Abstract

In this paper, the preparation of Ni60 + WC/NbC composite coating by laser cladding technology was studied. The coating properties were analyzed by a scanning electron microscope (SEM), an energy dispersion spectroscope (EDS), X-ray diffraction (XRD), a hardness tester, and a friction and wear tester. The results show that WC and NbC, as two typical ceramic reinforcing phases, play a positive role in improving the wear resistance and hardness of the coating. Under the action of a high-temperature (about 2500 °C) laser beam, some complex compounds, such as Ni3Fe and M23C6 (M=Fe, Cr) are formed in the coating, which leads to the left deviation of XRD peak position. With the decrease in WC and the increase in Nb particles, the wear mechanism of the coating changes from abrasive wear to adhesive wear. When adding 10% WC, the microhardness of the coating reaches 809.5 HV, the coefficient of friction is 0.496, and the wear rate is 1.1804 × 10−7 mm3 N−1·m−1, which shows the best wear resistance.

1. Introduction

Q235 steel has good toughness, weldability, and ductility, rich raw materials, and a low manufacturing cost, and is widely used in buildings, docks, bridges, and marine engineering [1,2,3,4]. However, Q235 steel also has low hardness and insufficient wear resistance, which limits its applications. Preparing high-performance metal coating on a Q235 surface can not only maintain the advantages of Q235 steel itself, but also create a high-performance surface, which is a new idea for breaking through its limitations. Common surface modification technologies include plasma beam cladding [5], brazing [6], flame spraying, chemical depiction [7], vacuum cladding [8], plasma electrolytic borocarburizing [9], annealing [10], physical vapor deposition [11], and laser cladding [12,13,14,15,16]. Laser cladding technology is a form of laser additive manufacturing, which is an advanced surface modification method with high efficiency, environmental friendliness, convenience, and rapidity, which can create corresponding high-performance coatings on the surface of a substrate according to the requirements of modification. Ceramic carbides, such as TIC and WC, are often used to treat metal materials by laser cladding to obtain surface coatings with high hardness, high wear resistance, and high corrosion resistance [17].

Ma, W. et al. [18] prepared a Ti-based coating on the surface of Q235 steel by laser cladding technology. It was found that the phase of Ti-based coating was divided into four characteristic regions from the interface to the surface. Initially, the phases evolve from α-Fe/TiFe2 phases to the TiFe2 phase, then to the TiFe phase, and finally to Fe0.2Ti0.8/TiFe/Ti2Fe. The main influencing factors were temperature transfer and solidification speed of molten pool. The obtained titanium coating has better corrosion resistance. Zhou, J.L. et al. [19] added TiC ceramic particles to high-entropy alloy powder, and used high-speed laser cladding to prepare a composite coating with good metallurgical bonding and dilution ratio less than 1%. The average microhardness of the coating reached 636, 651, 698, and 886 HV, and the mechanical strength and corrosion resistance were also effectively improved. Gao, Z.M. et al. [20] prepared TiC-reinforced CoCrFeNi high-entropy alloy coating by in situ synthesis, which proved that the mechanical properties of the CoCrFeNi high-entropy alloy composite coating can also be improved by indirectly generating TiC. Recently, Li, S.Z. et al. [21] prepared Ni/WC + TiC composite coating on 65 Mn steel by laser cladding. The mass fractions of WC were 10%, 20%, and 30%, respectively. The results show that the WC/TiC reinforcing phase not only affects the phase composition of the coating, but also has an important influence on the microhardness and wear resistance of the coating. The coating has columnar grains, cytosolic grains, and equiaxed grains. Fan, Z.Z. et al. [22] studied the joint enhancement effect of WC and TiC in Ti-6Al-4V by laser cladding. Adding two kinds of ceramic reinforcing particles to the coating at the same time is a novel approach. Compared with a single ceramic phase, there may be cooperation and competition effects between the two ceramic phases, which will have a more intense influence on the coating properties and create a more complicated physical mechanism.

Up to now, the study of adding WC and NbC to a coating at the same time has rarely been reported. In this paper, Q235 was used as the base material and NI60 as the main powder component. By adjusting the mass fraction ratio of WC and NbC, the cooperative and competitive effects of these two kinds of ceramic particles are studied.

2. Experimental Processes

2.1. Materials

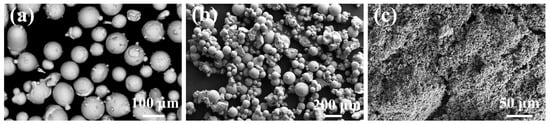

The basic material was Q235 steel, the coating material was Ni60, and the mixed powder of WC and NbC were the ceramic powder particles. The SEM images of the three powder materials are shown in Figure 1. Table 1 shows the chemical composition of Q235. The main components of Ni60 are (mass fractions) C: 0.80%; Si: 4.00%; B: 3.55%; Cr: 15.50%; Fe: 15.00%; and Ni: Bal. WC and NbC are both high-purity powders with a purity of 99.99%. Q235 steel was cut into a size of 100 mm × 50 mm × 3 mm. After grinding the stains and rust on the surface with sandpaper, we cleaned it with alcohol and put it in a ventilated place until it was dry. Using a preset method, 2 mm thick mixed powder was laid with a standard mold. This experiment used continuous fiber laser machinery for processing (model: XL-F2000T, Shenzhen, China; maximum output power: 2000 W; laser beam wavelength: 1080 ± 5 nm), with a power of 1300 W, an overlapping of 40%, a defocus of +5 mm, and a scanning speed of 500 mm/min. The protective gas was argon with a purity of 99.99%, The ventilation rate was about 3 L/min. First of all, in terms of laser power selection, when the laser power was greater than 1500 W, the coating was well bonded, but the dilution rate of the interface exceeded 10%, and the coating showed excessive melting. However, when the laser power was less than 1200 W, the coating was not firmly combined with the substrate, and the powder could not be fully melted. Therefore, the laser power selected in this experiment was 1300 W.

Figure 1.

SEM morphology: (a) Ni60A powders; (b) WC powders; (c) NbC powders.

Table 1.

Chemical composition of Q235 (mass fraction %).

Secondly, through 20 pre-experiments, the coating forming effect was compared and evaluated, and it was found that the coating forming effect was the best under the conditions of 40% overlapping, + 5 mm defocus, and 500 mm/min scanning speed.

Finally, in the aspect of sample design, because this is the first study in which the performance of two mixed ceramic powder materials has been analyzed, we hoped to see an influence of the change in the mass fraction of ceramic powder on the phase composition, hardness, and wear resistance of the coating, so we designed the following five samples. Table 2 shows the chemical composition and design details of the samples.

Table 2.

Coating symbols under different mass fractions of WC and NbC.

2.2. Characterization

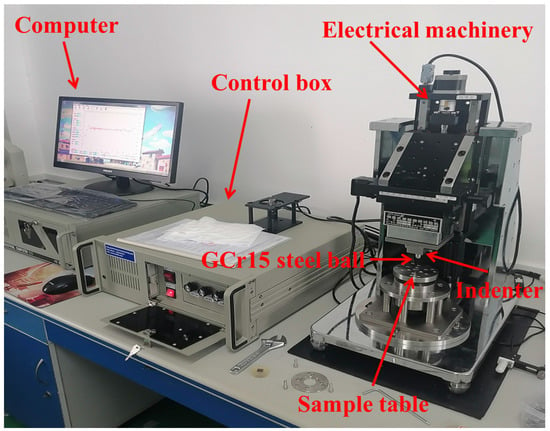

The microstructures were analyzed by SEM (FEI, QUANT 250, Eindhoven, The Netherlands) with an EDS. The phase analyzation was identified by XRD (SmartLab 9 KW, Rigaku, Tokyo, Japan). The wear resistance was performed using a pin-disc-type friction wear tester (SFT-2M, Lanzhou, China). Figure 2 presents the physical diagram of the wear test set up. The friction and wear test was carried out at room temperature. The test load was 20 N, the rotation radius was 2 mm, the rotation speed was 200 rpm, and the duration was 30 min. A 6 mm GCr15 steel ball was used as a counterpart for the wear conditions, which was located at the bottom of the indenter. Microhardness was examined by a Vickers hardness tester (MHVD-1000AT, Shanghai, China). The load was 200 g, the holding time was 10 s, the measuring interval was 0.1 mm, and 18 points were taken from each sample. All the above tests were carried out at room temperature, and were measured three times and averaged.

Figure 2.

The physical diagram of the wear test set up.

3. Results

3.1. Microstructure and EDS

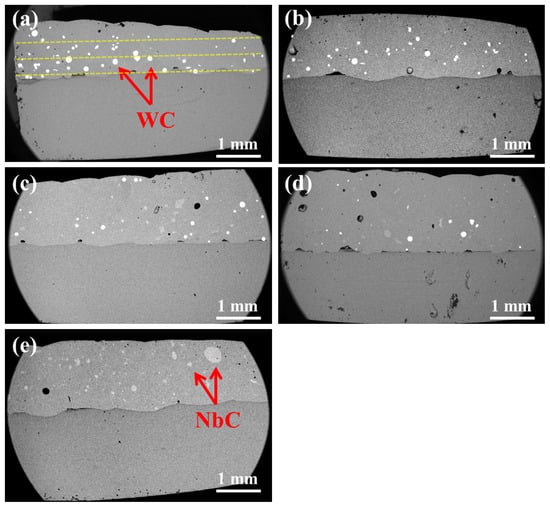

Figure 3 shows the SEM of the cross section of S1–S5. The bright white spherical particles are WC and the pale white, nearly spherical particles are NbC. The yellow dotted line indicates the upper layer, middle layer and lower layer of the coating respectively. Firstly, it can be seen from Figure 3a–d that the proportion of WC gradually decreases, and by Figure 3e, WC has disappeared. The proportion of NbC increases gradually from Figure 3b–e, which fully shows that the proportion and content in this experiment are strictly controlled and evenly mixed. Secondly, WC particles in the coating show an obvious delamination phenomenon, as shown in Figure 3a. Large WC particles are mainly distributed in the bottom layer, medium WC particles are mainly distributed in the middle layer, and there are almost no WC particles in the upper layer. On the one hand, this may be because the density of WC is relatively high, so the high-density WC sinks under the action of gravity, and sedimentation occurs near the interface. On the other hand, it may be due to the convection formed by the laser in the micro-molten pool [15,23,24].

Figure 3.

SEM of the cross section of the samples, (a) S1; (b) S2; (c) S3; (d) S4; (e) S5.

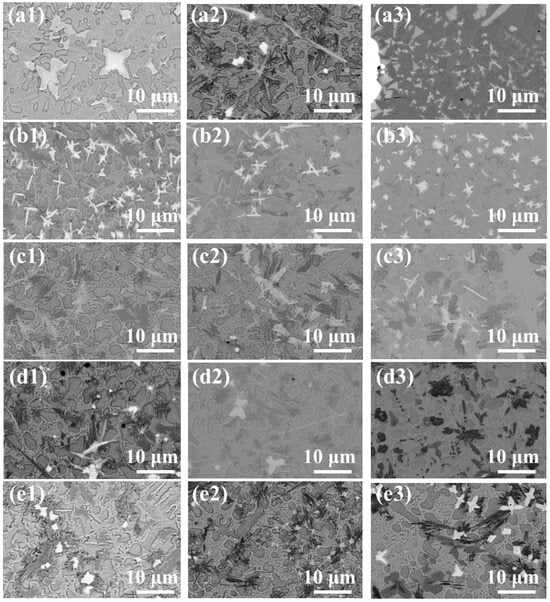

Figure 4 shows the SEM images of different areas of five samples. Firstly, different regions of the same sample have different morphologies. In Sample 1, there are large star crystals in the upper region (see Figure 4(a1)), medium-sized cellular crystals in the middle region (see Figure 4(a2)), and small flaky crystals in the lower region (see Figure 4(a3)). However, there is almost no difference in the grains of the three regions in Sample 2 (see Figure 4(b1–b3)). Samples 3 and 4 have obvious cellular crystals in the upper region (see Figure 4(c1,d1)), but no crystal grains in the middle and lower regions (see Figure 4(c2,c3,d2,d3)). In Sample 5 (as shown in Figure 4(e1–e3)), the main grains in the three regions are uniform cellular crystals, but there are a few flaky crystals in the upper region and flaky crystals and star crystals in the lower region. The crystal forms in different regions are closely related to the temperature gradient during laser rapid solidification [25,26]. Secondly, it is also found that the same area in different samples has different crystal shapes, which shows that the addition of ceramic powder affects the formation characteristics of coating crystals. WC tends to form star dendrites, while NbC tends to form lamellar crystals with a nucleus.

Figure 4.

SEM of each sample. (a1–a3) are the upper, middle, and bottom regions of S1; (b1–b3) are the upper, middle, and bottom regions of S2; (c1–c3) are the upper, middle, and bottom regions of S3; (d1–d3) are the upper, middle, and bottom regions of S4; and (e1–e3) are the upper, middle, and bottom regions of S5, respectively.

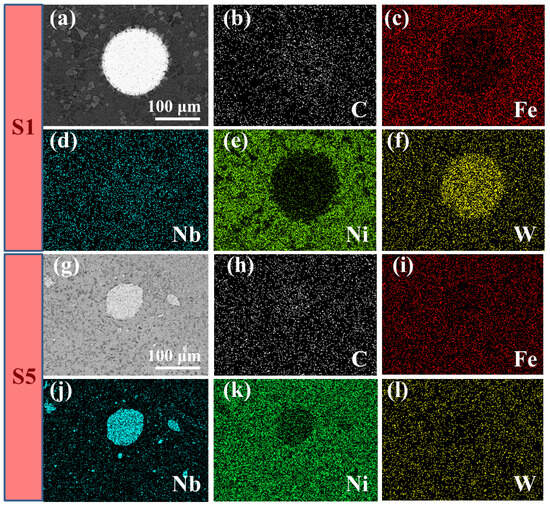

Figure 5 shows the EDS scanning results of Samples 1 and 5. It can be seen from Figure 5b that C is distributed on the whole surface, and from Figure 5f that W is concentrated in the circular area, which proves that the white circular particles in Figure 5a are WC particles; there are similar results in other studies [27,28,29]. Fe and Ni (see Figure 5c,e) are evenly distributed around WC particles. Figure 5d indicates that there is no Nb in sample 1. Through similar analysis, it is concluded that NbC exists in Sample 5 from the results in Figure 5g–l.

Figure 5.

(a) Gray diagram of Sample S1, (b) C, (c) Fe, (d) Nb, (e) Ni, and (f) W; (g) gray diagram of sample S5, (h) C, (i) Fe, (j) Nb, (k) Ni, and (l) W.

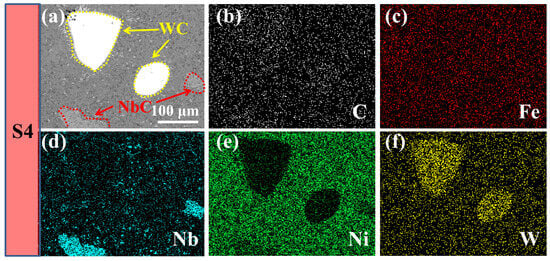

Figure 6 is the EDS diagram of S4. In Figure 6a, the white part is WC particles and the gray part is NbC particles. Spherical WC particles partially melted in the laser molten pool, forming a small amount of finely divided WC, while the original spherical WC particles became nearly triangular and ellipsoid due to edge melting, which is consistent with the conclusion in references [26,30]. However, ultrafine NbC particles are formed in the diffusion process, resulting in local enrichment. Figure 6b,c show that C and Fe are uniformly distributed throughout the coating. Figure 6d shows the Nb, indicating that Nb is enriched and some of it is dispersed in the coating. Figure 6e shows the Ni. It is found that the overall content of Ni is very high, while the content of WC and NbC particles is lower. The overall content is high because Ni is the main component in the coating, while less content is occupied by WC and NbC particles. Figure 6f shows the EDS of W, and its shape is consistent with the white area in Figure 6a, which further proves the existence of WC.

Figure 6.

EDS of S4. (a) Gray diagram of S4; (b) C;(c) Fe; (d) Nb; (e) Ni; (f) W element.

3.2. Phase Compositions of the Coatings

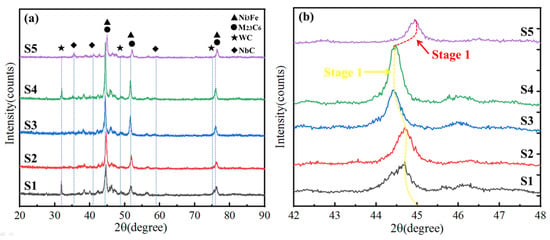

Figure 7a shows the XRD patterns of the five samples. It can be seen that from Samples S1 to S5, the WC peaks at 31.5° and 48.2° gradually weaken and finally disappear, while the NbC peaks at 34.8° and 41.7° gradually increase. This is due to the decrease in WC and the increase in NbC in the samples, which is consistent with the experimental design parameters. Ni3Fe and M23C6 (M = Fe, Cr) compounds were formed, and the peak position became the strongest and the content was the highest in Sample S4 [31]. The composition and content of the compound affect the microhardness and wear resistance of the material, which will be discussed in detail below. Figure 7b is an enlarged XRD pattern of the sample at the main peak position. From Samples S1 to S4, the main peak shifts to the left, which may be due to the increase in NbC, which makes the coating produce more complex compounds and leads to the lattice distortion of the coating [32,33]. However, the main peak position of Sample S5 shifted to the right, which was mainly due to the disappearance of WC and only NbC.

Figure 7.

(a) XRD patterns of the five samples; (b) XRD patterns enlarged from 42° to 48° of the five samples.

3.3. Wear Behavior

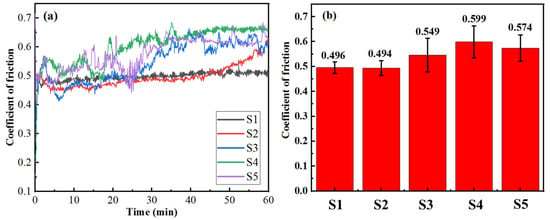

Figure 8a shows the friction curve of S1. It can be seen that the friction curve of S1 is very smooth, with little fluctuation and a small coefficient of friction (COF) of 0.496, which is due to the outstanding wear resistance of WC [14]. The friction curve of S2 is also smooth, which shows that adding a small amount of NbC does not affect the friction properties of the coating. However, after 45 min, the COF gradually increased. When the mass fraction of WC is less than 5% and the mass fraction of NbC is more than 5%, the friction curve fluctuates violently and the COF increases accordingly (see S3, S4, and S5). This may be due to two reasons. Firstly, the wear resistance and WC particles decrease, which makes the COF increase. Secondly, because two kinds of ceramic particles exist at the same time and multi-component brittle intermetallic compounds are generated in the coating, the wear resistance is reduced [34]. Figure 8b shows the average COF. It can be seen that the COFs of S1 and S2 are very small, at 0.496 and 0.494, respectively. The COFs of S4 and S5 are relatively large, which are 0.599 and 0.574 WC, respectively. The COF of S3 with 5% WC and NbC is in the middle, which shows that the mass fraction of WC and NbC plays a decisive role in the wear resistance of the coating.

Figure 8.

Friction factor and average COF for all composite coatings. (a) COF of the five samples; (b) Average COF of the five samples.

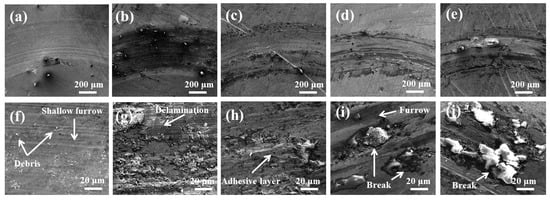

Figure 9a–e show the wear profiles. It is found that the wear profiles of S1 and S2 are relatively flat, while the profiles of S3, S4, and S5 are very rough. In order to study the wear mechanism, Figure 9f–j show the wear morphology at high magnification. It can be seen from Figure 9f that a small amount of shallow furrows and some abrasive particles appear in the wear marks, mainly showing abrasive wear. The delamination phenomenon is shown in Figure 9g, and the adhesive layer is shown in Figure 9h, which shows that the wear mode of S1 to S3 has evolved from abrasive wear to adhesive wear. However, in Figure 9i–j, the coating is broken, and the furrow depth is obviously increased.

Figure 9.

The SEM images of the wear profiles and wear trace morphology of the samples. (a) Wear trace of S1 at 100 times; (b) Wear trace of S2 at 100 times; (c) Wear trace of S3 at 100 times; (d) Wear trace of S4 at 100 times; (e) Wear trace of S5 at 100 times; (f) Wear trace of S1 at 1000 times; (g) Wear trace of S22 at 1000 times; (h) Wear trace of S3 at 1000 times; (i) Wear trace of S4 at 1000 times; (j) Wear trace of S5 at 1000 times.

Table 3 shows the wear depth, wear volume, and wear rate of the five samples. S1 has the lowest wear depth, while S4 has the highest wear depth. S1 has the smallest wear rate, and S5 has the largest wear rate. The wear rate is an important index for judging the wear resistance of the coating [35]. Therefore, it can be judged that S1 has the best wear resistance. This further shows that the wear resistance of WC ceramic particles is more prominent than that of NbC.

Table 3.

Wear depth, wear volume, and wear rate of the samples.

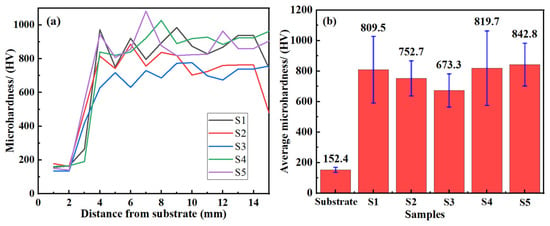

3.4. Microhardness

Figure 10a,b show the microhardness and average microhardness of the five samples. Among them, the average microhardness of Q235 is 152.4 HV, while that of S1 is 809.5 HV, and that of S2 is 842.8 HV, which are 5.31 and 5.53 times higher than that of Q235, respectively. The average microhardness of S3, S4, and S5 is 752.7 HV, 673.3 HV, and 819.7 HV, respectively. First of all, it is obvious that the microhardness of the coating can be effectively improved no matter what proportion of ceramic particles is added. This shows that ceramic particles can improve the microhardness [28]. Secondly, the microhardness when adding ceramic particles independently (only adding WC in S1 and only adding NbC in S5) is higher than that when adding two kinds of mixed ceramic particles at the same time, which may be because the mixed particles make the crystal lattice more unstable.

Figure 10.

(a) Cross-sectional microhardness of composite coatings for each samples; (b) average microhardness value of each composite coating and substrate.

4. Conclusions

In this paper, NI60 composite coating was deposited on the surface of Q235 steel by laser cladding technology, and the effects of adding WC and NbC ceramic particles at the same time on the wear resistance and hardness of the coating were studied. The main conclusions are as follows.

- (1)

- Each area of the coating had different micro-morphology, which is mainly due to the differences in coating compound composition. The formation of compounds was also the main cause of the phase shift.

- (2)

- Adding WC and NbC can effectively improve the hardness and resistance of the coating. S1 has the lowest COF and wear rate, high microhardness, significantly improved coating properties, and the best comprehensive properties.

- (3)

- With the decrease in WC and the increase in NbC, the wear mechanism of the coating changed from abrasive wear to adhesive wear, and finally the coating was damaged by friction.

Author Contributions

Conceptualization, C.G.; methodology, Z.X.; software, J.H.; validation, Z.X.; formal analysis, J.H.; investigation, A.A.; resources, J.H.; data curation, A.A.; writing—original draft preparation, A.A.; writing—review and editing, J.H.; visualization, Z.X.; supervision, C.G.; project administration, W.S.; funding acquisition, C.G. All authors have read and agreed to the published version of the manuscript.

Funding

Supported by the National Natural Science Foundation Projects of China (No. 62073089), the Project of Postgraduate Demonstration Courses of Department of Science and Technology of Guangdong Province (No. 2023SFKC_041), the Projects of Young Innovative Talents in Colleges and Universities in Guangdong Province (No. 2019WQNCX038), and the Laser Processing Team Project of Guangdong Ocean University (No. CCTD201823).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhou, Z.; Wang, Y.; Zhai, X.; Zhou, H. Compressive mechanical behaviors of Q235B steel over a wide range of temperatures and strain rates. Int. J. Impact Eng. 2025, 198, 105222. [Google Scholar] [CrossRef]

- Dong, Q.; Borisovich, T.T.; Grigorievicth, B.S.; Wang, H.F.; Song, W.W.; Pu, J.F.; Ju, Y.; Cao, S.Z. Effect of laser cladding process parameters on the microstructure and corrosion resistance of Ni55A alloy coatings on Q235 steel. Int. J. Electrochem. Sci. 2025, 20, 100932. [Google Scholar] [CrossRef]

- Feng, R.; Pan, J.; Zhang, J.; Shao, Y.; Chen, B.; Fang, Z.; Roy, K.; Lim, J.B. Effects of corrosion morphology on the fatigue life of corroded Q235B and 42CrMo steels: Numerical modelling and proposed design rules. Structures 2023, 57, 105136. [Google Scholar] [CrossRef]

- Yang, Q.; Xiong, Y.; Huang, Y.; Cheng, J.; Lou, D.; Chen, L.; Li, Q.; Liu, D. Nanosecond laser passivation mechanism of Q235B carbon steel surface. J. Mater. Eng. Perform. 2024, 34, 2371–2379. [Google Scholar] [CrossRef]

- Yu, J.; Zhou, H.; Lu, L.; Lu, D. Microstructure and properties of modiffed layer on the 65Mn steel surface by pulse detonation-plasma technology. J. Mater. Eng. Perform. 2024, 31, 1562–1572. [Google Scholar] [CrossRef]

- Long, W.; Lu, Q.; Zhong, S.; Qin, J.; Yu, H.; Wu, A. Research on interface structure and performance of diamond brazed coating based on non-vacuum environment. Weld World 2022, 66, 1043–1052. [Google Scholar] [CrossRef]

- Hupfer, M.L.; Meyer, R.; Deckert, T.; Ghosh, S.; Skabeev, A.; Deckert, V.; Dietzek, B.; Presselt, M. Supramolecular reorientation during deposition onto metal surfaces of quasi-two-dimensional Langmuir monolayers composed of bifunctional amphiphilic, twisted Perylenes. Langmuir 2021, 37, 11018–11026. [Google Scholar] [CrossRef]

- Zhang, H.F.; Zhang, C.H.; Wang, Z.Y.; Cui, X.; Zhang, S.; Chen, H.T. Microstructure and corrosion behaviour of WC/NiCrBSi coatings by vacuum cladding. Mater. Sci. Technol. 2022, 38, 19–29. [Google Scholar] [CrossRef]

- Wang, B.; Xue, W.B.; Wu, J.; Jin, X.Y.; Hua, M.; Wu, Z.L. Characterization of surface hardened layers on Q235 low-carbon steel treated by plasma electrolytic borocarburizing. J. Alloys Compd. 2013, 578, 162–169. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Liu, B.X.; He, J.N.; Fang, W.; Zhang, F.Y.; Zhang, X.; Chen, C.X.; Yin, F.X. Microstructure and mechanical properties of SUS304/Q235 multilayer steels fabricated by roll bonding and annealing. Mater. Sci. Eng. A 2019, 740–741, 92–107. [Google Scholar] [CrossRef]

- Pougoum, F.; Qian, J.; Laberge, M.; Martinu, L.; Klemberg-Sapieha, J.; Zhou, Z.F.; Li, K.Y.; Savoie, S.; Schulz, R. Investigation of FeAl-based PVD/HVOF duplex coatings to protect stainless steel from sliding wear against alumina. Surf. Coat. Technol. 2018, 350, 699–711. [Google Scholar] [CrossRef]

- Deng, C.; Wang, C.; Chai, L.J.; Wang, T.; Luo, J. Mechanical and chemical properties of CoCrFeNiMo0.2 high entropy alloy coating fabricated on Ti6Al4V by laser cladding. Intermetallics 2022, 144, 107504. [Google Scholar] [CrossRef]

- Ren, L.R.; Shi, Z.C.; Chu, M.Y.; Mo, T.Q.; Xiao, H.Q. Preparation and characterization of laser cladded Ti-Al-C composite coatings using Ti2AlC/TiAl powders. Mater. Today Commun. 2025, 46, 112514. [Google Scholar] [CrossRef]

- Chen, J.; Lian, G.; Lin, T.; Lu, H.; Wang, Y. Effects of the proportions of carbon on the microstructure and properties of NbC-reinforced Ni-WC composite coatings by laser cladding in-situ synthesis. Mater. Today Commun. 2024, 38, 107896. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Wang, L.; Yang, X.; Zeng, T.; Sun, L.; Wang, R. Microstructure evolution and wear resistance of laser cladded 316L stainless steel reinforced with in-situ VC-Cr7C3. Surf. Coat. Technol. 2022, 435, 128264. [Google Scholar] [CrossRef]

- Zhang, Z.; Hua, K.; Cao, Y.; Song, Y.; Li, X.; Zhou, Q.; Wang, H. Microstructures and properties of FeCrAlMoSix high entropy alloy coatings prepared by laser cladding on a titanium alloy substrate. Surf. Coat. Technol. 2024, 478, 130437. [Google Scholar] [CrossRef]

- Tang, J.; Wang, K.; Fu, H. Laser Cladding In Situ CarbideReinforced Iron-Based Alloy Coating: A Review. Metals 2024, 14, 1419. [Google Scholar] [CrossRef]

- Ma, W.; Xu, X.; Xie, Y.S.; Bei, Z.H.; Yuan, Y.; Yu, H.Y. Microstructural evolution and anti-corrosion properties of laser cladded Tibased coating on Q235 steel. Surf. Coat. Technol. 2024, 477, 130383. [Google Scholar] [CrossRef]

- Zhou, J.L.; Cheng, Y.H.; He, B.; Wan, Y.X.; Chen, H.; Wang, Y.F.; Yang, J.Y. Enhancement of high-entropy alloy coatings with multi-scale TiC ceramic particles via high-speed laser cladding: Microstructure, wear and corrosion. App. Surf. Sci. 2025, 685, 162061. [Google Scholar] [CrossRef]

- Gao, Z.M.; Niu, Z.M.; Gao, Z.T.; Li, J.Z.; Bai, G.H.; Ke, L.C.; Yu, Y.; Zhang, C.W. Microstructure and wear behavior of in-situ synthesized TiC-reinforced CoCrFeNi high entropy alloy prepared by laser cladding. App. Surf. Sci. 2024, 670, 160720. [Google Scholar] [CrossRef]

- Li, S.Z.; Huang, K.P.; Zhang, Z.J.; Zheng, C.J.; Li, M.K.; Wang, L.L.; Wu, K.K.; Tan, H.; Yi, X.M. Wear mechanisms and micro-evaluation of WC + TiC particle-reinforced Ni-based composite coatings fabricated by laser cladding. Mat. Charct. 2023, 197, 112699. [Google Scholar] [CrossRef]

- Fan, Z.Z.; Ren, W.B.; Zuo, W.H.; Wang, Y.J. Comparative study on the reinforcement effects of WC and TiC in the laser cladding layer of Ti-6Al-4V alloy. J. Manuf. Proc. 2025, 134, 589–602. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, L.; Sun, J.; Wu, W.; Yu, T. Microstructure evolution and wear resistance of in-situ synthesized (Ti, Nb) C ceramic reinforced Ni204 composite coatings. Ceram. Int. 2022, 48, 17518–17528. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, S.; Zhang, C.H.; Wu, C.L.; Zhang, J.B.; Abdullah, A.O. Phase evolution and wear resistance of in situ synthesized V8C7 particles reinforced Fe-based coating by laser cladding. Opt. Laser Technol. 2018, 105, 58–65. [Google Scholar] [CrossRef]

- Rutter, J.W.; Chalmers, B. A prismatic substructure formed during solidification of metals. Can. J. Phys. 1953, 31, 15–39. [Google Scholar] [CrossRef]

- Peng, Y.B.; Zhang, W.; Li, T.C.; Zhang, M.Y.; Wang, L.; Song, Y.; Hu, S.H.; Hu, Y. Microstructures and mechanical properties of FeCoCrNi high entropy alloy/WC reinforcing particles composite coatings prepared by laser cladding and plasma cladding. Int. J. Refract. Met. Hard Mater. 2019, 84, 105044. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, Z.; Wang, H.; Li, K.; Shi, W.; Jiao, T. Effect of WC Content on Microstructure and Properties of CoCrFeNi HEA Composite Coating on 316L Surface via Laser Cladding. Materials 2023, 16, 2706. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, Z.; Li, K.; Shi, W.; Zhao, Y.; He, M. Microstructures and Mechanical Properties of an AlCoCrNiFe HEA/WC Reinforcing Particle Composite Coating Prepared by Laser Cladding. Materials 2022, 15, 8020. [Google Scholar] [CrossRef]

- Cao, Q.Z.; Fan, L.; Chen, H.Y.; Hou, Y.; Dong, L.H.; Ni, Z.W. Wear behavior of laser cladded WC-reinforced Ni-based coatings under low temperature. Trib. Inter. 2022, 176, 107939. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Li, Y.; Lu, B.W.; Tan, N.; Cai, L.R.; Yong, Q.S. Effect of WC content on microstructure and properties of high-speed laser cladding Ni-based coating. Opt. Laser Technol. 2022, 155, 108449. [Google Scholar] [CrossRef]

- Jin, H.T.; Luo, F.Y.; Chen, Z.H.; Luo, Y.Z.; Shi, W.Q.; Huang, J. Mechanical properties and corrosion resistance analysis of Fe-based amorphous −2 % CNTs coatings with low crack prepared by laser cladding. Diam. Relat. Mater. 2025, 155, 112288. [Google Scholar] [CrossRef]

- Luo, F.Y.; Wang, S.S.; Shi, W.Q.; Zhao, Y.; Xiong, Z.Y.; Huang, J. Corrosion resistance and wear behavior of CoCrFeNiMn@ Gr high entropy alloy-based composite coatings prepared by laser cladding. J. Mater. Res. Technol. 2024, 33, 3769–3789. [Google Scholar] [CrossRef]

- Gu, Z.; Xi, S.Q.; Sun, C.F. Microstructure and properties of laser cladding and CoCr2.5FeNi2Tix high-entropy alloy composite coatings. J. Alloys Compd. 2020, 819, 152986. [Google Scholar] [CrossRef]

- Zhang, H.F.; Zhang, S.; Wu, H.; Wang, R.; Zhang, C.H.; Wu, C.L.; Chen, J.; Chen, H.T. brittle intermetallic compounds. Surf. Coat. Technol. 2024, 479, 130558. [Google Scholar] [CrossRef]

- Luo, F.; Wang, S.; Shi, W.; Zhao, Y.; Xiong, Z.; Huang, J. Wear behavior and corrosion resistance of laser-clad Ni60-1% carbon nanotubes coating. Surf. Coat. Technol. 2024, 482, 130686. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).