Abstract

This study investigates the nanomechanical and tribological behavior of multilayered nitride/carbonitride nanostructured superlattice type coatings (NTCs) composed of alternating TiAlSiNb-N and TiCr-CN sublayers, deposited via high-power ion-plasma magnetron sputtering (HiPIPMS) technique. Reinforced with refractory elements Cr and Nb, the NTC samples exhibit high nanohardness (39–59 GPa), low friction, and excellent wear resistance. A novel analytical approach was introduced to extract stress–strain field (SSF) gradients and divergences from nanoindentation data, revealing alternating strain-hardening and strain-softening cycles beneath the incrementally loaded indenter. The discovered oscillatory behavior, consistent across all samples under the investigation, suggests a general deformation mechanism in thin films under incremental loading. Fourier analysis of the SSF gradient oscillatory pattern revealed a variety of characteristic dominant wavelengths within the length-scale interval (0.84–8.10) nm, indicating multi-scale nanomechanical responses. Additionally, the NTC samples display an anisotropic coating morphology exhibited as unidirectional undulating surface roughness waves, potentially attributed to atomic shadowing, strain-induced instabilities, and limited adatom diffusion. These findings deepen our understanding of nanoscale deformation in advanced PVD coatings and underscore the utility of SSF analysis for probing thin-film mechanics.

1. Introduction

Nitride/carbonitride superlattice-type coatings surpass amorphous carbon-based films and conventional monolayer coatings in tribological applications. The alternating nanolayers enhance hardness by promoting interfacial bonding and impeding dislocation motion across boundaries, yielding superior mechanical strength to amorphous carbon coatings [1,2], which lack a long-range crystalline structure. This multilayer architecture improves toughness and crack propagation resistance. While amorphous carbon coatings achieve high hardness, they remain brittle under mechanical stress. Conversely, superlattice coatings provide low friction while maintaining excellent wear resistance [3,4,5], as their layered structure distributes stress effectively and enables controlled deformation, reducing wear under severe operational conditions [6,7,8,9].

Here, we investigate the nanomechanical properties of TiAlSiNb-N/TiCr-CN bilayer system for advanced nanostructured tribological coatings (NTCs) produced using an advanced physical vapor deposition (PVD) technique known as high-power ion-plasma magnetron sputtering (HiPIPMS) [10]. This NTC composition combines specific elements and layer types to enhance hardness, toughness, thermal stability, and wear resistance.

The TiAlSiNb-N layer functions as a high-performance nitride, with the base TiAlN system providing high hardness and good oxidation resistance [11]. Silicon (Si) addition typically forms a nanocomposite structure—nanocrystalline nc-TiAlN grains embedded in an amorphous a-Si3N4 matrix—which enhances hardness, wear resistance, thermal stability, and oxidation resistance [12]. Silicon can improve the adherence of protective oxide films, thereby reducing wear rates [13], and such nanocomposites have achieved superhardness (e.g., 49.5 GPa in TiAlSiN/AlSiN systems [12]). Niobium (Nb) incorporation imparts several crucial benefits, such as enhanced toughness and thermal stability of TiAlN-based coatings by delaying the formation of detrimental hexagonal AlN phase and slowing diffusion kinetics, which maintains coherency strains and hardness retention. Nb also contributes to strengthening in TiMe-CN/TiAlSi-N systems (where Me=Nb), with microhardness values up to 3000 HV [10], and improves corrosion resistance in related systems like TiNbCN [13,14].

The TiCr-CN layer serves as a complementary carbonitride. The base TiCN system offers inherent wear resistance, hardness, and ductility [15]. Chromium (Cr) addition elevates hardness (up to 40 GPa in TiCrCN), improves wear and corrosion resistance, and can produce very low friction coefficients [15]. Cr enhances the thermal stability of TiN-based structures [16], and CrN itself is hard and wear-resistant [17]. Related TiCrN coatings demonstrate high hardness (26–31 GPa) and good wear resistance, optimized at specific Cr/Ti ratios [16].

The bilayer configuration provides synergistic benefits beyond individual layer properties. Interfaces in multilayer systems enhance mechanical properties by impeding dislocation of motion, deflecting cracks, and managing internal stresses. The combination of TiAlSiNb-N (optimized for hardness, thermal stability, and toughness) with TiCr-CN (designed for wear resistance and potentially low friction) aims to create a coating with balanced superior performance. Diffused interfaces in TiN/TiAlN multilayers increase wear resistance [18], while TiAlN/CrN multilayers exhibit higher hardness through interface strengthening [19,20].

Compared to other advanced nitride/carbonitride superlattices, the TiAlSiNb-N/TiCr-CN system offers unique optimization. TiAlSiN-based multilayers (TiAlSiN/AlSiN, TiAlSiN/NiCr, and TiAlSiN/VSiN) achieve high hardness (41–49.5 GPa) with good high-temperature hardness retention [12]. Our TiAlSiNb-N layer targets similar attributes with enhanced toughness and thermal stability from Nb, while the TiCr-CN counter-layer offers potentially superior wear and friction characteristics. TiAlN/CrN multilayers have shown high hardness (16–36 GPa, sometimes with Nb implantation) and good interface strength [19], whereas our system advances this by using the more complex TiAlSiNb-N for superior properties and TiCr-CN instead of CrN for better chemical compatibility and distinct tribological behavior.

Similar {TiMe-CN/TiAlSi-N}n (Me=Hf or Nb) systems have demonstrated high microhardness and significantly improved wear resistance [10]. Our approach differs through strategic elemental distribution by incorporating Nb specifically into the TiAlSi-N layer while alloying Cr into the Ti-CN layer. This tailored configuration leverages Nb primarily for enhancing toughness and thermal stability in the nitride layer and Cr for optimizing tribological performance in the carbonitride layer—which may differ from configurations where Nb is primarily in the carbonitride phase.

The successful realization of such a complex coating, however, is highly dependent on the precise control of the PVD process parameters, which govern the individual layer thicknesses, interface quality, stoichiometry, and phase constitution within each layer. This inherent complexity and the potential for achieving a unique combination of properties underscore the necessity for detailed experimental investigation, as the nanomechanical behavior of this advanced multilayered coating system has not yet been adequately elucidated.

The primary focus of this research was on the nanomechanical properties of the NTC samples, using depth-sensing nanoindentation techniques complemented by preliminary tribological measurements. Surface-near regions of coatings at shallow indentation depths often exhibit heterogeneity, complicating the measurement of consistent hardness and elastic modulus values [5]. This heterogeneity may result from reverse indentation size effects [1,2,8], structural imperfections, or substrate influence on thin coating properties [6,9,10]. In such cases, typically used analytical approaches have significant limitations, and it is valuable to analyze the local stress–strain field (SSF) gradient and divergence caused by microstructural inhomogeneities to gain deeper insight into the nanomechanical behavior of the coatings. We propose a straightforward method to extract the local SSF gradient and divergence information from nanoindentation data. These strain-gradient representations can reveal subtle structural heterogeneities, including interfaces between mechanically distinct micro-zones (such as sublayer interfaces in superlattice structures) and grain boundaries within sublayers in surface-near regions. Applied to NTCs, this SSF gradient-divergence method identified strain-hardening and strain-softening processes occurring beneath the indenter during nanoindentation.

2. Materials and Methods

2.1. Preparation of the NTC Samples

Thin-film coatings were successfully deposited onto 100Cr6-bearing steel substrates using the advanced PVD technique denoted here as high-power ion-plasma magnetron Sputtering (HiPIPMS). This process was conducted within a thin-film modular deposition system (TF-MDS) [10]. HiPIPMS, a cutting-edge PVD technique, achieves a discharge power density exceeding 60 W/cm2 in the erosion zone of the magnetron sputtering target (MST). This high-power density is critical for achieving equal sputtering rates of various materials, including transition metals with differing sputtering yields during PVD processes [10].

The magnetron sputtering devices (MSDs) used in the HiPIPMS deposition process were equipped with MSTs without backing plates. This differs from conventional DC PVD methods, which utilize MSTs with backing plates and insufficiently effective water-cooling systems with low flow rates beneath the backing plate. Importantly, achieving a discharge power density beyond the 60 W/cm2 threshold in conventional setups is unattainable due to technological limitations. In contrast, HiPIPMS systems employ MSDs with magnetic field strength exceeding 800 mT and MSTs without backing plates. These devices are supported by highly efficient, bubble-free water-cooling systems, delivering high flow rates directly beneath the copper membrane of the MST. During the PVD process, the cooling water pressure at the MSD inlet was maintained at approximately 4–5 bars.

Conventional PVD methods are limited by their inability to provide a discharge power density greater than 40 W/cm2 in the MST’s erosion zone. This value is insufficient to achieve equal sputtering rates for mosaic-type MSTs composed of different materials [10]. At power densities below this threshold, the sputtering rates are primarily determined by the sputtering yields of the MST components. Consequently, controlling the atomic ratio of the sputtered particles in the vapor phase becomes challenging, complicating the deposition of coatings with complex chemical compositions. This limitation restricts the broader application of conventional PVD techniques.

Additionally, the production of mosaic-type MSTs from transition or refractory metals presents significant challenges in terms of alloying or pressing materials into targets with precise chemical compositions and geometric shapes. For example, producing coatings with carbon and a transition metal requires separate sputtering of graphite and chromium targets. This approach necessitates solving complex issues, such as optimizing target geometry, selecting sputtering rates, and fine-tuning process parameters to ensure uniform atomic vapor mixing and homogeneous coating deposition. Separate sputtering is particularly problematic for coatings with three or more components, where sputtering coefficients vary significantly, with parameters such as gas pressure, temperature, magnetic permeability, current, and discharge voltage.

The HiPIPMS-PVD process overcomes these limitations by precisely controlling critical parameters including (i) base pressure in the vacuum chamber before deposition, pb = 0.129 mPa; (ii) total operating gas pressure of the Ar/N2 sputtering gas mixture, psg = 0.31 Pa; and (iii) partial nitrogen flow rate, qgN2 = 11.7 L/h. The substrate was prepared by pre-heating and in situ sputter cleaning with collimated linear ion beam etching at 1750 V × 140 mA. Target-to-substrate distance, L, was 78 mm. Substrate temperature varied between 240–390 °C during deposition. The electrical discharge power regime varied between 650–690 V × 7.6–10.7 A, depending on the sputtering gas ratio, MST design, and its surface area. The DC discharge power density exceeded 60 W/cm2, enabling equal-rate sputtering for mosaic-type MSTs [10]. The deposition rate was maintained at 180 nm/min during 2D substrate rotation. Negative bias voltage was held at 95 V, with a bias current of 310–490 mA, depending on discharge power. Careful control of these parameters enabled precise execution of the HiPIPMS-PVD process, facilitating efficient MST sputtering and the growth of NTCs with tailored properties.

2.2. Nanoindentation Hardness Testing Experiment

The nanoindentation response of the nanostructured tribological coatings (NTCs), including load–displacement, P/h-curves, nanohardness (H), and elastic modulus (E), was measured using the TriboIndenter system TI980 (Bruker Nano Surfaces, Minneapolis, MN, USA), equipped with a sharp diamond Berkovich indenter and a Herzan™ AVI-200 S/LP active vibration isolation system (Irvine, CA, USA). This system comprises a control unit and two rails positioned on either side of the granite base within an acoustic enclosure. Each rail contains four piezo-electric accelerometers that continuously monitor vibrations through an internal feedback loop. Vibration damping is achieved through a dual mechanism: four electro-dynamic transducers apply counteracting forces to attenuate low-frequency vibrations (0–200 Hz), while higher-frequency vibrations are passively dampened by the mass of the granite base in conjunction with the spring system integrated within the rails. To ensure comprehensive surface assessment, 10 positions were selected within the chosen indentation matrix for testing peak load (Pmax) and 10 load–displacement (P-h) loops were measured in load interval (0, Pmax).

Thus, a series of load-controlled nanoindentation experiments were conducted at the selected peak load of 100 µN. The segment time was kept constant, and the load function was used by the segment time within the load interval between zero and peak load. The test time for each single successive measurement was kept consistent for all the load–displacement curves independently of the testing load. The segment time parameter determined the duration of each hardness testing experiment, with the loading rate being automatically calculated. Data acquisition was performed using the Hysitron TriboScan TI 10.0.0.2 software, while the Tribo-IQ Indentation Explorer 1.0.0.2 software was utilized for data processing and calculation of mechanical properties.

Load–displacement data were processed using the bin-averaging approach, with a bin width of 0.25 nm to mitigate measurement noise. This technique involves segmenting data into fixed-width intervals, calculating the arithmetic mean within each interval, and using these averages to represent the corresponding segments. This approach effectively reduces random fluctuations while preserving the underlying mechanical response characteristics.

Before the nanoindentation experiments, the TI980 instrument was calibrated using a reference sample of fused silica. Following calibration, the elastic modulus, hardness, and standard deviations of the load–displacement measurements were calculated based on the experimentally obtained loading–unloading datasets. These calculations were performed using the established instrumented depth-sensing data set treatment methods, with the TriboIQ Indentation Explorer software facilitating the analysis [21,22,23,24,25,26,27,28,29,30,31,32,33].

2.3. Tribological Tests of the NTC Samples

The tribological performance of the nanostructured tribological coating (NTC) samples was evaluated using a ball-on-disc tribometer (TRB3 model, CSM Instruments SA, Peuseux, Switzerland). These tests were conducted under dry friction conditions following the guidelines specified in ISO standards, which outlines the procedure for determining the friction and wear characteristics of diamond-like carbon films using the ball-on-disc method.

A 100Cr6 steel ball with a 6 mm diameter was used as the static friction partner, a widely adopted standard in tribological studies to ensure consistency and facilitate comparisons with a variety of previous research [10,20,34,35].

The experimental parameters included: (i) a sliding distance of 100 m; (ii) an applied load of 3 N; (iii) a wear track radius of 3 mm; and (iv) a linear sliding speed of 0.05 m/s. All tests were executed at a controlled temperature of 22 ± 1 °C. A steady-state coefficient of friction (CoF) was used to compare coatings’ friction properties. Steady-state CoF values were determined from regions of the CoF vs. time curves that exhibited stable values over a distance not less than twenty meters, designated as plateau regions. For a section to qualify as a plateau region, the relative standard deviation (standard deviation/average) of CoF values was maintained below 10% for each test. We report the test results as the average CoF value ± standard deviation.

After the tribological tests, the wear track profiles on the samples were analyzed at four evenly spaced locations using a profilometer (Surftest SJ-500, Mitutoyo, Kawasaki, Japan). The worn cross-sectional areas of the wear tracks were calculated using MCube Map Ultimate 8.0 software (Mitutoyo, Kawasaki, Japan) [10,28,29]. The specific wear rate of the NTC samples was determined by averaging the cross-sectional area values from all four locations.

The wear on the static friction partner (100Cr6 steel ball) was measured using a digital microscope (KH-7700, Hirox, Tokyo, Japan).

2.4. Electron Microscopy Examinations of the NTC Samples

The morphology of the NTC sample structures was investigated with a scanning electron microscope (SEM) Lyra3 (Tescan, Czech Republic, Brno), equipped with an energy-dispersive X-ray spectrometer (EDS), AZtecCrystal (Oxford Instruments, United Kingdom). SEM and EDS measurements were performed using a beam-accelerating voltage of up to 30 kV and a beam current of 500 pA.

2.5. Surface Roughness Evaluation Combining 2D Roughness Measurements and SEM Imaging

Two-dimensional roughness measurements were performed for the reference sample using a Surftest SJ-500 (Mitutoyo, Japan) roughness tester. Roughness measurement conditions were set according to ISO 21920-3:2021 (Geometrical product specifications (GPS) Surface texture: Profile—Part 2: Terms, definitions, and surface texture parameters). Three profiles were measured from the reference sample center towards its outer perimeter, and average Ra (arithmetic mean deviation of the profile), Rq (root mean square deviation of the profile), and Rz (maximum height of the profile) values were calculated. Thereafter, the SEM micrograph plan view of the same reference sample was examined using ImageJ software 1.52v to transform 2D to 3D roughness values Sa, Sq, and Sz, and to calibrate grayscale values to nanometers.

3. Results and Discussion

3.1. Preparation and Characterization of the NTC Film Samples

We explored the fabrication, characterization, and analysis of the micromechanical properties and tribological performance of nanostructured tribological coatings (NTCs) with a multilayered alternating nitride/carbonitride bilayer substructure. During the deposition of these NTCs using the reactive HiPIPMS process, enhancements were introduced to the nitride/carbonitride bilayered structure TiAlSiNb-N/TiCr-CN by alloying with refractory metals Cr and Nb. These modifications were intended to reinforce the core bilayer architecture of the NTCs. The chemical composition of the bi-layered structure of the NTC superlattice was determined according to the MSD-MST configuration used in the relevant PVD process and SEM imaging.

Custom-designed mosaic-type magnetron sputtering targets (MSTs) were developed to implement these bilayer structures. These MSTs incorporated Cr and Nb inserts positioned strategically within the annular erosion zone of circular planar MSTs [23]. Combined with the arrangement of the MSTs and the rotating carousel mechanism of the substrate holder, this configuration facilitated the deposition of superlattice-type nanostructured coatings with a period of about 17–20 nm.

Nanoindentation experiments were conducted using the TriboIndenter apparatus model TI980, yielding experimental datasets of load–displacement loops (LDLs). A total of 60 nanoindentation experiments with six NTC samples (Table 1) were performed, with the load–displacement data obtained at the testing peak loads of 100 µN. For each NTC sample, an indentation matrix was localized on the sample surface by careful microscopic examination. The indentation matrix contained 10 positions with controllable coordinates (Xi, Yi), which were chosen using an optical microscope and selecting the smoothest possible surface area. Positions were spaced about 4500 nm apart to prevent potential mutual influence between neighboring positions caused by indentation. Thus, 10 indentation experiments were performed with each NTC sample, and load–displacement data for the corresponding 10 LDL were obtained, containing 2600 measurement readings in successive loading, drift, and unloading segments. All experiments were performed in one session so that the measurement conditions were maximally identical, and results were safely comparable between all NTC samples.

Table 1.

Overview of the nanomechanical and tribological properties of NTC samples.

An increase in the substrate temperature from 240 °C to 390 °C during the PVD process influenced the calculated contact nanohardness of the NTC samples. Higher substrate temperatures, e.g., 390 °C, resulted in a noticeable increase in coating hardness, primarily due to improved microstructure, favoring stress–strain state, and interfacial quality of mutual compliance of sublayers. Higher substrate temperatures increase adatom surface diffusion because adatoms can move more freely across the substrate, finding energetically favorable accommodation sites, which might lead to larger grains and denser films. Conversely, temperatures around 250 °C are too low for significant surface diffusion. If the substrate temperature is too low, adatoms do not move much, leading to more defects and porous structures. Therefore, temperature affects how much the adatoms can move and arrange themselves, competing with shadowing effects.

Grain refinement, solid solution strengthening, and precipitation hardening might play critical roles in determining strengthening mechanisms contributing to the enhanced nanohardness observed in our NTC samples. Grain refinement contributes to strengthening through the Hall–Petch effect, where grain boundaries act as barriers to dislocation movement. Solid solution strengthening occurs as refractory elements (Cr and Nb) dissolve into the host lattice, creating distortion fields that impede dislocation motion. Precipitation hardening results from the formation of fine, hard precipitates that serve as obstacles to dislocation propagation. While a comprehensive investigation of these mechanisms exceeds our current research scope, their relative contributions are likely influenced by the superlattice architecture, composition, and processing conditions.

3.2. Scanning Electron Microscopy Examinations of the NTC Film Samples

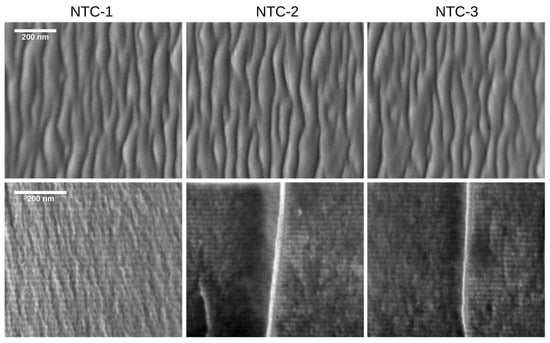

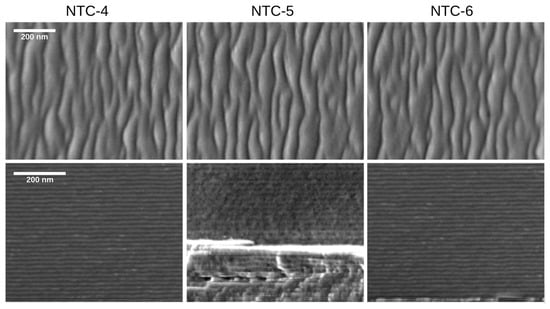

The SEM plan view micrograph study of the bilayered nitride/carbonitride superlattice NTC film samples revealed a one-directional undulating pattern. The wavelengths of the undulations span between 0.98 and 79.82 nm, while the average wavelength was 53.96 nm for the NTC-1 sample. The narrow bands run through the entire image height of 1476 nm. Thus, the fine-grained nodule-like morphology pattern contains very pronounced narrow bands, which could be characterized as having a very high aspect ratio of about 27:1. The one-directional undulating surface pattern suggests that the coating morphology is governed by a combination of atomic-scale self-organization mechanisms, strain effects, and directional growth influences (Figure 1 and Figure 2). The one-directional undulating morphology pattern did not depend on the substrate temperature.

Figure 1.

SEM micrographs of plan-view (top panel) and cross-sectional view (bottom panel) of the NTC film samples NTC-1, NTC-2, and NTC-3. The scale bars correspond to 200 nm for all the NTCs. SEM micrographs revealed film growth mechanisms leading to anisotropic coating morphology that presents itself as a one-directional undulating surface roughness pattern.

Figure 2.

SEM micrographs of plan-view (top panel) and cross-sectional view (bottom panel) of the NTC film samples NTC-4, NTC-5, and NTC-6. The scale bars correspond to 200 nm for all the NTCs. SEM micrographs revealed film growth mechanisms leading to anisotropic coating morphology that presents itself as a one-directional undulating surface roughness pattern.

Several interconnected mechanisms could be responsible for the observed pattern. An atomic shadowing effect during the PVD deposition process, due to the sputtered material flux arriving at the substrate at an angle rather than a perfectly normal incidence, could result in preferential growth directions, where some regions receive more flux and grow faster, leading to an undulating or rippled structure. The undulations could be further amplified by self-shadowing, reinforcing surface roughness.

Additionally, strain-driven surface instabilities may contribute to the undulating pattern as well. The bilayered {TiAlSiNb-N/TiCr-CN}n superlattice structure introduces internal stress variations due to the alternating composition, with a strain gradient across sublayers. Surface undulations can develop to relieve compressive stresses, which might be an example of the Asaro–Tiller–Grinfeld instability [24,25,26], where surface perturbations grow due to anisotropic stress relaxation.

The undulating pattern with nanometer-scale wavelengths indicates that limited surface diffusion also plays a significant role. Because adatoms have limited mobility, roughness increases over time due to kinetic roughening. Comparably low-temperature deposition or high deposition rates can enhance this effect, reinforcing the undulating pattern. Finally, the bilayered superlattice nature of the NTC film samples could contribute to periodic growth modulation as well.

In summary, we propose a possible NTC growth model based on a competitive columnar growth mechanism against a strain-driven instability factor. At the initial phase of the PVD process, growth starts with a fine nucleation stage, forming an initial separate grain-island structure. Atomic shadowing contributes to local thickness variations, and columnar growth is the initially dominating mechanism. Further, as alternating TiAlSiNb-N/TiCr-CN sublayers of the NTC are deposited, strain accumulates at their interfaces. This excessive strain induces the formation of periodic wavelength-modulated structures. Since the adatom mobility is usually limited, kinetic roughening can reinforce undulations. The self-organized nature of morphology suggests anisotropic diffusion-driven instability.

The morphological anisotropy discussed above likely produces direction-dependent frictional behavior or anisotropic tribology [36,37,38]. When tribological contact occurs parallel to the undulation ridges, the surface offers reduced resistance, functioning similar to rails and potentially decreasing friction and wear in that direction. Conversely, sliding perpendicular to these undulations requires greater energy to overcome topographical barriers, resulting in higher friction coefficients and possibly increased abrasive wear. Furthermore, the periodic surface roughness (with average wavelengths of 54–57 nm in our samples) may promote stick-slip motion at nano- or microscale contacts. These undulations can interact with asperity sizes or lubricant molecular dimensions, significantly affecting friction dynamics. In dry or boundary lubrication regimes, such one-directional undulations may provide an additional benefit by channeling lubricants along specific directions, enhancing hydrodynamic lubrication along these paths while restricting it in others.

3.3. Surface Roughness Assessment Combining SEM Imaging and Profilometric Measurements

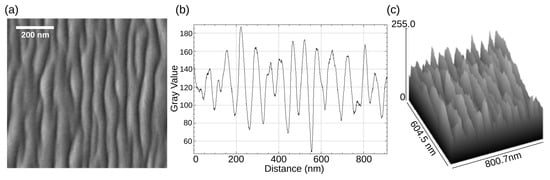

The surface 3D roughness parameters Sa, Sq, and Sz of the NTC samples were calculated from grayscale values obtained via SEM plan-view micrographs (Figure 3), which were then calibrated by corresponding profilometric measurements of the reference sample.

Figure 3.

Surface 3D roughness evaluation using SEM micrograph regarding NTC-4 sample: (a) SEM micrograph plan-view rectangle X*Y-selection of 800 × 604 nm; (b) average surface roughness profile of the selection in arbitrary units; (c) surface plot of the selection in arbitrary units produced by ImageJ software. SEM analysis reveals an anisotropic one-directional undulating surface roughness pattern with spatial wavelengths ranging from 0.68 nm to 79.82 nm and an average wavelength of 53.96 nm.

In SEM surface images (Figure 3a), the grayscale represents apparent height differences visualized by contrast. Rectangle selections X*Y were made, and average grayscale intensity values along the X axis were calculated, where each value represents the mean grayscale across a vertical slice (Y range) of the selected rectangle. Such an X*Y grayscale intensity can be treated as height, assuming grayscale values correlate with topography, which is the common approach in the SEM imaging technique under consistent SE-imaging conditions. Thus, the SEM images were used as a true topographical map from which Sa, Sq, and Sz parameters were calculated in arbitrary units, somewhat unlike measurements by AFM or profilometry, producing Saqz-values directly in absolute units. Using a known mapping between grayscale values and height (the relationship between grayscale and height of the reference sample), the X*Y-averaged grayscale surface roughness profiles of the NTC samples were converted to nanometers. The obtained Sa, Sq, and Sz values are presented in Table 2.

Table 2.

Three-dimensional surface roughness parameters Saqz-values in nm of the NTC samples.

As expected, the obtained Sa, Sq, and Sz values were relatively high due to the steel substrate’s “inherent” surface roughness, i.e., after its polishing and cleaning and before implementation of the PVD process. We observed that despite the intensive PVD process, when the film thickness reached a few microns, the NTC samples retained some of the imperfections of the initial polished steel substrate, such as shallow scratches, grooves, pitting, and indentations. In other words, the NTC samples copied the initial polished steel substrate texture. Overall, NTC-1, NTC-4, NTC-5, and NTC-6 exhibited comparatively lower surface roughness, whereas the NTC-2 and NTC-3 samples’ surface roughness could be playing some disruptive influence on the indentation data acquired at shallow indentation depths.

3.4. Nanoindentation Response Analysis Using the Loading Segment P/h Curves Obtained at the Testing Peak Load of 100 µN

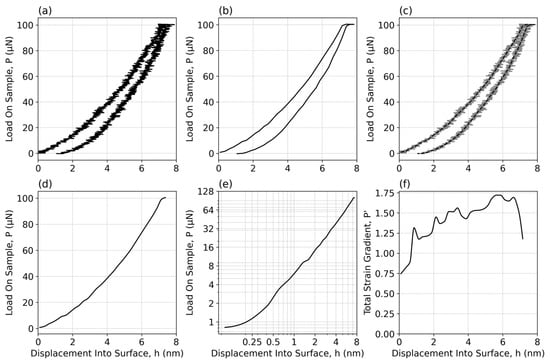

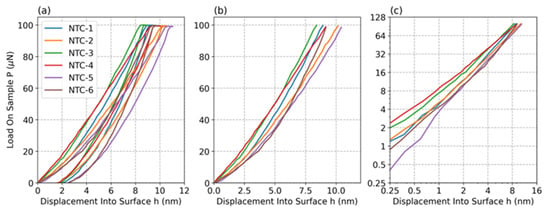

Load–displacement loop (LDL) data, P/h, obtained at the testing peak load of 100 µN, were pre-processed before any further analysis by applying low-pass filtering to minimize the influence of measurement fluctuations that are prominent at lower testing peak loads. Still, it was somewhat challenging to calculate the contact hardness, h values, of the NTC samples very near the sample surface (i) to minimize the potential influence of the comparably soft 100Cr6-steel substrates on the P/h testing readings, (ii) to overcome the comparably high surface roughness which is usually present due to steel substrate “inherent” roughness even after its careful polishing, and finally (iii), at the same time, to eliminate the fluctuations of the P/h testing readings caused by indentation process itself at very low testing peak loads. To this end, a simple bin-averaging approach was used with a bin-width of 0.25 nm (Figure 4).

Figure 4.

Individual LDL obtained during the indentation experiment at the testing peak load of 100 µN (a) LDL data as-measured before pre-processing; (b) the same LDL after low-pass filtering applying the bin-averaging method; (c) LDL aligned both as measured and filtered, demonstrating the effectiveness of the applied low-pass filtering method; (d) filtered P/h curve of the loading segment in conventional linear plot; (e) the same P/h curve in a log–log plot to check its compliance with the power law. (f) P′/h-profile fine structure presenting the SSF gradient was derived from the load-displacement indentation data.

We then aimed to better understand the strain-hardening and strain-softening phenomena observed in the NTC film samples during the nanoindentation experiments. This analysis was guided by a simplified mechanical model of elastic–plastic deformation processes, grounded in Hertzian elastic contact theory [39,40,41,42,43]. The measured P/h curves were used to calculate the strain gradient P′/h profiles relating to the stress–strain field (SSF) beneath the loaded indenter as well as the corresponding SSF divergence P″/h profiles [44,45,46]. The estimated P′/h and P″/h profiles revealed irregular oscillatory patterns, which were analyzed using the fast Fourier transform (FFT) technique, a common practice in signal processing and materials science akin to methodologies for surface roughness analysis.

LDLs measured for all NTC samples at a constant test time of 5 ms and pre-processed using the bin-averaging approach are presented in Figure 5a. Loading segments of the LDL (Figure 5b) viewed in log–log coordinates (Figure 5c) can reveal to what extent the load–displacement curves correspond to a power–law relationship across the whole indentation depth. We observed that Meyer’s power law, denoted as P = C*hn, where C and n have been historically considered constant parameters, does not hold at shallow indentation depths below 2 nm. Conversely, Meyer’s power law holds well when displacement, h, exceeds 2 nm, with R-squared values of power law trendlines of about 0.9999 across the h interval of 2–8 nm. In turn, the exponent n, also known as Meyer’s index and measured using power law trendlines within the h interval of 2–8 nm, was 1.5260, 1.3077, 1.4030, 1.1354, 1.3106, and 1.4588 for the NTC-1, NTC-2, NTC-3, NTC-4, NTC-5, and NTC-6 samples, respectively.

Figure 5.

Low-pass filtered LDLs and P/h curves regarding the NTC samples: (a) pre-treated LDLs; (b) pre-treated loading P/h curves in a conventional linear plot; (c) the same P/h curves in a log–log plot to consider their agreement with the power law, which holds well at displacement h values exceeding 2 nm.

Meyer’s index is a valuable indicator of the indentation size effect (ISE), which is always present in nanoindentation testing experiments. When the exponent n is less than 2, it signifies normal ISE behavior. Conversely, when n > 2, it indicates the presence of reverse ISE behavior. At n = 2, ISE is absent for the given material at the applied load interval and corresponding indentation depths. The range of n values observed between 1.1354 and 1.5260 indicates a significant influence of the above-mentioned size-dependent deformation events. The fact that n is significantly less than 2 contrasts with what is typically observed in bulk materials, where n is close to 2 due to the expected quadratic relationship between the projected contact area, A(h), and the indentation depth, h [29,31]. This suggests that the film/substrate system’s mechanical behavior is influenced by nanoscale and microscale deformation effects that deviate from classical bulk material behavior during the self-similar deformation process.

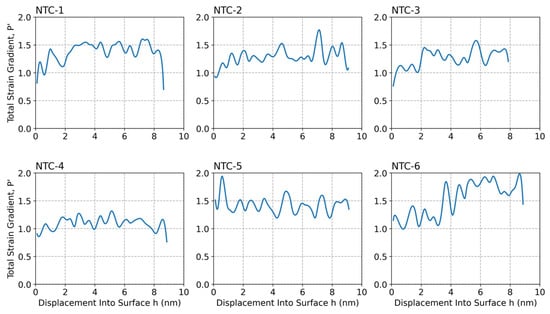

To further characterize the dynamical deformation processes taking place during the nanoindentation experiment, total strain gradient P′/h profiles were derived from the low-pass filtered P/h curves using Meyer’s power–law relationship (Figure 6). P′(h) function was defined as the normalized derivative of P/h-curve in the following way: P′(h) = (h/P) × (dP/dh), which can be considered as the generalized exponent n in Meyer’s power law, i.e., n = P′(h). In addition, the generalized exponent n(h) and the expression for the total strain gradient differ by a constant number of “−2”. Therefore, it can be thought that the exponent n(h) and the total strain gradient describe the same deformation processes occurring under the loaded indenter across the indentation depth. Therefore, we can refer to “total strain gradient” or “P′/h profile” instead of “generalized exponent n”. Historically (since 1908), the parameters C and exponent n in Meyer’s power law have been assumed as constant parameters—an assumption that holds sufficiently well for considerably higher loads causing greater indentation imprint sizes or depths. Here, the P′/h profiles calculated from nanoindentation data allow tracking the deformation processes throughout the entire indentation depth in terms of strain-hardening and strain-softening phenomena.

Figure 6.

The P′/h-profile fine structures presenting the SSF gradient oscillations were derived from the load–displacement P/h curves regarding the NTC samples NTC-1, NTC-2, NTC-3, NTC-4, NTC-5, and NTC-6. Here, the corresponding P′/h-profile hyperfine structures are suppressed due to the low-pass filtering of the load–displacement indentation data.

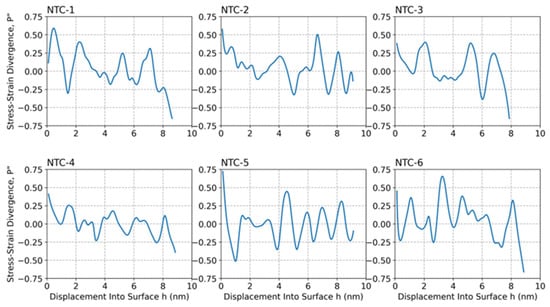

Figure 6 shows the P′/h profiles for all six NTC samples, revealing irregularly oscillating dynamics of the stress-strain field gradient as the indentation depth increases. In turn, Figure 7 shows the P”/h profiles of the stress–strain divergence derived from the relevant P′/h profiles, showing corresponding oscillatory dynamics indicating alternating strain-hardening (P”(h) > 0) and strain-softening cycles (P”(h) < 0) [44,45,46].

Figure 7.

The P″/h-profile fine structures presenting the SSF divergence oscillations around the zero line were derived from the load-displacement P/h curves regarding the NTC samples NTC-1, NTC-2, NTC-3, NTC-4, NTC-5, and NTC-6. Here, the corresponding P″/h-profile hyperfine structures are suppressed due to the low-pass filtering of the load-displacement indentation data.

Due to the oscillatory behavior of the P′/h profiles, Fourier frequency analysis was performed to obtain a deeper insight regarding the deformation processes caused by nanoindentation at these particularly small testing loads and corresponding shallow indentation depths. The Fourier spatial frequency spectrum of the P′/h profiles allowed determining the dominant wavelengths (DWLs) and two characteristic asymptotic wavelengths WL1 (small-scale region) and WL2 (large-scale region), which featured the multilevel length-scale dimensions of the SSF gradient profiles.

The DWLs were extracted from the Fourier spatial wavelength spectrum derived from the fine structures of the P′/h profiles regarding each NTC sample. One can select one, two, three, or even more DWLs based on the power spectral density (PSD) function across the full Fourier spectrum. In this way, relevant DWLs such as DWL1, DWL2, and DWL3 can be identified in descending order of their PSD values. Conversely, WL1 and WL2 represent two characteristic asymptotic wavelengths calculated from the entire Fourier spectrum dataset using the corresponding PSD values. Therefore, WL1 and WL2 values are unique for the given P′/h-profile dataset.

The DWL represents a characteristic scale of variation in the indentation response, which could be influenced by the NTC samples’ microstructure, surface/subsurface features, micromechanical effects, or even experimental conditions. The identified three most prominent DWL1, DWL2, and DWL3 values for the NTC samples were as follows: 1.23, 2.29, and 1.45 nm for the NTC-1; 0.84, 1.23, and 3.21 nm for the NTC-2; 1.43, 4.00, and 2.29 nm for the NTC-3; 4.00, 1.43, and 2.63 nm for the NTC-4; 4.00, 1.60, and 2.00 nm for the NTC-5; and 4.00, 2.29, and 1.45 nm for the NTC-6. The largest DWL values correlate with the one-quarter of the superlattice period, i.e., roughly 17 nm, or are approximately one-third of the maximum indentation depths (hmax) of about 12–15 nm. In turn, the intermediate DWL values likely correspond to the average fine-grained domain size of the NTC microstructure. In contrast, the smallest DWL values of about 1 nm or even less may be associated with the small separate grain size within larger microstructural domains of the coating.

WL1, calculated as the reciprocal value of the weighted average Fourier frequency, for samples NTC-1, NTC-2, NTC-3, NTC-4, NTC-5, and NTC-6 varied between 2.22, 2.20, 1.95, 2.18, 2.50, and 2.45 nm, which correlates well with the undulations of the strain gradient profile structure across the entire indentation depth for each NTC sample. The WL1 length scale between 1.95 nm and 2.50 nm suggests that these values are closely related to the intrinsic alternating strain-hardening and strain-softening deformation mechanisms of the material under indentation.

WL2, determined directly from the Fourier wavelength spectrum as the weighted average wavelength for each NTC sample for the NTC samples NTC-1, NTC-2, NTC-3, NTC-4, NTC-5, and NTC-6 had values of 7.35, 7.46, 6.63, 7.65, 8.10, and 8.00 nm, respectively. Here, as the weighted average WL2 is calculated directly from the wavelength distribution, that procedure produces considerably larger values (~7.3–8.1 nm) than WL1, accenting the large-scale deformation events.

While the dominant wavelengths (~4.1–5.2 nm) represent a characteristic scale that may be linked to larger material structures (e.g., stress fields, subsurface effects, or periodic features in the NTC samples as superlattice bilayered structure), the weighted average wavelength WL1 (~2–3 nm range) seems to reflect finer-scale undulations in the strain gradient-profile fine structures. This difference suggests a multi-scale response: larger-scale structural influences (dominant wavelength) and more localized deformation characteristics (weighted average wavelength). WL2 captures larger-scale deformation patterns and is comparable to the indentation depth, suggesting that the nanoindentation is capturing information about larger-scale material features rather than just the indentation process itself. The WL2 might reflect convoluted properties of the intrinsic material structures, such as grain boundaries, phase separations, or residual stress patterns that extend beyond the indentation depth.

We note that the examination of the SEM micrographs described in the previous sections indicated the presence of an anisotropic, unidirectional undulating surface roughness pattern within the selected X × Y plane, with corresponding spatial wavelength distribution from 0.68 nm to 79.82 nm with an average value of 53.96 nm (Figure 3). While the SSF gradient wavelengths reported here fall within a similar length-scale range, it is important to distinguish that the surface roughness features are confined to the X × Y plane adjacent to sample surface, while the Fourier waves “propagate” perpendicularly to this plane along the Z axis. Owing to their orthogonal orientation, these two types of wave phenomena are non-interacting with each other, and therefore, there is no reason to compare them.

Ultimately, the three length-scale parameters DWL, WL1, and WL2 complement each other. The first two highlight fine-scale effects, while the third one provides a broader view of the deformation field. The choice of them depends on whether we are more interested in localized interactions (smaller wavelengths) or bulk strain distribution (larger wavelengths). The frequency-based methods (DWL and WL1) emphasize fine-scale features and are useful for understanding localized deformation behavior, whereas the wavelength-based method (WL2) provides a more holistic view, likely capturing larger-scale deformation patterns closer to the indentation depth.

4. Conclusions

Mosaic-type HiPIPMS deposition enabled the growth of dense TiAlSiNb-N/TiCr-CN superlattice coatings with contact hardness measured between 39 GPa and 59 GPa depending on the substrate temperature. The NTC film sample superlattice structure, {TiAlSiNb-N/TiCr-CN}n, plays a crucial role in the observed one-directional undulating pattern, likely driven by atomic shadowing effects (directional growth anisotropy), stress-induced Asaro–Tiller–Grinfeld instability (strain relaxation through surface modulations), alternating bilayer deposition influences growth rates, and limited surface diffusion leading to kinetic roughening. This combination creates well-defined nanometer-scale undulations in the NTC morphology shown in SEM micrographs.

Adapting Meyer’s power–law formalism allowed for a consistent description of the indentation size effect (ISE) over the 1–16 nm depth interval. The power law exponent n was shown to vary between samples (1.14 ≤ n ≤ 1.52) but was consistently significantly less than 2, contrasting typical values observed in bulk materials and suggesting that the film/substrate system’s mechanical behavior is influenced by nanoscale and microscale deformation effects that deviate from classical bulk material behavior.

We further introduced a strain gradient–divergence approach leading to decomposition of the load–displacement P/h curves into corresponding P′/h and P″/h profiles, which captures the spatial deformation patterns due to strain-hardening and strain-softening processes occurring under the incrementally loaded indenter. These profiles revealed highly dynamic, irregular oscillatory dynamics caused by the indentation testing experiment. Fourier analysis of the P′/h profiles disclosed three characteristic wavelengths DWL, WL1 and WL2 of about 2.2, 4.9, and 7.7 nm, respectively. The undulating P′/h profile captures a low-pass filtered, smoothened response of the NTC film samples to the indentation process, reflecting the overall trend of the strain-hardening and strain-softening phenomena. It can be viewed as representing the quasi-equilibrium mechanical response of the material, and as such, it is influenced by the inherent micromechanical properties of the nanostructured NTC film samples, for example, (i) elastic–plastic transition, with the undulations of the strain gradient fine structure marking transitions from elastic deformation to plastic flow; (ii) material heterogeneity, with variations in the fine structure likely correlating with structural features such as grain boundaries or sublayer interfaces; and (iii) strain accumulation during progressing loading.

Author Contributions

Conceptualization, U.K., K.K., I.B. and A.K.; investigation, U.K., K.K., E.J., A.L. and J.L.; writing—original draft preparation, U.K. and K.K.; writing—review and editing, U.K., K.K., A.K. and I.B.; visualization, K.K. and U.K.; supervision, A.K.; project administration I.B.; funding acquisition I.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Latvian Council of Science, project “Carbon-rich self-healing multifunctional nanostructured smart coatings (NSC) for high-tech applications using high-power confined plasma technology for their deposition”, project No. 2019/1-0385.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors are grateful to V. Kovalenko for the preparation of the NTC samples, K. Kundzins for SEM measurements, and I. Jerane for conducting the nanoindentation testing experiments.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wu, W.Y.; Ting, J.M. Growth and Characteristics of Metal-Containing Diamond-like Carbon Using a Self-Assembled Process. Carbon 2006, 44, 1210–1217. [Google Scholar] [CrossRef]

- Persson, K.; Gåhlin, R. Tribological Performance of a DLC Coating in Combination with Water-Based Lubricants. Tribol. Int. 2003, 36, 851–855. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Recent Advances of Superhard Nanocomposite Coatings: A Review. Surf. Coat. Technol. 2003, 167, 113–119. [Google Scholar] [CrossRef]

- Musil, J. Hard and Superhard Nanocomposite Coatings. Surf. Coat. Technol. 2000, 125, 322–330. [Google Scholar] [CrossRef]

- Musil, J.; Vlček, J. Magnetron Sputtering of Hard Nanocomposite Coatings and Their Properties. Surf. Coat. Technol. 2001, 142–144, 557–566. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, Y.; Liu, J.; Tian, Y.; Chi, Y.; Yang, Y. Hardening Mechanism of Thick (Ti,Cr,V)N Composite Coatings with Multi-Layer Nano-Columnar Dendrites Microstructure. J. Eur. Ceram. Soc. 2023, 43, 2013–2025. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Smyrnova, K.; Bondar, O. Nanocomposite Multilayer Binary Nitride Coatings Based on Transition and Refractory Metals: Structure and Properties. Coatings 2019, 9, 155. [Google Scholar] [CrossRef]

- Gao, N.; Lu, D.H.; Zhao, Y.Y.; Liu, X.W.; Liu, G.H.; Wu, Y.; Liu, G.; Fan, Z.T.; Lu, Z.P.; George, E.P. Strengthening of a CrMnFeCoNi High-Entropy Alloy by Carbide Precipitation. J. Alloys Compd. 2019, 792, 046120. [Google Scholar] [CrossRef]

- Su, Y.L.; Kao, W.H.; Sung, K.H. Mechanical and Tribological Properties of NbAl, NbAlN, and NbAlN-CH Coatings Deposited Using Various Niobium Target Currents and Acetylene Flow Rates. J. Mater. Eng. Perform. 2022, 31, 3594–3610. [Google Scholar] [CrossRef]

- Leitans, A.; Jansons, E.; Lungevics, J.; Kundzins, K.; Boiko, I.; Kanders, U.; Kovalenko, V.; Linins, O. Tribological and Micromechanical Properties of the Nanostructured Carbonitride/Nitride Coatings of Transition Metals Alloyed by Hf and Nb. Coatings 2023, 13, 552. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single Layer and Multilayer Wear Resistant Coatings of (Ti,Al)N: A Review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Kolchev, S.; Kolaklieva, L.; Kovacheva, D.; Atanasova, G.; Cholakova, T.; Chitanov, V.; Zlatareva, E.; Kakanakov, R.; Pashinski, C. Mechanical and Tribological Behavior of TiAlSiN/AlSiN Coatings Depending on the High-Temperature Treatment. Coatings 2025, 15, 542. [Google Scholar] [CrossRef]

- Sriniva, R.G.; Palani, S.; Rajaravi, C.; Karthik, S. Comparative Analysis Over Tribology Characterization of TiAlN and TiAlSiN PVD Coating On Plasma Nitride Alloy 20. J. Inorg. Organomet. Polym. 2022, 32, 2082–2093. [Google Scholar] [CrossRef]

- Das, P.; Anwar, S.; Bajpai, S.; Anwar, S. Structural and Mechanical Evolution of TiAlSiN Nanocomposite Coating under Influence of Si3N4 Power. Surf. Coat. Technol. 2016, 307, 676–682. [Google Scholar] [CrossRef]

- Kenzhegulov, A.; Mamaeva, A.; Panichkin, A.; Alibekov, Z.; Kshibekova, B.; Bakhytuly, N.; Wieleba, W. Comparative Study of Tribological and Corrosion Characteristics of TiCN, TiCrCN, and TiZrCN Coatings. Coatings 2022, 12, 564. [Google Scholar] [CrossRef]

- Mohapatra, S.; Oh, M.S. Evaluating the Tribological Properties and Residual Stress of TiCrN Thin Films Deposited by Cathodic-Arc Physical Vapor Deposition Technique. Appl. Sci. 2025, 15, 2466. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Clemens, H.; Fischer, F.D. Materials Science-Based Guidelines to Develop Robust Hard Thin Film Materials. Prog. Mater. Sci. 2024, 146, 101323. [Google Scholar] [CrossRef]

- Azadi, M.; Rouhaghdam, A.S.; Ahangarani, S.; Mofidi, H.H.; Valiei, M. Effect of Number of Layers on the Toughness of TiN/TiC Multilayer Coatings. Int. J. Microstruct. Mater. Prop. 2014, 9, 500–515. [Google Scholar] [CrossRef]

- Akkili, V.G.; Lee, H.G.; Kim, S.; Choi, J.; Chung, C.; Park, J.S.; Lee, J.; Ahn, B.; Kim, Y.-K.; Lee, S. Influence of Multilayer Structure on the Structural and Mechanical Properties of TiAlN/CrN Coatings for Advanced Machining Applications. Arch. Metall. Mater. 2024, 69, 479–484. [Google Scholar] [CrossRef]

- Espitia-Rico, M.J.; Casiano-Jiménez, G.; Ortega-López, C.; De la Espriella-Vélez, N.; Sánchez-Pacheco, L. A Comparative Study of TiC/TiN and TiN/CN Multilayers. DYNA 2014, 81, 188. [Google Scholar] [CrossRef]

- Münz, W.D.; Donohue, L.A.; Hovsepian, P.E. Properties of Various Large-Scale Fabricated TiAlN- and CrN-Based Superlattice Coatings Grown by Combined Cathodic Arc–Unbalanced Magnetron Sputter Deposition. Surf. Coat. Technol. 2000, 125, 269–277. [Google Scholar] [CrossRef]

- Bakhytuly, N.; Kenzhegulov, A.; Nurtanto, M.; Aliev, A.; Kuldeev, E. Microstructure and Tribological Study of TiAlCN and TiTaCN Coatings. Kompleks. Ispolz. Miner. Syra 2023, 327, 99–110. [Google Scholar] [CrossRef]

- Devarajan, D.K.; Rangasamy, B.; Amirtharaj Mosas, K.K. State-of-the-Art Developments in Advanced Hard Ceramic Coatings Using PVD Techniques for High-Temperature Tribological Applications. Ceramics 2023, 6, 301–329. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Maiti, R.; Mills, R. Wear Properties of Diamond-like-Carbon Coatings with Silicon and Chromium as Adhesion Layer Using a High Frequency Reciprocating Rig. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 1605–1615. [Google Scholar] [CrossRef]

- Miletić, A.; Panjan, P.; Škorić, B.; Čekada, M.; Dražič, G.; Kovač, J. Microstructure and Mechanical Properties of Nanostructured Ti–Al–Si–N Coatings Deposited by Magnetron Sputtering. Surf. Coat. Technol. 2014, 241, 105–111. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Lai, H.M. Wear Behavior and Cutting Performance of CrAlSiN and TiAlSiN Hard Coatings on Cemented Carbide Cutting Tools for Ti Alloys. Surf. Coat. Technol. 2014, 259, 152–158. [Google Scholar] [CrossRef]

- Vicen, M.; Bronček, J.; Nový, F. Investigation of Tribological Properties of CarbonX Coating Deposited on 100Cr6 Steel. Prod. Eng. Arch. 2019, 25, 52–55. [Google Scholar] [CrossRef]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef]

- Yun, W.; Liew, H.; Lim, H.P.; Jet, G.; Melvin, H.; Dayou, J.; Jiang, Z.-T.; Liew, W.Y.H. Thermal Stability, Mechanical Properties, and Tribological Performance of TiAlXN Coatings: Understanding the Effects of Alloying Additions. J. Mater. Res. Technol. 2022, 17, 961–1012. [Google Scholar] [CrossRef]

- Spatschek, R.; Brener, E.A. Grinfeld Instability on Crack Surfaces. Phys. Rev. E 2001, 64, 046120. [Google Scholar] [CrossRef] [PubMed]

- Köhler, C.; Backofen, R.; Voigt, A. Relaxation of Curvature-Induced Elastic Stress by the Asaro-Tiller-Grinfeld Instability. EPL 2015, 111, 48006. [Google Scholar] [CrossRef]

- Alderighi, M.; Ierardi, V.; Fuso, F.; Allegrini, M.; Solaro, R. Size Effects in Nanoindentation of Hard and Soft Surfaces. Nanotechnology 2009, 20, 235703. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, S.; Shi, Q.; Ge, X.; Wang, W. Multilayer Coatings for Tribology: A Mini Review. Nanomaterials 2022, 12, 1388. [Google Scholar] [CrossRef]

- Sharifi Malvajerdi, S.; Sharifi Malvajerdi, A.; Ghanaatshoar, M.; Habibi, M.; Jahdi, H. TiCrN-TiAlN-TiAlSiN-TiAlSiCN Multi-Layers Utilized to Increase Tillage Tools Useful Lifetime. Sci. Rep. 2019, 9, 1023. [Google Scholar] [CrossRef] [PubMed]

- Carpick, R.W.; Sasaki, D.Y.; Burns, A.R. Large Friction Anisotropy of a Polydiacetylene Monolayer. Tribol. Lett. 1999, 7, 79–85. [Google Scholar] [CrossRef]

- Gao, Y.; Choudhury, N.R.; Dutta, N.K.; Morozov, I.A.; Reid, M. Tribological Properties of Polymer Nanocomposites. Tribol. Lett. 2016, 61, 27. [Google Scholar] [CrossRef]

- Choi, J.S.; Kim, J.-S.; Byun, I.-S.; Lee, D.H.; Lee, M.J.; Park, B.H.; Lee, C.; Yoon, D.; Cheong, H.; Lee, K.H.; et al. Friction Anisotropy-Driven Domain Imaging on Exfoliated Monolayer Graphene. Science 2011, 333, 607. [Google Scholar] [CrossRef]

- Sneddon, I.N. The Relation between Load and Penetration in the Axisymmetric Boussinesq Problem for a Punch of Arbitrary Profile. Int. J. Eng. Sci. 1965, 3, 47–57. [Google Scholar] [CrossRef]

- Fischer-Cripps, A. Nanoindentation; Springer: New York, NY, USA, 2004. [Google Scholar]

- Fleck, N.; Hutchinson, J. Strain Gradient Plasticity. Adv. Appl. Mech. 1997, 33, 295–362. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Attaf, M.T. Connection between the Loading Curve Models in Elastoplastic Indentation. Mater. Lett. 2004, 58, 3491–3498. [Google Scholar] [CrossRef]

- Kanders, U.; Kanders, K.; Maniks, J.; Mitin, V.; Kovalenko, V.; Nazarovs, P.; Erst, D. Nanoindentation Response Analysis of Cu-Rich Carbon–Copper Composite Films Deposited by PVD Technique. Surf. Coat. Technol. 2015, 280, 308–316. [Google Scholar] [CrossRef]

- Petrík, J.; Blaško, P.; Mihaliková, M.; Mikloš, V. The Relationship between the Deformation and the Indentation Size Effect (ISE). J. Appl. Res. Technol. 2018, 16, 267–275. [Google Scholar] [CrossRef]

- Broitman, E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview. Tribol. Lett. 2017, 65, 23. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).