Abstract

Induction motors are popularly used in various applications because of the proposed modest construction, substantiated process, and limited size of specific power. The traditional AC traction drives are experimentally analyzed. There is a high circulating current due to the high Common-Mode Voltage (CMV). The high Circulating Bearing Current (CBC) is a major problem in conventional two-level voltage source inverter fed parallel-connected sensor-based induction motors for traction applications. A sensorless method is well known for shrinking costs and enhancing the reliability of an induction motor drive. The modified artificial neural network-based model reference adaptive system is designed to realize speed estimation methods for the sensorless drive. Four dissimilar multilevel inverter network topologies are being implemented to reduce CBC in the proposed sensorless traction motor drives. The multilevel inverter types are T-bridge, Neutral Point Clamped Inverter (NPC), cascaded H-bridge, and modified reduced switch topologies. The four methods are compared, and the best method has been identified in terms of 80% less CMV compared to the conventional one. The modified cascaded H-bridge inverter reduces the CBC of the proposed artificial neural network-based parallel connected induction motor; it is 50% compared to the conventional method. The CBC of the modified method is analyzed and associated with the traditional method. Finally, the parallel-connected induction motor traction drive hardware is implemented, and the performance is analyzed.

Keywords:

induction motor; artificial neural network; neutral point-clamped inverter; circulating bearing currents; common-mode voltage; cascaded H-bridge inverter MSC:

68T07-18B20-13P25

1. Introduction

An induction motor comprises numerous advantages, mainly with a clear structure, substantiated operation, and the limited capacity of definite power. In conventional electric traction, sensor-based parallel connected induction motors require an inverter set up for every motor. The standard traction drives include a boost converter, one voltage source inverter for one induction motor, and combined rectifiers that have faded eventually. To achieve the energy-efficient traction drive, the complexity and cost of the conventional method are reduced by the proposed setup of single inverter fed polyphase induction motors in parallel. The polyphase has several advantages compared to three-phase machines. Initially, scalar control methods were used to control the induction motors, but the technique was complicated because of computations. Speed of the motor was sensed using tacho-generators, and the Lyapunov formula verified the speed deviation of the feedback system. The system requires better control performance, precision, and quicker torque response [1].

For designing the controllers for the machine and detecting faults in the machine, the accurate modeling of the induction motor is necessary. Any parameter of the system such as speed, torque, or flux depends on the design of a controller, which is based on the transfer function. The different types of mathematical modeling are the first method, system identification methods, finite element method, equivalent magnetic circuit approach, ordinary differential equation, linear/nonlinear differential equation, a model with lumped parameter and distorted parameter, and static and dynamic modeling. The mathematical model described by ordinary differential equations is used in the theory of electrical machines. They describe the relationship between electromagnetic torque and main electrical and mechanical quantities. To describe the magnetic field, temperature distribution, and another quantity of electrical machines, partial differential equations can be used as they describe these more completely. However, the drawback while using partial differential equations is that they are considerably complicated for investigation purposes [2].

For both industries and academics, induction motors’ simulation and dynamic modeling carry significant importance. Their value increases more because of the widespread presence of induction motor drives in dissimilar construction settings and for sensor-less control induction motors. Therefore, this paper presents a detailed discussion about the dynamic modeling of an asynchronous motor [3].

Generally, an AC motor is driven by a DC to AC converter equipped with a speed sensor, but this speed sensor may tend to lower the system’s reliability and increase the investment cost. Moreover, its implementation is difficult. To conquer this difficulty, many researchers focus on sensorless induction motor drives. Under feedback conditions, various speeds and production were contrasted under internal parameter variation and external disturbances. It was reached to the conclusion that the staging of model reference Adaptive System (MRAS) has the upper hand over variant speed estimators [4].

The MRAS model for the speed approximation of AC motor drive. Many of these choices provide high accuracy and also the alteration of parameters is consequently vigorous. Two-layer artificial neural networks (ANN) could be with the controller in the previous MRAS techniques, yet the input design has always been required to determine the motor flux manipulated as a speed adjustment signal [5].

The ability to detect the faults in the motor is termed induction motor monitoring. During its period of operation, an induction motor faces problems such as over-voltage, above-rated current, high temperature, high rated speed, and high circulating bearing current. Keeping the perspective of enhanced system design, sanctuary, and fault unbiased control, it becomes extremely important to develop the awareness of an induction motor drive system under high circulating current conditions. Electrical researchers’ intrinsic and challenging topic was the behavioral study of induction motor during parameter variation conditions [6].

The circulating bearing current is a major problem in the inverter fed parallel-connected traction motors. The high CMV in a two-level DC to AC converter led to high changes in voltage () and generated high-frequency CBC. The ratio of bearing and CMC is analyzed for the various ratings of machines [7,8]. The conclusion of voltage in common mode makes the machine ready to remove the bearing current. This work introduces a creative answer to reduce the bearing currents by supporting a fourth limb circuitry in the inverter, and procedures are simulated using MATLAB [9].

A numerical prototype is produced for a summed-up drive framework, including common mode components; it is utilized to investigate the problems of soft switched resonant systems. The control techniques effectively make up for sinking the common-mode voltage instabilities [10].

In this work, a scientific prototype for parallel frameworks in the drive is created to incorporate Discrepancy and common mode characteristics. The prototype has been checked by PC re-enactment as a real apparatus for creating answers for the current regulator in common mode and relief in parallel drive frameworks. This method is reasonable for foreseeing the odd things irregular to converters. A parallel drive framework was planned and worked out to achieve the challenging input and output voltage THD. The output voltage THD prerequisite was uniquely achieved using a regulator system to increase the highest yield voltage usage to reduce the common-mode voltage [11,12].

Due to their high powerful exhibitions, variable speed drives are developing significance in modern applications. PWM inverters are essentially in charge of VSDs dynamic activity; however, they increase bearing flows [13]. The parasitic capacitance existing in the mechanism is not an issue at lesser frequencies, yet at developed carrier frequencies, it gives indicting pathways and fabricates shaft voltages [14]. This paper displays a functioning answer for the typical 3 phase CMV shaped by a characteristic 3 phase inverter. It is demonstrated that the expansion of a fourth limb to the orientation of a three-stage inverter reduces the CMV to the ground made by a variation of the DC to AC converter [15].

A high-performance induction motor drive with PWM techniques for lessening CMV in the direct torque control method is discussed. Because the projected technique did not use sector identification and angle data, it reduced the quality which is a concern in typical strategies. Active voltage vectors are adapted to the output voltage to cut back CMV within the projected technique. Simulation studies are administrated with the hardware setup [16].

The numerous revisions for minimizing the CMV of induction motor drive are considered. These interpretations focused on the look of choke in common mode and numerous kinds of dynamic filters. Since these strategies need further prototype and have disadvantages of growth in electrical converter mass and capacity that are ineluctable. Direct force management is arising technique for dominant the PWM induction motor drives compared to the vector-controlled induction motor [17].

Almost all the researchers adopted uniquely one organization to estimate the transient behavior of the machine. The d-q axis-based modeling is projected to analyze the temporary representation of induction motor in different reference frames: stationary organization, rotor organization, and synchronously rotating organization. The common-mode current reduction of induction motor drive using PWM techniques is associated with tentative results [18,19].

The system needs improved control performance and precision. These were tough demands because of the complex calculations involved. Taco-generators or encoders are used as sensors to calculate the motor’s speed. This led to an increase in overall expenses. Nowadays, motor drives do not have sensors for calculating speed due to improvements and modifications. The proposed method deals with the problems that took place in the ripple force LHSM drive [20].

The modification took place in the electric traction for rail and road vehicles. The discussion focuses on the increase in the modularity of new traction inverters in all sizes and the introduction of new hybrid vehicles which use advanced power electronics. In vector control, connecting orientation in the steady and transient states can be obtained by controlling the instantaneous positions of voltage, current, and flux space control variables, and torque can be obtained by coordinating transformations to new field coordinates [21]. The staging of MRAS has the upper hand over the variant speed estimator, but the fact that MRAS demands a precise model of the drive system and speed difference between two motors added to its disadvantage. If the speed differences between two motors tend to be large, the system cannot achieve complete stability. Therefore, a new sensorless device was proposed based on an adaptive observer and a modified decoupling-controlled technology. However, this technology was not much feasible as the speed estimation was found to be unstable in the regenerative region. This paper focuses on analyzing parameters such as speed and flux evaluations of an asynchronous motor without a sensor using reduced-order observers [22]. All gain selections which provide stability are found. In addition to the above, this paper also describes some freshly identified properties of reduced-order observers. For a dual induction motor in parallel, the authors work on a method called vector control. This method requires high-speed digital processors and is based on averages and differences of system parameters.

It concluded that the system remained stable for only unequal load conditions and was unable to gain stability for heavily loaded conditions. The SVPWM based constant voltage by frequency closed-loop method without sensor is used to analyze the performance of the high-power asynchronous motor. A dc to ac converter with a DC link used for driving induction motor has been proposed. The SVPWM technique helps to reduce the losses and current values of secondary switches. It is important to decrease the losses and current value of secondary switch for commutation circuit as it is active for a considerate period [23].

The proposed work uses four dissimilar Multilevel Inverter (MLI) topologies for ANN-based sensorless induction motor drive x to reduce the CBC. The modified, reduced switch topology is simulated and compared with the NPC topology, T-bridge, and H-bridge topology. The modified H-bridge DC to AC converter requires a lesser number of mechanisms at apiece level, and hence, the expense switching loss of the inverters are less also reduced common-mode voltage with fewer harmonics than the conventional inverters. Multilevel inverter overcomes the high switching loss and harmonics to a required level which is apt for medium to large voltage and power applications.

Section 2 points out the five-phase inverter’s modeling and analysis in this paper. The multilevel inverter topologies are discussed in Section 4. Section 5 describes the simulation results of the modified method. Section 6 describes the hardware implementations of inverter fed two induction motors in parallel for traction applications. Section 7 concludes the results and analysis of induction motor drive.

2. Modelling and Analysis of Five-Phase Inverter

A five-phase voltage source inverter has 22 switching states in addition to the ten states described already. The quantity of switching is dependent on the number of output phases. Multi-phase AC motor drives have higher compensation compared to conventional AC motor drives. As a result, they are included in numerous applications than three-phase ac motor drives. Adjustable speed drives have voltage source inverters for their input supply; it is crucial to properly model the voltage source inverter to devise an appropriate control algorithm.

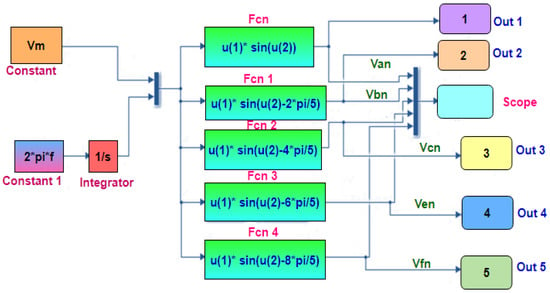

The simulation of five phases as illustrated in Figure 1 and switching states of the five-phase inverter are depicted in Table 1 and Table 2. The voltage equation is represented by

Figure 1.

Modeling of five-phase inverter.

Table 1.

Switching states of five-phase inverter for phase voltage.

Table 2.

Switching states of five-phase inverter for line voltage.

Adding (1) + (2) + (3) + (4) + (5),

The voltages across the load are represented by the Equations (9)–(13):

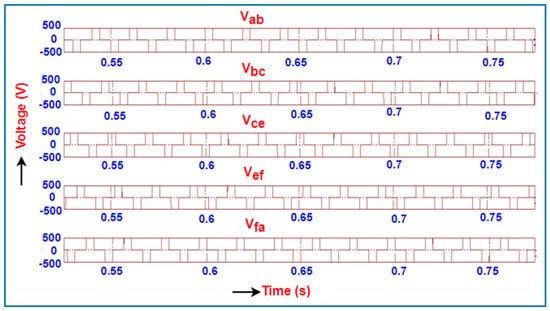

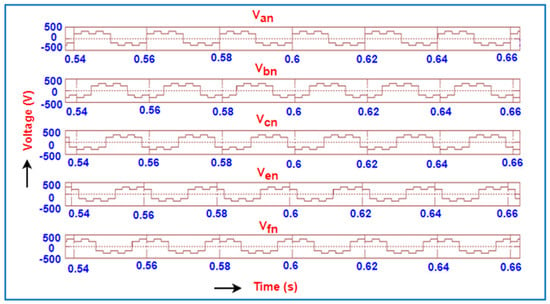

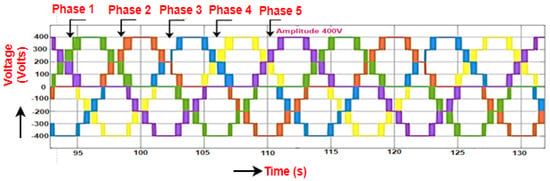

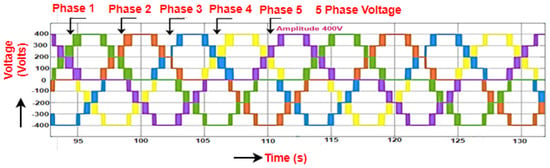

The productivity voltage of a five-phase DC to AC converter is produced by modeling inverter-based upon 72-degree phase displacement. The line voltage is depicted for all the five phases of the inverter, starts from zero, and has a maximum value of 500 V to a minimum value of −500 V as illustrated in Figure 2. The phase voltages for all the five phases of the inverter starting from zero and having a maximum value of 290 V to a minimum value of −290 V are illustrated in Figure 3.

Figure 2.

Five phase-inverter—line voltage.

Figure 3.

Five-phase inverter—phase voltage.

3. Artificial Neural Network Controlled Proposed Model Reference Adaptive System Technique

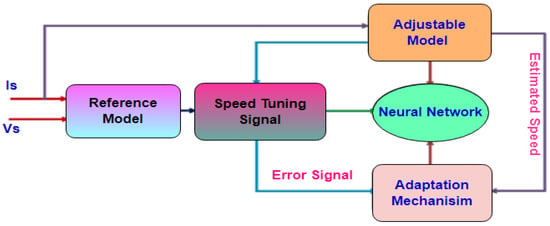

It was concluded that the staging of MRAS has the upper hand over different speed estimators. However, the attribute that MRAS demand a precise drive system model and large speed difference between two motors added to its disadvantage. A new sensorless device was proposed based on an adaptive observer and a modified decoupling-controlled technology. This technology was not much feasible as the speed estimation was found to be unstable in the regenerative region; to rectify the above problem; the proposed research concentrates on the neural network-based model reference adaptive system and hyper plane-based Luenberger observer and EKF model.

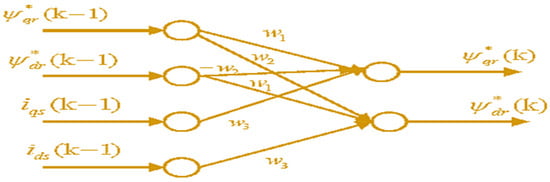

An input and output model is present for the MRAS depending on the strategy depicted in the foregoing section. However, if a neural network changes the statistical approach, a greater exactness and robustness can be obtained, as demonstrated in Figure 4. The separate PI controller can also be dropped out in this way since this can be interspersed into the neural network-based adaptive device. An artificial neural network (ANN) on a fuzzy neural network is one of the frames of the neural network-based model.

Figure 4.

Proposed ANN-based model reference adaptive system technique.

There is a probability of using divergent types of speed adjustable signals. Some of these selections offer high precision and are correspondingly vigorous to parameter modification. The adjustable model and mechanism of adaptive with a controller in the previous methods of MRAS can be exchanged by two-layer ANN. The proposed MRAS techniques are very delicate to parameter deviations and low-speed regions. The modified artificial neural network model is depicted in Figure 5. The estimated flux of the reference model is compared with the ANN-based adaptive model. The error is processed through the adaptation mechanism until the error becomes zero.

Figure 5.

Neural network-based adaptive model.

The following equations give the neural network-based adaptive model equations

where W1 = , W2 = , W3 = .

The error signal is given by Equation (25). It is being fed to the P-I regulator to obtain the speed signal (26).

4. Modelling and Its Analysis of Multilevel Inverter Topologies for Induction Motor Traction Drive

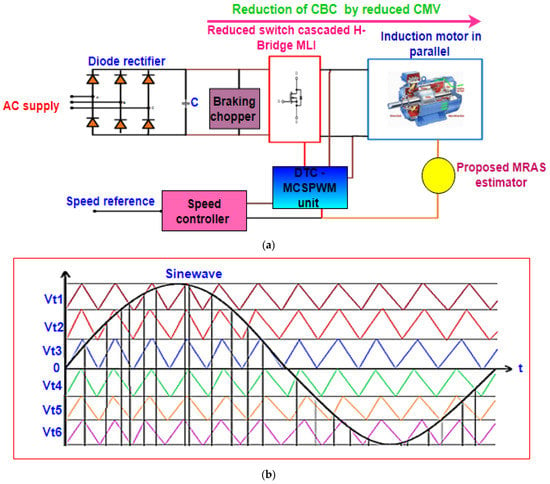

The proposed work is carried out using four dissimilar inverter models. The models are diode-clamped, flying capacitor, H-bridge, and reduced switch topology. The cascaded H-bridge inverter requires fewer mechanisms in all the levels. Hence, the inverters’ expense, switching loss, and heaviness are less than the conventional inverters. Multilevel inverter overcomes the high switching loss and brings harmonics to a required level which is apt for medium to large voltage and power applications. The methodology of reduced switch cascaded H-bridge inverter fed induction motor drive for traction application is depicted in Figure 6a. The circulating current of the induction motor is reduced by reducing the common-mode voltage of the inverter to increase the lifetime and efficiency of the proposed system.

Figure 6.

(a) Proposed induction motor traction drive using modified ANN based MRAS-methodology; (b) multicarrier modulation scheme for five phases.

The pulse width modulation scheme decides the sequence of switching. The state-of-the-art technology of PWM techniques includes a multicarrier pulse width modulation scheme (MCPWM). The MCPWM techniques are represented in Figure 6b.

4.1. T-Type Multilevel Inverter

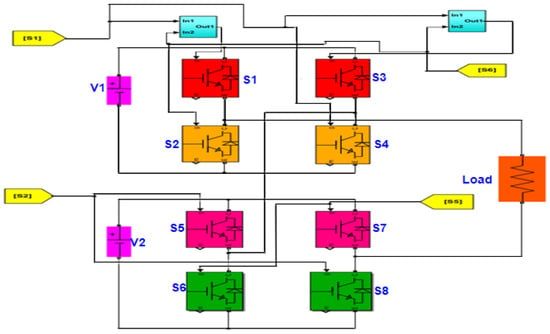

In this research, a new topology created on a T-type five-level inverter is projected, primarily based on multicarrier-based pulse width modulation technique. This topology shows five levels of voltage and reduced common-mode voltage. To verify whether it is efficient and feasible, a design and its output waveform are compared with the conventional methods. The proposed T-type multilevel inverter is depicted in Figure 7.

Figure 7.

Modified 5 level T-bridge topology.

The supply voltage is given to the MOSFETS through the filters, and the transformer is connected between switches and R load for isolation. The CMV was measured among the system load and neutral points.

The demand is for high-performance converters that have reduced size in low voltage applications. For using the passive elements that have their weight and size reduced, the switching frequency is usually within 10–25 kHz for better system efficiency. Multilevel inverters have a very efficient solution that presents the required higher efficiency, high output voltage, and reduction in the size per inverter leg. However, 2-level topologies are still in use as the standard industrial solution for applications related to low voltage.

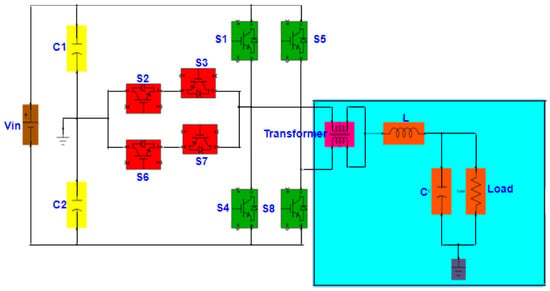

A 5 level T-type topology using eight bidirectional controlled switches S1–S8. One autotransformer with windings N1 and N2. In this proposed inverter, the voltage levels are in sequence of +Vin/4, +Vin/2, 0, −Vin/4, −Vin/2. The proposed topology consists of 8 MOSFET switches, 2 RC filters, a linear transformer, and an R Load.

4.2. Neutral Point Clamped (NPC) Multilevel Inverter

The voltage source DC to AC converter used in the existing locomotive traction drive consists of distorted output. The proposed model has replaced a conventional two-level VSI with NPC multilevel DC to an AC converter. It can reduce small disturbance using the improved modulation procedure. Production voltages of five-level five-phase inverters are obtained using different capacitors at different switching frequencies. For controlling the switches in the inverter, a modified PWM technique is implemented. For instance, Switches 1 to 4 should run simultaneously to have in the output. The Four switches are carried out for each voltage level, as shown in Table 3. Half the DC source is the highest output voltage in the proposed method.

Table 3.

Switching positions of NPC -MLI.

It is necessary to calculate the switching positions so that the output voltage THD becomes as small as possible. Calculating the switching angle used in this dissertation is the harmonic elimination technique. This technique can eliminate the dominant harmonics by selecting calculated switching angles. The diode clamped multilevel inverter is shown in Figure 8.

Figure 8.

A five-level diode clamped multilevel inverter.

4.3. Cascaded H-Bridge Topology Inverter

The cascaded H bridge is created with four switches and is depicted in Figure 9. H-bridge topology is more favorable than diode clamped topology because a greater number of diodes are used, which also affects the cost of the inverter. The switching states of the cascaded H-bridge multilevel inverter are depicted in Table 4.

Figure 9.

Cascaded H-bridge MLI with 8 switches.

Table 4.

Switching positions of cascaded H-bridge MLI.

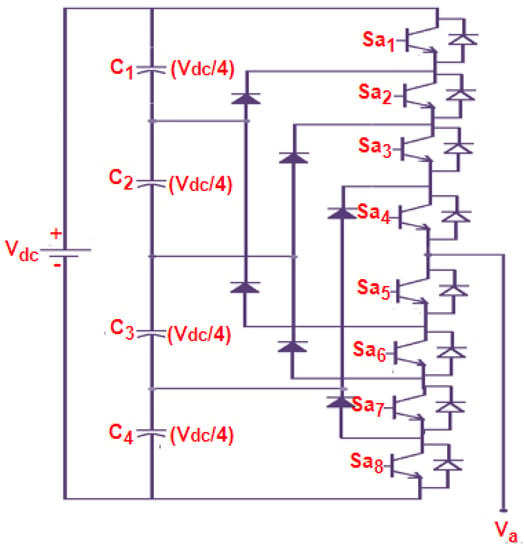

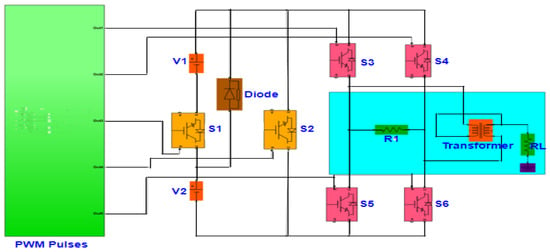

4.4. Proposed Reduced Switch Topology

Two input DC voltages are provided to obtain the desired output, and 6 numbers of switches are used instead of 8 switches in the proposed method. Four repeating sequences are provided at the input side with different time values and output values; this will provide 4 voltages for the switching sequence, as shown in Figure 10. The switching sequence acts as a driver circuit. The circuit makes up the maximum critical portion of the circuitry unit. It is the most important part of the inverter and provides a triggering pulse to the IGBT switches in the desired sequence. The proposed work deals with the reduction of switches with modified MCPWM. As the number of stages is improved in the inverter, there is a drop in harmonics distortion, resulting in reduced common-mode voltage and circulating bearing current. They are used for increasing the levels in the circuit. The switching states of the proposed topology are given in Table 5. Modified Pulse Width Modulator is used for giving the input to the circuit.

Figure 10.

Proposed cascaded H-bridge MLI with 6 switches.

Table 5.

Switching states of proposed multilevel inverter.

Proposed cascaded H-bridge can be defined as when witches are connected in H formation back-to-back, and level output can be obtained from this formation.

The conventional H-bridge consists of 8 IGBT switches. In the proposed topology, the number of switches is reduced from 8 to 6. This means switching losses are also decreased, making this topology more efficient and useful. Switches inthe five-phase 5 Level inverter have been presented in this proposed work. The benefits of this require a lowernumber of IGBT than conventional topologies.

5. Simulation Results and Discussion

The simulation is carried out using four dissimilar Multilevel Inverter (MLI) Topologies. The modified, reduced switch topology is simulated and compared with the NPC topology, T-bridge topology, and H-bridge topology. The modified H-bridge DC to AC converter requires a lesser number of mechanisms at an apiece level. Hence, the expense switching loss of the inverters is less than that of the conventional inverters. Multilevel inverter overcomes the high switching loss and harmonics to a required level which is apt for medium to large voltage and power applications.

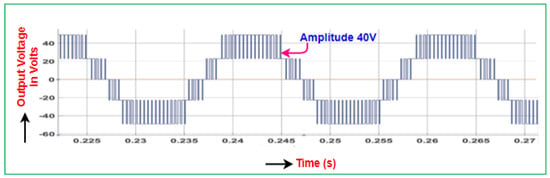

The output voltage of the T-bridge multilevel inverter is 400 V in amplitude for the 400 V input voltage and common-mode voltage is 100 V in amplitude using sinusoidal pulse width modulation techniques and 40 V amplitude using multi-carrier sinusoidal pulse width modulation techniques as depicted in Figure 11, Figure 12 and Figure 13. The common-mode voltage of the T-bridge inverter has less amplitude compared to the conventional two-level inverter.

Figure 11.

Output voltage of T-bridge multilevel inverter.

Figure 12.

Common mode voltage of T-bridge MLI using SPWM.

Figure 13.

Reduced common mode voltage of T-bridge MLI using MCSPWM.

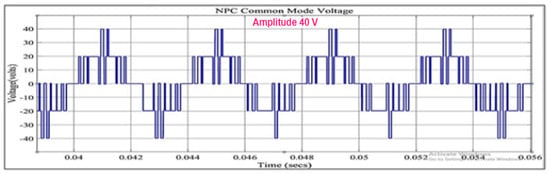

The output voltage of NPC multilevel inverter is 400 V in amplitude for the 400 V input voltage, and the common-mode voltage is 40 V in amplitude using sinusoidal pulse width modulation techniques and 20 V amplitude using multi-carrier sinusoidal pulse width modulation techniques as depicted in Figure 14, Figure 15 and Figure 16. The common-mode voltage of NPC multilevel inverter has less amplitude compared to the conventional two-level inverter and T-bridge multilevel inverter.

Figure 14.

Output voltage of NPC—MLI.

Figure 15.

CMV of NPC-MLI using SPWM.

Figure 16.

Common-mode voltage of NPC multilevel inverter using MCSPWM.

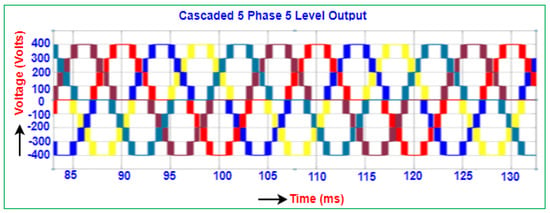

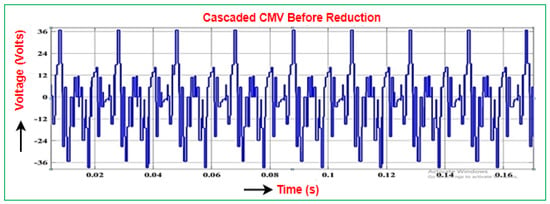

The output voltage of 8 switches five-level cascaded H-bridge inverter is 400 V in amplitude for the 400 V input voltage, and the common-mode voltage is 36 V in amplitude using sinusoidal pulse width modulation techniques and 10 V amplitude using multi-carrier sinusoidal pulse width modulation techniques as depicted in Figure 17, Figure 18 and Figure 19. The common-mode voltage of 8 switches five-level cascaded H-bridge has less amplitude compared to the conventional two-level inverter and T-bridge multilevel inverter and NPC multilevel inverter.

Figure 17.

Output voltage of cascaded H-bridge MLI.

Figure 18.

CMV of cascaded H-bridge MLI using SPWM.

Figure 19.

Reduced common mode voltage of H-bridge MLI using MCSPWM.

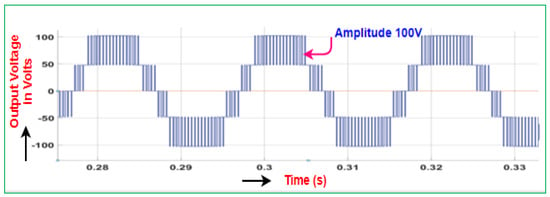

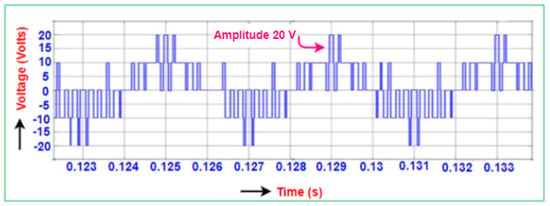

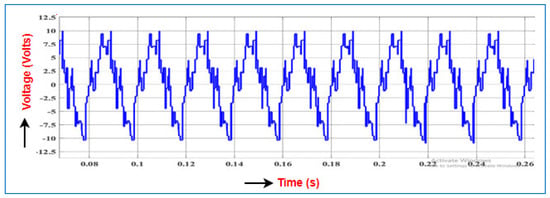

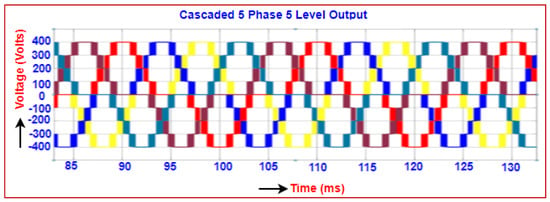

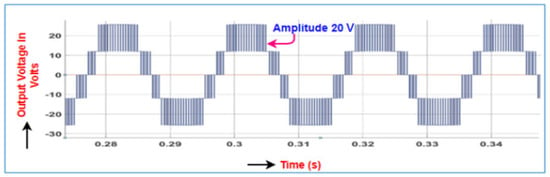

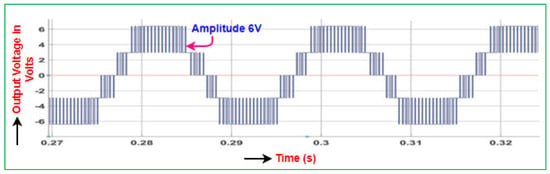

The output voltage of 6 switches five-level cascaded H-bridge inverter is 400 V in amplitude for the 400 V input voltage, and the common-mode voltage is 20 V in amplitude using sinusoidal pulse width modulation techniques and 6 V amplitude using multi-carrier sinusoidal pulse width modulation techniques as depicted in Figure 20, Figure 21 and Figure 22. The common-mode voltage of 6 switches five-level cascaded H-bridge inverter has less in amplitude compared to the conventional two-level inverter and T-bridge multilevel inverter, NPC multilevel inverter, and 8 switches five-level cascaded H-bridge inverter.

Figure 20.

Output voltage of proposed reduced switch multilevel inverter.

Figure 21.

CMV of reduced switch multilevel inverter using SPWM.

Figure 22.

Reduced CMV of cascaded H-bridge MLI using MCSPWM.

The use of five phases in this technique enhances the machine’s productivity and reduces the losses in the machine compared to the three-phase machine. The proposed five-phase induction motor drives are simulated with four different multilevel inverter topologies. The simulated results are compared with the theoretical calculation, and the optimized method has been identified based on reduced CMV and CBC.

6. Hardware Results and Discussion

The power electronics converter built the adjustable speed drives for various applications. As per the facts, the DC to AC converter induced common-mode voltage is the principal cause of current in a common mode which originates the bearing current. The high Circulating Bearing Current (CBC) could lead to damage at the output terminal resulting in damage of motor bearings and leading to malfunctioning of electric components of the machine. The different methods to limit the circulating currents are the design of the filter, repetition of switching, multilevel inverter with modified PWM techniques, common-mode hardware, and insulated ground system.

The improved performance attained in the simulation is analyzed experimentally. In the proposed ANN-BASED MRAS, the conventional adjustable model was replaced by the artificial neural network, and ANN in the adaptation mechanism replaced the PI controller. The outputs of the two models are compared until there is no error between the two models. With a proper estimation of rotor speed, the fluxes solved by the two models must be equivalent.

CBC and the common mode current path are attached with common-mode flux

The simulated values are compared with the theoretical values using the following equations, and the comparisons are also illustrated in Table 6.

Table 6.

Comparison of common mode voltage of induction motor drive.

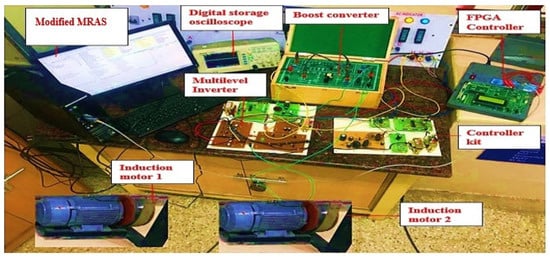

An adjustable system with the ANN controller could monitor the speed until the two-flux values are matched. The FOC-based voltage source inverter fed sensorless induction drive performance has been improved compared to the conventional method, but energy efficiency is also adequate due to the sensorless drive hardware setup, which is shown in Figure 23.

Figure 23.

Hardware setup for proposed sensor less MLI fed parallel-connected induction motor.

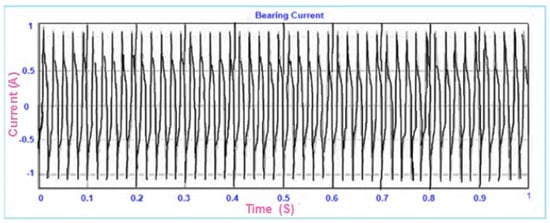

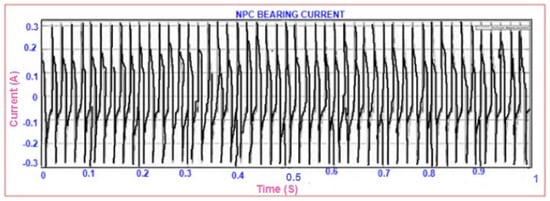

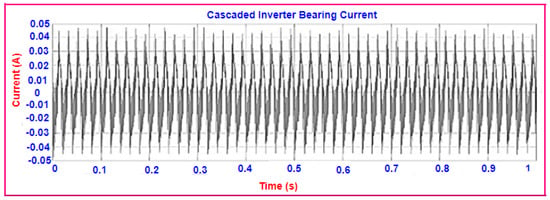

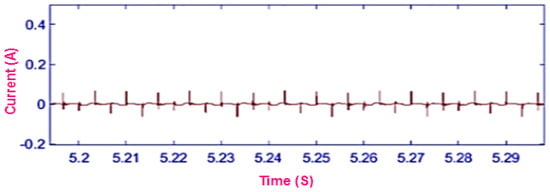

The circulating bearing current of the proposed induction motor drive has been reduced to 0.036 ampere compared to T-bridge, NPC, and cascaded H-bridge multilevel inverters, depicted in Figure 24, Figure 25, Figure 26 and Figure 27.

Figure 24.

CBC of modified ANN-based sensorless induction motor with T-bridge inverter.

Figure 25.

CBC of modified ANN-based sensorless induction motor with NPC inverter.

Figure 26.

CBC of modified ANN-based sensorless induction motor with cascaded H-bridge inverter.

Figure 27.

Circulating bearing current of modified ANN-based sensor-less induction motor with modified cascaded H-bridge inverter.

Proposed methods have improved performance, such as reduced common-mode voltage, reduced switches, and circulating bearing current, compared to the conventional methods.

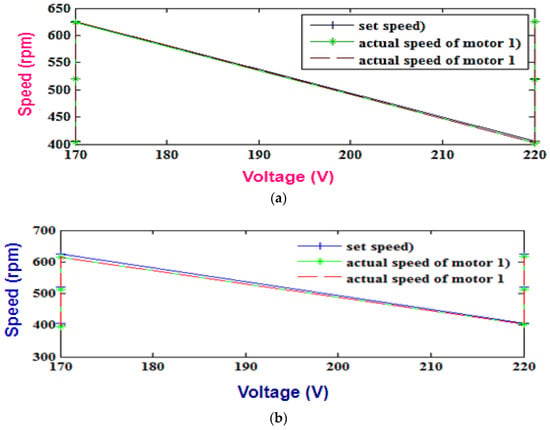

The problem of the conventional method is compensated by the proposed method. The error in the speed, nearly zero, in the proposed method is depicted in Figure 28. The circulating bearing current of the modified H-bridge multilevel inverters induction motor drive has been reduced to 0.036 Ampere compared to T-bridge, NPC, and H-bridge multilevel inverters. The simulated values are associated with the mathematical equations using the theoretic standards. The comparison is made between theoretical and hardware depicted in Table 6. The input voltage and output voltage of multilevel inverter topologies are 400 V in amplitude.

Figure 28.

Speed response of sensorless IM drive: (a) steady-state condition; (b) parameter variation.

7. Conclusions

The enhanced speed performance of a modified ANN-based sensor-less traction system has been achieved in the proposed method compared to the conventional sensor-based method. The modeling of the five-phase inverter has also been analyzed, and the four different topologies of the multilevel inverter have been simulated. The proposed reduced switch cascaded topology has a common-mode voltage of 5.8 V and a circulating bearing current of 0.036 A, compared to the conventional cascaded topology common-mode voltage of 9.98 V and circulating bearing current of 0.06 A. The enhanced results of the proposed method have been associated with other topologies. The proposed method’s decreased circulating bearing current and common-mode voltage have been achieved compared to a conventional voltage source inverter fed induction motor for traction application. The hardware setup for the proposed ANN-based sensorless traction drive was also analyzed, and improved performance was achieved compared to the conventional method. The suggested improvement of the proposed work is the five-phase motor which has numerous compensations over the conventional motor in terms of torque and speed performance of induction motor drive. In the future, the design and construction of the conventional polyphase motor may be altered by replacing all the stator coils with magnets to increase the efficiency and to reduce the losses, size, and cost of the machine available in the market.

Author Contributions

All authors have contributed equally work. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Taif University Researchers Supporting Project number (TURSP-2020/86): Taif University, Taif, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Matsuse, K.; Kawai, H.; Kouno, Y.; Oikawa, J. Characteristics of speed sensorless vector controlled dual induction motor drive connected in parallel fed by a single Inverter. IEEE Trans. Ind. Appl. 2004, 40, 153–161. [Google Scholar] [CrossRef]

- Yazid, K.; Ibtiouen, R.; Touhami, O.; Fadel, M. Application of EKF to Parameters Estimation for Speed Sensorless and Neural Network Control of an Induction Motor. In Proceedings of the 6th WSEAS International Conference on Power Systems, Cambridge, UK, 23–25 February 2006; pp. 279–283. [Google Scholar]

- Abraham, L.A.; Arunchand, K.; Sudharshan, R. An Artificial-Intelligence Based Induction Motor Speed control and Estimation using conventional MRAS with dynamic reference modal. Int. J. Eng. Res. Appl. 2012, 2, 87–92. [Google Scholar]

- Zhen, L.; Xu, L. Sensorless field orientation control of induction machines based on a mutual MRAS scheme. IEEE Trans. Ind. Electron. 1998, 45, 824–831. [Google Scholar] [CrossRef]

- Gazafroodi, S.M.M.; Dashti, A. A Novel MRAS Based Estimator for Speed-Sensorless Induction Motor Drive. Iran. J. Electr. Electron. Eng. 2014, 10, 304–313. [Google Scholar]

- Julian, A.L.; Oriti, G.; Lipo, T.A. Elimination of common-mode voltage in three-phase sinusoidal power converters. IEEE Trans. Power Electron. 1999, 14, 982–989. [Google Scholar] [CrossRef]

- Dhatrak, R.K.; Nema, R.K.; Deshpande, D.M. Comparative Analysis of Common-Mode Voltage, Bearing Current and Shaft Voltage of Diode Clamped SPWM Multilevel Inverter Fed Induction Motor. Int. J. Electr. Electron. Eng. 2015, 4, 115–129. [Google Scholar] [CrossRef]

- Zou, B.; Guo, Y.; Xiao, X.; Yang, B.; Wang, X.; Shi, M.; Tu, Y. Performance Improvement of Matrix Converter Direct Torque Control System. Energies 2020, 13, 3247. [Google Scholar] [CrossRef]

- Muetze, A.; Binder, A. Calculation of Circulating Bearing Currents in Machines of Inverter-Based Drive Systems. IEEE Trans. Ind. Electron. 2007, 54, 932–938. [Google Scholar] [CrossRef]

- Cuzner, R.M.; Nowak, D.J.; Bendre, A.; Oriti, G.; Julian, A.L. Mitigating Circulating Common-Mode Currents between Parallel Soft-Switched Drive Systems. IEEE Trans. Ind. Appl. 2007, 43, 1284–1294. [Google Scholar] [CrossRef]

- Metz, A.; Binder, A. Don’t lose your bearings—Mitigation techniques for bearing currents in inverter-supplied drive systems. IEEE Ind. Appl. Mag. 2006, 12, 22–31. [Google Scholar]

- Firouzkouhi, H. Control of cascaded H-bridge multilevel inverter based on optimum regulation of switching angles, with FPGA implementations. Eur. J. Electr. Comput. Eng. 2019, 3, 1–5. [Google Scholar] [CrossRef][Green Version]

- Van Der Broeck, H.W.; Skudelny, H.C.; Stanke, G.V. Analysis and Realization of a Pulse width Modulator Based on Voltage Space Vectors. IEEE Trans. Ind. Appl. 1998, 24, 142–150. [Google Scholar] [CrossRef]

- Liu, R.; Ma, X.; Ren, X.; Cao, J.; Niu, S. Comparative Analysis of Bearing Current in Wind Turbine Generators. Energies 2018, 11, 1305. [Google Scholar] [CrossRef]

- Zalhaf, A.; Abdel-Salam, M.; Ahmed, M. An Active Common-Mode Voltage Canceler for PWM Converters in Wind-Turbine Doubly-Fed Induction Generators. Energies 2019, 12, 691. [Google Scholar] [CrossRef]

- Bharatiraja, C.; Selvaraj, R.; Chelliah, T.R.; Munda, J.L.; Tariq, M.; Maswood, A.I. Design and Implementation of Fourth Arm for Elimination of Bearing Current in NPC-MLI-Fed Induction Motor Drive. IEEE Trans. Ind. Appl. 2018, 54, 745–754. [Google Scholar] [CrossRef]

- Severson, E.; Gandikota, S.; Mohan, N. Practical Implementation of dual-purpose no-voltage drives for bearingless motors. IEEE Trans. Ind. Appl. 2016, 52, 1509–1518. [Google Scholar]

- Akagi, H.; Tamura, S. A passive EMI filter for elimination both bearing current and ground leakage current from an inverter-driven motor. IEEE Trans. Power Electron. 2006, 21, 1459–1469. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Lee, H.H. Modulation strategies to reduce common-mode voltage for indirect matrix converters. IEEE Trans. Ind. Electron. 2012, 59, 129–140. [Google Scholar] [CrossRef]

- Sengamalai, U.; Chinnamuthu, S. Experimental fault analysis and speed control of an induction motor using a motor solver. J. Electron. Eng. Technol. 2017, 12, 761–768. [Google Scholar] [CrossRef]

- Usha, S.; Subramani, C.; Padmanaban, S. Neural Network-Based Model Reference Adaptive System for Torque Ripple Reduction in Sensorless Poly Phase Induction Motor Drive. Energies 2019, 12, 920. [Google Scholar] [CrossRef]

- Białoń, T.; Pasko, M.; Niestrój, R. Developing Induction Motor State Observers with Increased Robustness. Energies 2020, 13, 5487. [Google Scholar] [CrossRef]

- Adamczyk, M.; Orlowska-Kowalska, T. Self-Correcting Virtual Current Sensor Based on the Modified Luenberger Observer for Fault-Tolerant Induction Motor Drive. Energies 2021, 14, 6767. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).