Investigation of Cavitation Inception in Aviation Hydraulic Fluid AMG-10 in a Small-Scale Rectangular Throttle Channel

Abstract

1. Introduction

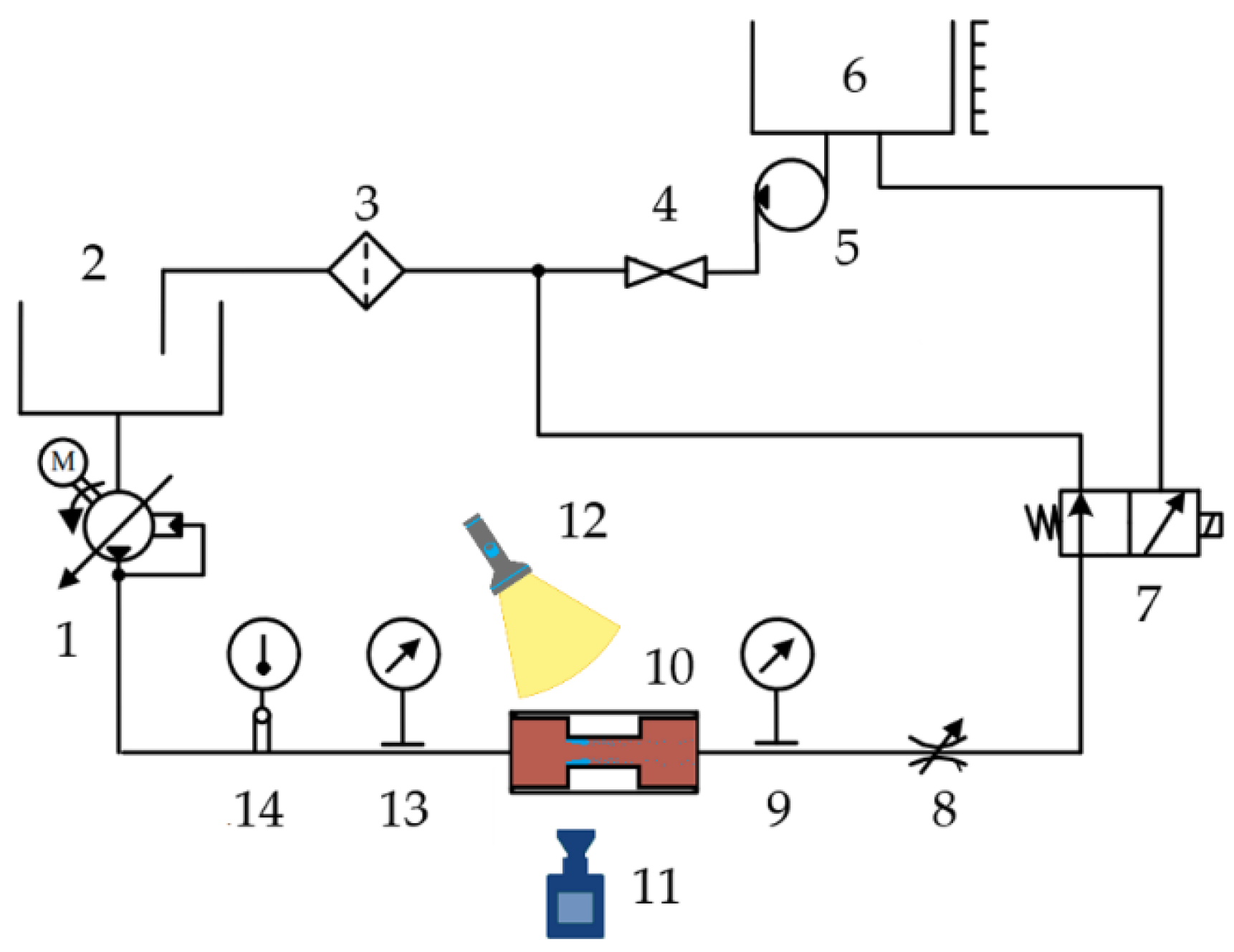

2. Experimental Setup and Method

3. Numerical Simulation of Cavitation Process

3.1. Description of Governing Equations

- evaporation ( ≤ psat) isand condensation ( > psat) iswhere psat is the saturation vapor pressure; p∞ is the local absolute static pressure in the flow field; rnuc is the volume fraction at the bubble nucleation site with a value of 3 × 10−4, and other constants are Cevap = 35, Ccond = 0.0012, RB = 1.2 × 10−6.

3.2. Mesh Configuration and Numerical Methods

3.3. Numerical Methods

4. Results and Discussion

4.1. Wall Pressure Validation

4.2. Cavity Shape Validation

4.3. Pressure, Velocity, and Turbulent Kinetic Energy Distributions Inside the Channel

4.3.1. Pressure Distribution

4.3.2. Velocity Distribution

4.3.3. Distribution of Turbulent Kinetic Energy (TKE)

5. Conclusions

- The applied quasi-steady-state numerical model, based on the Realizable k–ϵ turbulence model combined with the Enhanced Wall Treatment method and the Zwart–Gerber–Belamri cavitation model, reliably reproduces the shape and size of the cavitation regions, demonstrating good qualitative and quantitative agreement with the experimental data. Comparison of the pressure between numerical simulations and experimental measurements along the upper and lower walls of the investigated channel shows differences of less than 10%, confirming the accuracy of the model.

- Quantitatively, the volume delineated by the vapor fraction isosurface decreases significantly as the threshold is raised. For instance, an isosurface of 0.2 occupies approximately 3.18% of the channel volume, whereas at a threshold of 0.8, it constitutes merely 0.048%. This sharp decrease indicates a strong localization of regions with high vapor concentration, which is crucial for assessing the spatial structure of cavitation. The analysis of vapor volume fraction iso-surfaces at different threshold values revealed a consistent asymmetric nature of the cavitation. Specifically, the upper cavity consistently exhibited a larger volume compared to the lower cavity. This asymmetry was observed in both experimental and numerical results, confirming the reliability of the computational model in capturing this mean feature. While this study confirms the consistency of the phenomenon, identifying its physical cause remains an important challenge for future research.

- Numerical modeling identifies points of minimum mean absolute pressure located ~0.19 mm from the inlet, with values of 214 Pa at the upper wall and 236 Pa at the lower wall. These pressures are within the saturation pressure of AMG-10. The spatial location of these calculated low-pressure values coincides with the region where the model predicts a high vapor volume fraction, confirming the internal consistency of the numerical solution.

- In the investigated channel, the velocity field exhibits a structure with double peaks of maximum velocity near the upper and lower walls. The local velocity maxima in these peaks reach approximately 41.98 m/s, exceeding the maximum velocity along the channel axis (40.88 m/s).

- The maximum level of turbulent kinetic energy (TKE ≈ 164.5 m2/s2) is localized in section S2, immediately downstream of the channel constriction. This region of peak TKE spatially coincides with the zones of highest vapor fraction and intense velocity shear. Further downstream, the TKE magnitude decreases, and its distribution becomes increasingly uniform across the channel cross-section. At the outlet, the TKE field is characterized by low intensity and minimal spatial variation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chahine, G.L.; Franc, J.-P.; Karimi, A. Cavitation and Cavitation Erosion. In Advanced Experimental and Numerical Techniques for Cavitation Erosion Prediction; Kim, K.-H., Chahine, G., Franc, J.-P., Karimi, A., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 3–20. ISBN 978-94-017-8539-6. [Google Scholar]

- Konami, S.; Nishiumi, T. Hydraulic Control Systems: Theory And Practice; World Scientific Publishing Company: Singapore, 2016; ISBN 978-981-4759-66-3. [Google Scholar]

- Manring, N.D.; Fales, R.C. Hydraulic Control Systems; John Wiley & Sons: Hoboken, NJ, USA, 2019; ISBN 978-1-119-41647-0. [Google Scholar]

- Andrenko, P.; Hrechka, I.; Khovanskyi, S.; Rogovyi, A.; Svynarenko, M. Improving the Technical Level of Hydraulic Machines, Hydraulic Units and Hydraulic Devices Using a Definitive Assessment Criterion at the Design Stage. J. Mech. Eng. 2021, 18, 57–76. [Google Scholar] [CrossRef]

- Wang, S.; Tomovic, M.; Liu, H. Commercial Aircraft Hydraulic Systems: Shanghai Jiao Tong University Press Aerospace Series; Elsevier Science: Amsterdam, The Netherlands, 2015; ISBN 978-0-12-419972-9. [Google Scholar]

- Ma, L.; Yan, H.; Ren, Y.; Li, L.; Cai, C. Numerical Investigation of Flow Force and Cavitation Phenomenon in the Pilot Stage of Electrical-Hydraulic Servo Valve under Temperature Shock. Machines 2022, 10, 423. [Google Scholar] [CrossRef]

- Peng, J.; Saha, B.K.; Shakib, M.S.N.; Li, S.; Jihan, J.I. A Numerical Analysis of Pressure Characteristics in the Deflector Jet Pilot Stage Valve with an Innovative Deflector Deflection. Flow Meas. Instrum. 2024, 99, 102674. [Google Scholar] [CrossRef]

- Aung, N.Z.; Li, S. A Numerical Study of Cavitation Phenomenon in a Flapper-Nozzle Pilot Stage of an Electrohydraulic Servo-Valve with an Innovative Flapper Shape. Energy Convers. Manag. 2014, 77, 31–39. [Google Scholar] [CrossRef]

- Chen, M.; Aung, N.Z.; Li, S.; Zou, C. Effect of Oil Viscosity on Self-Excited Noise Production Inside the Pilot Stage of a Two-Stage Electrohydraulic Servovalve. J. Fluids Eng. 2018, 141, 011106. [Google Scholar] [CrossRef]

- Yang, H.; Xu, Y.; Chen, Z.; Wang, W.; Aung, N.Z.; Li, S. Cavitation Suppression in the Nozzle-Flapper Valves of the Aircraft Hydraulic System Using Triangular Nozzle Exits. Aerosp. Sci. Technol. 2021, 112, 106598. [Google Scholar] [CrossRef]

- Li, L.; Yan, H.; Zhang, H.; Li, J. Numerical Simulation and Experimental Research of the Flow Force and Forced Vibration in the Nozzle-Flapper Valve. Mech. Syst. Signal Process. 2018, 99, 550–566. [Google Scholar] [CrossRef]

- Kang, J.; Yuan, Z.; Tariq Sadiq, M. Numerical Simulation and Experimental Research on Flow Force and Pressure Stability in a Nozzle-Flapper Servo Valve. Processes 2020, 8, 1404. [Google Scholar] [CrossRef]

- Yao, J.; Li, M.; Li, X.; Wang, Y.; Kong, D. Cavitation Evolution Mechanism and Periodic Flow of Aviation Pressure Poppet Valve. Flow Meas. Instrum. 2025, 102, 102811. [Google Scholar] [CrossRef]

- Yan, H.; Ren, Y.; Yao, L.; Dong, L. Analysis of the Internal Characteristics of a Deflector Jet Servo Valve. Chin. J. Mech. Eng. 2019, 32, 31. [Google Scholar] [CrossRef]

- Brazhenko, V.N.; Mochalin, E.V.; Jian-Cheng, C. Mechanical Admixture Influence in the Working Fluid on Wear and Jamming of Spool Pairs from Aircraft Hydraulic Drives. J. Frict. Wear 2020, 41, 526–530. [Google Scholar] [CrossRef]

- Saha, B.K.; Peng, J.; Li, S. Numerical and Experimental Investigations of Cavitation Phenomena Inside the Pilot Stage of the Deflector Jet Servo-Valve. IEEE Access 2020, 8, 64238–64249. [Google Scholar] [CrossRef]

- Ren, Y.; Yan, H.; Mao, Q.; Zuo, Z.; Hao, H. A Model-Based Investigation of the Performance Robustness of the Deflector Jet Servo Valve. Appl. Sci. 2022, 12, 10428. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, Y. Analysis and Optimization of the Pilot Stage of Jet Pipe Servo Valve. Alex. Eng. J. 2022, 61, 41–50. [Google Scholar] [CrossRef]

- Lu, L.; Wang, J.; Li, M.; Ryu, S. Experimental and Numerical Analysis on Vortex Cavitation Morphological Characteristics in U-Shape Notch Spool Valve and the Vortex Cavitation Coupled Choked Flow Conditions. Int. J. Heat Mass Transf. 2022, 189, 122707. [Google Scholar] [CrossRef]

- An, W.; Ren, L.; Bai, Y.; Bao, G. Numerical Simulation of the Temperature Rise and Cavitation Flow in a Hydraulic Slide Valve. Flow Meas. Instrum. 2024, 96, 102553. [Google Scholar] [CrossRef]

- An, W.; Yang, Q.; Bao, G. Numerical Simulation of the Multiscale Cavitation Flow in a Hydraulic Slide Valve. Flow Meas. Instrum. 2025, 102, 102805. [Google Scholar] [CrossRef]

- Choi, D.; Lee, S.; Ahn, K. Effects of Non-Uniform Center-Flow Distribution and Cavitation on Continuous-Type Pintle Injectors. Aerospace 2024, 11, 847. [Google Scholar] [CrossRef]

- Li, P.; Pei, Q.; Liu, Z.; Luo, S.; Zhou, L.; Li, J.; Chen, L. Parametric Optimization of Surface Textures in Oil-Lubricated Long-Life Aircraft Valves. Lubricants 2024, 12, 405. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, C.; Meng, B.; Li, S. Challenges and Solutions for High-Speed Aviation Piston Pumps: A Review. Aerospace 2021, 8, 392. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, C.; Hong, H.; Cheng, G.; Yang, H.; Feng, S.; Zhai, J.; Xiao, W. Optimization of the Outlet Unloading Structure to Prevent Gaseous Cavitation in a High-Pressure Axial Piston Pump. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 3459–3473. [Google Scholar] [CrossRef]

- Yu, M.; Peng, X.; Meng, X.; Jiang, J.; Ma, Y. Influence of Cavitation on the Heat Transfer of High-Speed Mechanical Seal with Textured Side Wall. Lubricants 2023, 11, 378. [Google Scholar] [CrossRef]

- Kazama, T. Experimental Study of Jet Cavitation Erosion Applicable to Oil and Water-Hydraulic Equipment. Mater. Perform. Charact. 2018, 7, 355–373. [Google Scholar] [CrossRef]

- Brazhenko, V. The Influence of Contaminated Hydraulic Fluid on the Relative Volume Flow Rate and the Wear of Rubbing Parts of the Aviation Plunger Pump. Aviation 2019, 23, 43–47. [Google Scholar] [CrossRef]

- Li, M.; Yang, G.; Wu, G.; Li, X. Oxidative Deterioration Effect of Cavitation Heat Generation on Hydraulic Oil. IEEE Access 2020, 8, 119720–119727. [Google Scholar] [CrossRef]

- Kazama, T.; Aoki, S.; Kobessho, M. Cavitation Erosion Characteristics of High Bulk Modulus Oils: Preliminary Evaluation Experiment for Hydraulic Equipment. Mater. Perform. Charact. 2020, 9, 357–364. [Google Scholar] [CrossRef]

- Zhang, J.; Qi, N.; Jiang, J. Effect of Oil Viscosity on Hydraulic Cavitation Luminescence. Fluid Dyn. 2021, 56, 371–382. [Google Scholar] [CrossRef]

- Osterland, S.; Müller, L.; Weber, J. Influence of Air Dissolved in Hydraulic Oil on Cavitation Erosion. Int. J. Fluid Power 2021, 22, 373–392. [Google Scholar] [CrossRef]

- Iga, Y.; Okajima, J.; Takahashi, S.; Ibata, Y. Occurrence Characteristics of Gaseous Cavitation in Oil Shear Flow. Phys. Fluids 2022, 34, 023313. [Google Scholar] [CrossRef]

- Osterland, S.; Günther, L.; Weber, J. Experiments and Computational Fluid Dynamics on Vapor and Gas Cavitation for Oil Hydraulics. Chem. Eng. Technol. 2023, 46, 147–157. [Google Scholar] [CrossRef]

- Polášek, T.; Bureček, A.; Hružík, L.; Ledvoň, M.; Dýrr, F.; Olšiak, R.; Kolář, D. Experimental Study of Multiphase Flow Occurrence Caused by Cavitation during Mineral Oil Flow. Phys. Fluids 2024, 36, 113377. [Google Scholar] [CrossRef]

- Bureček, A.; Hružík, L.; Vašina, M. Determination of Undissolved Air Content in Oil by Means of a Compression Method. Stroj. Vestn. J. Mech. Eng. 2015, 61, 477–485. [Google Scholar] [CrossRef]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A New k-ϵ Eddy Viscosity Model for High Reynolds Number Turbulent Flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Kaddour, A.; Ouadha, A. Numerical Study of the Flow in a Two-Phase Nozzle for Trilateral Flash Cycle Applications. Int. J. Thermofluids 2023, 19, 100393. [Google Scholar] [CrossRef]

- Dai, Y.-J.; Shi, J.-W.; Cheng, X.-L.; Zhang, Z.; He, Y.-Q.; Tao, W.-Q. Numerical Study on the Cavitation Flow Characteristics of High-Pressure Fuel in Injector Orifices Based on Compressible Non-Isothermal Model. AIP Adv. 2023, 13, 115205. [Google Scholar] [CrossRef]

- Mutlu, Y.; Dönmez, A.H.; Karadağ, M.A.; Göklüberk, P. Pressure Drop and Cavitation Optimization of a Relief Valve Featuring Quick Coupling Used in Radar Systems. Arab. J. Sci. Eng. 2025, 50, 2321–2334. [Google Scholar] [CrossRef]

- Zhang, J.; Jin, H.; Wang, C.; Liu, X. Investigation on Flow and Cavitation Characteristics in Flow Channel of Multistage Depressurization Valve. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2025, 09544089251318109. [Google Scholar] [CrossRef]

- Wang, X.; Chen, Y.; Li, M.; Xu, Y.; Wang, B.; Dang, X. Numerical Study on the Working Performance of a Streamlined Annular Jet Pump. Energies 2020, 13, 4411. [Google Scholar] [CrossRef]

- Li, W.; Guo, R.; Wang, G.; Zhao, J.; Zhang, Q.; Yu, L.; Zhang, Q. Study on Cavitation of Port Plate of Seawater Desalination Pump with Energy Recovery Function. Processes 2023, 11, 743. [Google Scholar] [CrossRef]

- Kevorkijan, L.; Palomar-Torres, A.; Torres-Jiménez, E.; Mata, C.; Biluš, I.; Lešnik, L. Obtaining the Synthetic Fuels from Waste Plastic and Their Effect on Cavitation Formation in a Common-Rail Diesel Injector. Sustainability 2023, 15, 15380. [Google Scholar] [CrossRef]

- Onishi, T.; Peng, Y.; Ji, H.; Peng, G. Numerical Simulations of Cavitating Water Jet by an Improved Cavitation Model of Compressible Mixture Flow with an Emphasis on Phase Change Effects. Phys. Fluids 2023, 35, 073333. [Google Scholar] [CrossRef]

- Zwart, P.J.; Gerber, A.G.; Belarmi, T. A Two-Phase Flow Model for Predicting Cavitation Dynamics. In Proceedings of the Fifth International Conference on Multiphase Flow, Yokohama, Japan, 30 May–4 June 2004. [Google Scholar]

- Jansson, M. Implementing a Zwart-Gerber-Belamri Cavitation Model; CFD with OpenSource Software; Chalmers University of Technology: Gothenburg, Sweden, 2018; p. 18. [Google Scholar]

- Singhal, A.K.; Athavale, M.M.; Li, H.; Jiang, Y. Mathematical Basis and Validation of the Full Cavitation Model. J. Fluids Eng. 2002, 124, 617–624. [Google Scholar] [CrossRef]

- Tarasenko, T.; Badakh, V.; Makarenko, M.; Lukianov, P.; Dubkovetskiy, I. Determining the Mechanism for Generating Cavitation Pressure Fluctuations in Throttle Devices at High-Head Throttling of Liquid. East. Eur. J. Enterp. Technol. 2024, 4, 21–31. [Google Scholar] [CrossRef]

| Hydraulic Fluid Parameters | |

| Temperature, °C | 50.1 |

| Kinematic viscosity, m2/s | 1.02 × 10−5 |

| Density, kg/m3 | 815 |

| Pressure saturation, Pa | 200–300 |

| Inlet–Outlet Parameters | |

| Inlet absolute pressure, MPa | 1.06 |

| Outlet absolute pressure, Pa | 0–445,000 |

| Cell Size, mm | Upper Wall | Lower Wall | Volume Fraction of Vapor | ||||

|---|---|---|---|---|---|---|---|

| Pmin, Pa | Δ, % | Tcav, mm | Pmin, Pa | Δ, % | Tcav, mm | ||

| 0.1 | 210 | ̶ | 0.48 ± 0.02 | 230 | ̶ | 0.47 ± 0.02 | 0.00355 |

| 0.15 | 208 | −0.95 | 0.48 ± 0.02 | 228 | −0.87 | 0.47 ± 0.02 | 0.00355 |

| 0.2 | 214 | 2.88 | 0.48 ± 0.02 | 236 | 3.51 | 0.47 ± 0.02 | 0.00355 |

| 0.25 | 1871 | 774.30 | 0 | 1990 | 743.22 | 0 | 0 |

| 0.3 | 21,560 | 1052.32 | 0 | 23,940 | 1103.02 | 0 | 0 |

| Point | Experiment, Pa | Simulation, Pa | Absolute Error, Pa | Relative Error, (%) |

|---|---|---|---|---|

| M1 | 210,000 | 219,000 | 9000 | 4.29 |

| M2 | 430,000 | 388,000 | 42,000 | 9.77 |

| M3 | 520,000 | 472,000 | 48,000 | 9.23 |

| M4 | 490,000 | 474,000 | 16,000 | 3.27 |

| K1 | 200,000 | 213,000 | 13,000 | 6.50 |

| K2 | 410,000 | 371,000 | 39,000 | 9.51 |

| K3 | 500,000 | 458,000 | 42,000 | 8.40 |

| K4 | 470,000 | 451,000 | 19,000 | 4.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Brazhenko, V.; Tarasenko, T. Investigation of Cavitation Inception in Aviation Hydraulic Fluid AMG-10 in a Small-Scale Rectangular Throttle Channel. Aerospace 2026, 13, 83. https://doi.org/10.3390/aerospace13010083

Brazhenko V, Tarasenko T. Investigation of Cavitation Inception in Aviation Hydraulic Fluid AMG-10 in a Small-Scale Rectangular Throttle Channel. Aerospace. 2026; 13(1):83. https://doi.org/10.3390/aerospace13010083

Chicago/Turabian StyleBrazhenko, Volodymyr, and Taras Tarasenko. 2026. "Investigation of Cavitation Inception in Aviation Hydraulic Fluid AMG-10 in a Small-Scale Rectangular Throttle Channel" Aerospace 13, no. 1: 83. https://doi.org/10.3390/aerospace13010083

APA StyleBrazhenko, V., & Tarasenko, T. (2026). Investigation of Cavitation Inception in Aviation Hydraulic Fluid AMG-10 in a Small-Scale Rectangular Throttle Channel. Aerospace, 13(1), 83. https://doi.org/10.3390/aerospace13010083