Abstract

Industrial workplaces, especially in vulnerable, hot, and arid developing countries, face major challenges in maintaining indoor comfort conditions due to the escalating problem of global temperature rise. This study investigates passive scenarios of adaptive retrofitting for a case study carpet and rug industrial plant in Cairo, Egypt to achieve indoor comfort conditions and energy efficiency. The research method included a Post Occupancy Evaluation (POE) for the operational phase of individual work units through measurements and simulations to investigate indoor thermal, visual, and acoustic comfort conditions as well as air quality concerns. Thus, the study presents a set of recommendations for building unit(s) and collectively for the entire facility by applying integrated application of building envelope enhancements; optimized opening design, thermal wall insulation and high-albedo (reflective) exterior coatings for wall and roof surfaces. Comparing the modified case to the base case scenario shows significant improvements. Thermal comfort achieved a 16% to 33% reduction in discomfort hours during peak summer, primarily through a 33% increase in air flow velocity and better humidity control. Visual comfort indicated improvements in daylight harvesting, with Daylighting Autonomy increasing by 47% to 64% in core areas, improving light uniformity and reducing glare potential by decreasing peak illuminance by approximately 25%. Thus, the combined envelope and system modifications resulted in a 60 to 80% reduction in monthly Energy Use Intensity (EUI). The effectiveness of the mitigation measures using acoustic insulation was demonstrated in reducing sound pollution transferring outdoors, but the high indoor sound levels require further near-source mitigation or specialized acoustic treatment for complete success. Eventually, the research method helps create a mechanism for measuring and controlling indoor comfort conditions, provide an internal baseline or benchmark to which future development can be compared against, and pinpoint areas of improvement. This can act as a pilot project for green solutions to mitigate the problem of climate change in industrial workplaces and pave the way for further collaboration with the industrial sector.

1. Introduction

Industrial workplaces face many challenges due to the escalating climate change problems causing global rising temperature. This is heightened with the operating machines radiating heat as well as the building’s high occupational densities and long-term stay periods. Developing countries are greatly vulnerable to these impacts, principally the case of the Middle East and North Africa (MENA) region with its arid and semi-arid climates. Thus, industrial workplaces in hot and arid developing countries in the MENA region face significant challenges in maintaining indoor comfort conditions while ensuring energy efficiency and workers’ productivity []. This is particularly stressing for workplaces which primarily operate depending on passive measures with limited or no mechanical systems. All of these are major contributors against climate resilience and require immediate action. This has intensified the need for sustainable adaptive retrofitting strategies that address these challenges without overburdening energy resources. In this regard, the carpet and rug industry attracts attention due to the many challenges it faces to ensure proper indoor comfort conditions []. This type of project relies heavily on synthetic fibers, dyes, and adhesives, which are particularly susceptible to high temperatures, humidity, and releasing volatile organic compounds (VOCs), particulate matter (PM), and other pollutants.

This calls for the necessity of establishing a continuous measurement and monitoring mechanism for indoor comfort conditions and air quality. Post Occupancy Evaluation (POE) is crucial to guarantee continuous inspection and corrective action are in place. Measurements, surveys, and simulations are some of the common POE techniques used to portray the current conditions, inspect systems, and stand on root causes [].

Relevant standards and guidelines include The Occupational Safety and Health Administration (OSHA) 1910.94 (Ventilation) and 1910.1000 (Air Contaminants) [] and The Environmental Protection Agency (EPA) Clean Air Act (Title III for Hazardous Air Pollutants) []. Green Building Rating Systems (GBRSs) prioritize Indoor Environmental Quality (IEQ) to ensure occupant well-being and operational efficiency. They provide prescriptive and performance requirements related to IEQ []. An example of this is the Leadership in Energy and Environmental Design (LEED) [], which includes an IEQ credit category covering air quality, thermal comfort, lighting, and acoustics. The system’s requirements include using low-VOC materials, CO2 monitoring, and daylight optimization. WELL Building Standard focuses exclusively on health and well-being []. It mandates air filtration, proper lighting levels, and noise control.

This study discusses climate-resilient retrofitting for enhanced indoor comfort in industrial workplaces using a POE for a case study carpet and rug industrial workplace in a hot and arid country, Cairo, Egypt. This evaluates the effectiveness of retrofitting interventions through measurements and simulations and compares it to standard benchmarks to provide practical steps for assessing thermal, visual, and acoustic comfort. The novelty of this discussion unveils the environmental implications of achieving indoor comfort conditions in industrial workplaces in developing countries, where regulatory enforcement and sustainable industrial practices remain underdeveloped. It is noted that, in this context, environmental problems associated with climate change raises the level of complexity and necessity for addressing this topic using passive measures.

2. Reviewing Research Trends in IEQ in Industrial Workplaces: The Case of the Carpet and Rug Industry

IEQ is a critical factor in industrial workplaces, directly impacting workers’ health, comfort, and productivity []. A study by the World Green Building Council found that improved IEQ can enhance productivity by 8–11% [] and increase cognitive function by 61%, which is higher than those in poor IEQ conditions []. A poor IEQ can lead to Sick Building Syndrome (SBS), a condition where occupants experience acute health and comfort effects linked to the time spent in a particular building. Industrial environments, often characterized by high pollutant levels, inadequate ventilation, and thermal discomfort, are particularly susceptible to IEQ-related issues. Symptoms of SBS include headaches, dizziness, nausea, and respiratory issues—often due to overheating, poor ventilation, and chemical exposure [,]. It is well noted that IEQ is dependent on factors attributed to building design, material selection, as well as existing restoration and renovation activities. Indoor comfort conditions include a variety of parameters, e.g., thermal, visual, and acoustic comfort, as well as proper air quality []. Each parameter has its own measurement and benchmarking scale which should be assessed to decide which corrective actions to take.

The carpet and rug manufacturing industry presents unique IEQ challenges due to its production processes, material handling, and workspace requirements. Concerns about carpets and rugs have always been associated with indoor air quality (IAQ), relating it to SBS [,,]. This may result due to some parts of the typical carpet manufacturing process, including primary backing, secondary backing, vulcanizing or foaming, carpet dyeing, as well as special treatment, e.g., stain-resistant fiber treatments, antistatic and antimicrobial treatments, and mothproofing chemicals in the carpet [,].

2.1. Thermal Comfort

Thermal comfort in industrial workplaces is a critical component of IEQ, directly affecting worker health, safety, productivity, and overall operational efficiency. Optimal thermal conditions improve cognitive function by 10–15%, reduce absenteeism, accident rates, and human error []. Other studies show that optimal thermal conditions (20–24 °C, 40–60% RH) improve productivity by 5–10% [,]. Industrial settings often involve extreme temperatures (due to machinery, processes, or lack of climate control), making thermal regulation a major challenge. Poor thermal conditions can lead to thermal stress, fatigue, and increased accident rates, while optimal conditions enhance performance and reduce absenteeism. The International Organization for Standardization (ISO) 7730 and The OSHA [,] reports that thousands of workers suffer heat-related illnesses annually, with some cases leading to death. Chronic exposure to extreme temperatures may lead to cardiovascular strain, respiratory issues, and musculoskeletal disorders. In hot climates, studies show that productivity drops by 2–4% per each increase of 1 °C above 24–26 °C [].

It is worth noting that there are some associated challenges in maintaining thermal comfort in industrial workplaces—particularly, the carpet and rug industry. The large, open indoor space design makes uniform temperature control difficult. Also, the high heat-generating equipment (during the tufting, dyeing, and drying processes) creates localized hot zones, while the glue application areas may require ventilation. Problems of temperature control and humidity fluctuations are mostly pronounced during the dyeing and washing stages, causing discomfort and mold risks; also, dry climates in fiber processing can cause static electricity build-up [,]. This is coupled with the workers’ high metabolic rate, performing heavy labor, and putting on protective clothing, which limits their body’s ability for thermal regulation []. Eventually, the previous factors lead to high ventilation rate demands in the form of air change rates and cooling loads, which puts the burden on the mechanical system, thus leading to high energy consumption [].

Nevertheless, indoor thermal comfort can be achieved via passive means through proper design considering building orientation, openings, thermal material properties… etc. [,]. Proper natural ventilation allows for thermal exchange, replacing hot air with fresh, cold air, and provides proper ventilation rates according to the number of occupants and type of indoor activity []. This is in addition to considerations for the direction of air flow and distribution of air inside the space []. According to the national ventilation code of Egypt, the ventilation rate inside closed spaces is classified according to the metabolic activity inside a space []. Mechanical ventilation considers muti-variables, which may have trade-off relationships, i.e., providing a sufficient air flow rate to flush out indoor pollutants and provide a clean ambient environment with proper air quality, in addition to energy efficiency through applying heat recovery []. Hybrid ventilation systems achieve a mix of both natural and mechanical systems, with the main aim of achieving indoor thermal comfort according to climatic considerations [,].

Complying with GBRSs such as LEED [] and WELL [] requires achieving thermal comfort—referring to ASHRAE 55 []. Also, The ISO 7730 and The OSHA [,] guidelines set safety limits for thermal exposure.

2.2. Visual Comfort

Studies show that visual comfort improves productivity, and it is important for task performance, safety, and worker well-being []. Industrial settings require specialized lighting solutions to accommodate high-risk tasks, varying workspaces, and operational demands []. Poor visual comfort leads to eye strain, fatigue, increased errors, and higher accident rates [].

Visual comfort accounts for both natural light and artificial lighting features []. Different design parameters affect the efficiency of daylighting and visual comfort, noting that excessive daylight can cause glare and heat gain []. Proper daylight design should consider the proper collection and reflection of solar radiation indoors. This should depend on its functional activity and the targeted light levels of the space without causing glare []. The parametric design approach investigates the effect of design decisions related to openings’ sizing and orientation as well as material selection []. This includes design concerns for the opening’s sizing proportional to the façade and space requirement (window to wall ratio), and orientation, as well as employing skylights []. Reflective shelves and using light colors on ceiling, walls, and furniture contribute to better indoor light reflection and distribution []. Artificial lighting features used in indoor industrial workplaces should be energy efficient, with a long service life and high durability, in addition to low-maintenance and replacement requirements []. They should be properly distributed indoors to complement natural light while providing sufficient light levels according to the functional space requirements [].

Light level is measured on the work plane level—usually in a unit of lux, which measures light falling on a surface. The Daylight Factor (DF) measures the ratio of indoor to outdoor illuminance. Daylight Autonomy (DA) assesses the percentage of time daylight meets a target illuminance. The Spatial Daylight Autonomy (sDA) with a threshold of 300 lux for more than or equal to 50% of time ensures daylight sufficiency. The Annual Sunlight Exposure (ASE) with a threshold of 1000 lux for more than 250 h/yr is another unit for assessing visual comfort which aims at minimizing excessive light causing glare [,]. In this regard, the illuminance level in industrial workplaces for general work areas is estimated to fall within the range of 200–500 lux, 500–1000 lux for precision tasks (e.g., machining), and 1000–2000 lux for high-detail inspections (e.g., quality control) [].

Challenges to achieving visual comfort in industrial workplaces, particularly the carpet and rug industry, include inadequate task lighting, which is crucial for precision work (e.g., weaving, quality inspection), which requires high color rendering index lighting (equals or exceeds 85) for color accuracy. The high ceilings and large spaces make it difficult to ensure uniform light distribution. Poor lighting and glare from reflective surfaces lead to eye strain, defects in patterns, and increased waste. Additionally, concerns about energy efficiency versus light quality should be considered [].

Guidelines and standards associated with visual comfort include The OSHA 1910 [], which mandates safe lighting in hazardous areas, as well as The EN 12464-1 [] and The Illuminating Engineering Society of North America (IESNA) RP-7 [], which provide industrial lighting guidelines. Also, GBRSs, e.g., WELL certifications, reward natural light integration and glare control, and the LEED system presents a set of prescriptive and performance guidelines to guide proper light design and assess the efficiency of indoor visual comfort [].

2.3. Acoustic Comfort

Acoustic comfort is another main concern for IEQ in industrial workplaces for an optimized sound environment, as well as enhanced safety, efficiency, and worker well-being []. Poor acoustic conditions above 70 decibels (dB) may reduce cognitive performance and lead to hearing loss where prolonged exposure to above 85 dB causes permanent hearing damage []. It may also lead to communication errors, increased stress, and reduced productivity [].

The sound level should be properly distributed according to engineering requirements and specifications of the space and its functional activity []. It should adhere to the standards of health organizations. The OSHA’s Permissible Exposure Limit (PEL) = 90 dB (8 hours’ Time Weighted Average (TWA)) []. The European Union (EU) Noise Directive [] mandates an 85 dB daily exposure limit, with hearing protection required above 80 dB.

Industrial workplaces face unique challenges due to heavy machinery, high ceilings, and reverberant surfaces, making noise control a complex but necessary investment []. The source of noise can be external, which requires acting on the building envelope, and/or it can internal, which requires studying the inter and intra relationship of spaces to avoid noise pollution []. Controlling the source of noise and the path of sound propagation are the two possible passive ways for noise control. Engineering sound regulator measures are the most effective type of noise control, in addition to employing acoustic insulation materials and sound masking systems [].

Key challenges for acoustic comfort in the carpet and rug industry include high noise levels (85–95 dB) because of machinery noise, which may lead to long-term risks, e.g., hearing loss, communication errors, and fatigue. This is coupled with the problem of reverberation in large spaces, because hard floors and high ceilings amplify noise, worsening speech intelligibility [,].

Relevant standards include The OSHA 1910.95 [] (Occupational Noise Exposure) and ISO 11690 [] (Acoustic Design for Workplaces). Also, LEED and WELL certifications reward noise reduction strategies [,].

2.4. Indoor Air Quality

IAQ is defined as the quality of a building’s indoor environment with relation to occupants’ health and safety []. Critical challenges in industrial workplaces are associated with balancing air exchange rates with energy consumption, considering local exhaust ventilation requirements for point-source emissions, and maintaining IAQ during extreme temperature operations []. Poor ventilation exacerbates these problems, increasing the risk of SBS symptoms for occupants []. The key issues associated with IAQ in the carpet and rug industry are attributed primarily to chemical off-gassing resulting from VOCs, PM2.5/PM10, and chemical fumes, which can cause respiratory issues and cognitive impairment [].

The carbon dioxide concentration level is one of the parameters that affects air quality inside indoor spaces. Previous studies pointed to the importance of monitoring CO2 levels as a significant indication of the quality of ventilation rates [,], favoring natural ventilation where possible []. CO2 levels above 1000 parts per million (ppm) and VOC exposure at 10 mg/m3 decrease cognitive function []. CO2 levels are measured in the breathing zone by CO2 sensors and monitored by CO2 monitors to provide real-time reading and immediate response. It is noted that CO2-based demand control achieves ventilation requirements in response to CO2 concentration level monitoring []. The minimum fresh air in industrial workspaces according to ASHRAE [] and the Egyptian code for ventilation [] is 5 L/s, while the mechanical ventilation is 0.9 L/s.

In sum, synergies and trade-offs may be demonstrated while trying to achieve the three forms of indoor comfort conditions. Examples of this include the following: when allowing more natural light in, this may increase thermal heat loads, jeopardizing indoor thermal comfort. Shutting off openings attempting to control outdoor noise may also jeopardize natural ventilation flow and affect indoor thermal comfort. Furthermore, excessive dependence on mechanical systems can lead to high energy consumption. This requires careful investigation through structured POE techniques and the comprehensive implementation of sustainable adaptive retrofitting measures.

3. Research Method

The research method comprised the following steps:

- Site analysis to investigate the building envelope detecting thermal bridges and leakages as well as thermal material properties.

- Field measurements for temperature, humidity, CO2 concentration level, air movement, light level, and noise level. Data loggers recorded extreme weather conditions in the summer (14–21 July) and winter (13–20 January), and in (16–23) November of 2024 for a whole week, comprising 6 working days and 1 day off to record the variations during working days and weekends. This step was used as a calibration for the building model simulation.

- Base case simulations.

- Developing and testing retrofitting scenario proposals.

3.1. Case Study Building Description

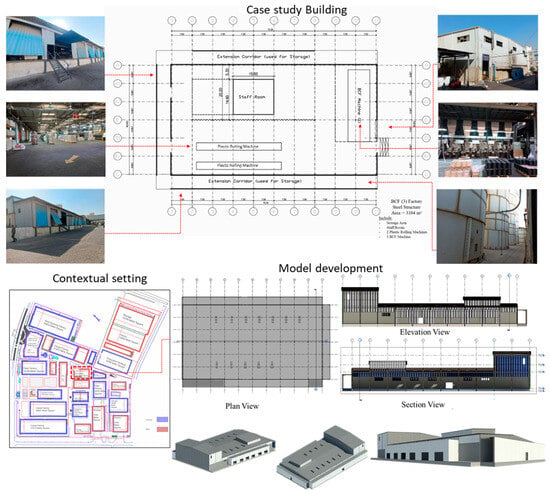

The case study building is located in the 10th of Ramadan city in Cairo within an industrial setting, as shown in Figure 1. It is a steel frame structure with an open floor rectangular plan of 75 × 40 m2. The case study was selected to represent a prototype of other industrial workplaces, whether in this industrial plant or others. This is because they share the same construction type, material specifications, and window to wall ratio.

Figure 1.

Contextual setting and case study building description.

A survey of the building was carried out to document the current state, showing design modifications as well as furniture settings.

- Area: 75 × 40 m2.

- Structure: steel frame structure with height levels of 8, 12, and 15 m.

- The external building envelope is made out of a concrete wall mounted by corrugated metal sheet and surrounded by three corridors of 4 m width each, acting as a double wall providing an inner space for storage. This also had a significant effect in reducing the direct solar radiation falling on the wall facades of these sides; nevertheless, the rate of natural ventilation was reduced.

- The building hosts two types of equipment: two Bulked Continuous Filament (BCF) and plastic rolling machines.

3.2. Selecting the Needed Equipment

Table 1 shows the measurement and monitoring equipment needed to assess the indoor comfort conditions, noting that they were all calibrated before use.

Table 1.

The IEQ tools used for measurement and monitoring.

3.3. Field Measurements

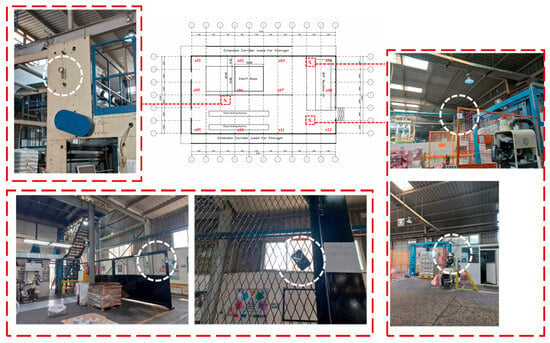

Measurement and monitoring activities were carried out to investigate the indoor comfort conditions. In the next figures, the numbered (x) symbol represents the locations in the plan drawing where measurements were taken.

The average outdoor conditions in July were recorded as follows: a dry bulb temperature of 35 °C, high light intensity of 5000 lux. The relative humidity averages around 50%, which, combined with the high temperature, contributes to significant heat stress. A mild, average wind speed of 1–2 m/s, blowing from the north and northwest directions, provides some heat mitigation. The industrial environment generates a noise level of approximately 70 dB, while the ambient CO2 concentration remains at a background level of 450 ppm.

During January, the average outdoor conditions were recorded as follows: a dry bulb temperature of 18 °C, light intensity of 2450 lux. The relative humidity averaged around 60%, which contributes to it feeling colder. The wind speed ranges between 2.5 and 3.5 m/s, blowing from the southeast and northwest directions. The ambient noise level remains consistent at approximately 70 dB, while the background CO2 concentration stays at a global baseline of 450 ppm.

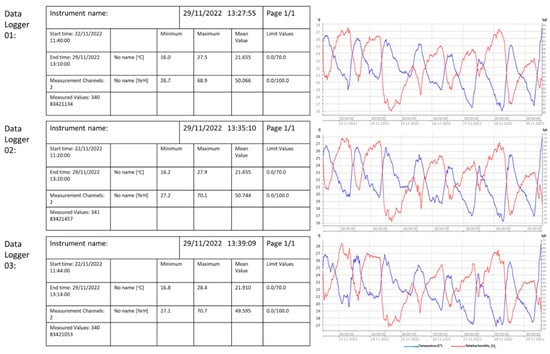

3.3.1. Assessing Thermal Comfort Conditions

For air temperature, three data loggers were distributed, as shown in Figure 2, according to the locations of the two BCF machines (data logger 01 and 02), and data logger 03 was used to investigate the effect of the plastic rolling machine on the indoor space. The exact locations were chosen to be in a highly occupied area, noting not disturb the usual work activities, not be close to radiant surfaces, and the readings were taken at an average height of 1.5 m above the finished floor level, which represents the average height of the breathing zone. The loggers were set to record the temperature and humidity every 30 min for each measurement round. The readings were taken in different locations to detect existing problems and stand on root causes and solutions and to present a comprehensive study of indoor conditions across the entire building floor plan.

Figure 2.

Thermal data loggers’ location settings.

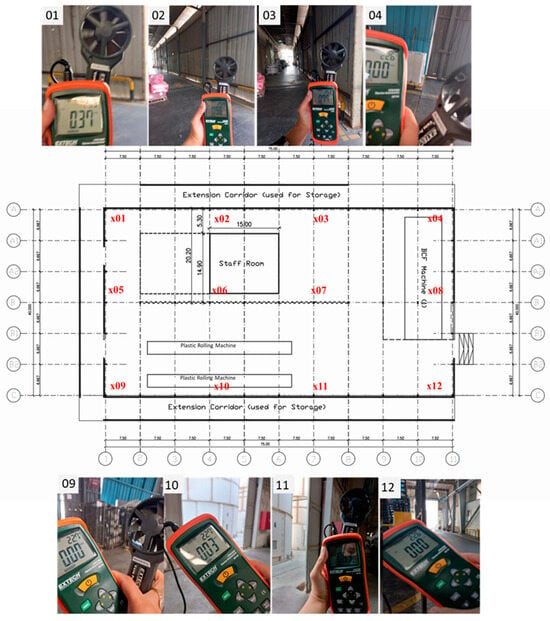

The building was passively operated using natural ventilation. Hence, it was necessary to measure the air movement at the opening locations, as shown in Figure 3. Eight readings were recorded for each measurement round, as shown in Figure 4.

Figure 3.

Anemometers’ location settings.

Figure 4.

The hourly data loggers’ recordings of temperature and humidity.

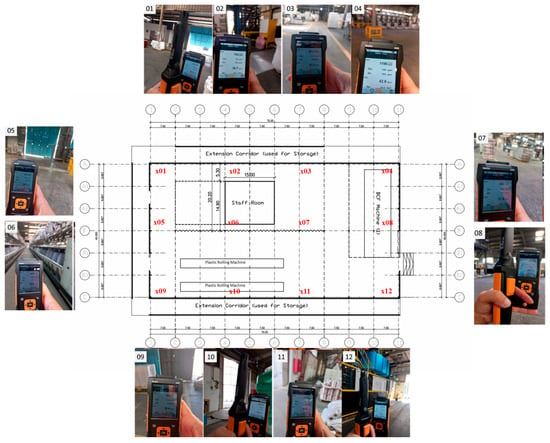

3.3.2. Assessing Indoor Air Quality Referring to CO2 Concentration Level

CO2 concentration levels were documented at different locations of the building following the grid shown in Figure 5, and twelve readings were recorded for each measurement round.

Figure 5.

CO2 measurement devices’ location settings.

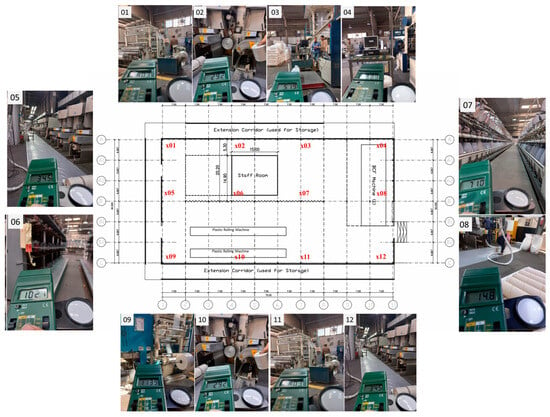

3.3.3. Assessing Visual Comfort Referring to Light Levels and Light Distribution

The light levels were documented at different locations of the building following the grid shown in Figure 6, and twelve readings were recorded for each measurement round. It was noted that the building operated using natural light penetrating through the huge openings as well as upper skylights; this is in addition to upper artificial lighting units that fully operate during the building’s operation period.

Figure 6.

Light meters’ location settings.

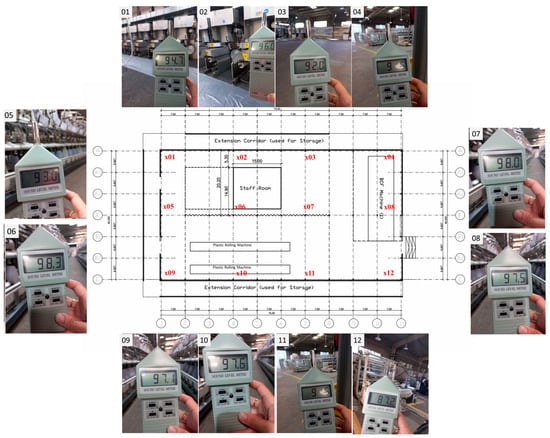

3.3.4. Assessing Acoustic Comfort Referring to Indoor Sound Levels

The sound levels were documented at different locations of the building following the grid shown in Figure 7, and twelve readings were recorded for each measurement round.

Figure 7.

Sound meters’ location settings.

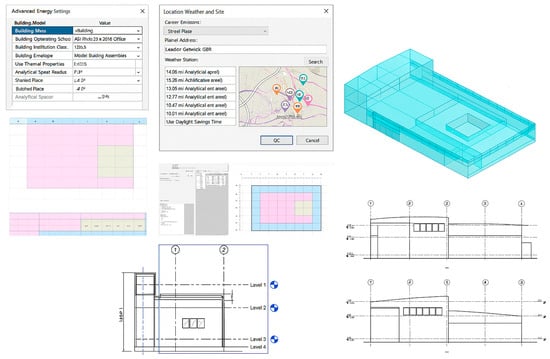

3.4. Model Development and Design Modifications

Computer programs were used to model and simulate the current building condition using Autodesk Revit 2024, including information regarding the building type, activity, and operational schedule, as well as the building’s structure and materials (Table 2 and Table 3). The industrial process area template was selected by defining the operating hours and adding machine power (625 w/m2 for each machine) in order to consider their effect on the thermal and energy consumption simulation.

Table 2.

Specifications of cast-in-site concrete and corrugated steel sheets.

Table 3.

Case specifications.

After modeling the current state, the energy model was created using Revit, as seen in Figure 8, where it was used by the Revit (2024) Insight and Design Builder program version 7.1 to simulate the current state. Then, the model was exported as an STL for simulation by Autodesk Flowdesign software version 2019.

Figure 8.

Developing the building model.

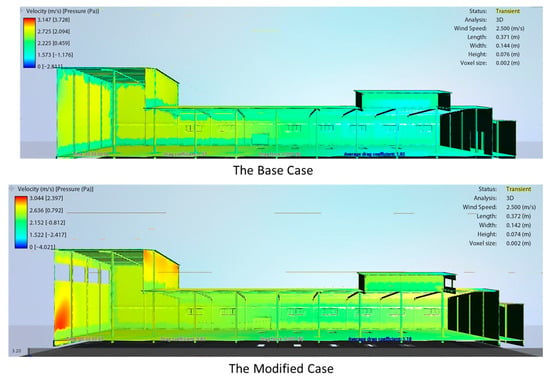

Adjustments were proposed to the building envelope to improve the air flow as well as its thermal and acoustic properties, as shown in Figure 9. These can be summed up as follows:

Figure 9.

Air velocity simulation for the base case and the modified case scenarios.

- -

- Adding openings in the western and eastern walls to adjust the entry and existing pressure points for better cross-ventilation.

- -

- Adding sound absorbing materials to the external wall of the building made up of polyurethane foam with a reinforced aluminum face to resist the high radiant heat from the manufacturing equipment.

- -

- Adding a layer of paint with a high Solar Reflective Index (SRI) to the external walls and roof.

4. Results

The results of the on-site measurement confirmed the results obtained from the base case simulation for indoor comfort conditions. It was noted that the proposed scenario improved the thermal, visual, and acoustic comfort conditions using passive measures.

4.1. Thermal Comfort Conditions

The base case showed that the indoor air flows at a velocity range of 0 to 0.3 m/s. After introducing the openings, the air flows at a velocity range of 0.4 to 0.8 m/s. The increase in air flow velocity to acceptable limits shows a potential for improving indoor natural air flow.

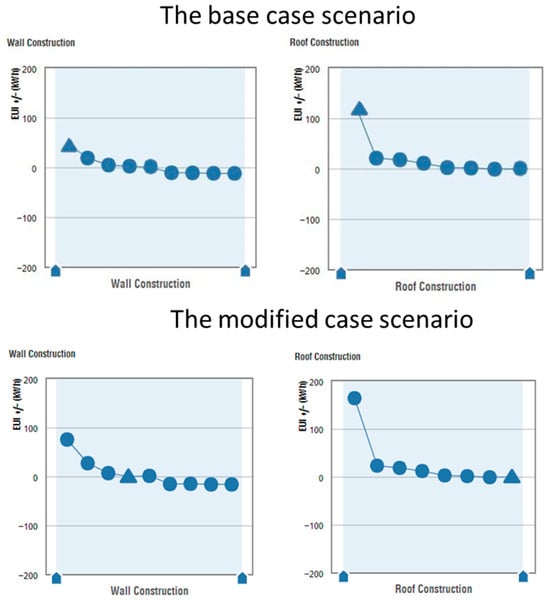

Secondly, it was found that the walls and roof provide a high Energy Use Intensity (EUI) level because they were not insulated. In this regard, the modified case showed that adding insulation provided great potential for reducing the EUI level, and adding paints with high SRI to the external walls and roof surfaces reduced the solar heat gain.

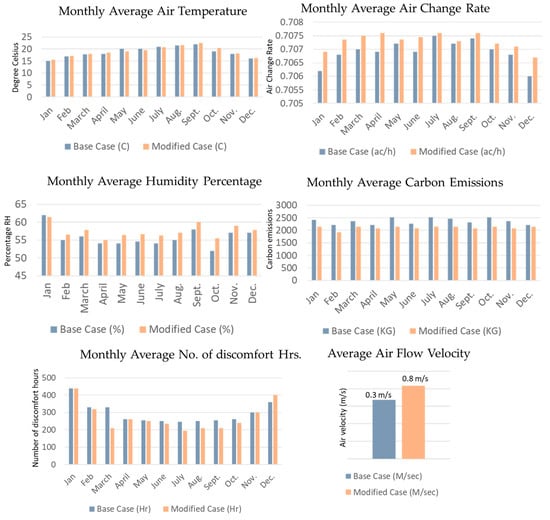

The result of studying the indoor comfort conditions in the case study building shows an improved building performance for the proposed case scenario, as shown in Figure 10 and Figure 11. The average air flow velocity increased to extend the comfort zone conditions to acceptable limits. Thus, the monthly average number of discomfort hours is reduced, particularly during the period from June to August. Further, the monthly average air change rate improved, which allows for better natural ventilation air flow and eventually flushes out indoor air pollutants. This also led to a reduction in the CO2 concentration level, which improved the quality of indoor air.

Figure 10.

Comparing the base case and proposed case measurement scenarios.

Figure 11.

Comparing the wall structure and roof structure for the base case and proposed case scenarios.

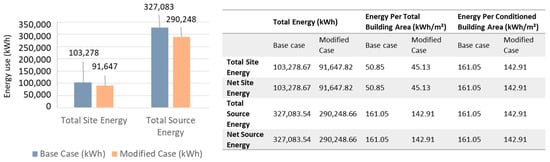

Figure 12 compares the base case to the modified case, showing that the site and source energy use were decreased by 11.26%.

Figure 12.

Comparing the site and source energy for the base and proposed case scenarios.

Based on a comparative performance analysis, the implementation of the modified building design resulted in a profound enhancement of both environmental comfort and energy efficiency within the studied hot arid climate. The most significant outcome was a substantial reduction in thermal discomfort hours, ranging from 16% to 33% during peak summer, which is attributed primarily to a considerable 33% increase in average air flow velocity (to reach an average of 0.8 m/s) and a consistent reduction in humidity ratio. This demonstrates the successful leveraging of elevated air movement to maintain thermal comfort, even with minimal changes to absolute air temperature, thereby validating the principles of elevated air speed provisions within standards like ASHRAE 55 and ISO 7730. Concurrently, the modifications achieved a major energy performance improvement, reducing the EUI by approximately 60% to 80%.

4.2. Visual Comfort Conditions

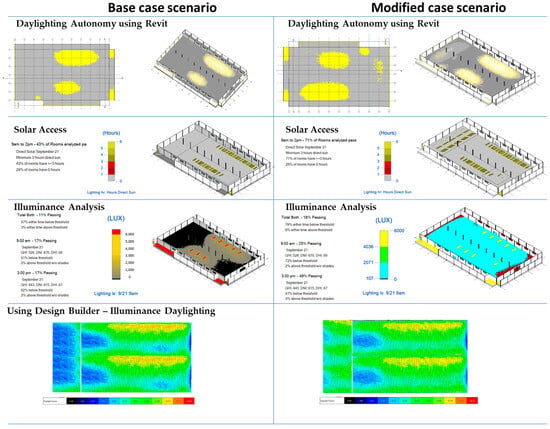

Visual comfort was investigated in terms of solar access, daylight autonomy, and illuminance levels, as shown in Figure 13. The analysis compared the light levels to standards and marked the daylighting areas that complied in a yellow color and zones that failed to comply with a gray color.

Figure 13.

Visual comfort analysis for the base case and modified case scenarios.

Based on an analysis of daylighting performance, the modified building design achieves a significant enhancement in both the sufficiency and quality of natural illumination. The most substantial improvement is observed in daylight autonomy, with the percentage of the floor area meeting required illuminance levels during core working hours increasing by approximately 64% relative to the base case. Concurrently, the design yields superior visual comfort through a more uniform distribution of light, successfully illuminating deeper areas of the space while reducing peak illuminance by approximately 25%, which mitigates potential glare. A substantial 28-percentage-point increase in the floor area receiving adequate solar radiation further indicates optimized solar access.

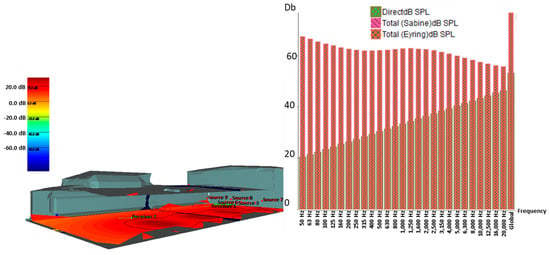

4.3. Acoustic Comfort Conditions

To investigate sound levels, three sound sources were placed for each machine (start–middle–end) at a height of 4 m (approx. half the machine height). Concrete sound absorption was set at 30%, and metal cladding sound absorption was set at 0%. Using I-Simpa version V1.5.4, an acoustic analysis, sound level distribution was scrutinized for the building and its surroundings to investigate the outdoor–indoor sound propagation effect. The sound level recordings are shown in Figure 14, indicating a reduction in noise pollution to acceptable levels following the application of acoustic insulation.

Figure 14.

Acoustic comfort analysis for the proposed case scenario.

Based on an acoustic performance analysis, the implementation of acoustic insulation in the modified case yields a mixed outcome, successfully addressing environmental noise pollution but failing to improve the internal occupational environment. Externally, the insulation achieved a substantial noise reduction from 85 dB(A) to a final level of 68 dB(A), which may be sufficient for outdoor source control but still above indoor acceptable limits for industrial spaces.

5. Discussion

This research adopted a multi-scale approach to scrutinize the critical problem of indoor comfort in industrial workplaces. The following discussion is organized by levels of complexity to reflect this sequential refinement, from the global context to the specific, of tailored solutions identified from the case study.

5.1. Positioning the Research Within Global and Local Contexts

The impetus for this study originates from the macro-scale challenge of global climate change (Level 1). The findings align with the growing recognition that developing countries are severely underrepresented in climate mitigation and adaptation strategies despite being highly vulnerable to its effects. This research directly addresses this gap by focusing on a vulnerable region (Level 2), providing much-needed data and a structured, quantifiable methodology for a context that often lacks the resources for such investigations.

Furthermore, the study responds to rising local concerns and aligns with international sustainability initiatives. The findings demonstrate a direct contribution to several Sustainable Development Goals (SDGs), including SDG 3 (Good Health and Well-being), SDG 7 (Affordable and Clean Energy), SDG 8 (Decent Work and Economic Growth), SDG 11 (Sustainable Cities and Communities), and SDG 13 (Climate Action). This work also operationalizes recommendations from bodies like the World Health Organization and OSHA, translating global agendas into actionable local strategies.

5.2. A Context-Driven Methodology for a Complex Problem

The focus then narrows to the specific climatic context: the hot–arid climates of the MENA region (Level 3) within a developing country, Egypt (Level 4). These conditions dictated the methodological choices. The selection of the carpet and rug industry (Level 5) as a case study was deliberate, as it represents a complex challenge to attain IEQ, including machinery heat gain, airborne particulates, and large, poorly insulated spaces. The complications noted, such as the building’s high occupancy and passive operation, were not merely limitations but central to defining the realm of retrofit scenarios.

To properly diagnose this multi-faceted problem, a comprehensive POE (Level 6) was essential. This integrated approach, assessing thermal, visual, and acoustic comfort alongside IAQ, allowed for a holistic understanding, ensuring that solutions for one parameter did not exacerbate another. This empirical data was then synthesized (Level 7), comparing measurements obtained from the actual base case scenario to possible development scenarios tested through simulations.

5.3. Implications and the Path to Achieveable Retrofit Solutions

The investigation identified possible retrofit strategies for the case study building (Level 8). The results demonstrate that passive measures, such as the minor yet impactful opening design modifications as well as applying thermal wall insulation and applying SRI painting to the external wall and roof surfaces, were able to improve indoor comfort conditions while reducing energy consumption. This is a critical finding for the constrained economic context of a developing country. The outcome is a set of targeted, pragmatic, and context-aware recommendations designed for maximum applicability and impact.

5.4. Limitations and Avenues for Future Research

The study focused on minor modifications for practicality. Future work should investigate major retrofits, such as using corrugated sheets with better thermal conductivity, optimizing opening sizes and locations for cross-ventilation, and utilizing outside corridors as cooling wind tunnels.

To enhance the breadth of this research, the model can be developed to address interconnected climate projection risks and include a value engineering assessment [,]. Feasibility studies and life cycle cost analyses are recommended to discuss the economic impact of the proposed measures [,].

Given the noted harmful emissions from the industrial process, future research should scrutinize IAQ more deeply, using advanced measurement devices and simulation methods. This can be expanded to quantitatively link environmental improvements to measurable outcomes in workers’ productivity, well-being, and health and safety metrics.

By building upon these limitations, future studies can continue to refine tailored, integrated solutions for industrial indoor comfort, moving from global problems to locally viable, high-impact solutions.

6. Conclusions

The research aims to enhance resilience in industrial workplaces located within hot–arid, developing regions, which are contexts disproportionately vulnerable to the escalating challenges of climate change. Focusing on the ecologically and operationally demanding carpet and rug industry in Cairo, Egypt, this study demonstrates a viable pathway for achieving indoor environmental comfort and energy efficiency through passive, adaptive retrofitting measures.

The investigation employed a comprehensive POE, integrating on-site measurements with calibrated simulations to diagnose multi-faceted comfort conditions—thermal, visual, acoustic, and air quality—within a representative industrial facility in the 10th of Ramadan City. The findings indicated that implementing passive measures including opening design (opening size and orientation) to leverage cross-ventilation and enhanced building envelope (e.g., applying thermal wall insulation and SRI to the external walls and roof surfaces), can attain acceptable indoor comfort conditions.

Based on a holistic performance evaluation, the modified building design demonstrates substantial improvements in energy efficiency, thermal comfort, and daylighting. The design achieved a profound reduction in EUI by 60–80%, while simultaneously enhancing thermal comfort through a 33% increase in air flow velocity and humidity control, which reduced summer discomfort hours by 16–33%. Daylighting performance was also significantly improved, with a 64% increase in spatial daylight autonomy and a 25% reduction in peak illuminance for better uniformity and glare control. The effectiveness of the mitigation measures using acoustic insulation was demonstrated in reducing sound pollution transferring outdoors. Nevertheless, the high indoor sound levels require further near-source mitigation or specialized acoustic treatment for complete success.

Beyond these specific technical recommendations, this study delivers a critical methodological contribution for assessing and improving industrial indoor environments in resource-constrained settings. The detailed assessment acts as a baseline for monitoring future performance and comparing against peer projects, pinpointing specific areas for continued improvement. This can act as a pilot study for green solutions for similar projects and pave the way for further collaboration with the industry, which is currently considered a rising attention. Furthermore, the resulting set of recommendations can be integrated into local building codes and standards to address different climate conditions and work environments.

Author Contributions

W.S.E.I.: Conceptualization, Visualization, Resources, Data curation, Writing—original draft, Writing—review & editing. F.O.A.: Methodology, Software Simulation, Validation, Formal Analysis, Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

Young Investigator Research Grant (YIRG), 2021 provided by the British University in Egypt (Grant Number: BUE YIR21).

Data Availability Statement

All data can be made available upon request from the author.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Kumar, S.; Mathur, A.; Singh, M.K.; Rana, K.B. Adaptive Thermal Comfort Study of Workers in a Mini-Industrial Unit during Summer and Winter Season in a Tropical Country, India. Build. Environ. 2021, 197, 107874. [Google Scholar] [CrossRef]

- Haines, S.R.; Adams, R.I.; Boor, B.E.; Bruton, T.A.; Downey, J.; Ferro, A.R.; Gall, E.; Green, B.J.; Hegarty, B.; Horner, E.; et al. Ten Questions Concerning the Implications of Carpet on Indoor Chemistry and Microbiology. Build. Environ. 2020, 170, 106589. [Google Scholar] [CrossRef]

- Mewomo, M.C.; Toyin, J.O.; Iyiola, C.O.; Aluko, O.R. Synthesis of Critical Factors Influencing Indoor Environmental Quality and Their Impacts on Building Occupants Health and Productivity. J. Eng. Des. Technol. 2023, 21, 619–634. [Google Scholar] [CrossRef]

- OSHA Occupational Safety and Health Administration. Available online: https://www.osha.gov/ (accessed on 1 May 2025).

- United States Environmental Protection Agency: Washington, DC, USA, 2012. Available online: www.epa.gov (accessed on 1 May 2025).

- Elakkad, N.; Ismaeel, W.S.E. Coupling Performance-Prescriptive Based Daylighting Principles for Office Buildings: Case Study from Egypt. Ain Shams Eng. J. 2021, 12, 3263–3273. [Google Scholar] [CrossRef]

- LEED Rating System. Available online: https://www.usgbc.org/leed (accessed on 1 May 2025).

- WELL Rating System, International WELL Building Institute. 2014. Available online: www.wellcertified.com (accessed on 1 May 2025).

- Zhang, Y.; Chen, Y.; Su, Q.; Huang, X.; Li, Q.; Yang, Y.; Zhang, Z.; Chen, J.; Xiao, Z.; Xu, R.; et al. The Use of Machine and Deep Learning to Model the Relationship between Discomfort Temperature and Labor Productivity Loss among Petrochemical Workers. BMC Public Health 2024, 24, 3269. [Google Scholar] [CrossRef]

- World Green building Council. Health, Wellbeing & Productivity in Offices; World Green building Council: London, UK, 2014; Volume 1, Available online: https://worldgbc.org/ (accessed on 1 May 2025).

- Matticoli, O. The Value of Healthy Offices by the Numbers. 2023. Available online: https://delos.com/blog/the-value-of-healthy-offices-by-the-numbers/ (accessed on 1 May 2025).

- Ismaeel, W.S.E.; Adel Elsayed, M.; Salaheldin Ismail Elsayed, D. Revisiting ‘Sabil’ Buildings as Nuclei of Sustainable Urban Mobility in Fatimid Cairo: An Urban-Touristic Approach Considering Urban and Environmental Qualities. Ain Shams Eng. J. 2022, 13, 101774. [Google Scholar] [CrossRef]

- Ismaeel, W.S.E.; Alamoudy, F.O.; Sameh, R. How Renovation Activities May Jeopardise Indoor Air Quality: Accounting for Short and Long-Term Symptoms of Sick Building Syndrome in Educational Buildings. Archit. Eng. Des. Manag. 2022, 19, 360–377. [Google Scholar] [CrossRef]

- Costanzo, V.; Donn, M. Thermal and Visual Comfort Assessment of Natural Ventilated Office Buildings in Europe and North America. Energy Build. 2017, 140, 210–223. [Google Scholar] [CrossRef]

- The Carpet and Rug Institute (CRI). Carpet and Indoor Air Quality; The Carpet and Rug Institute: Dalton, GA, USA, 2023. [Google Scholar]

- Becher, R.; Øvrevik, J.; Schwarze, P.E.; Nilsen, S.; Hongslo, J.K.; Bakke, J.V. Do Carpets Impair Indoor Air Quality and Cause Adverse Health Outcomes: A Review. Int. J. Environ. Res. Public Health 2018, 15, 184. [Google Scholar] [CrossRef] [PubMed]

- Abbas, S.; Najafabadi, N.; Sugano, S. Applied Sciences. In Early Writings on India; Routledge: London, UK, 2018; pp. 124–134. [Google Scholar] [CrossRef]

- Altomonte, S.; Allen, J.; Bluyssen, P.M.; Brager, G.; Heschong, L.; Loder, A.; Schiavon, S.; Veitch, J.A.; Wang, L.; Wargocki, P. Ten Questions Concerning Well-Being in the Built Environment. Build. Environ. 2020, 180, 106949. [Google Scholar] [CrossRef]

- Yin, B.; Fang, W.; Liu, L.; Guo, Y.; Ma, X.; Di, Q. Effect of Extreme High Temperature on Cognitive Function at Different Time Scales: A National Difference-in-Differences Analysis. Ecotoxicol. Environ. Saf. 2024, 275, 116238. [Google Scholar] [CrossRef]

- Porras-Salazar, J.A.; Schiavon, S.; Wargocki, P.; Cheung, T.; Tham, K.W. Meta-Analysis of 35 Studies Examining the Effect of Indoor Temperature on Office Work Performance. Build. Environ. 2021, 203, 108037. [Google Scholar] [CrossRef]

- Avci, A.B.; Balci, G.A.; Basaran, T. Optimizing Thermal Comfort in Physical Exercise Spaces: A Study of Spatial and Thermal Factors. Energy Build. 2024, 303, 113782. [Google Scholar] [CrossRef]

- ISO 7730:2005; Ergonomics of the Thermal Environment. International Organization for Standardization: Geneva, Switzerland, 2005.

- International Labour Organization. Working on a WARMER Planet: The Impact of Heat Stress on Labour Productivity and Decent Work; International Labour Office: Geneva, Switzerland, 2019; ISBN 9789221329671. [Google Scholar]

- International Labour Organization. The Employment Impact of Climate Change Adaptation; International Labour Office: Geneva, Switzerland, 2018; ISBN 9789220311141. [Google Scholar]

- Lila, A.; Sharmin, T.; Khalil, A.; Ismaeel, W.S.E.; Karram, M.; Ewida, S.; Zacharia, M.M.; Ammar, H.M. Thermal Comfort Study in MSMEs in Cairo Using Onsite Measurements and Optimization Algorithm. Build. Simul. Conf. Proc. 2023, 18, 1579–1586. [Google Scholar] [CrossRef]

- Dabaieh, M.; Wanas, O.; Hegazy, M.A.; Johansson, E. Reducing Cooling Demands in a Hot Dry Climate: A Simulation Study for Non-Insulated Passive Cool Roof Thermal Performance in Residential Buildings. Energy Build. 2015, 89, 142–152. [Google Scholar] [CrossRef]

- Alaa, R.; Elbalazi, A.; Ismaeel, W.S.E. Optimal Roof Strategy for Mitigating Urban Heat Island in Hot Arid Climates: Simulation and Python-Based Multi-Criteria Decision Analysis. Urban Sci. 2025, 9, 310. [Google Scholar] [CrossRef]

- Housing and Building Research Center. The National Egyptian Code for Ventililation and Air Conditioning; Housing and Building Rsearch Center: Giza, Egypt, 2023. [Google Scholar]

- Kamendere, E.; Zogla, G.; Kamenders, A.; Ikaunieks, J.; Rochas, C. Analysis of Mechanical Ventilation System with Heat Recovery in Renovated Apartment Buildings. Energy Procedia 2015, 72, 27–33. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X. Techno-Economic Evaluation of a Hybrid HVAC System Combining Double-Layer Pipe-Embedded External Wall and Multi-Stage Fresh Air Treatment. Appl. Therm. Eng. 2024, 256, 124025. [Google Scholar] [CrossRef]

- Dou, X.; Xie, D.; Wang, Z.; Xiao, P.; Wang, H. Improved Buoyancy-Driver Hybrid Ventilation System for Multiple-Heat-Source Industrial Buildings. Case Stud. Therm. Eng. 2021, 26, 101059. [Google Scholar] [CrossRef]

- ANSI/ASHRAE 55:2004; Thermal Environmental Conditions for Human Occupancy. ASHRAE: Atlanta, GA, USA, 2004. Available online: https://www.ditar.cl/archivos/Normas_ASHRAE/T0080ASHRAE-55-2004-ThermalEnviromCondiHO.pdf (accessed on 1 May 2025).

- Konstantzos, I.; Sadeghi, S.A.; Kim, M.; Xiong, J.; Tzempelikos, A. The Effect of Lighting Environment on Task Performance in Buildings—A Review. Energy Build. 2020, 226, 110394. [Google Scholar] [CrossRef]

- National Institute for Occupational Safety and Health (NIOSH). NIOSH Light-Emitting Diode (LED) Cap Lamp Improves Illumination and Decreases Injury Risk for Underground Miners; NIOSH: Cincinnati, OH, USA, 2014. [Google Scholar]

- Shen, E.; Hu, J.; Patel, M. Energy and Visual Comfort Analysis of Lighting and Daylight Control Strategies. Build. Environ. 2014, 78, 155–170. [Google Scholar] [CrossRef]

- ElBatran, R.M.; Ismaeel, W.S.E. Applying a Parametric Design Approach for Optimizing Daylighting and Visual Comfort in Office Buildings. Ain Shams Eng. J. 2021, 12, 3275–3284. [Google Scholar] [CrossRef]

- Al-Obaidi, K.M.; Ismail, M.A.; Abdul Rahman, A.M. Assessing the Allowable Daylight Illuminance from Skylights in Single-Storey Buildings in Malaysia: A Review. Int. J. Sustain. Build. Technol. Urban Dev. 2015, 6, 236–248. [Google Scholar] [CrossRef]

- Sherif, N.; Yehia, A.; Ismaeel, W.S.E. Simulation and Statistical Validation Method for Evaluating Daylighting Performance in Hot Climates. Urban Sci. 2025, 9, 303. [Google Scholar] [CrossRef]

- IESNA RP-7; Recommended Practice for Lighting Industrial Facilities. The Illuminating Engineering Society of North America: New York, NY, USA, 2001; ISBN 0-87995-176-1. Available online: https://webstore.ansi.org/preview-pages/IESNA/preview_ANSI+IESNA+RP-7-01.pdf?srsltid=AfmBOorm3_S2X7lLqqPlWksWP56QAiL3mww2gp0w7iXwFk3Nmo3UUD3A (accessed on 1 May 2025).

- BS EN 12464-1:2021; Light and Lighting—Lighting of Work Places. BSI Standards Limited: London, UK, 2021. Available online: https://webstore.ansi.org/preview-pages/bsi/preview_30385601.pdf?srsltid=AfmBOopfAudg2__jINVLm6mhMP0ojtZCWNpjXHuHH9_SbTh77QkuanAE (accessed on 1 May 2025).

- Ferrara, M.; Vallée, J.C.; Shtrepi, L.; Astolfi, A.; Fabrizio, E. A Thermal and Acoustic Co-Simulation Method for the Multi-Domain Optimization of Nearly Zero Energy Buildings. J. Build. Eng. 2021, 40, 102699. [Google Scholar] [CrossRef]

- Ouyang, Y.; Huang, G.; He, S. Impacts of Adverse Environmental Factors on Construction Workers’ Attention Allocation during Hazard Identification: A Study of Noise and Heat Exposure. Eng. Constr. Archit. Manag. 2024, 32, 7469–7485. [Google Scholar] [CrossRef]

- Cellai, G.; Carletti, C.; Sciurpi, F.; Secchi, S. Transparent Building Envelope: Windows and Shading Devices Typologies for Energy Efficiency Refurbishments. In Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- European Commission. EU Noise Directive; European Commission: Brussels, Belgium, 2002. [Google Scholar]

- Hassanain, M.A.; Almhbash, T.S.; Zami, M.S.; Ibrahim, A.M. Design and Management Considerations towards Productively Sustainable Work Places in Saudi Arabia. J. Corp. Real Estate 2025, 27, 19–46. [Google Scholar] [CrossRef]

- ISO 11690; Noise Control Strategies. International Organization for Standardization: Geneva, Switzerland, 2020.

- Baumann, O.; Reiser, C.; Schafer, J. LEED Green Building Rating System. Bauphysik 2004, 31, 99–105. [Google Scholar] [CrossRef]

- Karapetsis, A.; Alexandri, E. Indoor Environmental Quality and Its Impacts on Health—Case Study: School Buildings. In Proceedings of the 5th International Conference Energy in Buildings Impacts, Athens, Greece, 12 November 2016; pp. 1–2. [Google Scholar]

- Arya, M.; Rajput, S. Monitoring and Analysis of Indoor Air Quality at Different Heights in Industrial Room by Using CFD. Int. J. Environ. Sci. 2011, 1, 1062–1071. [Google Scholar]

- Kim, K.H.; Kabir, E.; Kabir, S. A Review on the Human Health Impact of Airborne Particulate Matter. Environ. Int. 2015, 74, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Marques, G.; Saini, J.; Dutta, M.; Singh, P.K.; Hong, W.C. Indoor Air Quality Monitoring Systems for Enhanced Living Environments: A Review toward Sustainable Smart Cities. Sustainability 2020, 12, 4024. [Google Scholar] [CrossRef]

- Ha, Q.P.; Metia, S.; Phung, M.D. Sensing Data Fusion for Enhanced Indoor Air Quality Monitoring. IEEE Sens. J. 2020, 20, 4430–4441. [Google Scholar] [CrossRef]

- Yang, D.; Mak, C.M. Relationships between Indoor Environmental Quality and Environmental Factors in University Classrooms. Build. Environ. 2020, 186, 107331. [Google Scholar] [CrossRef]

- ASHRAE-62.1-2013; Ventilation for Acceptable Indoor Air Quality. ASHRAE: Atlanta, GA, USA, 2013.

- Pavlovas, V. Demand Controlled Ventilation. Energy Build. 2011, 36, 1029–1034. [Google Scholar] [CrossRef]

- Abdelkareem, M.; Mansour, A.M. Risk Assessment and Management of Vulnerable Areas to Flash Flood Hazards in Arid Regions Using Remote Sensing and GIS-Based Knowledge-Driven Techniques. Nat. Hazards 2023, 117, 2269–2295. [Google Scholar] [CrossRef]

- Chandrappa, R.; Gupta, S.; Kulshrestha, U.C. Hazard and Risk Assessment. In Coping with Climate Change; Springer: Berlin/Heidelberg, Germany, 2011; pp. 201–212. [Google Scholar] [CrossRef]

- Ismaeel, W.S.E.; Lotfy, R.A.E.R. An Integrated Building Information Modelling-Based Environmental Impact Assessment Framework. Clean Technol. Environ. Policy 2022, 25, 1291–1307. [Google Scholar] [CrossRef]

- Ismaeel, W.S.E.; Elsayed, M.A. The Interplay of Environmental Assessment Methods; Characterising the Institutional Background in Egypt. J. Environ. Assess. Policy Manag. 2018, 20, 1850003. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).