Abstract

Industry 4.0 is a recent trend representing the vision for the integration of information, objects and people in cyber-physical scenarios in order to transform factories into intelligent environments. Although this transition is still ongoing, the corresponding vision of Industry 5.0 has already emerged. Industry 5.0 aims to bring the human factor back into the production system, with the collaborative work paradigm of human–robot collaboration (HRC) at its core. This paper first discusses how Industry 4.0 has conceptually evolved and is being implemented in the context of construction, through the lens of a literature review and bibliometric analysis. Additionally, it clarifies the scope of Industry 5.0 and assesses its momentum as a literature trend, drawing on bibliometric comparisons with the Industry 4.0/Construction 4.0 vision. Furthermore, it makes a realistic assessment of the potential of the Industry 5.0 paradigm to evolve into Construction 5.0. In this context, it reviews the prospects of HRC use in construction, highlights its distinct challenges and proposes new directions. This paper is, to the author’s best knowledge, the first consideration of ‘Construction 5.0’ and the first bibliometric analysis comparing data from Industry 4.0, Construction 4.0 and Industry 5.0 literature.

1. Introduction

Industry 4.0 was publicly introduced in 2011 by the Director and CEO of the German Research Centre for Artificial Intelligence as an approach aimed to strengthen the competitiveness, safety and transparency of the German manufacturing industry [1]. The main idea is that automated production operations can be networked together, enabling direct communication and, thus, coordination among them, along the value stream, resulting in highly autonomous production processes [2].

The technologies and concepts most commonly associated with the Industry 4.0 vision is the internet of things (IoT), artificial intelligence, cloud computing, big data, RFID, robots and cyber-physical systems (CPS), advanced sensors and RFID systems for tracking purposes, augmented and virtual reality (AR/VR) and blockchain technology [3].

According to Reischauer [4], Industry 4.0 should be viewed as a policy-driven innovation discourse in manufacturing industries that aims to institutionalize innovation systems. Acknowledging Industry 4.0 as discourse, allows development as a common point of reference, representing a shared understanding among enterprises, academia and government bodies. Additionally, a discursive approach emphasizes that the use and advancement of technologies is not predetermined or fixed but rather shaped by social and political dynamics. In this very context, Bongomin et al. [5] observe that the concept of Industry 4.0 has expanded enormously towards a general concept with mainstream appeal and applicability, as this is evidenced by a multitude of 99 neologisms covering many different fields, ranging from processes, quality and methods to various industrial subsectors, education and society. Indicative examples are the cases of ‘Operator 4.0’, ‘Robotics 4.0’, ‘Lean 4.0’, ‘Quality 4.0’, ‘Agriculture 4.0’, ‘Construction 4.0’, Education 4.0’, ‘Teaching Factory 4.0’, ‘ HR 4.0’, ‘Work 4.0’, ‘Skills 4.0’ and ‘Leadership 4.0’.

As a result, the number ‘4.0’ has not only become a meme to signal discussions about the future of business, innovation and society as a whole [6] but the use of terms labeled with a number also implies that these are not the final versions [7]. This seems to be particularly true for several fields, where ‘5.0’ versions have already started spreading, and the manufacturing sector is no exception: despite Industry 4.0 still unfolding and remaining at a low level of actual implementation, Industry 5.0 has already been introduced as a human-centric approach responding to the repeatedly noted need for human elements to work in tandem with the technical systems (e.g., [8,9,10]). According to Maddikunta et al. [11], Industry 5.0 represents not just an evolution but the next industrial revolution, characterized by collaborative work between humans and robots. Kim [12] also supports the view that the use of collaborative robots (cobots) is increasing rapidly and will have a significant impact on the workplace in the near future. The International Federation of Robotics (IFR) defines cobots as robots designed with a variety of technical features that ensure they do not cause harm when a worker comes into direct contact with them, either deliberately or by accident. These features include lightweight materials, rounded contours, padding, ‘skins’ (padding with embedded sensors) and sensors at the robot base or joints that measure and control force and speed and ensure these do not exceed defined thresholds if contact occurs [13].

The disruptive innovation of Industry 4.0 has also expanded—albeit with a few years of lag—to the building sector, which is the main focus of this paper. The literature surrounding the potential implementation of Industry 4.0 applications and key technologies in construction has been growing exponentially since the first attempt by Oesterreich and Teuteberg [14], and at the same time, the conceptually equivalent vision of ‘Construction 4.0’, has also come very dynamically into play as a transformational paradigm aimed at the sector’s digitization. Although construction research has not yet shown signs of acknowledging ‘Construction 5.0’ as a future industry paradigm, the emergence of a strong relevant research trend is likely to be very imminent. This view is nurtured by the fact that academic publication processes are slow-moving and as Industry 4.0 grows old and shows signs of entering a downsizing phase [3], there could be attempts to relaunch the concept to stay relevant [7].

In this context, this paper’s main aim is to track the spreading of the digitalization vision in the construction sector as ‘version 4.0’ and consider the potential of its evolution into the next stage of ‘Construction 5.0’. Specifically, this paper discusses how Industry 4.0 has conceptually evolved in the context of construction and what the practical challenges it currently faces are. It also assesses the momentum of Industry 5.0 as a literature trend, drawing on bibliometric comparisons with the Industry 4.0/Construction 4.0 vision. Furthermore, it confirms that human–robot collaboration (HRC) is the core feature of Industry 5.0 and in light of this, it makes a realistic assessment of the potential of the Industry 5.0 paradigm to evolve into Construction 5.0. This is to the author’s best knowledge, the first consideration of ‘Industry 5.0’ in the context of the construction industry and the first bibliometric analysis comparing data from Industry 4.0, Construction 4.0 and the Industry 5.0 literature. This paper also contributes to the research for HRC in construction, which is among the least researched topics of the ongoing technological transformations.

The structure of this paper is as follows: after a presentation of the assumptions of the bibliometric search in Section 2, Section 3 explains how the concept of Industry 4.0 was diffused in the construction industry and how Construction 4.0 was gradually shaped into its current form. Bibliometric data and a discussion of adoption challenges conclude this section. Section 4 investigates the differing perspectives concerning the scope of Industry 5.0, confirms the dominance of HRC amongst the various themes associated with it and sheds light on adoption drivers and concerns for the workforce. Bibliometric data concerning Industry 4.0 and Construction 4.0 are also presented in Section 4 with the aim of demonstrating the dynamic progress of Industry 5.0 as a literature trend. Section 5 contemplates Construction 5.0 as a potential paradigm for the sector and assesses its adoption prospects. Section 6 presents the conclusions of the paper and its contributions, research limitations and future research directions.

2. Methodology

This study involves a systematic search of publications from journals indexed in the Scopus database. The use of Scopus for a literature review is very common in the engineering and technology research fields due to its strong coverage of journal articles, predominantly, but also because of its capacity to capture literature developments, analytical capabilities and ease of downloading [15]. The search for the relevant literature focused on published journal articles, based on the fact that articles from journals are considered to publish current research findings and are also believed to be more rigorous and detailed when compared to conference proceedings [16,17]. Thus, other types of publications were not considered (i.e., conference proceedings, books, book chapters).

The aim of the literature search was twofold. Firstly, to give a qualitative profile of the current research focus in the field of Construction 4.0 and Industry/Construction 5.0, and secondly, to generate bibliometric data, such as the volume and time of publications, sources and citations, to inform the relevant analysis and comparisons.

The process was based on searching specific terms, i.e., ‘Construction’ and ‘4.0’ for the part of the research concerning the implementation of Industry 4.0 technologies in Construction and ‘Industry’/‘Construction’ and ‘5.0’ for the aspects related to Industry 5.0. For the second search, the terms ‘Society’ and ‘Energy’ were excluded so as to avoid confusion with the relevant Society 5.0 and Energy 5.0 trends. The search field was restricted to publication titles and at a secondary level, to the keywords selected by the authors. These fields were chosen to ensure that the returned results were relevant and focused on the subject matter while comprising a manageable total number. All the results were further checked in terms of their relevance, and in cases where the relevance was not satisfactory enough, the respective entries were removed from the list. No restriction in publication times was set, as the time when these concepts were first introduced is known. The literature search was conducted at the beginning of February 2023.

3. Tracing the Path from Industry 4.0 to Construction 4.0

3.1. Scope and Conceptual Interactions

Industry 4.0 is characterized by three primary elements as follows: (1) horizontal integration among different organizations, which involves integrating IT systems, processes and data flows to improve collaboration; (2) the end-to-end digital integration of the entire value chain utilizing CPS to enable highly customized products and cost reduction; and (3) the vertical integration of manufacturing systems within the company, which involves integrating IT systems, processes and data flows to enhance cross-functional collaboration within a smart manufacturing environment [14]. Industry 4.0 has been associated with multiple positive impacts on companies’ productivity, performance and competitiveness as well as the efficiency of production processes. This is attributed to the collective belief that the highly integrated, smart and automated manufacturing environment generates the aforementioned benefits [3]. Governmental subsidies and attention have also played a significant role in shaping ‘Industry 4.0’ into a thriving and profitable, ever-expanding market, where technology vendors and consulting firms, as well as conference organizers, are all competing for their share [7]. Bongomin et al. [5] report that the attention given to the Industry 4.0 topic in the engineering field is greater than in any other field, e.g., computer science and business management, and is referred to with terms such as ‘incredible’, ‘fascinating, ‘enormous expansion’ and ‘explosive use’. Similar are the expressions by [3], who refer to an ‘astronomical rise’ while criticizing the unrealistically positive rhetoric that presents Industry 4.0 as panacea. Along the same lines, Madsen [7] reports the ‘meteoric rise’ of a ‘big and influential concept’ which has attained ‘a meme-like status’ despite being ‘astonishingly vague’.

The disruptive innovation of Industry 4.0 expanded—albeit with a few years of lag—to the building sector, bringing to the fore the vision for construction’s digital transformation. As first introduced by the international consulting company Roland Berger in 2016 [18], the concept of ‘Construction 4.0’ encompassed the key concepts of digital data, automation, connectivity and digital access, as well as eight associated technological developments/approaches as follows: 1. the electronic tendering of public contracts; 2. the use of digital procurement platforms for material sourcing; 3. digital applications for site organization and resource tracking and planning (e.g., GPS, RFID); 4. the use of advanced technological tools and applications, including drones, robots, 3D laser technology, mobile cloud and 3D Printers; 5. digital applications for building product customization, quality control and tracking; 6. mobile apps leveraging data analytics for personalized offerings to customers; 7. digital after-sales tools to facilitate long-term relationships with customers; and 8. the wide use of building information modeling (BIM) as a standard.

Although this document included minimal references to the Industry 4.0 concept, numerous authors have then since referred to and established the concept of “Construction 4.0” as the counterpart of Industry 4.0 in construction [19], while the rapidly growing digital construction literature of the past 5 years has systematically shed light on the links between Construction 4.0 and Industry 4.0 (e.g., [20,21,22,23]). As a result, various Industry 4.0 applications not originally mentioned in the report by Roland Berger Ltd. [18], such as Virtual/augmented reality, the IoT and blockchain have been effectively incorporated into the scope of ‘Construction 4.0’ and at the same time, the first two points in the report by Roland Berger Ltd. [18]—related to the digitization of public procurement—were phased out as a result of their lack of direct links with the production-oriented Industry 4.0 implementation framework. This trend was substantially enhanced by a concurrently growing literature stream, which in the first place sought to investigate how Industry 4.0 applications could be implemented in the construction sector, without necessarily acknowledging ‘Construction 4.0’ as a separate concept (e.g., [14,24,25,26]).

As far as BIM is concerned, it is worth noting that when Construction 4.0 first appeared in 2016, BIM technology and implementation had already reached a considerable level of maturity in many countries worldwide, e.g., in the UK. Nevertheless, BIM is strongly associated with the Industry 4.0 vision for construction, as it acts as a digital backbone for the implementation of its technologies. As Sawhney et al. [27] explain, BIM’s common data environment (CDE) functions as a repository of data for the constructed asset throughout its life, independent of any application. In parallel, BIM enables design, construction and downstream processes to occur in a model-centric manner, with the resulting model providing a 3D visual representation of the asset being constructed and after its completion. Consequently, BIM and CDE are critical components for developing the digital twin that forms the foundation for other elements in the Construction 4.0 framework. Sacks et al. [2] are also of the opinion that the Construction 4.0 framework is built around BIM. In this context, BIM is amongst the most popular applications of the Construction 4.0 era [15,17], despite the fact that, strictly speaking, it is not an element of the ‘Industry 4.0’ vision.

3.2. Bibliometric Data

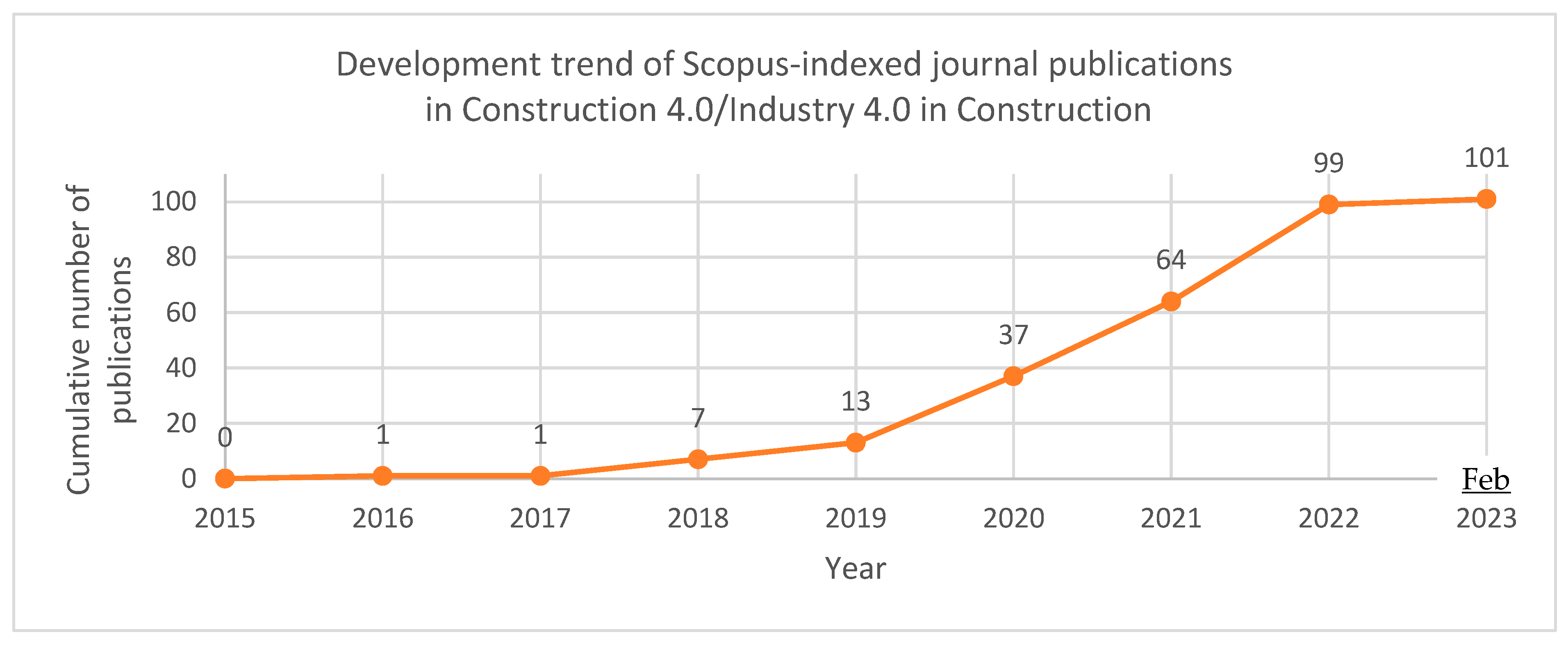

The literature search reveals that these two conceptually similar approaches, i.e., the ‘adoption of Industry 4.0 in construction’ and ‘Construction 4.0’, are largely equivalent in terms of the number of publications in the Scopus database (February 2023) and together number 101 journal publications (found in 50 different journals), which contemplate the generic or more specific applications, implications and prospects of the use of Industry 4.0 technology in construction. These publications were detected by searching Scopus, on the basis of having the term ‘Construction’ and the term ‘4.0’ (associated with either construction or industry) in their title. The initial search returned 120 journal publications, which were reduced to 101 after the careful screening of their content and the evaluation of their relevance to the subject matter.

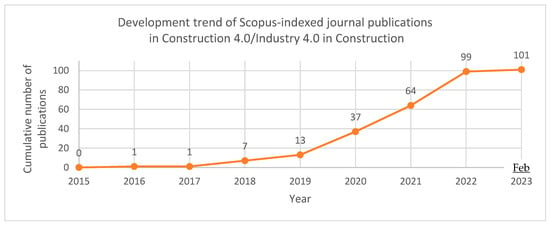

Figure 1 shows how the research output in this area has quantitatively evolved over time, while Table 1 presents the subset of 14 publications, which currently (February 2023) have more than 40 citations on Scopus. The table includes details of authorship, title, exact number of citations, year of publication and source title.

Figure 1.

Total number of journal publications (2015–February 2023) with ‘Construction 4.0’/‘Industry 4.0 in construction’ in their title.

Table 1.

Most highly cited journal papers with ‘Construction 4.0’/‘Industry 4.0 in construction’ in their title (February 2023).

It can be observed that amongst those papers (Table 1) there are five reviews—one of which is focused on off-site construction; four discuss the implications, challenges and opportunities emerging from the implementation of Industry 4.0 in construction; one proposes a methodological-technological framework for this transformation; and one attempts to assess the construction industry’s readiness for this transition. The three remaining publications of the list are more focused and concern the use of specific AI applications, i.e., additive manufacturing, SVM (support vector machines) and CPS. A similar thematic distribution can also be observed in the full list of the 101 publications, as the majority of publications (including 19 generic reviews) have a conceptual focus or aim to shed light on various organizational or social requirements associated with the industry’s digitization vision and investigate the respective opportunities and challenges.

Regarding the sources, Table 2 shows the most frequent journals, i.e., those appearing in the list of 101 publications five times or more, and the respective total citations of the publications in the list. ‘Buildings’ (MDPI) leads with sixteen occurrences (22.7%), while the second place is shared between ‘Sustainability’ (MDPI) and the ‘Proceedings of the Institute of Civil Engineers—Management, Procurement and Law’ with eight occurrences (7.9%) each. The third place belongs to ‘Construction Innovation’ (Emerald) and the ‘Journal of Information Technology in Construction’ (published by the International Council for Research and Innovation in Building and Construction) with five occurrences (5%) each. It is also worth mentioning that the two most highly cited papers of the list, with 700 and 231 citations, respectively, were published in the same journal, i.e., ‘Computers in Industry’ (Elsevier), while ‘Automation in Construction’ (Elsevier), ‘Smart and Sustainable Built Environment’ (Emerald) and the ‘Ain Shams Engineering Journal’ also have a high overall performance in citations (Table 2).

Table 2.

Most influential journals in ‘Construction 4.0’/‘Industry 4.0 in construction’ (February 2023).

3.3. Adoption Drivers and Barriers for Industry 4.0/Construction 4.0

Industry 4.0 is a concept that can be easily adapted and has already been tailored to a multitude of different contexts. This universal trend, which will leave almost no area of business and society unaffected, has resulted in significant promises and high expectations [7]. As a matter of fact, Industry 4.0 is shaped by an emotionally charged, positive and enthusiastic, as well as a largely uncritical environment that is aimed to promote its economic benefits, including improved efficiency, quality, productivity and competitive advantages [3]. The actual success of the proclaimed fourth industrial revolution depends crucially on whether it is sustainably anchored in an organization and implemented in a targeted way [37]. In that respect, the review of the literature leaves no doubt that despite the enthusiasm, there is only minimal evidence of actual effects and merits resulting from the implementation of Industry 4.0 by organizations [7,38].

Oesterreich et al. report in [3] that the main factors contributing to the slow adoption of Industry 4.0 are the limited resources, the high costs, and the increased risks. Additionally, social factors such as inadequate training and education, a scarcity of specialized knowledge, and a lack of trust towards the use of new technologies also have an adverse impact on the implementation prospects. They also note that companies seemingly perceive Industry 4.0 as an umbrella term used to promote their engagement in digitization or automation initiatives, regardless of whether these efforts indeed have anything to do with Industry 4.0. As a result, the actual implementation level—even amongst German companies—is far from the holistic level required for best practices and concrete success stories to emerge and enable the paradigm’s institutionalization. In other words, companies are currently led by optimistic faith rather than tangible achievements, which highlights the need for the Industry 4.0 discourse to move towards a more rational and dispassionate basis.

In the field of construction, the circumstances present remarkable analogies and similarities. The idea of the Construction 4.0, developed from the need of the sector to overcome the existing horizontal, vertical and longitudinal fragmentation and to take a holistic approach to the improvements needed in the industry [27]. More specifically, Sawhney et al. [39] highlight that the drivers of construction’s digital transformation include sustainability aspirations requiring the prudent use of resources, energy and emissions; the need for lower cost, greater efficiency and less waste; as well as the sector’s sustained but still insufficient efforts to increase safety, quality and project cost and time predictability. These are placed in the context of the vision for the sector’s image upgrade and transformation into a collaborative and value-centric industry, oriented towards the satisfaction of its customer needs.

In response to the above, the literature on Construction 4.0 sees the use of advanced technology and AI tools as the means to alleviate numerous problems that have historically been plaguing the construction industry, such as safety concerns, inadequate planning and scheduling, subpar site management and supervision, insufficient skilled labor, cost overruns, delays, frequent design changes during construction, low productivity, labor absenteeism, underutilization of equipment, waste and poor quality [40,41,42]. Regona et al. [43] have presented a relevant extensive review of opportunities associated with the use of AI in construction. These include the increased productivity and efficiency of on-site personnel, reduced time spent on repetitive tasks, the identification of high-risk issues, the avoidance of possible delays through predictive modelling, increased consistency in project related work that will result in higher quality, the reduced probability of on-site accidents and organized safety risks mitigation, the accurate plans and understandable outcomes of enhanced consistency and reliability resulting from AI’s efficiency.

Nevertheless, despite the optimism, it is also very well known that the construction industry’s unique characteristics make it much more difficult to fully reap technological rewards, compared to the manufacturing sector. For instance, construction occurs in an unpredictable, unstandardized environment and the construction process involves multiple interconnected steps and many participants at different locations and stages, while project customization within a limited timeframe presents further difficulties. Furthermore, the construction industry’s supply chain is also fragmented and consists of multiple small and medium-sized enterprises (SMEs), which are challenging to coordinate and have limited resources to invest in innovative technologies. In this context, various implementation challenges, including high initial set-up costs [44], significant worker training expenses and resistance to change [45]; interoperability issues, practical difficulties and health concerns [46,47]; and workspace limitations, as well as immature level of technology [48,49], currently restrict the actual implementation of Industry 4.0 technologies in construction and keep it at an experimental stage. The same overall picture is reflected in the recent ‘Digitalisation in Construction’ survey by Sawhney and Knight, published through the RICS in May 2022 [50]. The findings reveal that there is significant variation in usage of digital processes and practices even within the same organizations, with an average of 40% of all respondents reporting that they are not using digital technologies in any of their projects. The same survey confirms a significant gap between the actual adoption on the one hand and the perceived value on the other hand, as this is reflected in the favorable views of the potential benefits of digitalization. The examination of the barriers associated with this adoption gap shows that the top obstructions include ‘cost, effort, and changes needed’, ‘shortage of skills, ’no clear demand from clients and stakeholders’, ‘inconsistent approaches adopted by supply chain partners’ and ‘difficulty in realizing benefits’. These results confirm the view by Sacks et al. [2] that the transfer of the Industry 4.0 paradigm in construction is far from complete due to the driving principle of interconnectedness and the autonomy of systems being absent from construction operations. In this context, they note that although Construction 4.0 offers inspiration, it lacks the necessary implementation framework, which prevents it from becoming a coherent, comprehensive and actionable paradigm.

3.4. Industry/Construction 4.0 Compared to Lean Production/Construction

The expansion of the Industry 4.0 vision from the manufacturing sector to the construction sector is not the first instance of knowledge and practice transfer between the two sectors. The most successful similar case is this of lean construction, i.e., the counterpart of the ‘lean’ manufacturing paradigm, aimed to eliminate unnecessary effort and complexity, human errors and quality defects from production processes [51]. Lean construction has attracted massive interest in the construction management research for a very long period since the 1990s, which places it amongst the most influential paradigms in the sector [52]. In this context, the exploration of the circumstances of successful embracement of lean construction as a sector-variant would be of particular interest, with the aim to compare and contrast it with the case of Construction 4.0.

What can be observed in the first place is that in contrast to Industry 4.0, which still remains conceptually ambiguous [3], the lean production paradigm originated from well-established principles and tools, clearly documented in the manufacturing literature (e.g., [53,54]). Further to this, lean construction first emerged in the construction industry through the systematic work of Koskela (1992) [55], where the concept of flow in construction was introduced and the manufacturing paradigm was translated into a ‘new production philosophy’ for construction, based on eleven principles. This was an innovative approach, which, according to Bertelsen [56], constituted a contribution of utmost importance for the understanding of the construction process under the prism of lean production. In this context, it becomes clear that the implementation of the lean paradigm in construction was based on a concrete theoretical framework. This is certainly not the case with Industry 4.0, which is widely accepted as an unclear concept reflecting a fashionable societal mega-trend that fits with the current zeitgeist [7].

Furthermore, the lean paradigm was further promoted by the fact that Womack and Jones (1996), in their homonymous bestselling book [57], successfully established ‘Lean Thinking’, i.e., a generic concept used to describe the application of the lean paradigm beyond manufacturing. This gave the lean construction community the liberty to develop an ‘interpretative flexibility’ around the lean construction tools and concepts, which ultimately led to lean applications uniquely developed for construction, such as the last planner system of production control by Ballard [58] and the integrated project delivery approach by Matthews and Howell [59], as well as the target value delivery by Ballard [60]. At the same time, the original tools of the lean paradigm started being used in a construction-oriented contexts/purposes [61]. The above points show that in contrast to Industry 4.0/Construction 4.0, the conceptual basis of lean production was significantly adapted to the needs of construction, and this enabled lean construction to become a holistic perspective of the industry with deep implications for the organizational practice, structure, supply chain management and human resources [51].

Therefore, it is clear that the circumstances of the popularization, spread and implementation of lean construction have fundamental differences from the Industry 4.0/Construction 4.0 vision, and therefore, the embracement gap observed between the two paradigms is fully justified.

4. Tracing the Path from Industry 4.0 to Industry 5.0

4.1. Scope and Conceptual Interactions

Despite the fact that the vision of Industry 4.0 is still unfolding, Industry 5.0 has already emerged in the manufacturing sector [62] and is also expanding exponentially in the literature. Industry 5.0 is a new concept, so there is little agreement on how it is defined [63], but it is based on the observation that Industry 4.0 overfocuses on digitalization and AI-driven technologies at the expense of the original principles of social fairness and sustainability [64]. Along the same lines, Maddikunta et al. [11] note that Industry 5.0 can bring back the human force to factories and promote more skilled jobs. This occurs through replacing the limited machine–human interaction present in the Industry 4.0 context with highly collaborative, adaptable and personalized scenarios in the context of Industry 5.0 [65]. Nahavandi (2019) [62] confirms that the fundamental difference between Industry 4.0 and Industry 5.0 concerns the use of robots and, specifically, the fact that in Industry 5.0, robots are expected to become ‘cobots’, i.e., collaborators with the human operators. The same perspective is also supported by Adel [66], who describes Industry 5.0 as a changing paradigm based on collaboration between humans and machines. Along the same lines, Akundi et al. [63] observe that the primary trend of Industry 5.0 is the introduction of human–robot co-working environments and the creation of a smart society. Other research aimed at highlighting HRC in the context of Industry 5.0 have also been conducted by numerous researchers, including [67,68,69,70,71].

According to Muller [72], additional concepts/technologies associated with Industry 5.0 are bioinspired technologies, technologies for energy efficiency, digital twins, cybersecurity and artificial intelligence. Clearly, the three last concepts are also in the core of Industry 4.0, and therefore, they do not highlight the distinctive character of Industry 5.0. As far as the bioinspired technologies and energy efficiency are concerned, these topics have a minimal presence in the currently available Industry 5.0 literature as the bibliometric search reveals (see Section 4.2). Therefore, HRC can rightfully be considered as the core technology typifying Industry 5.0 and distinguishing it from Industry 4.0.

Notably, the Directorate General for Research and Development (DGRD) of the European Commission (EC) recently supported the Industry 5.0 vision as the way forward, noting that it is not to be seen as a chronological continuation of, or an alternative to, the existing Industry 4.0 paradigm but as a forward-looking exercise, which complements and extends the existing Industry 4.0 paradigm [73]. However, it should be highlighted that the Industry 5.0 concept presented in a series of publications by the EC’s DGRD (i.e., [72,73,74]) is less focused on the technological features and more emphatic regarding the sustainability dimension of the paradigm, prioritizing the limitations of the planet and employee well-being. For instance, [74] presents designing out waste, the circular economy and decarbonization as core features of Industry 5.0, while [73] describes Industry 4.0 as a winner-takes-all model that creates a technological monopoly and fails to respond to the sustainability challenges that societies are currently facing. A political dimension can also be clearly observed, as [74] presents the Industry 5.0 concept as a means to bring into being a ‘post capitalist’ world, away from ‘neo-liberal capitalism models’, based on the lessons learnt from the COVID-19 pandemic. The above show that there is a differing perception between the reports by the EC-DGRD and the here-presented academically led literature regarding the scope of Industry 5.0, and the research community has never created a clear distance from technology as part of the shaping of the vision; on the contrary, it has consistently placed its hopes in its most advanced applications for the delivery of social and environmental benefits, as discussed earlier in this section.

4.2. Bibliometric Data

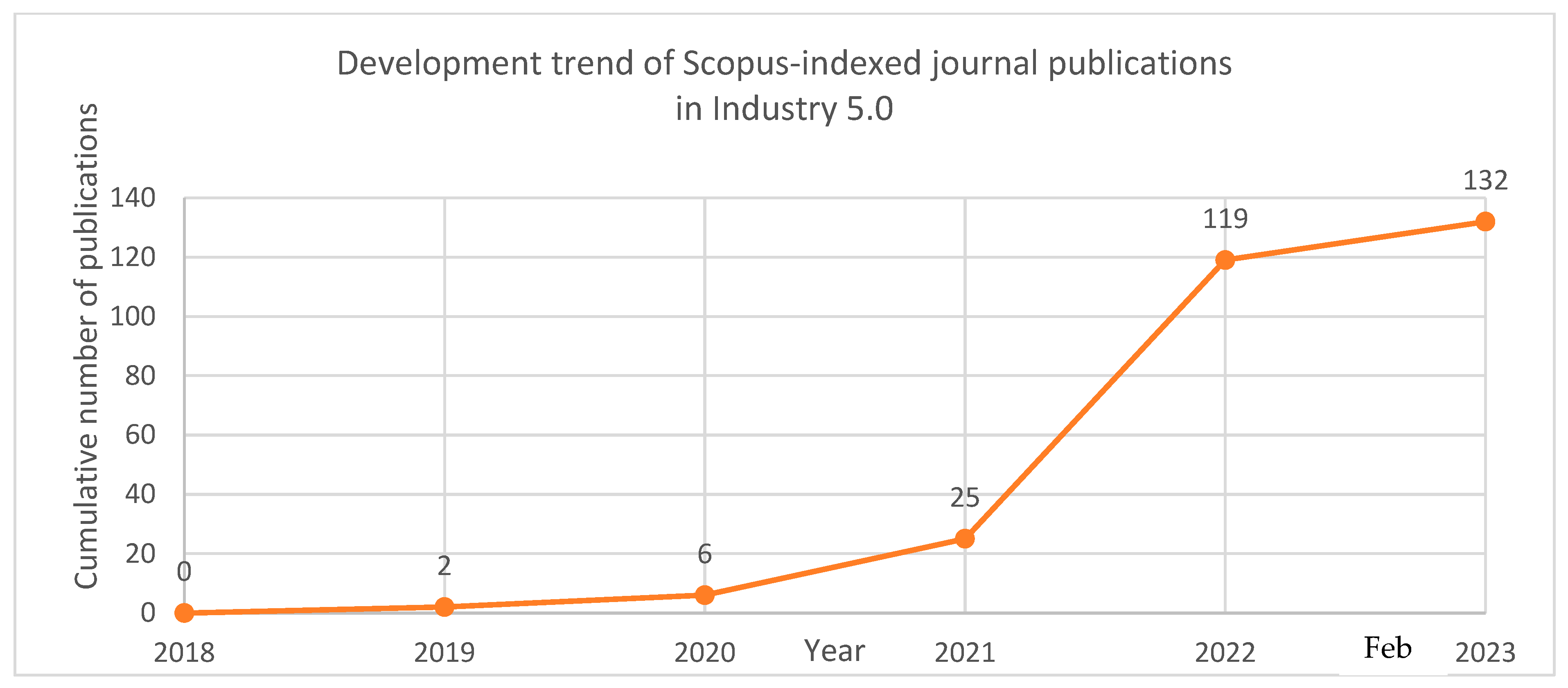

The first journal publications in the area of Industry 5.0 comes from the field of biology/clinical medicine (i.e., [75,76]), while Nahavandi (2019) [62] was the one who introduced the concept into the manufacturing sector, with a primary focus on pairing human brainpower with artificial intelligence in the production floor. Currently, the literature includes 132 journal publications indexed in Scopus with ‘Industry 5.0’ in their titles, 8 of which (6 different journals) are cited 40 times or more (Table 3). The titles of the publications reflect the exploratory stage that the field is currently going through, with the emphasis being placed on its conceptual establishment as a human-centric approach and the investigation of its adoption framework.

The further investigation of the trends within the ‘Industry 5.0’ publications’ keywords and titles reveals that the bulk of the publications are only linked to generic concepts, such as digitization, AI and smart manufacturing. However, there is a dominant trend related to the use of collaborative robots/cobots in twenty-six relevant documents, while the area of bioinspired technologies/energy efficiency is represented with three documents associated with the production of bioenergy from algae (e.g., [77]). Another discernible trend is formed by the concepts of digital twins and blockchain, which however, are also central concepts of Industry 4.0. The above allow us to quantitatively confirm that the strongest conceptual difference between Industry 4.0 and Industry 5.0 emerges from the feature of HRC, as also reported by multiple authors (e.g., [11,62,63]).

Table 3.

Most highly cited journal papers with ‘Industry 5.0’ in their title (February 2023).

Table 3.

Most highly cited journal papers with ‘Industry 5.0’ in their title (February 2023).

| Authors | Title | Year | Source Title | Cited by |

|---|---|---|---|---|

| Nahavandi S. [62] | Industry 5.0-a human-centric solution | 2019 | Sustainability (Switzerland) | 281 |

| Maddikunta P.K.R., Pham Q.-V., B P., Deepa N., Dev K., Gadekallu T.R., Ruby R., Liyanage M. [11] | Industry 5.0: A survey on enabling technologies and potential applications | 2022 | Journal of Industrial Information Integration | 195 |

| Xu X., Lu Y., Vogel-Heuser B., Wang L. [64] | Industry 4.0 and Industry 5.0—Inception, conception and perception | 2021 | Journal of Manufacturing Systems | 171 |

| Longo F., Padovano A., Umbrello S. [78] | Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future | 2020 | Applied Sciences (Switzerland) | 102 |

| Javaid M., Haleem A., Singh R.P., Ul Haq M.I., Raina A., Suman R. [79] | Industry 5.0: Potential applications in COVID-19 | 2020 | Journal of Industrial Integration and Management | 64 |

| Javaid M., Haleem A. [80] | Critical components of industry 5.0 towards a successful adoption in the field of manufacturing | 2020 | Journal of Industrial Integration and Management | 59 |

| Aslam F., Aimin W., Li M., Rehman K.U. [81] | Innovation in the era of IoT and industry 5.0: Absolute innovation management (AIM) framework | 2020 | Information (Switzerland) | 58 |

| Lu Y., Zheng H., Chand S., Xia W., Liu Z., Xu X., Wang L., Qin Z., Bao J. [82] | Outlook on human-centric manufacturing towards Industry 5.0 | 2022 | Journal of Manufacturing Systems | 40 |

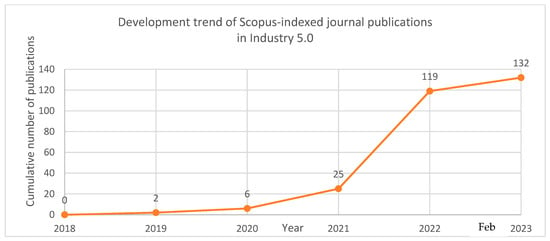

Madsen and Berg, in their bibliometric analysis of the birth and emergence of Industry 5.0, conducted in September 2021 [83], stated that it was difficult to forecast whether the future trajectory of the literature in the field would have the same level of growth as the respective Industry 4.0. The main reason for this reservation was their view that Industry 5.0 is not being that heavily promoted by consulting firms and also that the transition to Industry 5.0 may not be economically appealing to stakeholders. One and a half years later (February 2023), it is clear that the field is growing exponentially with 86% of the current 132 journal papers published in 2022–2023 (Figure 2).

Figure 2.

Total number of journal publications with ‘Industry 5.0’ in their title (2018–February 2023).

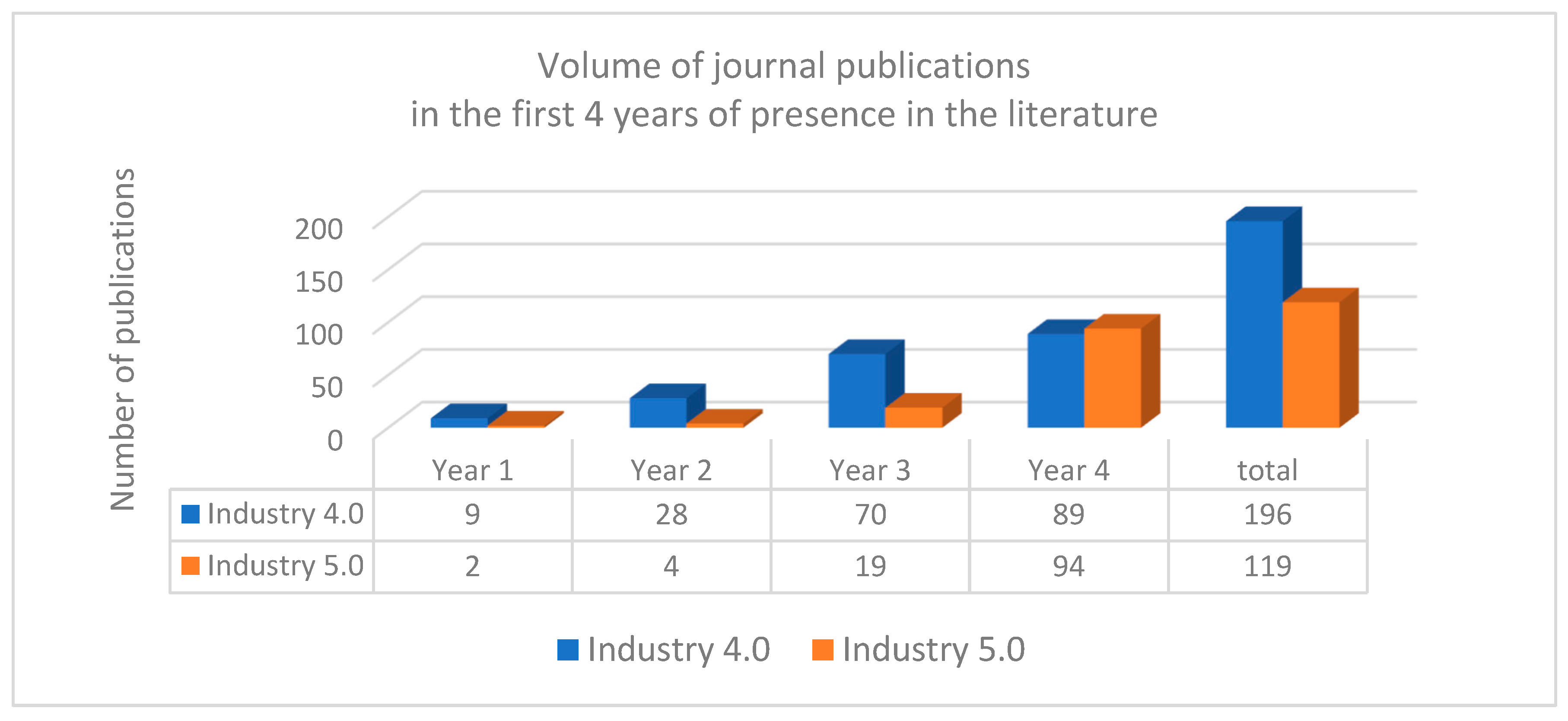

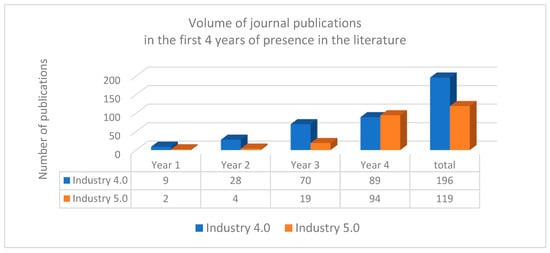

Looking at the trends through a comparative lens (Figure 3), it becomes evident that, compared to Industry 4.0, the overall presence of Industry 5.0 during its first 4 years as a research topic (2019–2022) is indeed at a lower total level than that of Industry 4.0 in its respective period (2013–2016).

Figure 3.

Publications with ‘Industry 4.0’/‘Industry 5.0’ in their title during the first 4 years after the concept’s introduction in the literature.

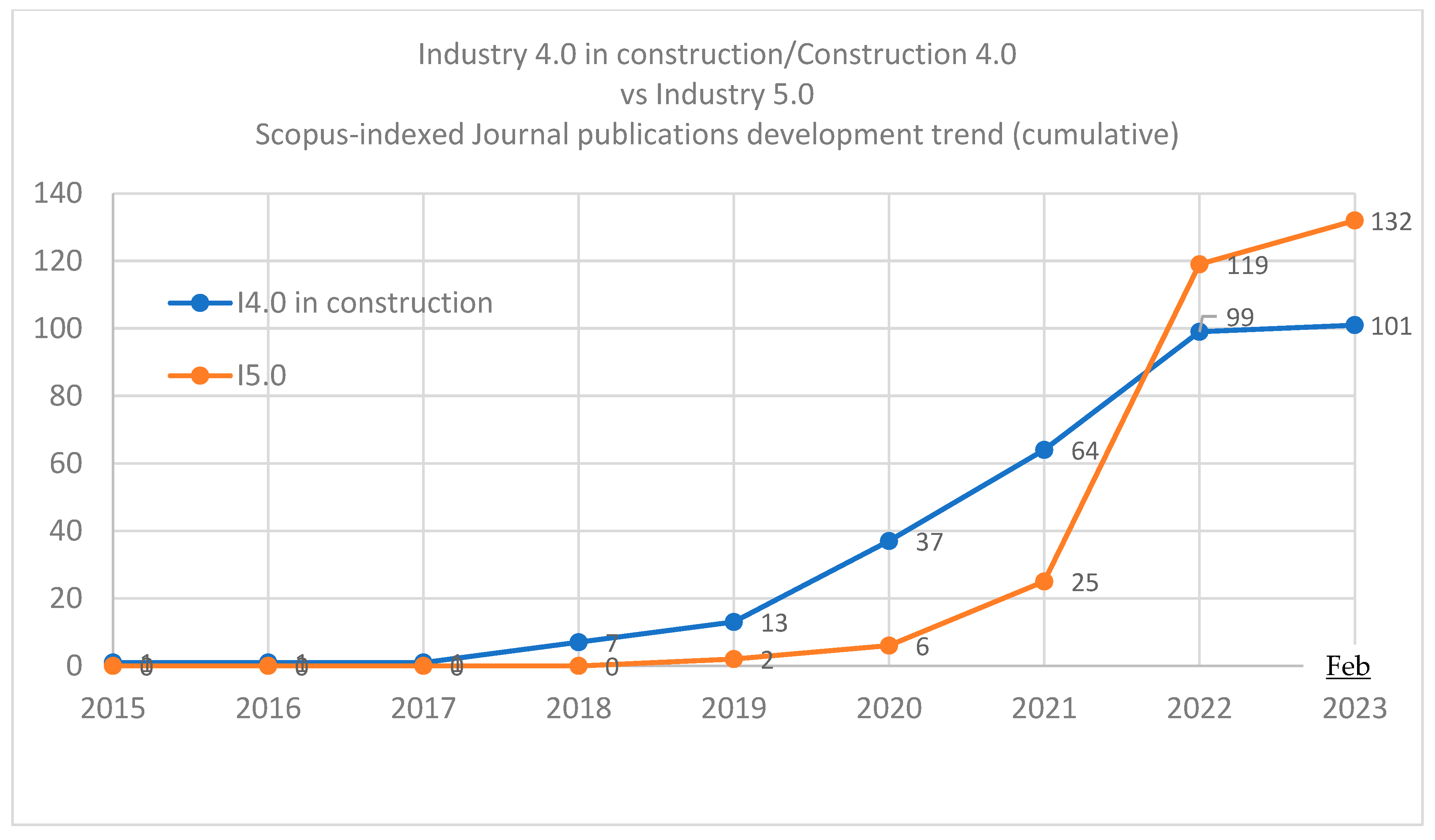

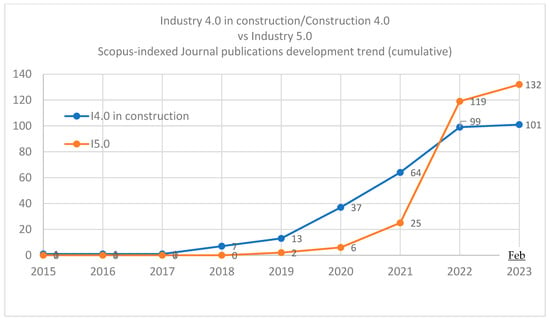

However, when comparing Industry 5.0 to the literature trend that has emerged as a result of the Construction 4.0/Industry 4.0 in construction vision, it also becomes clear that Industry 5.0 has generated a literature stream which has far exceeded the corresponding publications of Construction 4.0/Industry 4.0 in construction, in both growth rate and absolute numbers (Figure 4). What can also be observed is that Industry 5.0 has an unprecedented growth rate in the field, with an increase of 395% in its fourth year (from 19 publications in 2021 to 94 publications in 2022).

Figure 4.

Total number of journal publications with ‘Construction 4.0’or ‘Industry 4.0 in construction’ vs. ‘Industry 5.0’ in their titles (2015–February 2023).

Again, the results have emerged on the basis of the presence of the term ‘Industry 4.0’/‘Industry 5.0’ in the title of the publication. It is to be noted that this comparison only attempts to depict trends that emerge from the application of the same search criteria (keywords in titles) in the Industry 4.0 and the Industry 5.0 literature, and specifically, in journal publications indexed in Scopus. It goes without saying that the construction digitization literature is much wider and, given the extent of related technologies, tools and applications, there is no doubt that not all the authors will have chosen to mention the words ‘Industry/Construction 4.0’ in the title of their research, even though the content may be relevant.

4.3. Adoption Drivers and Concerns for Industry 5.0

4.3.1. Adoption Drivers

Industry 4.0 is a digital and technological revolution set to fundamentally change production and manufacturing. According to the IFR [84], the impact of automation on employment is not necessarily different from the previous waves of technology-driven change over the centuries. While media articles often reflect fears about automation and job displacement, there is no concrete evidence to support these concerns. In fact, automation is driving job creation; what may indeed be different this time is the pace of change in job profiles and skills requirements, which appears to be occurring faster than in the past. Furthermore, automation enables large companies to increase their competitiveness through faster product development and delivery as well as to bring back to their domestic base parts of the supply chain that they previously outsourced to sources of cheaper labor [84].

Industry 5.0, as a value-driven approach, makes a bold focus shift from individual technologies to a systematic approach, which empowers the industry to achieve societal goals beyond jobs and growth and places the wellbeing of the industry worker at the center of the production process [64]. Nahavandi [62] envisages Industry 5.0 as the era where humans trust cobots as effective partners and this collaboration leads to increased efficiency, improved production and reduced waste and costs. IFR [13] also confirms that cobots are tools to support employees in their work, relieving them of many heavy, unergonomic and tedious tasks. De Simone et al. [85] and Marinelli [52] express similar views regarding the enhancement of ergonomics and productivity, while Kim [12] also mentions the expected benefits of affordability, improved performance and creativity, task flexibility and improved safety. Furthermore, automation can create rewarding job profiles with a higher variety of tasks and worker autonomy in task and process planning and decision making as a result of a focus on effective human-cyber-physical systems [86].

4.3.2. Challenges and Concerns

Safety and wellbeing: One of the biggest challenges in the development of collaborative systems between humans and robots is to ensure operators’ psychophysical well-being in terms of Occupational Health and Safety (OHS) while preserving high robot performance [85]. The operator must accept that the working space is shared and there are no fences between them and the cobot, which can be perceived as a safety problem. Especially when the cobot needs to adjust to the motion of the worker, its movements are not completely predictable, and this raises technical challenges and safety limitations [13].

The HRC field recognizes the importance of protecting workers from accidents and injuries and has placed significant emphasis on developing reliable and secure operational environments and systems. This includes adhering to safety guidelines outlined in ISO standards that are specific to industrial settings, personal use and collaborative robots [12]. Additionally, the industry is focused on developing systems, such as control systems and motion/collision detection, which allow for collaboration while ensuring operation speed and separation from robots. Gualtieri et al. [87] and Proia et al. [88] have presented relevant reviews of the AI applications developed to control safety and ergonomic performance of the interface between the robot and the human operator. Furthermore, indicative examples of more focused relevant research include the work by Ibrahim et al. [89], who have thoroughly reviewed robotic control systems and Jantch et al. [90], Han et al. [91] and Xiao et al. [92], who studied robotic self–awareness, kinematic coordination for collision detection and kinaesthetic flexibility, respectively.

Factors widely accepted as impactful to an operator’s performance in HRC include stress, workload and trust [85]. Increased mental stress for humans working with robots can be caused by the physical attributes of the robot, including its size, shape and motion, especially when it moves close at high speeds and without warning [93]. Furthermore, although the introduction of collaborative robots involves a decrease in the physical workload, the mental workload can significantly increase. This can be due to misinterpretation of the cobot’s intentions, especially in cases where its degree of autonomy is high [94] or in cases where the operator has to undertake tasks involving cobot monitoring and supervision, which entail a significant cognitive cost [85]. Additionally, according to Gervasi et al. [95], trust plays a crucial role in achieving optimal HRC. When trust is lacking, operators may not fully utilize the robot, resulting in decreased performance or even non-use. The design of a cobot can also affect trust; for instance, a robot that is too large may discourage humans from collaborating, while a smaller robot or one with social cues may increase the operator’s comfort level. Kim [12] notes that employees who have little trust in robots should not be forced to work in HRC settings. Instead, organizations should provide guidance to employees on how to effectively treat and manage robots and educate them on their own human rights and responsibilities in the context of HRC.

Employment insecurity: The issue of machines replacing human labor is not a new concern, but the current smart technological revolution has advanced it to an unprecedented level. According to Bughin et al. for the global consultancy firm McKinsey [96], job profiles that involve monotonous tasks and necessitate minimal digital skills may witness the most significant decline in terms of overall employment, dropping from roughly 40% to nearly 30% by 2030. Conversely, nonrepetitive tasks and those that require advanced digital skills are projected to experience the greatest increase in employment, rising from approximately 40% to more than 50%. These employment shifts will likely have an impact on wages with employees in categories that entail repetitive tasks and low digital skills experiencing stagnant or reduced wages. There is no doubt that when some jobs are at risk of disappearing completely and the content of others is changing significantly, workers are expected to develop job insecurity and present hostility and suspicion toward the implementation of new technologies. According to Kozak et al. [97], low education is the strongest individual predictor of automation insecurity, while Schneiders and Papachristos [98] note that workers who already work with robots are more convinced that the widespread use of robots can create more job opportunities in the future compared to workers who have not yet been exposed to robots. Therefore, early exposure to industrial robots is crucial in changing workers’ perceptions of them. Moreover, workers from countries that have already adopted advanced technologies are less likely to fear robots as the labor market has already undergone changes and workers have adjusted their skills accordingly [97].

Ethical, training and legal issues: It is important for organizations to be mindful of unethical uses of robots, including programming them for malevolent purposes, hacking into other robots, sharing sensitive information with robots unnecessarily and encouraging social loafing among employees by shifting their responsibilities to robots [12]. Organizations must ensure that the data generated and collected by robots are stored and used ethically, with rigorous protocols to protect privacy [12,99].

Furthermore, tighter collaboration between industry, government and educational institutions is necessary to prepare existing and future employees with both the soft skills as well as the practical expertise needed for the new jobs [96]. HR departments should take the lead in ensuring that employees have adequate information about robots and are fully aware of the code of behavior and potential risks associated with HRC [12]. Moreover, a clear strategy and suitable training to make sure that the company has the required know-how and skills is crucial for employee acceptance and the success of technological transformation [99]. The role of governments is particularly important in terms of the above, as appropriate policy incentives and funding initiatives can encourage corporate investment in training [96].

In addition, cooperation and communication between different departments and across company boundaries is essential, with particular emphasis on the legal aspects concerning data access beyond departmental and company boundaries [99].

5. Reflecting on the Evolution from Construction 4.0 to Construction 5.0

5.1. Bibliometric Data

Currently, the construction literature presents minimal research activity in regard to the Industry 5.0 concept, as seen in the list of 132 publications referred to in Section 3, where only one paper relevant to construction is present [100], which, however, concerns BIM and digital twins, i.e., it is mostly relevant to Industry 4.0, despite having the term Industry 5.0 in its title. Furthermore, ‘Construction 5.0’ as a keyword currently appears in only two further Scopus-indexed journal publications: the first is by Kolaei et al. [46], a review of challenges and opportunities of the use of AR during the construction phase, and the second is by Marinelli [52], an investigation of the conceptual analogies between HRC and lean waste elimination in the field of off-site construction.

5.2. HRC in Construction

Given that HRC is the core concept of Industry 5.0, any future attempt of the construction industry to adopt this paradigm will require the sector to operationally incorporate the use of robots and, specifically, HRC. The concept is not unknown in the construction literature but it is being interpreted less strictly compared to the manufacturing sector, where HRC implies joint engagement and coordination between the robot and the human toward a shared goal [101] or working simultaneously on a shared object [102]. Kim et al. [48] define any construction operation completed through a human–robot partnership as HRC, irrespective of joint intentions or actions. Liang et al. [49] are also of the opinion that HRC for construction projects is not so well-defined, as the taxonomies of manufacturing origin are not well-suited to categorizing construction activities. In their proposed taxonomy for construction, the eight levels of collaborative interaction proposed for manufacturing by Beer et al. [103] are reduced to four (pre-programming, adaptive manipulation, imitation learning and improvisatory control) and the categorization criterion used is mainly the level of cognitive interaction as far as sensing, planning and acting are concerned, instead of safety requirements.

These four levels briefly include the following [49]: The category of pre-programming involves programming a construction robot with a predefined sequence of activities to perform the same task repeatedly. Such an example is a robot for brick or block laying, where a robotic arm lays the brick in predefined patterns and the human worker taps the brick and checks the alignment [49]. Similarly, robots that fit construction components, such as tiles, window panels or curtain walls, which are either tele-operated or monitored as they work on pre-defined patterns, also belong in this category. The same applies to the robotic assembly of various structural elements, such as timber structures, carbon-fiber winding ceiling structures or specific concrete elements. The next category, that of adaptive manipulation, describes methods where the human worker performs the planning of the construction work and assigns specific construction tasks to the robot. The robot is either tele-operated with direct feedback to the operator or utilizes sensors (e.g., for vision, force and inertial measurements) to measure the physical environment and adapt to the encountered geometry, as required per the readings. Large or heavy components, such as glass or curtain walls can be installed in an easier way (e.g., [104]), combining human guidance and the physical effort of the robot. The third category is the imitation learning category and describes cases where robots learn a specific task by observing human experts. This is particularly relevant to complicated construction tasks where the feedback from sensors does not suffice and additional guidance of the robot is required. This category is very under-researched and represents an emerging trend in HRC in construction with promising future applications [49]. Lastly, the improvisatory control category is the fourth and higher collaborative category of the taxonomy and involves tasks where robots plan and execute all aspects of a task under the supervision of a human worker, who can take over and control the robot manually when needed. The currently available research in this category concerns single-task robots in a continuous space.

5.3. Current State of Adoption and Future Prospects

The integration of robotics in the construction industry can provide several advantages to companies, including increased competitiveness, the creation of new skilled job opportunities and, ultimately, the contribution to economic growth. Although the important potential benefits have prompted growing interest in robotic technologies in construction [48], robots are still amongst the least researched and least used areas of the ongoing technological transformation in the construction industry [33,105].

Saidi et al. [106] notes that the heavy and large components are difficult for robots to operate, while complicated assembly techniques may sometimes be too skillful for them. Furthermore, the AI aspect of robotics has a much lower presence in construction compared to manufacturing, given that robots are perceived as an advanced form of operational mechanization (automation) aimed at achieving lower costs. Furthermore, construction tasks are significantly different from the manufacturing assembly line, as they are not typically performed in a linear sequence and each project is unique with no standardized characteristics. Moreover, the resources often encounter spatial-temporal conflicts, the plans are uncertain and prone to change, while the construction environment is typically risky and harsh [24]. Moreover, unlike the industrial-assembly robot, the construction-assembly robot has to navigate to different working locations on-site in order to perform a task [49]. For all the above reasons, robots are much more relevant to prefabrication (industrialized construction), where building components are individually designed, produced and assembled in a controlled environment [52]. In confirmation of all the above, Gharbia et al. [107] report that very few robotic technologies are mature enough to be used in actual building projects and the vast majority remain in the category of ‘challenging’ or ‘achievable’ (in the distant future). This is of course related to the fact that the current level of robotic reasoning, perception and adaptability is not sufficient for complex and dynamic construction environments [48]. Pradhananga et al. [108] confirm that immature technology and the nature of the construction industry are the most-mentioned barriers as per the findings of their scientometric analysis of the literature.

Regarding HRC, it is argued that construction presents an ever greater complexity and uniqueness compared to manufacturing, as a result of three distinct factors: (1) the fact that construction simultaneously involves multiple communication and interaction modes; (2) the fact that it stresses safety requirements due to the unavoidable proximity and the impracticable use of fences; and (3) the fact that humans and robots show different characteristics in collaboration, i.e., human workers are likely to forget or feel tired, which also affects their robotic partner’s efficiency [109]. Onososen and Musonda [110] confirm in their scientometric review on the use of robotics in construction that the presence of HRC is sparse and relevant research at an early stage. Wang et al. [111] further add that the difference of scale makes the existing HRC studies in the manufacturing sector potentially unsuitable for construction projects: most of the manufacturing systems are on a tabletop scale with fixed robotic arms able to manipulate small objects, while in construction tasks both the robot workspace and the target objects (e.g., drywall panels) are much larger than typical human workers.

Furthermore, Chen et al. [112] identified 21 risk factors for the implementation of HRC in construction, categorized as worker-related, robot-related, project-related and organizational factors. Their survey results show that the most impactful factors emerge from the organization’s culture and investment strategy in relation to technology, the human operator’s perception for safety, the accuracy of the robotic operator, the cost requirements and safety restrictions associated with the nature of the project. Bademosi and Issa [113] also confirm that the initial investment costs adversely affect the industry’s intention to adopt robotic technologies, despite the widely acknowledged long-term cost savings that such a decision would entail. Along the same lines, Pradhananga et al. [108] report that economic feasibility, low R&D investment, the complex implementation of robotics and aversion to change represent major obstacles to robotics adoption in construction. You et al. [114] emphasize the perceived safety aspect, noting that although it is possible for humans to develop a strong personal relationship with robots, this is less likely to occur in the context of construction work, as the fear of being hit by construction equipment is very common on construction sites and on-site robots are therefore likely to be perceived by workers as safety threats.

The above show that the construction’s complex, unique and unstandardized conditions make the adoption of the HRC-oriented Industry 5.0 paradigm much harder compared to the (not yet achieved) adoption of the Industry 4.0 with respect to their respective technological frameworks. Therefore, further research is expected in the fields of machine learning and machine vision to ensure a Construction 5.0 era with safe, efficient and intuitive interactions between robots and humans in construction environments.

6. Conclusions

6.1. Concluding Remarks

The vision of Construction 4.0 to transform the traditional construction industry into a smart, digitalized and connected ecosystem is well established in the recent literature, which has systematically strengthened and expanded its connections with the respective manufacturing vision of Industry 4.0. At the same time, Industry 5.0 has already emerged, as a paradigm that focuses on the collaborative interaction of man and machine with the aim to improve the quality and efficiency of production. Rather than representing a technological leap forward, Industry 5.0 actually provides a new direction for the currently evolving Industry 4.0 approach by putting in focus the human-centered use of technology and, particularly, HRC. In the field of construction, however, the use of robots and especially HRC remains at the vision or experimental proof-of-concept stage. This reflects the actual circumstances of the construction practice and its fundamental differences to the manufacturing sector, including increased complexity and scale, the lack of standardization and repeatability and increased risk and planning uncertainty, to name a few. This effectively means that the construction industry first needs to find ways to efficiently and safely incorporate the use of robots in its core operations—as per the Industry 4.0/Construction 4.0 paradigm—and then make the transition to the Industry 5.0/Construction 5.0 paradigm, which involves much more complex collaborative scenarios between human and robotic partners.

The fact that the field of robotics is still one of the least researched and least used areas in the ongoing technological transformation of the construction industry shows that this path cannot possibly be an easy or a short one. The research experience already accumulated from the manufacturing sector in the fields of machine learning and machine vision undoubtedly forms a strong foundation, but further research is needed for the attainment of a Construction 5.0 era typified by increased safety, efficiency and quality resulting from intuitive interactions between robots and humans within the complex construction environments.

6.2. Research Contributions

Although the literature in field of Industry 4.0/Construction 4.0 is vast, both concepts remain conceptually vague, with dozens of varying interpretations and implementation tools associated with them. This paper sheds light on the emergence and evolution path of Construction 4.0 and uses bibliometric data and literature evidence to quantify its dynamic as a literature trend. It also compares and contrasts its transfer and implementation circumstances to the lean manufacturing/construction paradigm. Furthermore, this research clarifies the conceptual basis of Industry 5.0, confirms through bibliometric data that HRC is the paradigm’s core technology and assesses its momentum in the literature, drawing on bibliometric comparisons with the Industry 4.0/Construction 4.0 paradigms. Finally, it makes a realistic assessment of the potential of the Industry 5.0 paradigm to evolve into Construction 5.0 in the future. This paper contributes to the limited research for HRC in construction and is, to the author’s best knowledge, the first consideration of ‘Construction 5.0’ as the counterpart of ‘Industry 5.0’ in the context of the construction industry and the first comparative bibliometric analysis involving data from the Industry 4.0, the Construction 4.0 and the Industry 5.0 literature.

6.3. Research Limitations

This research in based on literature reviews and bibliometric data. One limitation emerges from the use of the Scopus database as the sole data source and the author’s decision to only include journal papers in the presented bibliometric analyses. Given that not all publications are part of academic journals indexed in Scopus, some relevant studies, especially from conference proceedings, have not been accounted for. Furthermore, given how extensive the relevant literature is, the bibliometric results were selected on the basis of the presence of the terms Industry/Construction 4.0 in the title of the publication only. There is no doubt that there will be studies which, although relevant, will not include these specific terms in their title, and thus, those studies have been overlooked. Furthermore, the quantitative results would give much higher values if a more inclusive search (e.g., title, abstract, keywords) had been implemented instead, but this would be at the expense of the relevance and feasibility of the analysis.

Moreover, the bibliometric search only provides a snapshot of publication numbers and citations, which undoubtedly has a very limited time of validity, given the rapidity and exponential rate of the increase in publications in the field of Industry 4.0 and 5.0. Therefore, follow-up studies are needed to examine how the various trends evolve and shift over time.

6.4. Future Research Directions

The presented analysis of the literature shows that further research is needed in the fields of machine learning and machine vision to ensure a Construction 5.0 era with safe, efficient and intuitive interactions between robots and humans in construction environments. Given that the actual use of interactive robots in construction is currently only experimental, it would be rational for the academic community to extend/adapt the Construction 5.0 concept to include other technologies and applications with equivalent impacts on workers’ wellbeing and the sustainability targets of the sector. This practice has been successful in the past, in the context of the transfer of the lean paradigm from manufacturing in construction, in which case, not only the original lean concepts were adapted to the needs of construction but new, construction-specific applications were also developed. Moreover, both Industry 4.0 and 5.0 are typified by interpretive flexibility; therefore, there is room for such an approach. The aforementioned ‘Construction 5.0’ applications should be human-centric, as the spirit of Industry 5.0 requires, but also compatible with the nature and the current needs of construction so that practical application is actually achievable.

In this context, the use of advanced IT applications for the prevention of site accidents and the detection of ergonomically poor or unsafe working practices could be proposed. Another alternative could concern the use of IT tools and applications for workforce training and skill upgrades, as well as occupational stress control. All the above could provide a direct and substantial contribution to the advancement of the construction worker’s wellbeing and, although there are well-known problems, there is no doubt that placing them under the umbrella of the EU-supported Industry 5.0 will increase public awareness as well as governmental attention and interest. Furthermore, future research in Construction 5.0 could also expand the neglected Construction 4.0 aspect of digital procurement platforms, which, especially in the case of public construction projects, can translate to promoting efficiency, reducing waste and providing greater transparency and collaboration among stakeholders, all of which constitute important sustainability gains for the construction industry.

Funding

This research received no external funding.

Data Availability Statement

All data relevant to this research is contained within the article.

Conflicts of Interest

The author declares no conflict of interest.

References

- Bolpagni, M.; Gavina, R.; Ribeiro, D.; Arnal, I.P. Shaping the Future of Construction Professionals in Industry 4.0. In Industry 4.0 for the Built Environment: Methodologies, Technologies and Skills; Bolpagni, M., Gavina, R., Ribeiro, D., Eds.; Structural Integrity book series 20; Springer: Cham, Switzerland, 2022; pp. 1–28. [Google Scholar]

- Sacks, R.; Brilakis, I.; Pikas, E.; Xie, H.S.; Girolami, M. Construction with digital twin information systems. Data-Cent. Eng. 2020, 1, e14. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Schuir, J.; Teuteberg, F. The Emperor’s New Clothes or an Enduring IT Fashion? Analyzing the Lifecycle of Industry 4.0 through the Lens of Management Fashion Theory. Sustainability 2020, 12, 8828. [Google Scholar] [CrossRef]

- Reischauer, G. Industry 4.0 as policy-driven discourse to institutionalize innovation systems in manufacturing. Technol. Forecast. Soc. Chang. 2018, 132, 26–33. [Google Scholar] [CrossRef]

- Bongomin, O.; Yemane, A.; Kembabazi, B.; Malanda, C.; Chikonkolo Mwape, M.; Sheron Mpofu, N.; Tigalana, D. Industry 4.0 Disruption and Its Neologisms in Major Industrial Sectors: A State of the Art. J. Eng. 2020, 2020, 8090521. [Google Scholar] [CrossRef]

- Pfeiffer, S. The vision of “Industrie 4.0” in the making—A case of future told, tamed, and traded. Nanoethics 2017, 11, 107–121. [Google Scholar] [CrossRef]

- Madsen, D.Ø. The Emergence and Rise of Industry 4.0 Viewed through the Lens of Management Fashion Theory. Adm. Sci. 2019, 9, 71. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J.; Taisch, M. The Operator 4.0: Towards socially sustainable factories of the future. Comput. Ind. Eng. 2020, 139, 106128. [Google Scholar] [CrossRef]

- Davies, R.; Coole, T.; Smith, A. Review of socio-technical considerations to ensure successful implementation of Industry 4.0. Procedia Manuf. 2017, 11, 1288–1295. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 integration with socio-technical systems theory: A systematic review and proposed theoretical model. Τechnol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2021, 26, 100257. [Google Scholar] [CrossRef]

- Kim, S. Working with Robots: Human Resource Development Considerations in Human–Robot Interaction. Hum. Resour. Dev. Rev. 2022, 21, 48–74. [Google Scholar] [CrossRef]

- International Federation of Robotics (IFR). Demystifying Collaborative Industrial Robots. Positioning Paper 2020. Available online: https://ifr.org/papers/demystifying-collaborative-industrial-robots-updated-version (accessed on 8 March 2023).

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Newman, C.; Edwards, D.; Martek, I.; Lai, J.; Wellington, D.T.; Rillie, I. Industry 4.0 deployment in the construction industry: A bibliometric literature review and UK-based case study. Smart Sustain. Built Environ. 2020, 10, 557–580. [Google Scholar] [CrossRef]

- Aghimien, D.O.; Aigbavboa, C.O.; Oke, A.E.; Thwala, W.D. Mapping out research focus for robotics and automation research in construction-related studies: A bibliometric approach. J. Eng. Des. Technol. 2020, 18, 1063–1079. [Google Scholar] [CrossRef]

- Adekunle, S.A.; Aigbavboa, C.; Ejohwomu, O.; Thwala, W.D. Digital Transformation in the Construction Industry: A Bibliometric Review. J. Eng. Des. Technol. 2021, in press. [Google Scholar] [CrossRef]

- Berger, R. Digitization in the Construction Sector. 2016. Available online: https://www.rolandberger.com/en/Media/Digitization-in-the-construction-sector.html (accessed on 8 March 2023).

- Muñoz-La Rivera, F.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2021, 28, 689–711. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrar, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Boton, C.; Rivest, L.; Ghnaya, O.; Chouchen, M. What is at the Root of Construction 4.0: A Systematic Review of the Recent Research Effort. Arch. Comput. Methods Eng. 2021, 28, 2331–2350. [Google Scholar] [CrossRef]

- Karmakar, A.; Delhi, V.S.K. Construction 4.0: What we know and where we are headed? J. Inf. Technol. Constr. 2021, 26, 526–545. [Google Scholar] [CrossRef]

- Kozlovska, M.; Klosova, D.; Strukova, Z. Impact of industry 4.0 platform on the formation of construction 4.0 concept: A literature review. Sustainability 2021, 13, 2683. [Google Scholar] [CrossRef]

- You, Z.; Feng, L. Integration of Industry 4.0 Related Technologies in Construction Industry: A Framework of Cyber-Physical System. IEEE Access 2020, 8, 122908–122922. [Google Scholar] [CrossRef]

- Mansour, H.; Aminudin, E.; Mansour, T. Implementing industry 4.0 in the construction industry- strategic readiness perspective. Int. J. Constr. Manag. 2021, 1–14. [Google Scholar] [CrossRef]

- Demirkesen, S.; Tezel, A. Investigating major challenges for industry 4.0 adoption among construction companies. Eng. Constr. Archit. Manag. 2022, 29, 1470–1503. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J.; Pérez, C.T. A proposed framework for Construction 4.0 based on a review of the literature. EPiC Ser. Built Environ. 2020, 1, 301–309. [Google Scholar]

- Dallasega, P.; Rauch, E.; Linder, C. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Comput. Ind. 2018, 99, 205–225. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- Fan, M.; Sharma, A. Design and implementation of construction cost prediction model based on SVM and LSSVM in industries 4.0. Int. J. Intell. Comput. Cybern. 2020, 14, 145–157. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the construction industry-How ready is the industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A systematic review of digital technology adoption in off-site construction: Current status and future direction towards industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Maresova, P.; Krejcar, O.; David, O.O. Industry 4.0 for the construction industry: Review of management perspective. Economies 2019, 7, 68. [Google Scholar] [CrossRef]

- Turner, C.J.; Oyekan, J.; Stergioulas, L.; Griffin, D. Utilizing Industry 4.0 on the Construction Site: Challenges and Opportunities. IEEE Trans. Ind. Inform. 2021, 17, 746–756. [Google Scholar] [CrossRef]

- García de Soto, B.; Agustí-Juan, I.; Joss, S.; Hunhevicz, J. Implications of Construction 4.0 to the workforce and organizational structures. Int. J. Constr. Manag. 2022, 22, 205–217. [Google Scholar] [CrossRef]

- Kopp, R.; Howaldt, J.; Schultze, J. Why Industry 4.0 needs Workplace Innovation: A critical look at the German debate on advanced Manufacturing. Eur. J. Workplace Innov. 2016, 2, 7–24. [Google Scholar] [CrossRef]

- Liao, Y.; Loures, E.R.; Deschamps, F.; Brezinski, G.; Venâncio, A. The impact of the fourth industrial revolution: A cross-country/region comparison. Production 2018, 28, e20180061. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J. Construction 4.0: Introduction and overview. In Construction 40: An Innovation Platform for the Built Environment; Sawhney, A., Riley, M., Irizarry, J., Eds.; Routledge: London, UK, 2020; pp. 3–22. [Google Scholar]

- Yap, J.B.H.; Chow, I.N.; Shavarebi, K. Criticality of Construction Industry Problems in Developing Countries: Analyzing Malaysian Projects. J. Manag. Eng. 2019, 35, 04019020. [Google Scholar] [CrossRef]

- Antoniou, F.; Merkouri, M. Accident factors per construction type and stage: A synthesis of scientific research and professional experience. Int. J. Inj. Control Saf. Promot. 2021, 28, 439–453. [Google Scholar] [CrossRef] [PubMed]

- Antoniou, F. Delay risk assessment models for road projects. Systems 2021, 9, 70. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and Adoption Challenges of AI in the Construction Industry: A PRISMA Review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A critical review of 3D printing in construction: Benefits, challenges, and risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Dardouri, S.; BuHamdan, S.; Al Balkhy, W.; Dakhli, Z.; Danel, T.; Lafhaj, Z. RFID platform for construction materials management. Int. J. Constr. Manag. 2022, 1–11. [Google Scholar] [CrossRef]

- Kolaei, A.Z.; Hedayati, E.; Khanzadi, M.; Amiri, G.G. Challenges and opportunities of augmented reality during the construction phase. Autom. Constr. 2022, 143, 104586. [Google Scholar] [CrossRef]

- Li, X.; Yi, W.; Chi, H.-L.; Wang, X.; Chan, A.P.C. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, H.; Murphy, R.; Lee, S.; Ahn, C.R. Delegation or Collaboration: Understanding Different Construction Stakeholders’ Perceptions of Robotization. J. Manag. Eng. 2022, 38, 04021084. [Google Scholar] [CrossRef]

- Liang, C.J.; Wang, X.; Kamat, V.R.; Menassa, C.C. Human-Robot Collaboration in Construction: Classification and Research Trends. J. Constr. Eng. Manag. 2021, 147, 03121006. [Google Scholar] [CrossRef]

- Sawhney, A.; Knight, A. Digitalisation in Construction Report 2022, RICS Research Report. Available online: https://www.rics.org/news-insights/digitalisation-in-construction-report-2022 (accessed on 8 March 2023).

- Green, S.D.; May, S.C. Lean construction: Arenas of enactment, models of diffusion and the meaning of ’leanness. Build. Res. Inf. 2005, 33, 498–511. [Google Scholar] [CrossRef]

- Marinelli, M. Human–Robot Collaboration and Lean Waste Elimination: Conceptual Analogies and Practical Synergies in Industrialized Construction. Buildings 2022, 12, 2057. [Google Scholar] [CrossRef]

- Dennis, P. Lean Production Simplified: A Plain-Language Guide to the World’s Most Powerful Production System; Productivity Press: New York, NY, USA, 2015. [Google Scholar]

- Liker, J. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Koskela, L. Application of the New Production Philosophy to Construction; Technical Report, No. 72; CIFE, Stanford University: Stanford, CA, USA, 1992. [Google Scholar]

- Bertelsen, S. Lean construction: Where are we and how to proceed. Lean Constr. J. 2004, 1, 46–69. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking; Free Press: New York, NY, USA, 1996. [Google Scholar]

- Ballard, G. The Last Planner System of Production Control. Ph.D. Thesis, The University of Birmingham, Birmingham, UK, 2000. [Google Scholar]

- Matthews, O.; Howell, G.A. Integrated project delivery an example of relational contracting. Lean Constr. J. 2005, 2, 46–61. [Google Scholar]

- Ballard, G. Target value design. In Proceedings of the DESIGN 2012, the 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012. [Google Scholar]

- Paez, O.; Salem, S.; Solomon, J.; Genaidy, A. Moving from lean manufacturing to lean construction: Toward a common socio-technological framework. Hum. Factors Ergon. Manuf. 2005, 15, 233–245. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0-a human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and Identification of Current Research Trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]