Abstract

This systematic literature review examines the integration of Machine Learning techniques within industrial system architectures using OPC-UA for process automation. Through analyzing primary studies published between 2018 and 2024, the review identifies key trends, methodologies, and implementations across various industrial applications. The review identifies a marked increase in research focused on hybrid architectures that integrate Machine Learning with OPC-UA, particularly in applications such as predictive maintenance and quality control. However, despite reported high accuracy rates—often above 95%—in controlled environments, there is limited evidence on the robustness of these solutions in real-world, large-scale deployments. This highlights the need for further empirical validation and benchmarking in diverse industrial contexts. Implementation patterns range from cloud-based deployments to edge computing solutions, with OPC-UA serving as a communication protocol, information modeling framework, and specifically using the finite state machine specification. The review also highlights current challenges and opportunities, providing valuable insights for researchers and practitioners working on intelligent industrial automation.

1. Introduction

The evolution of Industry 4.0 encompasses multiple technological pillars, including cyber-physical systems, IoT, cloud computing, big data analytics, and advanced human–machine interfaces. Among these, Open Platform Communications-Unified Architecture (OPC-UA) and artificial intelligence have emerged as critical enablers for standardized communication and intelligent decision making in industrial automation. OPC-UA standardizes secure, vendor-neutral communication between heterogeneous systems (from legacy devices to IoT machinery), while Machine Learning (ML) techniques empower capabilities such as predictive analytics, adaptive control, and autonomous decision making in areas such as predictive maintenance and resource optimization. However, this integration faces challenges, such as fragmented standards, cybersecurity risks, and the rigidity of traditional industrial architectures []. The convergence of these technologies seeks to overcome these barriers, promoting intelligent, reconfigurable, and data-driven industrial ecosystems capable of driving operational efficiency and continuous improvement in automated environments [,,].

The proliferation of ML methods—spanning supervised, unsupervised, and reinforcement learning—has expanded their applicability across industrial domains. However, their integration into existing architectures remains challenging due to incompatible standards and rigid system designs, which often hinder the embedding of adaptive intelligence directly into physical workflows [,]. This gap has spurred the emergence of intelligent industrial process automation, an approach that synergizes ML’s autonomy and adaptability with industrial architectures to create reconfigurable, collaborative ecosystems [].

Recent studies underscore this trend. For instance, Schindler et al. [] explore the fusion of reinforcement learning (RL) with OPC-UA, identifying its potential in direct industrial applications and data inference while highlighting challenges like simulation-to-reality transitions and interface standardization. Xia et al. [] analyze heterogeneous industrial networks, emphasizing OPC-UA’s role in harmonizing devices like PLCs and sensors alongside edge-cloud computing and blockchain. Balador et al. [] further validate OPC-UA’s interoperability strengths in distributed systems, advocating its integration with real-time protocols like DDS for scalable IIoT solutions. Collectively, these works highlight the critical need for standardized, secure, and adaptive frameworks to realize Industry 4.0’s potential fully.

This systematic literature review examines the dual convergence of OPC-UA and ML in industrial automation, assessing methodologies, frameworks, and applications that leverage OPC-UA’s data exchange capabilities to embed ML-driven intelligence. By evaluating strengths, weaknesses, and implementation challenges, the study identifies key success factors and unresolved barriers—such as real-time adaptability and cybersecurity—while proposing future directions for intelligent automation.

This article is organized into four sections. Section 3 describes the process applied and the results obtained at each stage of the systematic review. In Section 5, the results obtained from the literature review are presented. Section 5.6 describes the main strengths, opportunities, weaknesses, and threats associated with the intelligent automation process, as well as the main challenges and future lines of research that arise as a result. This analysis is carried out in terms of the models proposed to create networks of intelligent industrial systems. Section 6 presents future directions of the current work. Finally, in Section 7, the conclusions of the study are described in detail.

2. OPC-UA

OPC-UA [] is an open, cross-platform industry standard designed for secure, reliable, and scalable communication between devices, systems, and applications in automation and IoT environments. Although often used interchangeably in literature, OPC-UA is more than just a communication protocol because it constitutes a comprehensive industrial standard that defines both a complete communication framework and an information model. While traditional protocols primarily focus on data transmission mechanisms, OPC-UA as a standard encompasses security models, information modeling, service definitions, and interoperability specifications. This distinction is crucial for understanding OPC-UA’s role in industrial automation because it provides not only the means to communicate but also the semantic structure to represent complex industrial information consistently across heterogeneous systems.

Unlike its predecessor, OPC Classic, it eliminates technology dependencies such as COM/DCOM, and is based on a service-oriented architecture (SOA), compatible with modern protocols (TCP, HTTP, MQTT), and adaptable from simple sensors to complex infrastructures. Its core integrates a unified information model, which organizes data hierarchically through nodes (objects, variables, methods) and relationships, along with a robust security framework (encryption, authentication, and access control). OPC-UA is key to Industry 4.0, facilitating interoperability between manufacturers, IT/OT integration, and advanced applications such as digital twins, predictive analytics, cyber-physical systems, and others. Its flexibility and standardization position it as the essential protocol for industrial digital transformation. Below are the most relevant parts of the standard that are essential for integration with artificial intelligence techniques.

OPC 10000-1: UA Part 1: Overview and Concepts []: This section of OPC 10000 introduces the fundamental concepts and provides a comprehensive overview of the OPC-UA. Familiarity with this document facilitates understanding of subsequent parts in the OPC 10000 series. The document briefly outlines each component of the series and recommends an optimal sequence for reviewing the documentation.

OPC 10000-2: UA Part 2: Security []: This section delineates the OPC-UA security model, addressing potential threats across physical, hardware, and software environments where OPC-UA operates. It articulates how OPC-UA leverages existing security standards, defines key terminology used throughout the specification series, and outlines general security features. The document connects these features to security concepts detailed in other OPC-UA specifications, references normative services, mappings, and profiles from companion documents, and offers implementation best practices. Any perceived inconsistencies between this document and other normative specifications do not diminish requirements established in those normative documents.

OPC 10000-3: UA Part 3: Address Space Model []: Describes how information is structured through nodes (objects, variables, methods) and hierarchical relationships, allowing complex data and contextual semantics to be represented in a standardized format that facilitates interoperability.

OPC 10000-4: UA Part 4: Services []: Specifies basic communication services, such as reading/writing variables, method execution, real-time subscription management, and event handling. These services are the basis for interaction between clients and servers.

OPC 10000-5: UA Part 5: Information Model []: The specified section of OPC Unified Architecture establishes the Information Model framework, which delineates standardized nodes within a server’s AddressSpace. These nodes comprise both standardized types and instances that serve diagnostic functions or act as entry points to server-specific nodes. Consequently, the Information Model defines the AddressSpace architecture for a baseline OPC-UA server, though it should be noted that comprehensive implementation of all defined nodes is not an expectation for all server deployments.

OPC 10000-6: UA Part 6: Mappings []: Details how OPC-UA is implemented over transport protocols such as TCP, HTTP, or MQTT, ensuring compatibility with traditional and modern industrial networks, including integration with web-based and cloud-based systems.

OPC 10000-16: UA Part 16: State Machines []: Models the dynamic behavior of systems using state machines (states, transitions, and events), enabling the management of complex lifecycles in industrial processes, such as manufacturing sequences or diagnostics.

3. Systematic Review

Before detailing the proposed systematic review methodology, a review of the state-of-the-art surveys is conducted. Schindler et al. [] conducted a mini-review showing that reinforcement learning applications with OPC-UA highlight the protocol’s potential for enabling adaptive control systems that can learn and optimize industrial processes in real-time. This work reveals that OPC-UA’s publish-subscribe mechanisms and historical data access capabilities provide the necessary infrastructure for reinforcement learning agents to observe system states, execute actions, and receive feedback from industrial processes. This work focuses specifically on the reinforcement learning area. Furthermore, the systematic literature review proposed by Velesaca et al. [] shows that the integration of data mining and natural language processing with OPC-UA demonstrates how the protocol’s semantic information models can be leveraged to extract meaningful insights from industrial data streams. This enables more sophisticated Machine Learning applications such as anomaly detection, pattern recognition, and automated decision-making. Similar to the previous work, it only focuses on specific techniques for data mining and NLP. Finally, Balador et al. [] present a literature review showing that OPC-UA serves as a communication middleware. This allows for the seamless data exchange between diverse industrial systems and provides the standardized interface necessary for Machine Learning algorithms to access real-time operational data. The previously reviewed works show how OPC-UA can be integrated with Machine Learning models, which will be carried out. However, these works do not show implementation details, specific architectures, or a complete detail of all existing technique categories.

Unlike surveys focused solely on ML in manufacturing, this review centers on the convergence with OPC-UA. We analyze not only techniques and applications but also the specific roles of OPC-UA (communication protocol, information model, state machines, companion specifications), deployment topologies (edge/fog/cloud), and system-level constraints (latency, reliability, security). This perspective yields integration patterns and actionable guidance for architecting ML systems grounded in industrial standards.

A systematic review of the literature involves identifying, evaluating, and interpreting the most relevant studies on a specific topic, research question (RQ), or phenomenon. Therefore, the general objective of such a process is to provide evidence that answers a set of RQs derived from primary studies in which the subject of study has been previously addressed. To carry out the systematic review process, this article followed the methodological guidelines proposed by [] for developing literature reviews in the field of Software Engineering. However, since the detailed process is quite general, its application in this study has been deemed feasible after contrasting it with another methodological tool oriented toward the development of studies of the same nature in the area of Computer Sciences proposed by []. The application of this process is detailed in the sections below.

3.1. Definition of RQs

Given the recent interest of the scientific community in applying Machine Learning techniques to industrial system architectures for process automation, this systematic review answers six research questions. These questions, which other similar studies have not addressed, served as the primary guide for the review process and are detailed as follows:

- RQ1: What integration patterns and system architectures leveraging OPC-UA enable the adoption of Machine Learning in industrial automation?

- RQ2: How are Machine Learning techniques implemented and deployed across different layers of an industrial system, and what role does OPC-UA play at each level?

- RQ3: What are the most common Machine Learning algorithms used in OPC-UA-based industrial systems, and what are the specific criteria that influence their selection and suitability for different applications?

- RQ4: What methodologies and implementation strategies are applied to deploy Machine Learning techniques with OPC-UA?

- RQ5: What measurable outcomes are reported, and how are these improvements evaluated to enable comparison of effectiveness across different studies?

- RQ6: What are the strengths, weaknesses, opportunities, and threats (SWOT) of the Machine Learning + OPC-UA paradigm, and what benchmark and validation frameworks are needed?

3.2. Selection of Information Sources

The previously defined research questions guided the selection of key terms for the search process. These primary terms include (machine learning, machine learning technique), (industrial system, industrial system architecture, industrial process), (intelligent, artificial intelligence), and (automation, automation process). Using these terms, three search strings (SS) are strategically formulated to follow the structure described below:

- SS1: (“opc-ua” OR “OPC-UA”) AND “machine learning” AND (“manufacturing” OR “embedded” OR (“industrial” AND “automation”));

- SS2: (“opc-ua” OR “OPC-UA”) AND “machine learning” AND (“control” OR “controller”) AND “based” AND (“industrial” OR “industry”);

- SS3: (“opc-ua” OR “OPC-UA”) AND “deep learning”;

Once the SS have been defined, the next step is to identify the information sources for executing the search equations. This is done to retrieve the most relevant studies addressing the integration of Machine Learning and OPC-UA, published in high-impact scientific journals. Following the methodological frameworks proposed by [,] for conducting literature reviews, a total of five primary information sources (PIS) are considered.

ACM Digital Library (PIS1) stands out for being the most complete and specialized digital library in the field of computer science, with a fundamental historical collection for computer science research; the IEEE Digital Library (PIS2) stands out for its specific focus on electrical engineering, electronics and computer science; the ISI Web of Science (PIS3) is distinguished by its rigorous system of academic citation indexes and impact analysis of scientific publications; Scopus (PIS4) stands out for being Elsevier’s largest bibliographic database of abstracts and citations, covering multiple academic fields; and finally, Springer (PIS5) is characterized by its extensive collection of scientific, technical and medical publications, with a strong emphasis on books and academic journals.

- PIS1: Association for Computing Machinery (ACM) Digital Library, accessed on 7 February 2025, available at: https://dl.acm.org/

- PIS2: Institute of Electrical and Electronics Engineers (IEEE) Digital Library, accessed on 7 February 2025, available at: http://ieeexplore.ieee.org/

- PIS3: Institute for Scientific Information (ISI) Web of Science Database, accessed on 7 February 2025, available at: https://webofknowledge.com/

- PIS4: Scopus of Elsevier Database, accessed on 7 February 2025, available at: https://www.scopus.com/

- PIS5: Springer Database, accessed on 7 February 2025, available at: https://link.springer.com/

4. Selection of Studies

The search process conducted in December 2024 involved utilizing each of the specified search engines to query the titles of relevant publications. This approach allowed us to eliminate numerous studies related to Machine Learning and industrial processes that did not specifically focus on Machine Learning techniques within industrial systems. Many of these discarded studies are centered only on digital twins, which are not pertinent to our investigation. Our primary focus is on studies where Machine Learning techniques are employed within industrial system architectures for process automation using OPC-UA.

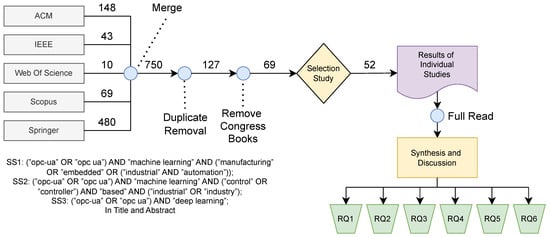

The exploration and discovery process produced a total of 750 studies. After the removal of duplicates and congress books, 69 unique studies remained. Following a review of the article summaries, 17 proposals are determined to be irrelevant to the study area, resulting in 52 studies for comprehensive analysis. Therefore, the analysis of the results in this systematic review considers 52 proposals as primary sources. The details of the process are illustrated in Figure 1, and the results of the selection process are presented in Table 1.

Figure 1.

Method applied for the systematic literature review.

Table 1.

Main primary information sources reviewed.

5. Results

We have structured our findings to directly answer each of the revised RQs outlined in Section 3.1. To help readers navigate our analysis, Table 2 acts as a guide, showing where each RQ is addressed through specific sections, figures, and tables. This systematic structure provides clear insight into how the reviewed literature addresses each research question.

Table 2.

Mapping research questions by sections, tables, and figures.

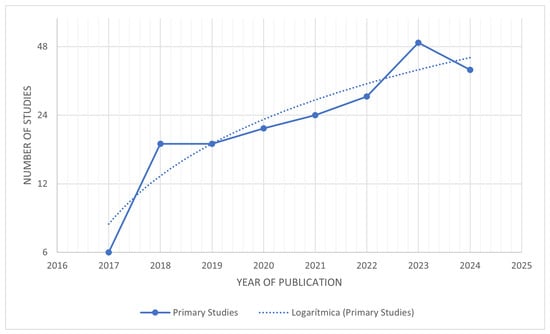

The result is a set of articles to read and answer the research questions and, based on the results, write this research. Figure 2 shows the temporal evolution of primary studies from 2017 to 2024, with a logarithmic trend line. Starting with 6 studies in 2017, a significant increase is observed up to 18 studies in 2018, followed by a period of more gradual growth. The number of studies peaks in 2023 with 48 publications, then declines to approximately 40 studies in 2024. The logarithmic trend line suggests that, although the field has experienced sustained growth, the growth rate is leveling off over time.

Figure 2.

Trend of the Machine Learning techniques within industrial processes according to current scientific publications.

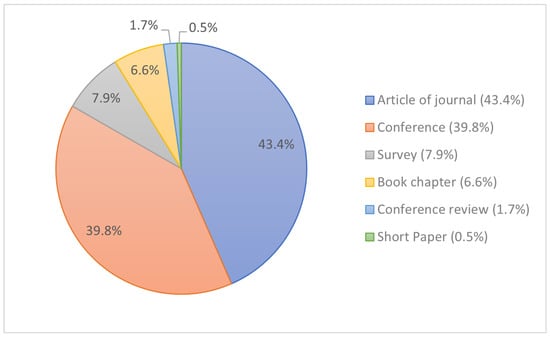

On the other hand, Figure 3 shows the distribution of different types of academic publications. Articles of journals account for the largest proportion with 43.4% of the total, closely followed by conferences with 39.8%. Surveys account for a smaller proportion with 7.9% and book chapters at 6.6%. The smallest categories are conference reviews with 1.7% and short papers with just 0.5% of the total. This distribution suggests that most publications in this field are done mainly through scientific journals and conferences.

Figure 3.

Nature of the studies that have addressed the process of Machine Learning techniques within the industrial process.

5.1. Applications

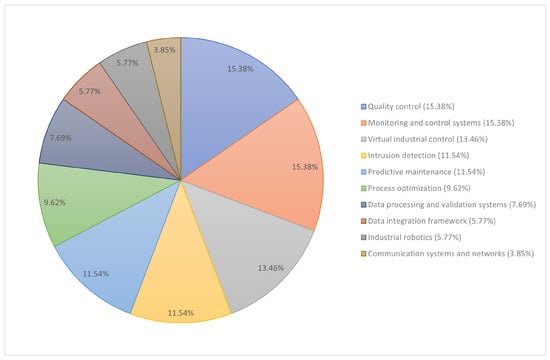

This systematic analysis identifies ten key application areas where Machine Learning and OPC-UA technologies converge. Table 3 provides a comparative summary of these applications, while Figure 4 illustrates their percentage distribution. Additionally, Table 4 highlights real-world examples from primary sources, offering a practical perspective on these implementations.

Table 3.

Applications found in the main primary information sources.

Figure 4.

Percentage distribution of the applications analyzed.

Table 4.

Examples of applications found in the main primary information sources.

Quality control: The fusion of OPC-UA with deep learning has revolutionized industrial inspection systems. Fernández et al. [] pioneered this integration by using thermal imaging and CNN-LSTM architectures to detect welding defects in real time. Rath et al. [] expanded this approach to textile manufacturing, creating vendor-independent protocols for predictive quality control across distributed production chains. Velesaca et al. [] now represent the cutting edge, combining thermographic imaging with deep neural networks to achieve unprecedented accuracy in defect classification.

Monitoring and control systems: The evolution of these systems began with Arévalo et al. [], who integrated Machine Learning into cloud-based platforms using evidence theory to fuse heterogeneous data streams. Iatrou et al. [] achieved a technological breakthrough by embedding OPC-UA servers directly into hardware, bridging operational devices with IT infrastructure. Kedari et al. [] further advanced remote monitoring capabilities, enabling secure supervision of critical processes with controlled latency thresholds.

Intrusion detection: Modern intrusion detection systems build on foundational work by Anton et al. [], who identified anomalous patterns in OPC-UA network traffic. Hildebrandt et al. [] elevated this approach by detecting supply chain vulnerabilities through encrypted data flow analysis. The current state of the art features Bindra and Aggarwal [], who implemented convolutional neural networks to detect multi-stage cyberattacks in real time, reducing false positives by 40% compared to conventional methods.

Virtual industrial control: Industrial process virtualization has evolved from Park et al. [] foundational frameworks to hybrid physical-digital architectures. Nam et al. [] developed OPC-UA interfaces that synchronize digital twins with physical equipment, enabling dynamic process adjustments. Rehmer et al. [] advanced this further with predictive simulation systems that anticipate production line failures with 92% accuracy.

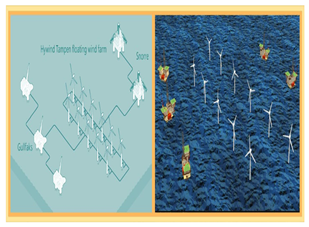

Predictive maintenance: The transition from reactive to predictive models began with Arévalo et al. [] cloud-based vibration analysis systems. Soller et al. [] enhanced these models by incorporating multisensory data and multivariate trend analysis. Friedrich et al. [] now demonstrate self-optimizing algorithms that adjust maintenance schedules based on operational wear patterns, reducing unplanned downtime by 68%.

Process optimization: Modern optimization strategies combine real-time data streams with adaptive analytics. Torres et al. [] established the groundwork by correlating process variables with key performance indicators. Nohl et al. [] implemented unified OPC-UA architectures enabling operational adjustments in under 200 ms. Gong et al. [] now employ recurrent neural networks to model nonlinear processes, achieving 15–20% energy efficiency gains in pilot installations.

Data processing and validation systems: Current validation frameworks benefit from Bakakeu et al.’s [] semantic ontologies for multi-source data verification. Tufek [] enhanced these systems with contextual inference engines that detect data anomalies in real time. Tufek et al. [] further advanced this field by integrating federated learning techniques for distributed validation without compromising data confidentiality.

Data integration framework: Interoperability in complex environments is enabled by Kirmse et al. [] framework for heterogeneous data ingestion. Lockner et al. [] optimized integration processes through adaptive preprocessing, reducing implementation timelines by 70%. Hirsch et al. [] now demonstrate scalable OPC-UA architectures capable of managing petabyte-scale operational data with sub-50 ms latency.

Industrial robotics: Robotic system integration began with Pereira et al.’s [] DINASORE architecture for multi-robot coordination. Webb et al. [] enhanced these systems with reinforcement learning interfaces for contextual adaptation. Diprasetya et al. [] now combine 3D vision systems with remote haptic controls, enabling human-robot collaboration with micrometer-level precision.

Communication systems and networks: The evolution of industrial networks is exemplified by Sharma et al. [], who designed fault-tolerant architectures for critical environments. Pospisil and Fujdiak [] improved interoperability through dynamic protocol identification mechanisms. Current developments prioritize AI-driven network segmentation and adaptive security protocols to counter multi-vector cyber threats while maintaining sub-millisecond latency.

Finally, Table 3 synthesizes the industrial application landscape enabled by OPC-UA and related ecosystems, linking sensors/devices with dominant data modalities and suitable ML families. Clear cross-cutting patterns emerge: convergence on PLCs, OPC-UA servers/gateways, and vision/telemetry; multimodal data (images, multivariate time series, network flows) with challenges of class imbalance, drift, and interoperability; and a toolbox spanning classical ML (RF/XGBoost, SVM), anomaly detection (One-Class, autoencoders), deep learning (CNN/LSTM/Transformers), and control/optimization methods (RL, Bayesian surrogates). This structure reflects growing maturity in quality control, predictive maintenance, and robotics, while data integration and cybersecurity continue to drive robust and interpretable methodologies. Overall, the mapping provides a practical guide to align instrumentation and data management with the most appropriate ML techniques for each operational objective.

5.2. Techniques

The convergence of artificial intelligence and OPC-UA has undergone a remarkable transformation in recent years, revealing significant patterns and trends in its implementation and evaluation. Our analysis of the specialized literature highlights a preference for certain techniques that have proven particularly effective in industrial settings, supported by a diverse set of performance metrics. Table 5 provides the details of the techniques found in the analyzed articles. On the other hand, the description of the abbreviation of the techniques and metrics shown in Table 5 is listed in the last section, Abbreviations.

As a starting point, it is important to highlight the studies related to FUT, encompassing 16 references. These works present approaches specifically designed to facilitate the future incorporation of Machine Learning techniques in industrial environments. While they currently do not directly implement ML algorithms, they establish the necessary structural foundations for future integration, underscoring their crucial role in the evolution toward more intelligent industrial systems [,,].

Among specific techniques, Convolutional Neural Networks (CNNs) have established themselves as one of the most robust and reliable approaches in OPC-UA implementations. Recent studies by Bindra, Revankar, and Rahadian [,,] consistently report accuracies above 98%, setting a high standard for industrial applications that demand visual analysis and real-time signal processing.

On the other hand, Random Forest (RF) is another highly effective technique, distinguished by its robustness and consistency across various application scenarios. Research by Kedari and Anton [,] demonstrates RF implementations achieving accuracies between 98–100%, significantly outperforming alternative techniques such as SVM and SLR. Its ability to handle non-linear data and resistance to overfitting have contributed to its widespread adoption in industrial settings.

Hybrid architectures, particularly CNN-LSTM integration, have gained prominence in applications requiring simultaneous temporal and spatial processing. Fernandez’s work [] demonstrates the effectiveness of this combination, achieving 98.9% accuracy by leveraging the complementary strengths of both techniques.

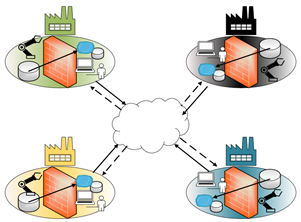

Federated learning (FL) represents an emerging trend, as evidenced by studies from Friedrich, Pop, Parto, and Kaymakci [,,,]. This technique has gained relevance due to its ability to maintain data privacy while enabling distributed learning, a crucial aspect in modern industrial environments.

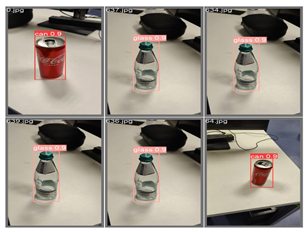

Recent implementations also show a clear trend toward more sophisticated architectures such as YOLOv8, which has demonstrated exceptional performance in real-time detection and classification tasks. The works of Filimonov and Velesaca [,] validate the effectiveness of this technique, achieving accuracies up to 99% with notably low processing times.

In the domain of collective decision-making, Majority Voting Classifiers (MVC) have emerged as an elegant and effective approach. Their fundamental principle of combining multiple algorithmic perspectives allows them to overcome the limitations inherent to individual classifiers [,]. This consensus capability is especially valuable in industrial environments where reliability and robustness are a priority, allowing heterogeneous data and complex situations to be handled competently.

In unstructured information processing, Named Entity Recognition (NER) is opening new horizons, transforming how industrial systems interpret and process technical documentation. This technology facilitates the digital transition of legacy systems and significantly improves interoperability between different industrial platforms [,].

Recent studies reveal a clear trend towards more diversified Machine Learning techniques, particularly hybrid models such as CNN-LSTM for handling complex time-series and image data. However, a significant limitation is that most published results are derived from small datasets or simulated environments. This highlights a critical need for standardized benchmarks and open datasets to enable fair comparisons and enhance reproducibility across studies. Furthermore, while techniques like DetNet and DQN are promising, their computational requirements may limit their widespread adoption in resource-constrained industrial settings.

The ongoing evolution of artificial intelligence in industrial environments consistently demonstrates the adaptability and robustness of various algorithmic approaches. From the versatile capabilities of ANNs in handling dynamic operational environments to the strength of MVC in building reliable consensus, each technique brings unique advantages to industrial applications. The increasing integration of multiple techniques, exemplified by combinations like DBN-BPNN, suggests a future where technological convergence will be the primary driver of innovation in industrial automation.

In conclusion, while CNNs, RF, and hybrid CNN-LSTM models report high accuracy, their relative advantages are scenario-dependent:

- Visual inspection (thermal or RGB): CNNs/YOLO excel when sufficient labeled data and controlled optics are available; performance degrades with domain shifts (illumination, angle, lens contamination) unless data augmentation or domain adaptation is applied.

- Tabular/heterogeneous signals: RF delivers robust performance on mixed, non-linear features with limited tuning, often outperforming SVMs in noisy environments; however, it may underperform deep sequential models on long temporal dependencies.

- Temporal dynamics: CNN-LSTM hybrids are preferable when spatio-temporal patterns matter (e.g., welding beads, robot trajectories), but they increase compute and latency costs at the edge.

Drivers of disparities observed across studies include dataset size (small/simulated vs. large/real-world), sensor noise and environmental variability, operator-induced process changes, and strict real-time constraints. Studies reporting near-perfect accuracy often rely on small or controlled datasets; reproducibility under diverse industrial conditions remains limited, highlighting the need for open benchmarks (see Section 5.6 and Future Work Section 6).

5.3. Metrics

In terms of evaluation metrics, there is an evolution towards more comprehensive approaches that go beyond simply measuring accuracy. While accuracy continues to be the most reported metric, more rigorous studies incorporate a broader set of metrics, including F1-Score, Precision, and Recall, providing a more complete assessment of system performance.

Metrics specific to regression and prediction applications, such as Root Mean Squared Error (RMSE) and Mean Absolute Percentage Error (MAPE), have proven to be fundamental in the evaluation of predictive models. For example, the work of Minh et al. [] reported impressive MAPE errors below 2% and coefficients of determination (R2) above 0.94, showing high accuracy in predictions.

Performance evaluation in industrial implementations has evolved to include domain-specific metrics such as quality of control (QoC) and production efficiency. The work proposed by Wang et al. [] exemplifies this trend, reporting 100% production efficiency and 95% resource utilization rates, crucial metrics in industrial production environments.

The current trend in the evaluation of OPC-UA-based systems clearly favors multi-metric evaluation frameworks. These frameworks consider not only technical accuracy, but also practical aspects such as computational efficiency, scalability, and system robustness. In this way, metrics to evaluate real-time and latency considerations have gained significant importance, reflected in the use of metrics such as RTT (Round Trip Time) and E2E (End-to-end delay) [,]. The study by Nam et al. [] demonstrates the importance of these metrics in robotic applications, reporting low RTTs (83–156 ms), while Sharma et al. [] obtain low E2E (5–20 ms) using the DetNet approach.

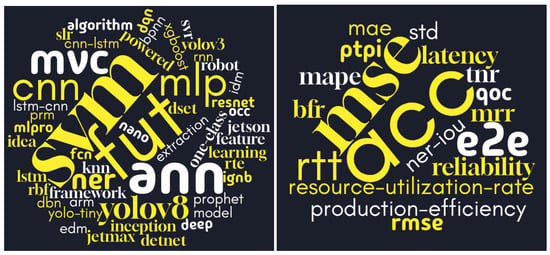

To visually analyze the techniques and metrics, word cloud graphics are used. The two-word clouds created reveal different aspects of a study related to Machine Learning and performance metrics. The first-word cloud Figure 5 (left) emphasizes frequently mentioned deep-learning algorithms and technologies, such as “SVM”, “ANN”, “CNN”, “MVC”, and “MLP”. Interestingly, the term “FUT” also appears prominently, indicating ongoing efforts to design architectures for future integration with Machine Learning techniques. Furthermore, frameworks such as “YOLOv3” and “YOLOv8” are mentioned. The second-word cloud Figure 5 (right) focuses on metrics and evaluation measures, highlighting terms like “Latency”, “Reliability”, “Resource utilization rate”, and “Production Efficiency”, along with technical metrics such as “Acc.”, “MSE”, “MAPE”, “E2E”, and “RTT”. This distribution suggests a study that encompasses both performance and efficiency aspects, as well as specific implementations of deep-learning algorithms and their specific industrial implementation.

Figure 5.

(left) Word cloud based on techniques. (right) Word cloud based on metrics.

Table 5.

Techniques found in the main primary information sources.

Table 5.

Techniques found in the main primary information sources.

| Reference | Year | Techniques | ML Metrics | OPC-UA Metrics |

|---|---|---|---|---|

| Bindra and Aggarwal [] | 2024 | CNN, RF, GB, SVM | CNN (Acc. = 98%, P = 98%, F1 = 97%, R = 97%); RF, GB, SVM (Acc. = 86–91%); RF, GB, SVM (P = 85–90%); RF, GB, SVM (F1 = 84–89%); RF, GB, SVM (R = 84–89%) | |

| Revankar et al. [] | 2024 | CNN (Inception Model V3) | Acc. = 98.84% | - |

| Rahadian et al. [] | 2022 | CNN | Acc. = 99.9%, P = 99.9%, R = 1.0, F1 = 0.999 | - |

| Kaymakci et al. [] | 2021 | FL, LSTM-CNN | MAE = 0.12 | - |

| Fernandez et al. [] | 2020 | CNN-LSTM | Acc. = 98.9% | - |

| Kedari et al. [] | 2022 | RF, SLR | RF (Acc. = 98%), SLR (Acc. = 75%) | - |

| Pereira et al. [] | 2020 | RF, SVM, ANN | Best RF; Metrics (P, R, F1); No values are presented | - |

| Anton et al. [] | 2019 | RF, SVM | RF (Acc. = 99.84–99.98%); SVM (Acc. = 90.81–92.53%, F1 = 85.2–94.9%) | - |

| Arévalo et al. [] | 2018 | RF, AB, ANN MLP, DSET | RF (Acc. = 99.83–100.00%); ANN MLP (Acc. = 71.31–96.65%); AB (Acc. = 87.80–100%); DSET (Acc. = 99.83–100%) | - |

| Friedrich et al. [] | 2024 | FL | - | - |

| Pop et al. [] | 2021 | FL | QoC = 0.4103 | - |

| Parto et al. [] | 2020 | FL, IGNB | - | Latency of IGNB prediction in the fog cluster = 828.8 ± 24.2 ms, Latency of IGNB federated learning in the cloud = 2.4 ± 0.4 ms |

| Filimonov et al. [] | 2024 | YOLOv8 | Acc. = 100%, F1 = 1.0 | PTPI = 80.4 ms |

| Velesaca et al. [] | 2024 | YOLOv8 | Acc. = 93% | E2E = 159 ms, RTT = 168 ms |

| Gichane et al. [] | 2020 | YOLOv3, YOLO-Tiny | YOLOv3 (Acc. = 79.21%), YOLO-Tiny (Acc. = 47.75%) | - |

| Minh et al. [] | 2023 | ANN | RMSE (X = 0.0150, Y = 0.0104, Z = 0.0100); MAPE (X = 1.598%, Y = 1.707%, Z = 1.824%), R2 (X = 0.944, Y = 0.975, Z = 0.964) | - |

| Park et al. [] | 2022 | ANN | Acc. = 99.4% | - |

| Bonomi et al. [] | 2021 | MVC, DT, RF, MLP, AB, GB | Best MVC (Acc. = 100%, R = 100%, TNR = 100%, F1 = 100%) | - |

| Arévalo et al. [] | 2018 | MVC, KNN, SVM, NB | MVC (Acc. = 96.99–99.88%); KNN (Acc. = 96.34–99.54%); SVM (Acc. = 93.07–99.77%); NB (Acc. = 89.64–94.75%) | - |

| Tufek [] | 2023 | NER | No final metrics are specified as this is an ongoing research proposal | - |

| Tufek et al. [] | 2023 | NER, SVM with RBF | NER (IoU = 0.21–0.27); SVM (P = 0.55–0.57, R = 0.55–0.57, Acc. = 0.52–0.57, F1 = 0.53–0.57) | - |

| Schäfer et al. [] | 2022 | RL | - | - |

| Bakakeu et al. [] | 2020 | RL | MRR = 76–83, HITS@10 = 88–96, HITS@3 = 76–88, HITS@1 = 68–85 | - |

| Lockner et al. [] | 2023 | SVM, RNN, AB, SVR | SVM (R2 = 0.92); RNN (MSE = 0.031); AB (R2 = 0.805); AB with SVR (MSE = 0.0032, STD = 0.0055) | - |

| Soller et al. [] | 2021 | One-Class SVM, IF, AE, MVC | One-Class SVM (Acc. = 46.97%, P = 0.57, R = 0.57); AE (Acc. = 45.43%, P = 0.34, R = 0.64); IF (Acc. = 27.73%, P = 0.26, R = 0.64); MVC (Acc. = 46.52%, P = 0.59, R = 0.57) | - |

| Wang et al. [] | 2024 | DQN | Production efficiency = 100%, Resource utilization rate = 95% | - |

| Gönnheimer et al. [] | 2023 | LSTM, RF, FCN, ResNet | LSTM (Acc. = 95.71%) | - |

| Haghshenas et al. [] | 2023 | Prophet Algorithm | - | - |

| Nam et al. [] | 2023 | JetMax robot arm powered by Jetson Nano and Deep Learning | - | RTT (Min = 83 ms, Max = 156 ms) |

| Pospisil and Fujdiak [] | 2023 | XGBoost | Acc. = 90.91%, P = 93.18%, R = 90.91%, F1 = 90.65% | - |

| Tiwari et al. [] | 2023 | GA, RTE | Path tracking accuracy (up to 0.23 mm), MSE position = 0.53 mm2 | - |

| Hildebrandt et al. [] | 2020 | OCC | Acc. = 89.5% | - |

| Pinto et al. [] | 2022 | iDCA | Acc. = 93% | - |

| Rehmer et al. [] | 2024 | MLP, PRM, EDM, IDM | All techniques BFR = >90% | - |

| Sharma et al. [] | 2023 | DetNet | Reliability = >99.999% | E2E = 5–20 ms |

| Wang et al. [] | 2021 | DBN, BPNN | DBN (Acc. = 97.1%, MSE = 4.2%); BPNN (Acc. = 88.2%, MSE = 11.2%) | - |

| Poka et al. [] | 2024 | FUT | - | - |

| Diprasetya et al. [] | 2023 | FUT, MLPro Framework | - | - |

| Hirsch et al. [] | 2023 | FUT | - | - |

| Rosa et al. [] | 2023 | FUT | - | - |

| Schneider et al. [] | 2023 | FUT | - | - |

| Webb et al. [] | 2023 | FUT | - | - |

| Gong et al. [] | 2022 | FUT | - | - |

| Nohl et al. [] | 2021 | FUT | - | - |

| Rath et al. [] | 2021 | FUT | - | - |

| Céspedes and Barrera [] | 2020 | FUT | - | - |

| Anton et al. [] | 2019 | FUT | - | - |

| Cupek et al. [] | 2019 | FUT | - | - |

| Torres et al. [] | 2019 | FUT | - | - |

| Iatrou et al. [] | 2019 | FUT | - | - |

| Hormann et al. [] | 2018 | FUT, Feature extraction | - | - |

| Kirmse et al. [] | 2018 | FUT | - | - |

5.4. OPC-UA Based Topology Using Machine Learning Techniques

The implementation of ML techniques in industrial environments with OPC-UA shows diverse deployment patterns across different architectural levels. Table 6 shows an OPC-UA-based topology using Machine Learning techniques. Cloud deployments represent a significant trend, with studies like Rath et al. and Friedrich et al. [,] demonstrating the effective use of OPC-UA as a communication protocol in cloud-based architectures. Some implementations extend beyond simple cloud deployment, incorporating fog layer capabilities and federated learning approaches, as shown in the works of Parto and Pop [,], leading to more sophisticated distributed architectures.

Table 6.

OPC-UA-based topology using Machine Learning techniques.

Edge computing has also emerged as another prominent deployment location. Basic edge deployments, as demonstrated by Rosa et al. [] and Gong et al. [], primarily utilize OPC-UA as a communication protocol. More specialized edge implementations, such as the DINASORE framework used by Pereira et al. [] and Pinto et al. [], leverage OPC-UA’s information model and address space model capabilities. Furthermore, hardware-specific edge implementations using Raspberry Pi and Nvidia Jetson Nano platforms, as shown in Revankar and Torres’ work [,], demonstrate the versatility of OPC-UA on resource-constrained edge devices.

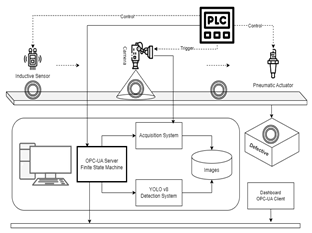

Local computer implementations represent the largest category of deployments, with numerous studies from researchers like Gonnheimer, Bindra, and Wang [,,], demonstrating the effectiveness of OPC-UA as a communication protocol in traditional computing environments. These implementations often focus on specific industrial applications and demonstrate the protocol’s versatility in handling various Machine Learning tasks. Table 6 further details specialized deployment scenarios. For instance, Hardware-in-the-Loop (HiL) simulation demonstrated by Schafer et al. [] uniquely utilizes both OPC-UA’s information modeling and communication protocol capabilities. Process control level implementations, as shown in Poka’s work [], and workstation-based deployments, including Anton’s [] anomaly detection system and Velesaca’s [] implementation using OPC-UA Finite State Machine, represent more specific architectural approaches. On the other hand, Fernandez et al. [] use a part of the OPC-UA specification that proposes a finite state machine for vision tasks.

Another key use of OPC-UA involves leveraging its information model to extract data and logs for subsequent specific analyses, as performed by Kedari et al. [], Park et al. [], and Pospisil et al. []. Interestingly, a significant number of studies, including works by Anton, Bakakeu, and Hildebrandt [,,], utilize OPC-UA as a communication protocol without explicitly specifying their deployment location. This suggests that the protocol’s core functionality can be effectively employed regardless of the specific underlying architecture.

Finally, this diverse range of deployment locations and implementation approaches demonstrates OPC-UA’s flexibility and scalability across different architectural levels, from resource-constrained edge devices to powerful cloud infrastructures, while maintaining its core functionality as either a communication protocol or information model framework.

5.5. ML Techniques Classification and OPC-UA

This section classifies the Machine Learning techniques found in the analyzed articles, aligning with the taxonomy proposed by Kotsiantis et al. [,], as detailed in Table 7. The table also includes the specific usage role of OPC-UA for each ML category.

Table 7.

Relationship between Machine Learning techniques and OPC-UA usage.

Detailed analysis reveals that OPC-UA plays a multifaceted role in ML implementations for industrial automation. Table 7 shows that OPC-UA primarily serves as a universal communication protocol (ComProto) in 71.43% of implementations, enabling interoperability between heterogeneous systems.

Additionally, 21.43% of implementations leverage its semantic information model (InfoModel) to structure data in a semantically rich manner, optimizing Machine Learning processing. A smaller portion, 7.14%, utilizes advanced features such as finite state machines and companion specifications (FSM and VDMA) for highly specific applications. This versatility is complemented by its architectural adaptability, supporting consistent deployments across cloud, edge, and on-premises environments.

Among the Machine Learning techniques found, Convolutional Neural Networks (CNN) establish themselves are the most popular technique in OPC-UA implementations, primarily utilizing the communication protocol while occasionally leveraging the information model for enhanced data structuring, as demonstrated in [,,]. These implementations excel in industrial quality control applications, where they perform real-time visual analysis and defect detection in manufacturing processes. The hybrid CNN-LSTM architectures, in [,], extend these capabilities by incorporating OPC-UA’s VDMA specification for complex temporal-spatial applications, particularly in welding defect detection using thermal imaging systems. CNN-YOLO implementations, referenced in [,], combine the communication protocol with the information model to enable intelligent object identification systems within CODESYS PLCs and industrial computer vision applications that require real-time processing capabilities.

On the other hand, Random Forest emerges as a highly effective technique that exclusively employs OPC-UA’s communication protocol, as shown in [,], specializing in critical intrusion detection systems and secure remote monitoring applications. This technique demonstrates exceptional robustness in handling non-linear industrial data and provides resistance to overfitting, making it particularly suitable for critical supervision systems where reliability is paramount. Naive Bayes techniques, proposed in [,], also utilize the communication protocol for process monitoring and optimization applications, though they are less common in industrial automation scenarios where deterministic performance is required.

Also, Support Vector Machines (SVM) and their One-Class variants exclusively utilize OPC-UA’s communication protocol, according to [,,,], specializing in anomaly detection and predictive maintenance applications within industrial environments. These techniques demonstrate particular effectiveness in integrating heterogeneous data sources and systems where model interpretability is crucial for operational decision making. The One-Class SVM variant has consolidated as a specialized solution for anomaly detection in complex industrial systems, where identifying atypical patterns is fundamental for preventive maintenance strategies and operational safety protocols in manufacturing environments.

Other techniques, such as reinforcement learning (RL), represent an advanced category that leverages both OPC-UA’s communication protocol and information model, according to [,], specializing in Hardware-in-the-Loop simulations and reasoning over information models through graph embeddings. These implementations are characterized by their adaptive optimization capabilities in complex industrial processes where dynamic decision making is required. Genetic Algorithms (GA), documented in reference [], use the communication protocol for process optimization applications, while techniques like Deep Q-Network (DQN) combine both OPC-UA approaches for intelligent control applications and automated decision-making systems in industrial automation scenarios.

The latest reviewed approach, combining techniques among which are AdaBoost (AB) and XGBoost, utilizes OPC-UA’s communication protocol according to [,,,], finding application in distributed monitoring systems and advanced communication networks for industrial IoT platforms. Federated learning (FL), documented in references [,], represents an innovative approach for industrial IoT platforms that maintains data privacy while enabling distributed learning across industrial networks. Specialized techniques like DetNet, referenced in [], focus on deterministic communications for 6G networks with stringent reliability requirements and ultra-low latency constraints. Lastly, techniques such as iDCA utilize the information model for anomaly detection by design in cyber-physical production systems, facilitating proactive quality control and system monitoring capabilities.

The integration of native security features and real-time communication services positions OPC-UA as a fundamental element for ML implementations in critical industrial environments that demand immediate response. This diversity of roles transcends the traditional function of a communications protocol, establishing OPC-UA as a comprehensive platform for the effective integration of Machine Learning in industrial environments, where the combination of interoperability, semantic data structure, robust security, and real-time capabilities is essential for the success of intelligent automation implementations.

5.6. SWOT

This systematic review highlights important aspects of the integration of Machine Learning techniques with OPC-UA in industrial environments. Through a literature analysis, the critical strengths, weaknesses, opportunities, and threats (SWOT) (see Table 8) that characterize current and prospective implementations have been identified. This SWOT analysis provides valuable insights for organizations considering or implementing ML-OPC-UA solutions, highlighting both potential benefits and challenges that need to be addressed.

Table 8.

Findings of strengths, weaknesses, opportunities, and threats (SWOT) in the systematic literature review.

5.6.1. Strengths

OPC-UA stands out as a central enabler for industrial process automation because it is more than a transport protocol. It is a comprehensive industrial standard that combines a communication framework with a rich, unified information model and profiles for interoperability [,]. Its service-oriented architecture (SOA) and information modeling capabilities (OPC 10000 Parts 3–5) facilitate semantic interoperability across heterogeneous devices and systems and provide a consistent data abstraction layer that is particularly well suited for ML pipelines [,,]. The standard’s security model (OPC 10000-2) integrates encryption, authentication, and access control, which is essential for ML-driven applications operating in safety-critical environments [].

A further strength is architectural flexibility from edge to cloud. The literature documents successful deployments that use OPC-UA as a universal communication protocol in cloud or cloud–fog settings [,,,] as well as on resource-constrained edge platforms such as Raspberry Pi and Nvidia Jetson Nano [,,,]. More specialized edge frameworks (e.g., DINASORE) and workstation/local-computer deployments leverage both the address space and information modeling to structure data for downstream analytics [,,,,]. OPC-UA’s domain-specific extensions also enable higher-level integrations: companion specifications such as VDMA Vision and finite state machine (FSM) models have been used to couple perception and stateful control with ML in vision and welding applications [,,].

OPC-UA’s support for timely data exchange further strengthens its role in ML-centric control loops. Studies that target deterministic networking report high reliability and bounded end-to-end latencies, which are conducive to near real-time ML inference in industrial scenarios []. In addition, multiple works exploit the information model to expose semantically structured telemetry and logs for feature extraction and model supervision [,,]. Taken together, these characteristics—standardized semantics, built-in security, and deployment portability—explain why OPC-UA most often appears as the interoperability backbone in ML-enhanced industrial systems (see also the distribution by role in Table 7).

5.6.2. Weaknesses

Despite these advantages, several weaknesses remain for ML-OPC-UA integration. First, there is a lack of standardized evaluation frameworks and openly available, domain-representative datasets tailored to OPC-UA-enabled ML scenarios, which hinders objective benchmarking and reproducibility (as synthesized in our review’s SWOT, Table 8). The heterogeneity of reported metrics across studies illustrates this gap: while ML task metrics are commonly reported (e.g., accuracy/F1 in [,,]; path/MSE metrics in []), OPC-UA/system-level metrics appear inconsistently—exceptions include explicit network/latency measurements such as RTT in [] and reliability/latency bounds in [] (Table 5).

Second, interoperability challenges persist when bridging OPC-UA with legacy controllers, PLC environments, and fragmented domain standards. Practical integrations often require mapping between OPC-UA address spaces and PLC/industrial stacks (e.g., CODESYS and process-control level integrations in [,]) or alignment across companion specifications (e.g., VDMA Vision, FSM usage in [,,]), which can introduce engineering overhead and semantic mismatch risks in multi-vendor settings.

Third, the computational demands of advanced ML/DL models can strain resource-constrained OPC-UA deployments at the edge. Although feasibility has been demonstrated on platforms like Raspberry Pi and Jetson Nano [,] and on embedded/robotic setups [,], these deployments typically require careful model optimization and scheduling to avoid contention with OPC-UA server loads and control-cycle constraints.

Finally, evidence of large-scale, real-world production rollouts remains limited in the surveyed literature. Many studies are conducted as lab-scale testbeds, workstation-based evaluations, or small pilots (e.g., local-computer categories in [,,]); specialized HiL or workstation cases in [,,], and a substantial subset does not specify the deployment context at all [,,,,,,,,]. This reporting pattern underscores the need for broader, longitudinal validations and standardized benchmarking suites to support technology transfer at scale.

5.6.3. Opportunities

The convergence of Machine Learning and OPC-UA technologies presents significant opportunities for advancing industrial automation, yet several critical areas require focused development to realize their full potential. Open benchmarks and evaluation suites represent a fundamental need, requiring curated and representative datasets that span common industrial tasks such as visual quality control (e.g., CNN/CNN–YOLO use cases in [,,,]), network intrusion detection [], and welding/vision applications leveraging FSM/VDMA models [,], complete with standardized train/validation/test splits and comprehensive metrics covering both task accuracy and system constraints including round-trip time and end-to-end performance as reported in system-level studies [,]—as well as reliability, throughput, and energy consumption (see the heterogeneity of reported metrics in Table 5). Federated learning in production environments offers promising solutions for privacy-preserving training across multiple plants through OPC-UA–secured data brokers, implementing lightweight aggregation at fog nodes while incorporating drift detection and client selection strategies specifically tailored to heterogeneous industrial devices [,,,]; OPC-UA’s native security model further supports these distributed designs []. The implementation of explainable AI for operators becomes crucial in industrial settings, necessitating saliency and attribution methods for visual quality control systems and counterfactual explanations for tabular and temporal models, and the utilization of OPC-UA information models as a semantic layer to anchor explanations directly to machine states for enhanced operator understanding [,,,,]. Edge optimization strategies must address the unique constraints of industrial environments through pruning, quantization-aware training, and knowledge distillation techniques—particularly on resource-constrained devices where OPC-UA is already deployed [,,,]—while developing scheduling policies aligned with OPC-UA server loads and programmable logic controller cycles [,], ultimately creating mixed-criticality pipelines that can bound worst-case inference latency leveraging deterministic networking insights [].

Emerging paradigms in artificial intelligence, particularly Vision Transformers, large language models, and generative approaches, are reshaping industrial automation capabilities while presenting unique deployment challenges in OPC-UA integrated environments. Vision Transformers have demonstrated superior performance in industrial visual inspection applications, with recent implementations showing enhanced capabilities for defect detection and quality control in manufacturing environments []. Large language models are being integrated into industrial systems for intelligent automation, with applications spanning from automated analysis to process optimization in manufacturing contexts []. Meanwhile, generative models, including diffusion-based approaches, are enabling synthetic defect data generation for addressing data scarcity in semiconductor manufacturing, particularly for rare fault scenarios in wafer defect detection []. The deployment strategy requires a tiered approach where computationally intensive models operate in edge-cloud hybrid architectures for comprehensive analytics, while optimized variants developed through industrial-specific quantization techniques support real-time inference under strict latency constraints in production environments. OPC-UA serves as the integration backbone for data exchange and semantic interoperability across manufacturing execution systems, enabling seamless communication between AI components and industrial infrastructure.

5.6.4. Threats

However, significant threats challenge the successful deployment of these technologies, particularly resource constraints arising from GPU and accelerator scarcity on legacy production lines; without lightweight model designs and careful runtime orchestration, systems may fail to meet critical real-time performance budgets on edge-class platforms where OPC-UA commonly operates [,,,].

Interoperability gaps pose another substantial challenge through companion specification fragmentation and inconsistent mappings between information models and Machine Learning feature schemas, which impede system reuse and integration across different industrial platforms—an issue made evident when bridging OPC-UA with PLC ecosystems and domain-specific companions such as CODESYS/PLC integrations and VDMA Vision/FSM models [,,,,].

The validation deficit in the field stems from the absence of open and realistic datasets, leading to overly optimistic results based on small or controlled test sets; this is compounded by heterogeneous reporting practices (Table 5) and frequent omissions of deployment context in several works [,,,,,,,,], which ultimately hinders meaningful comparability between approaches and slows widespread adoption. Security and safety concerns become amplified when Machine Learning attacks surface, including adversarial inputs and model extraction vulnerabilities, combined with operational technology risks; addressing these requires defense-in-depth strategies that extend beyond the traditional OPC-UA security provisions [] and align with the threat models motivating OPC-UA–monitored intrusion detection and secure monitoring use cases [].

6. Future Directions

Future research should prioritize edge-centric, secure, and explainable deployments under industrial constraints. Two primary areas emerge as the focal points of research. First, bringing lightweight Machine Learning directly to factory equipment through federated learning approaches that can handle real-world data variations while using OPC-UA for secure coordination [,,]. Second, developing AI systems that factory operators can actually understand and trust, with clear explanations and human oversight built into OPC-UA alarm systems [].

Safety must come first when deploying learning systems in industrial environments. This means testing AI models in shadow mode before they control real equipment, validating them through hardware-in-the-loop simulations, and using OPC-UA state machines to prevent dangerous actions [,]. To make lab research work in real factories, we need better synthetic data generation and techniques that help models adapt from simulated to actual plant conditions [,]. The research community also requires shared datasets, standardized testing pipelines, and common evaluation metrics that can be utilized by both industry and academia [].

Future automated Machine Learning systems should understand industrial constraints from the start. For edge deployments, this means finding the right balance between model performance and hardware limitations like processing power, memory, and response time. For cloud-based systems, it means optimizing entire data pipelines while considering both accuracy and practical factors like reliability and energy consumption [,]. By connecting these automated systems with OPC-UA’s information model [], we can track the evolution of datasets, features, and models throughout their entire lifecycle, making industrial AI systems more transparent and manageable.

Furthermore, future research directions can be expanded by exploring the integration of Large Scale Language Models (LLMs) with advanced workflow coordination protocols, such as the Model Context Protocol (MCP). LLMs have demonstrated significant advantages in managing complex industrial workflows [], including intelligent decision making for multi-step processes and dynamic adaptation of production tasks. MCP, for its part, is widely used for workflow coordination, offering robust capabilities for message transmission management and task scheduling in industrial environments [].

The synergy between LLMs and MCPs, combined with OPC-UA and Machine Learning technologies, could enable much more sophisticated and intelligent industrial workflow management. For example, LLMs could interpret and optimize production instructions, coordinate multi-agent tasks through MCPs, and leverage OPC-UA for secure and interoperable data exchange between heterogeneous systems, in addition to modeling and adding semantics to established plant architectures []. This integration would enable adaptive, explainable, and resilient automation, aligning the future perspective of industrial intelligence with the most advanced technological trends.

7. Conclusions

The integration of OPC-UA with Machine Learning techniques is consolidating as a key strategy for advancing industrial process automation. OPC-UA’s strengths—such as interoperability, security, and architectural flexibility—make it a robust foundation for deploying intelligent solutions across diverse industrial environments. However, the lack of standardized evaluation frameworks, persistent interoperability challenges with legacy systems, and the high computational demands of advanced ML models remain significant barriers to large-scale adoption.

Despite these challenges, the opportunities for OPC-UA are substantial. Its suitability for federated learning, privacy-preserving analytics, and advanced cybersecurity frameworks positions it as a central pillar for the next generation of smart manufacturing. To fully realize this potential, it is essential to address current weaknesses by developing open benchmarks, fostering empirical validation, and promoting best practices for integration. Overcoming resistance to change and reducing dependence on proprietary solutions will also be critical for sustainable and scalable deployment. In summary, OPC-UA, when combined with Machine Learning, offers a promising path toward more intelligent, secure, and adaptive industrial automation, provided that the identified challenges are systematically addressed.

Author Contributions

Conceptualization, H.O.V. and J.A.H.-T.; methodology, H.O.V. and J.A.H.-T.; validation, H.O.V., J.A.H.-T. and J.M.G.-G.; formal analysis, H.O.V.; investigation, H.O.V.; data curation, H.O.V.; writing—original draft preparation, H.O.V.; writing—review and editing, J.A.H.-T.; visualization, H.O.V.; supervision, J.A.H.-T. and J.M.G.-G.; project administration, J.A.H.-T.; funding acquisition, J.A.H.-T. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been partially supported by the University of Granada and the ESPOL Polytechnic University.

Data Availability Statement

Data are contained within the article.

Acknowledgments

We would like to extend our sincere gratitude to the anonymous reviewers for their time, insightful comments and constructive feedback.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AB | AdaBoost |

| Acc. | Accuracy |

| AE | Auto-encoder |

| ANN | Artificial Neural Network |

| BFR | Best Fit Rate |

| BPNN | Back Propagation Neural Network |

| CNN | Convolutional Neural Network |

| DBN | Deep Belief Network |

| DetNet | Deterministic Networking |

| DQN | Deep Q Network |

| DSET | Dempster-Shafer Evidence Theory |

| DT | Decision Tree |

| EDM | External Dynamics Model |

| E2E | End-to-end delay |

| FCN | Fully Convolutional Network |

| FL | Federated Learning |

| FUT | The architecture establishes a foundation for future integration of ML techniques |

| F1 | F1-Score |

| GA | Genetic Algorithms |

| GB | Gradient Boost |

| iDCA | Dendritic Cell Algorithm modified |

| IDM | Internal Dynamics Model |

| IF | Isolation Forest |

| IGNB | Incremental Gaussian Naive Bayes |

| KNN | K-Nearest Neighbors |

| LSTM | Long-Short-Term Memory |

| MAPE | Mean Absolute Percentage Error |

| MLP | Multi-Layer Perceptron |

| MRR | Mean Reciprocal Rank |

| MVC | Majority Voting Classifier |

| NB | Naive Bayes |

| NER | Named Entity Recognition |

| OCC | One-Class-Classifier |

| P | Precision |

| PRM | Polynomial Regression Model |

| PTPI | Processing Time Per Image |

| QoC | Quality of Control |

| R | Recall |

| RBF | Radial Based Function |

| ResNet | Residual Network |

| RF | Random Forests |

| RL | Reinforcement Learning |

| RMSE | Root Mean Square Error |

| RNN | Recurrent Neural Network |

| RTE | Regression Tree Ensembles |

| RTT | Round Trip Time |

| R2 | R-Squared or Determination Coefficient |

| SLR | Simple Linear Regression |

| SS | Standard Score |

| SVM | Support Vector Machines |

| SVR | Support Vector Regression |

| TNR | True Negative Rate |

References

- Drahoš, P.; Kučera, E.; Haffner, O.; Klimo, I. Trends in industrial communication and OPC UA. In Proceedings of the 2018 Cybernetics & Informatics (K&I), Lazy pod Makytou, Slovakia, 31 January–3 February 2018; pp. 1–5. [Google Scholar]

- Velesaca, H.O.; Sappa, A.D.; Holgado-Terriza, J.A. A case study of anomaly detection in tinplate lids: Supervised vs unsupervised approaches. In Proceedings of the 2025 11th International Conference on Automation, Robotics, and Applications (ICARA), Zagreb, Croatia, 12–14 February 2025; pp. 370–374. [Google Scholar]

- Busboom, A. Automated generation of OPC UA information models—A review and outlook. J. Ind. Inf. Integr. 2024, 39, 100602. [Google Scholar] [CrossRef]

- Velesaca, H.O.; Holgado-Terriza, J.A.; Guerrero, J.M.G. Optimizing smart factory operations: A methodological approach to industrial system implementation based on opc-ua. E3S Web Conf. EDP Sci. 2024, 532, 02004. [Google Scholar] [CrossRef]

- Weichert, D.; Link, P.; Stoll, A.; Rüping, S.; Ihlenfeldt, S.; Wrobel, S. A review of machine learning for the optimization of production processes. Int. J. Adv. Manuf. Technol. 2019, 104, 1889–1902. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.; Vita, R.; Francisco, R.d.P.; Basto, J.P.; Alcalá, S.G. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Bertolini, M.; Mezzogori, D.; Neroni, M.; Zammori, F. Machine Learning for industrial applications: A comprehensive literature review. Expert Syst. Appl. 2021, 175, 114820. [Google Scholar] [CrossRef]

- Schindler, S.; Uray, M.; Huber, S. A mini review on the utilization of reinforcement learning with OPC UA. In Proceedings of the 2023 IEEE 21st International Conference on Industrial Informatics (INDIN), Lemgo, Germany, 18–20 July 2023; pp. 1–6. [Google Scholar]

- Xia, D.; Jiang, C.; Wan, J.; Jin, J.; Leung, V.C.; Martínez-García, M. Heterogeneous network access and fusion in smart factory: A survey. ACM Comput. Surv. 2022, 55, 1–31. [Google Scholar] [CrossRef]

- Balador, A.; Ericsson, N.; Bakhshi, Z. Communication middleware technologies for industrial distributed control systems: A literature review. In Proceedings of the 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; pp. 1–6. [Google Scholar]

- OPC Foundation. OPC Unified Architecture. 2025. Available online: https://opcfoundation.org/ (accessed on 1 July 2025).

- OPC Foundation. OPC 10000-1: UA Part 1: Overview and Concepts; Technical Report; OPC Foundation: Scottsdale, AZ, USA, 2025. [Google Scholar]

- OPC Foundation. OPC 10000-2: UA Part 2: Security; Technical Report; OPC Foundation: Scottsdale, AZ, USA, 2025. [Google Scholar]

- OPC Foundation. OPC 10000-3: UA Part 3: Address Space Model; Technical Report; OPC Foundation: Scottsdale, AZ, USA, 2025. [Google Scholar]

- OPC Foundation. OPC 10000-4: UA Part 4: Services; Technical Report; OPC Foundation: Scottsdale, AZ, USA, 2025. [Google Scholar]

- OPC Foundation. OPC 10000-5: UA Part 5: Information Model; Technical Report; OPC Foundation: Scottsdale, AZ, USA, 2025. [Google Scholar]

- OPC Foundation. OPC 10000-6: UA Part 6: Mappings; Technical Report; OPC Foundation: Scottsdale, AZ, USA, 2025. [Google Scholar]

- OPC Foundation. OPC 10000-16: UA Part 16: State Machines; Technical Report; OPC Foundation: Scottsdale, AZ, USA, 2025. [Google Scholar]

- Velesaca, H.O.; Holgado-Terriza, J.A. OPC-UA in artificial intelligence: A systematic review of the integration of data mining and NLP in industrial processes. Manuf. Rev. 2025, 12, 9. [Google Scholar] [CrossRef]

- Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering; Technical Report, EBSE Technical Report EBSE-2007-01; Keele University: Keele, UK; Durham University: Durham, UK, 2007; Volume 1, p. 65. [Google Scholar]

- Kofod-Petersen, A. How To Do a Structured Literature Review in Computer Science. 2012, 1, 28. Available online: https://research.idi.ntnu.no/aimasters/files/SLR_HowTo2018.pdf (accessed on 1 July 2025).

- Bindra, S.S.; Aggarwal, A. Deep Learning-based Enhanced Security in Cyber-Physical Systems: A Multi-Attack Perspective. In Proceedings of the 2024 International Conference on Computational Intelligence and Computing Applications (ICCICA), Samalkha, India, 23–24 May 2024; Volume 1, pp. 347–352. [Google Scholar]

- Filimonov, D.; Onabek, A.; Smolyarchuk, K.; Alizadeh, T. Integrating Computer Vision in a CODESYS PLC to Enable Intelligent Object Identification. In Proceedings of the 2024 9th International Conference on Mechatronics Engineering (ICOM), Kuala Lumpur, Malaysia, 13–14 August 2024; pp. 65–70. [Google Scholar]

- Friedrich, C.; Vogt, S.; Rudolph, F.; Patolla, P.; Grützmann, J.M.; Hohmeier, O.; Richter, M.; Wenzel, K.; Reichelt, D.; Ihlenfeldt, S. Enabling Federated Learning Services Using OPC UA, Linked Data and GAIA-X in Cognitive Production. J. Mach. Eng. 2024, 24, 18–33. [Google Scholar] [CrossRef]

- Poka, K.; Ali, S.; Saeed, W.; Merz, B.; Epperlein, M.; Hilgenberg, K. Design and implementation of a machine log for PBF-LB/M on basis of IoT communication architectures and an ETL pipeline. Prog. Addit. Manuf. 2024, 9, 643–654. [Google Scholar] [CrossRef]

- Rehmer, A.; Klute, M.; Heim, H.P.; Kroll, A. A Digital Twin for part quality prediction and control in plastic injection molding. In Modeling, Identification, and Control for Cyber-Physical Systems Towards Industry 4.0; Elsevier: Amsterdam, The Netherlands, 2024; pp. 79–109. [Google Scholar]

- Revankar, A.; Halapeti, D.; Vengurlekar, S.; Giriyapur, A.C. Digital Shadow Enabled Integrated Multi-platform Automation System for Industrial Assembly. In Proceedings of the 2024 IEEE International Conference on Electronics, Computing and Communication Technologies (CONECCT), Bangalore, India, 12–14 July 2024; pp. 1–6. [Google Scholar]

- Velesaca, H.; Carrasco, D.; Carpio, D.; Holgado-Terriza, J.A.; Gutierrez-Guerrero, J.; Toscano, T.; Sappa, A. Anomaly Detection in Industrial Production Products Using OPC-UA and Deep Learning. In Proceedings of the 13th International Conference on Data Science, Technology and Applications-Volume 1: DATA, Dijon, France, 9–11 July 2024; INSTICC; SciTePress: Setúbal, Portugal, 2024; pp. 505–512. [Google Scholar] [CrossRef]

- Wang, X.; Hu, H.; Wang, Y.; Wang, Z. IoT Real-Time Production Monitoring and Automated Process Transformation in Smart Manufacturing. J. Organ. End User Comput. (JOEUC) 2024, 36, 1–25. [Google Scholar] [CrossRef]

- Diprasetya, M.R.; Yuwono, S.; Löppenberg, M.; Schwung, A. Integration of ABB Robot Manipulators and Robot Operating System for Industrial Automation. In Proceedings of the 2023 IEEE 21st International Conference on Industrial Informatics (INDIN), Lemgo, Germany, 18–20 July 2023; pp. 1–7. [Google Scholar]

- Gönnheimer, P.; Ströbel, R.; Dörflinger, R.; Mattes, M.; Alexander, P.; Wuest, T.; Fleischer, J. Generalizability of an Identification Approach for Machine Control Signals in Brownfield Production Environments. Procedia CIRP 2023, 120, 649–654. [Google Scholar] [CrossRef]

- Haghshenas, A.; Hasan, A.; Osen, O.; Mikalsen, E. Predictive digital twin for offshore wind farms. Energy Inform. 2023, 6, 1–26. [Google Scholar] [CrossRef]

- Hirsch, E.; Hoher, S.; Huber, S. An OPC UA-based industrial Big Data architecture. In Proceedings of the 2023 IEEE 21st International Conference on Industrial Informatics (INDIN), Lemgo, Germany, 18–20 July 2023; pp. 1–7. [Google Scholar]

- Lockner, Y.; Buske, P.; Rudack, M.; Kheirandish, Z.; Kröger, M.; Stoyanov, S.; Dokhanchi, S.R.; Janowitz, J.; Peitz, A.; Rudolph, F.; et al. Improving Manufacturing Efficiency for Discontinuous Processes by Methodological Cross-Domain Knowledge Transfer. In Internet of Production: Fundamentals, Methods and Applications; Springer International Publishing: Cham, Switzerland, 2023; pp. 247–279. [Google Scholar]

- Minh, T.B.; Do, X.P.; Nguyen, Q.H.; Nguyen, K.H.V.; Phan, T.T.T. A Digital Twin Implementation Framework for a Collaborative Robot Based on Iso 23247. In Proceedings of the International Conference on Sustainable Energy Technologies, Ho Chi Minh City, Vietnam, 10–11 November 2023; Springer: Singapore, 2023; pp. 747–755. [Google Scholar]

- Nam, L.P.; Cat, T.N.; Nam, D.T.; Van Trong, N.; Le, T.N.; Pham-Quoc, C. OPC-UA/MQTT-Based Multi M2M Protocol Architecture for Digital Twin Systems. In Proceedings of the International Conference on Intelligence of Things, Ho Chi Minh City, Vietnam, 25–27 October 2023; Springer: Cham, Switzerland, 2023; pp. 322–338. [Google Scholar]

- Pospisil, O.; Fujdiak, R. Identifying Industry Devices via Time Delay in Dataflow. In Proceedings of the 2023 13th International Conference on Communication and Network Security, Fuzhou, China, 6–8 December 2023; pp. 173–177. [Google Scholar]

- Rosa, L.; Garbugli, A.; Patera, L.; Foschini, L. Supporting vPLC networking over TSN with kubernetes in industry 4.0. In Proceedings of the 1st Workshop on Enhanced Network Techniques and Technologies for the Industrial IoT to Cloud Continuum, New York, NY, USA, 10 September 2023; pp. 15–21. [Google Scholar]

- Schneider, N.; Ruf, P.; Lermer, M.; Reich, C. ARTHUR: Machine Learning Data Acquisition System with Distributed Data Sensors. In Proceedings of the CLOSER, Prague, Czech Republic, 26–28 April 2023; pp. 155–163. [Google Scholar]

- Sharma, G.P.; Patel, D.; Sachs, J.; De Andrade, M.; Farkas, J.; Harmatos, J.; Varga, B.; Bernhard, H.P.; Muzaffar, R.; Ahmed, M.; et al. Toward deterministic communications in 6G networks: State of the art, open challenges and the way forward. IEEE Access 2023, 11, 106898–106923. [Google Scholar] [CrossRef]

- Tiwari, A.; Wang, Y.; Saleeby, K.; Reddy, A.N.; Bukkapatnam, S. Learning digital emulators for closed architecture machine tool controllers. J. Manuf. Syst. 2023, 68, 695–703. [Google Scholar] [CrossRef]

- Tufek, N. Semantic Information Extraction from Multi-modal Technical Document. In Proceedings of the 2023 18th Iberian Conference on Information Systems and Technologies (CISTI), Aveiro, Portugal, 20–23 June 2023; pp. 1–4. [Google Scholar]

- Tufek, N.; Thuluva, A.S.S.; Just, V.P.; Sabou, M. Towards Extraction of Validation Rules from OPC UA Companion Specifications. In Proceedings of the 2023 IEEE 28th International Conference on Emerging Technologies and Factory Automation (ETFA), Sinaia, Romania, 12–15 September 2023; pp. 1–8. [Google Scholar]

- Webb, L.; Tokhi, M.O.; Alkan, B. A Solution Architecture for Energy Monitoring and Visualisation in Smart Factories with Robotic Automation. In Proceedings of the Climbing and Walking Robots Conference, Florianópolis, Brazil, 2–4 October 2023; Springer: Cham, Switzerland, 2023; pp. 383–394. [Google Scholar]

- Gong, Y.; Zheng, Q.; Wang, Z. Research on an Edge Computing Architecture for Industrial Applications. In Proceedings of the 2022 IEEE 2nd International Conference on Power, Electronics and Computer Applications (ICPECA), Shenyang, China, 21–23 January 2022; pp. 207–210. [Google Scholar]