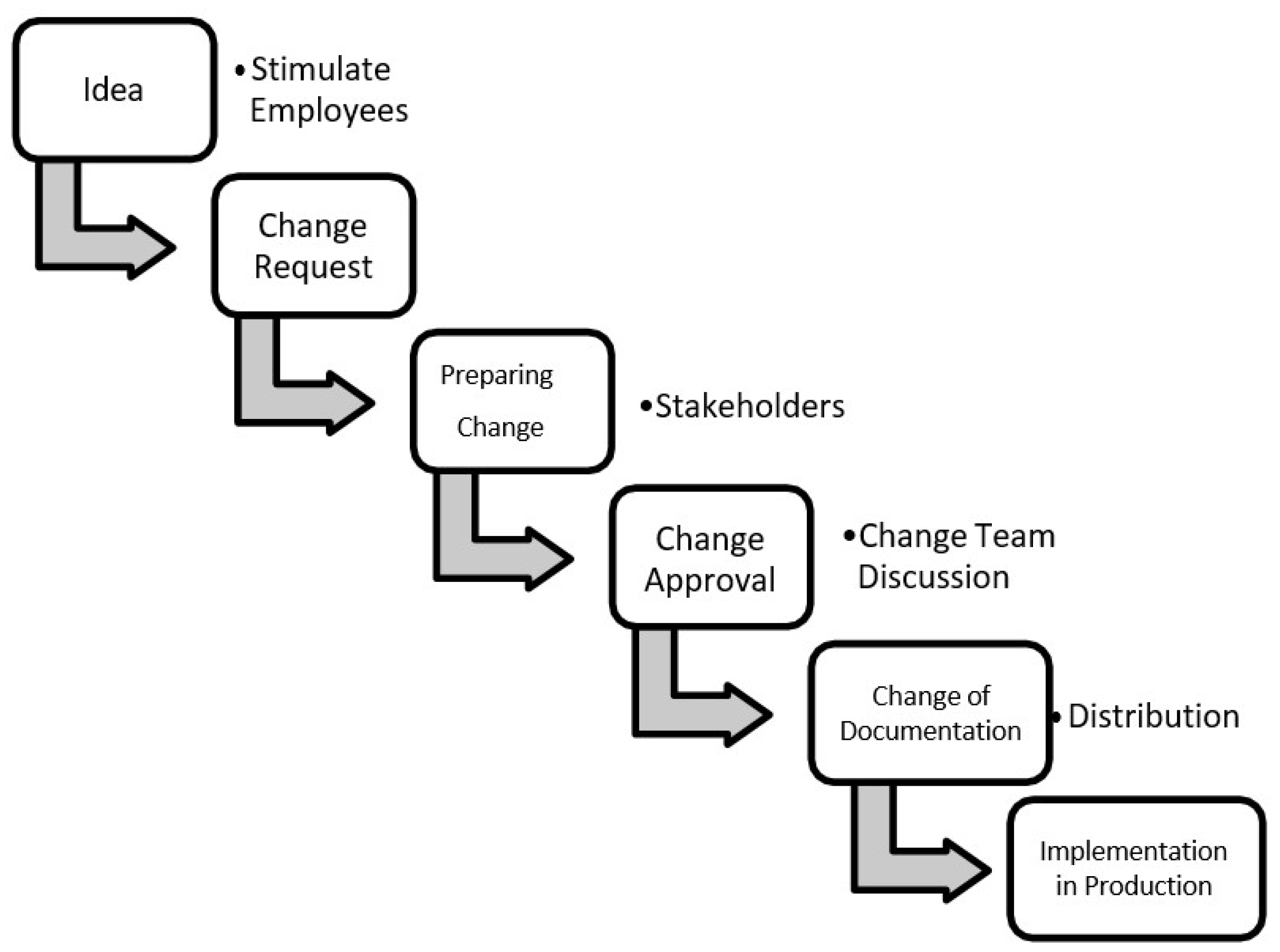

2.5. Change Management Process

2.6. ECM Tools and Techniques

- The Model-Based Definition (MBD) technique is utilized for creation of 3D CAD models during the design phase of the products. An MBD contains Product Manufacturing Information (PMI) and once an MBD is created it is utilized in all the domains of the organization in the downstream, e.g., manufacturing, quality control and assurance, supply chain, marketing, finance, etc.

- The digital twin technique is a modern way of integrating real-time data into a digital model of the product, continuously updating the virtual model to make effective communication, decision making, and change management during the complete lifecycle of the product.

- Various other algorithms and software-based solutions have been developed to seamlessly integrate and manage change throughout the lifecycle of the product. The solutions identified in research are both semantic and quantitative/annotated. Service-Oriented Architecture (SOA), Process-Oriented Semantic Knowledge Management (POSKM) towards integration during the lifecycle, unified feature modeling, and unified modeling languages utilized for CMPL are some of the techniques reviewed by the authors.

2.7. Model-Based Definition (MBD)

2.7.1. History

2.7.2. Application

2.8. Digital Twin (DT) History and Introduction

2.8.1. Applications

2.8.2. Future Trends

2.9. Unified Feature Modeling (UFM)

2.10. Unified Modeling Language (UML)

2.11. Process-Oriented Semantic Knowledge Management (POSKM)

2.12. Service-Oriented Architecture (SOA)

3. Methodology

4. Results

5. Discussion

- Extent of Integration (EoI);

- Standardization (S);

- Versatility of Application (VoA);

- Support of Existing Systems (SES);

- Extent of PLM Support (EPS).

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ameri, F.; Dutta, D. Product Lifecycle Management: Closing the Knowledge Loops. Comput. Aided Des. Appl. 2013, 2, 577–590. [Google Scholar] [CrossRef]

- Singh, S.; Misra, S.C.; Chan, F.T.S. Establishment of critical success factors for implementation of product lifecycle management systems. Int. J. Prod. Res. 2020, 58, 997–1016. [Google Scholar] [CrossRef]

- Singh, S.; Misra, S. Identification of barriers to PLM institutionalization in large manufacturing organizations: A case study. Bus. Process Manag. J. 2018, 25, 1335–1356. [Google Scholar] [CrossRef]

- Srinivasan, V. An integration framework for product lifecycle management. Comput. Aided Des. 2011, 43, 464–478. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Nee, A.Y.C. Chapter 3—Five-Dimension Digital Twin Modeling and Its Key Technologies. In Digital Twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A.Y.C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 63–81. [Google Scholar]

- Felic, A.; König-Ries, B.; Klein, M. Process-oriented Semantic Knowledge Management in Product Lifecycle Management. Procedia CIRP 2014, 25, 361–368. [Google Scholar] [CrossRef][Green Version]

- Thimm, G.; Lee, S.G.; Ma, Y. Towards unified modeling of product life-cycles. Comput. Ind. 2006, 57, 331–341. [Google Scholar] [CrossRef]

- Pfouga, A.; Stjepandić, J. Leveraging 3D geometric knowledge in the product lifecycle based on industrial standards. J. Comput. Des. Eng. 2018, 5, 54–67. [Google Scholar] [CrossRef]

- Hallmann, M.; Goetz, S.; Schleich, B. Mapping of GD&T information and PMI between 3D product models in the STEP and STL format. Comput. Aided Des. 2019, 115, 293–306. [Google Scholar]

- Terzi, S.; Bouras, A.; Dutta, D.; Garetti, M.; Kiritsis, D. Product lifecycle management—From its history to its new role. Int. J. Prod. Lifecycle Manag. 2010, 4, 360. [Google Scholar] [CrossRef]

- Lee, S.; Ma, Y.-S.; Thimm, G.; Verstraeten, J. Product lifecycle management in aviation maintenance, repair and overhaul. Comput. Ind. 2008, 59, 296–303. [Google Scholar] [CrossRef]

- Paschek, D.; Ivascu, L.; Draghici, A. Knowledge Management—The Foundation for a Successful Business Process Management. Procedia Soc. Behav. Sci. 2018, 238, 182–191. [Google Scholar] [CrossRef]

- Stark, J. Product Lifecycle Management: 21st Century Paradigm for Product Realisation; Springer: Cham, Switzerland, 2011; p. 584. [Google Scholar]

- Saaksvuori, A.; Anselmi, I. Product Lifecycle Management, 3rd ed.; Springer: Cham, Switzerland, 2008; p. 257. [Google Scholar] [CrossRef]

- Tavcar, J.; Duhovnik, J. Engineering Change Management in Distruted Environment with PDM/PLM Support, Manufacturing the Future. 2006. Available online: http://www.intechopen.com/books/manufacturing_the_future/engineering_change_management_in_distruted_environment_with_pdm_plm_support (accessed on 5 August 2022).

- Jarratt, T.A.W.; Eckert, C.M.; Caldwell, N.H.M.; Clarkson, P.J. Engineering change: An overview and perspective on the literature. Res. Eng. Des. 2011, 22, 103–124. [Google Scholar] [CrossRef]

- Quintana, V.; Rivest, L.; Pellerin, R.; Venne, F.; Kheddouci, F. Will Model-based Definition replace engineering drawings throughout the product lifecycle? A global perspective from aerospace industry. Comput. Ind. 2010, 61, 497–508. [Google Scholar] [CrossRef]

- Schuh, G.; Gartzen, T.; Soucy-Bouchard, S.; Basse, F. Enabling Agility in Product Development through an AdaptiveEngineering Change Management. Procedia CIRP 2017, 63, 342–347. [Google Scholar] [CrossRef]

- Cantamessa, M.; Montagna, F.; Neirotti, P. Understanding the organizational impact of PLM systems: Evidence from an aerospace company. Int. J. Oper. Prod. Manag. 2012, 32, 191–215. [Google Scholar] [CrossRef]

- ASME. Digital Product Definition Data Practices Y14.41; ASME: New York, USA, 2019. [Google Scholar]

- Lipman, R.; Lubell, J. Conformance checking of PMI representation in CAD model STEP data exchange files. Comput. Aided Des. 2015, 66, 14–23. [Google Scholar] [CrossRef]

- Quintana, V.; Rivest, L.; Pellerin, R.; Kheddouci, F. Re-engineering the Engineering Change Management process for a drawing-less environment. Comput. Ind. 2012, 63, 79–90. [Google Scholar] [CrossRef]

- Camba, J.D.; Contero, M.; Company, P.; Pérez-López, D. On the integration of model-based feature information in Product Lifecycle Management systems. Int. J. Inf. Manag. 2017, 37, 611–621. [Google Scholar] [CrossRef]

- Tchana, Y.; Ducellier, G.; Remy, S. Designing a unique Digital Twin for linear infrastructures lifecycle management. Procedia CIRP 2019, 84, 545–549. [Google Scholar] [CrossRef]

- Srinivas, M.M. Digital Twin for Product Lifecycle Management (PLM) (Part-1): Bridging the gap through Twinning. 2017. Available online: https://atos.net/en/blog/digital-twin-product-lifecycle-management-plm-part-1-bridging-gap-twinning (accessed on 3 April 2022).

- Marr, B. 7 Amazing Examples of Digital Twin Technology in Practice. 2019. Available online: https://bernardmarr.com/default.asp?contentID=1870 (accessed on 1 February 2022).

- Zhu, W.; Bricogne, M.; Durupt, A.; Remy, S.; Li, B.; Eynard, B. Implementations of Model Based Definition and Product Lifecycle Management Technologies: A Case Study in Chinese Aeronautical Industry. IFAC-Pap. 2016, 49, 485–490. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, G.; Thimm, G. Change propagation algorithm in a unified feature modeling scheme. Comput. Ind. 2008, 59, 110–118. [Google Scholar] [CrossRef]

- Marshall, C. Enterprise Modeling with UML: Designing Successful Software through Business Analysis; Addison-Wesley Object Technology Series; Addison Wesley: Boston, MA, USA, 1999; p. 288. [Google Scholar]

- Hock-Doepgen, M.; Clauss, T.; Kraus, S.; Cheng, C.F. Knowledge management capabilities and organizational risk-taking for business model innovation in SMEs. J. Bus. Res. 2020, 130, 683–697. [Google Scholar] [CrossRef]

- Niknejad, N.; Ismail, W.; Ghani, I.; Nazari, B.; Bahari, M.; Hussin, A.R.B.C. Understanding Service-Oriented Architecture (SOA): A systematic literature review and directions for further investigation. Inf. Syst. 2020, 91, 101491. [Google Scholar] [CrossRef]

- Burgess, K.; Singh, P.J.; Koroglu, R. Supply Chain Management: A Structured Literature Review and Implications for Future Research. Int. J. Oper. Prod. Manag. 2006, 26, 703–729. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A. Lean and Green—A Systematic Review of the State-of-the-Art Literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef]

- Alcaide-Munoz, C.; Gutierrez-Gutierrez, L. Six Sigma and Organisational Ambidexterity: A Systematic Review and Conceptual Framework. Int. J. Lean Six Sigma 2017, 8, 436–456. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Yang, E.C.L.; Khoo-Lattimore, C.; Arcodia, C. A Systematic Literature Review of Risk and Gender Research in Tourism. Tour. Manag. 2017, 58, 89–100. [Google Scholar] [CrossRef]

- Petticrew, M. Systematic Reviews from Astronomy to Zoology: Myths and Misconceptions. BMJ 2001, 322, 98–101. [Google Scholar] [CrossRef] [PubMed]

- De Lima, F.R.P.; Da Silva, A.L.; Godinho Filho, M.; Dias, E.M. Systematic Review: Resilience Enablers to Combat Counterfeit Medicines. Supply Chain. Manag. Int. J. 2018, 12, 117–135. [Google Scholar] [CrossRef]

- Parameswaran, U.D.; Ozawa-Kirk, J.L.; Latendresse, G. To live (code) or to not: A new method for coding in qualitative research. Qual. Soc. Work. 2020, 19, 630–644. [Google Scholar] [CrossRef]

- Li, L.; Zheng, Y.; Yang, M.; Leng, J.; Cheng, Z.; Xie, Y.; Jiang, P.; Ma, Y. A survey of feature modeling methods: Historical evolution and new development. Robot. Comput. Integr. Manuf. 2020, 61, 101851. [Google Scholar] [CrossRef]

- Zhang, Y.; Shi, L.; Ren, S.; Zhang, D. A model-driven dynamic synchronization mechanism of lifecycle business activity for complicated and customized products. Procedia CIRP 2019, 83, 748–752. [Google Scholar] [CrossRef]

- Fechter, M.; Neb, A. From 3D product data to hybrid assembly workplace generation using the AutomationML exchange file format. Procedia CIRP 2019, 81, 57–62. [Google Scholar] [CrossRef]

- Xin, Y.; Ojanen, V.; Huiskonen, J. Dealing with knowledge management practices in different product lifecycle phases within product-service systems. Procedia CIRP 2019, 83, 111–117. [Google Scholar] [CrossRef]

- Kattner, N.; Mehlstaeubl, J.; Becerril, L.; Lindemann, U. Data Analysis in Engineering Change Management—Improving Collaboration by Assessing Organizational Dependencies Based on Past Engineering Change Information. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management, Bangkok, Thailand, 16–19 December 2018; pp. 617–621. [Google Scholar] [CrossRef]

- Conlon, J. From PLM 1.0 to PLM 2.0: The evolving role of product lifecycle management (PLM) in the textile and apparel industries. J. Fash. Mark. Manag. Int. J. 2020, 24, 533–553. [Google Scholar] [CrossRef]

- Shilovitsky, O. “PLM Waves—The History of the Future,” Blog Beyond PLM. 2017. Available online: https://beyondplm.com/2017/02/04/plmwaves-history (accessed on 20 August 2022).

| Sr. No | Author/Year | Application |

|---|---|---|

| 1. | (Quintana, Rivest et al., 2012) [22] | ECM |

| 2. | (ASME, Contero et al., 2017) [20] | PLM |

| 3. | (Pfouga and Stjepandić 2018) [8] | PLM |

| 4. | (Hallmann, Goetz et al., 2019) [9] | GD&T and PMI |

| Establishing the Research Objectives |

|

|

| Defining the Conceptual Boundaries |

| PLM and CM |

|

| Setting the Inclusion Criteria |

| Agree search boundaries |

| Utilize SCOPUS and Web of Science academic databases |

| Agree keywords for search and period covered |

| Search Words: |

| “PLM” “CM” “PLM” AND “CM” |

| Search period: 2002–2022 |

|

| Applying the Exclusion Criteria |

| Remove gray literature (conference papers, books, white papers, etc.) |

| Remove non-English language articles |

| Remove duplicates |

| Remove articles not related to the search area or search period |

|

| Validation of Search Results |

| Cross comparison of articles among researchers |

| Revisiting of articles to confirm acceptance or exclusion |

| Ensure interrater reliability |

| Authors | Description | Technique/ Methodology Used | Merit | Demerit | Proposed Research Areas |

|---|---|---|---|---|---|

| Tao, Fei et al., 2019 [5] | The goal of the authors in this paper was to present a five-dimensional DT concept compared to the three-dimensional concepts. Inclusion of services, DT data, and connection enables greater versatility in managing engineering change constantly | Digital twin | Effective inclusion and usage of real-time change data in a virtual environment | Maintenance of virtual and physical entities at the same time | Process |

| Tchana, Yvan Ducellier et al., 2019 [24] | The objective of this paper is to implement DT concept in construction industry. Previously, Building Information Modeling (BIM) was used for the same purpose. This implementation is a step forward in homogenizing product lifecycle concepts in different domains of engineering | Application of digital twin concept in construction industry | Helps establish standardization of PLM in various domains of engineering | The existing software tools in construction industry do not support DT and PLM environments | The integration of this framework with construction industry’s current approach towards PLM needs to be established |

| Pfouga, Alain et al., 2018 [8] | This paper features the use of a 3D PDF file throughout the product lifecycle. Engineering changes, version control, digital collaboration, and semantic information are directly available on the file for manipulation and future use | MBD, PMI for data exchange, 3D PDF PRC file format | Strengthens the standardization of PRC file format as a universal format for utilization | Incorporation of 3D PDF in PLM software is key in maximizing benefits of PRC formats | Implementation of 3D PDF format in various industries |

| Camba et al., 2018 [23] | The goal of the authors is to present an approach to integrate 3D annotations in the digital thread of the product lifecycle. It proposes software element that integrates this information in a PLM server. The approach overcomes existing barriers in collaborative product development. This leads to concurrent design with increased flexibilities of engineering | Unified Modeling Language based on XML integration | The framework presented is comprehensive and utilizes standard formats of ASME Y14.41 | The effectiveness of developed software element needs industry testing | Validation of the proposed system in production environment |

| Schuh, Günther et al., 2017 [18] | The paper elucidates a step by step product development process incorporating different phases of agile manufacturing. The process is based on adaptive ECM in three layers. Adaptive communication, receptive engineering change process, and consolidated data structures | Application of adaptive ECM in agile manufacturing throughout the PL | The technique established in the paper has been effectively employed and tested in promising research in the field of agile manufacturing | The usefulness of this approach in areas related specifically to PLM needs to be evident. However, it is not | Relationship with existing models needs to be established in this area |

| Zhu, Wenhua Bricogne et al., 2016 [27] | The paper is an application of MBD, PLM, and related CAx technologies in a Chinese aeronautical company | MBD, PLM applied in aeronautical industry in China | Effective establishment of importance of MBD, PLM, and CAx in industry | Lacks comparative analysis of results before and after implementation on of MBD, PLM, and CAx | The outcomes of implementation have not been analyzed and established through empirical evidence |

| Felic, Artur König-Ries et al., 2014 [6] | The paper tries to support decision making, change management in the paradigm of semantic knowledge generated throughout the lifecycle of the product. The shared knowledge base generated and utilized during PLM lays the foundation of qualitative aspect of PLM and ECM | Process-Oriented Semantic Knowledge Management (POSKM) | Establishes basic framework for semantic knowledge management including ontologies | A relationship between quantitative approach to PLM and change management is missing in this paper | OSMOSE Project could be utilized to handle knowledge management and transfer between various platforms of real, virtual, and digital. This application needs exploration |

| Quintana, Virgilio Rivest et al., 2012 [22] | The purpose of this paper is to outline an engineering change process without a 2D drawing. This is an attempt to digitize the ECM process specifically. The technique is based on MBD datasets | ECM through MBD applied to two aviation industries | Specifically outlines the digital version of ECM process via MBD dataset | Lacks empirical evidence on integration with PLM environment | Simulation of integration with PLM environment needs to be undertaken to provide evidence of MBD-driven ECM |

| Srinivasan, Vijay 2011 [4] | The authors of this paper have highlighted different aspects of information exchange in detail. They have elaborated the file formats used for data exchange, languages developed for managing product data during its lifecycle, and finally they have developed a framework based on service-oriented architecture. SOA integrates various open standards in layers that helps interoperability of product data during the complete lifecycle of the product. This offers greater flexibility in change management and related management tasks | Describes the processes of PDM, STEP, and Service-Oriented Architecture (SOA) in PLM | The authors have exhausted the subject matter in detail and have compiled many of the new developments in SOA regimes | The effectiveness of every layer of SOA is not empirically evident in the paper. This needs to be addressed | OASIS PLCS PLM Web Services specification, ISA-95, OAGi, OMG have been introduced in the paper. Their current developments and use over time need to be assessed |

| Ma, Chen and Thimm, 2008 [28] | The aim of the paper is to introduce a novel method of modeling associative engineering relations by using unified feature modeling scheme for managing change propagation by utilizing an algorithm that ensures information consistency over the whole product lifecycle | JTMS-based dependency network, change propagation, unified feature modeling | The authors have devised the terminology syntax for use in JTMS | The efficacy of handling business processes and semantic engineering change decisions is not considered by the authors | The method has been extensively developed but has not been tested with reference to standard requirements of the same |

| Thimm et al., 2006 [7] | The authors have suggested the possible potential of modeling a product throughout its lifecycle based on Unified Modeling Language (UML). Constraints are utilized to better manage change during the complete lifecycle | Application of Unified Modeling Language for PLM and PLUML | The authors have effectively proposed UML-based PLM change management paradigm in which there is information consistency | The authors do not highlight the integration of existing PDM packages, and/or file formats with the proposed framework | Tools to translate PLUML models into representations such as BOM or Gantt charts need to be developed. Knowledge must be embedded in the product model and managed |

| Li, Lei Zheng, Y. 2020 [40] | The authors have studied and reviewed the feature modeling methods with respect to the developments of CAE, CAPP, and CAM within the paradigm of PLM | CAM, CAE, CAPP, IoT, Big Data, SCPS | The authors have described the progress from traditional techniques to modern ones and their review highlights demerits of each | The work is overarching and does not converge to specific key points | Implementation of ECM techniques vis-à-vis the modern technology trends needs further elaboration for each new technology/technique |

| Zhang, Yingfeng 2019 [41] | The paper outlines synchronization problems in engineering change management. The synchronization problem is addressed by using the model-driven approach | Model-Based Definition (MBD) | The paper highlights the use of intelligent modeling technology that connects all functions of the industry with sensors | The paper has described only a single approach. However, correlation with other techniques has not been made | Design of intelligent decision algorithms based on sensing data of manufacturing resources and products |

| Fechter, Manuel 2019 [42] | The paper has utilized the automation ML exchange format in detail to elaborate its use in different aspects of the industry | Automation ML exchange format | Innovative method of assembly connections using a systematic procedure based on CAD data that is further utilized to design workplaces | The approach was implemented for three lot sizes, demonstration of large-scale lot sizes is yet to be conducted | One-click assembly setup and layout generation, directly from CAD model and PLM data to implement a fully digital assembly workplace, is proposed |

| Xin, Yan 2019 [43] | The authors have studied knowledge management through different stages of PLM including beginning of life, middle of life, and end of life. They have identified knowledge gaps between stakeholders and have addressed the concerns of different management perspectives | Interviews, literature survey | The paper gives a brief overview of problems faced by management representatives in knowledge management | Research in this area carried out previously has not been cited by the authors in detail and how the trends have evolved overtime was also not studied | The research needs to be conducted on big industries, as the companies reviewed were of small scale |

| Kattner, N. 2019 [44] | The authors have applied novel techniques to assess the communication and collaboration gaps between different functions of the organization. The result of this research gives an understanding of the complexities involved in engineering change throughout the organization’s functions | Structural complexity management, graph-based analysis | The dependencies of different stakeholders have been studied in detail based on structural complexity management method to predict the future trends and decisions within the organization | The utilization of analyzed data was not strengthened by elaborating the impacts | Critical collaboration paths can be identified based on the methodology utilized in this paper |

| EoI | S | VoA | SES | EPS |

|---|---|---|---|---|

MBD  |  |  |  |  |

DT  |  |  |  |  |

UFM  |  |  |  |  |

UML  |  |  |  |  |

POSKM  |  |  |  |  |

SOA  |  |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Habib, H.; Menhas, R.; McDermott, O. Managing Engineering Change within the Paradigm of Product Lifecycle Management. Processes 2022, 10, 1770. https://doi.org/10.3390/pr10091770

Habib H, Menhas R, McDermott O. Managing Engineering Change within the Paradigm of Product Lifecycle Management. Processes. 2022; 10(9):1770. https://doi.org/10.3390/pr10091770

Chicago/Turabian StyleHabib, Hassan, Rashid Menhas, and Olivia McDermott. 2022. "Managing Engineering Change within the Paradigm of Product Lifecycle Management" Processes 10, no. 9: 1770. https://doi.org/10.3390/pr10091770

APA StyleHabib, H., Menhas, R., & McDermott, O. (2022). Managing Engineering Change within the Paradigm of Product Lifecycle Management. Processes, 10(9), 1770. https://doi.org/10.3390/pr10091770