Advances in Conductive Modification of Silk Fibroin for Smart Wearables

Abstract

1. Introduction

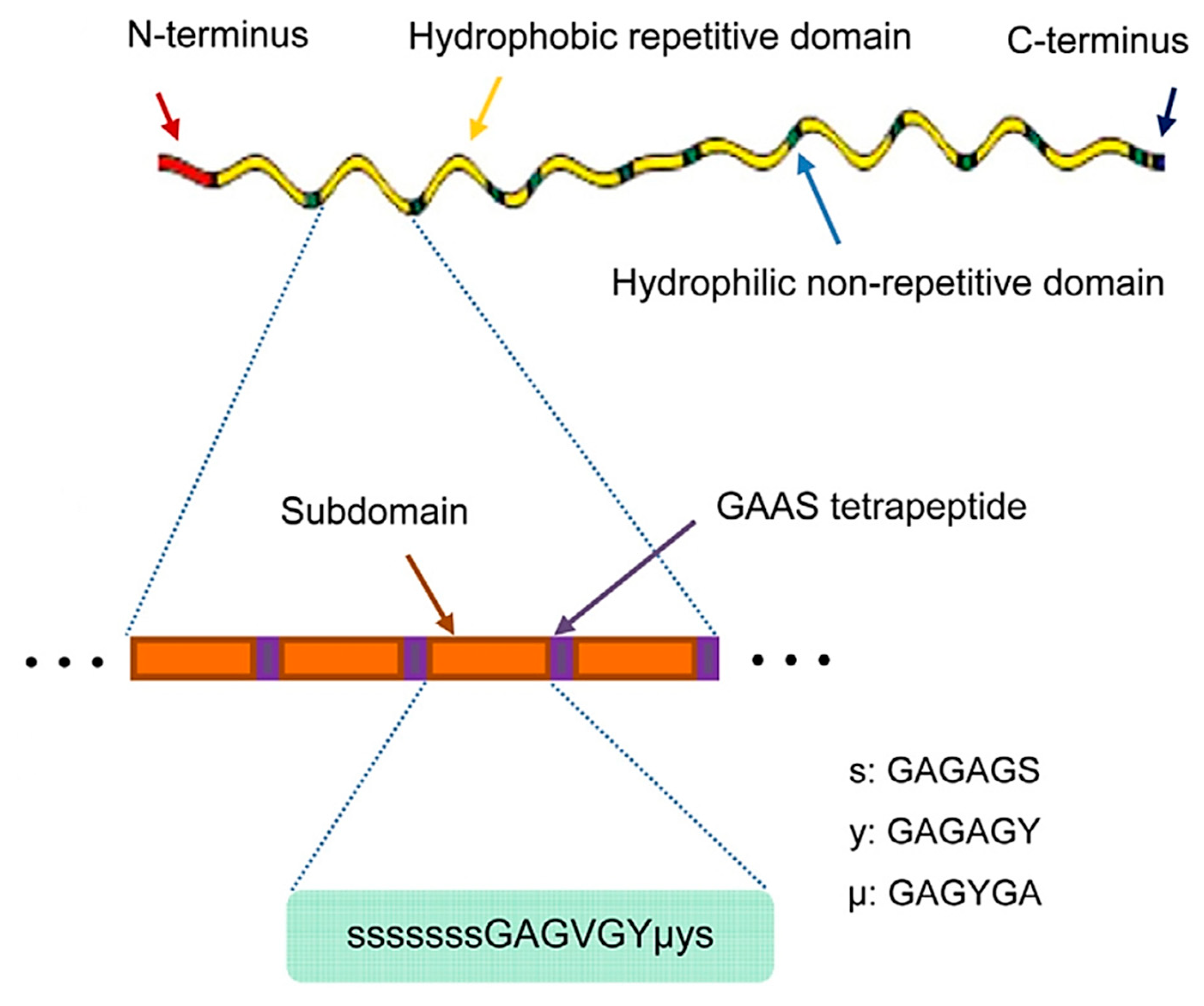

2. Structure and Properties of Silk Fibroin

- (1)

- Excellent biocompatibility and low immunogenicity: hydrophobic amino acid residues dominate the repetitive region of the heavy chain, exceeding 70% in total amino acid content. Their simple, stable, and electrically neutral side chains effectively inhibit non-specific protein adsorption and complement activation pathways, endowing silk fibroin with excellent biocompatibility and low immunogenicity.

- (2)

- Exceptional mechanical properties: The outstanding mechanical performance of silk fibroin is a direct result of its unique nanoscale structural organization. Highly ordered and densely packed β-sheet nanocrystalline regions act as rigid reinforcing phases, contributing high tensile strength and elastic modulus. Simultaneously, the hydrophilic non-repetitive sequence domains connecting these crystals and the disordered regions dominated by the light chain act as a flexible matrix phase, providing significant deformation capacity and toughness. This “rigid filler-flexible matrix” model, consisting of an amorphous network reinforced by nanocrystalline regions, is fundamental to its simultaneous combination of high strength and good flexibility [16].

- (3)

- Precisely controllable degradation: The in vitro and in vivo degradation rate of silk fibroin is one of its most critical parameters for applications, primarily controlled by the content, size distribution, spatial orientation of β-sheet nanocrystalline regions, and the density of the cross-linked network within the material. Physicochemical treatment strategies can systematically increase the material’s crystallinity and cross-linking density. This structural control can extend the degradation behavior from an initial timescale of days to weeks up to years. This characteristic significantly broadens the applicability of silk fibroin-based materials in fields requiring long-term functional maintenance.

- (4)

- Multi-scale processability: The inherent high processability of silk fibroin is closely related to its molecular assembly structure. The highly ordered arrangement of molecular dipole moments within the β-sheet layers endows the material with favorable solution rheological properties and solid-state plasticity. This allows silk fibroin solutions to be processed using various mature and highly controllable processing and molding technologies, enabling relatively easy transformation into precisely structured, morphologically diverse materials across scales—from micro/nano-scale microspheres, nanofibers, and porous scaffolds to macroscopic films, hydrogels, and bulk implants—tailored to customized requirements for diverse scenarios.

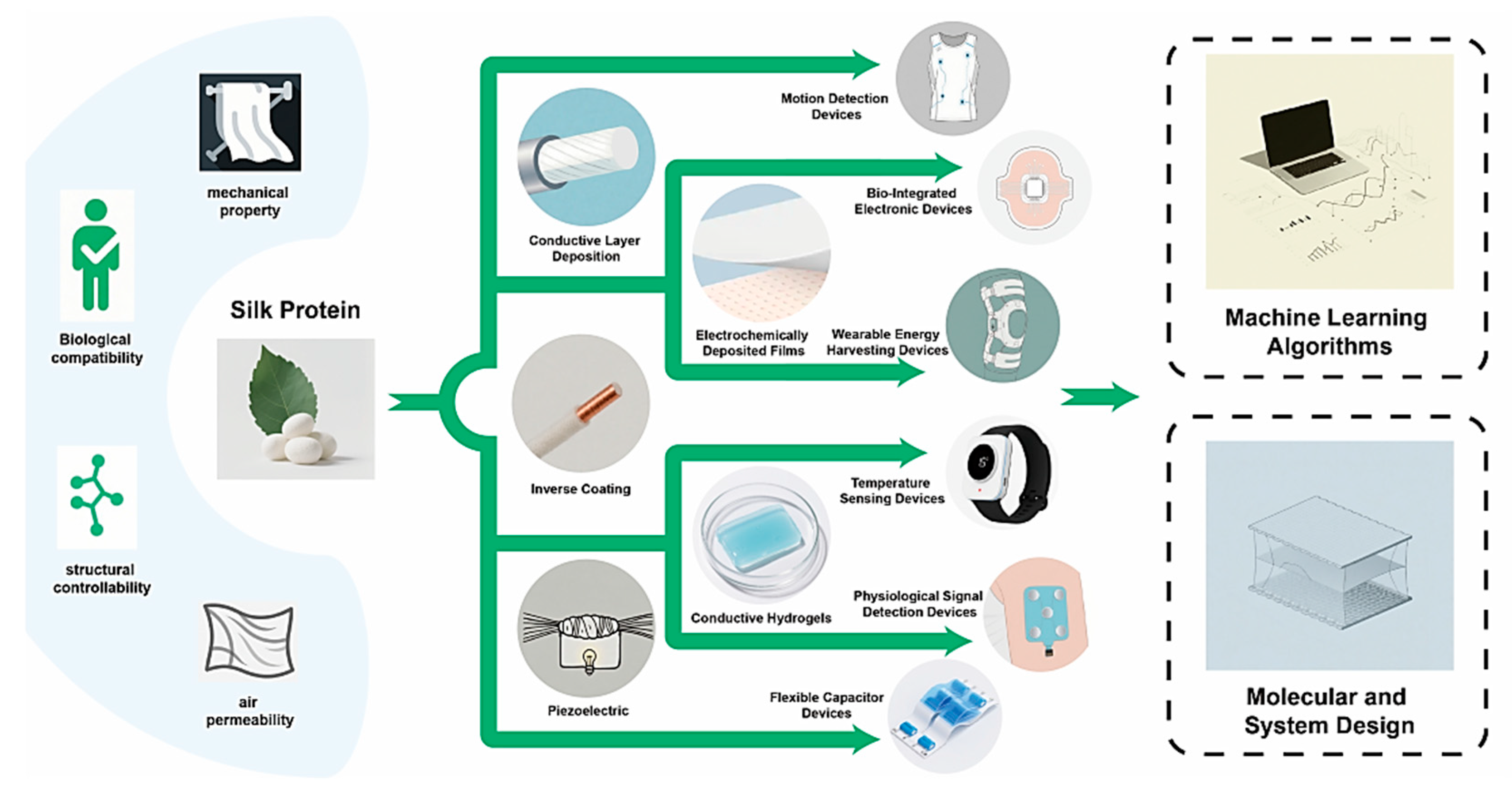

3. Conductive Modification of Silk Fibroin

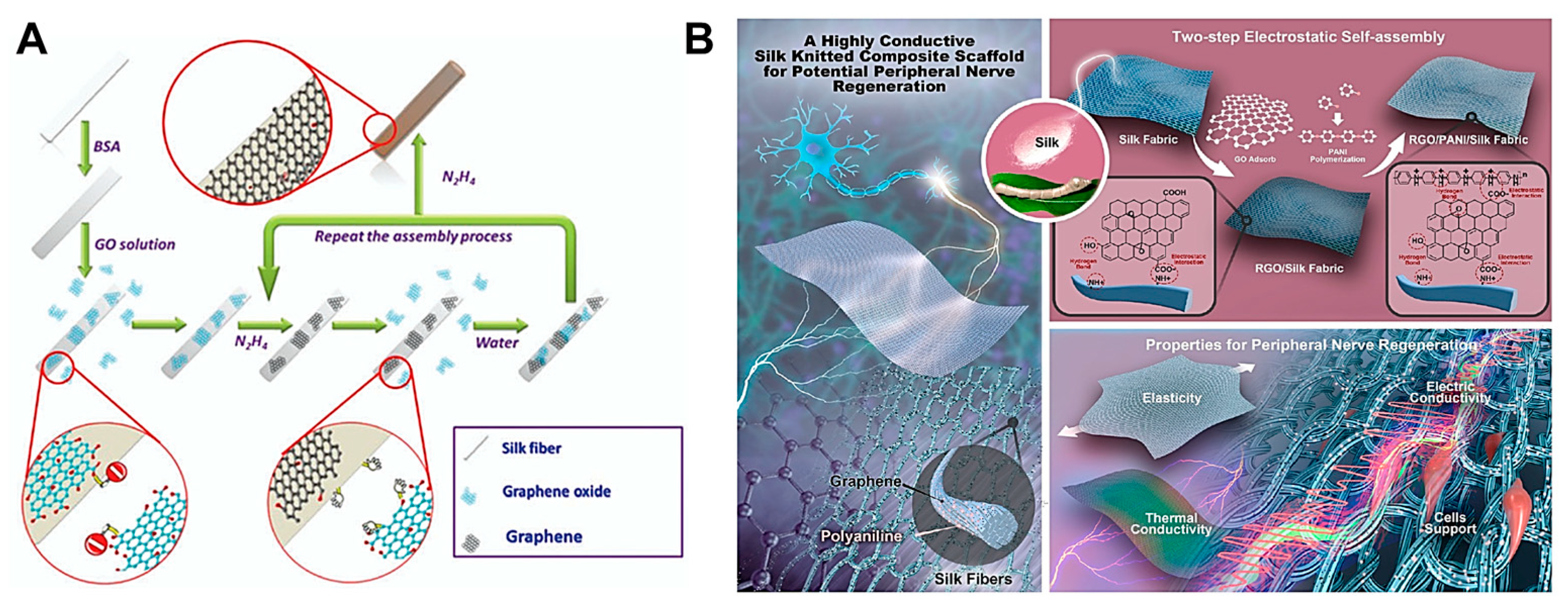

3.1. Conductive Layer Deposition on Silk Fibroin Surfaces

3.2. Conductive-Core/Silk-Shell Fibers via Inverse Coating

3.3. Electrochemically Deposited Silk Fibroin Conductive Films

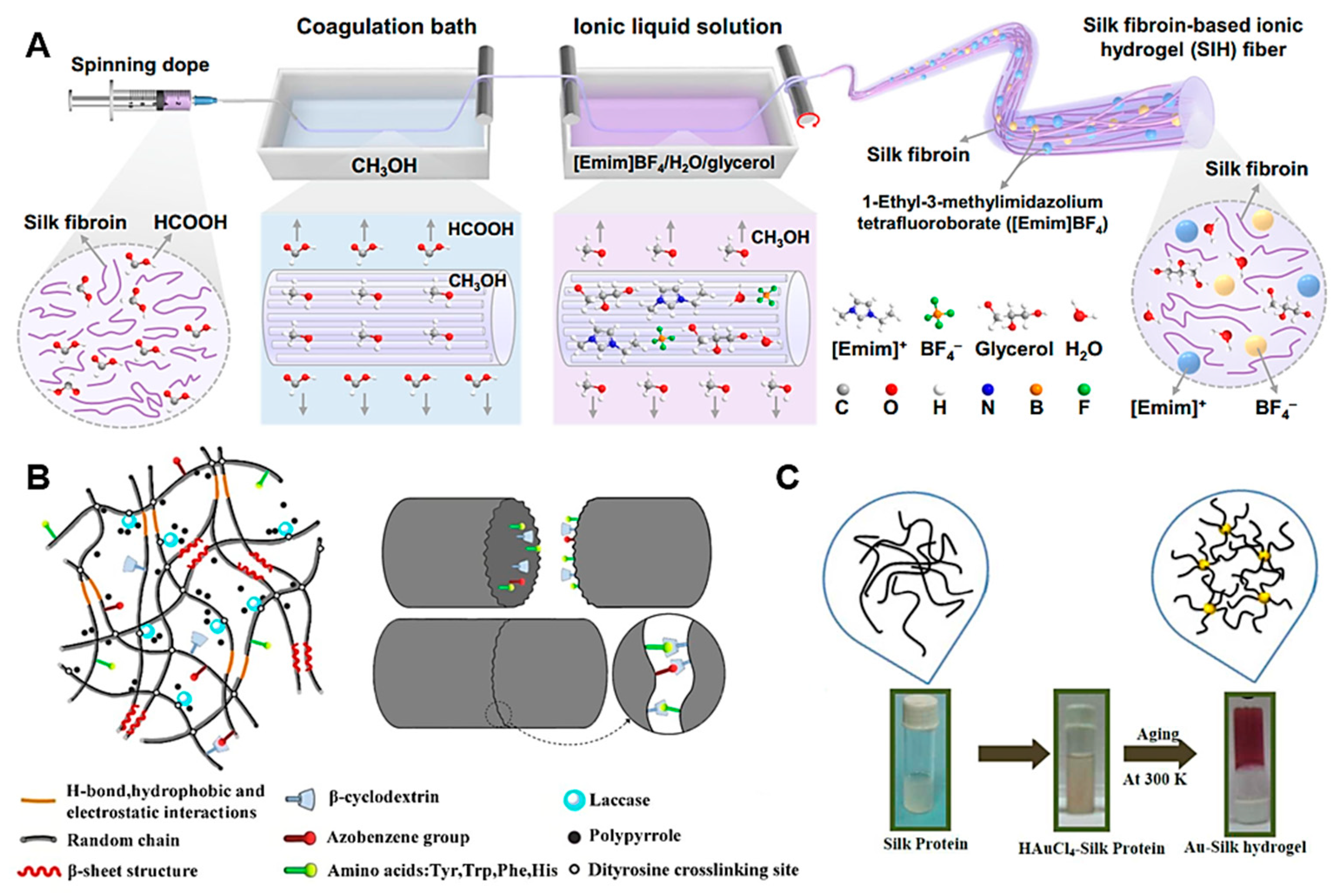

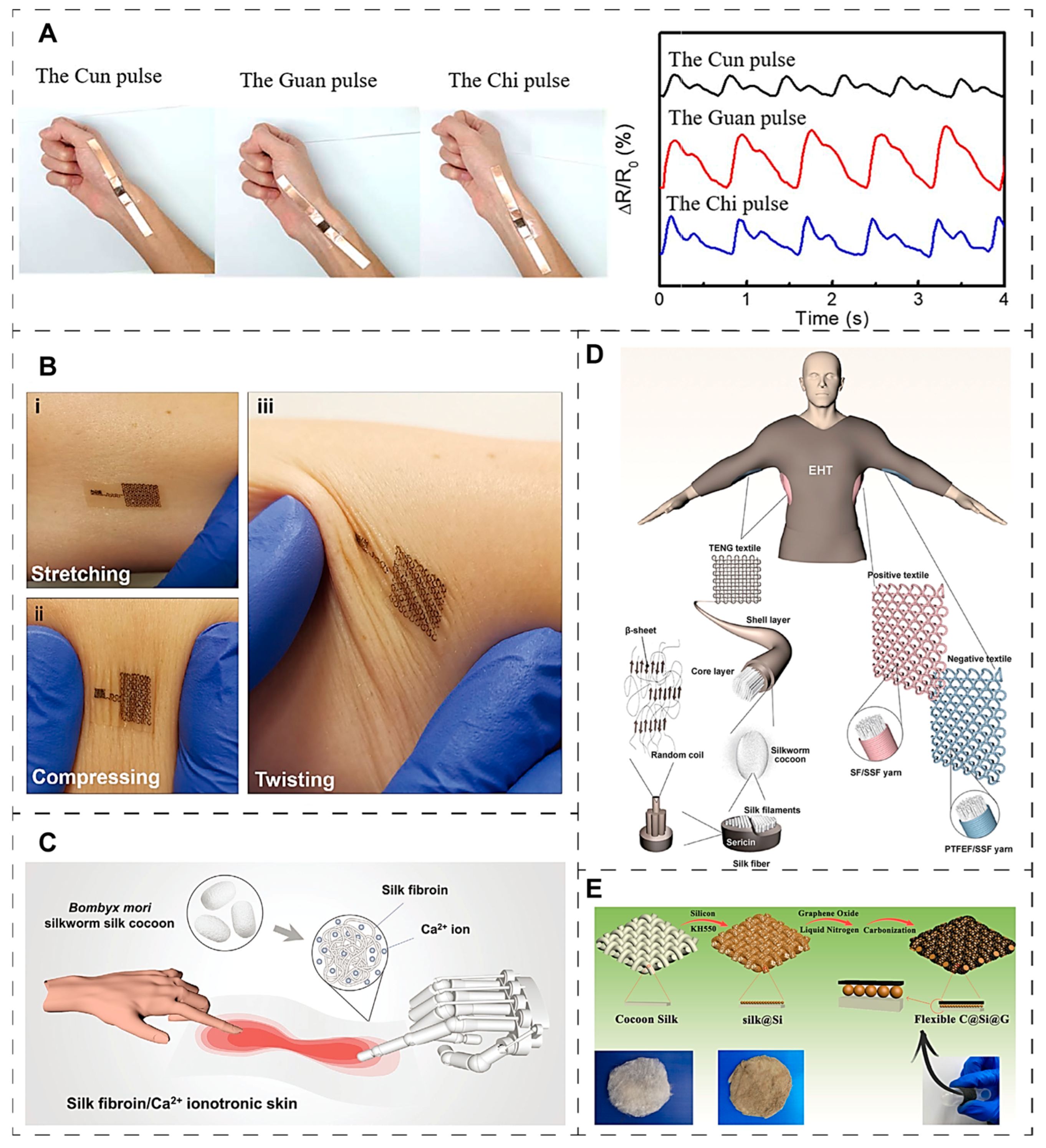

3.4. Silk Fibroin-Based Conductive Hydrogels

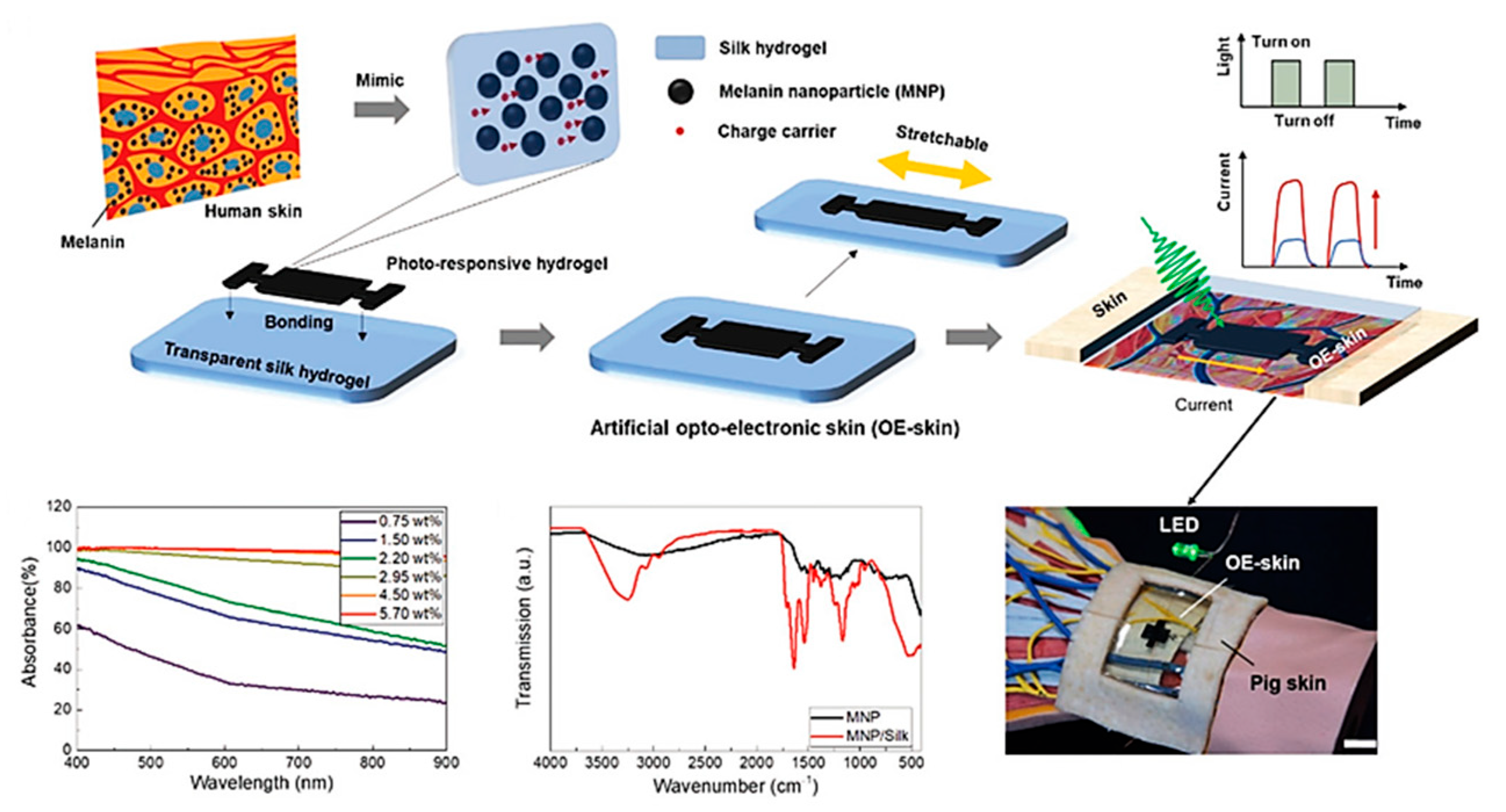

3.5. Silk Fibroin-Based Multi-Responsive Conductive Composites

3.6. Piezoelectric Silk Fibroin Materials

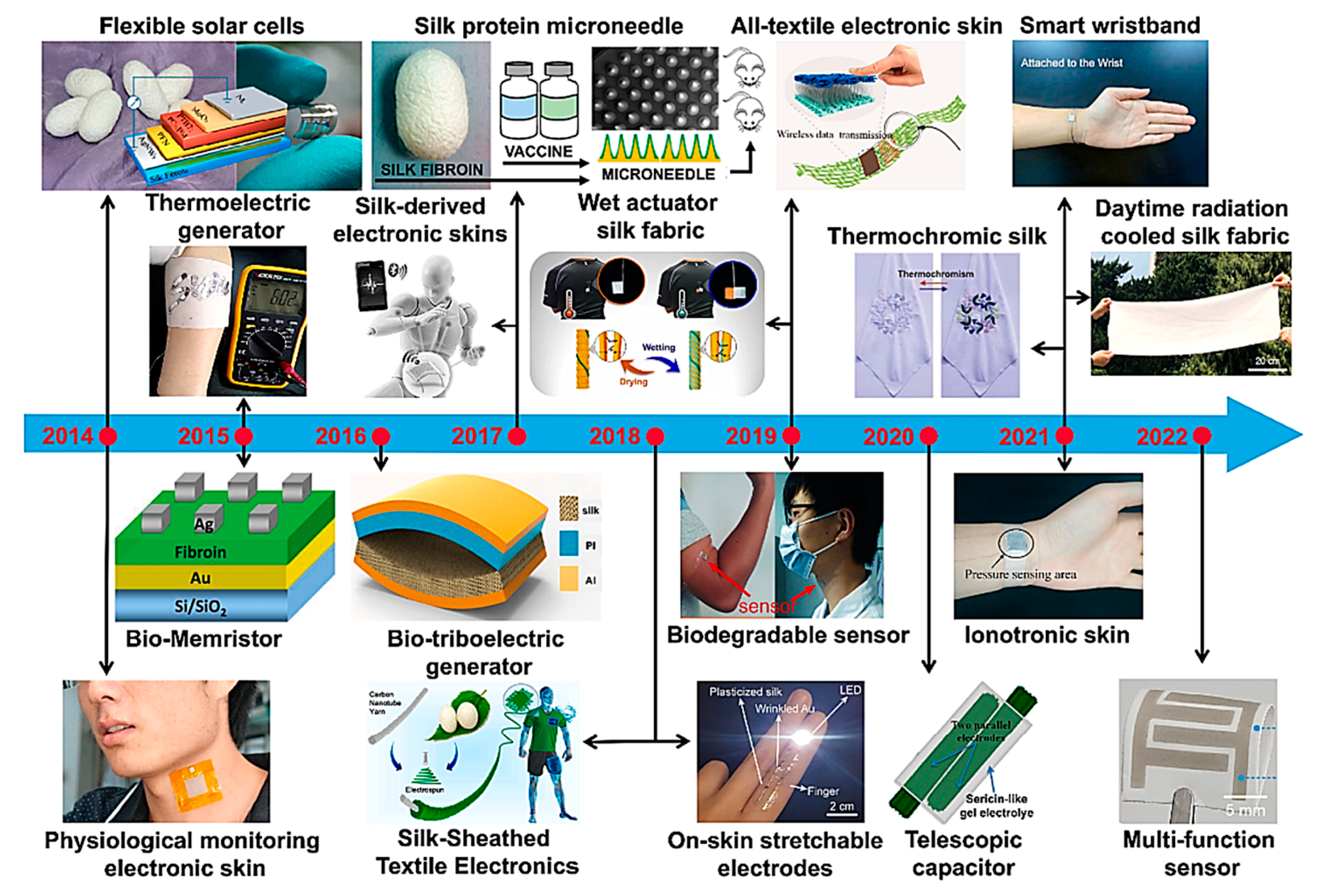

4. Applications of Conductive Silk Fibroin Materials in Smart Wearable Fields

4.1. Motion Detection Devices

4.2. Physiological Signal Detection Devices

4.3. Temperature Sensing Devices

4.4. Wearable Energy Harvesting Devices

4.5. Bio-Integrated Electronic Devices

4.6. Flexible Capacitor Devices

5. Conclusions and Outlook

Funding

Conflicts of Interest

References

- Amft, O.; Lukowicz, P. From backpacks to smartphones: Past, present, and future of wearable computers. IEEE Pervasive Comput. 2009, 8, 8–13. [Google Scholar] [CrossRef]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible electronics toward wearable sensing. Acc. Chem. Res. 2019, 52, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Corzo, D.; Tostado-Blázquez, G.; Baran, D. Flexible electronics: Status, challenges and opportunities. Front. Electron. 2020, 1, 594003. [Google Scholar] [CrossRef]

- Heo, J.S.; Eom, J.; Kim, Y.H.; Park, S.K. Recent progress of textile-based wearable electronics: A comprehensive review of materials, devices, and applications. Small 2018, 14, 1703034. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Li, W.; Hu, X.; Zhang, X.; Huang, X.; Li, Z.; Zhai, X.; Shen, T.; Shi, J.; He, Y.; et al. A novel sustainable biomass-based fluorescent probe for sensitive detection of salicylic acid in rice. Food Chem. 2024, 434, 137260. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Mei, C.; Chen, X.; Li, C.; Hua, Z.; Cui, H. Bio-responsive composite liposomes against Campylobacter jejuni in vitro and its application in chicken preservation. Innov. Food Sci. Emerg. Technol. 2022, 81, 103122. [Google Scholar] [CrossRef]

- Xing, T.; He, A.; Huang, Y.; Luo, Y.; Zhang, M.; Wang, Z.; Shi, G.; Ke, J.; Bai, S.; Zhao, F.; et al. Silk-based flexible electronics and smart wearable textiles: Progress and beyond. Chem. Eng. J. 2023, 474, 145534. [Google Scholar] [CrossRef]

- Pan, J.; Xu, H.; Cheng, Y.; Mintah, B.K.; Dabbour, M.; Yang, F.; Chen, W.; Zhang, Z.; Dai, C.; He, R.; et al. Recent insight on edible insect protein: Extraction, functional properties, allergenicity, bioactivity, and applications. Foods 2022, 11, 2931. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Luo, C.; Li, C.; Abdel-Samie, M.A.; Cui, H. Eugenol/silk fibroin nanoparticles embedded Lycium barbarum polysaccharide nanofibers for active food packaging. Food Packag. Shelf Life 2022, 32, 100841. [Google Scholar] [CrossRef]

- Xu, H.; Pan, J.; Ma, C.; Mintah, B.K.; Dabbour, M.; Huang, L.; Dai, C.; Ma, H.; He, R. Stereo-hindrance effect and oxidation cross-linking induced by ultrasound-assisted sodium alginate-glycation inhibit lysinoalanine formation in silkworm pupa protein. Food Chem. 2025, 463, 141284. [Google Scholar] [CrossRef] [PubMed]

- Shang, L.; Yu, Y.; Liu, Y.; Chen, Z.; Kong, T.; Zhao, Y. Spinning and applications of bioinspired fiber systems. ACS Nano 2019, 13, 2749–2772. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.Z.; Confalonieri, F.; Jacquet, M.; Perasso, R.; Li, Z.G.; Janin, J. Silk fibroin: Structural implications of a remarkable amino acid sequence. Proteins Struct. Funct. Bioinform. 2001, 44, 119–122. [Google Scholar] [CrossRef] [PubMed]

- Koh, L.D.; Cheng, Y.; Teng, C.P.; Khin, Y.W.; Loh, X.J.; Tee, S.Y.; Low, M.; Ye, E.; Yu, H.D.; Zhang, Y.W.; et al. Structures, mechanical properties and applications of silk fibroin materials. Prog. Polym. Sci. 2015, 46, 86–110. [Google Scholar] [CrossRef]

- Qiu, W.; Patil, A.; Hu, F.; Liu, X.Y. Hierarchical structure of silk materials versus mechanical performance and mesoscopic engineering principles. Small 2019, 15, 1903948. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yao, L.; Zhang, L.; Zhang, Y.; Zheng, T.; Liu, L.; Zhang, L. Enhanced physicochemical stabilities of cyanidin-3-O-glucoside via combination with silk fibroin peptide. Food Chem. 2021, 355, 129479. [Google Scholar] [CrossRef] [PubMed]

- Na, D.; Choi, J.; Lee, J.; Jeon, J.W.; Kim, B.H. Commercial silk-based electronic yarns fabricated using microwave irradiation. ACS Appl. Mater. Interfaces 2019, 11, 27353–27357. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ai, X.; Lu, S.; Xing, T.; Qi, N.; Chen, G. Fabrication of a type of silk/PEDOT conductive fibers for wearable sensor. Colloid Surface A 2021, 625, 126909. [Google Scholar] [CrossRef]

- Lu, Z.; Mao, C.; Zhang, H. Highly conductive graphene-coated silk fabricated via a repeated coating-reduction approach. J. Mater. Chem. C 2015, 3, 4265–4268. [Google Scholar] [CrossRef]

- Meng, C.; Jiang, W.; Huang, Z.; Liu, T.; Feng, J. Fabrication of a highly conductive silk knitted composite scaffold by two-step electrostatic self-assembly for potential peripheral nerve regeneration. ACS Appl. Mater. Interfaces 2020, 12, 12317–12327. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, D.; Kong, D.; Gautrot, J.; Vootla, S.K. Fabrication and characterization of conductive conjugated polymer-coated Antheraea mylitta silk fibroin fibers for biomedical applications. Macromol. Biosci. 2017, 17, 1600443. [Google Scholar]

- Wang, C.; Xia, K.; Zhang, Y.; Kaplan, D.L. Silk-based advanced materials for soft electronics. Acc. Chem. Res. 2019, 52, 2916–2927. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Xu, M.; Yadavalli, V.K. Silk fibroin-sheathed conducting polymer wires as organic connectors for biosensors. Biosensors 2019, 9, 103. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Liao, X.; Cui, H. Cold plasma treated thyme essential oil/silk fibroin nanofibers against Salmonella Typhimurium in poultry meat. Food Packag. Shelf Life 2019, 21, 100337. [Google Scholar] [CrossRef]

- Yin, Z.; Jian, M.; Wang, C.; Xia, K.; Liu, Z.; Wang, Q.; Zhang, M.; Wang, H.; Liang, X.; Long, Y.; et al. Splash-resistant and light-weight silk-sheathed wires for textile electronics. Nano. Lett. 2018, 18, 7085–7091. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, Y.; Shi, J.; Li, Z.; Wang, X.; Hu, X.; Gong, Y.; Zou, X. A novel gas sensor for detecting pork freshness based on PANI/AgNWs/silk. Foods 2022, 11, 2372. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Xu, J.; Yang, K.; Li, J.; Jin, Z.; Ding, Y.; Zhang, J.; Sun, W.; Tang, Z.; Hong, X. Highly conductive and elastic electronic silk fabrics via 3D textile macro-design and microscopic plasma activation for personal care and information interaction. Adv. Fiber Mater. 2025, 7, 130–143. [Google Scholar] [CrossRef]

- Dong, X.; Liu, Q.; Liu, S.; Wu, R.; Ma, L. Silk fibroin based conductive film for multifunctional sensing and energy harvesting. Adv. Fiber Mater. 2022, 4, 885–893. [Google Scholar] [CrossRef]

- Zulan, L.; Zhi, L.; Lan, C.; Sihao, C.; Dayang, W.; Fangyin, D. Reduced graphene oxide coated silk fabrics with conductive property for wearable electronic textiles application. Adv. Electron. Mater. 2019, 5, 1800648. [Google Scholar] [CrossRef]

- Liang, Y.; Mitriashkin, A.; Lim, T.T.; Goh, J.C.H. Conductive polypyrrole-encapsulated silk fibroin fibers for cardiac tissue engineering. Biomaterials 2021, 276, 121008. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, A.; Pan, Q.; Qian, Y.; Fan, S.; Yao, X.; Song, L.; Zhu, B.; Zhang, Y. Transparent conductive silk film with a PEDOT-OH nano layer as an electroactive cell interface. ACS Biomater. Sci. Eng. 2021, 7, 1202–1215. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Liu, J.; Gao, Y.; Xu, Z.; Dai, C.; Li, G.; Sun, C.; Yang, Y.; Zhang, K. Conductive biocomposite hydrogels with multiple biophysical cues regulate schwann cell behaviors. J. Mater. Chem. B 2022, 10, 1582–1590. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Zhang, Y.; Zhu, M.; Li, S.; Liang, H.; Bi, P.; Wang, S.; Wang, H.; Gan, L.; Wu, X.E.; et al. Intelligent perceptual textiles based on ionic-conductive and strong silk fibers. Nat. Commun. 2024, 15, 3289. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Han, Y.; Lv, S. Design of self-healing and electrically conductive silk fibroin-based hydrogels. ACS Appl. Mater. Interfaces 2019, 11, 20394–20403. [Google Scholar] [CrossRef] [PubMed]

- Yao, M.; Su, D.; Wang, W.; Chen, X.; Shao, Z. Fabrication of air-stable and conductive silk fibroin gels. ACS Appl. Mater. Interfaces 2018, 10, 38466–38475. [Google Scholar] [CrossRef] [PubMed]

- Gogurla, N.; Sinha, A.K.; Naskar, D.; Kundu, S.C.; Ray, S.K. Metal nanoparticles triggered persistent negative photoconductivity in silk protein hydrogels. Nanoscale 2016, 8, 7695–7703. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Liu, H.; Nail, A.; Meng, D.; Zhu, L.; Li, C.; Li, H. Design and Application of Stimuli-Responsive Nanocomposite Hydrogels: A Review. Macromol. Rapid Commun. 2025, 46, 2401095. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Wu, J.; Li, C.; Chen, X.; Cui, H. Fabrication of a dual-response intelligent antibacterial nanofiber and its application in beef preservation. LWT 2022, 154, 112606. [Google Scholar] [CrossRef]

- Xu, H.; Pan, J.; Dabbour, M.; Mintah, B.K.; Chen, W.; Yang, F.; Zhang, Z.; Cheng, Y.; Dai, C.; He, R.; et al. Synergistic effects of pH shift and heat treatment on solubility, physicochemical and structural properties, and lysinoalanine formation in silkworm pupa protein isolates. Food Res. Int. 2023, 165, 112554. [Google Scholar] [CrossRef] [PubMed]

- Wahab, A.; Gogurla, N.; Park, J.Y.; Kim, S. Architecting Silk Protein and Melanin for Photoresponsive and Self-Healable Optoelectronic Skins. Adv. Mater. Technol. 2022, 7, 2101271. [Google Scholar] [CrossRef]

- Yucel, T.; Cebe, P.; Kaplan, D.L. Structural origins of silk piezoelectricity. Adv. Funct. Mater. 2011, 21, 779–785. [Google Scholar] [CrossRef] [PubMed]

- Zhen, W.; Chen, J.; Fan, S.; Zhang, Y. Piezoelectric fibers based on silk fibroin with excellent output performance. Chin. Phys. B 2024, 33, 088701. [Google Scholar] [CrossRef]

- Fu, F.; Liu, D.; Wu, Y. Silk-based conductive materials for smart biointerfaces. Smart Med. 2023, 2, e20230004. [Google Scholar] [CrossRef] [PubMed]

- Ye, C.; Ren, J.; Wang, Y.; Zhang, W.; Qian, C.; Han, J.; Zhang, C.; Jin, K.; Buehler, M.J.; Kaplan, D.L.; et al. Design and fabrication of silk templated electronic yarns and applications in multifunctional textiles. Matter 2019, 1, 1411–1425. [Google Scholar] [CrossRef]

- Trung, T.Q.; Lee, N.E. Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoring and personal healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Liu, B.; Hu, N.; Fan, Q.; Zhan, F.; Zhang, Z.; Ni, Z.; Li, X.; Hu, T. A biodegradable, highly sensitive and multifunctional mechanical sensor based on rGO-silk fibroin hydrogel for human motion detection and gesture recognition. J. Mater. Chem. A 2024, 12, 3283–3293. [Google Scholar] [CrossRef]

- Xing, C.; Luo, M.; Sheng, Q.; Zhu, Z.; Yu, D.; Huang, J.; He, D.; Zhang, M.; Fan, W.; Chen, D. Silk fabric functionalized by nanosilver enabling the wearable sensing for biomechanics and biomolecules. ACS Appl. Mater. Interfaces 2024, 16, 51669–51678. [Google Scholar] [CrossRef] [PubMed]

- Mirbakht, S.S.; Golparvar, A.; Umar, M.; Kuzubasoglu, B.A.; Irani, F.S.; Yapici, M.K. Highly self-adhesive and biodegradable silk bioelectronics for all-in-one imperceptible long-term electrophysiological biosignals monitoring. Adv. Sci. 2025, 12, 2405988. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Chen, Q.; Liu, Q.; Zhao, B.; Ling, S.; Yao, J.; Shao, Z.; Chen, X. Intelligent silk fibroin ionotronic skin for temperature sensing. Adv. Mater. Technol. 2020, 5, 2000430. [Google Scholar] [CrossRef]

- Ye, C.; Dong, S.; Ren, J.; Ling, S. Ultrastable and high-performance silk energy harvesting textiles. Nano-Micro Lett 2020, 12, 12. [Google Scholar] [CrossRef] [PubMed]

- Liang, M.W.; Wang, W.J.; Jiang, Y.; Liao, C.Y.; Long, Q.; Lai, X.F.; Liao, L. Fabrication of C@Si@G for flexible lithium-ion batteries. J. Alloys Compd. 2021, 878, 160357. [Google Scholar] [CrossRef]

- Cao, L.; Ye, C.; Zhang, H.; Yang, S.; Shan, Y.; Lv, Z.; Ren, J.; Ling, S. An Artificial Motion and Tactile Receptor Constructed by Hyperelastic Double Physically Cross-Linked Silk Fibroin Ionoelastomer. Adv. Funct. Mater. 2023, 33, 2301404. [Google Scholar] [CrossRef]

- Cao, X.; Ye, C.; Cao, L.; Shan, Y.; Ren, J.; Ling, S. Biomimetic spun silk ionotronic fibers for intelligent discrimination of motions and tactile stimuli. Adv. Mater. 2023, 35, 2300447. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Aniruddha, P.; Hou, C.; Lu, D.; Qiu, W.; Kong, L.; Wu, R.; Ma, L.; Yu, R.; Yu, W.; et al. Reconstructed silk fibroin mediated smart wristband for physiological signal detection. Chem. Eng. J. 2022, 428, 132362. [Google Scholar] [CrossRef]

- Wu, R.; Ma, L.; Hou, C.; Meng, Z.; Guo, W.; Yu, W.; Yu, R.; Hu, F.; Liu, X.Y. Silk composite electronic textile sensor for high space precision 2D combo temperature-pressure sensing. Small 2019, 15, 1901558. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Shi, H.; Wei, H.; Wu, B.; Xia, Q.; Yeo, J.; Huang, W. Engineering natural and recombinant silks for sustainable biodevices. Front. Chem. 2022, 10, 881028. [Google Scholar] [CrossRef] [PubMed]

- Wu, R.; Ma, L.; Liu, X.Y. From mesoscopic functionalization of silk fibroin to smart fiber devices for textile electronics and photonics. Adv. Sci. 2022, 9, 2103981. [Google Scholar] [CrossRef] [PubMed]

- Feng, M.; Wu, Y.; Feng, Y.; Dong, Y.; Liu, Y.; Peng, J.; Wang, N.; Xu, S.; Wang, D. Highly wearable, machine-washable, and self-cleaning fabric-based triboelectric nanogenerator for wireless drowning sensors. Nano Energy 2022, 93, 106835. [Google Scholar] [CrossRef]

- Maxwell, R.; Costache, M.C.; Giarrosso, A.; Bosques, C.; Amin, S. Optimizing interactions between soluble silk fibroin and capryl glucoside for design of a natural and high-performance co-surfactant system. Int. J. Cosmet. Sci. 2021, 43, 68–77. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Kim, J.-T.; Yang, D.S.; Cho, D.; Yoo, S.; Madhvapathy, S.R.; Jeong, H.; Yang, T.; Luan, H.; Avila, R.; et al. Multifunctional materials strategies for enhanced safety of wireless, skin-interfaced bioelectronic devices. Adv. Funct. Mater. 2023, 33, 2302256. [Google Scholar] [CrossRef]

- Kim, T.; Kim, B.J.; Bonacchini, G.E.; Ostrovsky-Snider, N.A.; Omenetto, F.G. Silk fibroin as a surfactant for water-based nanofabrication. Nat. Nanotechnol. 2024, 19, 1514–1520. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Matsuhisa, N.; Liu, Z.Y.; Qi, D.; Cai, P.; Jiang, Y.; Wan, C.; Cui, Y.; Leow, W.R.; Liu, Z.; et al. Plasticizing silk protein for on-skin stretchable electrodes. Adv. Mater. 2018, 30, 1800129. [Google Scholar] [CrossRef] [PubMed]

- Yue, L.C.; Gong, M.; Wang, J.P.; Ma, S.Y.; Chen, Q.J.; Kong, X.Y.; Lin, X.; Zhang, L.; Wu, Z.; Wang, D.R. Hygroscopic MXene/protein nanocomposite fibers enabling highly stretchable, antifreezing, repairable, and degradable skin-like wearable electronics. ACS Mater. Lett. 2023, 5, 2104–2113. [Google Scholar] [CrossRef]

- Bhatta, T.; Maharjan, P.; Cho, H.; Park, C.; Yoon, S.H.; Sharma, S.; Salauddin, M.; Rahman, M.T.; Rana, S.S.; Park, J.Y. High-performance triboelectric nanogenerator based on MXene functionalized polyvinylidene fluoride composite nanofibers. Nano Energy 2021, 81, 105670. [Google Scholar] [CrossRef]

- Wen, D.L.; Sun, D.H.; Huang, P.; Huang, W.; Su, M.; Wang, Y.; Han, M.D.; Kim, B.; Brugger, J.; Zhang, H.X.; et al. Recent progress in silk fibroin-based flexible electronics. Microsyst. Nanoeng. 2021, 7, 35. [Google Scholar] [CrossRef] [PubMed]

| Conductive Modification Method | Conductivity Range | Mechanical Stability | Biodegradation Performance | Fabrication Difficulty |

|---|---|---|---|---|

| Surface-Conductive Layer-Coated Silk Fibers | 10−2–103 S/m | Low: Conductive layer prone to delamination | Reduced: Outer coating impedes core degradation | Low |

| Reverse-Coated Conductive Fibers (Core/Sheath) | 102–104 S/m | High: Excellent impact/damage resistance | Moderate: Sheath structure fully degradable | High |

| Electro-Deposited Silk Fibroin Films | 10−1–103 S/m | Moderate: Superior to fibers, but susceptible to delamination | Variable: Highly dependent on environmental conditions | Low |

| Silk Fibroin-Based Conductive Hydrogels (incl. Composites) | 10−3–10−1 S/cm | Highest: Superior extensibility and self-healing capability | Excellent | High |

| Silk Fibroin Piezoelectric Materials | Negligible | Variable: Strongly influenced by internal microstructure | Excellent | High |

| Conductive Filler | Degradation Products | Degradation Period | Biological Toxicity Analysis |

|---|---|---|---|

| Carbon Nanotubes | Polycyclic aromatic hydrocarbons (PAHs), CO2 | 6–12 months | Incompletely degraded residues may induce cellular damage and possess carcinogenic potential. |

| Graphene-based | |||

| Silver Nanomaterials | Metal ions (Ag+), metallic compounds | 3–6 months | Silver ions exhibit mitochondrial toxicity and neurotoxicity. |

| Copper Nanomaterials | |||

| Polyaniline (PANI) | Aniline dimers, quinone derivatives | 1–3 months | Degradation products are potentially carcinogenic. |

| Polypyrrole (PPy) | Nitrate ions, pyrrolidone derivatives | 2–4 months | Degradation products may induce DNA damage in cells. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Wang, Z.; Hu, P.; Yuan, L.; Zhang, F.; Liu, L. Advances in Conductive Modification of Silk Fibroin for Smart Wearables. Coatings 2025, 15, 829. https://doi.org/10.3390/coatings15070829

Yang Y, Wang Z, Hu P, Yuan L, Zhang F, Liu L. Advances in Conductive Modification of Silk Fibroin for Smart Wearables. Coatings. 2025; 15(7):829. https://doi.org/10.3390/coatings15070829

Chicago/Turabian StyleYang, Yuhe, Zengkai Wang, Pu Hu, Liang Yuan, Feiyi Zhang, and Lei Liu. 2025. "Advances in Conductive Modification of Silk Fibroin for Smart Wearables" Coatings 15, no. 7: 829. https://doi.org/10.3390/coatings15070829

APA StyleYang, Y., Wang, Z., Hu, P., Yuan, L., Zhang, F., & Liu, L. (2025). Advances in Conductive Modification of Silk Fibroin for Smart Wearables. Coatings, 15(7), 829. https://doi.org/10.3390/coatings15070829