Abstract

Crosslinked phenolic resin was prepared using hexamethylenetetramine (HMTA) as a crosslinking agent in hydrochloric acid solution. The ablation-heat-resistant material was prepared by a pressure-assisted RTM (resin transfer molding) process with reinforcing material (quartz fibre 2.5D needle-punched fabric/satin fibre cloth/fibre mesh tire) and matrix (crosslinked phenolic resin). The thermal stability of the cured product was studied by a thermogravimetric analyser (TG and DTG). The mechanical properties, heat resistance, and ablation properties of the composites were tested. The ablation morphology, element analysis, and phase structure of the composites were analysed by scanning electron microscopy (SEM), energy dispersive spectrometry (EDS), and X-ray diffraction (XRD), respectively. The results show that the phenolic resin has a lower initial viscosity and a longer pot life at 80 °C, and a higher carbon residue rate (70.18%). The tensile strength of the composites is close to 40 MPa, the tensile modulus is higher than 1.35 GPa, the compression modulus is higher than 10 MPa, and the elongation at break is higher than 1.55%. SiO2, SiC, and ZrO2 ceramic phases were formed after ablation, which effectively improved the ablation performance of the composites.

1. Introduction

With the development of the aerospace industry, the design and manufacture of aerospace vehicles has attracted increasingly more attention from the world, which is the key work of China’s construction of aerospace power [1,2]. As the pinnacle of industrial technology, it is more difficult to develop than ordinary aircraft, and it faces more challenges—improving the thermal protection capability of aerospace vehicles is one of them [3]. Aerospace vehicles can fly at a maximum speed of more than 5 Mach, providing excellent manoeuvrability while also posing extremely severe thermal environmental challenges. Aerodynamic heating caused by high-speed flight will lead to a sharp rise in surface temperature [4,5]. In order to ensure sufficient power output, space vehicles widely use rocket engines or air-breathing scramjet engines, which pose severe challenges to the thermal protection systems of engines and aircraft due to the high heat flux of combustion chambers and exhaust nozzles [6,7].

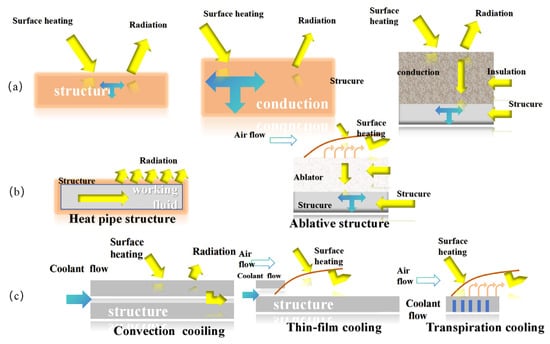

Thermal protection systems can be divided into three types—passive, semi-passive, and active—according to their operating principle [8]. Passive solutions rely on the material’s own characteristics to achieve thermal protection—mainly hot structure, heat sink structure, and insulated structure—through the material’s thermal absorption and radiation characteristics to dissipate heat. Active solutions use external cooling media to actively take away the heat, the main forms include convection cooling, thin-film cooling, transpiration cooling, etc. The characteristics of passive and active are combined by the semi-passive solution, with a heat pipe structure and ablative structures mainly being included. The three types of thermal protection structures are shown in Figure 1. As aerospace vehicles are moving towards hypersonic speeds, the thermophysical and other related properties of the thermal protection systems are becoming more demanding. The ablative structure in the semi-passive scheme not only has excellent ablative and thermal insulation properties but also has good mechanical properties, making it one of the main thermal protection materials widely used for hypersonic aerospace vehicles. In addition, being structurally lightweight is one of the core principles of thermal protection system design, and weight reduction in aerospace vehicles can bring significant benefits. Therefore, it is of great significance to develop a thermal protection system with light weight, high strength, and an excellent thermal protection effect to promote the development of aerospace vehicles and the aerospace industry [9]. The composite material achieves the effect of ‘1 + 1 > 2’ through the combination of the matrix and the reinforcing phase [10]. According to the different matrix types, composites can be divided into ceramic-matrix, carbon-matrix, and resin-matrix composites [11,12]. Among them, resin-based composites, namely fibre-reinforced plastics, enhance the strength of thermoplastic or thermosetting resins by short or continuous fibres. The density of existing resin-matrix composites is generally between 0.6 and 1.8 g/cm3 [13,14,15], while the density of ceramic-matrix composites is generally above 2.0 g/cm3 [16,17,18]. In contrast, the density of carbon-based composites is lower (up to 0.2 g/cm3) but the moulding conditions are more stringent than those of resin-based and ceramic-based composites (the sintering temperature is greater than 1000 °C), which limits its wide application [19]. Therefore, resin-matrix composites have become one of the most widely used composites in the aerospace industry due to their light weight, high strength, and easy processing [20].

Figure 1.

Three types of thermal protection systems: (a) passive structure; (b) semi-passive structure; (c) active structure [8].

The thermal environment faced by the thermal protection system of aerospace vehicles is more severe than that of ordinary aircraft. How to meet the requirements of being lightweight, improving thermal performance, and achieving synergistic enhancement of thermal performance under the condition of maintaining mechanical properties is the core challenge of the development of thermal protection materials [21,22]. Traditional thermal protective coatings such as ablation coatings and insulation tiles are gradually being replaced by fibre-reinforced resin-matrix composites due to their single function [23]. For example, the wing panel and compartment section of the X-33 Aerospace Vehicle of the United States are designed with bismaleimide-reinforced carbon fibre material, which reduces the mass of the body while ensuring a thermal protection effect [24]. Carbon-fibre-reinforced bismaleimide composites and glass-fibre-reinforced phenolic resin composites are widely used in the fuselage structure of X-37B aircraft. Based on the integrated design of composite support/thermal protection, the structural efficiency of the aircraft has been greatly improved and it has become the most successful reusable aerospace shuttle at this stage [25,26]. It can be seen that fibre-reinforced resin-matrix composites have significant advantages in realising the integration of thermal protection of functional structures and thermal protection materials. However, it is often difficult to achieve a synergistic enhancement of the mechanical properties and thermal properties of materials. Taking resin-matrix composites as an example, the heat resistance of the composites can be significantly improved by physical or chemical modification of the resin. However, the high proportion of resin in the composites and the poor interfacial adhesion between the resin matrix and the fibre-reinforced phase will lead to a loss of mechanical properties of the composites, which then find it difficult to meet the requirements of aerospace vehicles for the basic mechanical properties of the materials. The specific injection pressure regime is as follows: 0.2 M Pa holding pressure for 30 min, followed by pressurisation to 0.4 MPa, and holding pressure for 7 h. Therefore, the mechanical–thermal synergistic enhancement method and mechanism of fibre-reinforced resin-based thermal protection composites are the key technologies and scientific issues in this field.

In this paper, needled preform technology and a pressure-assisted RTM process were used to prepare quartz-fibre-reinforced phenolic-resin-matrix composites. The microstructure, mechanical properties, heat resistance, and ablation properties of the composites were tested. The experimental results show that the pressure-assisted RTM process can effectively reduce the output of voids by means of vacuum and pressurisation. The use of needle-punched preforms as reinforcing materials can overcome the defects of low interlayer performance and easy delamination of two-dimensional materials. The prepared three-dimensional ablation-heat-resistant composite material has improved overall mechanical properties and good ablation resistance and can adapt well to the flight conditions of the projectile. It has important application value in the field of aircraft thermal protection.

2. Experimental Methods

2.1. Raw Materials

Thermoplastic phenolic resin (number average relative molecular mass 2890, softening point 102–105 °C, solid content 36%, density 0.98 g/cm3) was obtained from Beijing Glass Steel Composite Co., Ltd. (Beijing, China). Hexamethylenetetramine and hydrochloric acid (analytically pure) were obtained from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). Quartz fibre 2.5D needle-punched fabric (warp yarn specification: 95tex*4 strands, weft yarn specification: 95tex*6 strands), satin fibre cloth (surface density: 280~300 g/m2) and fibre mesh tire (surface density: 60~70 g/m2) were obtained from Wuhan Xinyutai Optoelectronic Technology Co., Ltd. (Wuhan, China).

2.2. Main Instruments and Equipment

The electronic universal testing machine (TSE105D) was used to test the material’s tensile and compressive properties in accordance with national standards GB/T1447 (China) and GB/T1448 (China). A loading rate of 5 mm/min was used for the tensile and compressive strength tests, while a loading rate of 2 mm/min was adopted in the tensile and compressive modulus tests. The thermal conductivity meter (DTC300) was used during the test, and the temperature range was from room temperature to 200 °C. An oxygen-acetylene ablation testing machine (HDQCS-N, Xi’an HanDa Measurement And Control Technology Co., Ltd., Xi’an, China) was used—the test temperature was 2200 °C, heat flux density was 4160 ± 4160 * 5% kW/m2, and ablation time was 20 s. The thermal characteristics of the prepared sample were analysed by a comprehensive thermal analyser (TGA/DSC) with a flow rate of 50 mL/min. The temperature range was from room temperature to 1000 °C with a heating rate of 10 °C/min.

The structure of the cured phenolic resin was characterised by X-ray diffraction (XRD, Rigaku D/max-2500). The test target material was a copper target, the test scanning angle range was 10–80°, and the scanning speed was 2°/min. Oxygen-acetylene ablation morphology and element analysis were characterised by scanning electron microscopy and energy dispersive spectrometry (SEM-EDS, Hitachi Regulus 8100, Beijing, China), respectively. The testing instruments are shown in Figure 2.

Figure 2.

Testing instruments: (a) electronic universal testing machine; (b) thermal conductivity meter; (c) oxygen acetylene ablation testing machine; (d) comprehensive thermal analyser; (e) X-ray diffraction; (f) scanning electron microscope and energy dispersive spectrometer.

2.3. Preparation of Functional Gradient Weaving Body

The thermoplastic resin fibre was immersed in a mixed solution of 15 wt% HMTA and 18 wt% hydrochloric acid, then heated to 100 °C at 15 °C/h, and held for 1.5 h to obtain a pre-crosslinked phenolic resin. The quartz fibre 2.5D needle-punched fabric/satin fibre cloth/fibre mesh tire was allowed to stand for 2 h, coated with a vacuum bag and tested for air-tightness. It was placed in an 80 °C oven for 1 h and vacuumed for 30 min. The pre-crosslinked phenolic resin was loaded into a glue injection machine and slowly heated to 80 °C. The pre-crosslinked phenolic resin was injected into the performs at vacuum pressure 0.095 MPa, and the infusion was stopped after the resin filled the cavity. The specific injection pressure regime was as follows: 0.2 MPa holding pressure for 30 min, followed by pressurisation to 0.4 MPa, and holding the pressure for 7 h. Thermal protection gradient composite material can be obtained by heating the oven to 120 °C for 2 h and then heating to 180 °C for 4 h.

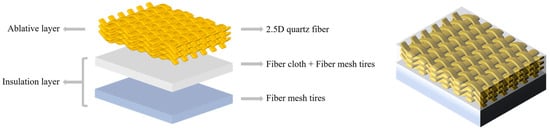

The structure of the thermal protection gradient functional material is shown in Figure 3. The surface layer is 2.5D quartz fibre braid (thickness: 5 mm, fibre volume content: 70%), which adopts the weaving form of a shallow cross-direct connection, and realises the function of high-temperature resistance and erosion resistance. The middle layer (thickness: 5 mm, fibre volume content: 60%) is alternately laid by a layer of fibre cloth and a layer of fibre mesh, which has a significant heat-resistance effect on the high-temperature zone and provides a thermal buffer for the low-density inner layer. The inner layer (thickness: 4 mm, fibre volume content: 50%) is the needle-punched fabric of the fibre web, which has low heat transfer efficiency and achieves efficient heat preservation. In addition, the thermal protection layer and the insulation layer are integrated and formed at the same time, with small density differences and no obvious performance change. The interlayer is connected by reinforced fibres, making the thermal protection material form a whole, greatly improving the material’s ability to resist heat and erosion [27].

Figure 3.

Functional gradient thermal protection design.

3. Results and Discussion

The average density of the gradient composite plate prepared by the pressure-assisted RTM process is 1.05 g/cm3, and the dispersion coefficient is 2.01%. Five different locations on the surface of the plate were selected to measure tensile strength, tensile modulus, compressive modulus, elongation, and density.

3.1. Mechanical Properties

Table 1 shows the mechanical performance test results of the composite material. The tensile strength of the composites is close to 40 MPa, the tensile modulus is higher than 1.35 GPa, the compression modulus is higher than 10 MPa, and the elongation at break is higher than 1.55%, which is much higher than that of the traditional bag-wound carbon cloth phenolic composites.

Table 1.

Mechanical properties of composite materials.

After curing 2.5D quartz braid and phenolic resin to form a composite material, due to the excellent mechanical properties of the braid itself and the excellent interfacial bonding ability between phenolic resin and fibre, the composite material can exhibit better performance than fibre cloth and fibre mesh tire under tensile and compressive conditions.

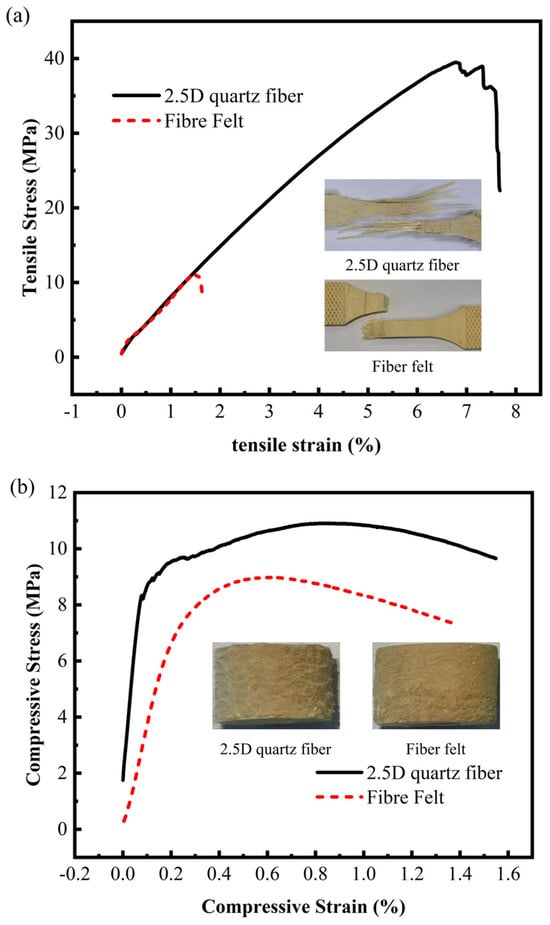

Figure 4a shows the tensile stress–strain curves of the ablation layer and insulation layer of composite material. It can be seen from the diagram that the inflection point of the tensile stress–strain curve of the ablation layer is much higher than that of the insulation layer. Therefore, the tensile strength of the ablation layer is greater than that of the insulation layer, which can be used as the main load-bearing structure. The tensile strain of the ablative layer composite material is less than 0.4%, and the tensile strain of the insulation layer composite material is less than 0.2%, which is the first stage of the tensile fracture process, namely the elastic stage. At this stage, the loading load is relatively small, and the defects or pores in the composite material are not destroyed. The interface layer between fibres and resin is not affected by tension, and after the tensile load disappears, the composite material can be restored to its original state. The tensile strain of the ablative layer composite material is less than 6.6%, and the tensile strain of the insulation layer composite material is less than 1.5%, which is the second stage of the tensile fracture process, namely the yield stage. The slope of the curve gradually decreases with increasing strain during this stage. As the loading load increases, the defects and pores inside the composite material begin to be destroyed, and the pores gradually expand along the tensile direction. The interface layer between fibres and resin gradually separates under tension, resulting in irreversible damage. Subsequently, the material enters the failure stage, where internal defects and pores are continuously stretched, and some pores merge into large pores, resulting in a significant decrease in the material’s load-bearing performance. By observing the failure stage curve of the ablation layer, it is found that the end curve shows ups and downs. With the increase in strain, the stress varies from high to low. This may be because when the ablation layer material starts to break, the resin matrix is pulled apart instantaneously, and the fibres tightly bonded to the resin matrix are not pulled apart the first time. As the strain increases, the fibres gradually straighten until the fibre tensile strength is exceeded and they break, and then the stress decreases significantly.

Figure 4.

Stress–strain curves in tension and compression.

The image in Figure 4a shows the fracture morphology of the tensile specimen, and the fracture surface of the resin matrix is basically flat after the composite material fractures. The fibre does not break at the same time as while the matrix breaks but after the matrix breaks, the fibre residue is connected between the two broken parts due to its good ductility, showing an interlocking state. The fibre at the fracture point is pulled out from the other half of the sample, reaching a maximum length of 59 mm. After the fibre breaks, the end is dispersed into a broom shape. The above phenomenon is also indirectly attributed to the low bonding strength between the warp fibres and the resin matrix. After the matrix is broken, the bonding strength is not enough to withstand a large tensile load, resulting in the pull-out phenomenon. The fibre at the fracture of the heat insulation layer is shorter and denser than those of the ablative layer because the fibre of the heat insulation layer is composed of fibre cloth and fibre mesh. The fibre is not woven, and its tensile properties are poor. After compounding with phenolic resin, it also shows poor tensile properties. When the matrix breaks, the fibre breaks. The image in Figure 4b shows the morphology of the compressed sample of the ablation and insulation layer. A clear 2.5D braided structure can still be observed in the ablation layer after compression, while the structural stratification of the insulation layer is no longer obvious.

Figure 4b shows the compressive stress–strain curves of the ablation layer and insulation layer of the composite material. It can be seen from Figure 4b that when the deformation is less than 0.1–0.24%, the stress–strain curves of the ablation layer and insulation layer are linear, and the material is in the elastic stage. In the elastic stage, the deformation of the ablation layer is less than 0.1%, and the deformation of the insulation layer is less than 0.24%. The elastic stage of the insulation layer is longer than that of the ablation layer, which is due to the composite structure of the fibre cloth and fibre mesh of the insulation layer. Compared with the 2.5D woven surface layer, the insulation layer structure composed of fibre cloth and fibre mesh has a lower density and more pores. The distance between the fibre and resin connection points is large, and a large number of nanopores in the cured insulation layer provides space for material compression, resulting in a longer elastic stage. At this stage, the connection point between the resin adhesive and the fibre gradually deforms under compression but is not destroyed. After the pressure disappears, the composite material can still return to its original state. When the deformation exceeds 0.1–0.24%, the composite material is in the yield stage. As the pressure increases, the connection between the resin matrix and the fibres is greatly damaged, and the resin matrix and fibres are compressed and gradually compacted.

3.2. Thermal Properties

Table 2 shows the thermal properties of the composite material of the ablation layer and insulation layer. The specific heat capacity of the ablation layer and the insulation layer are the same, both of which are 1.05. The larger specific heat capacity makes the composite material absorb part of the heat when heated, reduces the heat transferred to the metal parts, and plays the role of protecting the metal structure well. The thermal conductivity of the insulation layer is 50% lower than that of the ablation layer, and the thermal insulation effect is remarkable. Excellent thermal insulation performance depends on the nanoporous structure formed by the phenolic resin matrix, which can increase the heat transfer path and slow down the heat transfer rate [28]. This structure is more likely to be generated in low-density insulation layers. Compared with the ablation layer of 2.5D braided structures, the nanoporous structure is more distributed, and the anisotropy of the insulation layer is low, resulting in a more uniform distribution of nanopores and smaller spacing between micropores, giving it good heat insulation ability.

Table 2.

Thermal properties of composites.

Although the insulation layer has good insulation ability, the rate of wire erosion and mass loss is higher than that of the ablation layer. The linear ablation rate is 17.4% higher than the ablation layer, and the mass ablation rate is 47.2% higher than the ablation layer. From the density difference between the ablation layer and the insulation layer in Table 2, it can be seen that the density of the ablation layer is higher than that of the insulation layer. The higher the density of the material during ablation, the better the ablation performance. At the same time, good ablation performance is attributed to the 2.5D braiding method, which uses long fibres for interlocking and braiding. Compared with the chopped fibre in the fibre mesh tire, the 2.5D braiding has natural excellent sealing performance and better bonding ability with the resin matrix so the ablation performance is better than that of the insulation layer.

Based on the above thermal properties, it can be seen that there are obvious differences between the ablation layer and the insulation layer. Although use of the ablation layer as a thermal protection material alone can ensure the bearing capacity and ablation resistance of the material, its thermal insulation performance is poor. In this case, the metal parts will produce a high temperature rise, and the decline in various physical properties will affect the overall structural performance of the projectile, and even lead to the failure of the components in the projectile or damage due to excessive heating.

Therefore, it is urgent to find a thermal protection material with excellent load-bearing capacity, ablation ability, and excellent thermal insulation ability. Therefore, this paper proposes a functionally graded material to solve the above problems.

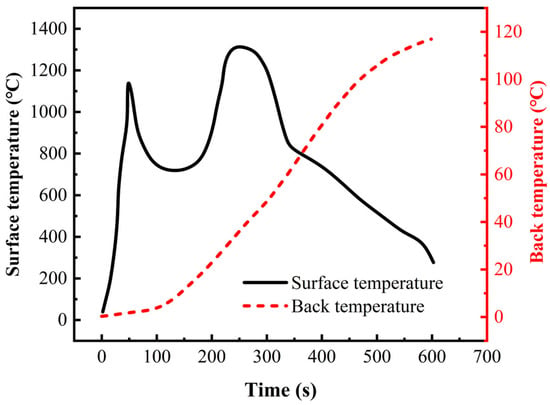

In order to verify the thermal insulation performance of the composite material more intuitively, a wind tunnel ablation test was carried out. Figure 5 shows the surface temperature of the material under wind tunnel ablation conditions and the corresponding metal liner temperature under ablation conditions. The surface temperature of the material is approximately obtained by converting the enthalpy and heat flux experienced by the projectile during flight. After the wind tunnel erosion test for more than 600 s, the material continuously eroded on the surface due to its own pyrolysis and airflow shear force but the erosion thickness was relatively small, and the maximum thickness was less than 1 mm. In the early stage of heating, the temperature rise rate of the back surface of the composite material is very small, and only increased by 3 °C from 0 s to 100 s. In the time from 0 s to 100 s, the surface temperature of the material experienced the first peak, reaching 1200 °C. The surface of the material severely eroded and an open flame is generated. The surface material began to erode under the action of shear force. In the period of 100–450 s, the temperature rise rate on the back of the material increases obviously, and after 450 s, the rise rate decreases slowly. During this process, the temperature of the composite material gradually increases. After reaching the pyrolysis temperature of the resin, the resin begins to decompose to produce small molecule gases such as H2O, CO, CO2, NO2, etc. Due to the low permeability of pyrolysis gases, they cannot overflow the carbon layer and accumulate inside, forming high pressure, resulting in material expansion. As the temperature continues to rise, the quartz fibre begins to melt, and the pyrolysis gas overflows, resulting in a decrease in the density of the carbon layer. Fibre melting and pyrolysis gas overflow can effectively remove heat, especially fibre melting, which accounts for 40% of the total amount of other heat absorption methods and is the main heat preservation method.

Figure 5.

Wind tunnel ablation test surface temperature and metal-back temperature curves.

At the end of the heat load for more than 600 s, the metal liner temperature of the test panel increased by 118 °C. Combined with the effective working temperature of the projectile metal parts (generally not higher than 200 °C), it is considered that the anti-thermal insulation material can meet the flight requirements of the projectile. The ablation amount and back temperature control meet the overall design requirements.

A comparison of the ablation performance and back-temperature rise is shown in Table 3 for several common thermal protection systems. These systems include carbon–carbon composites, ceramic composites, ceramic insulation tile-reinforced phenolic aerogels, and the phenolic resin composites studied in this paper. The results show that carbon–carbon composites have the lowest ablation rate but the fastest back-temperature rise. Moderate performance in terms of both ablation rate and back-temperature rise is demonstrated by ceramic-matrix composites and ceramic thermal tile-reinforced phenolic aerogels. The phenolic-resin-matrix composites employed in this study demonstrate superior ablation rates and exhibit the lowest back-temperature rise during 600-second ablation tests. This indicates that the material combines excellent ablation resistance and thermal insulation properties.

Table 3.

Comparison of ablative properties and back-temperature rise in common thermal protection systems.

3.3. Heat-Resistance Performance

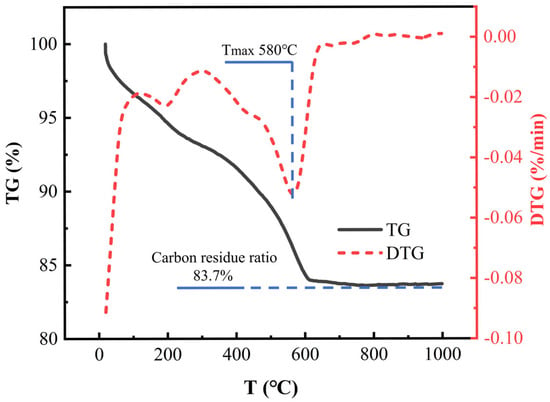

According to the results of the wind tunnel tests, the area where the composite material is ablated and carbonised is only in the ablation layer so the ablation layer was selected for thermogravimetric testing. Figure 6 shows the thermogravimetric curve of the ablated layer of functionally graded composites. When the temperature is higher than the critical temperature of the pyrolysis reaction, the resin matrix undergoes pyrolysis to produce small molecule gases such as H2O, CO, CO2, NO2, etc. After the gases escape from the material, the weight decreases. At a certain temperature, unreacted free formaldehyde, free phenol, and oligomers formed by the reaction in the composite material will also evaporate and escape the material, resulting in a decrease in the weight of the material. When the temperature is below 400 °C, the material loss is caused by the combined effect of matrix pyrolysis and volatile molecule release, resulting in a rapid decrease in the curve. Between 400 and 600 °C, the weight loss is mainly produced by the thermal decomposition of the resin matrix. When the temperature is higher than 600 °C, the mass drop rate declines and is basically in a horizontal state. In the process, the mass loss of the material is mainly caused by the fracture of the C-C bond.

Figure 6.

TG/DTG curve of the ablated layer.

The peak value of the DTG curve (red line) in Figure 6 represents the thermal decomposition rate. The thermal decomposition rate is fastest at 580 °C, and the carbon residue rate is 83.7% at 1000 °C, which is due to the excellent properties of Si-modified phenolic resin. Si is oxidised to SiO2 at high temperatures, and the melted SiO2 covers the surface of the carbonised layer, providing adhesion and protection for the carbonised layer. The molten SiO2 exists in the gap of the carbide layer, and the density of the original porous carbon layer is greatly increased due to the filling of the SiO2, resulting in a decrease in thermal decomposition rate.

3.4. Analysis of Ablation Results of Functionally Gradient Composite Materials

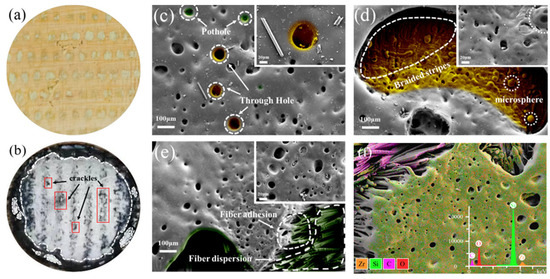

3.4.1. Oxygen Acetylene Ablation Morphology and Mechanism

Figure 7 is the morphology of the oxyacetylene ablation, including macroscopic morphology before and after ablation and scanning electron microscopy images. Figure 7a shows the macroscopic image of the material before ablation, in which the 2.5D braided structure can be clearly seen. The white part is the exposed part of the light crosslinked wavy yarn, and the light yellow part is the colour of the cured phenolic resin matrix. Figure 7b displays a macroscopic image of the material after ablation. The middle part is concave after ablation, and most of the ablation surface is covered by white ceramic melt. The black area around the periphery is the exposed pyrolytic charring layer. Due to the slow formation of ceramic layers on the surface to achieve isolation between the original layer from the environment, material indentation continues to move forward. The white ceramic melt has high density, although due to the thin coating layer, turtle cracks will occur under the action of shear force and during solidification. The turtle cracks are arranged regularly, forming black vertical stripes with equal spacing in an orderly manner.

Figure 7.

Oxy-acetylene ablation topography: (a) macroscopic view before ablation; (b) macroscopic view after ablation; (c–e) scanning electron microscopy after ablation; (f) element distribution.

Figure 7c presents a scanning electron microscope image of the white molten layer after ablation. Macroscopically, the coating layer is smooth and has no pores, although when the size is reduced to 100 μm, many tiny pores are found. Micropores are generated due to the escape of pyrolysis gas from the material. Part of the pores are generated through holes, connecting the outside world with the carbonised layer, and the other part of the pores are closed during the solidification process of the liquid cladding layer and only a depression is formed on the surface of the cladding layer. Figure 7d shows the formation state of the ceramic phase in a micropore of the cladding layer, and the ceramic cladding layer forms transverse and longitudinal intersecting stripes similar to a braided shape. The fringes are also attached to microspheres of different sizes, which may be caused by the high surface energy of the molten material. Figure 7e shows the uncoated fibres in the cladding layer. A small part of the fibres is coated with molten material, and part of the coating layer penetrates into the fibre gap, connecting adjacent fibres like tree branches, which play a certain role in fixing and protecting. However, because most of the fibres are not covered by the fusion layer, the adhesion between fibres is not obvious, and they are easily eroded by hot air flow, resulting in the burning of the material. Figure 7f shows the EDS elemental analysis after ablation. The ceramic cladding layer is mainly composed of C, O, Si, and Zr. The content of C and O is the highest, and the content of Zr is the lowest. According to the analysis, the main components of the ceramic phase materials are SiO2, SiC, and ZrO2, and SiC is formed by the reaction of SiO2 with activated carbon at high temperatures. SiC and SiO2 are excellent heat-resistant materials, which cover or are the carbonised layer in the form of thin films. The content of ZrO2 is very low. As a trace modifier, Zr mainly plays a role in strengthening the ceramic cladding layer. ZrO2 can exist in the ceramic cladding layer in the form of particles, and the cladding layer is anchored on the surface of the carbide layer, which improves the erosion resistance of the material.

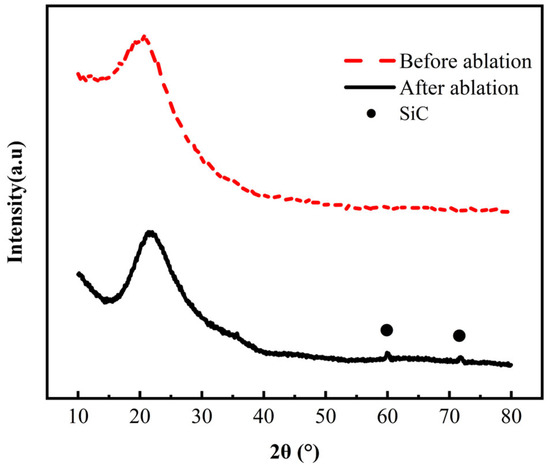

3.4.2. XRD Analysis

The XRD pattern of the functionally graded material surface after ablation at 1200 °C is shown in Figure 8. A new ceramic phase of SiC appears on the surface of the ablated material. A broad diffraction peak appears near 22°, which is generated by the adjacent chains of linear polymers. The diffraction peaks near 60° and 72° indicate the presence of SiC in the ceramic cladding layer. Based on Figure 8, it can be inferred that the cladding layer contains oxygen elements, and the trace amount of Zr element generating ZrO2 is not enough to consume all the oxygen elements. Therefore, it is speculated that the SiO2 element is also present in the cladding layer.

Figure 8.

XRD profile of surface material of functionally graded material after ablation at 1200 °C.

4. Conclusions

Based on the carried-out characterisations, it was found that reinforcement materials (quartz fibre 2.5D needle-punched fabric/satin fibre cloth/fibre mesh tire) and matrix (crosslinked phenolic resin) play a vital role in the mechanical–thermal properties of ablative thermal protection composites. HMTA can be decomposed under acidic conditions and provide sufficient methylene bridge bonds to help form a stable three-dimensional crosslinked network structure. The pressure-assisted RTM process can avoid or reduce the production of pores by means of vacuum and pressure. The use of needle-punched preforms as reinforcing materials can overcome the defects of low interlayer performance. The above process makes the gradient composites show significantly improved tensile strength, tensile modulus, compressive modulus, and elongation at break in terms of tensile and compressive properties, which are significantly better than fibre cloth and fibre web.

The insulating layer exhibits better insulation ability than the ablative layer due to its low density and nanoporous structure, while the ablative layer performs better in ablation performance and can meet the thermal protection requirements under long-term flight conditions. The SiO2 formed by oxidation of the phenolic resin effectively improves the thermal stability of the composites. The SiO2, SiC, and ZrO2 components in the ceramic coating layer together enhance the ablation resistance of the material so that it can resist the harsh high-temperature environment. This study provides a scientific basis and experimental guidance for the design of new high-performance thermal protection composite materials, and it is expected that this study can be applied to the field of high-performance composite materials such as modern aviation and aerospace.

Author Contributions

J.L.: Data Curation, Writing—original draft. W.C.: Conceptualisation, Supervision, Writing—review and editing. J.C.: Funding Acquisition, and Project Administration. All authors have read and agreed to the published version of the manuscript.

Funding

The grant support from the National Natural Science Foundation of China (62404209) and the Key Talent Team for Science and Technology Innovation in Shanxi Province (Grant No. 202204051002023) are greatly acknowledged.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author (chenweixiong@mail.xjtu.edu.cn) upon request.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

References

- Dai, P.; Yan, B.; Han, T.; Liu, S. Barrier lyapunov function based model predictive control of a morphing waverider with input saturation and full-state constraints. IEEE Trans. Aerosp. Electron. Syst. 2023, 59, 3071–3081. [Google Scholar] [CrossRef]

- Zhu, J.; Shi, Z.; Fu, J.; Chen, J. Aerodynamic characteristics of hypersonic airfoils based on jet flow control technology. AIP Adv. 2021, 11, 035036. [Google Scholar] [CrossRef]

- Uyanna, O.; Najafi, H. Thermal protection systems for space vehicles: A review on technology development, current challenges and future prospects. Acta Astronaut. 2020, 176, 341–356. [Google Scholar] [CrossRef]

- Qiao, Y.; Liu, W.; Liu, Z. Design and optimization study of discrete inclined ribs enhanced bend tube based on ‘Diamond’ active cooling thermal protection systems of hypersonic aircraft. Appl. Therm. Eng. 2023, 228, 120526. [Google Scholar] [CrossRef]

- Zhang, W.; Ding, B.; Shi, Z.; Shu, Y.; Sun, F. Investigation of drag reduction mechanism for blunt bodies with plasma spikes. Phys. Fluids 2023, 35, 086115. [Google Scholar] [CrossRef]

- Guo, L.; Pang, L.; Zhao, J.; Yang, X. Optimization of power and thermal management system of hypersonic vehicle with finite heat sink of fuel. Energies 2022, 15, 5332. [Google Scholar] [CrossRef]

- Wang, Z.G.; Liang, J.H.; Ding, M.; Fan, X.Q.; Wu, J.P.; Lin, Z.Y. A review on hypersonic airbreathing propulsion system. Adv. Mech. 2009, 39, 716–739. [Google Scholar] [CrossRef]

- Glass, D. Ceramic Matrix Composite (CMC) Thermal Protection Systems (TPS) and Hot Structures for Hypersonic Vehicles. In Proceedings of the 15th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, Dayton, OH, USA, 28 April–1 May 2008. [Google Scholar] [CrossRef]

- Marley, C.D.; Driscoll, J.F. Optimization of active and passive thermal protection systems for a hypersonic vehicle. J. Aircr. 2022, 59, 173–183. [Google Scholar] [CrossRef]

- Butenegro, J.A.; Bahrami, M.; Swolfs, Y.; Ivens, J.; Martínez, M.Á.; Abenojar, J. Novel Sustainable composites incorporating a biobased thermoplastic matrix and recycled aerospace prepreg waste: Development and characterization. Polymers 2023, 15, 3447. [Google Scholar] [CrossRef]

- Dhanasekar, S.; Ganesan, A.T.; Rani, T.L.; Vinjamuri, V.K.; Rao, M.N.; Shankar, E.; Dharamvir; Kumar, P.S.; Golie, W.M.; Chelladurai, S.J.S. A comprehensive study of ceramic matrix composites for space applications. Adv. Mater. Sci. Eng. 2022, 2022, 6160591. [Google Scholar] [CrossRef]

- Vasile, B.S.; Birca, A.C.; Surdu, V.A.; Neacsu, I.A.; Nicoară, A.I. Ceramic composite materials obtained by electron-beam physical vapor deposition used as thermal barriers in the aerospace industry. Nanomaterials 2020, 10, 370. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.H.; Guo, A.R.; Liu, J.C.; Du, H.Y.; Xian, L.; Wang, Y.; Zhang, S.; Chen, M.; Li, X.; Zhao, J.; et al. Preparation and properties of composite resin/hollow microspheres high temperature buoyancy materials. Mater. Rev. 2021, 35, 2185–2190. [Google Scholar] [CrossRef]

- Liu, J.; Cao, Y.; Qian, Z.; Liu, R.; Zhou, C.; Pan, H.; Zhang, Y.; Niu, B.; Long, D. Preparation and properties of rigid nanoporous phenolic resin-based composites. Acta Mater. Compos. Sin. 2023, 40, 5601–5610. [Google Scholar] [CrossRef]

- Mahmoud, K.G.; Sayyed, M.I.; Almuqrin, A.H.; Arayro, J.; Maghrbi, Y. Monte Carlo Investigation of gamma radiation shielding features for Bi2O3/epoxy composites. Appl Sci. 2023, 13, 1757. [Google Scholar] [CrossRef]

- Bilaç, O.; Duran, C. Mechanical, thermal, and dielectric properties of glass mullite composites for low-temperature cofired ceramic and rodomel applications. Int. J. Appl. Ceramic Tech. 2023, 20, 3287–3296. [Google Scholar] [CrossRef]

- Yuan, X.K.; Xu, B.S. Synthesis and properties of an SiC/SixOyCz discontinuous reinforced ceramic composite. Acta Mater. Compos. Sinica 2007, 24, 104–109. [Google Scholar] [CrossRef]

- Meng, X.L.; Cai, W.; Zhao, L.C.; Zheng, Y.F.; Fan, X.Q.; Wu, J.P. Effect of deformation on the phase transformation and two-way shape memory effect in a Ti-Ni-Hf high temperature shape memory alloy. Rare Metal Mat. Eng. 2005, 34, 355–358. [Google Scholar] [CrossRef]

- Tang, Z.-H.; Xiong, X.; Zhang, H.-B. Effect of carrier gas on bulk density and microstructure distribution of carbon/carbon composites fabricated by thermal gradient chemical vapor infiltration. Carbon 2012, 50, 1243–1252. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Z.; Qin, Y.; Shen, Y.; Zhou, Y.; Wang, D.; Hu, J.; Feng, W. Silicone resin-based composite materials for high thermal stability and thermal conductivity. J. Electron. Mater. 2020, 49, 4379–4384. [Google Scholar] [CrossRef]

- Palmer, G.E.; Henline, W.D.; Olynick, D.R.; Milos, F.S. High-fidelity thermal protection system sizing of reusable launch vehicle. J. Spacecr. Rockets 1997, 34, 577–583. [Google Scholar] [CrossRef]

- Misra, R.K.; Datta, C. Mechanical behavior of unidirectional glass fibers reinforced Resol/VAC-EHA Composites at different volume fraction of fibers. Soft Mater. 2008, 6, 99–118. [Google Scholar] [CrossRef]

- Le, V.T.; Goo, N.S.; Kim, J.Y. Thermomechanical behavior of superalloy thermal protection system under aerodynamic heating. J. Spacecr. Rockets 2019, 56, 1432–1448. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Zhang, D.; Gu, C.H.; Zhao, R.X.; Zuo, X.B.; Tong, L.Y.; Shang, C.Y.; Sun, H.J. Research and application progress of advanced resin matrix composites for aerospace reciprocating vehicle abroad. Acta Mater. Comopositae Sin. 2022, 39, 3029–3043. [Google Scholar] [CrossRef]

- Lei, X.; Xu, G.L.; Yang, J.; Hu, J. Study of molecular structure of water-soluble phenolic resin with different molecular weight by infrared spectrum. Adv. Mater. Res. 2014, 3051, 15–19. [Google Scholar] [CrossRef]

- Jiao, M.; Yang, K.; Diao, Q.; Gong, R.H.; Ren, D.; Cao, J. Effect of monophenol borate on properties of high-ortho phenolic fibers. Fibers Polym. 2017, 18, 875–881. [Google Scholar] [CrossRef]

- Liu, C.L.; Guo, Q.G.; Shi, J.L.; Liu, L. Effect of crosslinking of phenolic fibers on the structure and performance of carbon fibers. Chin. J. Mater. Res. 2006, 20, 245–249. [Google Scholar] [CrossRef]

- Kiskan, B.; Yagci, Y. The journey of phenolics from the first spark to advanced materials. Isr. J. Chem. 2020, 60, 20–32. [Google Scholar] [CrossRef]

- Chinnaraj, R.K.; Hong, S.M.; Kim, H.S.; Oh, P.Y.; Choi, S.M. Ablation experiments of ultra-high-temperature ceramic coating on carbon–carbon composite using ICP plasma wind tunnel. Int. J. Aeronaut. Space Sci. 2020, 21, 889–905. [Google Scholar] [CrossRef]

- Hu, Z.; Yang, F.; Liu, B.; Wang, S.; Wang, Q.; Kuang, G.; Xie, W.; Meng, S. Ablation behavior of gradient ceramic-polymer composites in wind tunnel environment. J. Eur. Ceram. Soc. 2024, 44, 6160–6168. [Google Scholar] [CrossRef]

- Liu, R.; Wang, H.; Hong, C.; Jin, X.; Pan, Y.; Zhang, X. Mechanical and dual-stage wind tunnel ablative behavior of ceramic fiber-tile reinforced phenolic aerogel. Compos. Commun. 2022, 36, 101386. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).