Abstract

Hydrocarbon fuels are extensively employed as coolants in the regenerative cooling systems of scramjet engines. However, the pyrolytic coking of hydrocarbon fuels at high temperatures introduces complex adverse effects on the flow and cooling processes. In this study, a numerical model was developed to investigate the coupling processes of fluid flow, heat transfer, pyrolysis and pyrolytic coking in the heated tube, under both a constant outer wall heat flux of 1.8 MW/m2 and a constant outer wall temperature of 1150 K. The multi-step pyrolytic reaction mechanism and the kinetic coking model were applied to simulate the pyrolytic coking processes of RP-3. The results reveal that the amounts of catalytic coking and lateral growth exhibit significant differences in magnitude, as well as in their spatial and temporal variations. Under a constant outer wall heat flux, coking evidently increases the outer wall temperature and thermal resistance, leading to a narrowed flow passage and a reduction in the residence time and RP-3 conversion rate. Under a constant outer wall temperature, coking decreases the heat absorption flux, resulting in a lower fluid temperature, which primarily affects the efficiency of the endothermic pyrolytic reaction. The results obtained in this research can provide practical insights for the development of regenerative cooling technology.

1. Introduction

High-efficiency thermal protection represents a critical technical challenge for scramjet engines and is essential for the development of hypersonic vehicles. Regenerative cooling technology has been extensively utilized for this purpose. Prior to entering the combustor, the hydrocarbon fuel carried by the aircraft serves as the coolant, flowing through the cooling channels of high-temperature structures [1]. In addition to functioning as a physical heat sink, the pyrolytic reactions of hydrocarbon fuel absorb a substantial amount of heat [2]. However, certain products of the pyrolysis process act as coking precursors, leading to surface coking within the cooling channel [3]. The coking layer reduces heat transfer between the fluid and the wall, while the flow area of the passage undergoes continuous changes during the coking process. These factors adversely affect both the flow dynamics and the cooling performance.

The complicated flow and heat transfer of RP-3, a typical hydrocarbon fuel, in heated tubes have aroused widespread concern among researchers over recent decades. Through extensive experimental and numerical studies, a comprehensive and in-depth understanding of RP-3 has been achieved, encompassing its thermophysical properties, flow resistance, empirical correlations for convective heat transfer and the onset of heat transfer deterioration under supercritical pressures [4,5,6,7,8,9,10,11]. Based on experimental measurements of the main pyrolysis products, Jiang et al. [12] established a multi-step molecular kinetic model applicable to high-conversion RP-3 pyrolysis, formulating a mathematical description of the pyrolytic chemical reactions of RP-3. This pyrolytic reaction model has been widely employed by researchers to numerically investigate the pyrolysis of RP-3 in channels with different conditions and configurations, as well as its influences on flow and heat transfer characteristics [13,14,15,16].

Some olefins and aromatic products generated during pyrolysis act as coking precursors and undergo dehydrogenation. Catalyzed by certain metal elements on the wall, coking precursors form filamentous fibrous coke, known as catalytic coking [17,18]. Additionally, coke particles in the fluid deposit on the tube surface or adhere to the filamentous fibrous coke, known as non-catalytic coking or the lateral growth mechanism [17,19]. In recent years, with the development of regenerative cooling technology in advanced scramjet engines and the expansion of operating temperature ranges, many researchers have conducted experimental measurements for pyrolytic coking of RP-3 at higher temperatures. These studies mainly focused on observations of coking morphology [20,21], the distributions of pyrolytic coking under different conditions [20,21,22], and methods of coking inhibition [23]. Liu et al. [20] developed a series of kinetic models of RP-3 coking based on different coke precursors and the coke deposition data from their experimental measurements. These models can predict the pyrolytic coking rate on the wall considering the effect of the coking precursor concentration, local wall temperature and operating time. Through continuous years of study, Xu and Meng [24] incorporated the pyrolytic coking kinetic model proposed in reference [20] into numerical simulations to predict the distribution of RP-3 coke deposition in a long straight circular pipe over short durations, validating the reliability of the coking model. Building on this approach, they further investigated the pyrolytic coking behavior of RP-3 in an artificially roughened tube [25]. Wang et al. [16] conducted numerical simulations to investigate RP-3 flow in U-bend pipes and compared the surface coking amount in U-bend and straight pipes. Gong et al. [26] numerically predicted the coke deposition distributions of RP-3 in cooling channels at various aircraft acceleration rates. However, the impact of coking on these steady-state solutions is considered negligible, since the coking thickness in these works is relatively thin. Feng et al. [27] numerically studied the coupled heat transfer process between RP-3 and wall coking layers with a specific uniform thickness under different inlet Reynolds numbers and turbulence intensities.

Existing investigations on the pyrolytic coking of RP-3 in heated tubes have achieved significant progress. However, experimental research is constrained by limitations related to conditions and techniques, making it difficult to dynamically measure all relevant physical parameters in the fluid region during the coking process. Although the development of pyrolytic coking models for RP-3 has led to a growing number of numerical studies in recent years, most of these studies simplify the actual problem. The harsher thermal challenges linked to scramjet engines mean that the hydrocarbon fuel is exposed to larger temperature variations and more complex physicochemical phenomena during the cooling process. Therefore, the complex interactions between convective heat transfer and the dynamic behavior of pyrolytic coking of RP-3 cannot be studied separately in practical applications.

Over the past decade, focusing on RP-3, our research group has dedicated much effort to the development of surrogate prediction models for thermophysical properties, numerical simulation algorithms, and convective heat transfer characteristics [28,29,30,31,32]. In the second part of the series, particular emphasis was placed on the heat transfer mechanism between the pyrolysis and flow of RP-3 in heated tubes [33]. Building upon this foundation, in this paper, a three-dimensional numerical study of the in-tube flow and convective heat transfer of RP-3 with pyrolytic coking is presented. The multi-step pyrolytic reaction mechanism and the kinetic coking model were integrated into the numerical simulation to model the pyrolytic coking of RP-3. The coupled phenomena of heat transfer, pyrolysis and surface coking were investigated over a 20 min period under both constant wall heat flux and wall temperature conditions. As the third part of this series, the present study provides novel insights into the impacts of coke deposition on flow fields, heat transfer efficiency, and endothermic pyrolysis, which could provide a theoretical foundation for the design of thermal protection systems in scramjet engines.

2. Numerical Methods

2.1. Solution of Governing Equations

The three-dimensional mass, momentum, energy and species conservation equations are numerically solved inside the fluid region:

where Yn represents the mass fraction of species n, S and Rn are the energy source term and mass generation rate of species n of chemical reactions, respectively. In addition, the turbulent flow characteristics are modeled with the k-ω turbulence model, which demonstrates strong predictive capabilities for the convective heat transfer of RP-3 at supercritical pressure, as evidenced in reference [26,27,28].

The heat conduction equation is numerically solved within the solid region:

The governing conservation equations were numerically solved using Hitrans, a proprietary in-house three-dimensional Computational Fluid Dynamics (CFD) code, which employs the Arbitrary Lagrangian–Eulerian (ALE) technique. Comprehensive information regarding the ALE algorithm and its application in simulating the coking process can be found in reference [28,34]. During surface coking, the mesh nodes at the inner wall are displaced inward according to the spatial distribution of coke deposition. The deformation of both the fluid and solid domains is computed through the “spring analogy” technique [35]. Simultaneously, the thermal conductivity in Equation (5) is dynamically updated based on the thermal resistance resulting from the growing thickness of the coke layer.

2.2. Chemical Kinetics Model

Jiang et al. [12] developed a pyrolysis mechanism for RP-3 based on experimental measurements, comprising a first-step reaction and 23 secondary reactions. This multi-step mechanism accurately predicts RP-3 pyrolysis at conversions of up to 90% and has been extensively validated under high-temperature conditions in previous studies [13,14,15]. The first-step reaction is described by Equation (6), and the 23 secondary reactions are summarized in reference [12].

The kinetic rate of reactions can be expressed as follows:

The values of pre-exponential factor Ac, the activation energy Ea for all 24 reactions, and the surrogate models (for C5+, CC5+ and CnH2n−6) can be found in reference [12].

As the coking model MC-Ⅱ is strongly recommended in reference [20], it is embedded into the CFD code to investigate the coking of RP-3 over a 20 min period in the present research. The model MC-Ⅱ regards propylene and aromatics as the primary precursors for catalytic coking and lateral coke deposition, respectively.

where Ac1 = 1.16 × 1015 μg·cm2·Ln1/(min·moln1), Ac2 = 2.21 × 105 μg·cm2·Ln2/(min·moln2), Ea1 = 232.3 kJ/mol, Ea2 = 80.5 kJ/mol, the reaction order n1 = 1.55, n2 = 0.14, and the decay constant γ = 0.14. Cp1, Cp2 and Tw,i are the molarities of the precursors and the inner wall temperature, respectively [20].

2.3. Thermophysical Property Calculations

According to the previous studies, the three-species surrogate model, consisting of 18% n-butylcyclohexane, 53% n-undecane, and 29% 1,3,5-trimethyl-benzene demonstrates excellent performance for the prediction of the physical properties of RP-3 under different pressures and temperatures [28,36]. The thermodynamic and transport properties of the surrogate fuel and each pyrolytic product are calculated based on the Extended Corresponding States principle [37,38]. The surrogate model and the calculation method have been rigorously validated in the previous works [28,36].

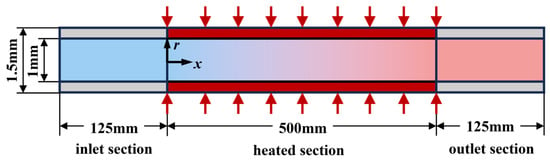

2.4. Physical Model and Mesh

Figure 1 displays the geometric configuration of the physical flow model in a circular tube with an outer diameter of 1.5 mm and an inner diameter of 1.0 mm. The tube has a total length of 750 mm, containing a 500 mm heated section, a 125 mm inlet section and a 125 mm outlet section. The solid region is made of steel, with a thermal capacity of 500 J/(kg·K), thermal conductivity of 16 W/(m·K) and density of 8000 kg/m3.

Figure 1.

Schematic of the physical model.

For the comparative analysis of distinct heat transfer and coking behaviors, the outer surface of the circular tube is heated with either a constant heat flux of 1.8 MW/m2 or a constant surface temperature of 1150 K, both under the supercritical pressure of 5.0 MPa. The inlet temperature is 300 K, with a mass flow rate of 1.5 g/s at a constant outer wall heat flux and 2.0 g/s at a constant outer wall temperature. The simulation is initialized from a steady-state flow corresponding to these operating conditions before surface coking occurs. To capture the rapid increase in coke deposition and its more pronounced effects, we consider a 20 min coking process in the present study. The coking model employed herein demonstrates higher accuracy and reliability within 20 min [20].

According to measurements by Gascoin et al. [39], the density of the coke formed via catalytic coking is 1883 kg/m3 with a porosity of δ1 = 6%, while the density of coke formed via lateral growth is 560 kg/m3 with a porosity of δ2 = 72%. In a study by Manafzadeh et al. [40], the thermal conductivity of carbon is recommended as 2.2 W/(m·K). The parallel arrangement model is applied to estimate the effective thermal conductivity of the coke layer [41].

where λc is the thermal conductivity of carbon, λf,w is the fluid conductivity near the inner wall, and δ is the volume-weighted average porosity of coke formed through different coking pathways.

where V1 is the coke volume formed by catalytic coking, and V2 is the coke volume formed by lateral growth.

It should be noted that the surface roughness and the porous media characteristics inherent in the coke layer structure led to a series of complex impacts on the adjacent fluid dynamics and thermal exchange. Considering that coke deposition mainly occurs through catalytic coking, creating coke with a low porosity (6% based on the measurements of Gascoin et al. [39]) and thus leading to the formation of a relatively dense and continuous layer with a homogeneous surface, the influence of surface roughness and porosity is assumed to be secondary compared to the dominant factors of thermal resistance and geometric blockage. The potential effects of coke erosion or ablation are also neglected. Therefore, only the thermal resistance of the coke layer and the geometric changes are considered in the current numerical model to reduce computational complexity.

Before performing extensive numerical simulations, a grid-independence analysis was conducted. A 1305 × 750 (cross-sectional × axial directions) structured grid was found to be adequate, with cross-sectional refinement in the near-wall region. Under the operating conditions investigated, the y+ value at the first node adjacent to the wall was maintained below 1.0, satisfying the criteria of the k-ω turbulence model.

3. Results and Discussion

3.1. Method Validation

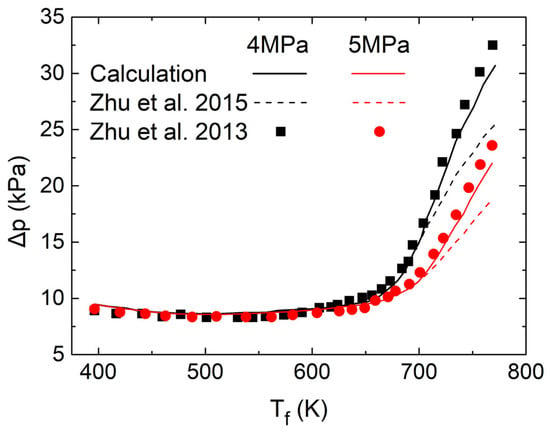

In previous work conducted by our research group, adopting the experimental conditions reported by Zhang et al. [42], the calculated wall temperature was compared with the experimental measurements, and the accuracy of the aforementioned calculation method for predicting the convective heat transfer process of RP-3 was verified [28]. Additionally, in accordance with the experimental parameters described by Zhu et al. [43], the calculation of flow resistance was also validated in our previous study. However, since RP-3 pyrolysis was not considered, the calculated flow resistance of RP-3 was much lower than the experimental value at temperatures above 720 K [28]. In the present research, the flow resistance was recalculated by taking the RP-3 pyrolysis into consideration. As shown in Figure 2, the pressure difference between the inlet and outlet of the adiabatic tube at temperatures above 720 K aligns more closely with the experimental results, with the maximum relative error reduced from 20% to 6%.

Figure 2.

Comparison between the experimental and calculated pressure drop [28,43].

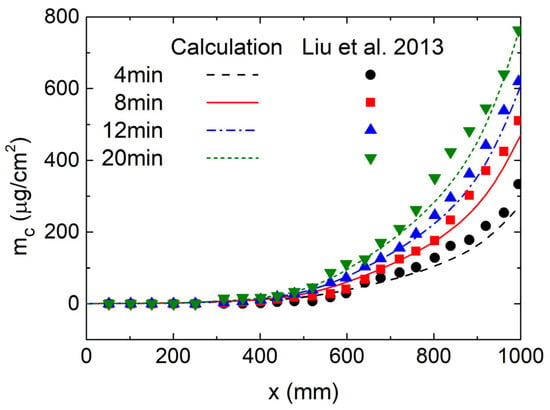

To validate the accuracy of coking calculations, the open published experimental data of Liu et al. [20] were utilized. The pyrolysis process and coke deposition of RP-3 were investigated using the MC-II model based on the experimental conditions in reference [20]. Figure 3 shows the variations in coke deposition in a heated tube with a length of 1000 mm and a diameter of 2 mm. The results exhibit good agreement with the experimental results in most locations. To quantitatively evaluate the accuracy of predictions of the coking process, the total coke mass inside the tube was used to measure the relative error between the numerical and experimental results, as shown in Table 1. It can be observed from the table that the calculated coke mass agrees well with the experimental data, with the relative error at each time point not exceeding 13.8%, indicating that the calculation accuracy is acceptable for engineering requirements.

Figure 3.

Comparison between calculated and experimental data of RP-3 coke deposition [20].

Table 1.

Comparison between the numerical and experimental results of coke mass inside the tube.

3.2. Pyrolytic Coking and Its Effects on Flow and Heat Transfer at a Constant Wall Heat Flux

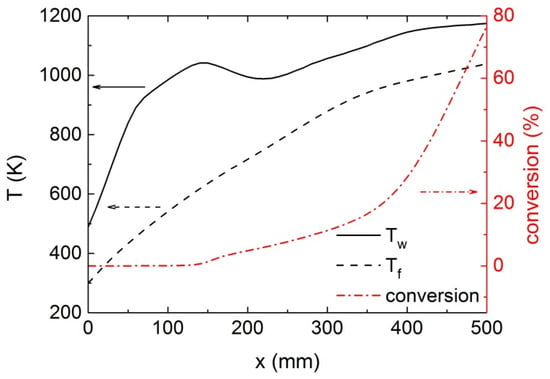

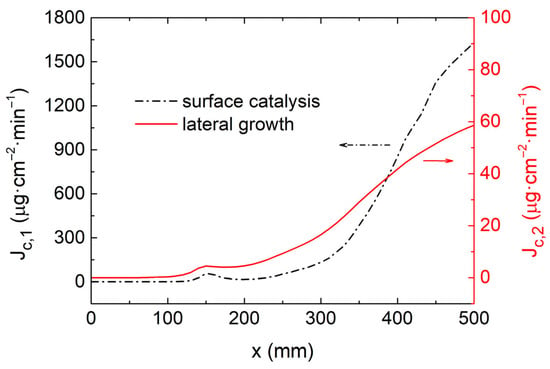

Figure 4 shows the distributions of the bulk fluid temperature, inner wall temperature and RP-3 conversion rate along the heated section at the initial time (t = 0 min), at a constant outer wall heat flux of 1.8 MW/m2. The RP-3 conversion rate and the bulk fluid temperature are defined by Equations (11) and (12), respectively. RP-3 pyrolysis is initiated at x = 120 mm, as shown in Figure 4; accordingly, the coking rate begins to increase, as depicted in Figure 5. In order to clearly show the variation in coking rate corresponding to different coking mechanisms, different longitudinal coordinate ranges are shown in Figure 5. Quantitative analysis reveals that, although both types of coking exhibit similar trends, the magnitude of the peak catalytic coking rate is approximately 30 times higher than that of lateral coking.

Figure 4.

Distributions of fluid temperature, inner wall temperature and RP-3 conversion rate at t = 0 min.

Figure 5.

Distributions of catalytic and the lateral coking rate at t = 0 min.

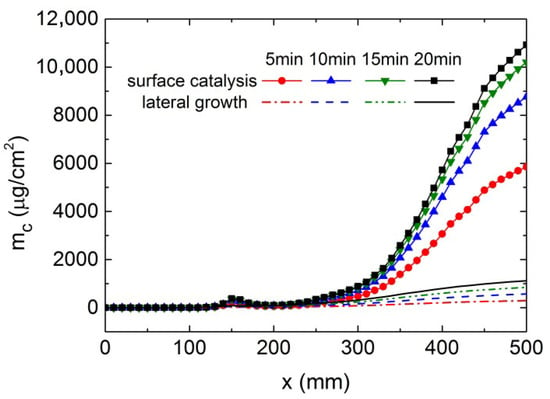

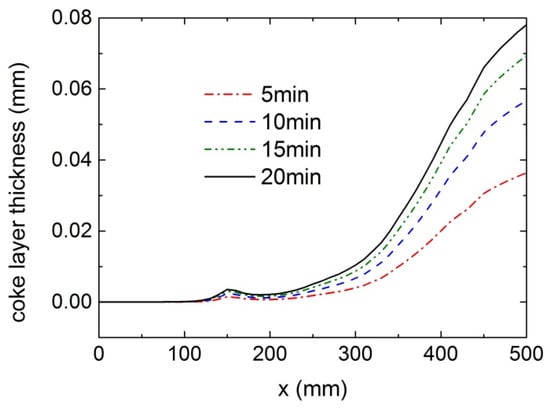

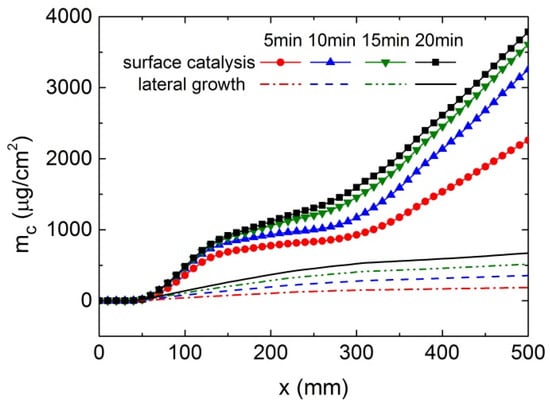

Figure 6 shows the coking distributions at different times. It is evident that catalytic coke depositions are much higher than lateral coke depositions. During the coking process, the catalytic coking increment decreases markedly over each 5 min interval, dropping from 5854 μg/cm2 near the outlet in the first interval to 718 μg/cm2 in the final interval. In contrast, the lateral coking increment remains relatively stable, at 293 μg/cm2 in the first interval and 274 μg/cm2 in the final interval. At t = 20 min, the amount of catalytic coking near the outlet is approximately 11,000 μg/cm2, the amount of lateral coking is around 1120 μg/cm2, and the coke thickness is nearly 0.08 mm, as shown in Figure 7.

Figure 6.

Variation in coke deposition.

Figure 7.

Variation in coking thickness.

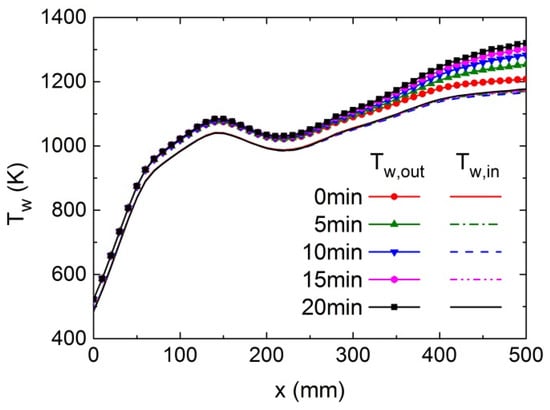

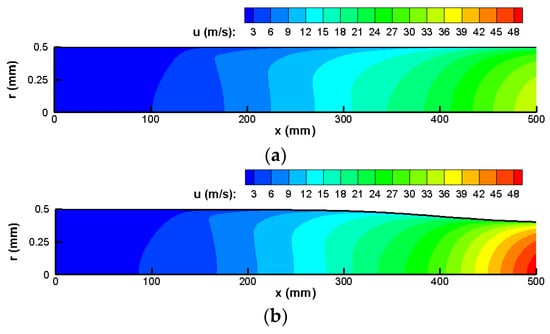

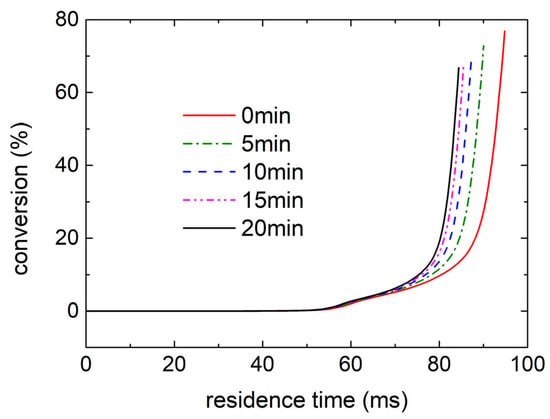

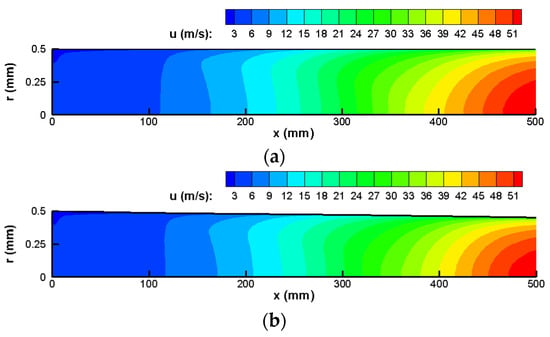

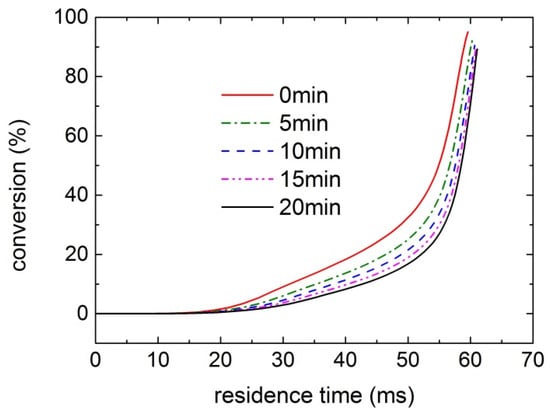

Figure 8 represents the temporal evolution of the inner and outer tube wall temperatures in the heated section. The inner wall transitions from the original interior surface of the tube to the newly formed coking layer surface at t > 0 min. The inner wall temperature exhibits little change after t = 0 min, while the outer wall temperature increases significantly, attributed to progressive coke deposition. This indicates that the thermal resistance of the coke layer has a serious adverse impact on the temperature of the cooling system. With the continuous thickening of the coke layer, the volume of the fluid region shrinks in the second half of the section, leading to changes in the flow field, as revealed in Figure 9. To clearly observe the changes induced by surface coking, the geometry and velocity distributions at t = 0 min and t = 20 min were depicted in half of the longitudinal section. It can be seen that the flow velocity increases as the flow passage becomes narrower in the second half. Accordingly, the residence time of the fluid in the heated region decreases, as illustrated in Figure 10, and the RP-3 conversion rate is reduced. This implies that surface coking has an indirect negative effect on the endothermic pyrolytic reaction. Therefore, in the thermal management design of scramjet cooling channels, it is crucial to account for the reductions in the heat transfer efficiency and chemical heat sink during the continuous coking process, as these factors collectively threaten the operational safety and endurance of the scramjet engine.

Figure 8.

Variation in the inner and outer wall temperatures.

Figure 9.

Changes in geometry and flow field in the fluid domain. (a) t = 0 min. (b) t = 20 min.

Figure 10.

Variation in the RP-3 conversion rate with residence time.

3.3. Pyrolytic Coking and Its Effects on Flow and Heat Transfer at a Constant Surface Temperature

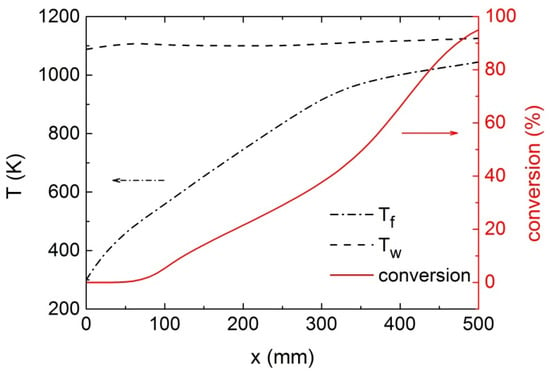

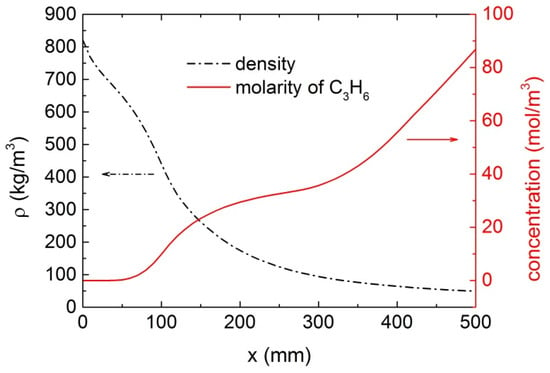

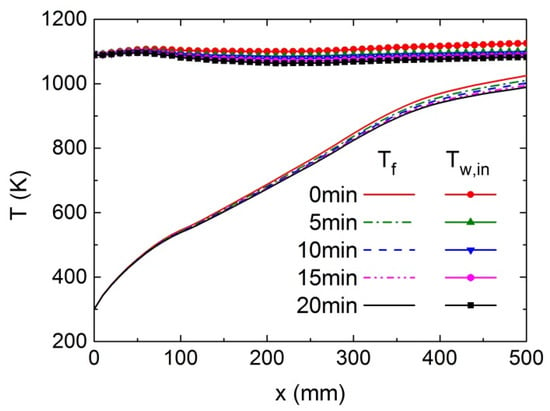

Figure 11 shows the distributions of the bulk fluid temperature, inner wall temperature and RP-3 conversion rate along the heated section at the initial time (t = 0 min), under a constant outer wall temperature of 1150 K. The pyrolysis of RP-3 begins when it enters the heated section. Since the outer wall temperature of the tube is constant, the inner wall temperature is nearly uniform (approximately 1100 K). The coking rate increases rapidly with the rise in RP-3 conversion, as shown in Figure 12, with the peak catalytic coking rate being approximately 17 times higher than the peak lateral coking rate. The catalytic coking rate increases slowly in the section between x = 120 mm and x = 300 mm. Due to the minimal changes in the inner wall temperature and because the reaction order n1 of catalytic coking in Equation (8) is 1.55, the molar concentration of the coking precursor is the primary determinant of the coking rate. Although continuous pyrolysis increases the proportion of propylene in the fluid, the rapid decrease in fluid density inhibits the increase in propylene molar concentration in the section between x = 120 mm and x = 300 mm, as shown in Figure 13, which leads to the observed phenomenon in Figure 12.

Figure 11.

Distributions of the fluid temperature, inner wall temperature and RP-3 conversion rate at t = 0 min.

Figure 12.

Distributions of the catalytic and lateral coking rates at t = 0 min.

Figure 13.

Distributions of fluid density and molar concentration of C3H6 at t = 0 min.

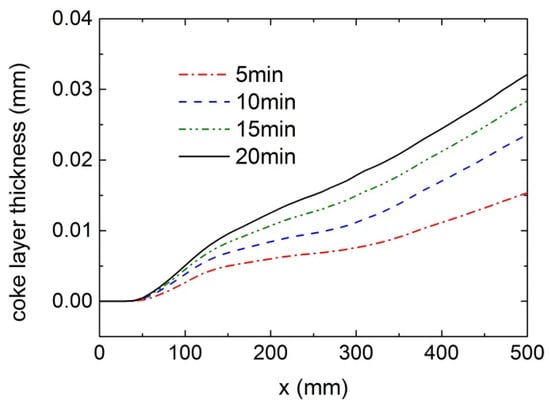

Figure 14 and Figure 15 illustrate the distributions of coke deposition and coking thickness at different time points, respectively. During the coking process, the catalytic coking increment drops from 2259 μg/cm2 near the outlet in the first 5 min interval to 183 μg/cm2 in the final interval, whereas the lateral coking increment varies from 185 μg/cm2 to 156 μg/cm2 over the same intervals. At t = 20 min, the amount of catalytic coking near the outlet reaches 3800 μg/cm2, the amount of lateral coking is around 670 μg/cm2, and the coke layer thickness is approximately 0.03 mm. Although the fluid temperatures under both constant wall heat flux and constant wall temperature conditions are similar, reaching approximately 1030 K near the outlet, as shown in Figure 4 and Figure 11, significant differences are observed in coke deposition on comparison of Figure 6 and Figure 14. It is evident that the constant wall temperature results in lower coke deposition and a thinner coke layer. This suggests that when designing cooling systems for scramjet engines, active control of the wall heat flux and temperature distribution could be a potential coking mitigation strategy.

Figure 14.

Variation in coke deposition.

Figure 15.

Variation in coking thickness.

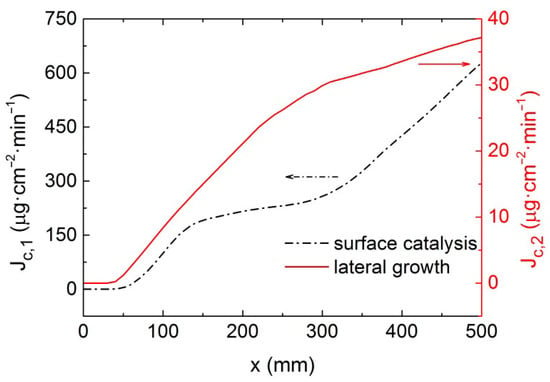

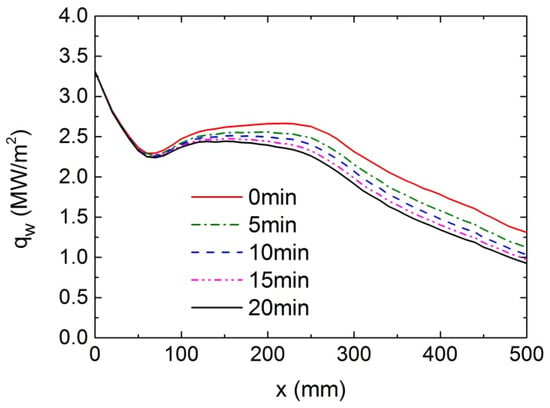

Figure 16 shows the distribution of heat flux on the outer wall of the heated section and its variation during the coking process. The heat flux decreases rapidly in the front part of the heated section, then goes up gradually and drops again in the second half. After t = 0 min, as is evident in Figure 16, the heat flux decreases by varying degrees in all parts of the heated section. This indicates that, at a constant outer wall temperature, the increased thermal resistance caused by coking reduces the heat input into the fluid and reduces the heat absorption capacity of the cooling channel. The reduction in heat entering the fluid region lowers the fluid temperature at the outlet; meanwhile, the temperature of the inner wall also slightly decreases, as can be seen from Figure 17.

Figure 16.

Variation in heat flux on the outer wall.

Figure 17.

Variations in fluid and inner wall temperatures.

Figure 18 illustrates the geometry of the fluid region and flow field at t = 0 min and t = 20 min in the semi-longitudinal plane. As shown in Figure 15, the coke thickness near the outlet of the heated section is about 3 mm at t = 20 min, resulting in a reduction in the diameter from 1 mm to 0.94 mm and a 12% reduction in the flow area. However, the change in fluid velocity in Figure 18 is not significant. This is because the occurrence of coking not only reduces the flow area but also lowers the fluid temperature, as depicted in Figure 17, leading to a higher fluid density. Consequently, the fluid velocity does not change markedly under the current conditions. Figure 19 shows the variation in the RP-3 conversion rate with residence time. It can be observed that due to the insignificant changes in the flow field, the difference in fluid residence time is negligible. Compared to t = 0 min, the fluid residence time at t = 20 min is reduced by only 1.5 ms. However, the conversion of RP-3 at the outlet decreased from 95% to 89%, mainly as a result of the lower fluid temperature slowing down the pyrolytic reaction rate.

Figure 18.

Changes in geometry and flow field in the fluid domain. (a) t = 0 min. (b) t = 20 min.

Figure 19.

Variation in RP-3 conversion rate with the residence time.

4. Conclusions

This study numerically investigated the supercritical pressure flow and heat transfer of RP-3 in a heated tube with pyrolytic coking. The main conclusions are summarized as follows:

- (1)

- Under a constant outer wall heat flux of 1.8 MW/m2, the catalytic coke deposition substantially exceeds the lateral coke deposition, with the amount of catalytic coking near the outlet reaching 11,000 μg/cm2 and that of lateral coking reaching approximately 1120 μg/cm2 at t = 20 min. The catalytic coking increment decreases rapidly over time, contrasting with the nearly constant lateral coking increment. Surface coking significantly increases the outer wall temperature and thermal resistance, leading to a narrowed flow passage and an accelerated flow velocity while also reducing the residence time and RP-3 conversion rate, consequently impairing the endothermic pyrolytic reaction efficiency.

- (2)

- Under a constant outer wall temperature of 1150 K, the pyrolysis of RP-3 is initiated immediately upon its entering the heated section. The catalytic coking rate rises slowly from x = 120 mm to x = 300 mm due to the dominant influence of the decreasing fluid density on the molar concentration of the coking precursors. Coking reduces both the heat flux and the heat absorption capacity in the cooling channel. Despite a 12% reduction in the flow area due to coking, the fluid velocity remains relatively unchanged due to the increased fluid density, while the RP-3 conversion rate decreases, primarily due to lower fluid temperature reducing the pyrolytic reaction rate.

- (3)

- The findings reveal that coking not only degrades the heat transfer efficiency of scramjet cooling channels but also critically reduces the chemical heat sink capacity of the fuel. The wall temperature and heat flux distribution should be properly controlled to mitigate coking. These factors need to be considered in cooling system design to maintain engine performance and avoid overheating.

- (4)

- It should be noted that this study did not account for certain factors such as the surface roughness, porosity effect, or other complex interactions within the coke layer. These simplifications may lead to a partial underestimation of the local impact of coking on heat transfer and flow dynamics. Consequently, more work is still needed to achieve more accurate heat transfer performance simulations.

Author Contributions

Methodology, J.Z. and Z.C.; Validation, J.Z. and Z.C.; Formal analysis, P.Z.; Investigation, X.H., P.Z. and S.S.; Writing—original draft, X.H.; Writing—review & editing, X.H. All authors have read and agreed to the published version of the manuscript.

Funding

The present investigation is being conducted under the support of Program for National Natural Science Foundation of China (No. 52106121 and No. 52476042), the Fundamental Research Funding Project for Central Universities of Civil Aviation University of China (3122019083).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CFD | Computational Fluid Dynamics |

| ALE | Arbitrary Lagrangian–Eulerian |

References

- Taddeo, L.; Gascoin, N.; Chetehouna, K.; Ingenito, A.; Stella, F.; Bouchez, M.; Le Naour, B. Experimental study of pyrolysis-combustion coupling in a regeneratively cooled combustor: Heat transfer and coke formation. Fuel 2019, 239, 1091–1101. [Google Scholar] [CrossRef]

- Ward, T.A.; Ervin, J.S.; Striebich, R.C.; Zabarnick, S. Simulation of Flowing Mildly-cracked normal alkanes incorporating proportional product distribution. J. Propuls. Power 2004, 20, 394–402. [Google Scholar] [CrossRef]

- Spadaccini, L.J.; Sobel, D.R.; Huang, H. Deposit Formation and Mitigation in Aircraft Fuels. J. Eng. Gas Turbines Power 2001, 123, 741–746. [Google Scholar] [CrossRef]

- Deng, H.W.; Zhang, C.B.; Xu, G.Q.; Tao, Z.; Zhang, B.; Liu, G.Z. Density measurements of endothermic hydrocarbon fuel at sub- and supercritical conditions. J. Chem. Eng. Data 2011, 56, 2980–2986. [Google Scholar] [CrossRef]

- Deng, H.W.; Zhang, C.B.; Xu, G.Q.; Zhang, B.; Tao, Z.; Zhu, K. Viscosity Measurements of Endothermic Hydrocarbon Fuel from (298 to 788) K under Supercritical Pressure Conditions. J. Chem. Eng. Data 2012, 57, 358–365. [Google Scholar] [CrossRef]

- Fu, Y.C.; Huang, H.R.; Wen, J.; Xu, G.Q.; Zhao, W. Experimental investigation on convective heat transfer of supercritical RP-3 in vertical miniature tubes with various diameters. Int. J. Heat Mass Transf. 2017, 112, 814–824. [Google Scholar] [CrossRef]

- Sun, X.; Xu, K.K.; Meng, H.; Zheng, Y. Buoyancy effects on supercritical-pressure conjugate heat transfer of aviation kerosene in horizontal tubes. J. Supercrit. Fluids 2018, 139, 105–113. [Google Scholar] [CrossRef]

- Pu, H.; Li, S.F.; Dong, M.; Jiao, S.; Wang, Y.N.; Shang, Y. Convective heat transfer and flow resistance characteristics of supercritical pressure hydrocarbon fuel in a horizontal rectangular mini-channel. Exp. Therm. Fluid Sci. 2019, 108, 39–53. [Google Scholar] [CrossRef]

- Wu, K.; Feng, Y.; Li, D.S.; Xu, S.; Qin, J.; Huang, H.Y. Experimental investigations on transient flow and heat transfer characteristics of RP-3 at supercritical pressure. Appl. Therm. Eng. 2022, 213, 118678. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, K.; Yu, Z.; Ma, H.; Huang, B. Convection Heat-Transfer Characteristics of Supercritical Pressure RP-3 in Horizontal Microchannels. Energies 2024, 17, 3247. [Google Scholar] [CrossRef]

- Fu, Y.C.; Liu, Y.L.; Wang, J.; Wang, Y.; Xu, G.Q.; Wen, J. Local resistance characteristics of elbows for supercritical pressure RP-3 flowing in serpentine micro-tubes. Propuls. Power Res. 2024, 13, 245–256. [Google Scholar] [CrossRef]

- Jiang, R.P.; Liu, G.Z.; Zhang, X.W. Thermal cracking of hydrocarbon aviation fuels in regenerative cooling micro channels. Energy Fuels 2013, 27, 2563–2577. [Google Scholar] [CrossRef]

- Zhao, G.Z.; Song, W.Y.; Zhang, R.L. Effect of pressure on thermal cracking of China RP-3 aviation kerosene under supercritical conditions. Int. J. Heat Mass Transf. 2015, 84, 625–632. [Google Scholar] [CrossRef]

- Xu, K.K.; Meng, H. Modeling and simulation of supercritical-pressure turbulent heat transfer of aviation kerosene with detailed pyrolytic chemical reactions. Energy Fuels 2015, 29, 4137–4149. [Google Scholar] [CrossRef]

- Tian, K.; Yang, P.; Tang, Z.C.; Wang, J.; Zeng, M.; Wang, Q.W. Effect of pyrolytic reaction of supercritical aviation kerosene RP-3 on heat and mass transfer in the near-wall region. Appl. Therm. Eng. 2021, 197, 117401. [Google Scholar] [CrossRef]

- Wang, R.T.; Ye, T.Q.; Bao, Z.W.; Zhu, Q. Numerical analysis of pyrolysis and coking of aviation kerosene in a rectangular U-bend tube under one-side heating. Int. J. Heat Mass Transf. 2023, 214, 124379. [Google Scholar] [CrossRef]

- DeWitt, M.J.; Edwards, T.; Shafer, L.; Brooks, D.; Striebich, R.; Bagley, S.P. Effect of aviation fuel type on pyrolytic reactivity and deposition propensity under supercritical conditions. Ind. Eng. Chem. Res. 2011, 50, 10434–10451. [Google Scholar] [CrossRef]

- Zhu, Y.H.; Yan, S.; Zhao, R.; Jiang, P.X. Experimental Investigation of Flow Coking and Coke Deposition of Supercritical Hydrocarbon Fuels in Porous Media. Energy Fuels 2018, 32, 2941–2948. [Google Scholar] [CrossRef]

- Cheng, Y.X.; Wang, Y.S.; Jiang, P.X.; Zhu, Y.H. Oxidative and pyrolytic coking characteristics of supercritical-pressure n-decane and its influence mechanism on heat transfer. Fuel 2024, 362, 130874. [Google Scholar] [CrossRef]

- Liu, G.Z.; Wang, X.Q.; Zhang, X.W. Pyrolytic depositions of hydrocarbon aviation fuels in regenerative cooling channels. J. Anal. Appl. Pyrolysis 2013, 104, 384–395. [Google Scholar] [CrossRef]

- Bao, Z.W.; Ye, T.Q.; Wang, R.T.; Zhu, Q. Experiment and modelling of supercritical pyrolysis and coking of RP-3 aviation kerosene in a U-bend tube. Chem. Eng. J. 2023, 454, 140234. [Google Scholar] [CrossRef]

- Wang, R.T.; Zhao, J.J.; Bao, Z.W. Thermal cracking and coke deposition characteristics of aviation kerosene RP-3 in an S-bend tube. Fuel 2022, 313, 122673. [Google Scholar] [CrossRef]

- Zhang, H.J.; Li, W.; Nian, Y.; Liu, M.H.; Zhang, J.L.; Han, Y. Insights into the pyrolytic coking process of RP-3 fuel from ReaxFF molecular dynamics. Chem. Eng. Sci. 2024, 291, 119935. [Google Scholar] [CrossRef]

- Xu, K.K.; Meng, H. Numerical study of fluid flows and heat transfer of aviation kerosene with consideration of fuel pyrolysis and surface coking at supercritical pressures. Int. J. Heat Mass Transf. 2016, 95, 806–814. [Google Scholar] [CrossRef]

- Xu, K.K.; Sun, X.; Meng, H. Conjugate heat transfer, endothermic fuel pyrolysis and surface coking of aviation kerosene in ribbed tube at supercritical pressure. Int. J. Therm. Sci. 2018, 132, 209–218. [Google Scholar] [CrossRef]

- Gong, K.Y.; Cao, Y.; Wang, Z.T.; Feng, Y.; Qin, J. Influence of flight acceleration on heat transfer and carbon deposits of aviation kerosene under supercritical conditions. Int. J. Heat Fluid Flow 2024, 109, 109539. [Google Scholar] [CrossRef]

- Feng, Y.; Cao, Y.; Liu, S.; Qin, J.; Hemeda, A.; Mac, Y. The influence of coking on heat transfer in turbulent reacting flow of supercritical hydrocarbon fuels. Int. J. Heat Mass Transf. 2019, 144, 118623. [Google Scholar] [CrossRef]

- Zhu, J.Q.; Tao, Z.; Deng, H.W.; Wang, K.; Yu, X. Numerical investigation of heat transfer characteristics and flow resistance of kerosene RP-3 under supercritical pressure. Int. J. Heat Mass Transf. 2015, 91, 330–341. [Google Scholar] [CrossRef]

- Tao, Z.; Cheng, Z.Y.; Zhu, J.Q.; Hu, X.Z.; Wang, L.Y. Correction of low-Reynolds number turbulence model to hydrocarbon fuel at supercritical pressure. Aerosp. Sci. Technol. 2018, 77, 156–167. [Google Scholar] [CrossRef]

- Tao, Z.; Li, L.W.; Zhu, J.Q.; Hu, X.Z.; Wang, L.Y.; Qiu, L. Numerical investigation on flow and heat transfer characteristics of supercritical RP-3 in inclined pipe. Chin. J. Aeronaut. 2019, 32, 1885–1894. [Google Scholar] [CrossRef]

- Tao, K.H.; Zhu, J.Q.; Cheng, Z.Y.; Li, D.K. Artificial neural network analysis of the Nusselt number and friction factor of hydrocarbon fuel under supercritical pressure. Propuls. Power Res. 2022, 11, 325–336. [Google Scholar] [CrossRef]

- Zhu, J.Q.; Jiao, Y.X.; Dong, H.; Cheng, Z.Y.; Tong, Z.X. Research on the flow and heat transfer characteristics of RP-3 and structural optimization in parallel bending cooling channels. Appl. Therm. Eng. 2024, 241, 122432. [Google Scholar] [CrossRef]

- Lin, D.S.; Li, H.W.; Cheng, Z.Y.; Zhu, J.Q. The heat transfer mechanism coupling pyrolysis and flow of hydrocarbon fuel in heated tube under supercritical pressure. Appl. Therm. Eng. 2024, 247, 123017. [Google Scholar] [CrossRef]

- Tao, Z.; Hu, X.Z.; Zhu, J.Q.; Cheng, Z.Y. Numerical Study of Flow and Heat Transfer of n-Decane with Pyrolysis and Pyrolytic Coking under Supercritical Pressures. Energy Fuels 2017, 31, 8698–8707. [Google Scholar] [CrossRef]

- Blom, F.J. Considerations on the spring analogy. Int. J. Numer. Methods Fluids 2000, 32, 647–668. [Google Scholar] [CrossRef]

- Cheng, Z.Y.; Zhu, J.Q.; Jin, Z. Study on surrogate model of endothermic hydrocarbon fuel RP-3. J. Aerosp. Power 2016, 31, 391–398. [Google Scholar]

- Younglove, B.A.; Ely, J.F. Thermophysical properties of fluids. II. Methane, ethane, propane, isobutane, and normal butane. J. Phys. Chem. Ref. Data 1987, 16, 577–798. [Google Scholar] [CrossRef]

- Huber, M.L. Transport Properties of Fluids, The Correlation, Prediction and Estimation; Cambridge Univ. Press: Cambridge, UK, 1996. [Google Scholar]

- Gascoin, N.; Gillarda, P.; Bernarda, S.; Bouchezb, M. Characterization of coking activity during supercritical hydrocarbon pyrolysis. Fuel Process. Technol. 2008, 89, 1416–1428. [Google Scholar] [CrossRef]

- Manafzadeh, H.; Sadrameli, S.M.; Towfighi, J. Coke deposition by physical condensation of poly-cyclic hydrocarbons in the transfer line exchanger (TLX) of olefin plant. Appl. Therm. Eng. 2003, 23, 1347–1358. [Google Scholar] [CrossRef]

- Kaviany, M. Principles of Heat Transfer in Porous Media; Springer: New York, NY, USA, 1996. [Google Scholar]

- Zhang, C.B.; Xu, G.Q.; Gao, L.; Tao, Z.; Deng, H.W.; Zhu, K. Experimental Investigation on Heat Transfer of a Specific Fuel (RP-3) Flows through Downward Tubes at Supercritical Pressure. J. Supercrit. Fluids 2012, 72, 90–99. [Google Scholar] [CrossRef]

- Zhu, K.; Xu, G.Q.; Tao, Z.; Deng, H.W.; Ran, Z.H.; Zhang, C.B. Flow Frictional Resistance Characteristics of Kerosene RP-3 in Horizontal Circular Tube at Supercritical Pressure. Exp. Therm. Fluid Sci. 2013, 44, 245–252. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).