Abstract

The rapid development of China’s manufacturing industry has brought about environmental problems that have aroused people’s attention to improving carbon emission efficiency and reducing carbon emissions. In this paper, 13 prefecture-level cities in Hunan Province from 2010 to 2020 were selected as research samples, and the coupling coordination degree model and super-efficiency slacks-based measure (SBM) model were used to calculate the level of integration of “two industries” (manufacturing and producer services, short for “TI”) and the efficiency of carbon emissions. Then, hypotheses are established: The integration of TI can promote the improvement of carbon emission efficiency; The integration of TI promotes technological innovation; Technological innovation can promote carbon emission efficiency; Technological innovation is an intermediary in integrating TI affecting carbon emission efficiency. By using the fixed effect model and the mediation effect test method, we empirically analyze the influence of the integration of TI on carbon emission efficiency and the mediating role of technological innovation in this process. The conclusions are as follows: the integration of TI has a significant promoting effect on carbon emission efficiency; The integration of TI improves carbon emission efficiency by promoting technological innovation, and technological innovation bears part of the intermediary effect in the process of the impact of the integration of TI on carbon emission efficiency. The policy implications for improving carbon emission efficiency are proposed based on the research results.

1. Introduction

Carbon emission efficiency means achieving economic growth with less energy consumption [1]. With the rapid development of China’s manufacturing industry, energy consumption continues to increase, resulting in excessive CO2 emissions [2]. Since implementing China’s reform and opening-up policy, the manufacturing industry has developed rapidly and gradually become an essential pillar of China’s national economy. According to the data from China’s National Bureau of Statistics, the total value added to China’s manufacturing industry in 2021 will be 31.4 trillion yuan, accounting for 27.4% of China’s gross domestic product (GDP) and nearly 30% of the world’s total [3]. However, China’s manufacturing industry is primarily traditional, with high energy consumption, pollution, and high emissions. The issue of “low technology content and strong substitution” is a major contributor to the excessive growth of carbon emissions. To deal with the rapid increase in carbon emissions, the Chinese government proposed the “double carbon” goal for the first time at the United Nations General Assembly in 2020: to achieve a carbon peak in 2030 and carbon neutrality in 2060. Improving carbon emission efficiency is a crucial way to achieve the “double carbon” goal while ensuring the healthy and sustainable development of the economy [4]. As the primary source of carbon emissions, the manufacturing industry has problems such as low carbon emission efficiency, and reducing carbon emissions is conducive to realizing the “double carbon” goal [5]. Some scholars pointed out that the integration of the manufacturing and productive service industries (starting now referred to as the integration of the TI) is conducive to promoting the improvement of carbon emission efficiency and promoting the development of industries towards low carbon. Developing a new business form, mode, and path of coupling and symbiosis between enterprises through innovative cooperation is called TI integration. We can guide manufacturing enterprises to extend the service chain, promote service value-added, and steer the manufacturing industry towards high-end, intelligent, green, and service-oriented development. The above factors can result in deeper business connections, industrial chain extensions, technology penetration, and more [6]. It is a critical way to achieve carbon emission reduction and improve carbon emission efficiency [7]. The new business form formed by integrating TI will further stimulate technological innovation, promoting the in-depth development of a joint technology development platform and standard key technologies, thus impacting carbon emission efficiency. There are several advantages to studying the mechanism of the influence of TI integration and technical innovation on carbon emission efficiency in the context of accomplishing the objective of “dual carbon” and fostering high-quality economic growth. For example, it is beneficial to explore an efficient technique to increase carbon emission efficiency through technical innovation, as well as to eliminate China’s crude production and indiscriminate development mode, which results in low resource utilization efficiency and major environmental degradation. At the same time, it has significant theoretical and practical value in accelerating green transformation and upgrading industrial structure, building a green, low-carbon, and circular economic system, and achieving the “dual carbon” aim.

Theoretically, deepening the integration of TI helps increase economic output and reduce carbon emissions. However, the existing literature on the integration of TI focuses on its level measurement [6,8], motivation analysis, and economic effect research [9,10]—however, there are few works of literature on the ecological and environmental effects. The measurement of carbon emissions is also based on the total amount of carbon emissions and the intensity of carbon emissions [11,12]. It fails to comprehensively reflect the efficiency relationship between carbon emissions and economic output. Therefore, several issues need to be addressed, such as determining the impact of integrating the TI on carbon emission efficiency and understanding how to improve carbon emission efficiency through technological innovation. If these issues are resolved, it will benefit regional industries’ green development. From 2010 to 2020, this paper uses 13 prefecture-level cities in Hunan Province as research samples. To assess the degree of integration of regional TI and carbon emission efficiency, we employ the coupling coordination degree model and the super-efficiency SBM model. In addition, a benchmark regression model and an intermediary function model are developed to investigate the mechanism of integration, technological innovation, and carbon emission efficiency between the two. The impact of TI integration on carbon emission efficiency has been verified from multiple perspectives, as is the specific role of technological innovation in the process of TI integration on carbon emission efficiency, and specific policy recommendations are made to further promote the integrated development of TI and improve carbon emission efficiency.

In comparison to earlier research, the following contributions are made by this study: First, from the perspective of research, the influence of TI integration on carbon emission efficiency is explored from the standpoint of technological innovation. Technological innovation is a major driving factor in encouraging the integrated growth of “the TI”, which has a significant influence on promoting resource conservation and process optimization, hence indirectly increasing carbon emission efficiency. Second, in terms of research content, the multi-dimensional comprehensive measurement evaluates carbon emission efficiency and the level of “TI”, and empirically tests the overall role, spatial differences, and mediating effects of TI integration on carbon emission efficiency, which not only enriches and expands the research scope of TI integration, but also seeks a new footnote for carbon emission reduction issue. Finally, in terms of research methodologies, regression analysis is used considerably in this study, as are robustness and heterogeneity testing. Meanwhile, the intermediary effect model performs intermediate mechanism tests to clearly identify the impact of TI integration on carbon emission efficiency, making the study findings more believable.

The rest of the paper is arranged as follows: Section 2 is the literature review, Section 3 is the research hypothesis, Section 4 is the research design, Section 5 is empirical results analysis, Section 6 introduces the discussion of the results, and Section 7 provides conclusions, limitations, and future research directions.

2. Literature Review

It is of theoretical and practical significance to clarify the relationship between the integration of “TI”, technological innovation, and carbon emission efficiency for China to achieve the “double carbon” goal and promote high-quality economic development.

2.1. Integration of TI and Carbon Emission Efficiency

From the existing research, academia generally believes that manufacturing service effectively reduces and improves carbon emission efficiency. Rothenberg studied the impact of manufacturing services on the environment, believing that manufacturing services can reduce resource consumption and environmental pollution by improving enterprise productivity and resource utilization [13]. Zhu Shujin et al. studied the energy-saving effect of China’s manufacturing service from the energy perspective [14]. They believed that manufacturing services could effectively reduce carbon emissions through the technological innovation effect, factor structure optimization effect, and scale expansion effect.

2.2. Integration of TI and Technological Innovation

Regarding the relationship between the integration of TI and technological innovation, relevant scholars mainly hold two views. One view is that manufacturing service has a significant role in promoting technological innovation. For example, LV et al. believe that manufacturing service investment will promote product quality improvement by strengthening the effect of technological innovation [15], thus enhancing the competitiveness of enterprises. Li found that the service of manufacturing input has a significant positive impact on enterprise innovation decision-making, innovation input, and innovation output [16]. Another point of view is that the impact of manufacturing services on technological innovation varies. For example, Liu Weigang et al. discovered that while China’s manufacturing service has a minor impact on technological innovation, modern service investment significantly promotes [17].

Furthermore, few academics have investigated the direct impact of integrating TI on technological innovation. Coreynen [18], for example, believes that integrating TI can help optimize enterprises’ high-pollution production processes, reduce energy utilization efficiency, and provide a solid foundation for improving green technology innovation. Technological Innovation and carbon emission efficiency.

Regarding the relationship between technological innovation and carbon emission efficiency, relevant scholars mainly hold four views. The first view is that improving the technological innovation level can effectively promote improving carbon emission efficiency. For example, Xu et al. discovered through research that green technology innovation contributes advanced green manufacturing and clean energy technology to developing a low-carbon economy and has a significant positive correlation with pilot cities’ carbon emission efficiency [19]. According to Liu et al. [20], scientific and technological innovation and carbon emission efficiency have strong coordination and can positively promote each other. Meanwhile, Li et al. discovered that technological progress and technological efficiency growth help to improve energy carbon emission efficiency [21]. The second point of view is that technological innovation limits carbon emission efficiency. In hindsight, Hu et al. believe that technological progress has not entirely played a role in restraining energy consumption and improving the efficiency of implicit carbon emissions and has also widened the gap between the carbon emission efficiency levels of various product sectors [22]; Zhang et al. found that the synergy of digital finance and technological innovation has somewhat inhibited the carbon emission efficiency of surrounding cities [23]. The third view is that the impact of technological innovation on carbon emission efficiency is heterogeneous. For example, Wang et al. found that the impact of technological innovation on carbon emission efficiency is regional heterogeneity, and technological innovation has an intermediate effect between FDI and carbon emission efficiency [4]. The fourth view is that technological innovation will not significantly impact carbon emission efficiency. For example, Han et al. found that technological progress does not significantly impact carbon emission efficiency [24].

To sum up, the relevant research on the relationship between TI integration, technological innovation, and carbon emission efficiency mainly has the following characteristics: First, in terms of the impact of TI integration on carbon emission efficiency, the relevant research mainly focuses on the energy-saving and emission reduction effect of manufacturing services, and few pieces of the literature directly analyze the impact of TI integration on carbon emission efficiency. Second, as for the relationship between TI integration and technological innovation, most research results show that TI integration can significantly improve technological innovation. Third, most scholars believe that technological innovation has the effect of reducing carbon emissions, but some scholars hold different opinions. Fourth, most studies focus on the influencing factors of carbon emission efficiency at the national or regional level, and there are few studies at the provincial level. Fifth, there is no literature to integrate “TI”, technological innovation and carbon emission efficiency, into the unified research framework.

3. Research Hypothesis

The integration of TI is an industrial symbiosis phenomenon. It is a phenomenon that the relationship between the manufacturing industry and the productive service industry in the input and use of various elements is gradually closed, cross-infiltrated, and finally integrated, which is conducive to improving the utilization of resources and reducing waste generation. Through sorting out the existing literature, it is found that integrating TI impacts carbon emission efficiency mainly through four aspects—first, production efficiency improvement effect. Manufacturers no longer undertake productive services with low internal efficiency and specialization while integrating TI but instead outsource them to professional, productive service providers with lower costs and higher efficiency. This move is intended to reduce the input cost of intermediate services, reduce resource waste, achieve higher expected output with the same or less resource input [25], and achieve effective carbon emission efficiency improvement. The second is the value-added effect. In the efficient integration of the “TI”, the productive service industry, as the intermediate input of the manufacturing industry, runs through the entire production process [26]. Its core value activities support the manufacturing industry in optimising production processes, changing development modes, and promoting the manufacturing industry chain to the top of the food chain. Thus, further realization on improving manufacturing product value and production efficiency [27], followed by improving regional carbon emission efficiency [28], is in the works. Third, consider the impact of industrial agglomeration. Integrating the TI makes the manufacturing and productive service industries realize collaborative agglomeration in space [29]. The intermediate input cost of the manufacturing industry is further reduced by the productive service industry’s learning effect, technology effect, and scale effect [30,31]. This promotes the transformation and upgrading of the manufacturing process and the improvement of green production and carbon emission efficiency [31]. Fourth, the upgrading effect of industrial structure. The “TI”, the manufacturing industry at the bottom of the value chain with high pollution and energy consumption, and the production service sector with high added value, such as scientific research and development, information transmission, and software development, are gradually modernizing. In contrast, artificial intelligence and green technology can assist in reducing the amount of energy required in the manufacturing process [32]. Based on this, this paper proposes the following:

Hypothesis H1:

The integration of TI can promote the improvement of carbon emission efficiency.

In the process of TI integration and interaction, the optimal allocation of human resources, knowledge, technology, and other resources is conducive to improving technological innovation [33]. First, integrating TI will produce a knowledge spillover effect. After the productive service industry with high-quality knowledge capital and human capital is embedded in the manufacturing value chain, it brings direct technology spillover to the manufacturing industry, which is conducive to promoting the innovative development of the manufacturing industry [34]. Secondly, integrating TI will produce a competitive incentive effect. Integrating the TI lowers the original barriers between industries, making it easier for new businesses to enter. This would increase competition among businesses, which has a strong incentive effect, forcing businesses to innovate to survive continuously [6]. Finally, integrating TI will produce economies of scale. In outsourcing, the productive service link is separated from the manufacturing link, making the productive service industry an intermediate input factor. The social specialization division is further deepened, creating conditions for the formation of economies of scale.

On the one hand, economies of scale can reduce the manufacturing industry’s production and transaction costs, raise more funds for innovation activities, and increase investment in technological innovation. On the other hand, manufacturing enterprises outsource their non-core businesses and use excellent external professional resources to focus more on core R&D activities with high added value, which is conducive to future growth. Based on this, this paper proposes the following:

Hypothesis H2:

The integration of TI promotes technological innovation.

Technological innovation is the fundamental way to improve carbon emission efficiency and can promote the low-carbon process from different perspectives, such as energy utilization and new energy development [35]. First, technological innovation can provide technical support for developing and utilizing new energy. Fossil energy consumption releases a large amount of carbon dioxide, the primary source of carbon emissions. The development of cleaner and green new energy can replace fossil energy, reduce fossil energy consumption, and thus reduce carbon emissions [2]. However, the development process of new energy cannot be separated from the accumulation of advanced technology and relevant knowledge, so technological innovation can improve carbon emission efficiency by promoting the development of new energy. Secondly, technological innovation is conducive to improving energy efficiency and maximizing the utility of energy input [36]. Through the research and development of environmental protection technology, cycle counting, and carbon emission monitoring technology, technological innovation makes input factors such as labor, capital, and energy change year on year with the substitution of factors. Therefore, energy consumption per unit product of the industrial sector is reduced, carbon emissions are reduced, and regional carbon productivity is improved, thereby improving carbon emission efficiency [21]. Based on this, this paper proposes the following:

Hypothesis H3:

Technological innovation can promote carbon emission efficiency.

It can be seen from the above analysis that the integration of TI has an important impact on technological innovation through the knowledge spillover effect, competition incentive effect, and scale effect. Technological innovation can alleviate the technical problems related to the development, storage, and transportation of new energy, promote the development and utilization of new energy, stimulate the upgrading of energy consumption structure, and reduce carbon emissions. Simultaneously, it can promote the rapid development of advanced environmental protection technology and the increased use of environmental protection materials and pollution monitoring equipment, further reducing fossil energy consumption and strengthening environmental monitoring to reduce the intensity of carbon emissions and promote the improvement of carbon emission efficiency. Based on this, this paper proposes the following:

Hypothesis H4:

Technological innovation is an intermediary in integrating TI, affecting carbon emission efficiency.

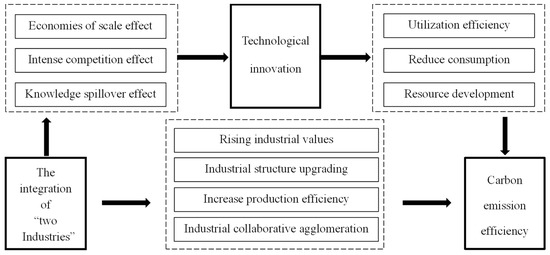

Based on the theoretical analysis presented above, this paper proposes that the integration of TI and technological innovation has a significant impact on carbon emission efficiency and that technological innovation serves as an intermediary between the integration of TI and carbon emission efficiency. Figure 1 depicts a speculative research model based on this foundation.

Figure 1.

The theoretical model of the integration of TI affecting carbon emission efficiency.

4. Research Design

4.1. Data Sources

This paper selects the panel data of 13 prefecture-level cities in Hunan Province from 2010 to 2020, except for Xiangxi Prefecture, which has many missing values. This paper defines the scope of productive services using the Industrial Classification of China’s National Economy. Those productive services are wholesale and retail, transportation, warehousing, postal services, information transmission, software and information technology, finance, leasing, business services, real estate, scientific research, and technical services. At the same time, the scope of the manufacturing industry covering industries is defined as C13-C37 and C39-C41 by the National Standard for Industry Classification. The rest of the data are from the China Energy Statistical Yearbook, the China Urban Statistical Yearbook, and the Hunan Provincial Statistical Yearbook. In order to eliminate the impact of price factors, various monetary indicators are deflated in 2010 as the base period, and the existing individual missing values are processed by linear interpolation [37].

4.2. Measurement Model Setting

This paper mainly studies the impact of the integration of TI in Hunan Province on carbon emission efficiency. Therefore, the integration level and carbon emission efficiency of the TI in Hunan Province are taken as the core variables of the benchmark regression model. At the same time, in order to further investigate the impact of other factors on carbon emission efficiency and reduce the bias caused by missing variables, economic development level, urbanization level, foreign direct investment, trade openness, and government intervention are taken as the control variables of the benchmark model. The benchmark regression model constructed in this paper is as follows:

Among them, (i = 1, 2, …, 13) means 13 prefecture-level cities in Hunan Province, t indicates the time, represents carbon emission efficiency, conver indicates the level of integration of “TI”, pat on behalf of technological innovation, it refers to control variables, including economic development level, urbanization level, foreign direct investment, trade openness, and government intervention, ε indicates the residual item.

4.3. Variable Definition

Variable explained: carbon emission efficiency (CRS). This paper employs the super-efficiency SBM model, with the labor force, capital stock, and total energy consumption as input variables and regional GDP and carbon emissions as desirable outputs and undesirable outputs, respectively. Carbon emission efficiency measurement of all cities in Hunan from 2010 to 2020 are calculated using Stata software, and the measurement indicators are selected as follows: (1) labor force: measured by the number of employees at the end of each year; (2) Capital stock: Refer to ZHANG’s study and use the perpetual inventory method [38], the calculation formula is: , of which, express city No t initial capital stock, by dividing the total fixed asset formation in 2010 by the average annual growth rate of 22.15% and the depreciation rate 9.6%, express city No t the actual total fixed asset formation in 2010 as the base period; (3) The energy consumption index is explained by the total energy consumption of each city; (4) The desirable output is the regional gross domestic product after the adjustment based on the GDP price index in 2010; (5) The calculation method of carbon emissions from undesirable output is based on the research of Ren et al. [39]. The calculation formula is: , of which, indicates the number of t total carbon emissions in, respectively represents the city’s No t annual consumption of natural gas and liquefied petroleum gas and electricity consumption of the whole society, is the proportion of coal electricity in total power generation. they are the carbon emission coefficients of 2.1622 kgCO2/m3 for natural gas, 3.1013 kgCO2/kg for liquefied petroleum gas and 1.32033 kg/(kW. h) for coal–electric fuel. The carbon emission coefficients come from the research of relevant scholars [39].

Explanatory variable: the level of integration of TI. Using Zhang Hu and other scholars [40] and Peng and other scholars [25] for reference to establish an evaluation index system for the integrated development level of TI (as shown in Table 1). The system includes four first-level indicators: (1) Establishing industry scale indicators in accordance with industrial development criteria. Labor costs in China are steadily growing as a result of factors such as sluggish population growth and dwindling labor availability. The rise in labor costs has resulted in a relative decrease in the price of intelligent and digital equipment, prompting manufacturing firms to increase investment in production factors such as information technology in the production chain, transforming towards digitalisation and servitisation, and forging a new path for efficient and low-carbon development. As a consequence, unambiguous indications in terms of employee numbers and fixed asset investment are offered in response to the features of industrial growth. (2) Developing economic efficiency indicators in accordance with economic development requirements. The boundaries between manufacturing and production services are gradually being broken down as a result of technological change and business model innovation, with the manufacturing industry gradually becoming service-oriented in its production processes and the service industry taking advantage of the extension of the industrial chain to integrate deeply with the manufacturing industry, increasing production efficiency while reducing costs and carbon emissions, and increasing productivity. As a result, certain objectives for economic development requirements in terms of GDP and retail sales are established. (3) Development potential indicators are calculated based on social development requirements. At the moment, the manufacturing industry is experiencing a labor supply and demand mismatch, with a scarcity of highly qualified employees in manufacturing firms coexisting with a growth in the number of employed personnel absorbed by the service industry. Cross-integration of the service industry into the value chain of advanced manufacturing firms is an efficient solution to overcome the labor supply and demand paradox and promote green and low-carbon societal development. As a result, clear indicators in terms of job absorption rate and other elements are provided, taking into consideration the needs of social development. (4) Developing environmental impact indicators in accordance with environmental protection requirements. Controlling greenhouse gas emissions can successfully reduce emissions of other environmental pollutants and lower the total cost of emission reduction for society as a whole. 2022 The “Implementation Plan for Reducing Pollution and Reducing Carbon Synergy” proposed by China believes that decreasing pollution and lowering carbon synergy is the essential road to tackling the pollution problem and achieving high-quality development. As a result, specific targets for SO2 emissions and wastewater emissions have been proposed in response to environmental protection standards.

Table 1.

Variable definition summary.

Intermediary variable: technological innovation (pat). Referring to the research of most scholars and considering the availability of data, this paper takes the number of patent applications as a measure of technological innovation and logarithmic processing.

Control variables: The ratio of each city’s GDP to the number of employees per unit explains the level of economic development (GDP). The permanent urban to permanent regional population ratio is used to calculate the urbanization level (urb). Foreign capital for foreign direct investment (FDI) is converted using the annual average exchange rate—open trade as measured by total import and export trade concerning regional GDP. Government intervention (gov), the degree of government intervention, will also impact regional carbon emissions, as explained by the proportion of expenditure in the general budget of local finance to GDP.

All variable definitions are summarized in Table 1.

To avoid a situation in which using raw data directly results in a deviation in the calculation of its weight, this paper uses the normalization method to standardize the number of each index. Then, for each comprehensive development level of the subsystem, the integration level of TI in Hunan Province from 2010 to 2020 is calculated using the coupling coordination model. Measurement indicators of integration level of TI are shown in Table 2.

Table 2.

Measurement indicators of integration level of TI.

5. Empirical Results

5.1. Descriptive Statistics of Variables

A total of 130 sample data were studied in this paper. For better data comparison and analysis, the variables in the table below are descriptive statistics before taking logarithms. In order to eliminate the influence of heteroscedasticity and avoid the phenomenon of false regression caused by the large trend of numerical changes between data due to units, the following regression model uses logarithmized variables. As can be seen from Table 3, the mean value of carbon emission efficiency is 0.679, the maximum value is 1.244, and the minimum value is 0.292; the minimum value of the level of integration of the TI is 0.350, and the maximum value is 0.931, which is a big difference.

Table 3.

Results of descriptive statistics for variables.

5.2. Carbon Emission Efficiency Measurements

The traditional DEA model has certain limitations in measuring efficiency. On the one hand, the output only includes desirable output without considering the significant impact of undesirable output as a product of input transformation on efficiency. On the other hand, the DEA model ignores the relaxation problem of input and output during the calculation process, and its accuracy needs to be improved. Although the SBM model effectively considers the undesirable output and input–output relaxation issues in the efficiency measurement process, there are often multiple decision-making units that are simultaneously effective in its calculation process, resulting in the inability to sort the results. Therefore, this article regards the carbon emissions generated by energy consumption as undesirable outputs and calculates the carbon emission efficiency of Hunan Province through the super-efficiency SBM model. The super-efficiency SBM model is a model that combines super-efficiency and SBM models, and it is a type of super-efficiency DEA model. Compared with the general radial DEA model, this method not only effectively avoids the problem of undesirable outputs and input–output relaxation in traditional efficiency calculation methods but also sorts the calculation results, which is more conducive to ensuring the accuracy of efficiency calculation and facilitating the analysis of measurement results. Therefore, this paper uses the super-efficiency SBM model to build the carbon emission efficiency calculation model of Hunan Province as follows:

First, set the production possibilities set:

Then, define the subset as

It is held only if set contains P\(x0, y0). When the input is made and the output is obtained, the subset has valid values. In the linear programming model of this paper, each city in Hunan Province is taken as a decision-making unit (DMU), and it is assumed that there are DMU, input indicators, desirable output indicators, undesirable output indicators. , , ; , , .

Finally, with reference to Tone’s practice [41], using the constant returns-to-scale assumption, when a certain DMU is DEA efficient, it is both technically efficient and scale efficient. Among them, technical efficiency means that the production is in the best state, and the system can obtain the best output by using the existing input volume. Efficiency of scale means that production is in a state of constant economies of scale; in this state, input increases by N times and output also increases by N times. This method reduces the influence of subjective factors to a certain extent and can conduct a comprehensive, objective, and accurate comprehensive evaluation of carbon emission efficiency in Hunan Province. Then, the super-efficiency SBM model considering undesirable output is defined as follows:

Among them, ; is carbon emission efficiency; is the number of decision units; is input; is the expected output; is an undesirable output; is an element of the input matrix; is an element of the expected output matrix; is an element of the undesirable output matrix.

In this paper, we use the super-efficient SBM model to measure through stata software and obtain the results of carbon emission efficiency of 13 prefecture-level cities in Hunan Province from 2010 to 2019, as shown in Table 4.

Table 4.

Carbon emission efficiency measurement results for 13 prefecture-level cities in Hunan Province.

Overall, from 2010 to 2019, the carbon emission efficiency of eastern Hunan and northern Hunan is in a state of change of first decline and then rise, southern Hunan is in a state of first rise and then decline, and western Hunan and central Hunan are in the fluctuating and rising state of carbon emission efficiency. The eastern part of Hunan is Changsha; the main reason is that in 2010, the proportion of Changsha’s logistics industry declined, which reduced the carbon emissions of the logistics industry, but in the following years, the development of the logistics industry was more rapid, and the carbon emissions increased substantially, and the corresponding carbon emissions efficiency was lower. 2016–2019 Changsha actively responded to the national strategy of energy conservation and emission reduction, and the efficiency of the carbon emissions has been significantly improved. The carbon emission efficiency of southern Hunan is in a depressed state, with a peak in 2015–2016, and then in a declining state over time. The northern part of Hunan benefits from the construction of the ecological chain of water resources in the Dongting Lake region, and the carbon emission efficiency has been in a fluctuating upward state. The western part of Hunan has a fragile ecosystem, which is easily damaged, so the carbon emission efficiency has some fluctuations.

5.3. Full-Sample Benchmark Regression

In order to determine the regression estimation method suitable for this paper, firstly, the data is subject to the Hausman test. The test results show that the original hypothesis is rejected at a 95% confidence interval, indicating that the fixed effect model is suitable for regression. In order to ensure the robustness of the results, this part uses the stepwise regression method to estimate the impact of the integration of TI on carbon emission efficiency in Hunan Province [42]. Model 1 first only considers the impact of integrating TI on carbon emission efficiency. Then, based on model 1, other variables are gradually included to examine the impact of the integration of TI on carbon emission efficiency in Hunan Province under the influence of other factors, which are model 2 to model 7. The results are shown in Table 5. It can be seen from the results that, without considering other factors, the improvement of the integration level of TI in Hunan Province can significantly promote the improvement of carbon emission efficiency. Furthermore, after introducing control variables gradually, the promotion effect of the integration of TI on carbon emission efficiency in Hunan Province still passes the test at the significance level of 1%. Therefore, through the above empirical analysis, it is found that although the impact of the integration of TI on carbon emission efficiency in various regions of Hunan Province fluctuates with the addition of control variables for regression analysis, it still has a pronounced promoting effect. After adding all control variables to the regression model, the empirical results show that, with the other variables in the model unchanged, each time the integration level of TI increases by 1%, the carbon emission efficiency will increase by about 4.22%. The above results show that the theoretical hypothesis 1 proposed in the previous article is valid.

Table 5.

Regression results of the impact of the integration of TI on carbon emission efficiency.

Furthermore, the regression results show that, in the 95% confidence interval, the number of patent applications, as a measure of technological innovation, significantly promotes carbon emission efficiency. This finding supports the previously proposed theoretical hypothesis 3 and demonstrates the importance of technological innovation in reducing carbon emissions. On the one hand, increased green technology innovation, such as new energy and pollution control, reduces carbon dioxide emissions directly. On the other hand, production technology innovation is conducive to optimizing the production process. It simplifies the production process, improving operation efficiency and reducing energy waste, hence allowing businesses to achieve higher output with the same energy input. Promoting new technologies may, to some extent, result in enterprises using cleaner energy to produce goods, thereby improving carbon emission efficiency.

5.4. Mediation Effect Test

Based on the previous assumptions 2, 3, and 4, technological innovation may play an intermediary role in the impact of the integration of TI on carbon emission efficiency. In order to verify its authenticity, this paper constructs the following mediation effects model:

Carbon emission efficiency CRS is the explanatory variable, technological innovation pat is the mediator variable, TI integration level conver is the explanatory variable, and at the same time, the rest of the control variable Z is also used as the control variable of the mediator variable model, and ε represents the residual term.

This paper uses the stepwise regression method to verify it. First, test whether integrating TI significantly impacts carbon emission efficiency. If the correlation coefficient is significant, then carry out the following test to test whether integrating the TI will significantly impact technological innovation. If it passes the test, the final step will be carried out; That is, the integration of TI and technological innovation are included in the same model to test the impact of both on carbon emission efficiency. If both are significant, it indicates a partial intermediary effect. If the integration of TI is not significant, but technological innovation is significant, it indicates a complete intermediary effect. The results are shown in Table 6.

Table 6.

Test results of the intermediary effect of technological innovation.

It can be seen from the test results that when technological innovation is not added to the regression model, the integration of TI can promote carbon emission efficiency at a significant level of 1%, further supporting the establishment of hypothesis 1. The impact of TI integration on technological innovation has been tested at the 5% significance level, indicating that improving the integration level of TI can significantly promote technological innovation. Hypothesis 2 is valid. Integrating TI has technological externalities such as sharing, matching, and knowledge spillover, which is conducive to forming an innovation environment with complementary and differential characteristics and the formation of knowledge, technology, and information exchange networks, thus promoting technological innovation. In addition, the integration level of TI and technological innovation significantly positively affect carbon emission efficiency. However, the impact coefficient of TI integration on carbon emission efficiency has decreased compared with the previous, indicating that technological innovation has assumed a part of the intermediary role in the process of TI integration affecting carbon emission efficiency. Hypothesis 3 and Hypothesis 4 are established. It shows that improving the integration level of TI can directly promote the improvement of carbon emission efficiency and further improve it by stimulating technological innovation.

5.5. Regional Heterogeneity Test

The industrial structure of different regions in Hunan Province is quite different, and the level of TI integration development is unbalanced. Therefore, the impact of TI integration development in different regions on carbon emission efficiency may be heterogeneous. Therefore, according to the economic development and geographical location, Hunan Province is divided into four regions: Changzhutan region (including Changsha, Zhuzhou, and Xiangtan), Dongting Lake region (including Yueyang, Changde, and Yiyang), southern Hunan region (including Hengyang, Chenzhou, and Yongzhou) and western Hunan region (including Zhangjiajie, Huaihua, Shaoyang, and Loudi) for regional heterogeneity test. The inspection results are shown in Table 7.

Table 7.

Regional heterogeneity test results.

It can be seen from the results that the integration of TI in western Hunan, Changsha-Zhuzhou-Xiangtan, and southern Hunan has a significant positive impact on carbon emission efficiency, and technological innovation plays a part in its intermediary role. However, the impact of the integration of TI on carbon emission efficiency in Dongting Lake has not passed the significance test, and the intermediary effect cannot be further tested. Therefore, technological innovation has no intermediary effect in it. This difference may be because western Hunan is dominated by the traditional manufacturing industry, which is more vulnerable to the favorable impact of productive services, which plays a more significant role in promoting. With a high level of economic development and an excellent industrial and technological foundation, integrating the TI has produced a positive spillover effect, thus promoting improved carbon emission efficiency. The economic development level of southern Hunan lags behind that of the Chang–Zhu–Tan region. The proportion of high-end productive services is not high, and the production process of the manufacturing industry is complex. The integration of TI promotes the increase of production scale, which may increase energy consumption to a certain extent and reduce the positive impact of the integration of TI on carbon emission efficiency. However, the industrial structure of the Dongting Lake region is dominated by the primary industry, and the development foundation of the manufacturing industry is relatively weak. The impact of integrating TI on carbon emission efficiency is insignificant.

5.6. Robustness Check

5.6.1. Main Effect Robustness Test

The stepwise regression method was used to analyze the impact of the integration of TI on carbon emission efficiency in Hunan Province, which has guaranteed the reliability of the results to a certain extent. In order to further ensure the robustness of the empirical results, this paper uses the following two methods to continue the regression analysis of the data: (1) Variable replacement method. Because the final expected output of energy input is an economic benefit, this paper will use the unit carbon emission benefit (GDP divided by carbon emissions) to measure the carbon emission efficiency of the explained variable, run the fixed effect model (FE) test again, and compare the results to prevent the return result from being accidental. The results show that the impact of integrating TI on carbon emission efficiency is positive at the significance level of 1%. (2) Multi-model regression. In general, due to the inertia of the economic system and the environmental system or various reasons, the carbon emission efficiency of the previous year may impact the current year’s carbon emission efficiency. Therefore, this paper incorporates the lag of the carbon emission efficiency into the model and uses the differential GMM to regress the data, which can also eliminate the endogenous impact of variables to a certain extent. The results in Table 8 show that AR(2) > 0.05, there is no second-order autocorrelation. In addition, the Sargan test result is 0.103, which indicates that the instrumental variables are valid. The impact of integrating TI on carbon emission efficiency is positive at the significance level of 5%, and the previous conclusion is still valid.

Table 8.

Results of direct effect robustness test.

5.6.2. Robustness Test of the Intermediary Effect

In order to avoid the randomness of the test results of the intermediary effect, this paper replaces the measurement index of the intermediary variable with the sales revenue of new products in cities at all levels in Hunan Province to test whether the empirical results of the intermediary effect are robust. The results are shown in Table 9. Integrating TI and technological innovation significantly impacts technological innovation. In the process of the impact of the integration of TI on carbon emission efficiency, part of the intermediary role of technological innovation has passed the test at the level of 5% significance. The above test results are still valid, indicating that the conclusions of this study are not accidental and relatively stable.

Table 9.

Robustness test results of the intermediary effect.

6. Discussion

In this paper, we present four research hypotheses that have been confirmed. This paper calculates the TI integration level and carbon emission efficiency of 13 prefecture-level cities in Hunan Province. We use the coupling coordination and super-efficiency SBM models based on a theoretical analysis of TI integration and carbon emission efficiency. It develops the benchmark regression and intermediary effect models to empirically investigate the relationship between TI integration, technological innovation, and carbon emission efficiency. The study’s findings indicate a significant positive correlation between the level of integration of TI and carbon emission efficiency in Hunan Province, implying that improving the level of integration of TI can promote improving carbon emission efficiency. Because technological innovation acts as a partial intermediary between TI integration and carbon emission efficiency, TI integration can further improve carbon emission efficiency by stimulating technological innovation. According to the regional heterogeneity analysis, the intermediary effect of Chang–Zhu–Tan, southern Hunan, and western Hunan is significant, whereas Dongting Lake is not. The research results support the conclusions of the existing literature to a large extent and provide a new perspective for studying carbon emission efficiency. This research has the following theoretical and practical significance.

6.1. Theoretical Implications

This study has enriched theoretical research on carbon emission efficiency. Carbon emission efficiency has emerged as an essential research topic. Many academics have discussed the factors influencing carbon emission efficiency from various perspectives. Wang et al. [43], for example, found that foreign direct investment decreases carbon emissions while boosting carbon emission efficiency. He et al. observed that the carbon trading regime has a considerable influence on carbon emission reduction and efficiency in the pilot region [44]. Li et al. investigated the influence of merging the TI on carbon emission efficiency from a heterogeneous approach [45], hence widening people’s awareness of carbon emission efficiency across China. In view of regional variability, this study examined the situation of carbon emission efficiency in Hunan Province. One such example significantly broadens deeper perspectives of carbon emission efficiency and serves as a useful reference for future study.

Second, this work broadened the theoretical scope of carbon efficiency studies. This paper included technical innovation into the theoretical model to examine changes in carbon emission efficiency, resulting in a novel approach to improve carbon emission efficiency. The addition of technological innovation has a significant impact on the relationship between TI integration and carbon emission efficiency, and technological innovation plays a partial mediating role in the process of TI integration affecting carbon emission efficiency. Incentivizing technical innovation has, therefore, become a key method for improving carbon efficiency, as well as providing fresh insights into this issue.

Third, this study has supplied theoretical guidance for conventional manufacturing businesses’ decision-making. The integration of TI is still in the early stages, and it is unclear what aspects businesses should consider while executing the plan to reduce carbon emissions. As a result, the emission reduction and efficiency enhancement effect of the TI integration is poor. Exploring the relationship between the integration of the TI and carbon emission efficiency through the mediating effect of technological innovation is conducive to creating a good business environment, promoting high-quality integrated development of manufacturing and producer services, and providing an important reference for manufacturing enterprises in various regions of Hunan Province to reduce energy consumption, promote energy conservation, and emission efficiency.

6.2. Practical Implications

It was first creating a favorable environment for integrating the TI. On the one hand, the government should increase policy support for the productive service industry, guide benign enterprise competition, create an excellent industrial environment, and lay the groundwork for achieving high-end production to maximize the sustainable energy and emissions effect of TI integration. On the other hand, the integrated development of the TI should be guided by industrial structure, constant technological innovation, and further optimization of the traditional manufacturing industry’s production process. Promoting the coordinated development of industry and ecology by utilising modern energy-saving and emission-reduction technology is possible.

Second, vigorously implement the strategy based on innovation. Implementing innovation-driven carbon emission reductions can enable governments to continue developing relevant policies and measures to stimulate the green innovation enthusiasm of manufacturing and producer services enterprises. Also, focusing on cultivating and supporting technology-based, green, and growth-oriented enterprises should be considered. At the same time, enterprises should actively implement green development, increasing investment in technology innovation, such as capital.

Third, we must systematically optimize the structure of the energy industry. Developing new energy, promoting industrial energy structure upgrading, and establishing a renewable energy technology development and industrial development system based on independent innovation is critical in constructing and developing structural consistency within an industry.

Additionally, by guiding enterprises to strengthen new energy technology research, we can cultivate excellent green technology innovation talents, encourage enterprises to grasp the core technology of new energy exploitation actively, and renewable research energy and multi-energy intel.

7. Conclusions

With China’s industrial structure’s rapid transformation and upgrading, the link between manufacturing and producer services has become increasingly important. As we can see, integrating the TI has gradually become a significant engine driving the low-carbon economy. Technological innovation, as a mix of the two development principles of green development and innovation drive, plays an essential role in increasing the efficiency of carbon emissions and supporting green transformation and upgrading of industries. To investigate how the integration of TI and technological innovation affects carbon emission efficiency, this paper employs a benchmark regression model to investigate the impact of TI integration on carbon emission efficiency. The theoretical model incorporates technological innovation. The results show that TI integration is a critical variable that directly improves carbon emission efficiency and that TI integration positively correlates with technological innovation. As we all know, technological innovation serves as a bridge between the integration of TI and reducing carbon emissions. The research findings also show that the development of technological innovation in Western Hunan, Southern Hunan, and Chang–Zhu–Tan areas favor the positive promotion of the impact of TI integration on carbon emission efficiency. However, there is no discernible impact on the Dongting Lake area. Based on these findings, the author proposes that Hunan Province deepen the integration of manufacturing and productive service industries and improve the efficiency of technological innovation in the western, southern, and Chang–Zhu–Tan regions. These areas are recommended because they have the potential to increase the efficiency of Hunan Province’s carbon emissions and, as a result, achieve the goal of high economic quality.

This study has some limitations. First, there is no in-depth analysis of promoting high-quality economic development by integrating “TI”. This study focuses on the impact of integrating manufacturing and producer services on carbon emission efficiency. It does not consider the impact of a single industry on carbon emission efficiency, such as the impact of manufacturing on carbon emission efficiency. Future research should consider the impact of manufacturing or producer services on carbon emission efficiency. Secondly, the research is only based on the data at the municipal level of Hunan Province, without analyzing the relationship between the integration of manufacturing and producer services at other provincial levels and carbon emission efficiency. Some results may be affected by local factors in Hunan Province.

Further research can take more provinces as research objects to enhance the applicability of the research on a broader range. Third, due to the availability and stability of data, the indicators of manufacturing and producer services are not comprehensive. A more scientific and practical TI integration measurement indicator system can be built in the future, and the above issues can be discussed in depth.

Author Contributions

Conceptualization, H.B. and Q.Y.; methodology, Q.Y., F.L. and Y.Z. (Yun Zhang); software, Q.Y. and Y.Z. (Yun Zhang); validation, Q.Y., F.L. and H.B.; formal analysis, Y.Z. (Yanling Zheng); resources, H.B. and Y.Z. (Yanling Zheng); data curation, Q.Y.; writing—original draft preparation, Q.Y., H.B. and F.L.; writing—review and editing, H.B., Q.Y., F.L. and Y.Z. (Yanling Zheng); visualization, Y.Z. (Yun Zhang) and H.B.; supervision, H.B., Q.Y. and Y.Z. (Yanling Zheng); project administration, H.B., Q.Y. and Y.Z. (Yanling Zheng); funding acquisition, H.B. and Y.Z. (Yanling Zheng). All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Social Science Foundation of China (grant No. 19BGL177) and 2021 Hunan Province’s Scientific Research Project From the Education Department (grant No. 21A0348).

Data Availability Statement

If interested scholars have data requirements, please contact the first author by e-mail (binhou413@gmail.com).

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Ma, D.; Chen, Z.; Wang, L. Spatial econometrics research on inter-provincial carbon emissions efficiency in China. China Popul. Resour. Environ. 2015, 25, 67–77. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, L.; Liu, G. Carbon Dioxide Emissions Reduction through Technological Innovation: Empirical Evidence from Chinese Provinces. Int. J. Environ. Res. Public Health 2022, 19, 9543. [Google Scholar] [CrossRef] [PubMed]

- All-China Federation of Industry and Commerce. Ministry of Industry and Information Technology: In 2021, the Add-ed Value of the Manufacturing Industry Reached 31.4 Trillion Yuan, Accounting for Nearly 30% of the Global Proportion. China’s Comprehensive Strength of the Manufacturing Industry Continues to Improve. Available online: https://baijiahao.baidu.com/s?id=1740302275673353824&wfr=spider&for=pc (accessed on 5 August 2022).

- Wang, Q.; Liu, S. How Do FDI and Technological Innovation Affect Carbon Emission Efficiency in China? Energies 2022, 15, 9209. [Google Scholar] [CrossRef]

- Zhang, L.; Mu, R.; Fentaw, N.M.; Zhan, Y.; Zhang, F.; Zhang, J. Industrial Coagglomeration, Green Innovation, and Manufacturing Carbon Emissions: Coagglomeration’s Dynamic Evolution Perspective. Int. J. Environ. Res. Public Health 2022, 19, 13989. [Google Scholar] [CrossRef]

- Yu, C.; Tang, D.; Tenkorang, A.P.; Bethel, B.J. The Impact of the Opening of Producer Services on the International Competitiveness of Manufacturing Industry. Sustainability 2021, 13, 11224. [Google Scholar] [CrossRef]

- Nie, X.; Zhou, X.; Zhou, M.; Xia, Q. Research on evaluation and influencing factors of energy saving and emission re-duction in producer services and manufacturing industry. J. China Univ. Min. Technol. 2020, 49, 7–18. [Google Scholar] [CrossRef]

- Ding, T.; Bai, G.; Xu, H. Study on the Level of Integration of Equipment Manufacturing Industry and Producer Service Industry in the Region Transforming Provinces and Its Influencing Factors: Taking Shanxi Province as an Example. Math. Probl. Eng. 2022, 2022, 1309293. [Google Scholar] [CrossRef]

- Kim, N.; Lee, H.; Kim, W.; Lee, H.; Suh, J.H. Dynamic patterns of industry convergence: Evidence from a large amount of unstructured data. Res. Policy 2015, 44, 34–48. [Google Scholar] [CrossRef]

- Lanaspa, L.; Sanz-Gracia, F.; Vera-Cabello, M. The (strong) interdependence between intermediate producer services’ attributes and manufacturing location. Econ. Model. 2016, 57, 1–12. [Google Scholar] [CrossRef]

- Cohen, G.; Jalles, J.T.; Loungani, P.; Marto, R.; Wang, G. Decoupling of emissions and GDP: Evidence from aggregate and provincial Chinese data. Energy Econ. 2019, 77, 5–18. [Google Scholar] [CrossRef]

- Sun, W.; Huang, C. Predictions of carbon emission intensity based on factor analysis and an improved extreme learning machine from the perspective of carbon emission efficiency. J. Clean. Prod. 2022, 18, 3–11. [Google Scholar] [CrossRef]

- Rothenberg, S. Sustainability through servicizing. MIT Sloan Manag. Rev. 2007, 48, 83–89. [Google Scholar] [CrossRef]

- Zhu, S.J.; Xie, Y.; Wu, D.S. A Study on the Energy-Saving Effect of Manufacturing Servitization and Its Intermediary Mechanism. Financ. Trade Econ. 2020, 41, 26–40. [Google Scholar] [CrossRef]

- Lv, Y.L.; Lv, Y. Servitization of Manufacturing Export and International Competiitiveness—Based on The Perspective of Value Added Trade. J. Int. Trade 2017, 15, 25–34. [Google Scholar] [CrossRef]

- Li, F. Input servitization of manufacture-ng and firms’ innovation. Sci. Res. Manag. 2020, 47, 6–9. [Google Scholar] [CrossRef]

- Liu, W.G.; Ni, H.F. Service lnput of Manufacturing and Enterprise Technological Progress: Effects and Mechanism. Financ. Trade Econ. 2018, 39, 26–40. [Google Scholar] [CrossRef]

- Coreynen, W.; Matthyssens, P.; Van Bockhaven, W. Boosting servitization through digitization: Pathways and dynamic resource configurations for manufacturers. Ind. Mark. Manag. 2017, 60, 42–53. [Google Scholar] [CrossRef]

- Xu, Y.; Cheng, Y.; Wang, J.; Liu, N. Low carbon pilot city in China carbon efficiency of time and space evolution and the influence factors. J. Nat. Resour. 2022, 37, 5–16. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, J.; Zhang, C. Technological innovation, industrial structure upgrading and carbon emissions efficiency: An analysis based on PVAR model of panel data at provincial level. J. Nat. Resour. 2022, 37, 8–20. [Google Scholar] [CrossRef]

- LI, J.; MA, J.; WEI, W. Study on Regional Differences of Energy Carbon Emission Efficiency in Eight Economic Areas of China. Quant. Tech. Econ. 2020, 37, 9–29. [Google Scholar] [CrossRef]

- Hu, J.; Yan, S.; Wang, L. Efficiency and convergence of China’s export trade embodied carbon emissions. China Popul. Resour. Environ. 2020, 30, 5–10. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y. Influence of digital finance and green technology innovation on China’s carbon emission efficiency: Empirical analysis based on spatial metrology. Sci. Total Environ. 2022, 32, 8–38. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Jiang, T. Does the development of the digital economy improve carbon emission efficiency? Front. Ecol. Evol. 2022, 10, 14–25. [Google Scholar] [CrossRef]

- Peng, F. Total Factor Productivity Driven by Industrial Integration in the Guangdong-Hong Kong-Macao Greater Bay Area: A Case of Manufacturing Industry and Producer Service Industry. Econ. Geogr. 2021, 41, 38–47. [Google Scholar] [CrossRef]

- Wang, X.B.; Chen, C.P.; Wen, M.L. On the Integration Development of Productive Service Industry and Manufacturing Industry. J. Hunan Univ. Sci. Technol. 2016, 19, 98–103. [Google Scholar] [CrossRef]

- Liu, Y.C.; Luan, W.X.; Wan, S.L. Whether Manufacturing Servitization Have Matched Manufacturing Production Efficiency?—Empirical Study of Multiple Mediating Effect Based on Simultaneous Equations. Shanxi Univ. Financ. Econ. 2020, 42, 56–71. [Google Scholar] [CrossRef]

- Huang, Y.X.; Xie, J.G. Input Servitization of Manufacturing Industry and Carbon Emission Intensity—Empirical Analysis Based on WIOD’s Cross-country Panel. Financ. Trade Econ. 2019, 8, 10–15. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, S.; Liu, J. Calculation of the Degree of Synergy and Integration Between Producer Service Industry and Manufacturing Industry and its Determinants. China Soft Sci. 2021, 7, 3–9. [Google Scholar] [CrossRef]

- Cai, H.Y.; Xu, Y.Z.; Zhao, Y.L. Industrial collaborative agglomeration, manufacturing efficiency and smog pollution. J. China Univ. Geosci. 2020, 20, 60–73. [Google Scholar] [CrossRef]

- Chen, X.F.; Zhou, J.J. Productive Services Agglomeration, Spatial Spillover and Urban Green Total Factor Productivity—Based on the Empirical Evidence from Yangtze River Delta. Jingjijingwei Econ. Surv. 2020, 37, 89–98. [Google Scholar] [CrossRef]

- Chen, D. Analysis of influence factors of marine fishery industry structure optimization on carbon emission efficiency based on depth feedforward model. J. Exp. Nanosci. 2023, 18, 34–45. [Google Scholar] [CrossRef]

- Wu, J.W.; Jiang, J. Producer Services Agglomeration, Industrial Convergence and Technological Innovation. Shanghai Econ. Res. 2021, 7, 69–80. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Y.; Yang, B. Manufacturing servicization, knowledge capital and technological innovation. Sci. Res. Manag. 2021, 42, 17–25. [Google Scholar] [CrossRef]

- Chen, G.; Chen, H.; Chen, Z.; Zhang, B.; Shao, L.; Guo, S.; Zhou, S.; Jiang, M. Low-carbon building assessment and multi-scale input-output analysis. Commun. Nonlinear Sci. Numer. Simul. 2011, 16, 23–35. [Google Scholar] [CrossRef]

- Song, J.; Wang, J.; Chen, Z. How Low-Carbon Pilots Affect Chinese Urban Energy Efficiency: An Explanation from Technological Progress. Int. J. Environ. Res. Public Health 2022, 19, 15563. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.L. Digital economy, green technology innovation and carbon emission intensity: An empirical study based on urban panel data in China. Bus. Res. 2023, 2, 73–80. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, G.Y.; Zhang, J.P. Estimation of China’s Inter-provincial physical capital stock: 1952–2000. Econ. Res. 2004, 10, 35–44. [Google Scholar] [CrossRef]

- Ren, X.; Liu, Y.; Zhao, G. The impact and transmission mechanism of economic agglomeration on carbon intensity. China Popul. Resour. Environ. 2020, 30, 95–106. [Google Scholar] [CrossRef]

- Zhang, H.; Han, A.H. Can the Coupling between Manufacturing and Productive Services Enhance Spatial Coordination—A Test Based on Data from 285 Cities in China. Stat. Res. 2019, 36, 39–50. [Google Scholar] [CrossRef]

- Tone, K.A. Slacks-based measure of super-efficiency in data envelopment analysis. Eur. J. Oper. Res. 2002, 143, 32–41. [Google Scholar] [CrossRef]

- Jiang, S.J.; Lu, C.B. Environmental regulation effects on the multiplicity of carbon efficiency. J. Bus. Res. 2023, 21, 29–39. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Q. Foreign Direct Investment and Carbon Emission Efficiency: The Role of Direct and Indirect Channels. Sustainability 2022, 14, 13484. [Google Scholar] [CrossRef]

- She, Q.N.; Jia, W.X.; Pan, C.; Zhu, X.; Yang, F.; Liu, M.; Xiang, W. Spatial and temporal differences of the impact of urban form on regional carbon emissions in the Yangtze River Delta. China Popul. Resour. Environ. 2015, 25, 4–51. [Google Scholar] [CrossRef]

- Li, L.; Zhao, H. A Study on the Relationship between “the Integration of Manufacturing and Producer Service” and Carbon Emission Efficiency. Econ. Surv. 2021, 38, 7–29. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).