Experimental and Machine Learning-Based Investigation on Forced Convection Heat Transfer Characteristics of Al2O3–Water Nanofluid in a Rotating Hypergravity Condition

Abstract

1. Introduction

2. Experimental System and Reliability Validation

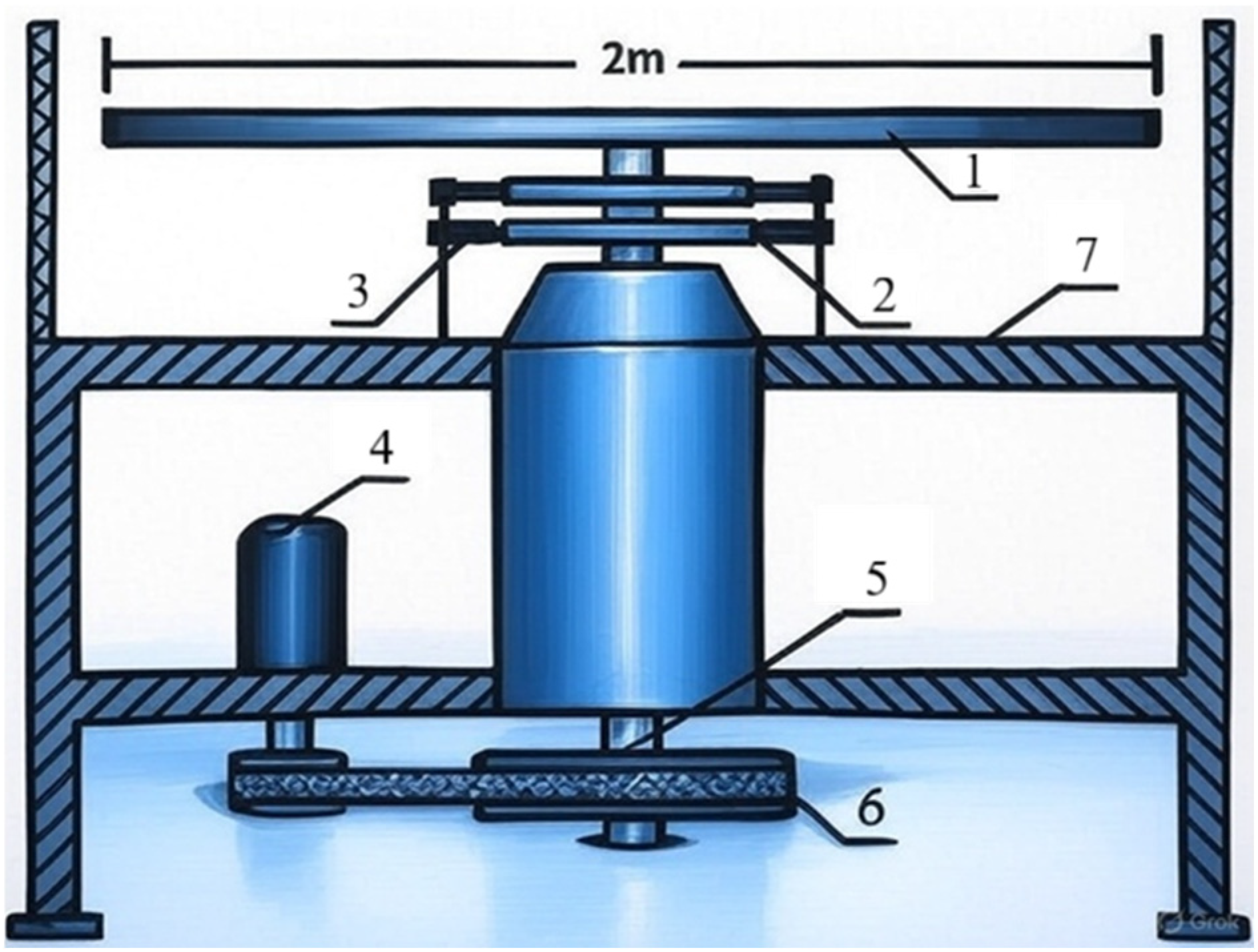

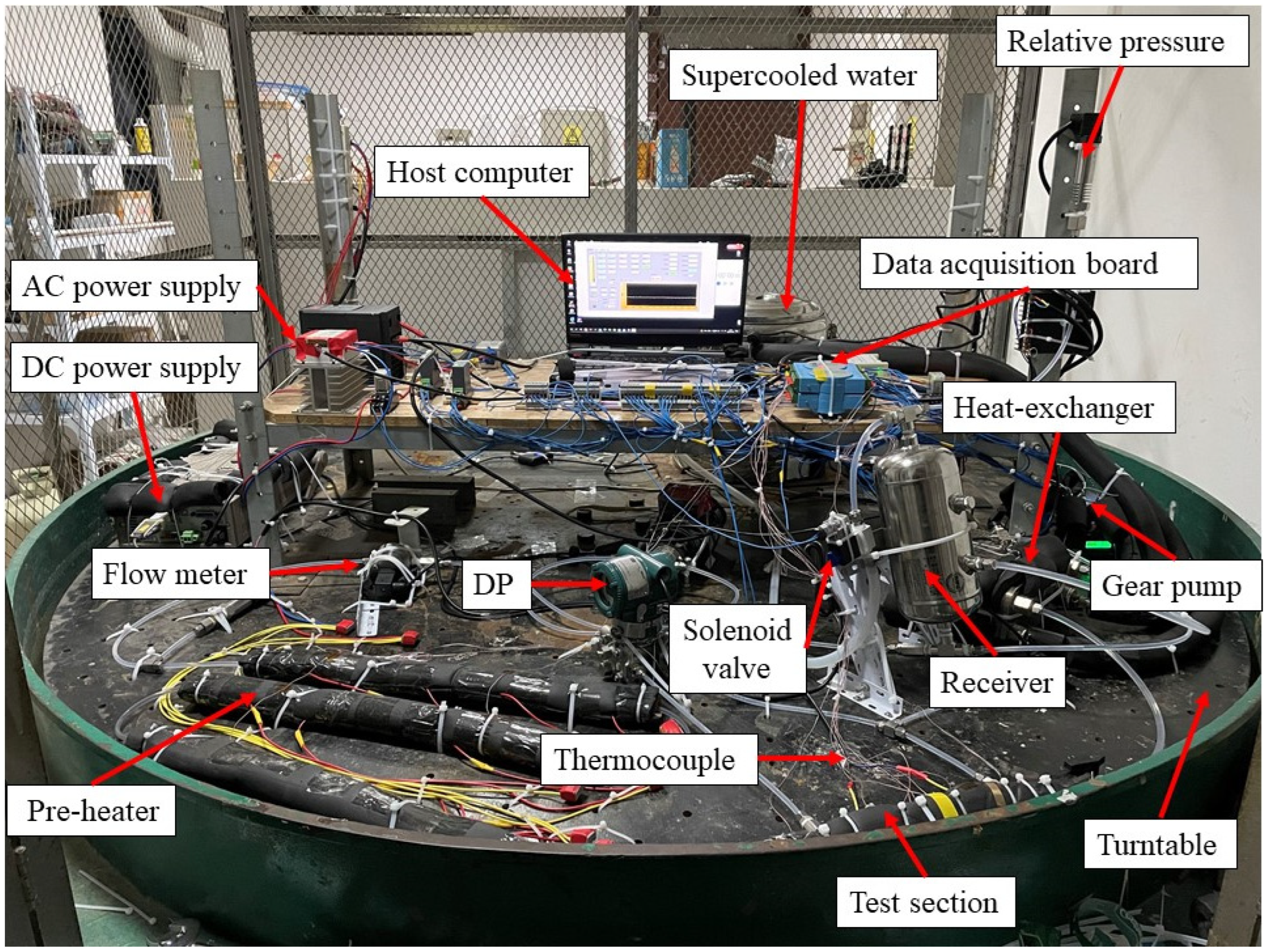

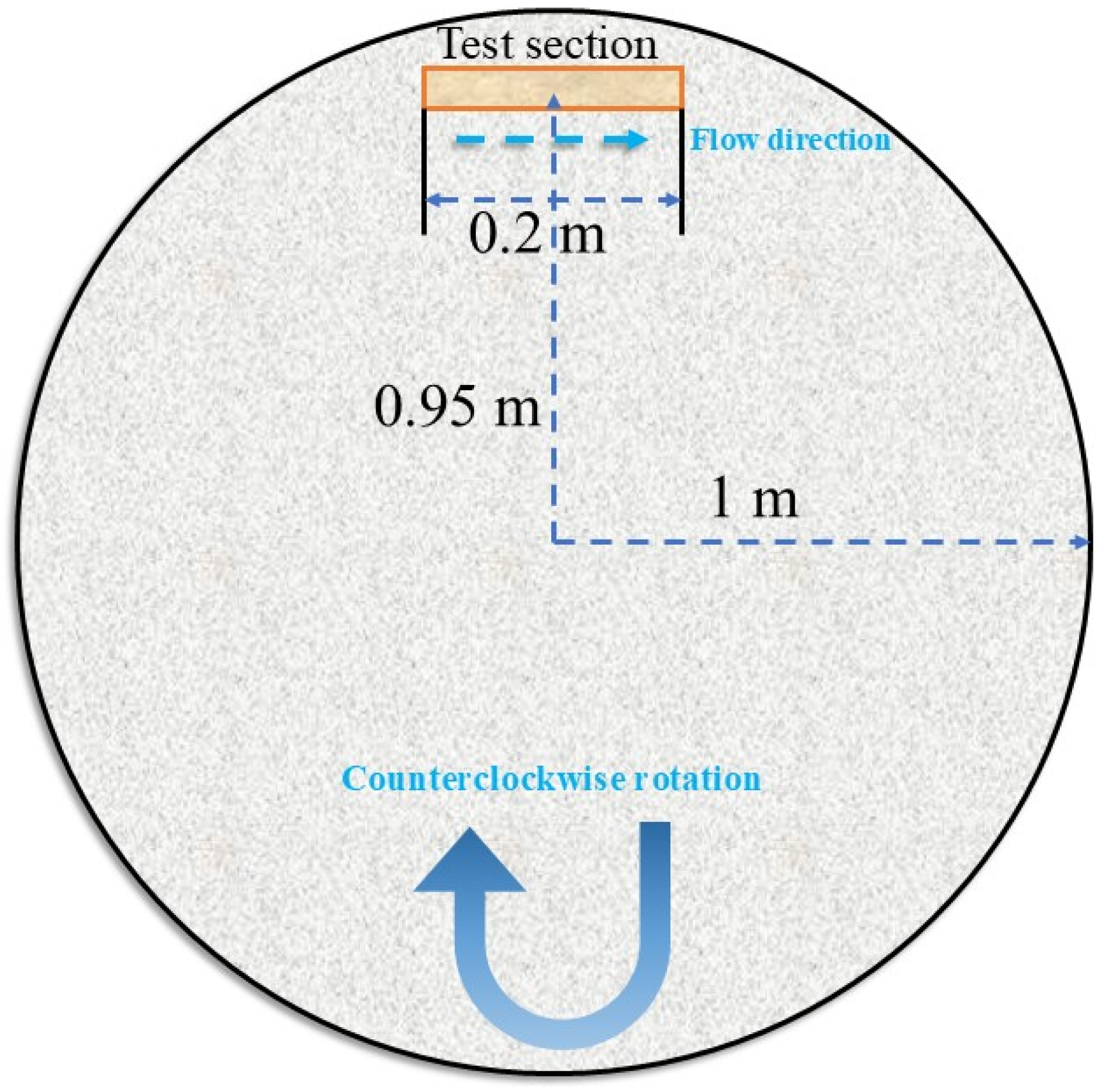

2.1. Centrifugal Accelerating Device

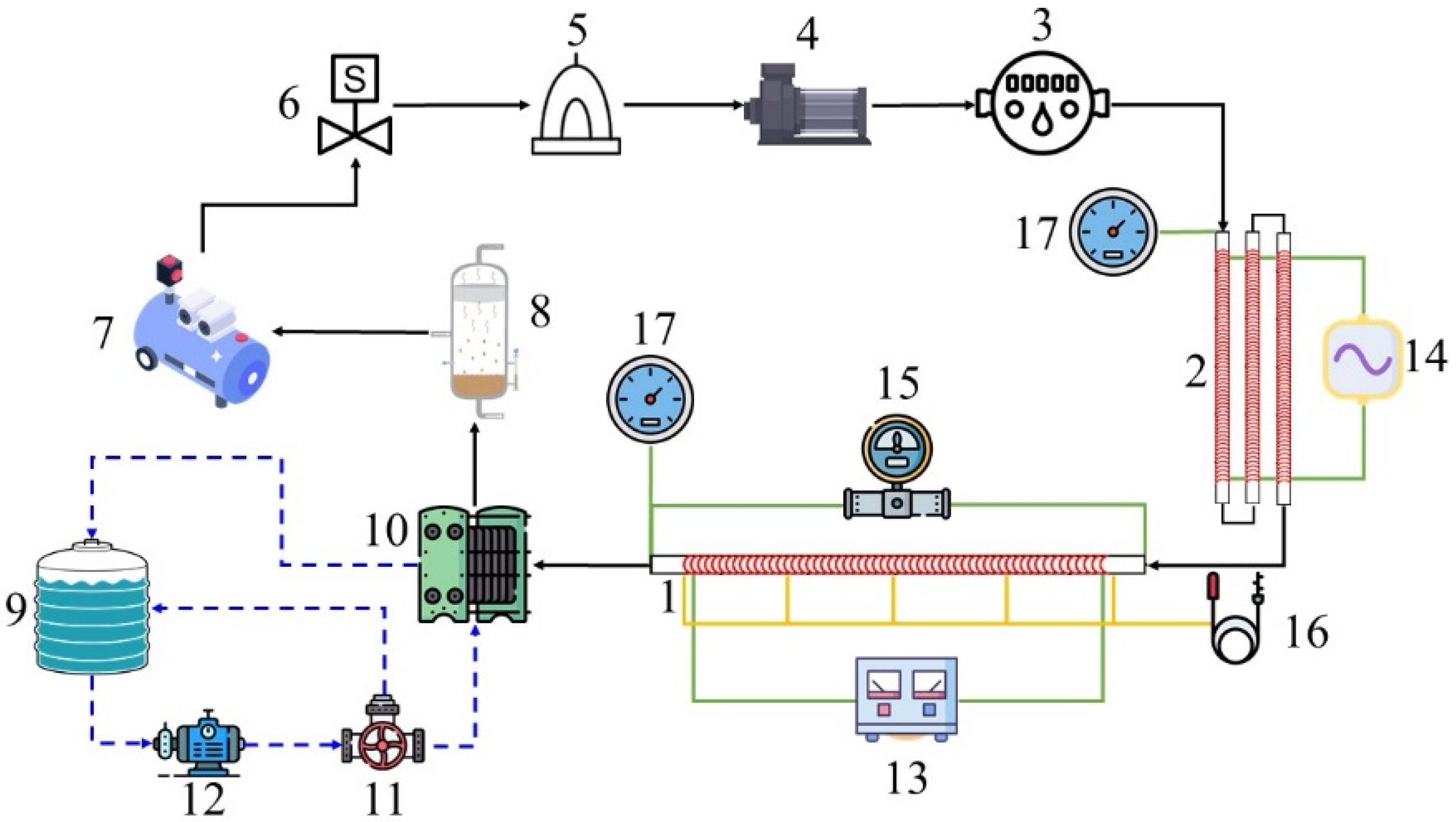

2.2. Flow Circulation System

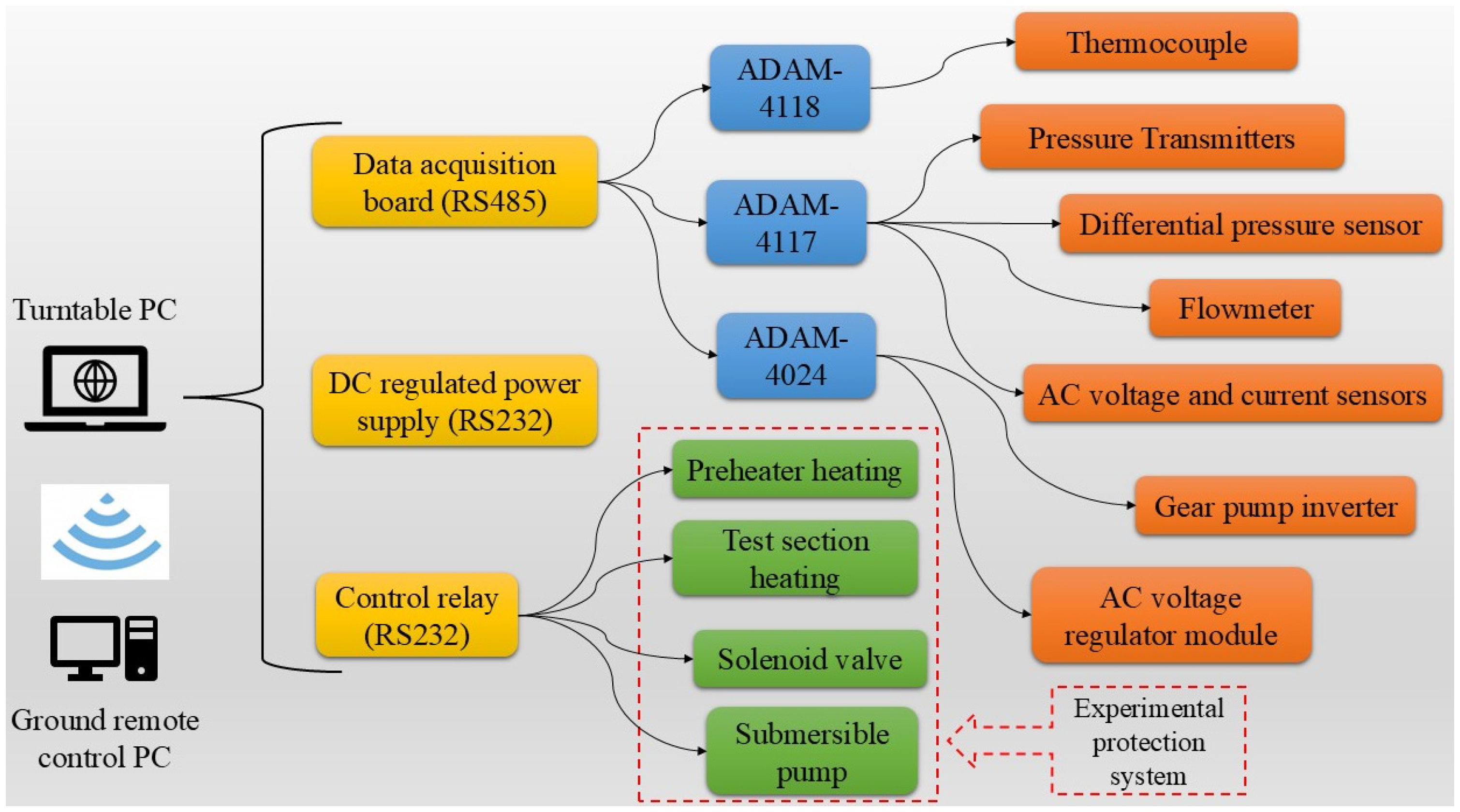

2.3. Data Acquisition and Control System

2.4. Uncertainty Analysis

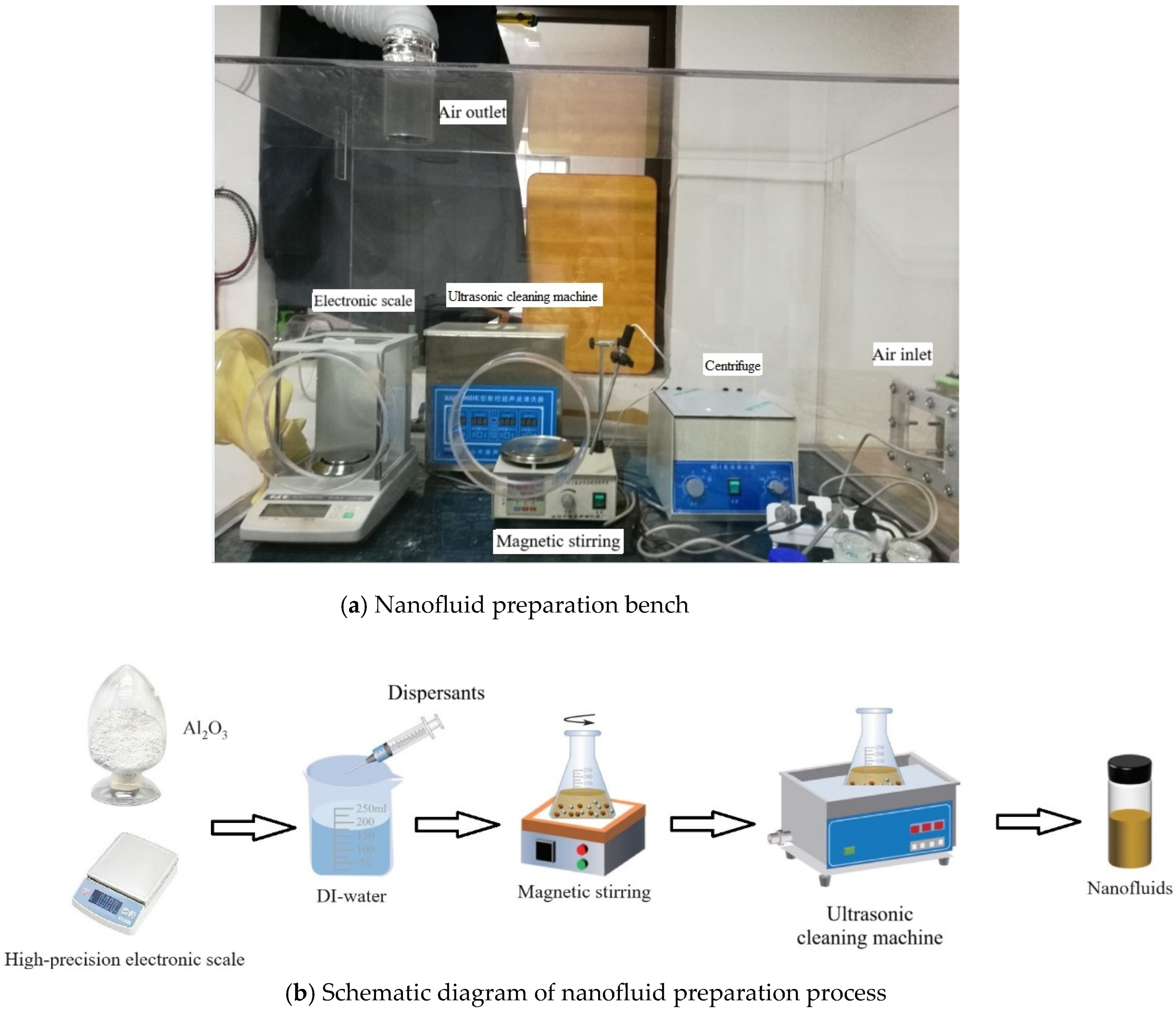

3. Nanofluids Preparation

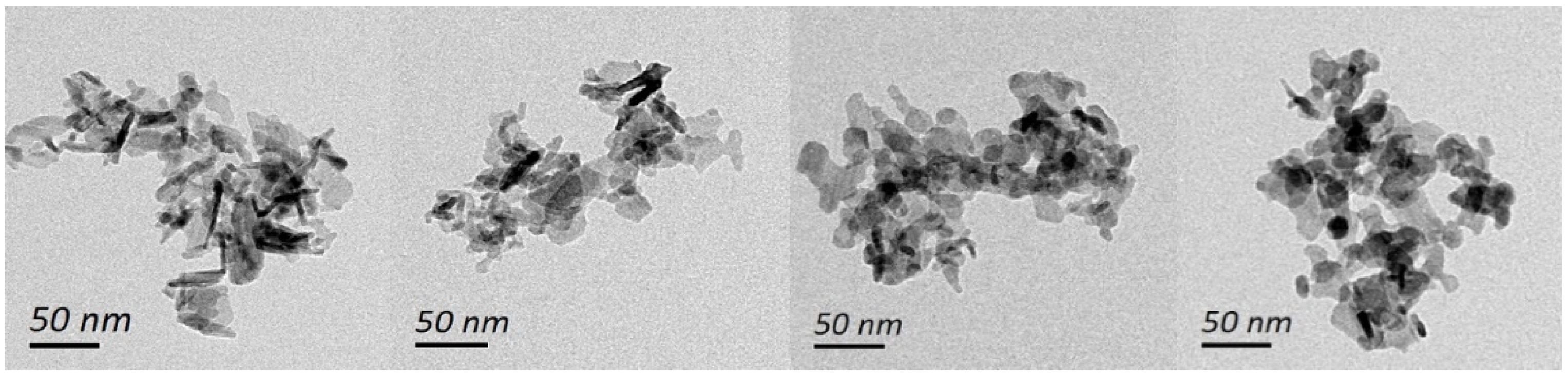

3.1. Materials and Dispersion

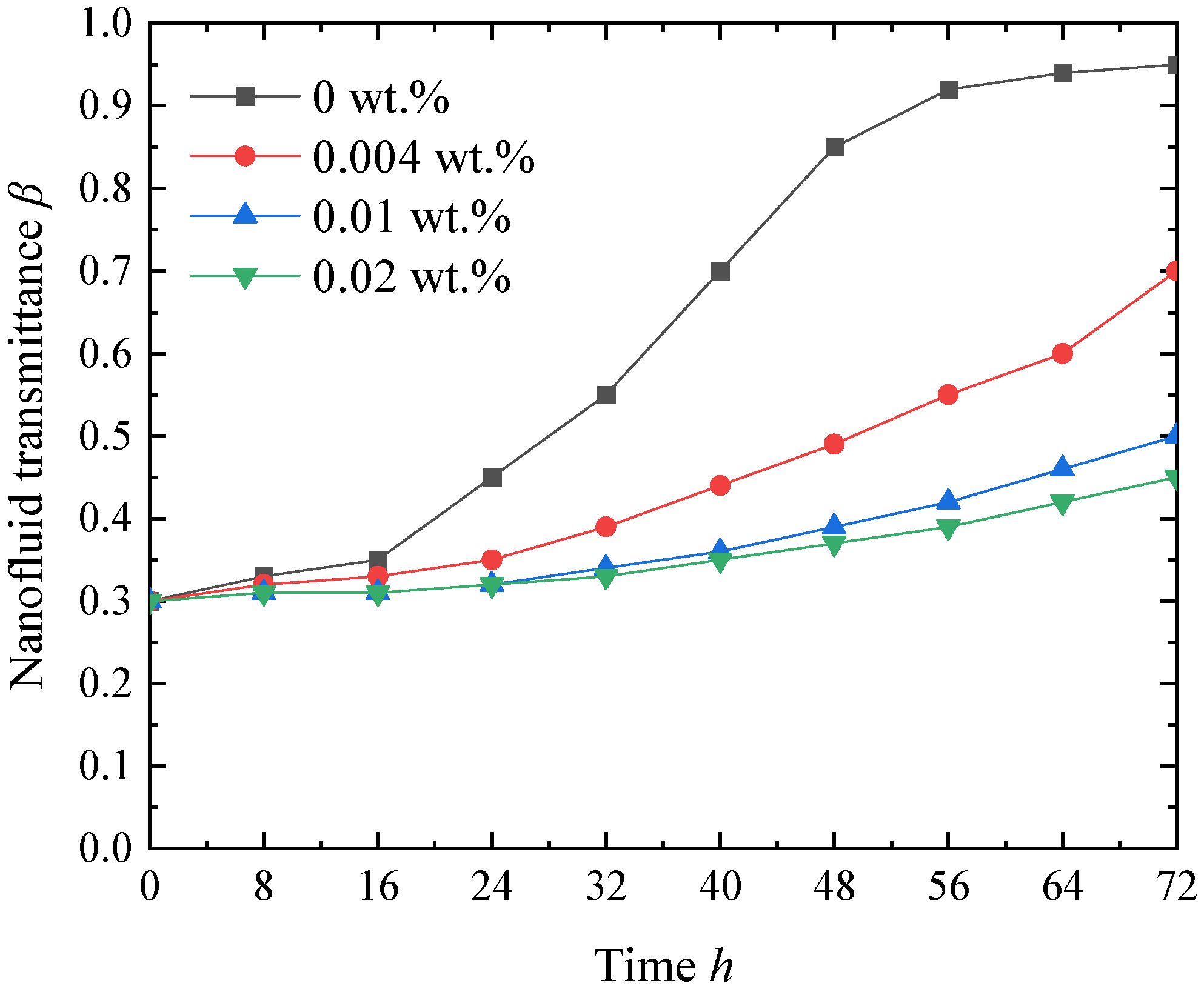

3.2. Stability Validation

3.3. Thermophysical Properties

3.3.1. Density

3.3.2. Specific Heat Capacity

3.3.3. Thermal Conductivity

3.3.4. Viscosity

4. Data Reduction

4.1. Hypergravity Acceleration

4.2. Coriolis Force

4.3. Convective Heat Transfer Coefficient

4.4. Nusselt Number

4.5. Friction Factor

4.6. Pressure Drop

5. Results and Discussion

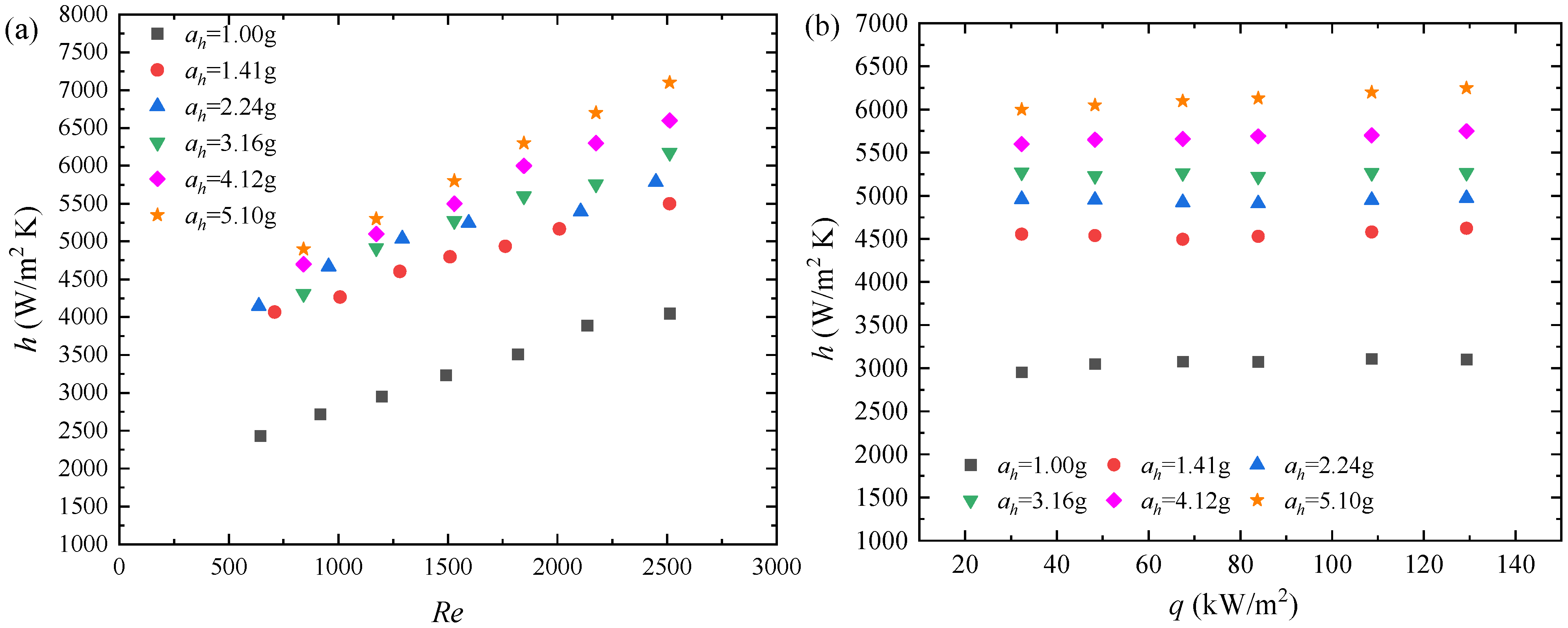

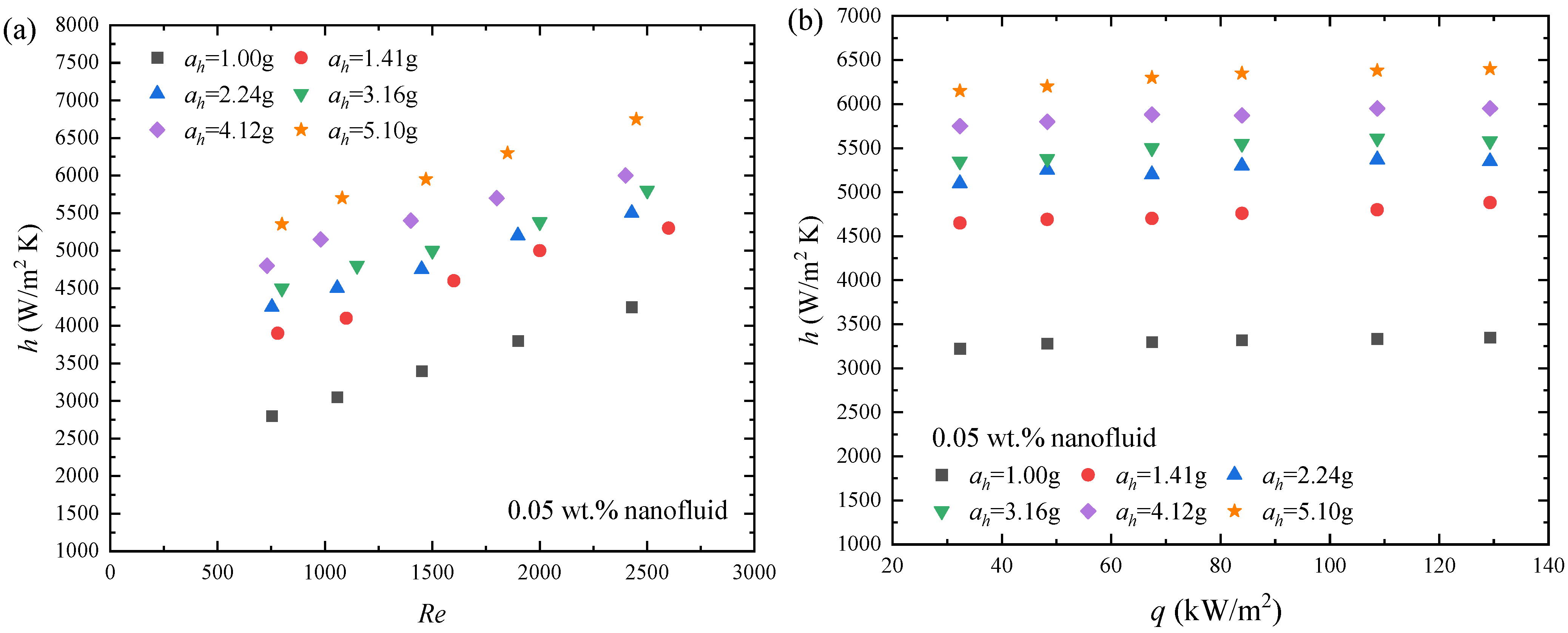

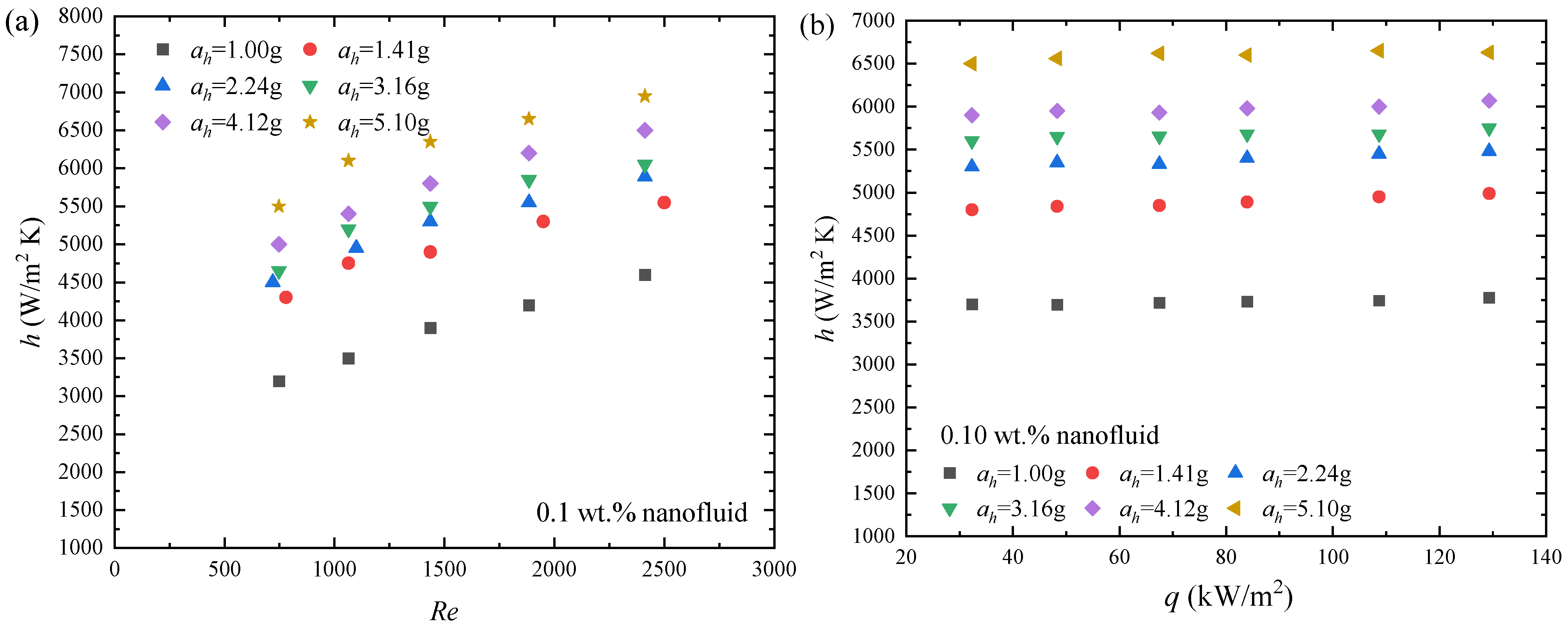

5.1. Effect of Hypergravity Conditions on HTC

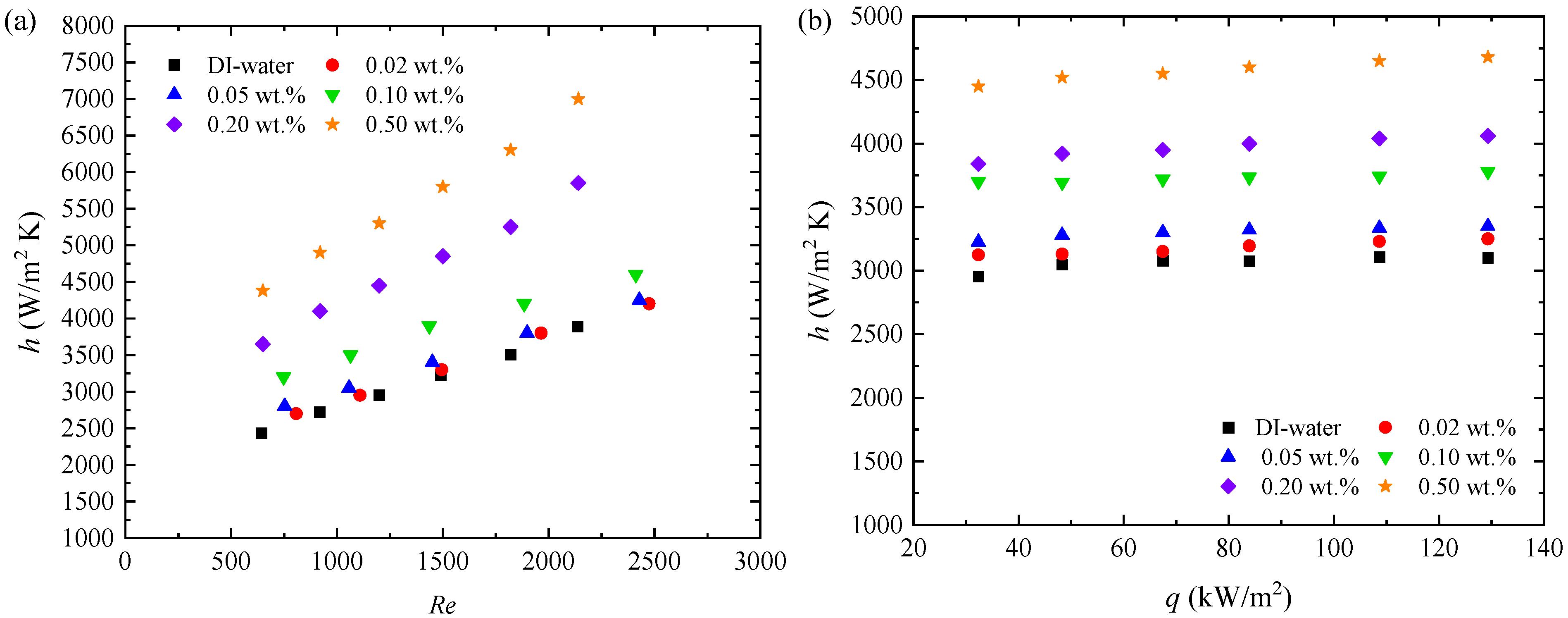

5.2. Effect of Nanoparticle Concentrations on HTC

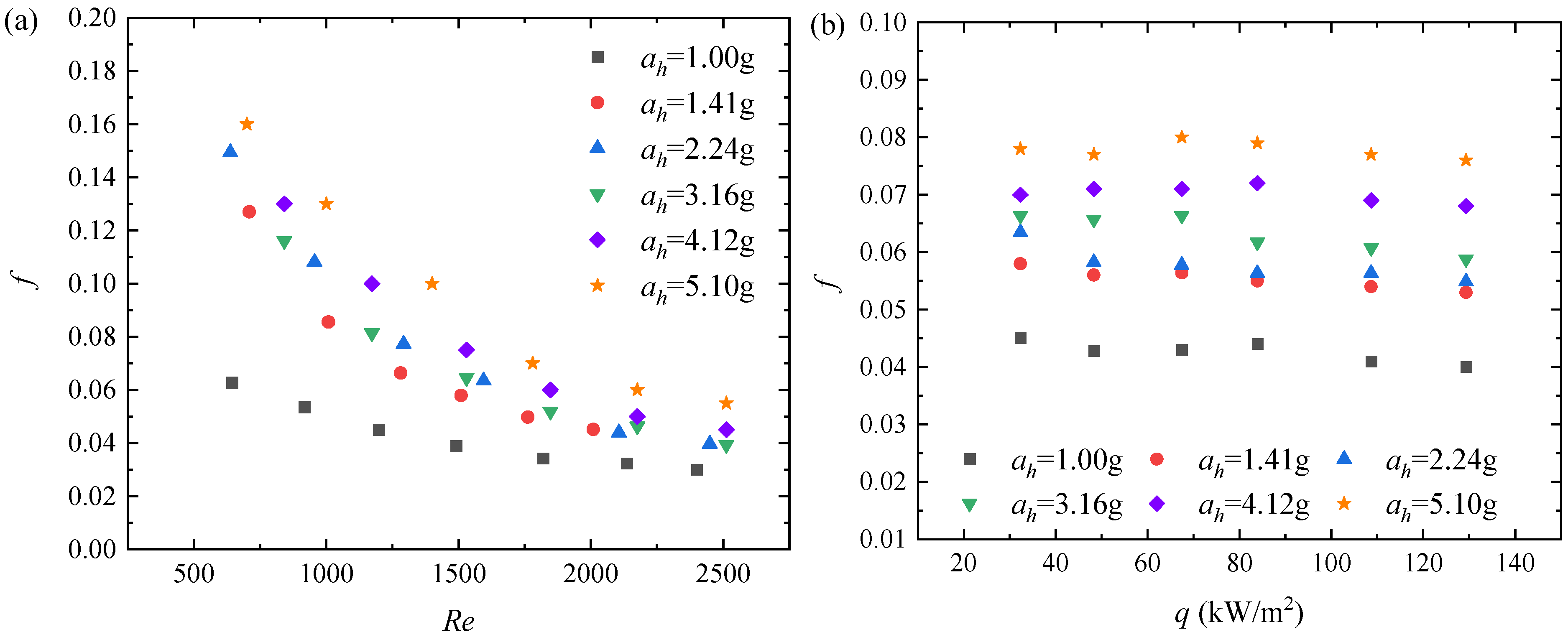

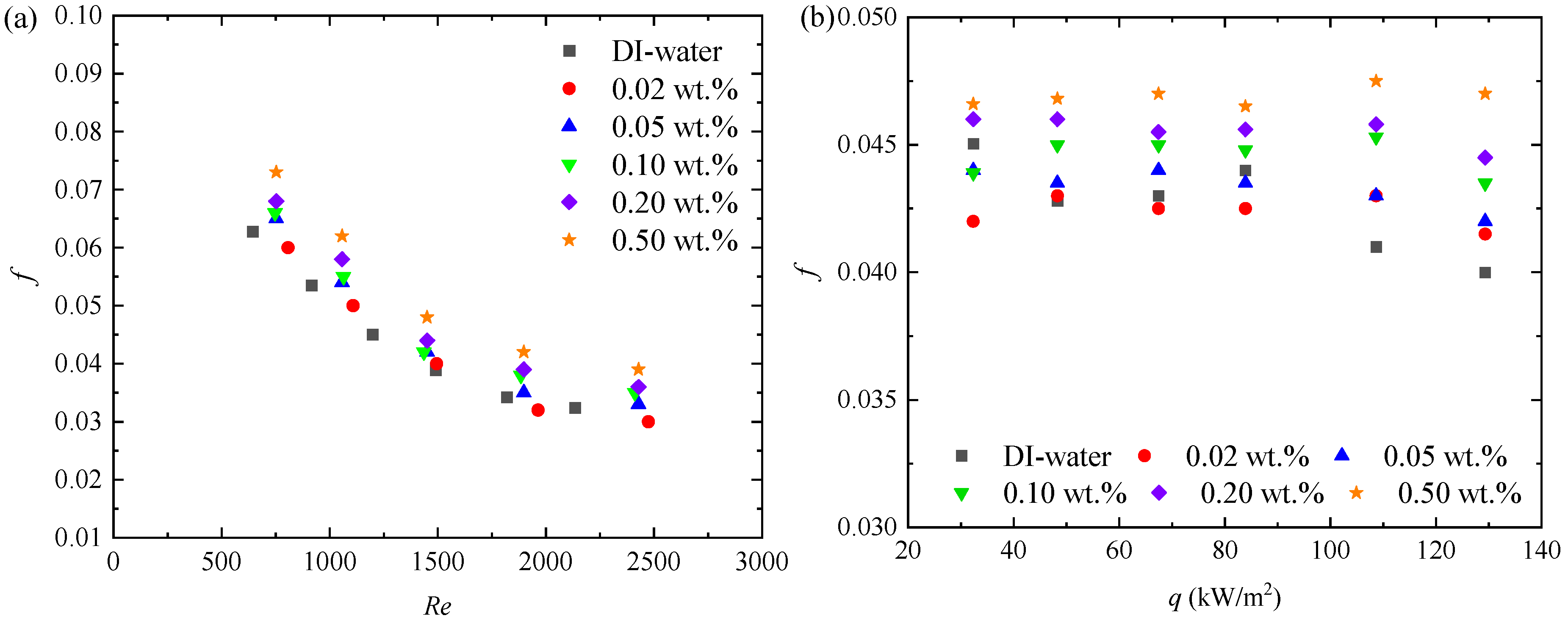

5.3. Variation Trend of Flow Friction Factor Under Different Conditions

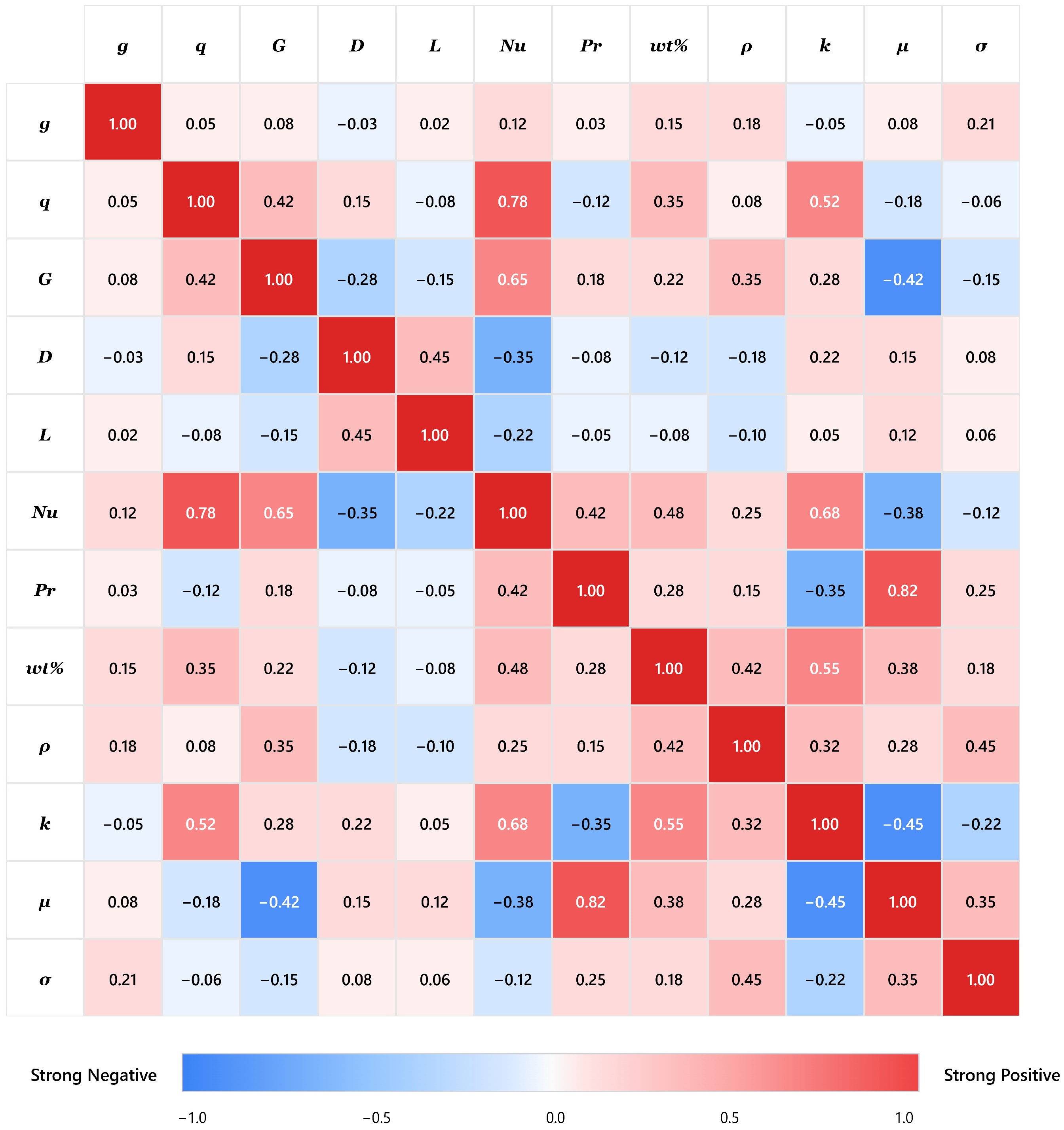

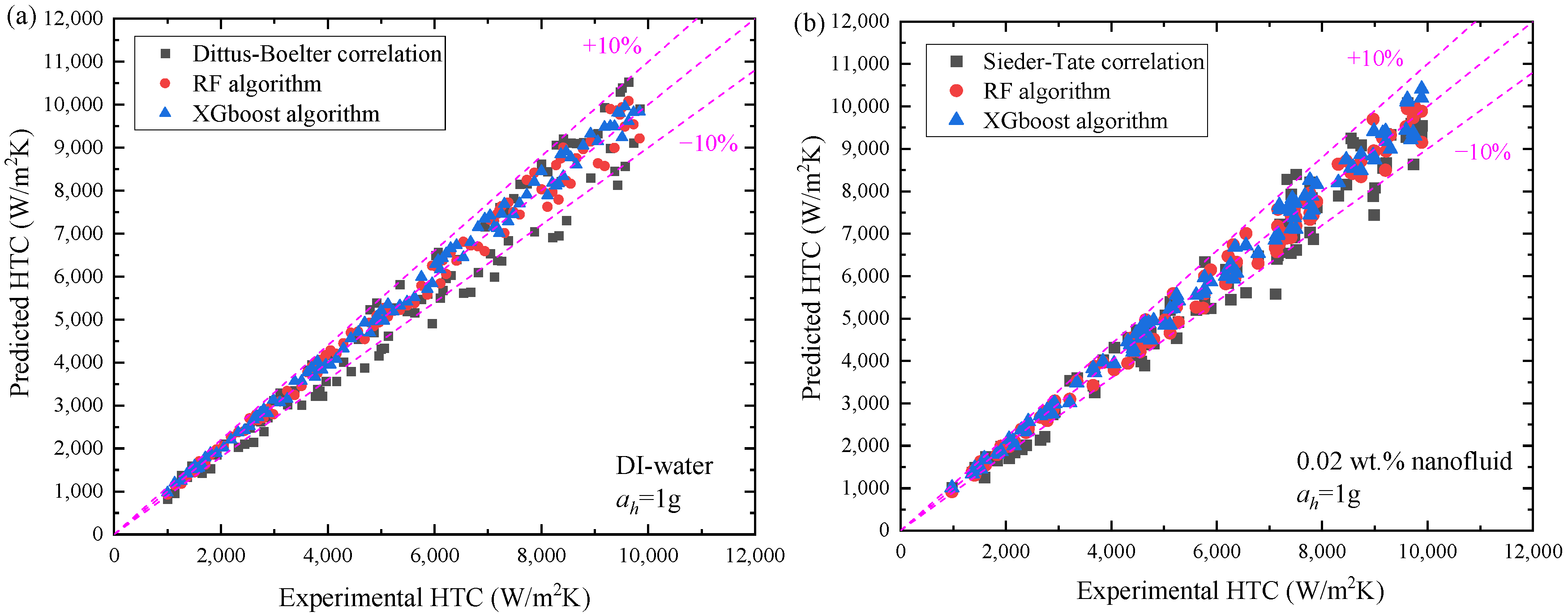

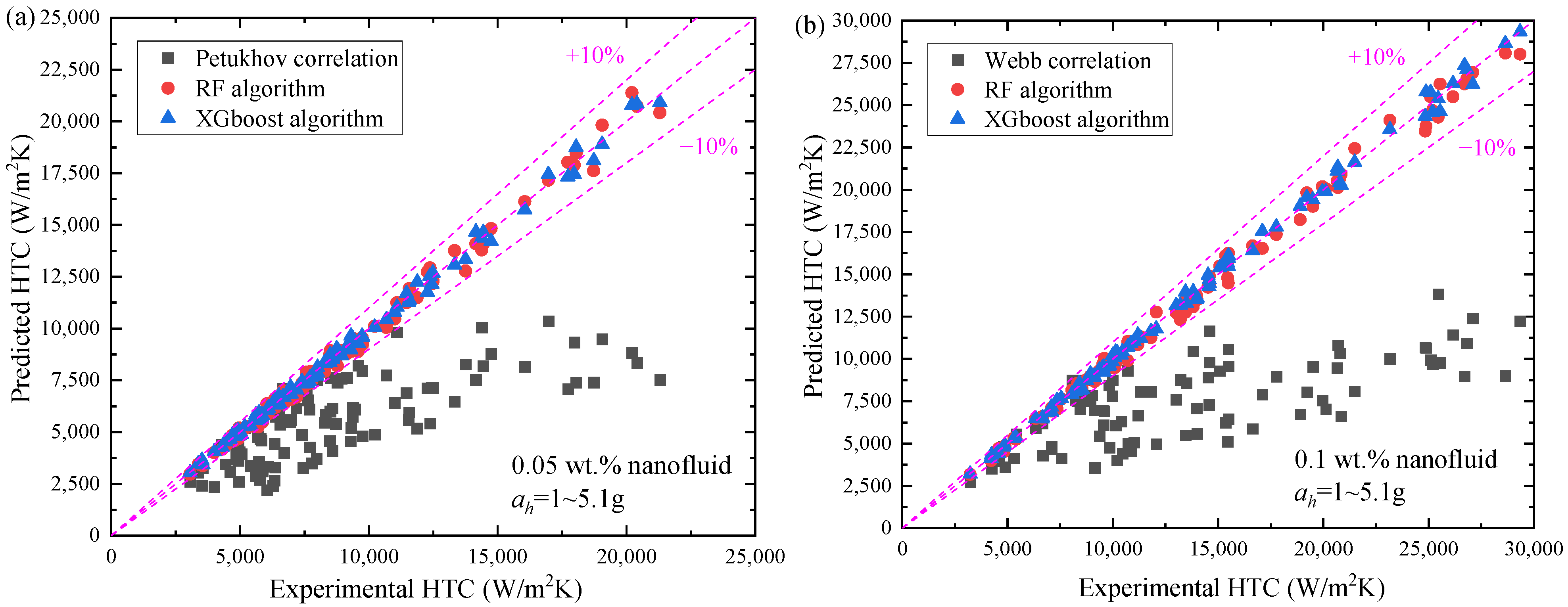

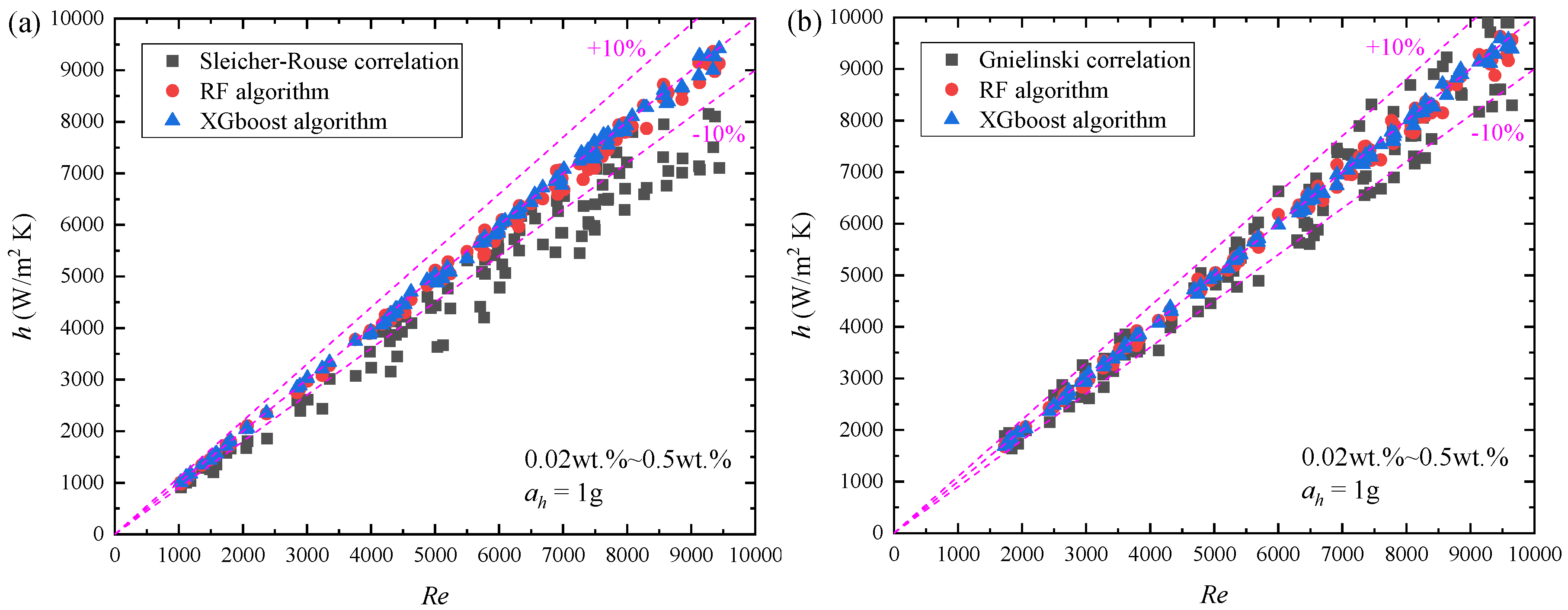

5.4. Comparative Analysis of Existing Correlations and Machine Learning Algorithms

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, Q.; Wang, J.; Li, K.; Wang, X.; Xu, Z.; Zhang, Y. Thermal analysis and thermal management of high power density electric motors for aircraft electrification. Appl. Therm. Eng. 2025, 260, 125006. [Google Scholar] [CrossRef]

- Ouyang, Z.; Nikolaidis, T.; Jafari, S. Integrated power and thermal management systems for civil aircraft: Review, challenges, and future opportunities. Appl. Sci. 2024, 14, 3689. [Google Scholar] [CrossRef]

- Wang, G.; Chen, Y.; Yu, W.; Hu, T.; Su, H.; Zhu, T. Heat transfer characteristics of flat-plate micro heat pipes with integrated copper foam for aerospace thermal management. Appl. Therm. Eng. 2025, 263, 125319. [Google Scholar] [CrossRef]

- Yang, R.; Fan, C.; Li, B.; Zhang, C.; Chen, Y. Role of hypergravity in minichannel flow boiling. Int. J. Heat Mass Transf. 2025, 237, 126429. [Google Scholar] [CrossRef]

- Nobrega, G.; Cardoso, B.; Souza, R.; Pereira, J.; Pontes, P.; Catarino, S.; Pinho, D.; Lima, R.; Moita, A. A review of novel heat transfer materials and fluids for aerospace applications. Aerospace 2024, 11, 275. [Google Scholar] [CrossRef]

- Kadhim, S.; Hammoodi, K.; Askar, A.; Rashid, F.; Wahhab, H. Feasibility review of using copper oxide nanofluid to improve heat transfer in the double-tube heat exchanger. Results Eng. 2024, 24, 103227. [Google Scholar] [CrossRef]

- Muneeshwaran, M.; Srinivasan, G.; Muthukumar, P.; Wang, C. Role of hybrid-nanofluid in heat transfer enhancement–A review. Int. Commun. Heat Mass Transf. 2021, 125, 105341. [Google Scholar] [CrossRef]

- Apmann, K.; Fulmer, R.; Scherer, B.; Good, S.; Wohld, J.; Vafaei, S. Nanofluid heat transfer: Enhancement of the heat transfer coefficient inside microchannels. Nanomaterials 2022, 12, 615. [Google Scholar] [CrossRef]

- Alami, A.; Ramadan, M.; Tawalbeh, M.; Haridy, S.; Abdulla, S.; Aljaghoub, H.; Ayoub, M.; Alashkar, A.; Abdelkareem, M.; Olabi, A. A critical insight on nanofluids for heat transfer enhancement. Sci. Rep. 2023, 13, 15303. [Google Scholar] [CrossRef]

- Guo, Z.; Cheng, L.; Cao, H.; Zhang, H.; Huang, X.; Min, J. Heat transfer enhancement—A brief review of literature in 2020 and prospects. Heat Transf. Res. 2021, 52, 65–92. [Google Scholar] [CrossRef]

- Adio, S.A.; Atofarati, E.O.; Muritala, A.; Huan, Z.; Veeredhi, V.R. Nanofluids flow boiling and convective heat transfer in microchannels: A systematic review and bibliometrics analysis. J. Therm. Anal. Calorim. 2025, 150, 8879–8911. [Google Scholar] [CrossRef]

- Ghasemi, S.; Ranjbar, A. Entropy generation study on natural and forced convection of nanofluid flow in vertical channels. Eng. Rep. 2025, 7, e13096. [Google Scholar] [CrossRef]

- Kamran, M.; Qayoum, A. Effect of silver doping on the forced convection heat transfer of magnetite-based nanofluids in a heated duct. Part. Sci. Technol. 2025, 43, 936–972. [Google Scholar] [CrossRef]

- Nazari, S.; Rezaei, E.; AMoshizi, S. Fluid flow and heat transfer of nanofluids inside helical tubes at constant wall temperature. ASME J. Heat Mass Transf. 2025, 147, 051802. [Google Scholar] [CrossRef]

- Chen, Y.; Li, X.; Fang, X.; He, Z.; Fang, Y. Experimental investigation of critical heat flux of nucleate pool boiling of water and nanofluid on platinum wire under hypergravity and earth gravity. Microgravity Sci. Technol. 2023, 35, 61. [Google Scholar] [CrossRef]

- Mattiuzzo, N.; Berto, A.; Brunetto, G.; Queeckers, P.; Bortolin, S.; Glushchuk, A.; Miscevic, M.; Azzolin, M.; Lavieille, P. Investigating condensation heat transfer and flow pattern of R1233zd (E) in hyper-, micro-and normal gravity conditions. Exp. Therm. Fluid Sci. 2025, 169, 111537. [Google Scholar] [CrossRef]

- Dittus, F.; Boelter, L. Heat transfer in automobile radiators of the tubular type. Int. Commun. Heat Mass Transf. 1985, 12, 3–22. [Google Scholar] [CrossRef]

- Gnielinski, V. On heat transfer in tubes. Int. J. Heat Mass Transf. 2013, 63, 134–140. [Google Scholar] [CrossRef]

- Sleicher, C.; Rouse, M. A convenient correlation for heat transfer to constant and variable property fluids in turbulent pipe flow. Int. J. Heat Mass Transf. 1975, 18, 677–683. [Google Scholar] [CrossRef]

- Liang, X.; Xie, Y.; Day, R.; Meng, X.; Wu, H. A data driven deep neural network model for predicting boiling heat transfer in helical coils under high gravity. Int. J. Heat Mass Transf. 2021, 166, 120743. [Google Scholar] [CrossRef]

- Godasiaei, S.; Chamkha, A. Exploring novel heat transfer correlations: Machine learning insights for molten salt heat exchangers. Numer. Heat Transf. Part A Appl. 2025, 86, 5047–5064. [Google Scholar] [CrossRef]

- Li, W.; Zhang, G.; Yang, D. Comparative study for flow condensation heat transfer in horizontal enhanced tubes based on machine learning. Int. J. Heat Mass Transf. 2024, 224, 125330. [Google Scholar] [CrossRef]

- Kumar, P.; Alruqi, M.; Hanafi, H.; Sharma, P.; Wanatasanappan, V. Effect of particle size on second law of thermodynamics analysis of Al2O3 nanofluid: Application of XGBoost and gradient boosting regression for prognostic analysis. Int. J. Therm. Sci. 2024, 197, 108825. [Google Scholar] [CrossRef]

- Riyadi, T.; Herawan, S.; Tirta, A.; Ee, Y.; Hananto, A.; Paristiawan, P.; Yusuf, A.; Venu, H.; Irianto Veza, I. Nanofluid heat transfer and machine learning: Insightful review of machine learning for nanofluid heat transfer enhancement in porous media and heat exchangers as sustainable and renewable energy solutions. Results Eng. 2024, 24, 103002. [Google Scholar] [CrossRef]

- Godasiaei, S.; Chamkha, A. Advancing heat transfer modeling through machine learning: A focus on forced convection with nanoparticles. Numer. Heat Transf. Part A Appl. 2025, 86, 3409–3431. [Google Scholar] [CrossRef]

- Dong, X.; Knani, S.; Ayed, H.; Mouldi, A.; Mahariq, I.; Alhoee, J. Deep learning with multilayer perceptron for optimizing the heat transfer of mixed convection equipped with MWCNT-water nanofluid. Case Stud. Therm. Eng. 2024, 57, 104309. [Google Scholar] [CrossRef]

- Mishra, A.; Rawat, S.; Yaseen, M.; Pant, M. Development of machine learning algorithm for assessment of heat transfer of ternary hybrid nanofluid flow towards three different geometries: Case of artificial neural network. Heliyon 2023, 9, e21453. [Google Scholar] [CrossRef]

- Li, G.; Zhao, Y.; Zhang, X.; Xie, J.; Fang, X. An Experimental study on the flow boiling heat transfer characteristics of deionized water under rotational hypergravity. Aerospace 2025, 12, 75. [Google Scholar] [CrossRef]

- Kline, S. Describing uncertainties in single-sample experiments. Mech. Eng. 1963, 75, 3–8. [Google Scholar]

- Xuan, Y.; Roetzel, W. Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, B.; Peng, X.; Du, X.; Yang, Y. On the specific heat capacity of CuO nanofluid. Adv. Mech. Eng. 2010, 2, 172085. [Google Scholar] [CrossRef]

- Brinkman, H. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 1952, 20, 571. [Google Scholar] [CrossRef]

- Sieder, E.; Tate, G. Heat transfer and pressure drop of liquids in tubes. Ind. Eng. Chem. 1936, 28, 1429–1435. [Google Scholar] [CrossRef]

- Petukhov, B. Heat transfer and friction in turbulent pipe flow with variable physical properties. Adv. Heat Transf. 1970, 6, 503–564. [Google Scholar]

- Webb, R. Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger design. Int. J. Heat Mass Transf. 1981, 24, 715–726. [Google Scholar] [CrossRef]

- Li, H.; You, H.; You, R.; Tao, Z. Experimental investigation of the secondary flow in a rotating smooth channel subjected to thermal boundary conditions. J. Therm. Sci. 2020, 29, 1463–1474. [Google Scholar] [CrossRef]

- You, R.; Li, H.; Wei, K.; Tao, Z. Two-dimensional heat transfer distribution in a rotating smooth rectangular channel with four surface heating boundary condition. Adv. Mech. Eng. 2017, 9, 168781401773324. [Google Scholar] [CrossRef]

- Wu, S.; Cai, R.; Zhang, L. Nanoparticle dynamics and aggregation behavior in nanofluids: A particle-scale simulation study. Phys. Rev. E 2025, 112, 015103. [Google Scholar] [CrossRef]

- Tsuchiya, H.; Nakamura, N.; Ohta, S. Centrifugal field-flow fractionation enables detection of slight aggregation of nanoparticles that impacts their biomedical applications. Anal. Chem. 2024, 96, 5976–5984. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, Z. Centrifugation-induced stable colloidal silver nanoparticle aggregates for reproducible surface-enhanced raman scattering detection. Biosensors 2025, 15, 298. [Google Scholar] [CrossRef]

- Pyttlik, A.; Kuttich, B.; Kraus, T. Microgravity removes reaction limits from nonpolar nanoparticle agglomeration. Small 2022, 18, 2204621. [Google Scholar] [CrossRef]

| Parameter | Uncertainty |

|---|---|

| Tube diameter, D | ±0.05 mm |

| Tube length, L | ±0.1 mm |

| Rotational speed, n | ±0.5% |

| Temperature, t | ±0.1 °C |

| Pressure, P | ±0.075% FS |

| Mass flux, G | ±5.1% |

| Heat flux, q | ±2.7% |

| Nanoparticle concentration, φ | ±0.01% |

| Reynolds number, Re | ±6% |

| Nusselt number, Nu | ±4.7% |

| Friction factor, f | ±3.8% |

| Hypergravity, ah | ±0.72% |

| HTC, h | ±3.0% |

| Correlations | R2 | MSE (%) | RMSE (%) | MAE (%) |

|---|---|---|---|---|

| Dittus-Boelter | 0.8124 | 182.45 | 13.51 | 10.82 |

| Sieder-Tate | 0.8356 | 156.28 | 12.50 | 9.94 |

| Petukhov | 0.8692 | 121.64 | 11.03 | 8.76 |

| Webb | 0.8458 | 143.85 | 11.99 | 9.48 |

| Sleicher-Rouse | 0.9042 | 89.76 | 9.47 | 7.38 |

| Gnielinski | 0.9215 | 68.92 | 8.30 | 6.52 |

| RF | 0.9658 | 28.14 | 5.31 | 3.85 |

| XGBoost | 0.9812 | 15.68 | 3.96 | 2.74 |

| Correlations | R2 | MSE (%) | RMSE (%) | MAE (%) |

|---|---|---|---|---|

| Dittus-Boelter | 0.5328 | 876.45 | 29.61 | 24.86 |

| Sieder-Tate | 0.5694 | 756.82 | 27.51 | 22.73 |

| Petukhov | 0.6215 | 628.94 | 25.08 | 20.45 |

| Webb | 0.5876 | 692.37 | 26.31 | 21.58 |

| Sleicher-Rouse | 0.6523 | 548.73 | 23.43 | 19.14 |

| Gnielinski | 0.6842 | 485.26 | 22.03 | 17.92 |

| RF | 0.9386 | 72.85 | 8.54 | 6.78 |

| XGBoost | 0.9542 | 52.38 | 7.24 | 5.42 |

| Prediction Model | R2 | MAE (%) |

|---|---|---|

| Dittus-Boelter | 0.8124 | 10.82 |

| Sieder-Tate | 0.8356 | 9.94 |

| RF | 0.9658 | 3.85 |

| XGBoost | 0.9812 | 2.74 |

| Prediction Model | R2 | MAE (%) |

|---|---|---|

| Petukhov | 0.6215 | 20.45 |

| Webb | 0.5876 | 21.58 |

| RF | 0.9386 | 6.78 |

| XGBoost | 0.9542 | 5.42 |

| Prediction Model | R2 | MAE (%) |

|---|---|---|

| Sleicher-Rouse | 0.9042 | 7.38 |

| Gnielinski | 0.9215 | 6.52 |

| RF | 0.9658 | 3.85 |

| XGBoost | 0.9812 | 2.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Z.; Li, G.; Xie, J.; Zhang, X.; Wang, Y.; Fang, X. Experimental and Machine Learning-Based Investigation on Forced Convection Heat Transfer Characteristics of Al2O3–Water Nanofluid in a Rotating Hypergravity Condition. Aerospace 2025, 12, 931. https://doi.org/10.3390/aerospace12100931

Luo Z, Li G, Xie J, Zhang X, Wang Y, Fang X. Experimental and Machine Learning-Based Investigation on Forced Convection Heat Transfer Characteristics of Al2O3–Water Nanofluid in a Rotating Hypergravity Condition. Aerospace. 2025; 12(10):931. https://doi.org/10.3390/aerospace12100931

Chicago/Turabian StyleLuo, Zufen, Gen Li, Jianxun Xie, Xiaojie Zhang, Yunbo Wang, and Xiande Fang. 2025. "Experimental and Machine Learning-Based Investigation on Forced Convection Heat Transfer Characteristics of Al2O3–Water Nanofluid in a Rotating Hypergravity Condition" Aerospace 12, no. 10: 931. https://doi.org/10.3390/aerospace12100931

APA StyleLuo, Z., Li, G., Xie, J., Zhang, X., Wang, Y., & Fang, X. (2025). Experimental and Machine Learning-Based Investigation on Forced Convection Heat Transfer Characteristics of Al2O3–Water Nanofluid in a Rotating Hypergravity Condition. Aerospace, 12(10), 931. https://doi.org/10.3390/aerospace12100931