Abstract

Nowadays, asbestos waste still remains a serious problem. Due to the carcinogenic properties of asbestos, which are related to its fibrous structure, the exposure to asbestos mineral and asbestos-containing materials (ACM) causes dangerous health effects. This problem can be solved by recycling techniques, which allow the re-use of neutralized asbestos waste, instead of disposing it in special landfills. The article presents the results of research aimed at investigating the possibility of obtaining aggregates from asbestos waste by the fusion process in the electric arc-resistance process. A mixture of ACM with selected fluxes was were melted and then cast to form a grain of aggregates. The chemical composition of the material was determined before and after the melting process. Scanning electron microscopy (SEM) and X-ray diffraction (XRD) were applied to evaluate the effects of the fusion process. The main properties of the obtained aggregate were also measured. The results confirmed that the fibrous structure of asbestos was destroyed in the obtained material, which can be successfully used for the production of artificial aggregates.

1. Introduction

Asbestos is the commercial name of a specific group of minerals, which occur in nature and belong to hydrated silicates containing mainly magnesium, sodium, calcium, and iron. These minerals are characterized by a specific crystalline structure, which in the microscopic examination is visible as a fibrous form. There are six asbestos minerals: Chrysotile, crocidolite (a fibrous form of riebeckite), amosite (a fibrous form of grunerite), anthophyllite, tremolite, and actinolite.

The characteristic fibrous structure of asbestos allows easy longitudinal splitting of thicker fibres, whereas transverse splitting of fibres is quite difficult, and results in their exceptional elasticity and high mechanical strength. The specific physical and chemical properties of asbestos, including its resistance to high temperatures and caustic substances, as well as the low costs of its obtaining (mining) has resulted in it commonly used in many branches of economy in the past. Due to its non-biodegradability and resistance to the attack of various agents, asbestos is a material difficult to destroy and, once placed in the environment, it can remain there for hundreds of years.

Only one type of asbestos belongs to the serpentine group, i.e. chrysotile (white asbestos), which is extracted and used in the largest quantities. The remaining minerals belong to a group of amphiboles, among which only two types are important for industrial practice: Amosite asbestos (brown asbestos) and crocidolite asbestos (blue asbestos) [1,2,3,4].

Asbestos was one of the most popular and cheapest raw materials used for the production of building materials. It was also applied in the machinery and shipbuilding industry. At the peak of its popularity, there were more than 3000 different asbestos-containing products on the market [5]. The major ones included: (a) Cement-asbestos products made from chrysotile and amphibole asbestos (roof slates, pressure pipes, stone cladding, and façade panels)—the largest group of asbestos products; (b) insulating products used to insulate steam boilers, heat exchangers, tanks, pipes, as well as clothing and fire-proof fabrics; (c) sealing products, which include cardboard, woven sealants, asbestos-rubber slabs; (d) abrasive products, such as: Friction linings and brake bands; (e) hydro-insulating products: Asphalt binders, sealing putties, refined road asphalts [3,6].

In many countries, the production of asbestos-containing materials has been limited and considerably reduced. As asbestos proved to have carcinogenic properties, for many years it has been included in Group 1 by the International Agency for Research and Cancer (IARC) [7]. The pathogenic effect of asbestos results from inhaling asbestos fibres suspended in the air. Inhalation of asbestos fibres does not cause immediate pathological changes—they are visible 10–60 years after the first contact. Exposure to asbestos dust can be a cause of many diseases, including among others: Asbestos pneumoconiosis (asbestosis), pleural changes, lung cancer, and mesotheliomas [7,8,9].

After discovering the harmful effects of asbestos fibres on human health, the extraction of asbestos minerals and manufacturing of asbestos-based products was gradually limited. Finally, many countries introduced regulations that not only banned the manufacturing of asbestos-containing products, but also made it mandatory to remove such products from the economy, in particular, from building facilities, and store them at controlled landfill sites. For example, in Poland, the Council of Ministers adopted a “programme for removal of asbestos and asbestos-containing products on the territory of Poland” [10], according to which the entire process of removal should have finished by 2032.

This is only a partial solution as it does not eliminate asbestos and its fibrous structure completely, but merely isolates it from society. This poses a secondary risk for the surrounding environment. Therefore, it seems necessary to search for methods based on complete degradation of asbestos and material recycling of the product obtained after treatment. The resolution of the European Parliament of 14 March 2013 [11] makes it clear that “delivering asbestos waste to landfills would not appear to be the safest way of definitively eliminating the release of asbestos fibres into the environment, and therefore, it would be far preferable to opt for asbestos inertisation plants.” It further points out that, “as regards the management of asbestos waste, measures must also be taken to promote and support research into, and technologies using, eco-compatible alternatives, and to secure procedures, such as the inertisation of waste-containing asbestos, to deactivate active asbestos fibres and convert them into materials that do not pose public health risks”.

The asbestos problem is widely known and raises concerns all over the world [12,13]. In Poland alone, the scale of this problem is particularly large. According to estimates, approximately 15.5 million tonnes of asbestos-containing materials are accumulated in Poland, of which 14.9 million tonnes (i.e. 96%) are cement-asbestos products [10]. The progress in the disposal of asbestos waste by landfilling in Poland seems to be insufficient. According to latest data [14], only slightly more than 6.2 million tonnes of asbestos-containing waste was inventoried in Poland, of which approximately 0.9 million tonnes was disposed of (through storage).

The process of neutralization, utilization, and recycling of asbestos has been the subject of numerous investigations. Most of the methods used involve destroying the harmful structure of asbestos fibres and turning the material into one that can be potentially reused. The vast majority of the described methods concern the thermic method of destroying the fibrous structure of asbestos [15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37]. There is a multitude of solutions proposed in this respect, depending on the source of heat and the manner of heating (conventional, microwave, plasma etc.), or the way asbestos fibres are destroyed (controlled recrystallization, vitrification, melting etc.). There are also reports of chemical [38,39,40,41,42,43] or mechanochemical methods [44,45]. Detailed information on various methods of dealing with asbestos waste is provided by review studies, which have appeared in recent years [46,47,48]. One of the proposed solutions is also a method of asbestos waste disposal by a melting process in a laboratory arc-resistance electric furnace. This issue was studied by the authors in their previous work [49]. The obtained results showed that the fibrous structure of asbestos, contained in cement-asbestos waste was completely changed and destroyed. As a result of this treatment, new mineral phases without dangerous properties were formed. The obtained results indicate that the melting process is an interesting method of neutralizing hazardous asbestos materials. On the other hand, finding new ways of managing the previously processed waste will allow for effective waste management. One such potential directions seems to be the production of artificial aggregates from asbestos waste. The problem of artificial aggregates made from various waste materials is common. Artificial aggregates from industrial by-products (fly ash, mining residues, sewage sludge etc.) are increasingly used on a large scale. They offer a solution to two significant problems of sustainable development, i.e. they may protect the environment against pollution and prevent natural resources from being depleted [50,51]. This work extends the scope of the authors’ previous research.

The aim of this work was to study the melting of asbestos-containing waste in an electric arc-resistance furnace, with the participation of specially-selected mineral additives, which enable the obtaining of a useful final material—artificial construction aggregate. In addition to laboratory tests that check the destruction of asbestos forms in the melting process, the usability of the material obtained was also assessed in terms of the requirements to be fulfilled by construction aggregates.

2. Materials and Methods

The following materials were selected for the study: (1) Cement-asbestos waste board (in Poland, it is commonly known as “eternit”) was used as a representative of asbestos-containing material (ACM)—it was very popular as a construction material for various buildings and systems in the second half of the twentieth century. It now represents the biggest group of ACM accumulated on the territory of Poland. It is assumed that cement-asbestos waste accounts for more than 90% of asbestos products accumulated in Poland; (2) a mixture of soda (sodium carbonate) and potassium feldspar were used as fluxes applied in the study; both raw materials were commercially available and had technical grades of purity. Based on previous investigations [49], these raw materials were selected for cement-asbestos melting, due to their relatively high efficiency, widespread occurrence, and the absence of hazardous substances formed during high-temperature treatment.

A mixture of ACMs, with the above-mentioned fluxes (85 wt% of ACM, 10 wt% of soda, and 5 wt% of feldspar) was melted for 100 minutes in an electric arc-resistance furnace and, then, cast into a ceramic mould to form a material for aggregates. Trials were carried out in a laboratory arc-resistance furnace (100 kVA autotransformer, 35 dm3 working chamber) coupled with two graphite electrodes (5-cm diameter, mounted in a “V” system). The melting process was carried out in a furnace with a magnesia lining.

The chemical analysis of the raw materials and melted product was performed by X-ray fluorescence (XRF; PANalytical, Almelo, The Netherlands), using a Panalytical Magix PW-2424 spectrometer, following the procedures contained in the PN-EN ISO 12677:2011 standard [52]. To obtain homogeneous samples, the fused cast-bead method was applied. The chemical analysis data was supplemented by the content of volatile components, measured by calcination at 1025 °C and expressed as a value of loss on ignition (LOI). A thermo-gravimetric analysis (TG-DTG; Netzsch, Selb, Germany), combined with an evolved gas analysis (EGA) was performed in an alumina crucible, using an STA 409PC NETZSCH thermal analyser with quadrupole mass spectrometer QMS 403C Aëolos in the 25–1450 °C temperature range, with a heating rate of 5 °C∙min−1 and a sample of 130 mg. The tests were carried out in a synthetic air atmosphere. The phase composition of the raw cement-asbestos waste, and the obtained melted product, was determined by powder X-ray diffraction (XRD; PANalytical, Almelo, The Netherlands). Analyses were conducted using a PANalytical X’pert Pro diffractometer (CuKα radiation, Ni filter, 40 kV, 30 mA, X’Celerator detector). A mineralogical quantitative phase analysis for the melted product was performed using the Rietveld method. The microstructure of raw samples, and the destruction of the fibrous nature of asbestos in ACM after melting, was observed by a scanning electron microscope (Mira III; Tescan, Brno, Czech Republic) in combination with the Energy Dispersive Spectroscopy (EDS) system, with AZtec Automated software (Oxford Instruments, Abingdon, UK).

The main properties of the obtained melted product, being potentially valuable material for aggregates, were checked by the procedures described below. The molten material was crushed in a single-toggle jaw crusher (Makrum, L44.41). Quality tests for the obtained artificial aggregate were carried out in accordance with PN-EN 12620 [53] and PN-EN 13043 [54] standards. The following parameters were determined for the obtained artificial aggregate: (a) Particle size distribution (according to PN-EN 933-1 [55]), (b) flakiness index (according to PN-EN 933-3 [56]), (c) crushed aggregate particle content (according to PN-EN 933-5 [57]), (d) grain density and absorbability (according to PN-EN 1097-6 [58]), (e) resistance to fragmentation by the Los Angeles test (according to PN-EN 1097-2 [59]), and (f) freezing resistance of the aggregate (according to PN-EN 1367-1 [60]).

3. Results and Discussion

3.1. Chemical and Phase Composition of the ACM

The chemical and phase compositions of raw cement-asbestos waste have been presented in Table 1 and Figure 1. Table 1 also contains chemical compositions of raw materials used for correcting the composition of asbestos-cement in the melting process.

Table 1.

Results of raw materials’ chemical analyses (values in wt%).

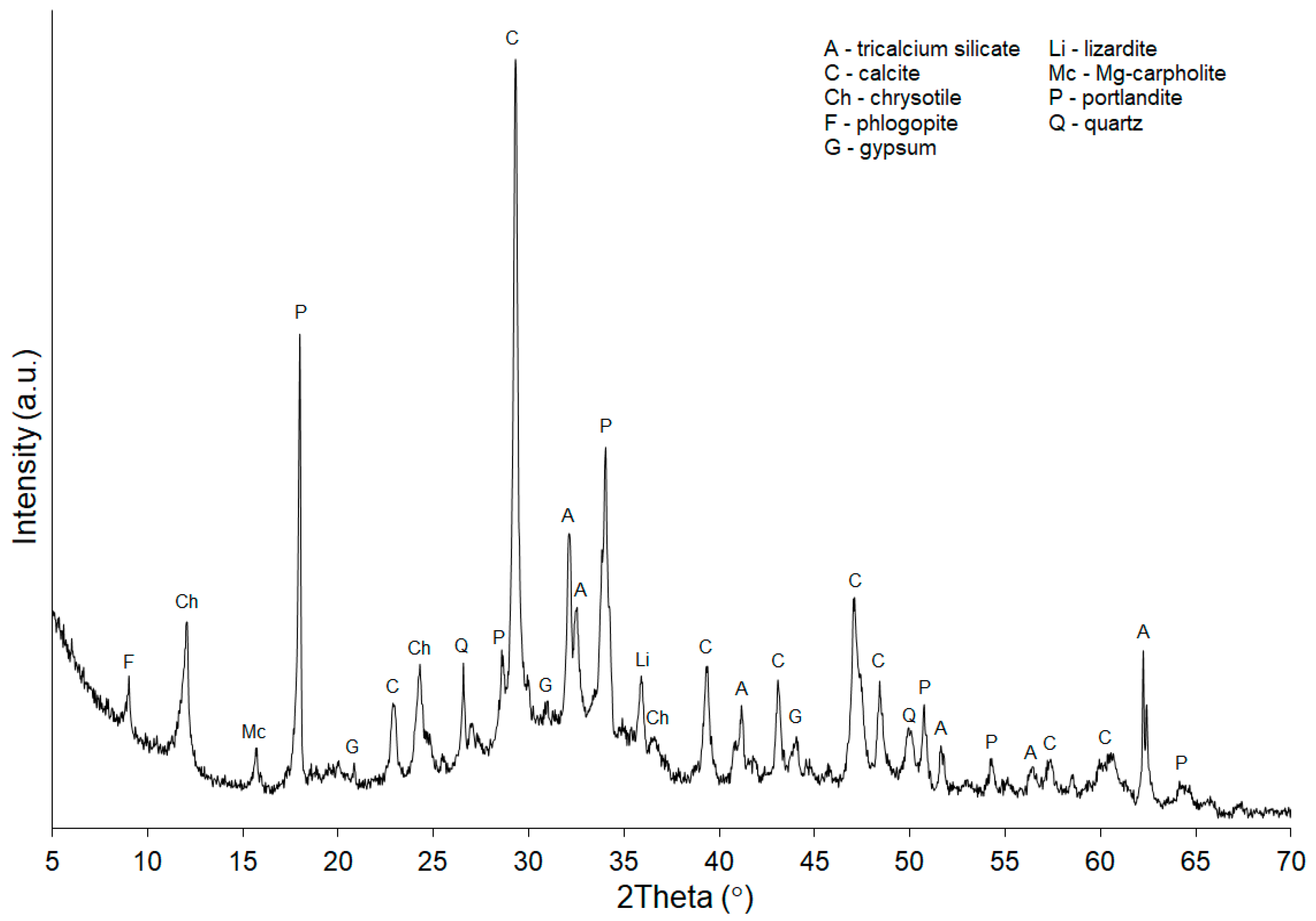

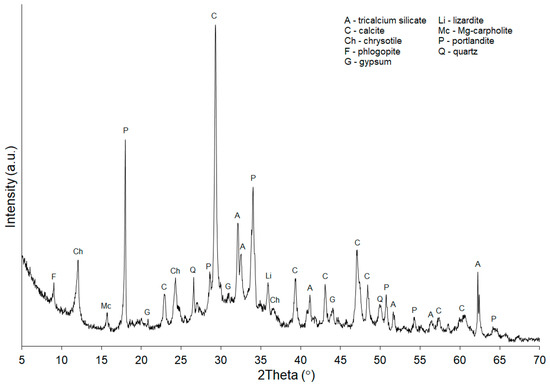

Figure 1.

X-ray diffraction (XRD) pattern of a cement-asbestos waste board.

In the case of the ACM sample, both chemical and phase compositions are typical of asbestos-cement products, in which the major components, apart from asbestos, included sand, Portland cement, and gypsum. The chemical composition is, therefore, dominated by CaO (ca 42 wt%), SiO2 (ca 19 wt%) and MgO (ca 6 wt%). The chemical composition and the manner of asbestos binding in the cement matrix are also related to high values of loss on ignition (ca 25 wt%), which result from the thermal decomposition of particular mineral components (point 3.2).

The phase composition (Figure 1) of the tested ACM was typical of this group of asbestos materials ad comparable with the results presented elsewhere [61]. One type of asbestos minerals in the ACM sample, i.e. chrysotile (ICDD-PDF 00-027-1275), was identified. This is confirmed by the main asbestos X-ray reflections at around 11–12° and 24–25° 2-Theta. Due to the presence of cementitious matrix, calcium carbonate (calcite; ICDD-PDF 01-072-1937) and calcium hydroxide (portlandite; ICDD-PDF 00-004-0733) were detected in the tested material. Calcite is present, due to cement matrix long-term weathering and gradual carbonation by atmospheric CO2. This is a slow process, during which calcium hydroxide and/or hydrated phases of cement hydration (CSH phase) react with carbon dioxide. The CSH phase usually displays a low degree of crystallinity, so it is hardly visible on XRD patterns. The presence of X-ray amorphous compounds in the ACM sample is only visible after increasing the halo at 25–35° 2-Theta. Tricalcium silicate (ICDD-PDF 04-011-1393) was also identified as an unreacted phase of cement clinker. Trace amounts of lizardite (ICDD-PDF 01-087-2052), phlogopite (ICDD-PDF 00-010-0495), and magnesiocarpholite (ICDD-PDF 00-027-0303) were identified in the aged asbestos-cement material.

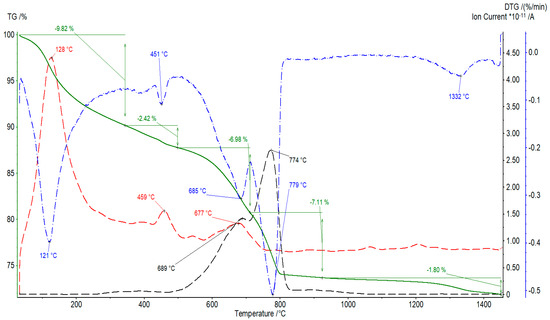

3.2. ACM Thermal Analysis Characterization

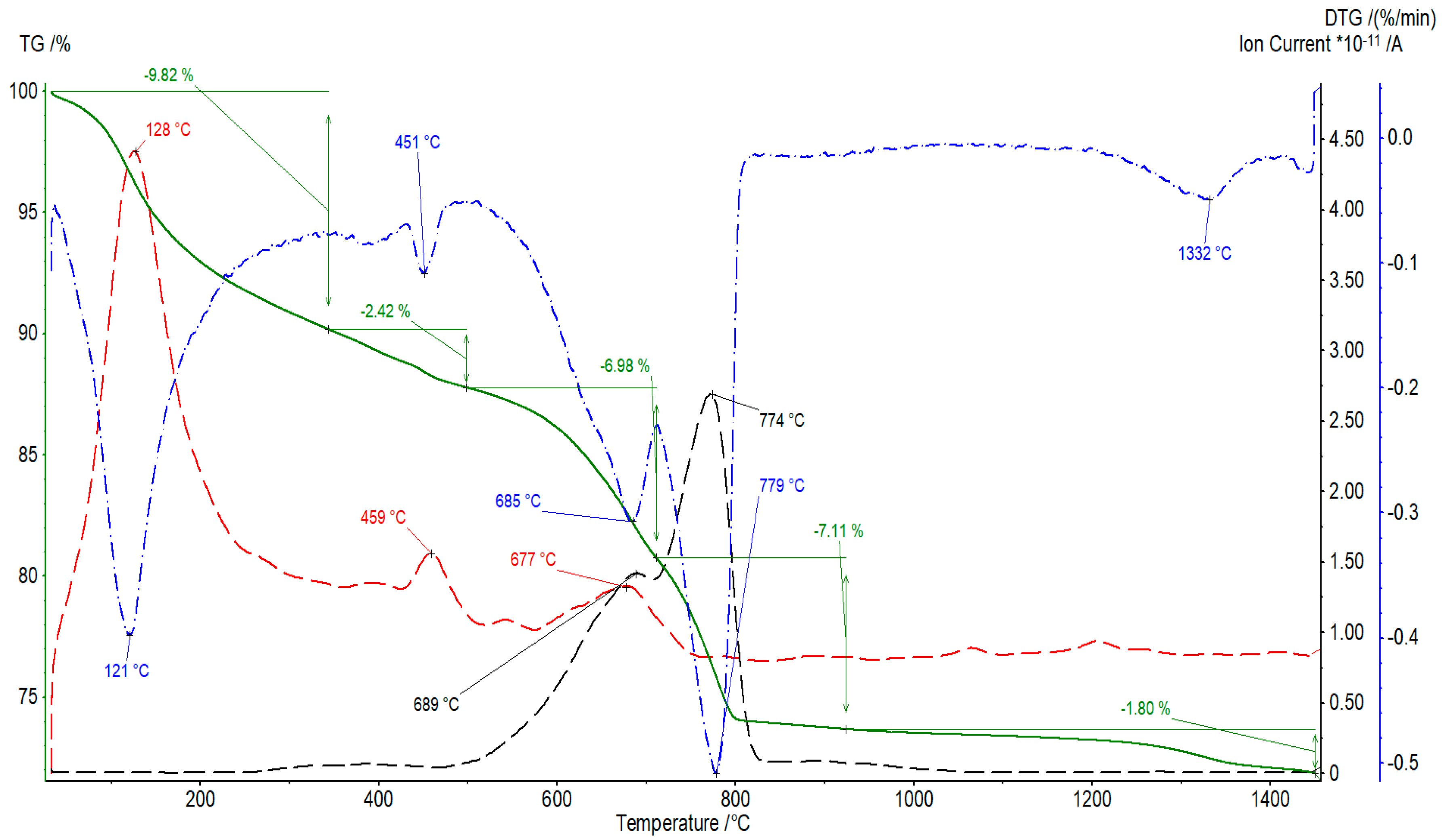

The results of the asbestos material thermal analysis (Figure 2) indicate that an approximately 10 wt% mass loss, at temperatures up to ca 300 °C, is related to the loss of physically bound water and dehydration of the CSH phase of bound cement and gypsum, which was put into the system as a binding time regulator. At a temperature of ca 450 °C, one can observe a visible effect of portlandite (calcium hydroxide) thermal decomposition, which is accompanied by a 2.5 wt% mass loss, related to water release according to the reaction: Ca(OH)2 → CaO + H2O. On the other hand, within a temperature range of 500–800 °C, a considerable mass loss (ca 14 wt%), combined with a release of both water and carbon dioxide can be observed, which is confirmed by peaks recorded on the mass spectra of gases released from the sample in this temperature range. The wide temperature range indicates the overlapping of several processes during the thermal decomposition of the ACM sample. One of them, of course, is the decomposition of calcium carbonate (calcite) according to the following reaction: CaCO3 → CaO + H2O. Stepkowska et al. [62] reported that, in this temperature range, the rest of the absorbed water escapes from aged cement pastes.

Figure 2.

Thermo-gravimetric analysis (TG-DTG) results combined with evolved gas analysis (EGA) analysis (H2O—red line; CO2—black line) for a cement-asbestos waste board.

Another phenomenon in this range of temperatures, which seems important from the point of view of this work, is also the dehydroxylation of minerals, like chrysotile (white asbestos) and lizardite, combined with their thermal decomposition and the formation of new mineral phases. The thermal decomposition of these minerals with the formation of new mineral phases, like forsterite (Mg2SiO4) and/or enstatite (MgSiO3), was thoroughly studied in the past few years [30,32,63]. The above transformations could be simplified and represented by the following overall reaction: Mg3(OH)4Si2O5 → Mg2SiO4 + MgSiO3 + 2H2O, which allows for the thermal transformation of asbestos fibers into new minerals, characterized by complete recrystallization. A slight loss of mass at ca 1300 °C (1.8 wt%) is most probably related to the decomposition of sulphates, mainly CaSO4, which are present in the tested ACM material in the form of gypsum.

3.3. Characterization of the Melted Product

The process of melting ran smoothly and was accompanied by a release of certain amounts of gases. This effect was related to the presence of compounds in the asbestos-cement material, which thermally decomposed at high temperatures, with a release of gaseous products (H2O, CO2, SO2). The yield of melt in relation to the mass of feed subjected to melting, reached approximately 70%. However, if the loss of ignition of the ACM material is taken into account, it can be assumed that this yield was practically 100% and the feed was completely melted. During the experiment the measured power consumption (the electricity consumed by the furnace), in relation to the mass of the obtained melt was approximately 2.2 kWh∙kg−1. However it should be taken into consideration that the mass of the lining of the furnace is significantly higher (nearly 10 times) compared to the melted raw material charge. A significant amount of energy is consumed to warm up the furnace ceramic lining. When the process is scaled up, the thermal and electric consumption will be lower. It can be assumed that the energy consumption of the proposed method has similar or even lower values than in other ACM thermal treatment processes (ranging from 0.5 to 1.5 kWh∙kg−1 [48]), so it can be considered to be economically competitive.

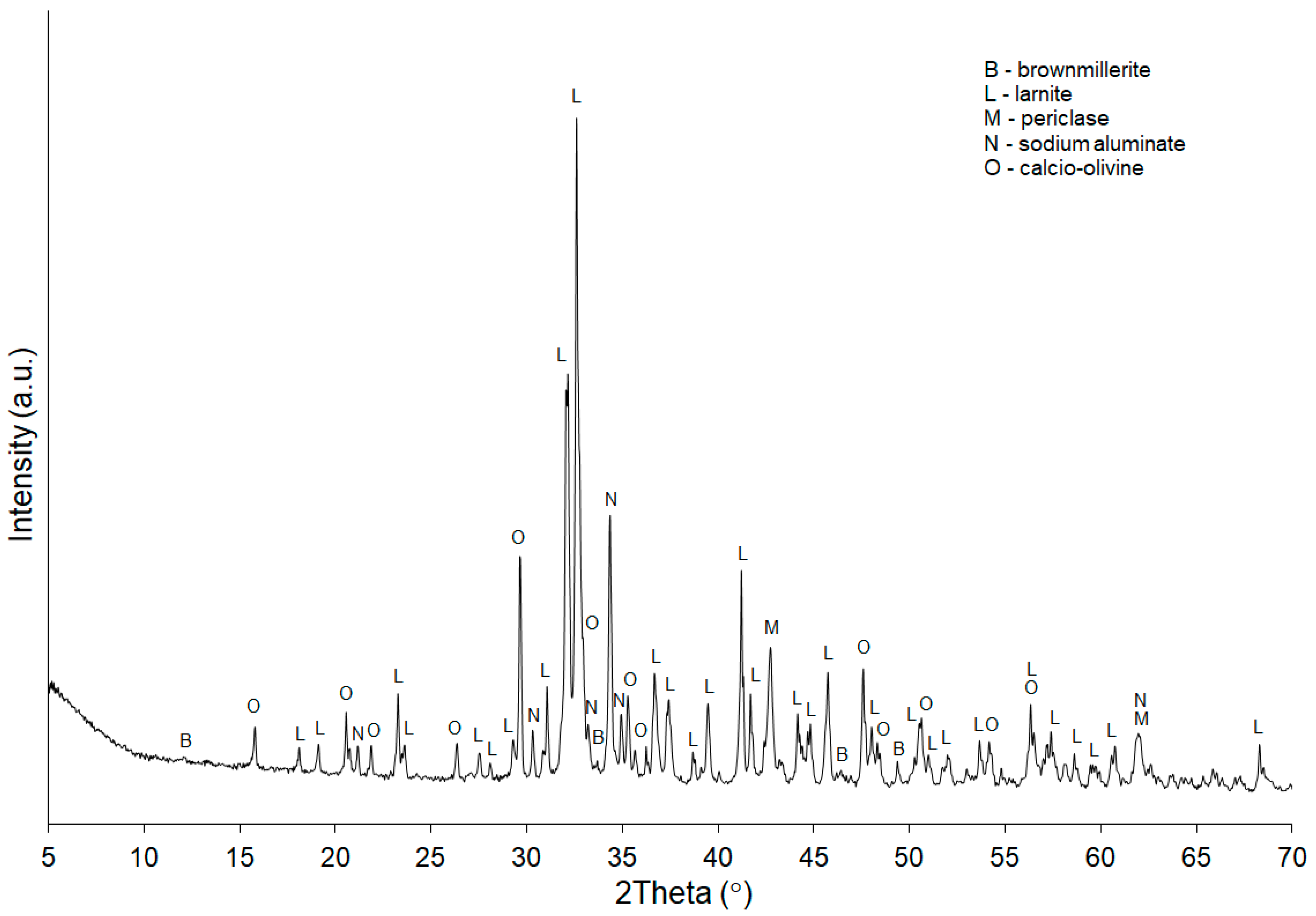

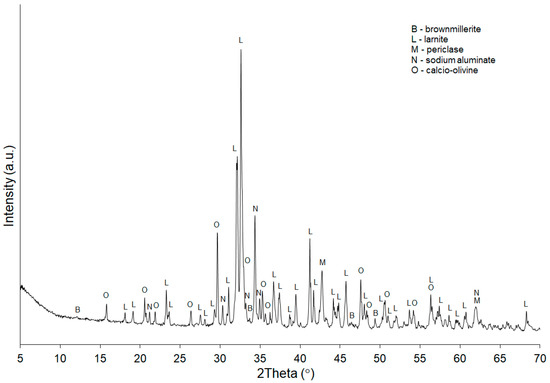

An analysis of the chemical composition (Table 2) and phase composition (Figure 3) indicates that the main phase in the product of melting of ACM with an addition of sodium carbonate and feldspar, is dicalcium silicate in the form of larnite crystals (β-Ca2SiO4; ICDD-PDF 01-077-0388) and calcio-olivine (γ-Ca2SiO4; ICDD-PDF 04-010-9508).

Table 2.

Results of the chemical analysis and quantitative X-ray phase analyses of the obtained aggregate (values in wt%).

Figure 3.

XRD pattern of the material obtained after the melting process.

The quantitative phase composition analysis demonstrated that their contents were 68.3 and 19.8 wt%, respectively. Moreover, approximately 7% of sodium aluminate (NaAlO2, ICDD-PDF 04-006-9358), and a small amount of brownmillerite (Ca2FeAlO5, ICDD-PDF 04-011-5939), were identified. An important observation resulting from the analysis of the phase composition revealed that the melted sample did not contain any asbestos, as the characteristic reflexes from chrysotile were not found on the diffraction pattern. On the other hand, approximately a 4 wt% content of magnesium oxide, in the form of periclase (MgO, ICDD-PDF 04-012-6481), was observed. The main component in the raw ACM sample, that was responsible for introducing magnesium compounds into the system, was asbestos fibre—chrysotile. As demonstrated by the research of Belardi and Piga [28], chrysotile asbestos in the presence of calcium compounds, for example from the thermal decomposition of portlandite or calcite, is subject to thermal decomposition to dicalcium silicate, with a release of free magnesium oxide according to the reaction: Mg3(OH)4Si2O5 + 4CaO → 2Ca2SiO4 + 3MgO + 2H2O. Therefore, it can be concluded that the presence of MgO in the melting product, indirectly confirms the decomposition of asbestos in the material.

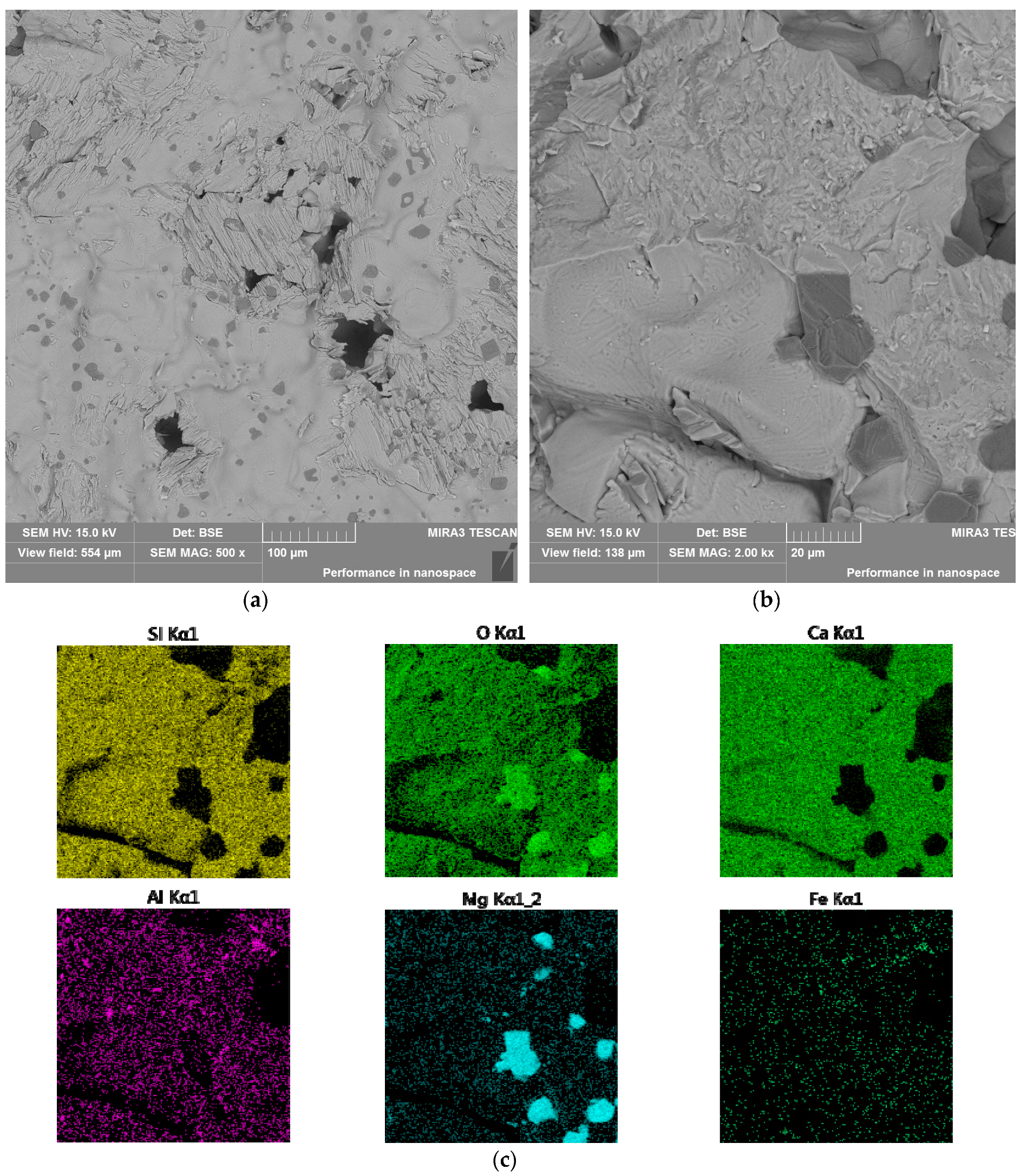

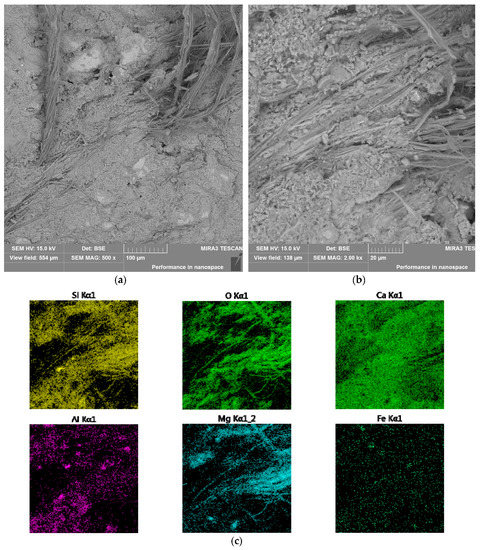

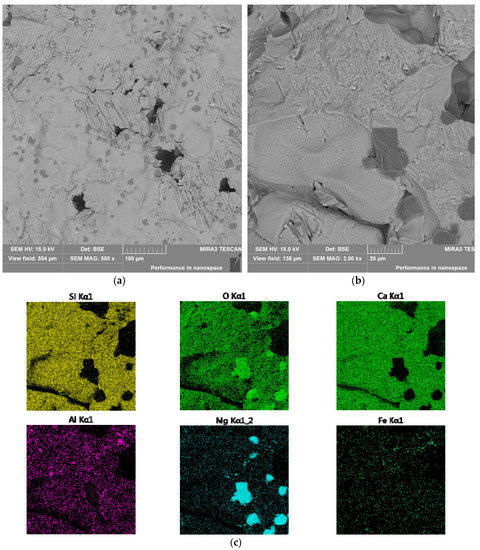

3.4. SEM Characterization of Materials before and after Treatment

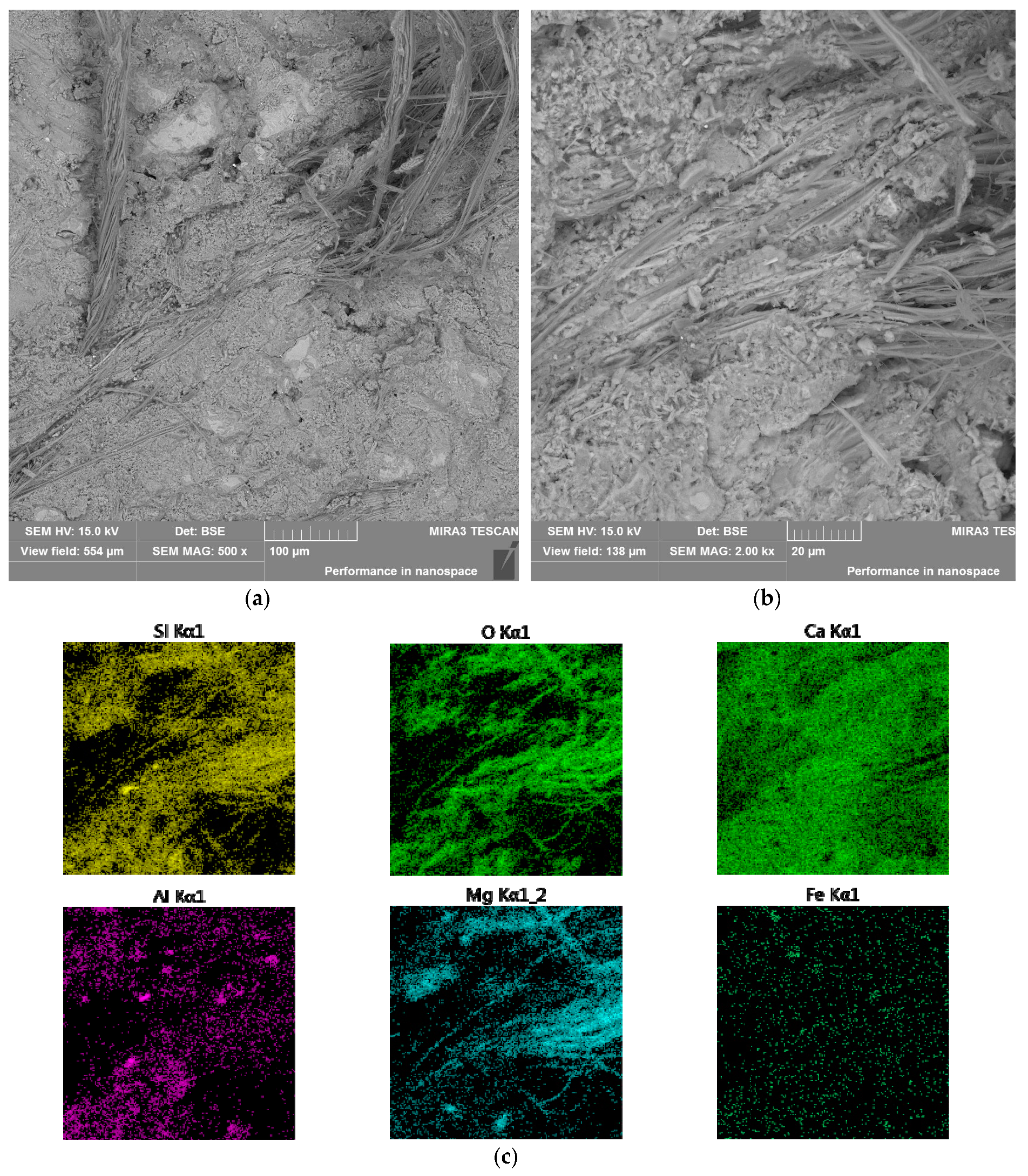

The most important feature, from the point of view of the aim of this work, was the presence of asbestos fibres in the cement-asbestos sample. The observations were conducted both after, and before, melting for comparison purposes. An Scanning electron microscopy (SEM)/EDS examination of the micro-area revealed the presence of chrysotile asbestos in the ACM material (Figure 4). On the other hand, the solidified material, obtained after melting, did not contain any fibrous forms (Figure 5). Microscopic observations of the ACM sample, subjected to melting, revealed that this material is characterized by a non-homogenous and fine-crystalline structure. The EDS measurement showed that the sample is mainly built of calcium silicate (represented by X-ray-identified larnite (β-C2S) and calcio-olivine (γ-C2S)). In the SEM photograph (Figure 5a), there are visible voids after asbestos utilization. These voids have the same chemical composition as the environment, which confirms asbestos utilization. Chrysotile destruction is also confirmed by the fact that magnesium, which is a chrysotile component in the sample before melting, occurs in the form of isolated MgO islands in the sample after melting. The identified contents of periclase were clearly separated from the remaining part of the material. Therefore, the conducted SEM/EDS analysis confirmed the complete destruction of asbestos fibres during the melting process.

Figure 4.

Scanning electron microscopy (SEM) images of the asbestos-containing materials (ACM) sample: Surface; 500× (a); fracture; 2000× (b) and corresponding fracture Energy Dispersive Spectroscopy (EDS) elemental maps (c).

Figure 5.

SEM images of the ACM sample after thermal treatment: surface; 500× (a); fracture; 2000× (b) and corresponding fracture EDS elemental maps (c).

3.5. Properties of the Obtained Artificial Aggregate

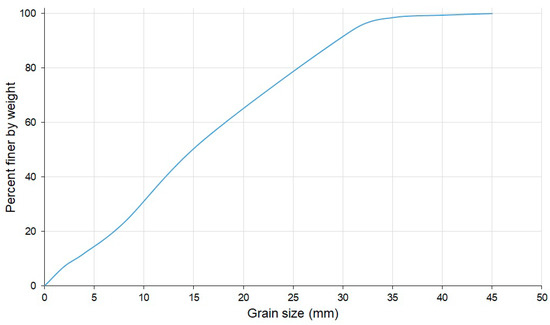

For the artificial aggregate obtained in the process of ACM melting with selected fluxes (composition: 85 wt% of ACM, 10 wt% of soda and 5 wt% of feldspar), the major quality characteristics were determined according to the the following standards: PN-EN 12620 and PN-EN 13043. The results of investigations into the basic functional properties have been presented in Table 3 and Figure 6.

Table 3.

Main properties of the artificial aggregate obtained from asbestos-containing material (ACM).

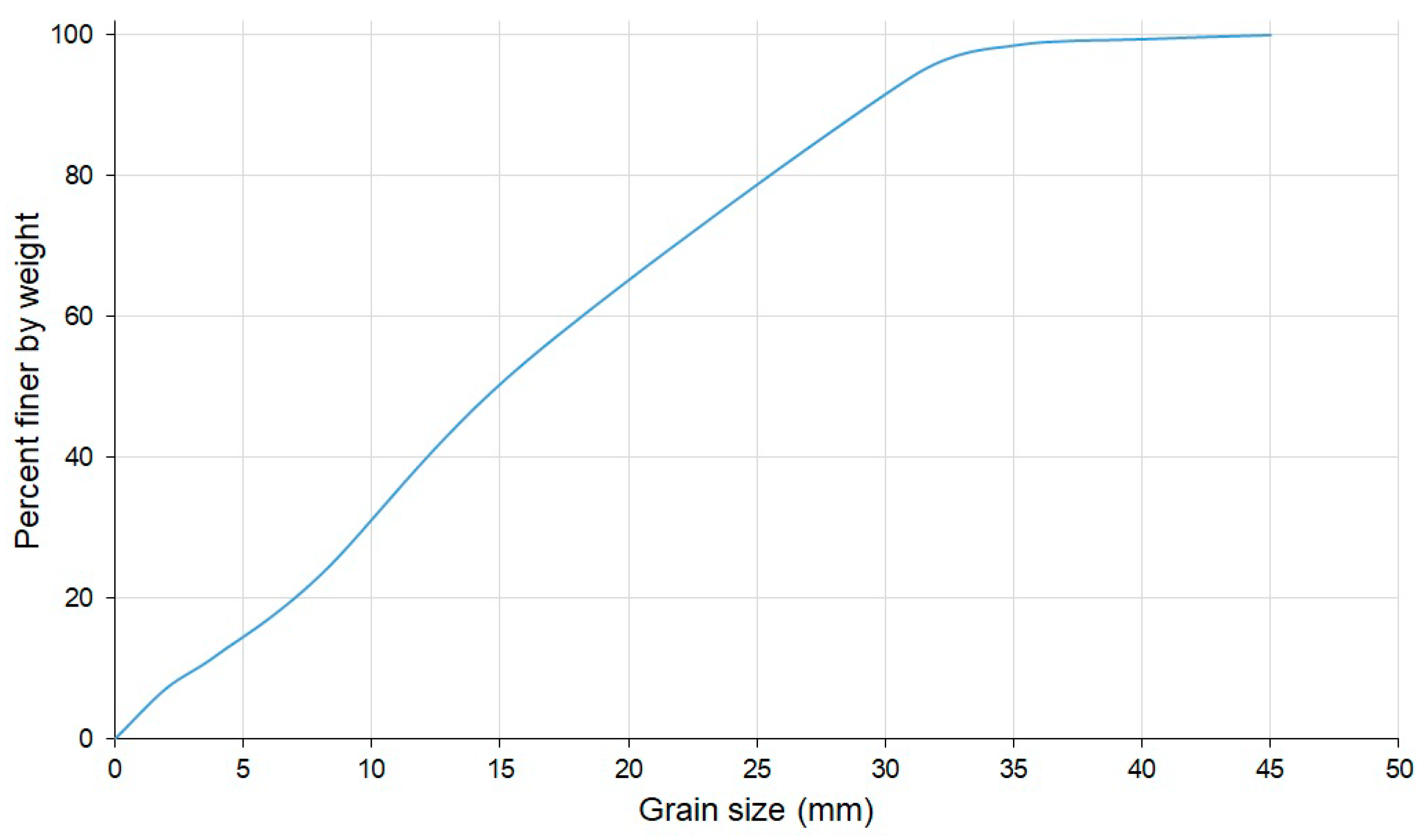

Figure 6.

Particle size distribution of the artificial aggregate obtained after crushing the material in a jaw crusher.

The investigated artificial aggregate obtained in the process of asbestos-cement melting is characterized—with a few exceptions—by good physical and mechanical properties. The grains of the aggregate, subjected to mechanical crushing, pass through a sieve with 45-mm mesh, more than 60 wt%, which have a size below 20 mm. Of course, the grain size distribution of the obtained artificial aggregate—depending on the needs—can be shaped by subjecting it to crushing and sieving in appropriately selected equipment. The artificial aggregate obtained in the process of ACM melting is characterized by a favourable size of grains. The flakiness FI of 18% results directly from the manner of aggregate preparation, as jaw crushers allow obtaining aggregates, with a relatively high content of shapeless grains. This result (18% of shapeless grains) allows the obtained aggregate to be classified into higher grades. According to the standards, it is assumed that the content of flat grains, required from the highest class aggregates, should be < 10% (according to PN-EN 13043) or < 15% (according to PN-EN 12620). On the other hand, the content of shapeless grains in the lowest grades of aggregates, can reach up to 50%. The obtained aggregate is characterized by a relatively high density of the grains. Grain density for natural aggregates usually ranges from 2.6 to 2.7 mg∙m−3, and in the case of the artificial aggregate obtained from ACM, reaches ca 3.2 mg∙m−3. It is worth noting that the obtained values of apparent, dry, and saturated-surface-dry (SSD) densities are very similar. For comparison—the highest values of bulk density among natural aggregates are obtained for basalts, reaching ca 3.0 mg·m−3. Slight differences in density values result from the very low value of water absorption, which was approximately 0.1%. Such a low value is the effect of melting and subsequent solidification of the waste into a non-porous block. As the artificial aggregate was obtained by breaking and crushing larger, homogenous blocks, the C100/0 category should be assumed, which corresponds to 100% content of totally, partially crushed, or broken grains with a complete absence of round ones. Resistance to crushing and fragmentation sd determined in the Los Angeles testing drum is very high, similar to that of aggregates obtained from magma rocks. For the highest categories, the LA index, according to PN-EN 13043 and PN-EN 12620, should be lower than 15%. For the aggregate obtained from ACM, the achieved value of LA index reached 12%. The aggregate’s freezing resistance was relatively low and resulted from the material’s low absorbability. In the case of the best natural aggregates obtained from magma and sedimentary rocks, the loss of mass of the aggregate, subjected to freezing and thawing, does not usually exceed 1–2%. In the case of the aggregate based on melted ACM, the value of resistance to freezing reached approximately 2–3%.

4. Conclusions

The obtained results demonstrated that the fibrous nature of asbestos was completely destroyed by melting the material with selected fluxes. The process of melting with appropriate additives allowed a new material to be obtained, which can be successfully used for the production of artificial aggregates. The investigated aggregates fulfil the requirements for different levels of categories, as defined in PN-EN 12620 Aggregates for concrete and PN-EN 13043 Aggregates for bituminous mixtures and surface treatments for roads, airfields, and other trafficked areas. In the future they can be used in road construction as well as in the production of concrete, when the processing of asbestos waste is allowed as the only possible method of its neutralization.

Author Contributions

J.W. conceived the research, performed technological measurements, and analysed the results; Z.N. determined the properties of the aggregate, B.P. performed SEM/EDS analysis, R.K. analysed the results and wrote the manuscript.

Funding

This work is the result of statutory activity at the Institute of Ceramics and Building Materials—Refractory Materials Division supported by the Polish Ministry of Science and Higher Education.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Virta, R.L. Mineral Commodity Profiles—Asbestos; Circular 1255-KK; U.S. Geological Survey: Reston, VA, USA, 2005.

- Gualtieri, A.F. (Ed.) Mineral Fibers: Crystal Chemistry, Chemical-Physical Properties, Biological Interaction and Toxicity; European Mineralogical Union: London, UK, 2017; Volume 18, ISBN 978-0903056-65-6. [Google Scholar]

- Obmiński, A. Asbestos in Buildings; Building Research Institute: Warsaw, Poland, 2017; ISBN 978-83-249-8477-0.

- Sporn, T.A. Mineralogy of asbestos. In Malignant Mesothelioma; Tannapfel, A., Ed.; Springer: Berlin, Germany, 2011; pp. 1–11. ISBN 978-3-642-10861-7. [Google Scholar]

- Harris, L.V.; Kahwa, I.A. Asbestos: Old foe in 21st century developing countries. Sci. Total Environ. 2003, 307, 1–9. [Google Scholar] [CrossRef]

- Pyssa, J.; Rokita, G.M. The asbestos—Occurence, using and the way of dealing with asbestic waste material. Min. Res. Manag. 2007, 23, 49–61. [Google Scholar]

- IARC. Overall Evaluations of Carcinogenicity: An Updating of IARC Monographs Volumes 1 to 42; IARC: Lyon, France, 1987; 440p. [Google Scholar]

- IARC. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans. Volumes 81 Man-Made Vitreous Fibres; IARC: Lyon, France, 2002; 433p. [Google Scholar]

- IARC. IARC Monographs on the Evaluation of Carcinogenic Risks to Humans. Volumes 100C Arsenic, Metals, Fibres and Dust; IARC: Lyon, France, 2012; 527p. [Google Scholar]

- Annex to the Resolution No. 39/2010 of the Council of Ministers; Programme for Asbestos Abatement in Poland 2009–2032; Polish Government: Warsaw, Poland, 15 March 2010.

- European Parliament resolution 2012/2065 (INI), Asbestos-Related Occupational health Threats and Prospects for Abolishing All Existing Asbestos; European Parliament: Brussels, Belgium, 14 March 2013.

- Li, J.; Dong, Q.; Yu, K.; Liu, L. Asbestos and asbestos waste management in the Asian-Pacific region: Trends, challenges and solutions. J. Clean. Prod. 2014, 81, 218–226. [Google Scholar] [CrossRef]

- Paglietti, F.; Malinconico, S.; Conestabile della Staffa, B.; Bellagamba, S.; De Simone, P. Classification and management of asbestos-containing waste: European legislation and the Italian experience. Waste Manag. 2016, 50, 130–150. [Google Scholar] [CrossRef] [PubMed]

- Asbestos Datebase. Available online: https://www.bazaazbestowa.gov.pl/en/ (accessed on 5 October 2018).

- Gualtieri, A.F.; Tartaglia, A. Thermal decomposition of asbestos and recycling in traditional ceramics. J. Eur. Ceram. Soc. 2000, 20, 1409–1418. [Google Scholar] [CrossRef]

- Gualtieri, A.F.; Cavenati, C.; Zanatto, I.; Meloni, M.; Elmi, G.; Gualtieri, M.L. The transformation sequence of cement–asbestos slates up to 1200 °C and safe recycling of the reaction product in stoneware tile mixtures. J. Hazard. Mater. 2008, 152, 563–570. [Google Scholar] [CrossRef] [PubMed]

- Dellisanti, F.; Rossi, P.L.; Valdrè, G. Remediation of asbestos containing materials by Joule heating vitrification performed in a pre-pilot apparatus. Int. J. Miner. Process. 2009, 91, 61–67. [Google Scholar] [CrossRef]

- Kusiorowski, R.; Zaremba, T.; Piotrowski, J.; Podwórny, J. Utilisation of cement-asbestos wastes by thermal treatment and the potential possibility use of obtained product for the clinker bricks manufacture. J. Mater. Sci. 2015, 50, 6757–6767. [Google Scholar] [CrossRef]

- Leonelli, C.; Veronesi, P.; Boccaccini, D.N.; Rivasi, M.R.; Barbieri, L.; Andreola, F.; Lancellotti, I.; Rabitti, D.; Pellacani, G.C. Microwave thermal inertisation of asbestos containing waste and its recycling in traditional ceramics. J. Hazard. Mater. 2006, 135, 149–155. [Google Scholar] [CrossRef]

- Anastasiadou, K.; Axiotis, D.; Gidarakos, E. Hydrothermal conversion of chrysotile asbestos using near supercritical conditions. J. Hazard. Mater. 2010, 179, 926–932. [Google Scholar] [CrossRef]

- Viani, A.; Gualtieri, A.F.; Pollastri, S.; Rinaudo, C.; Croce, A.; Urso, G. Crystal chemistry of the high temperature product of transformation of cement-asbestos. J. Hazard. Mater. 2013, 248, 69–80. [Google Scholar] [CrossRef]

- Gualtieri, A.F.; Boccaletti, M. Recycling of the product of thermal inertization of cement–asbestos for the production of concrete. Constr. Build. Mater. 2011, 25, 3561–3569. [Google Scholar] [CrossRef]

- Viani, A.; Gualtieri, A.F. Preparation of magnesium phosphate cement by recycling the product of thermal transformation of asbestos containing wastes. Cem. Concr. Res. 2014, 58, 56–66. [Google Scholar] [CrossRef]

- Gualtieri, A.F.; Giacobbe, C.; Sardisco, L.; Saraceno, M.; Gualtieri, M.L.; Lusvardi, G.; Cavenati, C.; Zanatto, I. Recycling of the product of thermal inertization of cement–asbestos for various industrial applications. Waste Manag. 2011, 31, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Viani, A.; Gualtieri, A.F. Recycling the product of thermal transformation of cement-asbestos for the preparation of calcium sulfoaluminate clinker. J. Hazard. Mater. 2013, 260, 813–818. [Google Scholar] [CrossRef] [PubMed]

- Kusiorowski, R.; Zaremba, T.; Piotrowski, J. The potential use of cement-asbestos waste in the ceramic masses destined for sintered wall clay brick manufacture. Ceram. Int. 2014, 40, 11995–12002. [Google Scholar] [CrossRef]

- Croce, A.; Allegrina, M.; Trivero, P.; Rinaudo, C.; Viani, A.; Pollastri, S.; Gualtieri, A.F. The concept of ‘end of waste’ and recycling of hazardous materials: In depth characterization of the product of thermal transformation of cement-asbestos. Mineral. Mag. 2014, 78, 1177–1191. [Google Scholar] [CrossRef]

- Belardi, G.; Piga, L. Influence of calcium carbonate on the decomposition of asbestos contained in end-of-life products. Thermochim. Acta 2013, 573, 220–228. [Google Scholar] [CrossRef]

- Yoshikawa, N.; Kashimura, K.; Hashiguchu, M.; Sato, M.; Horikoshi, S.; Mitani, T.; Shinohara, M. Detoxification mechanism of asbestos materials by microwave treatment. J. Hazard. Mater. 2015, 284, 201–206. [Google Scholar] [CrossRef]

- Bloise, A.; Catalano, M.; Barrese, E.; Gualtieri, A.F.; Gandolfi, N.B.; Capella, S.; Belluso, E. TG/DSC study of the thermal behaviour of hazardous mineral fibers. J. Therm. Anal. Calorim. 2016, 123, 2225–2239. [Google Scholar] [CrossRef]

- Yvon, Y.; Sharrock, P. Characterization of thermochemical inactivation of asbestos containing wastes and recycling the mineral residues in cement products. Waste Biomass Valoriz. 2011, 2, 169–181. [Google Scholar] [CrossRef]

- Kusiorowski, R.; Zaremba, T.; Piotrowski, J.; Adamek, J. Thermal decomposition of different types of asbestos. J. Therm. Anal. Calorim. 2012, 109, 693–704. [Google Scholar] [CrossRef]

- Kusiorowski, R.; Zaremba, T.; Piotrowski, J.; Gerle, A. Thermal decomposition of asbestos-containing materials. J. Therm. Anal. Calorim. 2013, 113, 179–188. [Google Scholar] [CrossRef]

- Osada, M.; Takamiya, K.; Manako, K.; Noguchi, M.; Sakai, S. Demonstration study of high temperaturę melting for asbestos-containing waste (ACM). J. Mater. Cycles Waste Manag. 2013, 15, 25–36. [Google Scholar] [CrossRef]

- Ruiz, A.I.; Ortega, A.; Fernández, R.; Miranda, J.F.; López Samaniego, E.; Cuevas, J. Thermal treatment of asbestos containing materials (ACM) by mixing with Na2CO3 and special clays for partial vitrification of waste. Mater. Lett. 2018, 232, 29–32. [Google Scholar] [CrossRef]

- Averroes, A.; Sekiguchi, H.; Sakamoto, K. Treatment of airborne asbestos and asbestos-like microfiber particles using atmospheric microwave air plasma. J. Hazard. Mater. 2011, 195, 405–413. [Google Scholar] [CrossRef] [PubMed]

- Iwaszko, J.; Zawada, A.; Przerada, I.; Lubas, M. Structural and microstructural aspects of asbestos-cement waste vitrification. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2018, 195, 95–102. [Google Scholar] [CrossRef]

- Sugama, T.; Sabatini, R.; Petrakis, L. Decomposition of chrysotile asbestos by fluorosulfonic acid. Ind. Eng. Chem. Res. 1998, 37, 79–88. [Google Scholar] [CrossRef]

- Pawełczyk, A.; Božek, F.; Grabas, K.; Chęcmanowski, J. Chemical elimination of the harmful properties of asbestos from military facilities. Waste Manag. 2017, 61, 377–385. [Google Scholar] [CrossRef]

- Yanagisawa, K.; Kozawa, T.; Onda, A.; Kanazawa, M.; Shinohara, J.; Takanami, T.; Shiraishi, M. A novel decomposition technique of friable asbestos by CHClF2-decomposed acidic gas. J. Hazard. Mater. 2009, 163, 593–599. [Google Scholar] [CrossRef]

- Rozalen, M.; Huertas, F.J. Comparative effect of chrysotile leaching in nitric, sulfuric and oxalic acids at room temperature. Chem. Geol. 2013, 352, 134–142. [Google Scholar] [CrossRef]

- Nam, S.N.; Jeong, S.; Lim, H. Thermochemical destruction of asbestos-containing roofing slate and the feasibility of using recycled waste sulfuric acid. J. Hazard. Mater. 2014, 265, 151–157. [Google Scholar] [CrossRef] [PubMed]

- Turci, F.; Tomatis, M.; Mantegna, S.; Cravotto, G.; Fubini, B. A new approach to the decontamination of asbestos-polluted waters by treatment with oxalic acid under power ultrasound. Ultrason. Sonochem. 2008, 15, 420–427. [Google Scholar] [CrossRef] [PubMed]

- Plescia, P.; Gizzi, D.; Benedetti, S.; Camilucci, L.; Fanizza, C.; De Simone, P.; Paglietti, F. Mechanochemical treatment to recycling asbestos-containing waste. Waste Manag. 2003, 23, 209–218. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Lavorgna, M.; Verdolotti, L.; De Stefano, L. Treatment and recycling of asbestos-cement containing waste. J. Hazrd. Mater. 2011, 195, 391–397. [Google Scholar] [CrossRef] [PubMed]

- Gualtieri, A.F. Recycling asbestos-containing material (ACM) from construction and demolition waste (CDW). In Handbook of Recycled Concrete and Demolition Waste; Pacheco-Torgal, F., Tam, V.W.Y., Labrincha, J.A., Ding, Y., de Brito, J., Eds.; Woodhead Publishing: Cambridge, UK, 2013; Volume 47, pp. 500–525. ISBN 978-0-85709-682-1. [Google Scholar] [CrossRef]

- Spasiano, D.; Pirozzi, F. Treatments of asbestos containing wastes. J. Environ. Manag. 2017, 204, 82–91. [Google Scholar] [CrossRef] [PubMed]

- Paolini, V.; Tomassetti, L.; Segreto, M.; Borin, D.; Liotta, F.; Torre, M.; Petracchini, F. Asbestos treatment technologies. J. Mater. Cycles Waste Manag. 2018. [Google Scholar] [CrossRef]

- Witek, J.; Kusiorowski, R. Neutralization of cement-asbestos waste by melting in an arc-resistance furnace. Waste Manag. 2017, 69, 336–345. [Google Scholar] [CrossRef]

- Priyadharshini, P.; Mohan Ganesh, G.; Santhi, A.S. A review on artificial aggregates. Int. J. Earth Sci. Eng. 2012, 5, 540–546. [Google Scholar]

- Tahmoorian, F.; Samali, B.; Tam, V.W.Y.; Yeaman, J. Evaluation of mechanical properties of recycled material for utilization in asphalt mixtures. App. Sci. 2017, 7, 763. [Google Scholar] [CrossRef]

- PN-EN ISO 12677:2011 Standard. Chemical Analysis of Refractory Products by X-ray Fluorescence (XRF)—Fused Cast-Bead Method; ISO: Geneva, Switzerland, 2011.

- PN-EN 12620:2010 Standard; Aggregates for Concrete; Polish Committee for Standardization: Warsaw, Poland, 2010.

- PN-EN 13043:2004 Standard; Aggregates for Bituminous Mixtures and Surface Treatments for Roads, Airfields and Other Trafficked Areas; Polish Committee for Standardization: Warsaw, Poland, 2010.

- PN-EN 933-1:2012 Standard; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method; Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN 933-3:2012 Standard; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness Index; Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN 933-5:2000 Standard; Tests for Geometrical Properties of Aggregates—Part 5: Determination of the Percentage of Crushed and Broken Surfaces in Coarse Aggregate Particles; Polish Committee for Standardization: Warsaw, Poland, 2000.

- PN-EN 1097-6:2013 Standard; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption; Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-EN 1097-2 2010 Standard; Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation; Polish Committee for Standardization: Warsaw, Poland, 2010.

- PN-EN 1367-1 2007 Standard; Tests for Thermal and Weathering Properties of Aggregates—Part 1: Determination of Resistance to Freezing and Thawing; Polish Committee for Standardization: Warsaw, Poland, 2007.

- Viani, A.; Gualtieri, A.F.; Secco, M.; Peruzzo, L.; Artioli, G.; Cruciani, G. Crystal chemistry of cement-asbestos. Am. Mineral. 2013, 98, 1095–1105. [Google Scholar] [CrossRef]

- Stepkowska, E.T.; Blanes, J.M.; Franco, F.; Real, C.; Perez-Rodriguez, J.L. Phase transformation on heating of an aged cement paste. Thermochim. Acta 2004, 420, 79–87. [Google Scholar] [CrossRef]

- Zulumyan, N.; Mirgorodski, A.; Isahakyan, A.; Beglaryan, H. The mechanism of decomposition of serpentines from peridotites on heating. J. Therm. Anal. Calorim. 2014, 115, 1003–1012. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).