Abstract

Corrosion difficulties have emerged as a key obstacle to the safe functioning of offshore wind turbine towers, prompting academics to focus on rust removal maintenance studies. Existing research focuses mostly on automated rust removal systems, which have limitations such as limited flexibility and poor performance. In contrast, intelligent laser rust removal has emerged as a revolutionary solution due to its great efficiency and environmental friendliness. As a result, this paper examines and summarizes the strengths and limits of laser rust removal research before presenting a new offshore wind power operation and maintenance solution—the drone-based intelligent laser rust removal system. This technology uses solar and wave energy coupling to power the drone, resulting in a completely green operation that includes power supply, rust removal, and corrosion avoidance. The results show that this system has major advantages, such as high efficiency, environmental friendliness, safety, and advanced intelligence, making it an efficient solution for intelligent operation and maintenance in the offshore wind power industry.

1. Introduction

The global energy structure is rapidly shifting toward greener alternatives. Wind power, as a critical component of new energy sources, drives the annual increase in offshore wind power projects. The hostile marine environment, which is characterized by high salt, humidity, and extreme UV radiation, presents substantial obstacles for the safe operation of offshore wind generation projects. The National Energy Administration’s 2023 Offshore Wind Farm Maintenance Regulations emphasize the importance of regular inspections of foundation structures and strict adherence to offshore operation safety standards to safeguard crew safety. As a consequence, safety inspections and operational maintenance of offshore wind generating plants have become a top research priority.

Current research, both domestically and internationally, centers on intelligent safety rust removal technologies. With advances in laser cleaning technology and artificial intelligence, intelligent laser rust removal has emerged as a revolutionary solution for ensuring the safe operation and maintenance of offshore wind turbines. By analyzing the fundamental mechanisms of laser rust removal, this study elucidates the reaction principles underlying the process. It subsequently reviews the advantages and limitations of intelligent laser rust removal technologies worldwide, encompassing domestic design approaches such as handheld laser rust removal equipment, wall-climbing robots, and three-dimensional cable-guided systems, alongside international control methodologies including image-based vision systems and adaptive control techniques. The research proposes an intelligent laser rust removal solution based on unmanned aerial vehicle (UAV) platforms, aiming to pioneer future research directions within the field of offshore wind turbine rust removal maintenance.

2. Laser Rust Removal Mechanism

The laser rust removal technique is a revolutionary, eco-friendly rust removal process. Its principle relies mostly on lasers’ high energy and short pulse characteristics. When a laser beam meets a rusty surface, the rust layer’s loose, porous structure absorbs laser energy at an extremely rapid rate. This allows the rusty surface to absorb a large amount of energy in an instant, rapidly heating it to temperatures over its melting point. At this phase, the rusted material is quickly removed using an ablation mechanism, resulting in sparks and yellow smoke on the surface. This method not only effectively eliminates rust but also prevents direct harm to the metal substrate.

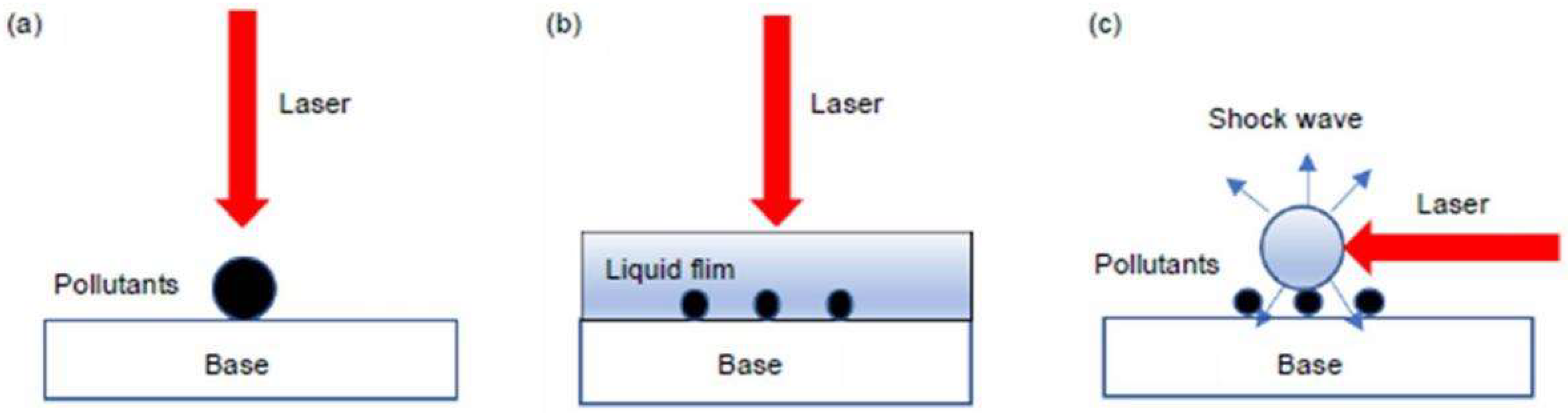

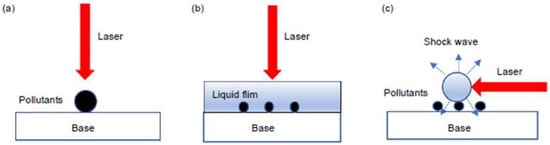

Laser cleaning techniques are divided into three categories: dry laser cleaning, wet laser cleaning, and plasma shock wave technologies, as shown in Figure 1. Dry laser cleaning is the process of directly irradiating impurities on the substrate surface with pulsed laser light, resulting in thermal expansion due to increased temperatures. This causes vibration in either the contaminants or the substrate, allowing them to overcome surface adhesion forces and separate from the substrate. Wet laser cleaning includes applying a liquid film on the surface before cleaning it. Laser irradiation rapidly warms and vaporizes the film, causing an explosive shockwave to dislodge and drive impurities away from the surface. The plasma shockwave approach includes projecting horizontal laser energy over the substrate. When energy hits the breakdown threshold, it ionizes the surrounding gas, producing a nearly spherical plasma shockwave. As the shockwave travels toward the substrate, its impact force eliminates impurities.

Figure 1.

(a) Dry laser cleaning. (b) Wet laser cleaning. (c) Laser cleaning of plasma shock wave [1].

3. Research on Automation of Laser Rust Removal in China

Laser rust removal equipment provides advantages such as high precision and ease of integration with control systems, which is driving current research into laser rust removal automation. Automation is essentially defined as achieving automated activities in complicated working environments using modern control technologies, sensor technologies, and artificial intelligence algorithms.

In recent years, domestic scholars have made great advances and produced significant outcomes in laser rust removal. Wang Mannan et al. [2] independently developed a handheld structural laser cleaning equipment. They completed rust removal research on metal surfaces by using Ezcad software to control factors, including laser scanning speed and pulse frequency. Their findings showed that combining low- and high-speed scanning modes considerably improves rust removal efficiency. Additionally, the customizable laser parameters allow for excellent rust removal while minimizing damage to the steel substrate. On the limited platforms of offshore wind farms, their flexibility and adaptability are key advantages.

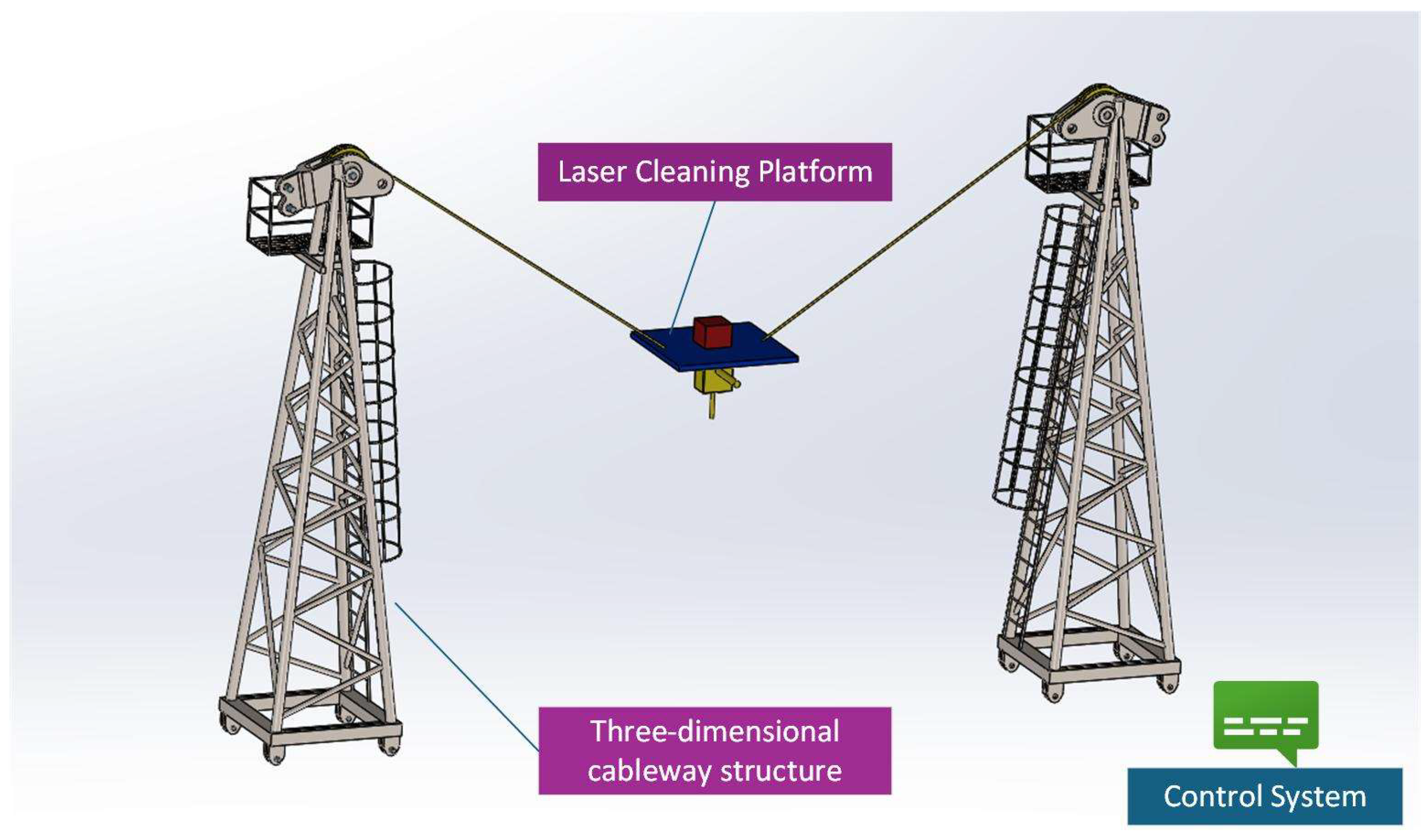

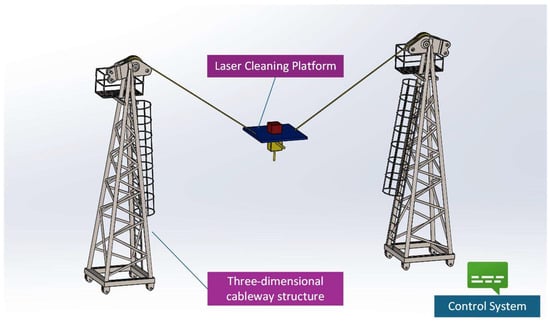

Shao Zhuang et al. [3] developed a three-dimensional cable-guided laser rust removal system using theoretical analysis, finite element simulation, and experimental verification, as illustrated in Figure 2. This three-dimensional cable-guided laser rust removal device is built around a lightweight design idea. It principally uses a support system similar to the “Flying Cat Cable Camera System,” with four support points and four cables forming a three-dimensional movement space. Fully automated operation removes direct manual handling, resulting in greatly improved safety performance. The modular, detachable architecture is also better suited to tough marine situations.

Figure 2.

Three-Dimensional Cableway Laser Cleaning Equipment diagram.

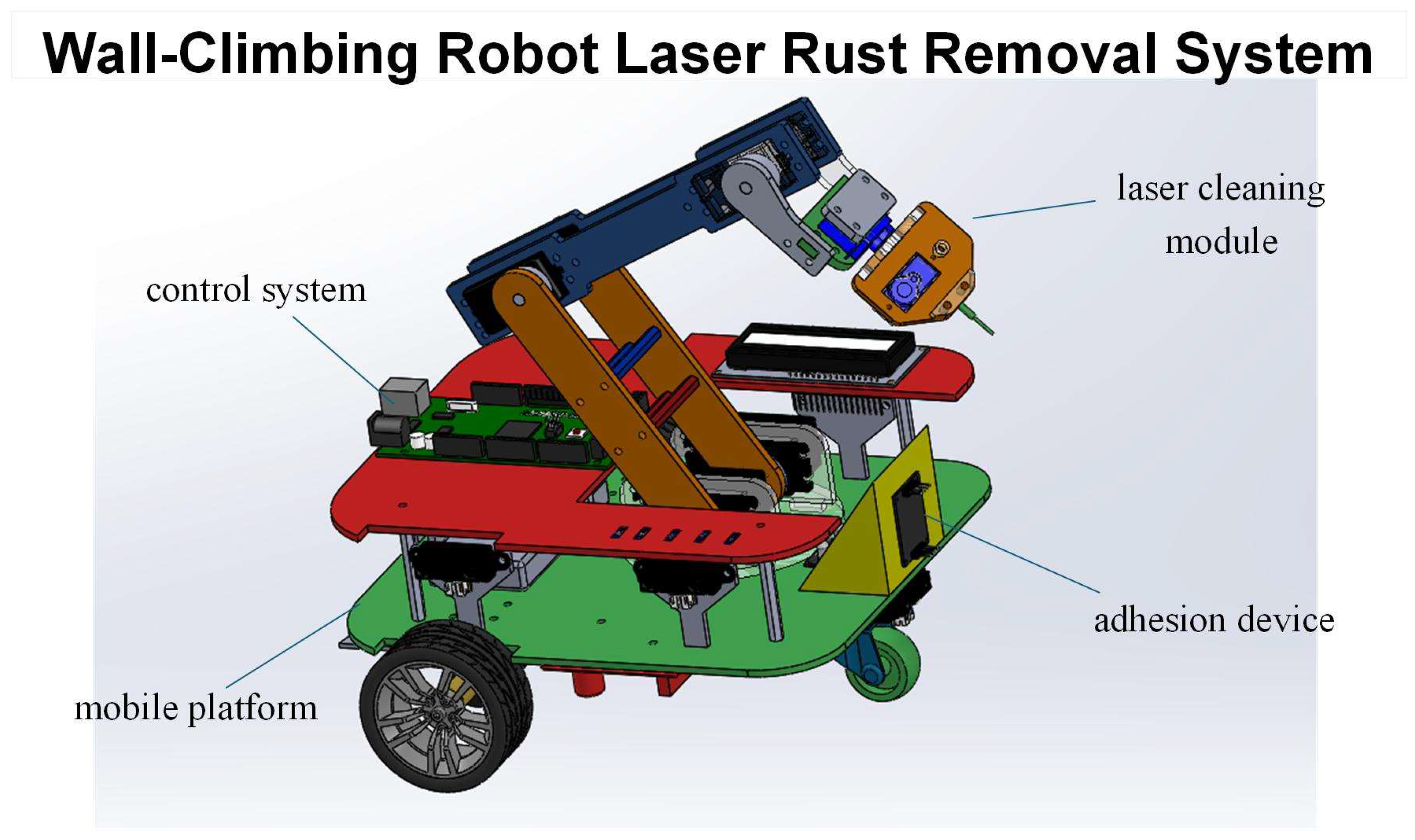

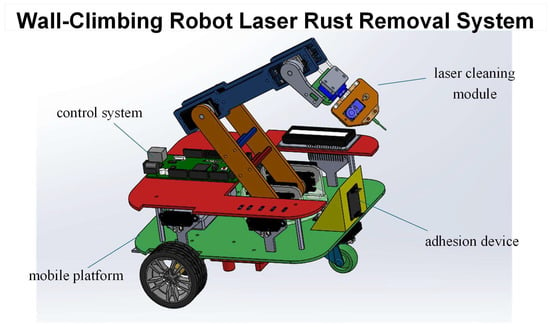

Jiang Mingming et al. [4] developed a pipeline robot with a rust-removal robotic arm. This gadget uses a three-degree-of-freedom robotic arm construction combined with a visual inspection system to precisely remove localized rust corrosion on the pipeline inner walls. Figure 3 depicts the wall-climbing robot’s essential components: a mobile platform, an adhesion device, a laser cleaning module, and a control system. The integrated intelligent sensing and identification modules not only provide improved safety performance but also highly standardized rust removal capabilities, making this an ecologically beneficial and highly efficient solution.

Figure 3.

Wall-Climbing Robot Laser Rust Removal System.

Li Xiang et al. [5] successfully organically integrated a six-axis industrial robotic arm, a visual recognition inspection system, and a laser cleaning module. The robot removes rust in cooperation with the robotic arm and laser by obtaining three-dimensional information from rusted areas and transmitting it back to the robot via the machine vision system. The primary benefit of self-positioning intelligent cleaning of the workpiece surface coating was obtained through a dual-station design. This six-axis robotic arm system has a repeatable positioning accuracy of ±0.05 mm. The system automatically detects rusted regions using camera calibration and image processing algorithms, then uses the D-H model and quintic polynomial interpolation to create trajectories, resulting in ideal cleaning paths with positional errors of less than 0.1 mm.

To summarize, intelligent rust removal technology has produced successes in a variety of industries, but it confronts significant obstacles in the offshore wind power sector. Domestic study suggests that portable laser rust removal solutions require a high labor effort and restricted power; three-dimensional cable systems lack flexibility and have low laser positioning accuracy; and wall-climbing robots have insufficient load capacity and agility. Meanwhile, robotic arm systems offer safety issues, incur significant system costs, and require enhanced rust detection capabilities. International research focuses on dynamic monitoring, process parameter optimization, and automated control, but it faces challenges in sustaining huge offshore equipment. Fundamental research on laser rust removal in high-salinity, high-humidity environments, as well as adaptive cleaning systems, is still in its early stages. As a result, this research presents a revolutionary approach to intelligent laser rust removal based on UAVs.

4. Research on Intelligent Rust Removal Methods Abroad

International research on intelligent laser rust removal technology is principally focused on three areas: dynamic monitoring, process parameter optimization, and automated intelligent control.

Keng Huat Koh et al. [6] used a remotely controlled robotic system with spark-free polishing equipment to examine online rust removal and protection approaches for the exterior walls of gas pipelines in high-rise structures. The device used a laser rangefinder for pipeline location, force-feedback grippers to stabilize the robot’s posture, and radial brush discs (25.4 mm diameter) for surface polishing. Their investigations showed that with a 15 V DC power source and a brush-to-pipe contact depth of 2 mm, the motor current stabilized at 1–2 A, resulting in a mechanical power output of 15–30 W. When the (Pulse Width Modulation) PWM driving signal duty cycle was set between 7.5% and 8.5%, rust layers could be successfully eliminated without generating sparks.

Tian et al. [7] used an automated rust detection method based on sequential camera images, incorporating Rapid Qualified Image Selection (RQIS) technology and fuzzy force control strategies, to investigate a robust rust recognition and visual servo control system suitable for practical rust removal processes. The approach was successful in selecting qualified images more than 90% of the time. Under 27 parameter combinations, its efficiency outperformed existing non-visual servo control systems, as demonstrated by the proposed performance metric (defined as the ratio of horizontal movement speed to cumulative needed pressure). For example, with the parameter combination “a0v10,” the metric increased from 0.027 to 1.000.

Yongding Tian, Chao Chen, Kwesi Sagoe-Crentsil, Jian Zhang, and Wenhui Duan [8] conducted a literature study to examine the use and future trends of intelligent robotic systems in bridge structural health monitoring (SHM). Their research categorizes existing robotic systems into three classes: the first includes rigid robotic systems for detecting surface/subsurface defects, including mobile robots, wall-climbing robots, cable-climbing robots, and flying drones; the second involves mobile robots, climbing robots, and flying drones for dynamic response measurements (e.g., acceleration, displacement), modal identification, and cable tension estimation; and the third includes multimodal rigid robots. The study also shows that combining various non-destructive testing (NDE) tools with multimodal robotic systems—such as flying and perching drones, land–aquatic hybrid robots, air–aquatic hybrid robots, and flying–walking hybrid robots—has a high potential for performing multiple inspection tasks.

Fang et al. [9] removed a 20 μm thick Fe3O4 rust layer from AH32 marine steel plates by quasi-continuous laser irradiation (wavelength 1070 nm, power 250 W). At laser energy densities of 0.5–5 J/mm2, the plate surface achieves SA1/2 cleanliness grade with adjustable surface roughness between 30 μm and 7 μm. Additionally, corrosion resistance meets traditional sandblasting criteria.

However, current international research still has severe limitations. While image-based rust detection and servo control have been achieved, model flexibility is still lacking. Remote operation of robotic systems is primarily reliant on manual intervention, with limited autonomy. Validation in process research is limited to single situations (ships, pipelines), and there are no robust cross-scenario investigations.

In summary, current domestic research on laser cleaning automation is primarily concerned with laser parameter optimization, mechanical motion control, and cleaning path planning. While basic studies in visual recognition exist, there is limited research on the adaptability of AI visual recognition models and their robustness in complicated contexts, which hinders the growth of AI-powered laser cleaning technology.

This approach draws on the expertise of domestic and international experts to address the constraints of present technology in offshore wind tower operation and maintenance. It increases the use of intelligent laser rust removal technologies in marine engineering while also providing fresh insights into the long-term growth of offshore wind turbines.

5. Technical Principles and Architecture of the Intelligent Laser Rust Removal System for Drones

5.1. Drone Work Process

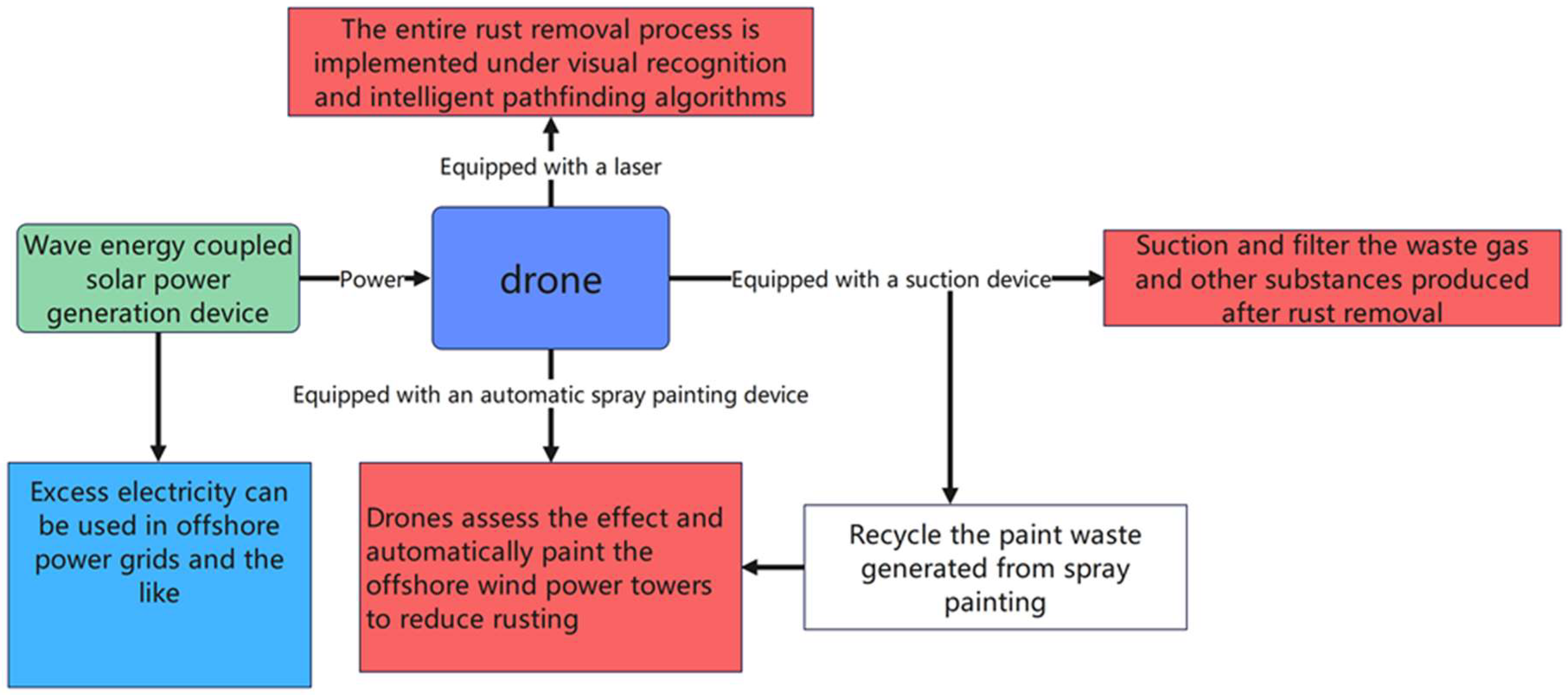

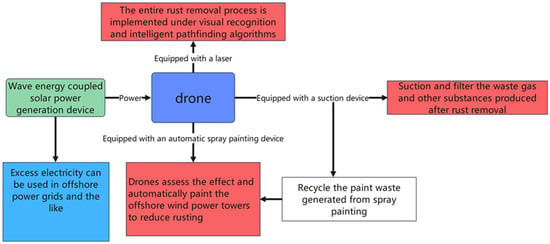

Based on the aforementioned study, our team suggests an intelligent laser rust removal solution for drones, which consists essentially of an energy supply module, a rust removal module, and an anti-corrosion module, as illustrated in Figure 4. Specifically, the drone is first powered by a power-producing system that combines wave and solar energy. The drone uses advanced path-finding and visual recognition algorithms to remove rust and clean offshore wind turbine towers. During rust removal, the drone’s suction filtration system collects aerosols, particles, and dangerous compounds produced by laser rust removal, preventing environmental contamination. After laser rust removal, the drone’s sophisticated spray-painting system sprays protective coatings on the tower structure to prevent additional corrosion. Additionally, the suction filtering system can recover extra paint, which reduces marine pollution and protects the ocean habitat.

Figure 4.

Schematic Diagram of Drone Work Process.

Surplus electricity generated by the wave–solar hybrid power system can be used to power the offshore grid or produce marine hydrogen, allowing for efficient energy recycling and sustainable development.

5.2. Section on Drone Structure and Energy Supply Architectures

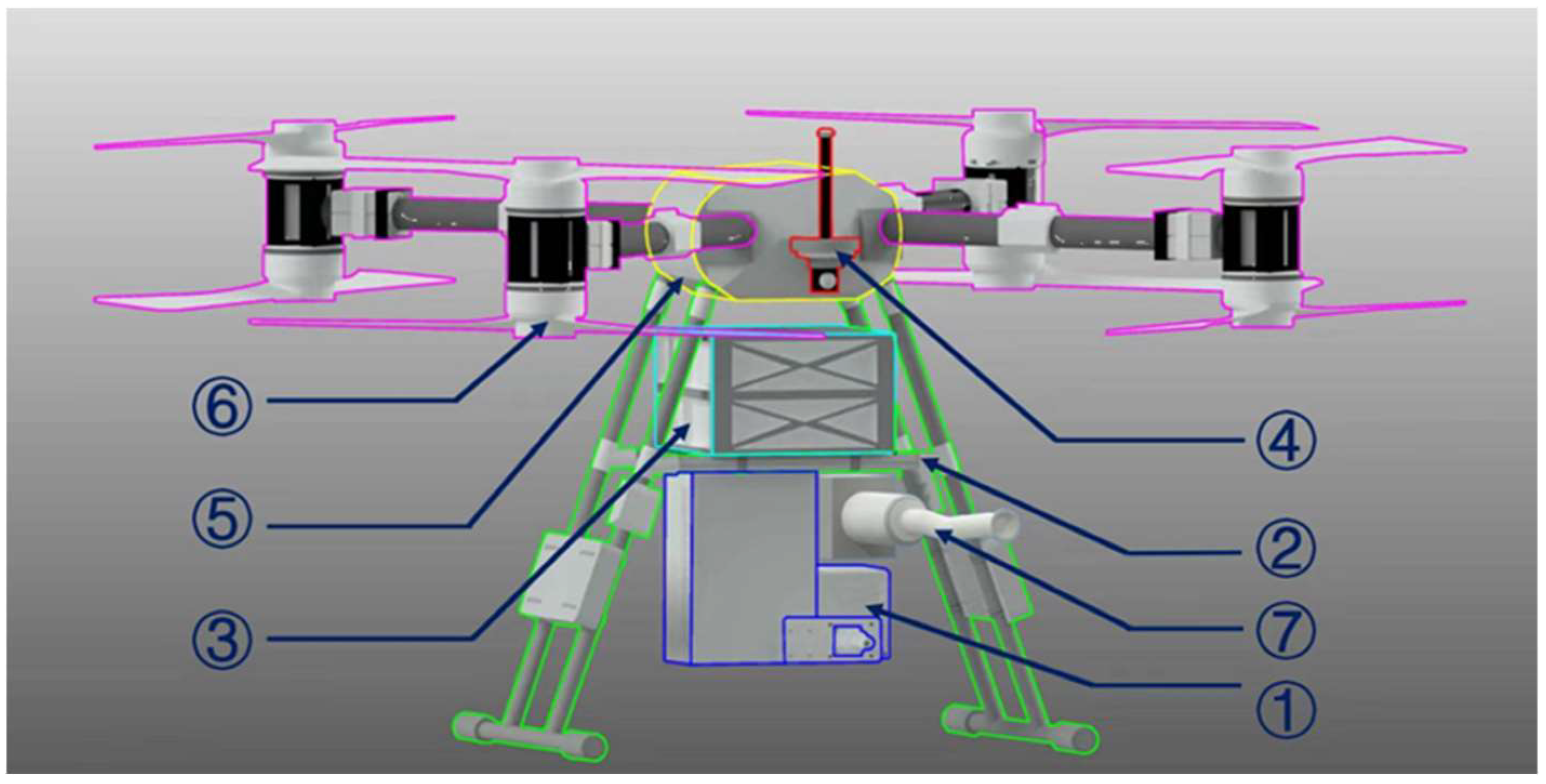

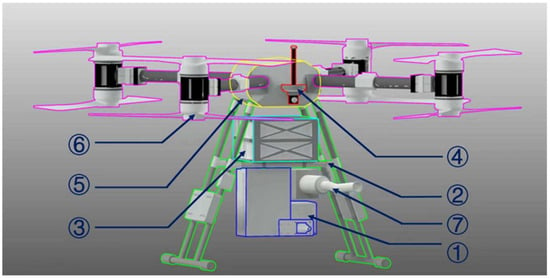

Figure 5 illustrates the modeling of a drone coupled with offshore solar and wave energy generation: The drone comprises seven components: ① laser rust removal instrument; ② drone frame; ③ battery; ④ camera with RTK positioning; ⑤ controller; ⑥ wings; and ⑦ suction filtration module.

Figure 5.

Drone Structural Diagram.

① is primarily used for long-distance laser rust removal. ② forms the drone’s basic structural support. ③ is a rechargeable battery that can be connected to the power generation platform, providing a stable power supply for subsequent drone operations. ④ is primarily used to determine the drone’s position. ⑤ is used to connect to a computer and control the drone’s operations. ⑦ is for the suction and filtration of dust particles generated after subsequent drone rust removal.

Its main performance and structural parameters are shown in Table 1.

Table 1.

Parameters of Unmanned Aerial Vehicle Performance Structure.

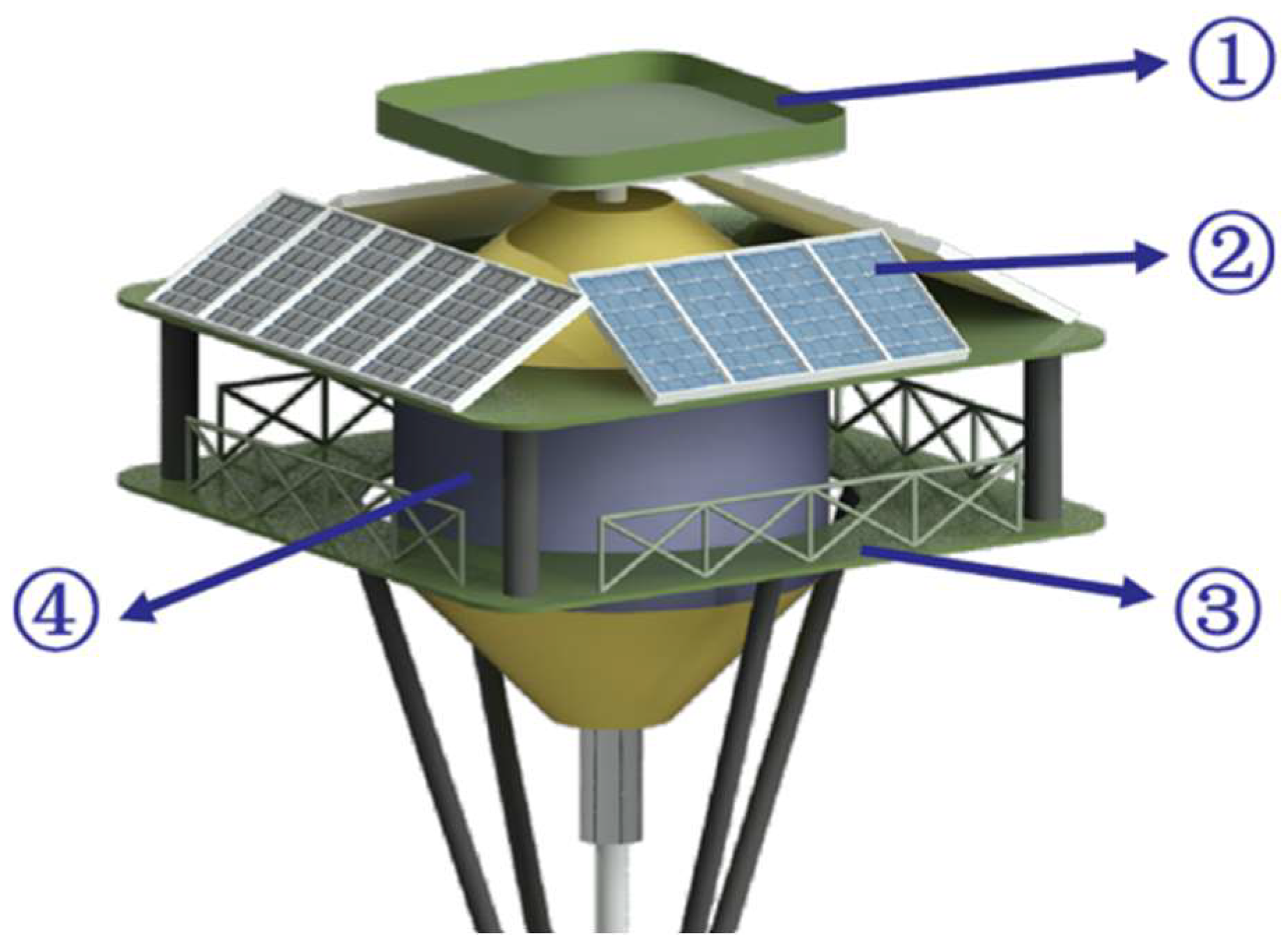

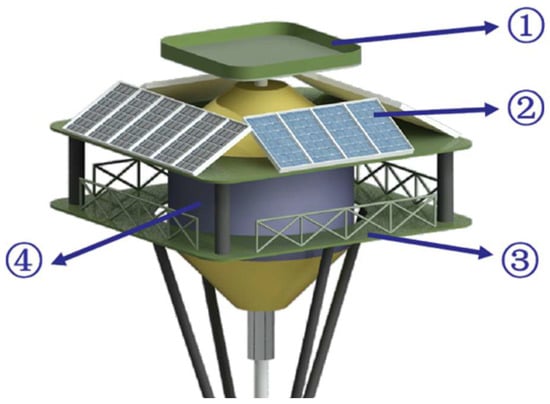

The solar–wave energy coupling device consists of four modules: ① drone landing pad, ② solar panels, ③ manned maintenance platform, and ④ wave energy power generation system. As shown in Figure 6.

Figure 6.

Structural Diagram of Wave Energy–Solar Power Generation Device.

Based on the characteristics of the modeling diagram above, a new generation of drones has been developed according to the architecture of each component. The physical drone is shown in Figure 7:

Figure 7.

Actual Image of the UAV.

6. Modular Design of the UAV Laser Rust Removal System

6.1. Energy Supply Module

6.1.1. Multi-Physics Coupling Model Construction

The study innovatively constructed a multi-physics coupling model integrating wave energy and solar energy [10]. Through a collaborative simulation platform combining Fluent and MATLAB, it achieved strong four-field coupling analysis of fluid, solid, thermal, and electrical phenomena. The wave energy generator employs an oscillating buoy + hydraulic energy storage structure, enabling adaptation to low, medium, and high wave conditions. At wave heights ranging from 0.5 to 3 m, the device generates power exceeding 300 W. The solar panels utilize flexible monocrystalline silicon panels with salt-fog-resistant coatings and a foldable design. Under light intensities exceeding 800 W/m2, power generation capacity surpasses 200 W.

Simultaneously, CFD simulation technology was employed to optimize the hydrodynamic profile of the oscillating buoy wave energy capture mechanism. This enhancement significantly improves the model’s stability under sea conditions.

6.1.2. Establishment of Energy Synergistic Control Model

To address the issue of unstable power supply for marine drones, an energy coordination control model integrating real-time sea condition monitoring was established using an improved Maximum Power Point Tracking (MPPT) algorithm and a dynamic power allocation strategy. This achieves a comprehensive power generation efficiency exceeding 75% and enhances overall system energy efficiency by 35%–45%. It also enables intelligent switching of energy inputs, prioritizing real-time generated power to overcome the technical bottleneck of intermittent single-energy supply. This provides stable, efficient, and sustainable energy for the system.

Under harsh marine conditions—including high salinity, humidity, and rough seas—the device demonstrates robust environmental interference resistance and excellent stability.

Specific environmental adaptability factors of this model are detailed in Table 2.

Table 2.

Environmental Adaptability of Power Generation Platforms.

6.2. Rust Removal Module

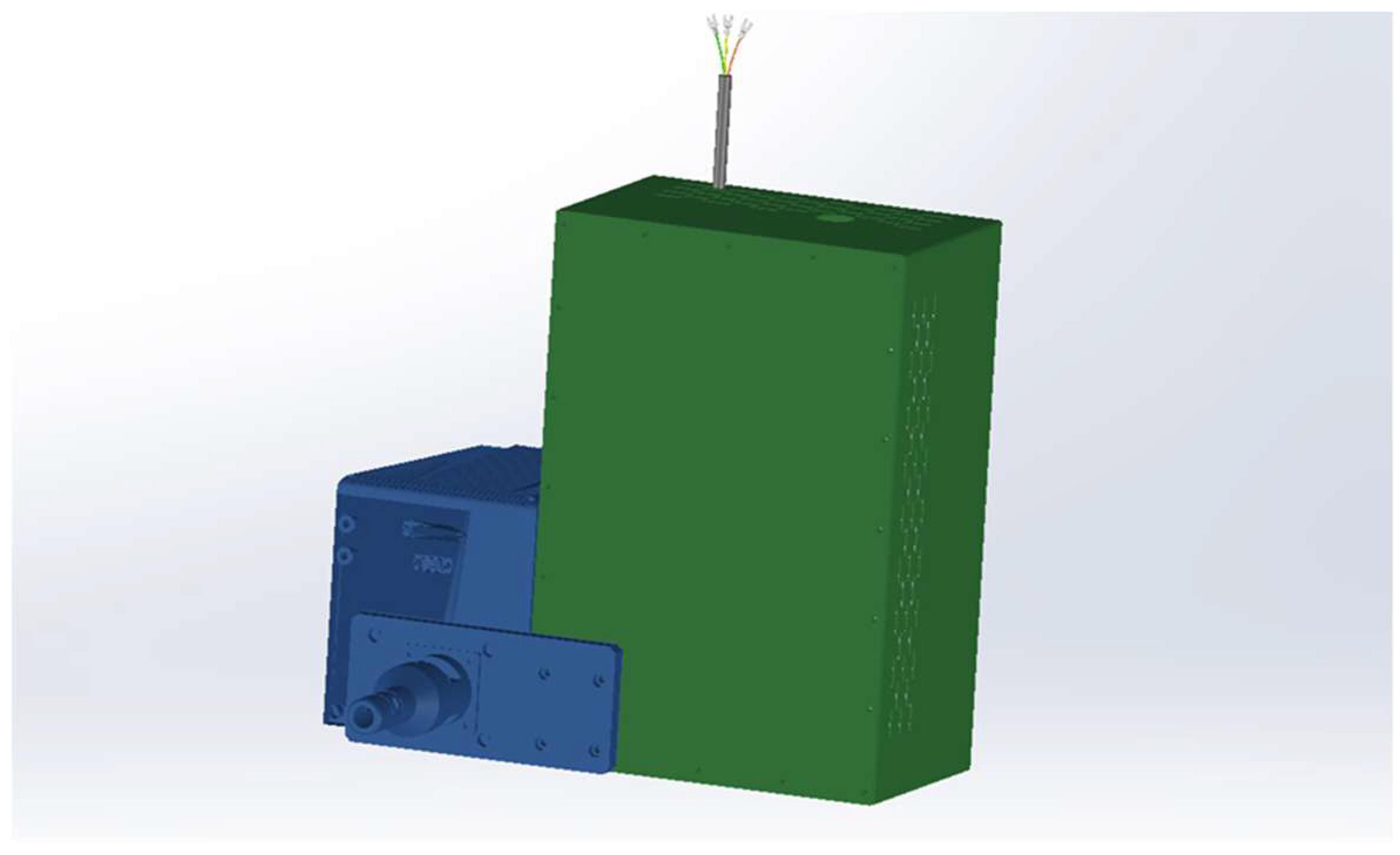

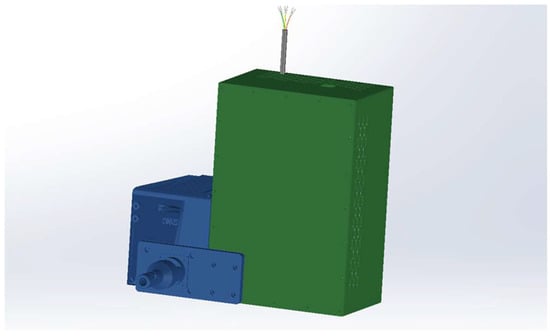

The core component of the rust removal module is the high-power laser system mounted on the drone (as shown in Figure 8). Laser rust removal offers advantages such as environmental friendliness and high levels of automation, enabling non-contact cleaning of rust deposits at elevated heights.

Figure 8.

Modeling Diagram of the UAV Laser System.

The specific parameters of this high-power laser are shown in Table 3.

Table 3.

Laser Performance Parameters.

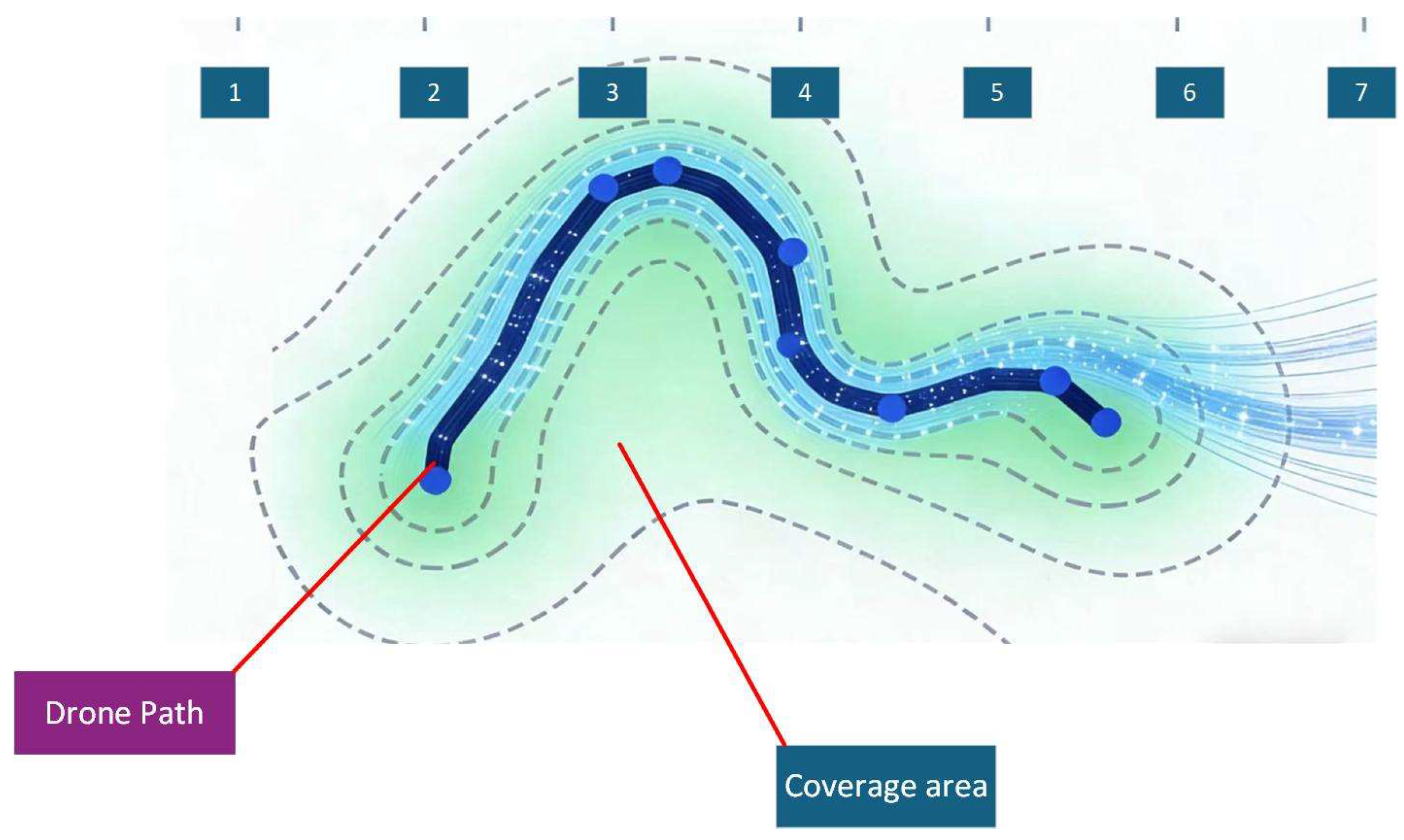

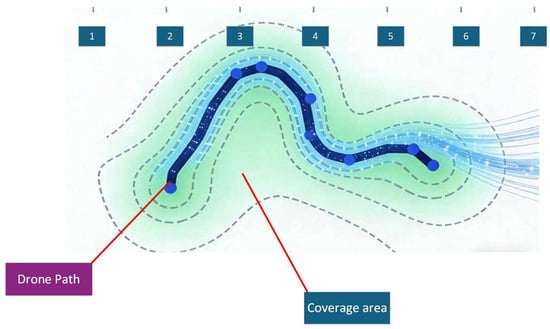

This unmanned aerial vehicle (UAV) possesses exceptional maneuverability, enabling comprehensive operational coverage of tower structures. The system employs a policy prioritization optimization (PPO) algorithm for three-dimensional path planning. As demonstrated in Figure 9, this approach autonomously learns through environmental interaction to generate efficient, full-coverage paths across complex steel surfaces. Experimental calculations demonstrate that this path planning method achieves 98% coverage with path overlap rates below 1%, effectively resolving inspection blind spots and motion redundancy issues.

Figure 9.

Drone Path Planning Algorithm Coverage Map.

Building upon this foundation, the research employs a high-precision finite element thermodynamic model for simulation analysis and parameter optimization. This establishes a laser power control strategy centered at 300 W, dynamically adjusting within the 200–500 W range based on rust layer thickness. This strategy maintains the maximum substrate temperature during rust removal within the safe range of 150 ± 5 °C, with a heat-affected zone depth below 0.1 mm. Consequently, it achieves non-destructive treatment of the substrate material while sustaining an operational efficiency of 2.5 m2/h.

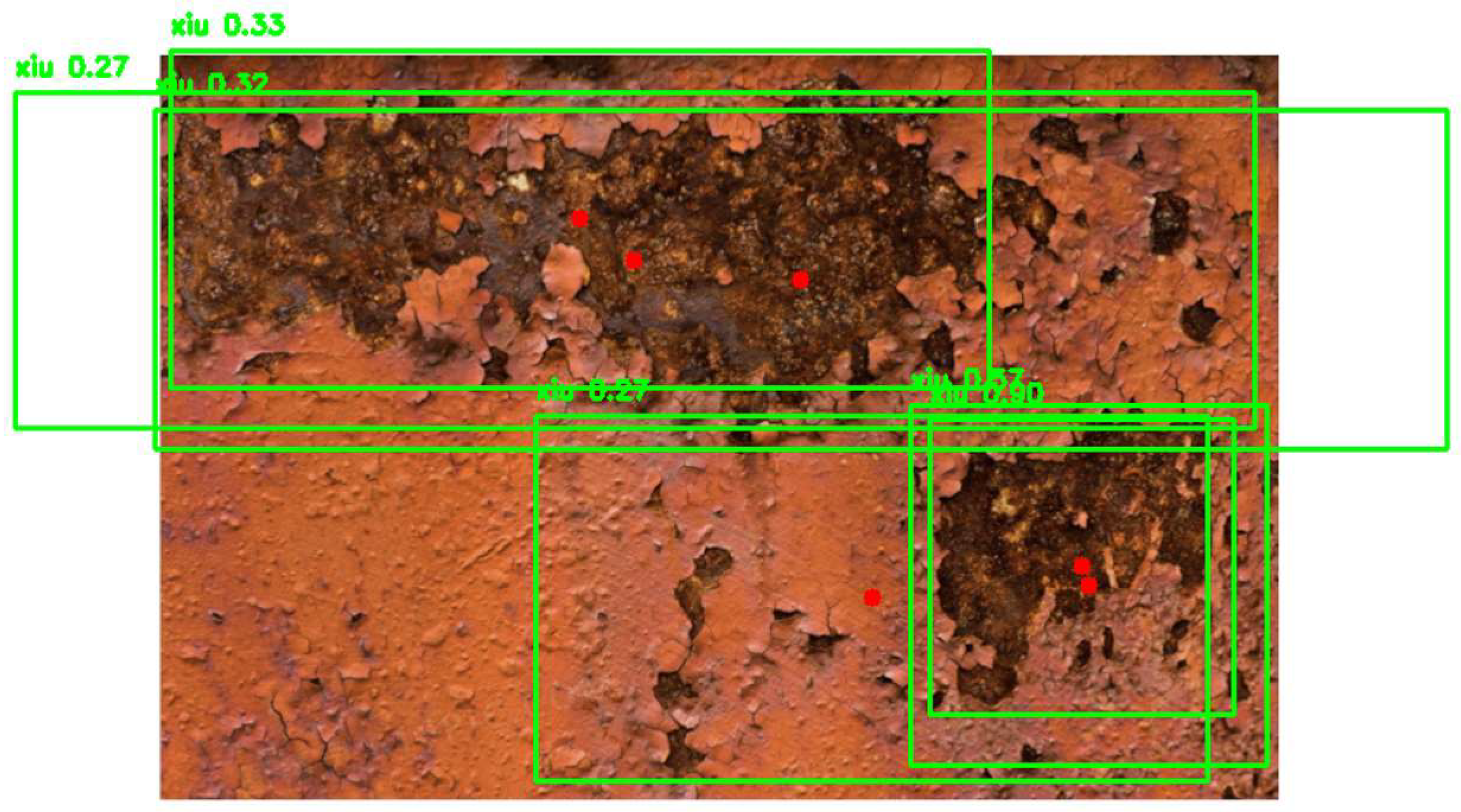

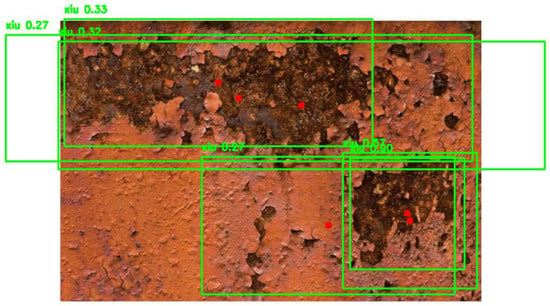

Additionally, this drone integrates the YOLO11 (You Only Look Once Version 11) visual recognition algorithm [11] with RTK (Real-Time Kinematic) positioning equipment, enabling it to accurately identify and locate rusted areas with over 95% precision. Figure 10 displays the inspection results from the drone’s visual recognition system. The proportion of the rusted area relative to the total rusted surface can be determined by analyzing the graphical representation below.

Figure 10.

Visual Recognition Algorithm Results Diagram.

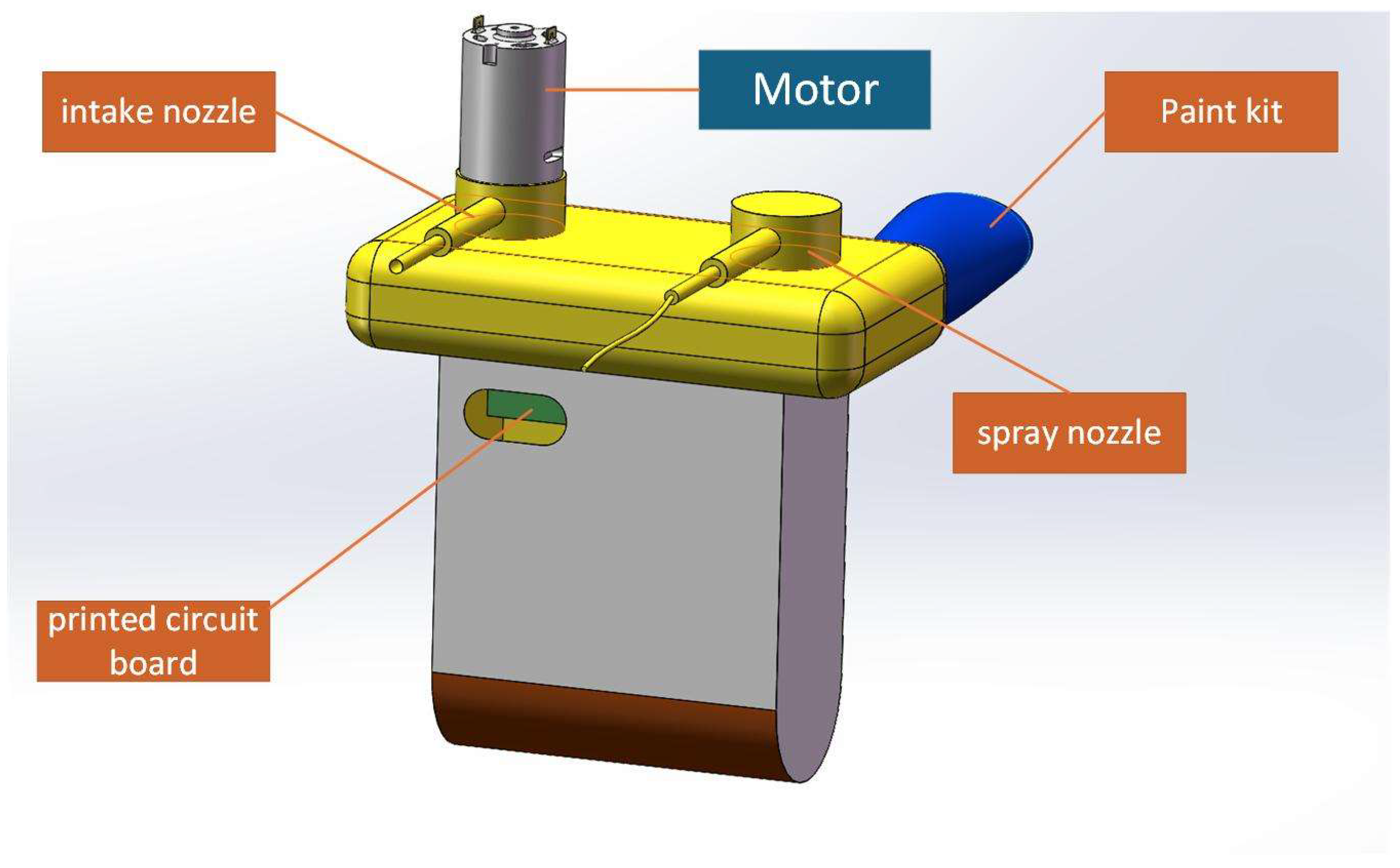

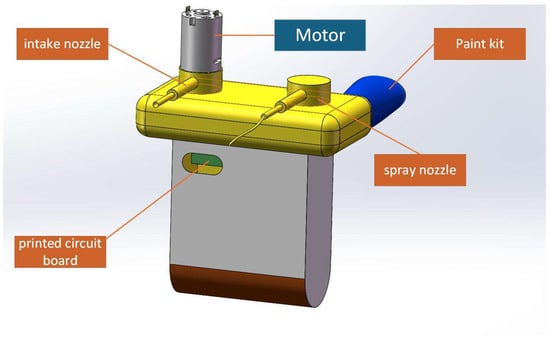

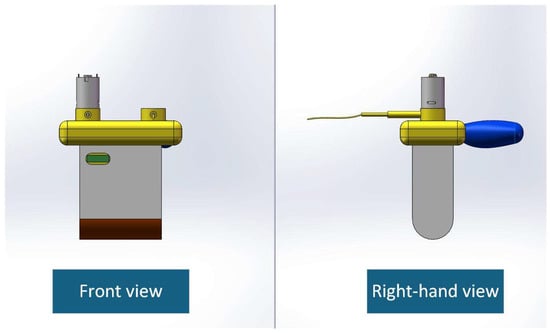

6.3. Rust Removal Module

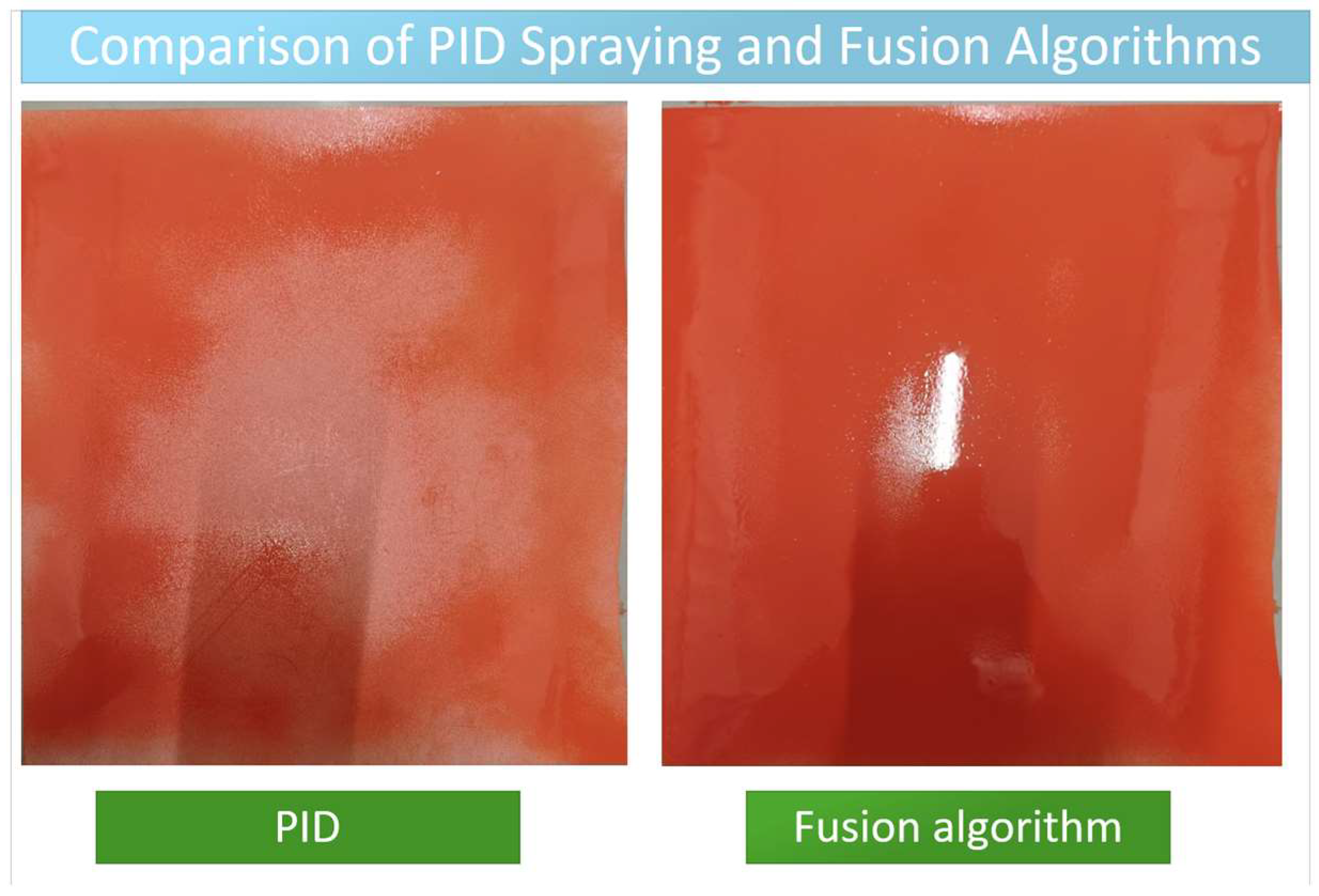

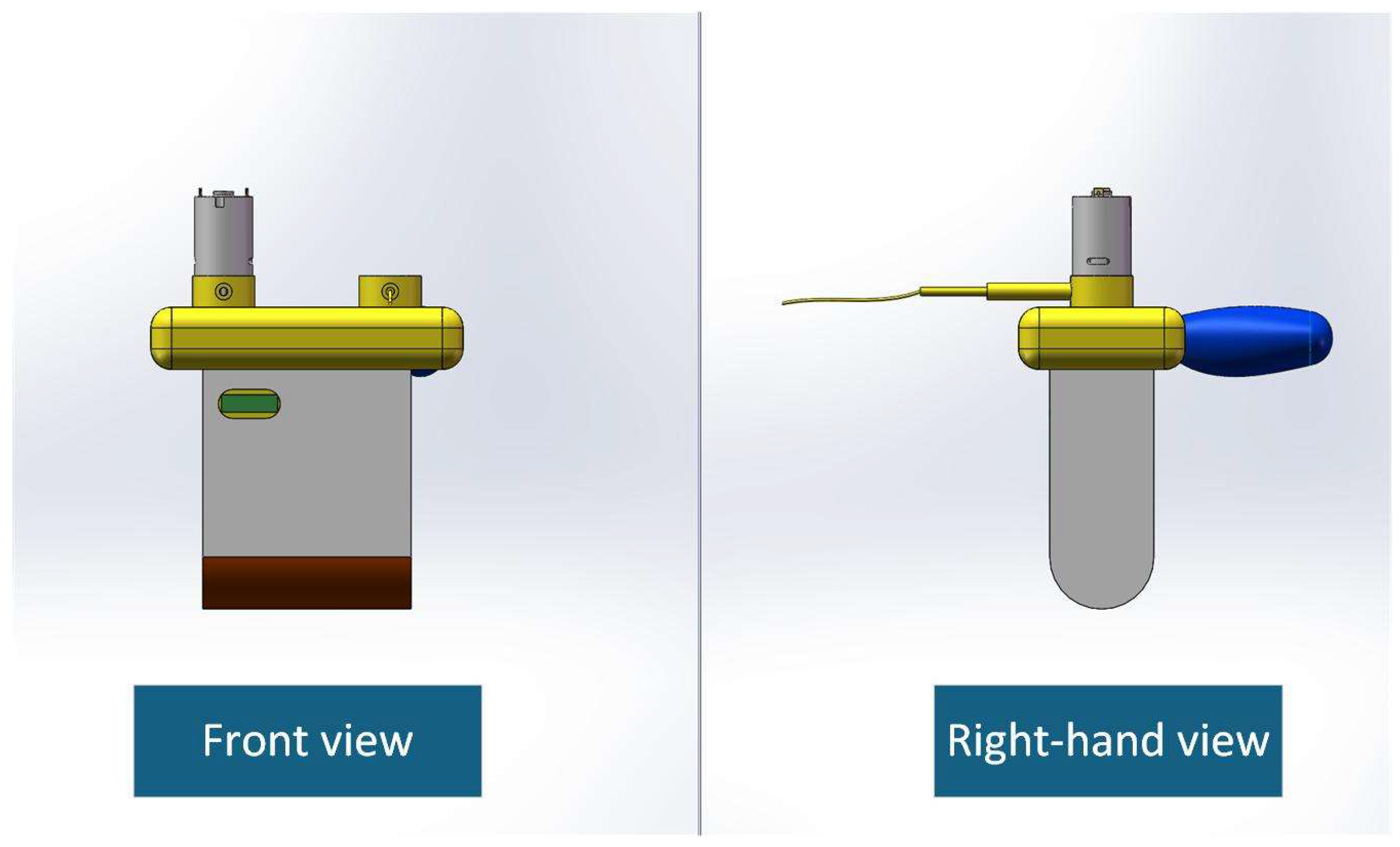

This intelligent drone is equipped with an automated spraying and adsorption module [12] (Figure 11 and Table 4). As illustrated in Figure 12, it comprises an intake nozzle, spray nozzle, motor, and processing module. The total weight of the unit is 14 kg. The front spray hose employs a telescopic design with an adjustable range of 0.5 to 2 m. The powered negative pressure suction unit measures 40 × 30 × 30 centimeters and achieves a maximum suction power of 6000 watts. Its front and right-side views are depicted in Figure 13.

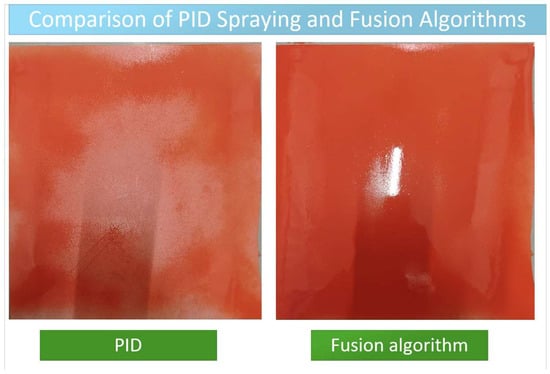

Figure 11.

Spray Comparison Diagram.

Table 4.

Spray Parameters Comparison Table.

Figure 12.

Suction Filtration Modeling Diagram.

Figure 13.

Front and rear views of the apparatus.

By comparing this with a conventional spray booth employing traditional PID control without an optimized structure, a 1 m × 1 m × 0.5 mm steel plate was positioned within the chamber. Both the novel spray system and the conventional booth applied coating to the steel plate while maintaining consistent key parameters: a spray distance of 1.5 m, a travel speed of 0.8 m/s, and a target coating thickness of 80 ± 5 μm. Purification efficiency was calculated using the formula: ‘Capture efficiency = (Inlet concentration − Outlet concentration)/Inlet concentration × 100%’. Concurrently, a VOC detector (detection limit 0.01 mg/m3) monitored real-time VOC concentration variations within the chamber, recording emission peaks and average emission rates. A coating thickness gauge (error ±0.1 μm) was employed to uniformly select 50 test points on the substrate surface (arranged in a 10 × 5 matrix). The coating thickness at each point was recorded, and the standard deviation was calculated. The regulatory effect was quantified using the formula ‘Uniformity improvement rate = (Control group standard deviation − Experimental group standard deviation)/Control group standard deviation ×100%’. Weigh the paint container mass before and after spraying using an electronic balance (accuracy 0.01 g) to calculate the paint utilization rate (Utilization rate = Actual sprayed quantity/Total dispensed quantity × 100%).

The module employs a CFD model optimized via Large Eddy Simulation (LES) to design the suction flow field. Practical testing revealed high capture efficiency for particles exceeding 0.3 micrometers, effectively filtering aerosols, particulates, and chemical hazards generated during rust removal processes. For spray control, the system innovatively integrates a Long Short-Term Memory Proportional Integral Derivative (LSTM-PID) hybrid algorithm. By dynamically predicting coating flow rate and atomization pressure, this algorithm achieves precise closed-loop regulation of the spraying process. Experimental results demonstrate that, under target coating thickness conditions of 80 ± 5 μm, the standard deviation of coating thickness controlled by this algorithm decreased from 12 μm using traditional methods to 3 μm, representing a 75% improvement in uniformity. Concurrently, coating utilization increased from 65% to 82%, reducing waste by approximately 17%. These enhancements not only markedly improve coating quality stability but also effectively reduce material consumption and volatile organic compound (VOC) emissions, achieving dual benefits in economic efficiency and environmental performance.

7. Advantages and Challenges of Laser Rust Removal Using Drones

The intelligent laser rust removal system, as a cutting-edge offshore wind power operation and maintenance technology, integrates multiple advanced technologies, including unmanned aerial vehicles, laser cleaning, artificial intelligence, and multi-energy collaborative power supply. It demonstrates significant advantages and innovation in addressing the challenges of traditional rust removal for offshore wind turbines.

In terms of performance, the UAV’s high maneuverability and flexibility enable rapid deployment to operational zones. Coupled with efficient laser rust removal equipment, visual recognition systems, and path planning algorithms, it precisely locates rusted areas and charts optimal paths for treatment. Regarding environmental impact, laser rust removal requires no chemical agents; aerosols and particulate dust generated throughout the process are filtered and recovered by the UAV’s suction and filtration apparatus. Regarding safety, the system employs autonomous drone operations, eliminating the need for personnel to perform high-altitude tasks. This fundamentally removes safety hazards associated with elevated work, effectively safeguarding personnel.

However, the system’s technical development remains incomplete. Stability control and precise positioning capabilities of the drone under extreme offshore conditions require further enhancement. The adaptability and stability of the laser rust removal equipment when addressing different materials, varying degrees of corrosion, and complex surface structures also need optimization. Regarding safety compliance and risk management, the system does not yet fully address critical safety elements and regulatory requirements. The use of Class IV lasers must strictly adhere to relevant standards such as the International Electrotechnical Commission (IEC 60825-1 [13]) and China’s ‘Safety of Laser Products—Part 1: Equipment Classification, Requirements’ (GB 7247.1-2012 [14]), necessitating enhanced compliance configurations including laser radiation protection and safety interlock designs. Human safety protocols remain underdeveloped, necessitating further refinement of systems, including operator certification, specialized safety training, and comprehensive operational procedures; Insufficient fail-safe mechanisms exist for extreme meteorological conditions such as high winds at sea. Critical technologies and solutions—including optimized wind resistance stability for drones, tiered emergency shutdown procedures, and fault response protocols—require urgent development. Mitigation measures for offshore infrastructure risks remain inadequate. Enhanced design considerations are needed for wind turbine tower foundation protection, marine ecological conservation, and safe navigation clearance around surrounding facilities. This will comprehensively improve the system’s operational safety, compliance, and reliability within hazardous marine environments.

8. Conclusions

Corrosion difficulties in offshore wind turbine towers have become a serious obstacle to their safe operation, with rust removal and maintenance research gaining a lot of attention. Domestic and international scholars have achieved significant advances in the field of laser rust removal. Domestic research is mostly focused on automating laser rust removal equipment, including handheld laser cleaning devices, Three-Dimensional Cableway Laser Cleaning Equipment, wall-climbing robots, and six-axis industrial robotic arms. These systems offer significant advantages in automated operations, cleaning route planning, and adaptive power adjustment. However, flexibility, load capacity, positioning precision, and adaptability to visual recognition are still limited. International research focuses on dynamic monitoring, process parameter optimization, and intelligent control, with notable advances in vision servo systems, rust identification, and multimodal robotic systems. However, flexibility, load capacity, positioning precision, and adaptability to visual recognition are still limited. International research focuses on dynamic monitoring, process parameter optimization, and intelligent control, with notable advances in vision servo systems, rust identification, and multimodal robotic systems. However, research on adaptability in high-salinity, high-humidity maritime conditions is sparse, with no all-weather adaptive laser cleaning systems designed for big offshore structures.

Based on these findings, this research suggests a wave–solar hybrid-powered intelligent rust removal drone as a more suitable solution for offshore wind power operation and maintenance. It consists largely of three major modules: a high-powered laser, vision-based recognition with RTK location, and an intelligent suction-spraying module. This system has characteristics such as environmental sustainability and high intelligence, making it a dependable alternative for intelligent offshore wind energy maintenance. It has substantial practical technical value and provides fresh insights into the sustainable construction of offshore wind towers. Although hurdles remain in assuring stability in extreme environments, this technique represents a step toward intelligent and green maintenance for offshore wind generation, with extensive application prospects in other large-scale marine infrastructure maintenance industries.

Author Contributions

Conceptualization, Y.Z. and Y.L.; methodology, Y.H.; software, Z.W.; validation, Y.L., Z.W. and X.L.; formal analysis, L.M.; investigation, X.R.; resources, X.R.; data curation, S.L.; writing—original draft preparation, Y.L., Z.W. and Y.W.; writing—review and editing, Y.L.; visualization, Y.L.; supervision, Y.Z. and W.L.; project administration, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are documented in the article. For further enquiries, please contact the corresponding author.

Acknowledgments

During the preparation of this manuscript/conduct of this research, the author utilized software including Visio, MATLAB, SolidWorks and AutoCAD for graphical representation, modeling, and related tasks. The author has reviewed and revised the generated content and assumes full responsibility for the contents of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ren, Z.; Wu, C.; Chen, H.; Lu, Y.; Qiao, H.; Hu, T. Mechanism of laser derusting and surfaceproperties of low carbon steel. Opto-Electron. Eng. 2017, 44, 1210–1216+1246. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, X.; Ding, Y. Development of Hand Held Laser Cleaning System. J. New Ind. 2017, 12, 1–6. [Google Scholar]

- Shao, Z. Research on Three-Dimensional Cable-Guided Laser Cleaning Technology. Master’s Thesis, Hebei University of Technology, Hebei, China, 2021. [Google Scholar] [CrossRef]

- Jiang, M.; Zhao, H. Structural Design and Optimization of a Pipeline Robot Equipped with a Rust Removal Manipulator. Eng. Mach. 2022, 53, 57–62+10. [Google Scholar]

- Li, X. Research on Laser Paint Removal Robot System Based on Machine Vision. Master’s Thesis, Suzhou University, Suzhou, China, 2024. [Google Scholar] [CrossRef]

- Koh, K.H.; Farhan, M.; Yeung, K.P.C.; Tang, D.C.H.; Lau, M.P.Y.; Cheung, P.K.; Lai, K.W.C. Teleoperated service robotic system for on-site surface rust removal and protection of high-rise exterior gas pipes. Autom. Constr. 2021, 125, 103609. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, G.; Morimoto, K.; Ma, S. Automated Rust Removal: Rust Detection and Visual Servo Control. Autom. Constr. 2022, 134, 104043. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Sagoe-Crentsil, K.; Zhang, J.; Duan, W. Intelligent robotic systems for structural health monitoring Applications and future trends. Autom. Constr. 2022, 139, 104273. [Google Scholar] [CrossRef]

- Fang, G.; Pan, Y.; Wu, D.; Zhao, W. Research progress of laser cleaning technology for industrial fields in the past decade. Optik 2025, 331, 172354. [Google Scholar] [CrossRef]

- Zhou, K.R. Research on Power Management System for Multi-Energy Complementary Power Supply. Master’s Thesis, Harbin Engineering University, Harbin, China, 2023. [Google Scholar] [CrossRef]

- Duan, J.; Shi, R.; Zhang, W.; Wang, Q.; Ren, X. Research on Laser Rust Removal Process for Carbon Steel Surfaces Based on Image Processing. Chin. J. Lasers 2024, 51, 135–144. [Google Scholar] [CrossRef]

- Wei, G.; Zhang, F.F.; Wei, Z.H.; Gu, S.F. A Negative Pressure Suction Filtration Device. CN Patent No. CN216756910U, 17 June 2022. [Google Scholar]

- IEC 60825-1:2014; Safety of Laser Products—Part 1: Equipment Classification and Requirements. IEC: Geneva, Switzerland, 2014.

- GB 7247.1-2012; Safety of Laser Products—Part 1: Equipment Classification and Requirements. Standardization Administration of China: Beijing, China, 2012.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.