Abstract

Due to the continuous improvement in the usage area and retention quality of plastic films in China, the serious residue film pollution faced by China has become a major threat to crop production. To address the aforementioned issues and in accordance with the actual demand for residue film recovery machines in the Xinjiang region of China, a residual film impurity separation device suitable for the recovery machine of crop residue films has been designed. The overall structure and working principle of the machine were elaborated. Numerical simulations of the through-flow fan device of the residual film recovery machine were carried out using the ANSYS 2022 (CFX) finite element analysis platform, and the corresponding wind speed range of the fan at rotational speeds of 1000–1400 r/min was obtained. Based on the simulation results, the Depth of Machine Insertion into the Ground, Fan Wind Speed, and Forward Speed of the Machinery were selected as experimental factors, while the residual film recovery rate was taken as the evaluation index. A response surface experiment was conducted, and the optimization analysis was performed using Design-Expert software. The final experimental validation results indicated that when the Depth of Machine Insertion into the Ground was 32 mm, the Forward Speed of the Machinery was 5.29 km/h, and the Fan Wind Speed was 13.67 m/s, the machine could effectively overcome the influence of complex field operating conditions. This parameter combination was identified as the optimal operating condition of the machine, providing a valuable reference for the design and optimization of related agricultural machinery.

1. Introduction

The full name of “ground covering film” is “ground covering plastic film”, which is a type of plastic film specifically produced by the industrial sector for agricultural ground covering cultivation [1]. Since the introduction of this technology into China in the last century, due to its advantages such as increasing temperature, retaining moisture, and inhibiting weed growth, it has been widely used in the cultivation of various crops, including cotton and corn, making China’s ground plastic film application area rank first in the world. The ground covering plastic film has also become an indispensable material in agricultural production [2,3,4]. As the country with the largest global area of ground covering cultivation, China has benefited significantly from ground covering plastic film technology, which has contributed greatly to increases in total crop yield. However, due to the lack of unified production standards in China, the thickness of the ground covering plastic film is generally only 0.01 mm [5], which results in poor mechanical strength and makes traditional reel-type recovery methods difficult to apply. This has increased the difficulty of residual film recovery and caused serious environmental pollution [6,7]. In contrast, most ground-covering plastic films used abroad are thicker than 0.015 mm, exhibiting superior mechanical properties. Consequently, foreign residual film recovery machines usually rely on simple reel-winding mechanisms to complete the recovery process. For example, the reel-type residual film recovery machine designed by ROOCA [8] manually winds the plastic film onto a collecting drum, which is driven to rotate by tractor traction to complete the film collection operation. Moreover, the residual film remains relatively intact after recovery. Considering that thicker plastic films are commonly used abroad and that residual film recovery can be achieved using simple reel-based principles, related foreign studies have limited reference value for the development of residual film recovery machinery in China.

Chinese research institutions have developed various types of residual film recovery machines operating in the soil layer, which have alleviated soil pollution caused by residual film to some extent. However, the currently designed machines generally suffer from a low residual film recovery rate and high impurity content in the recovered film, mainly due to the easy entanglement of residual film with soil, cotton stubble, and other impurities. Zhou et al. designed an air-suction-type residual film recovery machine, in which a nail-tooth roller was used to lift and transport the residual film, followed by separation of film and impurities through the scraping action of a discharge scraper combined with the airflow generated by a centrifugal fan [9]. Zhang et al. developed a rotary tillage and soil-throwing residual film recovery machine, in which rotary tillage was employed to break the soil and extract the residual film, while a soil-throwing mechanism, a crushing device, and a vibrating screen were used to separate film and impurities [10]. From the above designs, valuable experience can be gained for the design of residual film recovery machinery. However, in the soil layer environment, residual film is easily intertwined with soil, cotton stubble, and other impurities, which makes simple mechanical separation and airflow-based recovery result in unsatisfactory recovery performance. Based on this, this paper will design aplastic film separation device as the main focus of its research, aiming to increase the residual film recovery rate and working efficiency of the machinery.

Although these studies provide valuable design experience, in the soil-layer environment, residual film is often tightly intertwined with soil and cotton stubble, making simple mechanical separation or airflow-based recovery insufficient and resulting in unsatisfactory recovery performance. Therefore, this study focuses on the design of a film–impurity separation device, aiming to improve both the residual film recovery rate and the operational efficiency of the machinery. In recent years, extensive research has been conducted on pneumatic separation agricultural cleaning devices.

Ildar Badretdinov [11] performed a simulation analysis of the grain cleaning process, investigated the motion behavior of particles in airflow, and determined optimal operating parameters for the cleaning device. SRIVASTAV et al. [12] developed a double-drum coriander cleaning machine and demonstrated that vibration frequency, screen inclination angle, and feeding rate significantly affect cleaning performance, with optimal results achieved when the screen inclination angle ranged from 5° to 7°. Kang et al. [13] designed a cylindrical sieve-type film–impurity separation device, utilizing the combined effects of sieve rotation and airflow; however, the device requires an external fan and is therefore only suitable for stationary operation. Wang et al. [14] developed a wind–sieve-type cleaning device based on dual-layer vibrating screens and fan airflow, but its large size and high energy consumption limit its application in residual film recovery machines.

Based on existing studies on residual film recovery machines operating in the soil layer and pneumatic separation agricultural cleaning devices, this paper proposes a novel recovery concept combining “vibration screening and airflow separation”, and designs a film–impurity separation device suitable for residual film recovery machinery. By integrating a cross-flow fan with a vibration screening mechanism, multivariate fitting analysis was employed to determine the optimal operating parameter combination. Finally, the optimized results were verified through bench tests.

2. Materials and Methods

2.1. Structure and Working Principle

2.1.1. The Mechanical Structure and Principle of the Entire Machine

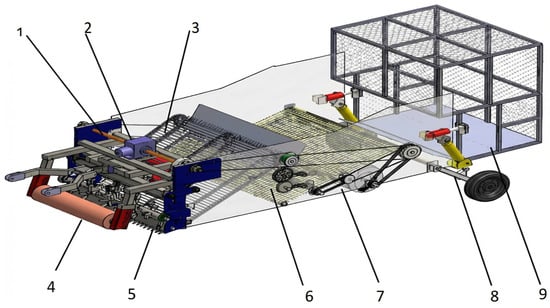

In response to the common problems of low residual film recovery rate and high impurity content in the film among existing residual film recovery machines, this study takes the field mixture of film and impurities as the main research object, aiming to significantly increase the residual film recovery rate and effectively reduce the impurity content in the recovered residual films. Based on this goal, a residual film recovery machine suitable for different terrain conditions has been developed, with the intention of providing new ideas for the optimization and innovative design of existing models. This recovery machine consists of a soil-drawing shovel device, a depth-limiting wheel device, a first-level conveying and screening device, a pair of rollers, a film-impurity separation device, etc. The overall structure is shown in Figure 1.

Figure 1.

Schematic diagram of the structure of the tillage layer residual film recovery machine. 1. Power take-off input shaft; 2. reduction gearbox; 3. Primary conveying and screening device; 4. Depth-limiting wheel device; 5. Soil-digging shovel device; 6. Twin-roller device; 7. Residual film impurity separation device; 8. travel wheel; 9. plastic film collection tank.

During operation, this recovery machine is pulled forward by a tractor. The power is transmitted from the output shaft of the tractor through a reduction gearbox and then passed back through a gear system. The depth of the operation is precisely controlled by the depth-limiting wheels. The working process is as follows: The soil-digging shovel first lifts the soil layer with the film. Then, the rotary tiller breaks the soil clumps initially. The first screening device immediately screens the larger soil-membrane mixture, and the plastic film and debris mixture with a particle size less than 50 mm enters the pair of rollers for secondary crushing and loosening. The processed mixture is finally transported to the residual film impurity separation device. Under the directional airflow generated by the through-flow fan, the efficient separation of the film and debris is achieved—the lightweight debris film is blown into the film collection box for recovery, while the soil and other heavy impurities fall back to the surface. The recovered residual film is finally collected into the plastic film collection tank. The actual model of the machine is shown in Figure 2.

Figure 2.

The actual model of the soil-layer residual film recovery machine.

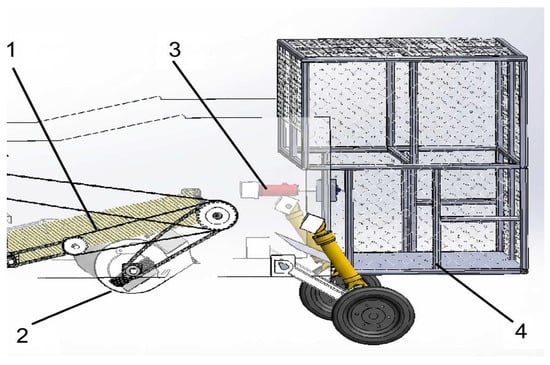

2.1.2. Mechanical Structure and Working Principle of Residual Film Impurity Device

The mechanical structure of the film–impurity separation device is shown in the figure. The device is mainly composed of a two-stage vibrating screening device, a collecting tank, a through-flow fan, and a hydraulic cylinder. As shown in Figure 3.

Figure 3.

Residual film impurity separation device. 1. Secondary vibrating screening device; 2. Through-flow fan; 3. Hydraulic cylinder; 4. Plastic film collection tank.

The plastic film mixture passes through the first conveying and screening device and then enters the Residual Film Impurity Separation Device. Under the action of the vibrating cam disk, it exhibits a throwing motion on the surface of the screen. The residual film is carried by the forced through-flow fan and enters the film collection tank, while the impurities fall to the ground. When the film collection tank is full, the hydraulic device will flip the tank and pour the residual film into the recovery area to complete the film recovery process.

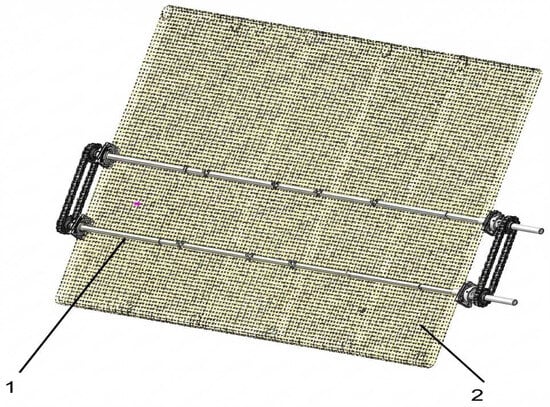

2.2. Design of the Secondary Vibrating Screening Device

The secondary vibrating screening mechanism is mainly composed of the vibrating device, the screen device and the transmission sprocket group, etc. Its main function is to screen and transfer the materials conveyed. As shown in Figure 4. If the size of this device is too large, it may cause the impurities to stay for a longer time, increasing the probability of impurity screening. If the size is too small, it will lead to insufficient screening on the screen surface, thereby reducing the residual film recovery rate [14].

Figure 4.

Secondary Vibrating Screening device. 1. Vibration device; 2. Screen device.

Therefore, the size of the secondary vibrating screening mechanism should match the overall size of the tillage layer residual film recovery machine. The overall size of this mechanism is 1800 × 1600 mm.

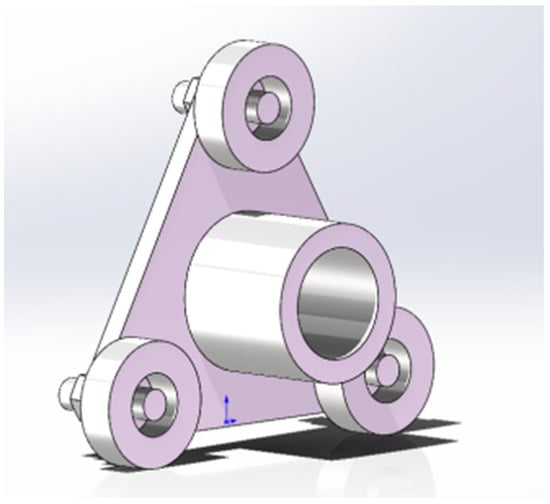

2.2.1. Design of Shaking Device

For the triangular cam disk of the vibration device. The frequency and amplitude of the cam driving the screen surface to vibrate are the key parameters affecting the screening effect of the vibrating screen, and their values are determined by the geometric structure and motion state of the cam. Its structure is shown in Figure 5.

The main components of the shaking device include the shaking shaft, triangular cam dis. As shown in Figure 6, it is driven by a chain transmission system, which rotates the cam and the shaking shaft. After the soil and residual film enter the vibrating screen, due to the shaking of the screen surface, the finer soil particles will pass through the screen and return to the field, while the residual film, due to its larger volume, cannot pass through the screen and is transported to the collection device. The shaking device can also prevent the screen holes from getting clogged, ensuring the continuous and stable operation of the screening process.

Figure 5.

Triangular cam disc.

Figure 6.

Structure of the shaking device.

The vibration frequency f (in Hz) is determined by the camshaft speed:

where n = the camshaft speed (r/min), take 150; f = the vibration frequency (Hz), take 2.5.

The maximum lift h max of the cam is a key geometric parameter that determines the maximum displacement of the follower, which can be expressed as:

where Dmax is the maximum outer diameter of the cam (mm), take 130; Dbass is the diameter of the base circle of the cam (mm), take 80; And hmax is the eccentricity or maximum lift of the cam (mm), take 25;

The shaking device transmits motion through a cam–rocker mechanism. Due to the geometric amplification effect of the rocker mechanism, the relationship between the single-sided vibration amplitude of the screen A and the cam lift hmax can be expressed as:

where k is the displacement amplification coefficient. In this study, k is taken as 1.8. Accordingly, hmax is 25 mm. Consequently, when hmax is 25 mm, the resulting single-sided vibration amplitude of the screen is A = 45 mm.

2.2.2. Design and Calculation of the Screen Device

The design of the screening device is mainly determined based on the characteristics of the screened materials, including the key parameters of the screen, such as the screen hole size and the screen surface inclination, as well as the calculation of the screening capacity. Due to the smaller soil particles after crushing and the larger average area of the residual film, to avoid film leakage, the screen hole size is set at 10 mm. For vibrating devices, a low frequency and large amplitude are often selected, with an amplitude of 20–50 mm and a vibration angle of 20–45°. Considering the similar design experience of the research group and the overall structure of the device, the vibration angle of this device is 25° and the amplitude is 45 mm.

The design of the screening device should focus on its screening capacity (i.e., the mass of materials processed per unit time). The design of the screening conveyor belt should revolve around the screening capacity (the amount of materials effectively processed per unit time), with a particular emphasis on the combined influence of material characteristics, equipment parameters, and operating conditions.

Mass flow rate calculation

where ρ = the soil density (kg/m3), take 1443 kg/m3; d = the sieve wheel diameter (m), take 0.016m; L = the length of the sieve shaft (m), take 2.45 m; n = the rotational speed of the sieve shaft (r/min), take 150 r/min; m = the number of sieve shafts, take 2; η = the sieving coefficient, take 0.4.

According to Formula (4), the calculated Q ≈ 5.12 × 103 kg/h.

2.3. Mechanical Structure and Fluid Simulation of Through-Flow Fans

2.3.1. Calculation of Air Volume and Air Pressure

Through-flow fans are commonly used in large combine harvesters. Due to their large air volume, compact structure, and uniform air distribution, they are often employed in large agricultural machinery. In response to the actual needs of the soil layer residual film recovery machine, this paper selects the through-flow fan as the fan for the film and debris separation process [15].

- Calculation of air volume

The required air volume for plastic film separation can be estimated based on the effective cross-sectional area of the air flow coverage area on the sieve surface and the required separation air velocity. The expression is as follows:

where A = the effective cross-sectional area of the screen surface covered by the air flow (m2); v = the theoretical velocity for achieving film-impurity separation (m/s), take 12 m/s; B = the screen width (m), take 2 m; h = the average thickness of the air flow (m), take 0.08 m; V = the air volume flow rate of the fan (m3/s), the calculated required air volume is 1.92 m3/s.

- 2.

- Calculation of wind pressure

Under the open-air blowing condition, the total pressure of the through-flow fan is mainly used to overcome the dynamic pressure required for the acceleration of air to form a high-speed airflow, as well as the local resistance losses caused by the internal flow channels and the deflection structures at the outlet of the fan. The total pressure required by the fan can be estimated by the following formula:

where Pₜ = the total pressure of the fan (Pa); Pi = the air engine pressure (Pa); ρ = the air density, taken as 1.20 kg/m; v = the airflow velocity at the fan outlet (m/s), taken as 12 m/s; ΔP = the total system resistance loss (Pa), including the resistance of the volute, guide vanes, and outlet structures.

When the outlet air velocity is 12 m/s, the dynamic pressure is 86.4 Pa. Considering that the internal resistance of the through-flow fan is relatively small, but there are still certain localized losses in the actual system, a certain safety factor based on the dynamic pressure is introduced to ensure that the air velocity can stably meet the design requirements under manufacturing and assembly conditions, as well as fluctuations in operating conditions. After comprehensive consideration, it is more reasonable to set the total pressure required for the fan design at 200–250 Pa [14].

2.3.2. Determination of Structural Parameters of Through-Flow Fans

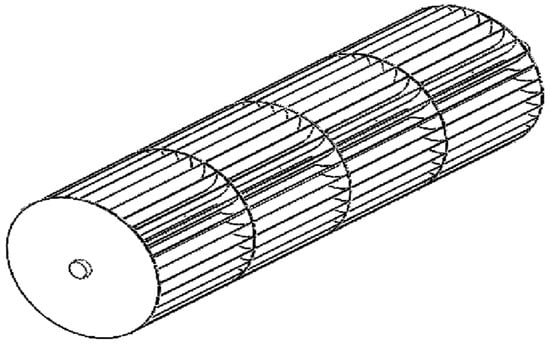

The working air flow used for plastic film separation cooperates with the secondary vibrating screening device during operation. Therefore, the width of the outlet should be slightly larger than the overall width of the secondary vibrating screening device, so as to ensure that the working air flow can effectively cover all the mixed plastic film debris. Therefore, the design of the outlet size of the through-flow fan is 1650 × 340 mm. The diameter D2 of the impeller and the rotational speed of the impeller are the key factors for analyzing the wind field intensity in the chart [14]. In this paper, the outer diameter of the impeller is 440 mm. The total width of the fan is 1200 mm, the outer diameter of the impeller is 440 mm, the inner diameter of the impeller is 312.4 mm, the inclination angle of the impeller is 25°, and the number of blades is 32. The model diagram of the impeller is shown in Figure 7.

Figure 7.

Impeller Model.

2.3.3. Numerical Simulation of the Flow Field of Through-Flow Fans

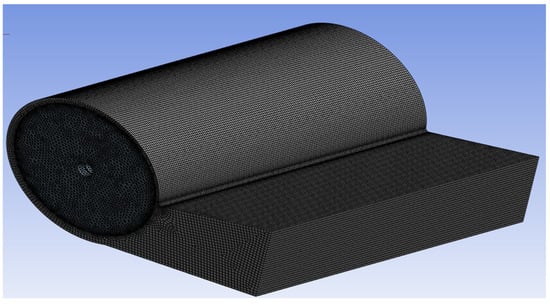

- mesh generation

This study generates the computational mesh using the Mesh module in Workbench. Prior to CFD simulation, mesh generation is a critical step, as a high-quality mesh directly affects the convergence behavior and computational accuracy of the fan simulation. The Mesh module provides multiple meshing approaches, such as automatic meshing, hexahedral meshes, and tetrahedral meshes. For the through-flow fan configuration, automatic meshing is adopted, and local refinement is applied based on the key geometric feature scales of the impeller and the distributions of velocity and pressure gradients: a mesh size of approximately 5 mm is used on the blade surfaces and in the adjacent inner flow field region to better capture near-wall flow and boundary-layer characteristics; a global mesh size of approximately 10 mm is applied in the outer flow field region to balance computational accuracy and cost. Meanwhile, the correlation between the inner and outer flow fields is set to 1, and the final mesh is shown in Figure 8.

Figure 8.

Mesh Generation.

After calculation, the mesh of the through-flow fan consists of 689,149 nodes and 2,004,838 elements. The mesh quality has a significant impact on the analysis process and results. Skewness is a commonly used tool for mesh quality inspection. The closer the value is to 0, the better the quality is, and the opposite is worse. The average skewness of this study is 0.2243, and the mesh quality is good with high calculation accuracy.

- 2.

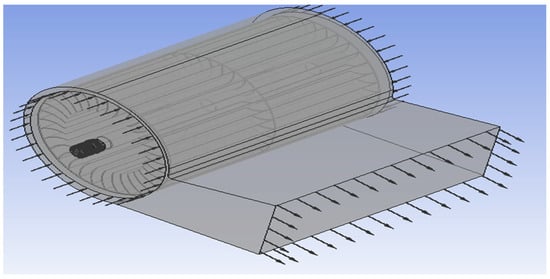

- Setting of the computational domain and boundary conditions

Import the stored grid file into the ANSYS CFX solver to set the calculation domain and boundary conditions. First, create the inlet, outlet and blade boundaries in the fluid domain, and name them “pressure_inlet”, “pressure_outlet” and “blades”, respectively. The calculation domain includes the rotating impeller area and the stationary volute area, which are connected by a “Transient Rotor-Stator” interface to accurately simulate the interaction between the rotating parts and the stationary parts. Inlet boundary (pressure_inlet): Set as a pressure inlet with total pressure of 0 Pa. Outlet boundary (pressure_outlet): Set as a pressure outlet with static pressure of 0 Pa. Wall boundary (blades): Set the blade wall as a no-slip wall. The flow in the near-wall region is processed using the standard wall function method, and the solution control adopts the high-order upwind difference scheme. The preset boundary conditions are shown in Figure 9. The selection of the turbulence model in the computational domain has a significant influence on the CFD simulation results. ANSYS CFX provides various turbulence models, such as the k–ε model and the k–ω model. Considering that the internal flow investigated in this study is dominated by fully developed turbulence, and that high requirements are imposed on computational stability and engineering applicability, the standard k–ε turbulence model was ultimately adopted. This model has been widely used in engineering flow simulations and exhibits good numerical stability and convergence characteristics, enabling accurate prediction of the overall flow behavior inside the fan [16].

Figure 9.

Boundary Settings.

- 3.

- analysis of simulation result

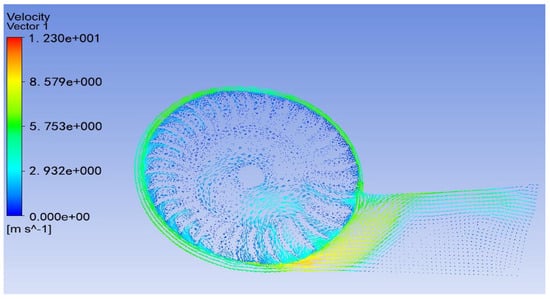

By simulating the working condition of 1300 r/min, the wind speed generated is shown in Figure 10. The wind speed at the outlet of this through-flow fan reaches 12 m/s, and the flow field distribution is reasonable, with uniform wind speed distribution. This result fully proves the effectiveness of the fan design. The sufficient air volume and wind speed provided by the fan are the decisive factors for ensuring the success of plastic film separation.

Figure 10.

Velocity vector distribution of the through-flow fan at 1300 r/min.

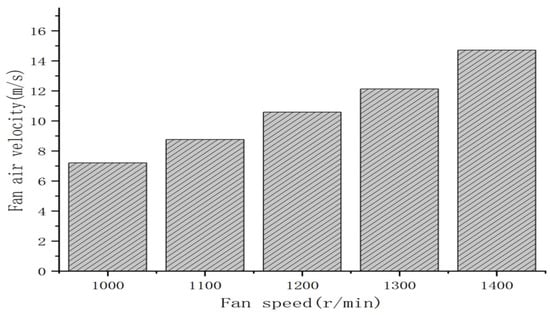

By simulating operating conditions with rotational speeds ranging from 1000 to 1400 r/min, the resulting wind speed distribution is shown in Figure 11. The wind speed increases with the increase in rotational speed. When the fan rotational speed is 1000 r/min, the wind speed is about 9 m/s, and when it increases to 1400 r/min, the generated wind speed reaches about 15 m/s. Based on the above simulation results, considering actual operating conditions and the feasibility of experimental parameter selection, this paper determines that the range of wind speed factors in the orthogonal experiment is 9–15 m/s.

Figure 11.

Wind speed of the fan at different rotational speeds.

3. Results

3.1. Test Conditions and Test Equipment

The field experiment was conducted in Weili County, Korla City, Xinjiang (86.19° N, 41.45° E). The experimental area was a cotton-growing region with an average continuous cultivation period of 20 years. The soil type was sandy soil, with a soil moisture content of 16.1%. The planting method was mechanical film mulching, as shown in the Figure 12. Experimental equipment: wind speed measuring instrument, stopwatch (measurement accuracy: 0.01 s), tape measure (measurement accuracy: 1 mm), electronic scale (measurement accuracy: 10 g), spade, etc. The test site is shown in Figure 12.

Figure 12.

Field testing of the residual film recovery machine for the topsoil layer. (The Chinese characters in the picture are the name of the manufacturer).

3.2. Test Method

The prototype conducted 17 test trips in the experimental area. For each trip, the five-point sampling method was adopted. Five random points were selected in the experimental area, with each sampling area being 5 m in length and 2 m in width. Before the operation began, sampling points were set in adjacent plots of the test area to collect the residual plastic film from the plough layer, which was washed and its mass was recorded as M. After each operation, the residual plastic film, cotton stalks and soil in the collection bag device were manually collected and their mass was recorded as M0. The recovery rate of the plastic film was calculated using the following formula:

where N = the residual film recovery rate (%); M = the mass of the recovered residual film (g); M0 = the mass of the unrecovered residual film (g).

3.3. Determination of Experimental Factors

Field experiments can be conducted to test the working performance of the machinery. According to GB/T 25412-2010 [17] and related research papers [18,19,20,21], the factors to be tested include the forward speed of the machinery, the wind speed of the fan, and the depth of soil penetration. A three-factor three-level response surface experiment was carried out. To evaluate the recovery effect, the residual film recovery rate was selected as the criterion. The factor and level coding are shown in Table 1, and the test results are presented in Table 2.

Table 1.

Experimental factors.

Table 2.

Experimental design and results.

Based on the data listed in Table 2, a regression equation model was constructed to relate the forward speed of the machinery, the depth of the machinery insertion into the ground, the fan wind speed, and the recovery rate of the plastic film. The variance analysis of the model was conducted, and the results are shown in Table 3.

Table 3.

Analysis of variance of the regression equation.

The regression equation for the residual film recovery rate is as follows:

In the regression equation, Y1 represents the residual film recovery rate (%); A denotes the Depth of Machine Insertion into the Ground, B represents the Fan Wind Speed, and C refers to the Forward Speed of the Machinery.

According to the analysis of variance (ANOVA) results presented in Table 3, the regression model is extremely significant, indicating that the established model can effectively explain the variation in the residual film recovery rate. The Depth of Machine Insertion into the Ground (A), Fan Wind Speed (B), Forward Speed of the Machinery (C), as well as their corresponding quadratic terms (A2, B2, and C2), all exhibit extremely significant effects on the residual film recovery rate.

In addition, the interaction between Fan Wind Speed and the Forward Speed of the Machinery (BC) and the interaction between Depth of Machine Insertion into the Ground and Fan Wind Speed (AB) are also significant, further demonstrating that the interactions among these factors play an important role in influencing the residual film recovery performance.

Based on the magnitude of the F-values obtained from the regression model, it can be concluded that the Depth of Machine Insertion into the Ground (A) has the greatest influence on the residual film recovery rate, followed by the Fan Wind Speed (B), while the Forward Speed of the Machinery (C) has a relatively smaller effect.

3.4. Response Surface Analysis

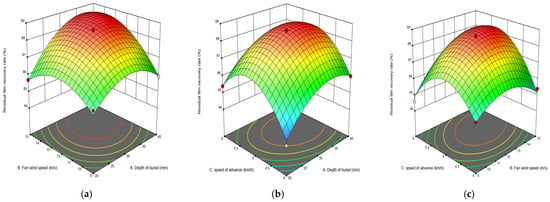

The experimental data were subjected to analysis of variance (ANOVA) using Design-Expert 13.0 software (Stat-Ease Inc., Minneapolis, MN, USA, https://www.statease.com/software/design-expert/), (Visit in 9 December 2025) [22] and the response surface plots showing the effects of the interactions among the three influencing factors on the residual film recovery rate were established, as illustrated in the Figure 13.

Figure 13.

(a) Effects of Depth of Machine Insertion into the Ground and Fan Wind Speed on the residual film recovery rate; (b) Effects of Depth of Machine Insertion into the Ground and the Forward Speed of the Machinery on the residual film recovery rate; (c) Effects of Fan Wind Speed and the Forward Speed of the Machinery on the residual film recovery rate.

As shown in Figure 13a, when the Forward Speed of the Machinery is 5 km/h, the residual film recovery rate first increases and then decreases with increasing Fan Wind Speed and Depth of Machine Insertion into the Ground. As illustrated in Figure 13b, when the Fan Wind Speed is 12 m/s, the residual film recovery rate also exhibits a trend of increasing first and then decreasing with increasing Forward Speed of the Machinery and Depth of Machine Insertion into the Ground. As shown in Figure 13c, when the Depth of Machine Insertion into the Ground is 30 mm, the residual film recovery rate shows a similar trend with increasing Fan Wind Speed and Forward Speed of the Machinery.

The above phenomena can be mainly attributed to the following reasons. Within a certain range, an appropriate increase in the Depth of Machine Insertion into the Ground promotes sufficient contact between the working components and the residual film in the soil, enhancing the disturbance and separation of the residual film and thereby improving the residual film recovery rate. However, when the insertion depth becomes excessive, soil compaction increases, which not only strengthens the bonding between the residual film and the soil but also weakens the lifting and conveying effects of the airflow generated by the fan, resulting in a decrease in the residual film recovery performance.

With a moderate increase in the Forward Speed of the Machinery, the operating area covered by the machine per unit time increases, leading to improved operational efficiency and a corresponding increase in the residual film recovery rate. Nevertheless, when the forward speed is too high, the interaction time between the working components and the soil is reduced, and part of the residual film cannot be sufficiently separated and collected, which easily causes missed recovery and ultimately reduces the residual film recovery rate.

Meanwhile, the Fan Wind Speed plays a crucial role in the lifting and separation of residual film. Within an appropriate range, increasing the fan wind speed enhances the airflow intensity, which facilitates the separation of residual film from soil, cotton stalks, and other impurities, thereby improving the film collection efficiency. However, excessively high fan wind speeds may cause secondary scattering of the residual film, deviation from the collection path, or even film damage, consequently leading to a decline in the residual film recovery rate.

3.5. Parameter Optimization and Validation

To determine the optimal operating parameters of the machinery, the Numerical optimization module in Design-Expert software was employed to optimize the experimental results, and a nonlinear parameter model was established.

The analysis indicated that when the Forward Speed of the Machinery was 5.29 km/h, the Fan Wind Speed was 13.67 m/s, and the Depth of Machine Insertion into the Ground was 32 mm, the residual film recovery rate reached 88.8%.

To verify the prediction accuracy of the model established by the software, five field validation experiments were conducted under the optimal parameter combination. The measured residual film recovery rates were 86.1%, 86.4%, 85.9%, 86.6%, and 86.0%, with an average measured value of 86.2%. The relative error between the experimental results and the predicted value was 2.93%, which is relatively small, indicating that the regression model is reliable.

4. Discussion

(1) The mechanical structure and working principle of the residual film recovery machine in the plough layer were introduced. In response to the problems of low residual film recovery rate and high impurity content in the current residual film recovery machines, a Residual Film Impurity Separation Device consisting of a secondary vibrating screening device, a through-flow fan, and a film collection box was designed. The vibration frequency of the cam disc was 2.5 Hz, and the vibration amplitude of the screen was 25 mm. The resulting single-sided vibration amplitude of the screen is A was 45 mm. Based on these parameters, the calculated mass flow rate of the screening device was 5.12 × 103 kg/h. The through-flow fan had an air volume of 1.92 m3/s

(2) Numerical simulations of the through-flow fan were conducted based on a high-quality computational mesh and appropriate boundary conditions, ensuring the reliability of the CFD results [13,14,16]. The simulation results demonstrated that the fan provided a stable and uniform airflow, with the outlet wind speed increasing from approximately 9 m/s to 15 m/s as the rotational speed rose from 1000 r/min to 1400 r/min, confirming the effectiveness of the fan design. Based on the numerical analysis and considering practical operating conditions, 9–15 m/s was determined as a reasonable range for the fan wind speed in subsequent experiments. These results indicate that the proposed CFD-based approach is effective for guiding parameter selection and optimizing the operating performance of residual film recovery machinery.

(3) Through response surface experiments and optimization analysis using Design-Expert software, the effects of the Depth of Machine Insertion into the Ground, Fan Wind Speed, and Forward Speed of the Machinery on the residual film recovery rate were clarified, and the optimal operating parameter combination was determined. The results indicate that when the Depth of Machine Insertion into the Ground is 32 mm, the Forward Speed of the Machinery is 5.29 km/h, and the Fan Wind Speed is 13.67 m/s, the machine achieves the best recovery performance and can effectively adapt to complex field operating conditions. These findings provide a valuable reference for the optimization and design of related agricultural machinery [19,23].

(4) Currently, the models of residual film recovery machines in China are still at the stage of simple mechanical picking. This machine proposes a method of “vibration screening + air separation”, which has good machine performance and a high residual film recovery rate, and has good economic benefits. However, the current machines have a relatively low level of automation. In the future, visual recognition and electrical control development routes can be added to further eliminate the blindness and randomness of mechanical picking and completely solve the problem of residual film recovery [24,25].

Author Contributions

Methodology, Z.X.; Data curation, A.S. and Z.Z.; Supervision, Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable .

Informed Consent Statement

Not applicable .

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yan, C.; Mei, X.; He, W.; Zheng, S. Present situation of residue pollution of mulching plastic filmand controlling measures. Trans. Chin. Soc. Agric. Eng. 2006, 22, 269–272. [Google Scholar]

- Zhang, F.; Wu, P.; Zhao, X.; Zhang, E.; Cheng, X. Effects of conservation tillage on soil water regimes in rainfed area. Acta Ecol. Sin. 2005, 6, 2326–2332. [Google Scholar]

- Wang, J.; Li, F.; Song, Q.; Li, S. Effects of plastic film mulching on soil temperature and moisture and on yield formation of spring wheat. Chin. J. Appl. Ecol. 2003, 14, 205–210. [Google Scholar] [CrossRef]

- Wang, S.; Deng, G. A Study on the Mechanism of Soil Temperature in Creasing under Plastic Mulch. Chin. Agric. Sci. 1991, 24, 74–78. [Google Scholar]

- Liu, L.; Zou, G.; Zhuo, Q.; Li, S.; Bao, Z.; Jin, T.; Liu, T.; Du, L. It is still too early to promote biodegradable mulch film on a large scale: A bibliometric analysis. Environ. Technol. Innov. 2022, 27. [Google Scholar] [CrossRef]

- Hu, L.; Hu, Z.; Hu, J. Discussion on the Development of Sweet Potato (Ipomoea batatas Lam.) Production Mechanization in Hills Poor Land of China. Chin. Agric. Mech. 2012, 5, 41–44. [Google Scholar]

- Wang, X.; Chen, X.; Sun, D.; Kang, J.; Peng, Q.; Zhang, C. Research progress and prospects of technology and equipment for controlling residual film pollution in farmland. Agric. Equip. Veh. Eng. 2025, 63, 1–9. [Google Scholar]

- Rocca, A.R.R. Plastic Mulch Retriever. 2012–11–06 2012. IL20100206428, 16 June 2010. [Google Scholar]

- Zhou, L.; Shi, A.; Shi, Q.; Ding, J.; Lu, J.; Li, D. Parameter Optimization and Experiment of the Combined Residual Film Reclaimer With Upper Conveyor Chain. Agric. Mech. Res. Mech. Res. 2023, 45, 164–170. [Google Scholar] [CrossRef]

- Shen, S.; Zhang, J.; Wang, Y.; Dong, W.; Li, J.; Zhang, X.; Li, J. Design and Experiment of the Elevating Device for the Rotating Dispersal-Type Soil Residue Recovery Machine. J. Agric. Mach. Sci. 2025, 56, 461–472. [Google Scholar]

- Badretdinov, I.; Bogomolov, A. Mathematical modeling and research of the grain combine harvester cleaning system. Comput. Electron. Agric. 2019, 165, 104966. [Google Scholar] [CrossRef]

- Srivastav, S.S.S. Mathematical Model for Design and Development of Double Drum Rotary Screen Cleaner-cum-grader for Cumin Seed. Ama Agric. Mech. Asia Afr. Lat. Am. 2013, 44, 70–74. [Google Scholar]

- Xie, C.; Kang, J.; Peng, Q.; Lin, X.; Hou, J. Numerical Simulation and Parameter Optimization of Drum Screen-Typeplastic film Impurity Separation Device. Chin. J. Agric. Mach. Chem. 2024, 45, 1–11. [Google Scholar] [CrossRef]

- Wang, F.; Li, B.; Zhu, R.; Wang, S.; Liu, Y.; Gao, X.; Yang, X. Design and test of the wind-sieve type cleaning equipment for cumin threshingmachine. Trans. Chin. Soc. Agric. Eng. 2024, 40, 39–50. [Google Scholar]

- Li, J.; Guo, L.; Ma, Y.; Zhang, T. Numerical Simulation of the Flow Field of the Through-flow Fan of the Combine Harvester. Jiangsu Agric. Sci. 2015, 43, 439–441. [Google Scholar] [CrossRef]

- Liu, X. Simulation Analysis and Optimization of the Cleaning Device of the Wheat Harvesting Machine Based on CFD-DEM Coupling. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2017. [Google Scholar]

- GB/T 25412-2021; Residual Film Recovery Machine. Standards Press of China: Beijing, China, 2021.

- Liu, J.; Yang, Z. Optimization Design and Industrial Promotion Research of Drum-type Residual Film Recovery Machine. Agric. Dev. Equip. 2025, 7, 116–118. [Google Scholar]

- Li, K. Theoretical Analysis and Experimental Research onthe Stripping and Impurity Removal Device for Spring-ToothResidual Plastic Film Collector. Master’s Thesis, Shandong University of Technology, Tai’an, China, 2023. [Google Scholar]

- Ren, W.; Wu, Z.; Han; Xang, K.; Lan, W.; Ma, S. Design and Parameter Optimization of the Picking Drum for the Toothed-type Plastic Film recovery Machine. J. N. AF Univ. 2025, 35, 1–12. [Google Scholar] [CrossRef]

- Yun, L. Research and Experiment on a Type of Trenching and Bundling Residual Film Harvester. Agric. Mach. Mark. 2025, 5, 95–97. [Google Scholar]

- Stat-Ease Inc. Design-Expert, Version 13; Stat-Ease Inc.: Minneapolis, MN, USA, 2021. Available online: https://www.statease.com (accessed on 25 May 2024).

- Huang, J.; Wang, D.; Shang, S.; He, X.; Guo, P.; Zuo, B.; Zhao, Z.; Cheng, D. Design and test of air-blown separation type film recovery machine for ridge farming. Agric. Equip. Veh. Eng. 2023, 61, 6–9. [Google Scholar]

- Yao, J.; Zhang, X.; Shi, Z.; Liu, X.; Kang, M.; Guo, L. Research status and development trend of tillage layer residual film recovery machine. J. Chin. Agric. Mech. 2024, 45, 290–295. [Google Scholar] [CrossRef]

- Wu, Z.; Ren, W.; Han, X.; Wang, K.; Lan, W.; Ma, S. Research Status and Suggestions on Residual Film recovery Machinery. Promot. Agric. Mach. Technol. 2025, 18, 49–55. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.