Optimizing Substrate Bias to Enhance the Microstructure and Wear Resistance of AlCrMoN Coatings via AIP

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Tests and Characterization

3. Results and Discussion

3.1. Microstructure and Chemical Composition

3.2. Mechanical Properties

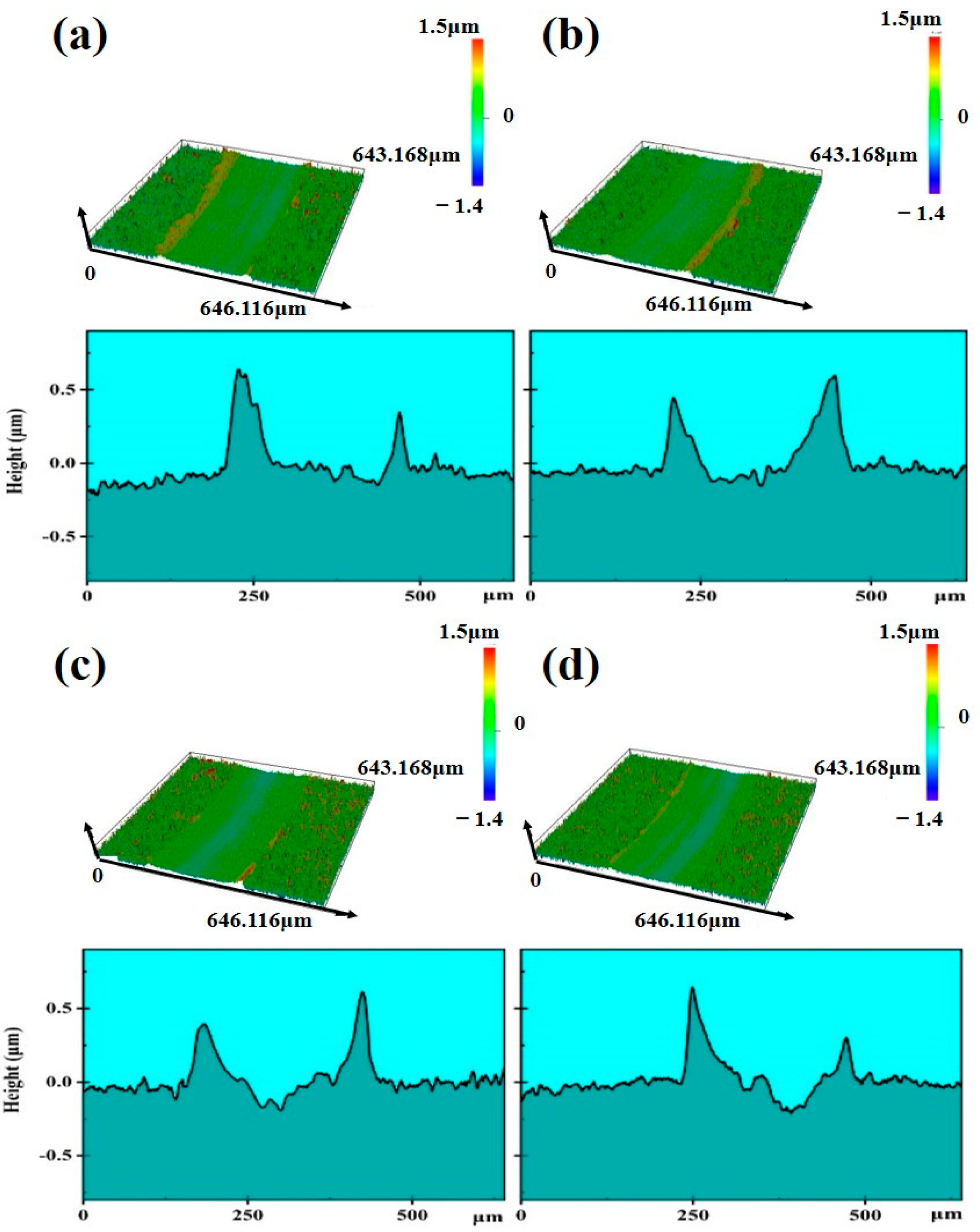

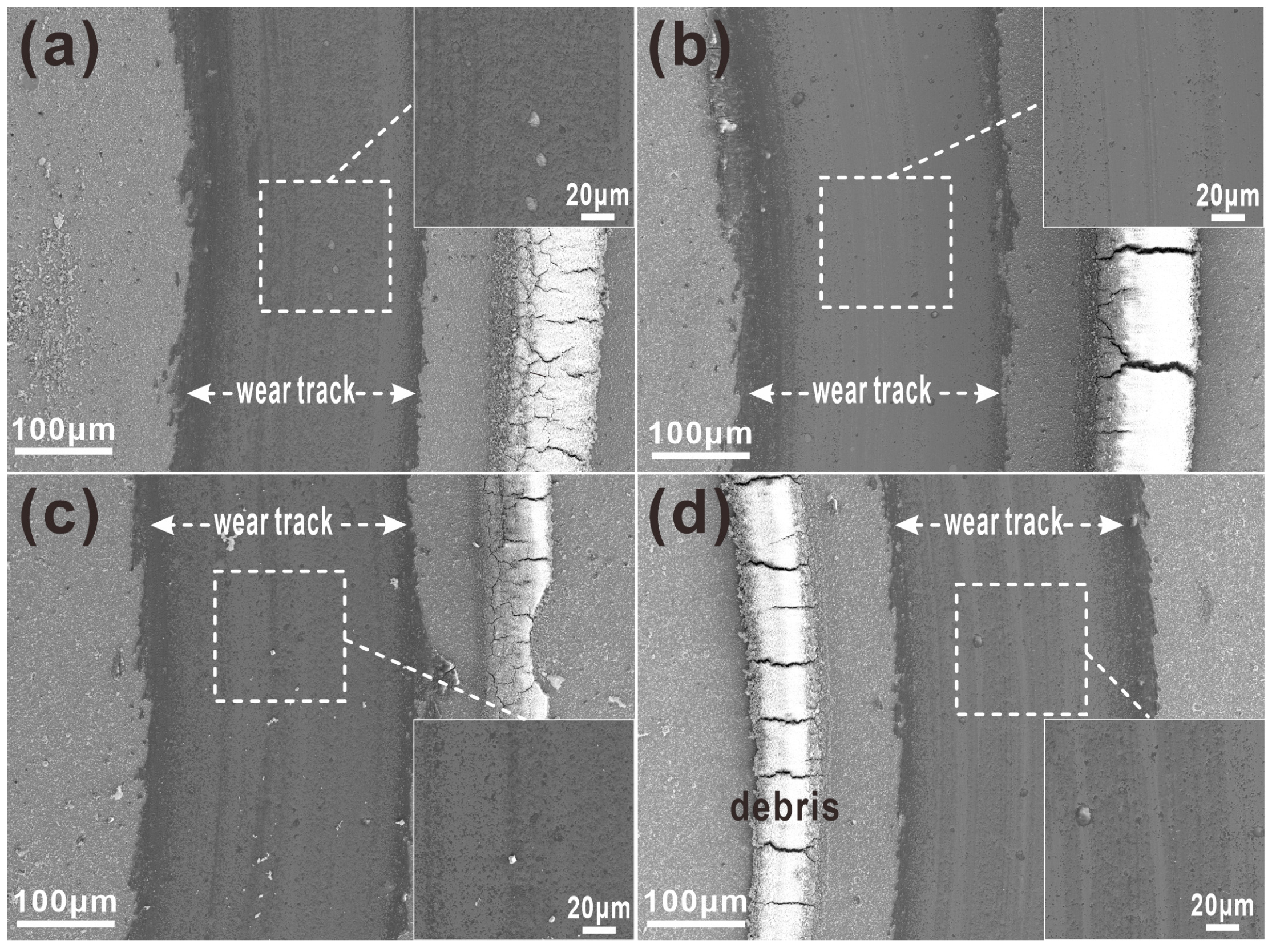

3.3. Tribological Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Žemlička, R.; Alishahi, M.; Jílek, M.; Souček, P.; Daniel, J.; Kluson, J.; Bolvardi, H.; Lümkemann, A.; Vašina, P. Enhancing mechanical properties and cutting performance of industrially sputtered AlCrN coatings by inducing cathodic arc glow discharge. Surf. Coat. Technol. 2021, 422, 127563. [Google Scholar] [CrossRef]

- Ling, C.L.; Yajid, M.A.M.; Tamin, M.N.; Kamarudin, M.; Taib, M.A.A.; Nosbi, N.; Wan Ali, W.F.F. Effect of substrate roughness and PVD deposition temperatures on hardness and wear performance of AlCrN-coated WC-Co. Surf. Coat. Technol. 2022, 436, 128304. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.X.; Chen, Y.; Peng, B.; Wei, T.; Zhang, F.; Li, H.; Wang, Q. Temperature-dependent oxidation behavior of arc evaporated Al–Ti–B–N coatings. Corros. Sci. 2022, 203, 110347. [Google Scholar] [CrossRef]

- Zhou, S.; Kuang, T.; Qiu, Z.; Zeng, D.; Zhou, K. Microstructural origins of high hardness and toughness in cathodic arc evaporated Cr-Al-N coatings. Appl. Surf. Sci. 2019, 493, 1067–1073. [Google Scholar] [CrossRef]

- Tritremmel, C.; Daniel, R.; Lechthaler, R.; Polcik, P.; Mitterer, C. Influence of Al and Si content on structure and mechanical properties of arc evaporated Al-Cr-Si-N thin films. Thin Solid Films 2023, 534, 403–409. [Google Scholar] [CrossRef]

- Mato, S.; Alcalá, G.; Brizuela, M.; Galindo, R.E.; Pérez, F.J.; Sánchez-López, J.C. Long-term high temperature oxidation of CrAl(Y)N coatings in steam atmosphere. Corros. Sci. 2014, 80, 453–460. [Google Scholar] [CrossRef]

- Kelly, P.J.; Hisek, J.; Zhou, Y.; Pilkington, R.D.; Arnell, R.D. Advanced coatings through pulsed magnetron sputtering. Surf. Eng. 2004, 20, 157–162. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High-temperature tribological properties of CrAlN, CrAlSiN and AlCrSiN coatings. Surf. Coat. Technol. 2011, 206, 1244–1251. [Google Scholar] [CrossRef]

- Rovere, F.; Music, D.; Schneider, J.M.; Mayrhofer, P.H. Experimental and computational study on the effect of yttrium on the phase stability of sputtered Cr-Al-Y-N hard coatings. Acta Mater. 2010, 58, 2708–2715. [Google Scholar] [CrossRef]

- Yan, C.; Yu, Y.; Mei, F.; Gao, J.; Lin, X.; Lin, J. A Si-Nb co-alloyed AlCrN coating with good mechanical properties, excellent thermal stability and resistance to high temperature oxidation. Surf. Coat. Technol. 2024, 484, 130825. [Google Scholar] [CrossRef]

- Wolfgang, T.; David, K.; Dominic, S.; Michael, P.; Christian, S.; Metin, T. Investigation of the influence of the vanadium content on the high temperature tribo-mechanical properties of DC magnetron sputtered AlCrVN thin films. Surf. Coat. Technol. 2017, 328, 172–181. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.G.J.; Karvankova, P.; Prochazka, J. Different approaches to superhard coatings and nanocomposites. Thin Solid Films 2005, 476, 1–29. [Google Scholar] [CrossRef]

- Devarajan, D.K.; Rangasamy, B.; Amirtharaj, M.K.K. State-of-the-art developments in advanced hard ceramic coatings using PVD techniques for high-temperature tribological applications. Ceramics 2023, 6, 301–329. [Google Scholar] [CrossRef]

- Lukaszkowicz, K.; Sondor, J.; Paradecka, A.; Pawlyta, M.; Chmiela, B.; Pancielejko, M.; Szczucka-Lasota, B.; Węgrzyn, T.; Tański, T. Structure and tribological properties of AlCrN+CrCN coating. Coatings 2020, 10, 1084. [Google Scholar] [CrossRef]

- Wu, W.; Chen, W.; Yang, S.; Lin, Y.; Zhang, S.; Cho, T.Y.; Lee, G.H.; Kwon, S.C. Design of AlCrSiN multilayers and nanocomposite coating for HSS cutting tools. Appl. Surf. Sci. 2015, 351, 803–810. [Google Scholar] [CrossRef]

- Kim, Y.J.; Byun, T.J.; Han, J.G. Bilayer period dependence of CrN/CrAlN nanoscale multilayer thin films. Superlattices Microstruct. 2009, 45, 73–79. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Arghavani, M. Investigations on mechanical and tribological behavior of DCMS/HPPMS CrN and (Cr, Al)N hard coatings using nanoscratch technique. Adv. Eng. Mater. 2017, 19, 1600632. [Google Scholar] [CrossRef]

- Wang, Y.; Ji, Y. Influence of Mo Doping on the Microstructure, Friction, and Wear Properties of CrAlN Films. J. Mater. Eng. Perform. 2021, 30, 1938–1944. [Google Scholar] [CrossRef]

- Lou, B.; Wang, Y. Effects of Mo content on the micro-structure and tribological properties of CrMoAlN films. Acta Metall. Sin. 2016, 52, 727–733. [Google Scholar] [CrossRef]

- Iram, S.; Cai, F.; Wang, J.; Zhang, J.; Liang, J.; Ahmad, F.; Zhang, S. Effect of addition of Mo or V on the structure and cutting performance of AlCrN-based coatings. Coatings 2020, 10, 298. [Google Scholar] [CrossRef]

- Shi, J.; Chen, Y.; Liu, H.; Kang, J.; Li, X.; Zhang, L.; Xian, G.; Du, H. Effect of Mo and C Contents on the Crystal Structure and Properties of AlCrN Films. China Surf. Eng. 2022, 35, 286–296. [Google Scholar] [CrossRef]

- Glatz, S.A.; Koller, C.M.; Bolvardi, H.; Kolozsvári, S.; Riedl, H.; Mayrhofer, P.H. Influence of Mo on the structure and the tribomechanical properties of arc evaporated Ti-Al-N. Surf. Coat. Technol. 2017, 311, 330–336. [Google Scholar] [CrossRef]

- Klimashin, F.F.; Mayrhofer, P.H. Ab initio-guided development of super-hard Mo-Al-Cr-N coatings. Scr. Mater. 2017, 140, 27–30. [Google Scholar] [CrossRef]

- Di, Y.; Zhang, P.; Cai, Z.; Yang, Z.; Li, Q.; Shen, W. Effect of Mo content on the structural and mechanical properties of CrMoN/MoS2 composite coatings. Rare Met. Mater. Eng. 2014, 43, 264–268. [Google Scholar] [CrossRef]

- Jaf, Z.N.; Jiang, Z.T.; Miran, H.A.; Altarawneh, M.; Veder, J.P.; Minakshi, M.; Zhou, Z.F.; Lim, H.N.; Huang, N.M.; Dlugogorski, B.Z. Physico-chemical properties of CrMoN coatings-combined experimental and computational studies. Thin Solid Film. 2020, 693, 137671. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Y.X.; Zhang, H.; Wang, Q.; Wei, T.; Zhang, F.; Kim, K.H. Improving high-temperature wear resistance of arc-evaporated AlCrN coatings by Mo alloying. Surf. Coat. Technol. 2023, 456, 129253. [Google Scholar] [CrossRef]

- Iram, S.; Wang, J.; Cai, F.; Zhang, J.; Ahmad, F.; Liang, J.; Zhang, S. Effect of bilayer number on mechanical and wear behaviors of the AlCrN/AlCrMoN coatings by AIP method. Surf. Eng. 2021, 37, 536–544. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, S.; Ma, G.; Dong, Y.; Zhang, X.; Liu, Y.; Wang, Z.; Wang, A. Achieving ultrastrong-tough CrAlN coatings with low friction coefficient by Y incorporating. Ceram. Int. 2024, 50, 23621–23633. [Google Scholar] [CrossRef]

- Zhao, Y.; He, Y.; Chen, Q.; Gong, Z.; Wang, Z.; Wang, K.; Shi, M.; Chen, R. Effect of substrate bias voltage on structure and corrosion resistance of AlCrN coatings prepared by multi-arc ion plating. Int. J. Electrochem. Sci. 2021, 16, 210938. [Google Scholar] [CrossRef]

- Lomello, F.; Sanchette, F.; Schuster, F.; Tabarant, M.; Billard, A. Influence of bias voltage on properties of AlCrN coatings prepared by cathodic arc deposition. Surf. Coat. Technol. 2013, 224, 77–81. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Cheng, X.; Zeng, Z.; Li, J.; Lu, X.; Wang, L.; Xue, Q. Continuously growing ultrathick CrN coating to achieve high load-bearing capacity and good tribological property. ACS Appl. Mater. Interfaces 2018, 10, 2965–2975. [Google Scholar] [CrossRef] [PubMed]

- Bemporad, E.; Sebastiani, M.; Pecchio, C.; Rossi, S.D. High thickness Ti/TiN multilayer thin coatings for wear resistant applications. Surf. Coat. Technol. 2006, 201, 2155–2165. [Google Scholar] [CrossRef]

- Smilgies, D.M. Scherrer Grain-size analysis adapted to grazing-incidence scattering with area detectors. J. Appl. Crystallogr. 2009, 42, 1030–1034. [Google Scholar] [CrossRef] [PubMed]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Effect of sputtering target power on microstructure and mechanical properties of nanocomposite nc-TiN/a-SiNx thin films. Thin Solid Films 2004, 447–448, 462–467. [Google Scholar] [CrossRef]

- Wan, X.S.; Zhao, S.S.; Yang, Y.; Gong, J.; Sun, C. Effects of nitrogen pressure and pulse bias voltage on the properties of Cr-N coatings deposited by arc ion plating. Surf. Coat. Technol. 2010, 204, 1800–1810. [Google Scholar] [CrossRef]

- Liu, A.; Deng, J.; Cui, H.; Chen, Y.; Zhao, J. Friction and wear properties of TiN, T99iAlN, AlTiN and CrAlN PVD nitride coatings. Int. J. Refract. Met. Hard Mater. 2012, 31, 82–88. [Google Scholar] [CrossRef]

- Tang, J.F.; Lin, C.Y.; Yang, F.C.; Chang, C.L. Influence of nitrogen content and bias voltage on residual stress and the tribological and mechanical properties of CrAlN films. Coatings 2020, 10, 546. [Google Scholar] [CrossRef]

- Kong, Q.; Ji, L.; Li, H.; Liu, X.; Wang, Y.; Chen, J.; Zhou, H. Influence of substrate bias voltage on the microstructure and residual stress of CrN films deposited by medium frequency magnetron sputtering. Mater. Sci. Eng. B 2011, 176, 850–854. [Google Scholar] [CrossRef]

| Coating | Bias, V | Elemental Concentration, at% | Al/Cr | Mo/(Al + Cr + Mo) | |||

|---|---|---|---|---|---|---|---|

| Al | Cr | Mo | N | ||||

| AlCrMoN | −80 | 26.2 | 22.6 | 7.4 | 43.8 | 1.16 | 0.13 |

| −100 | 26.8 | 23.1 | 7.4 | 42.7 | 1.16 | 0.13 | |

| −120 | 26.5 | 23.4 | 7.3 | 42.8 | 1.13 | 0.13 | |

| −140 | 25.9 | 23.0 | 7.8 | 43.3 | 1.13 | 0.14 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Liu, J.; Wang, X.; Wang, C.; Sun, H.; Zhang, H.; Jiang, T.; Yu, H.; Xu, L.; Wei, S. Optimizing Substrate Bias to Enhance the Microstructure and Wear Resistance of AlCrMoN Coatings via AIP. Coatings 2025, 15, 673. https://doi.org/10.3390/coatings15060673

Zhang H, Liu J, Wang X, Wang C, Sun H, Zhang H, Jiang T, Yu H, Xu L, Wei S. Optimizing Substrate Bias to Enhance the Microstructure and Wear Resistance of AlCrMoN Coatings via AIP. Coatings. 2025; 15(6):673. https://doi.org/10.3390/coatings15060673

Chicago/Turabian StyleZhang, Haoqiang, Jia Liu, Xiran Wang, Chengxu Wang, Haobin Sun, Hua Zhang, Tao Jiang, Hua Yu, Liujie Xu, and Shizhong Wei. 2025. "Optimizing Substrate Bias to Enhance the Microstructure and Wear Resistance of AlCrMoN Coatings via AIP" Coatings 15, no. 6: 673. https://doi.org/10.3390/coatings15060673

APA StyleZhang, H., Liu, J., Wang, X., Wang, C., Sun, H., Zhang, H., Jiang, T., Yu, H., Xu, L., & Wei, S. (2025). Optimizing Substrate Bias to Enhance the Microstructure and Wear Resistance of AlCrMoN Coatings via AIP. Coatings, 15(6), 673. https://doi.org/10.3390/coatings15060673