Experimental and Simulation Studies on Bird Strike Impact of Carbon Fiber Composite Laminates with Different Ply Directions

Abstract

1. Introduction

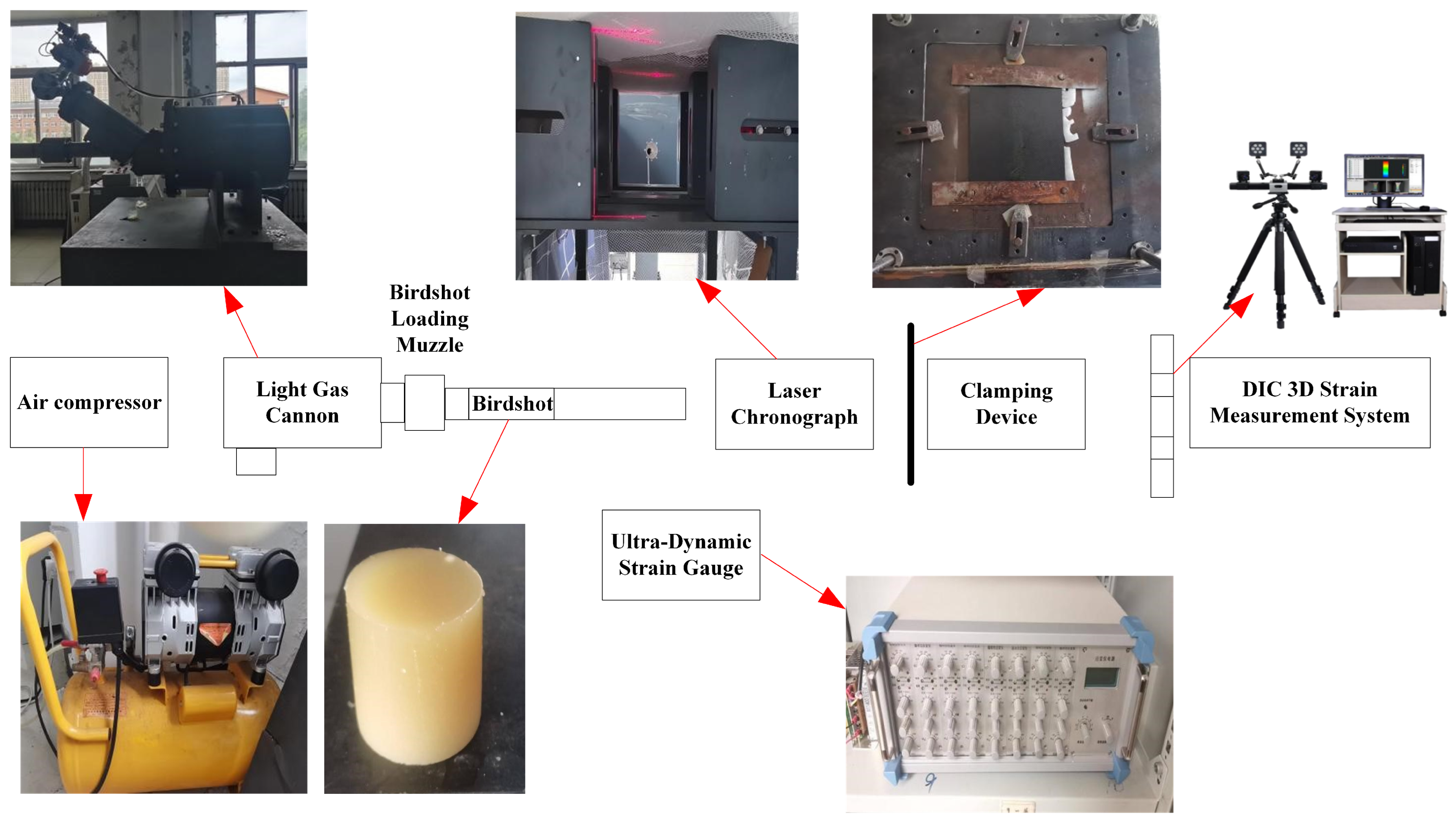

2. Experimentation

2.1. Experimental Scheme

2.2. Experimental Method

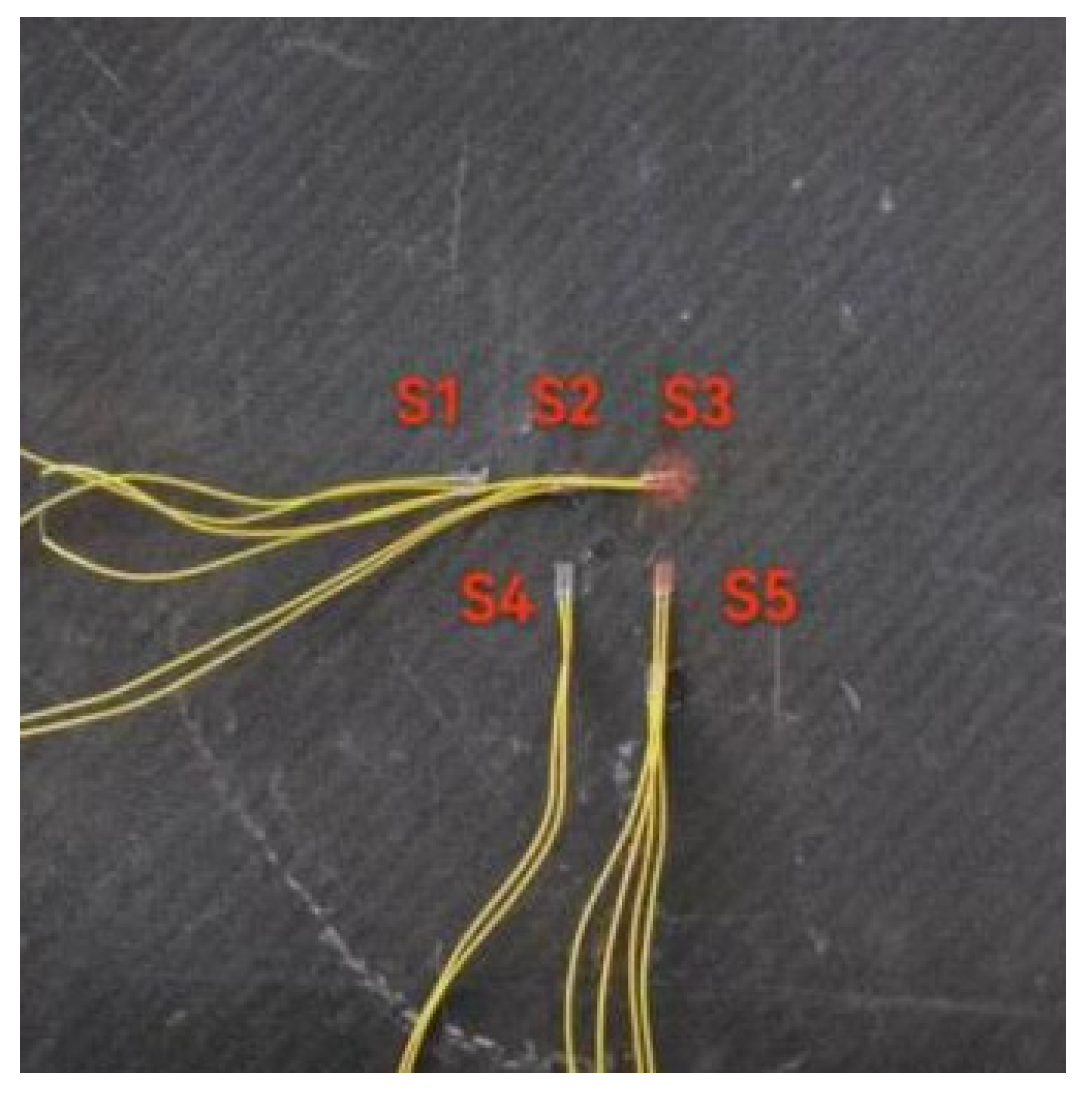

2.3. Strain Gauge

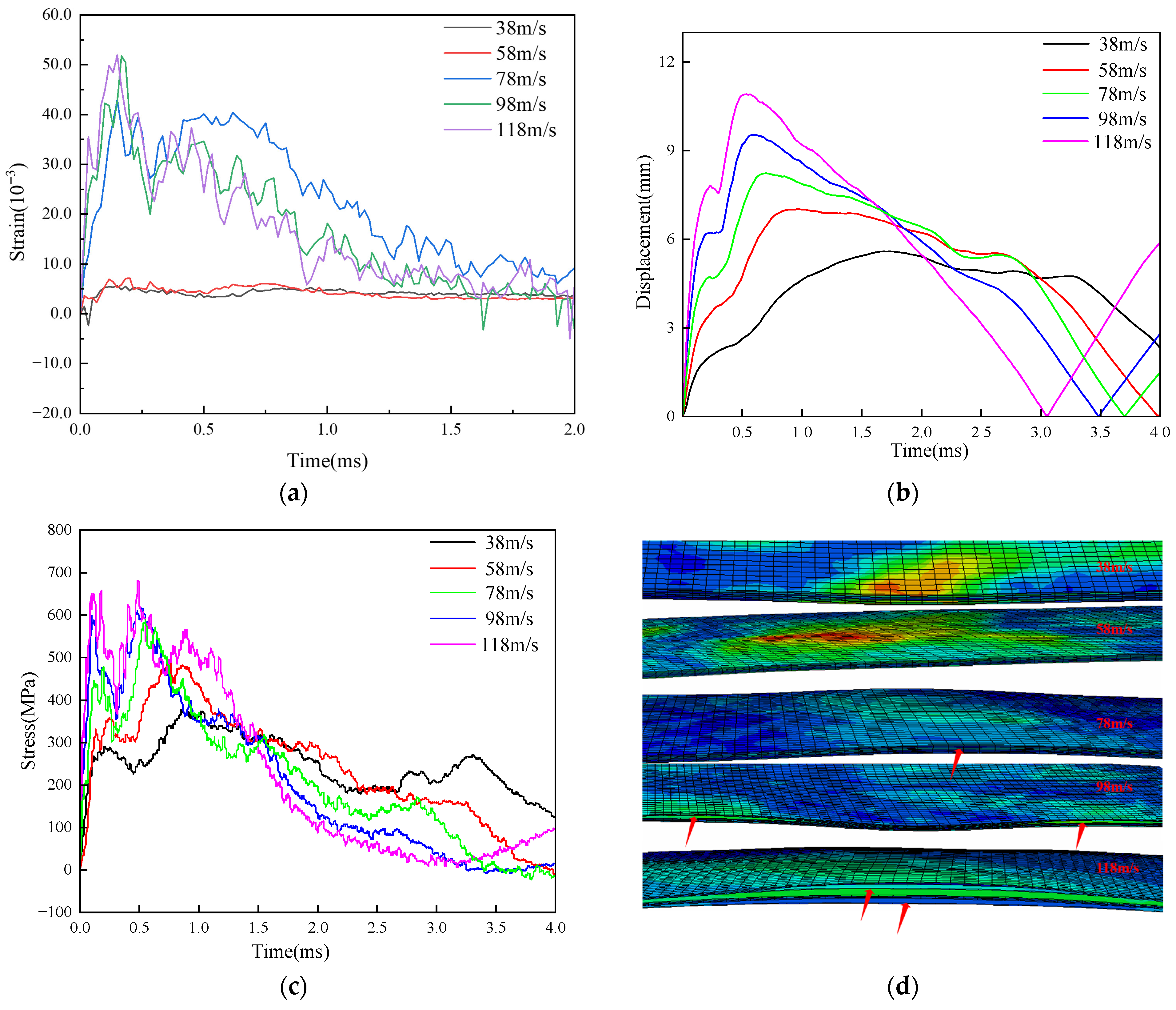

2.4. Experimental Results

3. Simulation Methods

3.1. Bird Collision Impact Simulation Modeling

3.1.1. Bird Bullet Modeling

3.1.2. Bird’s Body Constitutive State Equation

3.1.3. Composite Laminate Modeling

3.2. Composite Material Constitutive Model

In-Layer Stress–Strain Relationship

3.3. Failure Criterion and Damage Evolution Law of Composite Materials

3.3.1. Fiber’s Tension and Compression

3.3.2. Matrix Stretch

3.3.3. Matrix Compression

3.4. Interlayer Cracking Model

3.5. Material Parameters

4. Simulation Results

4.1. Comparison of Experiment and Simulation Results

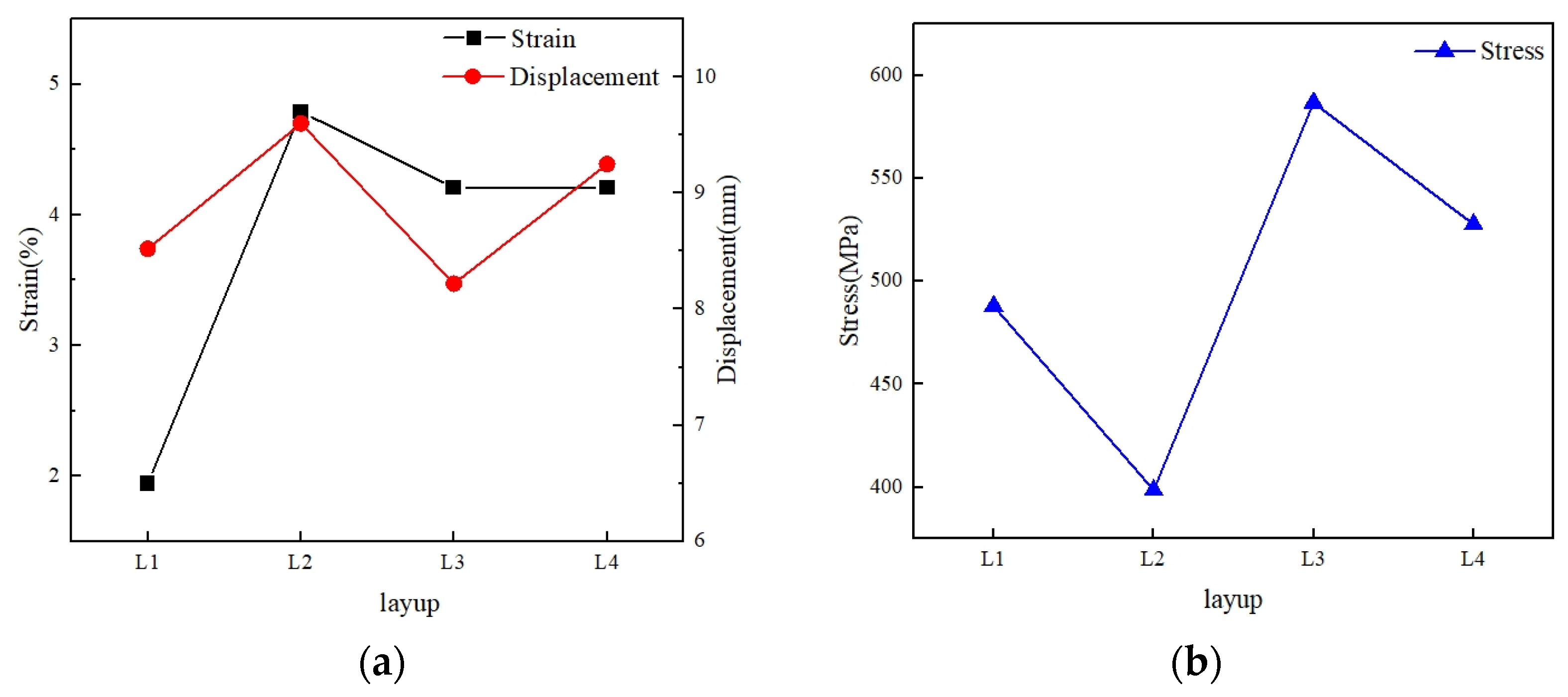

4.2. 115 g Bird Impacts on Different Carbon Fiber Layering

4.3. Influence of Various Impact Angles on Bird Impact

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Georgiadis, S.; Gunnion, A.J.; Thomson, R.S.; Cartwright, B.K. Bird-strike simulation for certification of the Boeing 787 composite moveable trailing edge. Compos. Struct. 2008, 86, 258–268. [Google Scholar] [CrossRef]

- Sebastian, H. Computational methods for bird strike simulations: A review. Comput. Struct. 2011, 89, 2093–2112. [Google Scholar] [CrossRef]

- Li, X.; Wu, L.; Ma, L.; Yan, X. Compression and shear response of carbon fiber composite sandwich panels with pyramidal truss cores after thermal exposure. Mech. Adv. Mater. Struct. 2019, 26, 866–877. [Google Scholar] [CrossRef]

- Rahmani, H.; Mahmoudi Najafi, S.H.; Ashori, A. Elastic Properties of Carbon Fibre-Reinforced Epoxy Composites. Polym. Polym. Compos. 2015, 23, 475–482. [Google Scholar] [CrossRef]

- Shams, S.S.; El-Hajjar, R.F. Overlay patch repair of scratch damage in carbon fiber/epoxy laminated composites. Compos. Part A Appl. Sci. Manuf. 2013, 49, 148–156. [Google Scholar] [CrossRef]

- Yashiro, S.; Ogi, K. Fracture Behavior in CFRP Cross-Ply Laminates with Initially Cut Fibers. Compos. Part A 2009, 40, 938–947. [Google Scholar] [CrossRef]

- Tserpes, K.I.; Labeas, G.N. Mesomechanical analysis of non-crimp fabric composite structural parts. Compos. Struct. 2009, 87, 358–369. [Google Scholar] [CrossRef]

- Wu, B.; Lin, J.; Xie, A.; Wang, N.; Zhang, G.; Zhang, J.; Dai, H. Flocking bird strikes on engine fan blades and their effect on rotor system: A numerical simulation. Aerospace 2022, 9, 90. [Google Scholar] [CrossRef]

- Sun, J.; Liu, M.; Li, N.; Jiang, B.; Guo, Y. Bird strike on aeroengine fan blades: A combined experimental and numerical study. Aerosp. Sci. Technol. 2026, 168, 110955. [Google Scholar] [CrossRef]

- Meguid, S.A.; Mao, R.H.; Ng, T.Y. FEanalysis of geometry effects of an artificial bird striking an aeroengine fan blade. Int. J. Impact Eng. 2008, 35, 487–498. [Google Scholar] [CrossRef]

- Puneeth, M.L.; JayaPrakash, D. Influence of bird mass and impact height on the fan- blade of an aero-engine. Mater. Today 2021, 44, 1028–1038. [Google Scholar] [CrossRef]

- Wu, B.; Hedayati, R.; Li, Z.; Aghajanpour, M.; Zhang, G.; Zhang, J.; Lin, J. Effect of impact and bearing parameters on bird strike with aero-engine fan blades. Appl. Sci. 2021, 12, 7. [Google Scholar] [CrossRef]

- Catalanotti, G.; Camanho, P.P.; Marques, A.T. Three-dimensional failure criteria for fiber reinforced laminates. Compos. Struct. 2013, 95, 63–79. [Google Scholar] [CrossRef]

- Tsai, S.; Wu, E. A general theory of strength for anisotropic materials. Compos. Mater. 1971, 5, 58–80. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A fatigue failure criterion for fiber reinforced materials. Compos. Mater. 1973, 7, 448–464. [Google Scholar] [CrossRef]

- Hashin, Z. Fatigue failure criteria for unidirectional fiber composites. Appl. Mech. 1980, 48, 846–852. [Google Scholar] [CrossRef]

- Chang, F.; Chang, K. A progressive damage model for laminated composites containing stress concentrations. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

- Zhao, G.; Cho, C. Damage initiation and propagation in composite shells subjected to impact. Compos. Struct. 2007, 78, 91–100. [Google Scholar] [CrossRef]

- Riccio, A.; De Luca, A.; Di Felice, G.; Caputo, F. Modelling the simulation of impact induced damage onset and evolution in composites (Article). Compos. Part B Eng. 2014, 66, 340–347. [Google Scholar] [CrossRef]

- Li, D.; Liu, Y.; Zhang, X. Low-velocity impact responses of the stiffened composite laminated plates based on the progressive failure model and the layer wise/solid-elements method. Compos. Struct. 2014, 110, 249–275. [Google Scholar] [CrossRef]

- Meo, M.; Morris, A.J.; Vignjevic, R.; Marengo, G. Numerical simulations of low-velocity impact on an aircraft sandwich panel. Compos. Struct. 2003, 62, 353–360. [Google Scholar] [CrossRef]

- Donadon, M.V.; Iannucci, L.; Falzon, B.G.; Hodgkinson, J.M.; de Almeida, S.F.M. A progressive failure model for composite laminates subjected to low velocity impact damage. Comput. Struct. 2008, 86, 1232–1252. [Google Scholar] [CrossRef]

- Faggiani, A.; Falzon, B.G. Predicting low-velocity impact damage on a stiffened composite panel. Compos. Part A Appl. Sci. Manuf. 2010, 41, 737–749. [Google Scholar] [CrossRef]

- Shi, Y.; Swait, T.; Soutis, C. Modelling damage evolution in composite laminates subjected to low velocity impact. Compos. Struct. 2012, 94, 2902–2913. [Google Scholar] [CrossRef]

- Feng, D.; Aymerich, F. Finite element modelling of damage induced by low-velocity impact on composite laminates (Article). Compos. Struct. 2014, 108, 161–171. [Google Scholar] [CrossRef]

- Liu, P.; Liao, B.; Jia, L.; Peng, X. Finite element analysis of dynamic progressive failure of carbon fiber composite laminates under low velocity impact. Compos. Struct. 2016, 149, 408–422. [Google Scholar] [CrossRef]

- Puck, A.; Schürmann, H. Failure analysis of FRP laminates by means of physically based phenomenological models (Article). Compos. Sci. Technol. 2002, 62, 1633–1662. [Google Scholar] [CrossRef]

- Huang, L.; Tao, Y.; Sun, J.; Zhang, D.; Zhao, J. Assessment of numerical modeling approaches for thin composite laminates under low-velocity impact. Thin-Walled Struct. 2023, 191, 14. [Google Scholar] [CrossRef]

- Miao, H.; Wu, Z.; Ying, Z.; Hu, X. The numerical and experimental investigation on low-velocity impact response of composite panels: Effect of fabric architecture. Compos. Struct. 2019, 227, 111343. [Google Scholar] [CrossRef]

- Rezasefat, M.; Gonzalez-Jimenez, A.; Giglio, M.; Manes, A. Numerical study on the dynamic progressive failure due to low-velocity repeated impacts in thin CFRP laminated composite plates. Thin-Walled Struct. 2021, 167, 108220. [Google Scholar] [CrossRef]

- Ren, R.; Zhong, J.; Le, G.; Ma, W. Research on intralaminar load reversal damage modeling for predicting composite laminates’ low velocity impact responses. Compos. Struct. 2019, 220, 481–493. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, L.; Ying, Z.; Ke, J.; Wu, X. Low-velocity impact performance of hybrid 3D carbon/glass woven orthogonal composite: Experiment and simulation. Compos. Part B Eng. 2020, 196, 108098. [Google Scholar] [CrossRef]

- Huang, C.H.; Lee, Y.J. Experiments and simulation of the static contact crush of composite laminated plates. Compos. Struct. 2003, 61, 265–270. [Google Scholar] [CrossRef]

- Ouyang, T.; Bao, R.; Sun, W.; Guan, Z.; Tan, R. A fast and efficient numerical prediction of compression after impact (CAI) strength of composite laminates and structures. Thin-Walled Struct. 2020, 148, 106588. [Google Scholar] [CrossRef]

- Benzeggagh, M.L.; Kenane, M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 1996, 56, 439–449. [Google Scholar] [CrossRef]

| Name | Parameters |

|---|---|

| Properties of carbon fiber composite material layers | |

| Interlayer properties | η = 1.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Su, C.; Li, F.; Wang, R.; Zhao, X.; Jiang, L. Experimental and Simulation Studies on Bird Strike Impact of Carbon Fiber Composite Laminates with Different Ply Directions. Aerospace 2025, 12, 1017. https://doi.org/10.3390/aerospace12111017

Chen B, Su C, Li F, Wang R, Zhao X, Jiang L. Experimental and Simulation Studies on Bird Strike Impact of Carbon Fiber Composite Laminates with Different Ply Directions. Aerospace. 2025; 12(11):1017. https://doi.org/10.3390/aerospace12111017

Chicago/Turabian StyleChen, Baixu, Changqing Su, Feng Li, Rufeng Wang, Xin Zhao, and Lili Jiang. 2025. "Experimental and Simulation Studies on Bird Strike Impact of Carbon Fiber Composite Laminates with Different Ply Directions" Aerospace 12, no. 11: 1017. https://doi.org/10.3390/aerospace12111017

APA StyleChen, B., Su, C., Li, F., Wang, R., Zhao, X., & Jiang, L. (2025). Experimental and Simulation Studies on Bird Strike Impact of Carbon Fiber Composite Laminates with Different Ply Directions. Aerospace, 12(11), 1017. https://doi.org/10.3390/aerospace12111017