Abstract

Aluminum bronze (CuAl10Fe5Ni5) is widely utilized in engineering machinery because of its excellent castability and corrosion resistance. However, CuAl10Fe5Ni5 has been unable to meet increasingly demanding working conditions, so researchers have focused on improving its tribological properties. In this study, two bionic textures were designed on a CuAl10Fe5Ni5 surface via laser processing, and diamond-like carbon (DLC) coatings were subsequently deposited on these hexagonal textures. The tribological properties of textured surfaces and DLC coatings in conjunction with textures under various loads were examined through reciprocating friction tests conducted under oil lubrication conditions. The results demonstrate that the textured surface significantly enhances the stability of the CuAl10Fe5Ni5 alloy and effectively reduces friction and wear under various loading conditions. Hexagonal textures exhibit superior anti-friction and wear-resistant compared to other textures. The friction coefficients of the hexagonal textures at higher loads of 15 N and 20 N are 25% and 16% lower than those of the substrate, and the wear rates are 64% and 12% lower, respectively. DLC coatings further improve the tribological properties of CuAl10Fe5Ni5. The friction coefficients of DLC coatings and textured DLC coatings are 25% and 20% lower than those of the substrate, and the wear rates are 95% and 96% lower than those of the substrate, respectively. These results demonstrate that both textures and DLC coatings effectively enhance the tribological properties of CuAl10Fe5Ni5’s surface. The interaction mechanism between textures and DLC coatings can be attributed primarily to secondary lubrication, debris capture by the textures, self-lubricating properties, and increased surface hardness.

1. Introduction

Aluminum bronze (CuAl10Fe5Ni5) is widely used in aerospace, mechanical engineering, marine and chemical engineering, and the automotive industry [1,2,3] because of its good castability, corrosion resistance, weldability, and excellent fatigue performance [4,5,6,7]. However, with the advancements in science and technology and the evolution of industry, the operating conditions in the application domains of CuAl10Fe5Ni5 have become increasingly stringent. Consequently, traditional CuAl10Fe5Ni5 has gradually failed to meet comprehensive requirements. In particular, the poor tribological properties of CuAl10Fe5Ni5 severely limit its applications. Therefore, improving its tribological performance has become a focal point for researchers.

In recent years, surface textures have been widely developed as an effective approach for reducing friction, enhancing load-carrying capacity, and improving wear resistance [8,9]. Among them, cylinder liner-piston rings [10], bearings [11], and mechanical seals [12] are particularly widely used in fluid lubrication conditions. Moreover, the application of laser surface textures to CuAl10Fe5Ni5 has great potential for improving its tribological properties [13,14]. The mechanisms through which surface textures improve lubrication and decrease friction and wear, including the microfluidic dynamic pressure effect, the “secondary lubrication” phenomenon, the entrapment of debris within textures, and the decrease in the contact area, are widely recognized. The design of the surface texture shape significantly affects the tribological properties of the material surface [15,16,17], and most surface textures are designed on the basis of the unique structures of animals and plants in nature [18]. Currently, bio-inspired textures with different geometries are increasingly being studied. Zhang et al. [19] fabricated snake-scale hexagonal textures with different surface densities on the AISI 1045 steel surface to investigate its tribological properties under oil lubrication. The results revealed that the friction coefficient of the hexagonal textures with a 25% area density was 41% lower than the substrate. The hexagonal textures increase the hydrodynamic pressure of AISI 1045 steel and establish better lubrication performance. Zhang et al. [20] fabricated bionic textures on gray cast iron, showing superior wear resistance attributed to enhanced stress distribution at the edges of the textures and storing the lubricating oil.

Diamond-like carbon (DLC) coatings are an amorphous material characterized by carbon atoms bonded through sp2 and sp3 hybridization. These coatings exhibit the exceptional properties of both graphite and diamond, including low shear strength, self-lubrication, and increased hardness. Consequently, DLC coatings offer an effective solution for enhancing friction and wear performance [21]. Because of these advantages, they are used as protective coatings for a wide variety of materials [22,23,24]. Recent studies have highlighted the growing research interest in applying DLC coatings, while publications using CuAl10Fe5Ni5 remain limited [25,26]. The available results show that the application of a DLC coating on the surface of CuAl10Fe5Ni5 has great potential to improve its tribological properties and corrosion resistance. Although DLC coatings have been widely used in engineering applications, researchers have carried out research to further improve their frictional properties [27,28,29]. Currently, the combination of textures and coatings is revealed to have a synergistic effect that improves anti-friction and wear performance [30,31,32]. Surface texturing is an effective method to further enhance the surface properties of DLC coatings. Studies have shown that the construction of textured DLC coatings can significantly improve the tribological properties of materials and reduce friction and wear [33,34]. He et al. [35] investigated the tribological performance of in situ textured DLC coatings under oil-lubricated conditions. Their findings revealed that a surface density of 52% for the textured coating resulted in the lowest friction coefficient and wear rate. The microtextures served dual functions as both wear debris traps and lubricating oil reservoirs. Xing et al. [36] studied the synergistic effect of surface textures and DLC coatings on tribological properties of Si3N4/TiC ceramics. The results showed that DLC coatings combined with textures had the greatest effect on reducing friction and wear attributed to the formation of lubrication film secondary lubrication, and debris capture of textures.

In summary, both surface texture technology and surface coating improve the tribological properties of material surfaces. However, few studies have investigated the application of bionic textures and DLC coatings on CuAl10Fe5Ni5. In this study, laser processing was employed to fabricate two types of bionic surface textures on CuAl10Fe5Ni5: circular textures (inspired by jewel beetles) and hexagonal textures (inspired by python scales). The effects of these textures on the tribological properties of CuAl10Fe5Ni5 were investigated under various loads. On the basis of these research findings, hexagonal textures were selected as the substrate for depositing DLC coatings. The effects of these hexagonal biomimetic textures and DLC coatings on the friction and wear properties of CuAl10Fe5Ni5 surfaces were investigated.

2. Experimental Details

2.1. Materials

The CuAl10Fe5Ni5 samples with a diameter of Φ50 mm and a thickness of 4 mm were used as substrate disks, which were supplied by Jiashan Jingcheng Machinery Co., Ltd, Jiaxing, China. The chemical composition is listed in Table 1. Before laser texturing, the substrate samples were ground with up to 2000# mesh SiC sandpaper, and then polished with diamond grinding paste to achieve a surface roughness Ra of less than 0.08 μm. All the samples were subsequently ultrasonically cleaned with anhydrous ethanol and acetone in an ultrasonic instrument for 30 min to remove residual grease, dust, and other pollutants. GCr15 steel balls with a diameter of Φ10 mm were utilized as counterface balls purchased from Shanghai Xinzhou Bearing Industrial In, Shanghai, China. The chemical composition of GCr15 steel balls is 1.00 wt.% C, 1.52 wt.% Gr, 0.32 wt.% Mn, and 0.26 wt.% Si. The hardness and surface roughness Ra of the GCr15 counterface balls were approximately 700 HV and 0.01 μm, respectively.

Table 1.

The chemical components of CuAl10Fe5Ni5 specimen.

2.2. Laser Surface Texturing and Coating Deposition

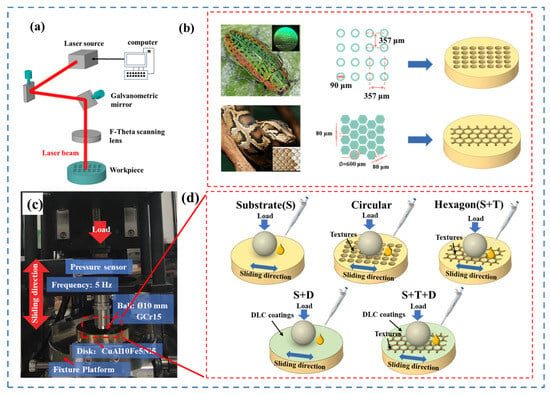

Nanosecond laser equipment (YLP-20f, Shenzhen, China) was used to produce circular and hexagonal bionic textures on the polished CuAl10Fe5Ni5 substrate surface. A schematic diagram of laser texture processing and laser texture parameter design is illustrated in Figure 1a,b. The two bionic textures selected in this work were inspired by the surface of the buprestid scale and the Python scale. From a tribological point of view, snake movement is the relationship between the mechanical force generated by the muscles and the motion resistance generated by the sliding between the skin and the ground; that is, the epidermis from the ventral side of the body must withstand high levels of friction [37]. There are three main types of snake scales under high friction [38]: regular polygons (mainly hexagonal), sawtooth, and fan, which are the result of the evolution of high levels of friction over a long period of time. To adapt for survival, the surface of the astragalus evolved into a nonsmoothed pit structure, which can effectively dredge water and dirt, so that the surface has good self-cleaning performance. The laser processing parameters were 8 W laser power, 200 mm/s scanning speed, 25 kHz pulse repetition rate, 8 μm filling spacing, and 5 processing rounds. The diameter of the circular bionic textures is 90 μm, and the distance between adjacent textures is 357 μm; these textures are uniformly arranged on the surface of CuAl10Fe5Ni5. The diameter of the outer circle of the hexagonal bionic textures is 600 μm and the width of the groove is 80 μm; these grooves are uniformly arranged on the surface of CuAl10Fe5Ni5. After laser texturing, all the CuAl10Fe5Ni5 samples were ground with grit of 2000, polished, and then ultrasonically cleaned in anhydrous ethanol for 30 min and dried. Before the DLC coating deposition process, the CuAl10Fe5Ni5 substrate was polished to achieve a surface roughness Ra of less than 0.08 μm. The DLC coating was deposited by using magnetron sputtering, (MS). The target selected was a graphite target with 99.99% purity (85 mm × 245 mm × 10 mm), and the working gas employed was Ar gas with a purity of 99.99%. The distance between the target and substrate was 100 mm. First, after the gas was pumped to a pressure lower than 1 × 10−3 Pa, Ar was injected at a rate of 16 cm3/min. The W transition layer was deposited for 5 min under a target current of 3.0 A and a bias voltage of −70 V. Then, the graphite target current was set to 3.5 A and the flow rate of the reaction gas isobutane was 16 cm3/min, and the deposition time was 4 h. Four different surface specimens were prepared to compare and analyze the effects of textures, DLC coatings, and the combination of textures and DLC coatings on tribological behavior, namely, a smooth substrate specimen (S), a textured surface specimen (S + T), a specimen with a smooth surface with a DLC coating (S + D), and a specimen with a textured surface with a DLC coating (S + T + D), respectively.

Figure 1.

(a) Schematic diagram of laser texturing; (b) two kinds of bionic laser texture parameter designs for the CuAl10Fe5Ni5 samples; (c) CFT-1 ball-on-disk tribometer; and (d) schematic diagram of the friction tests.

2.3. Friction and Wear Tests

Reciprocating sliding friction tests were carried out via a ball-on-disk CFT-1tribometer under oil lubrication conditions. The tribometer setup and friction diagram are shown in Figure 1c,d. During the friction test, a GCr15 steel ball was used as the upper sample for reciprocating movement, and a CuAl10Fe5Ni5 substrate was used as the lower sample for fixing the base. The friction experimental parameters were as follows: (i) To explore the influence of the bionic texture shape on the tribological properties of the CuAl10Fe5Ni5 surface under different loads, the nor al load was set at 5, 10, 15, and 20 N, the reciprocating frequency was 5 Hz, the reciprocating stroke was 5 mm, and the test time was 30 min. (ii) To explore the influence of surface texturing and DLC coatings on the tribological properties of the CuAl10Fe5Ni5 surface, the normal load was 5 N, the reciprocating frequency was 5 Hz, the reciprocating stroke was 5 mm, and the test time was 30 min. Each friction test was repeated at least three times to reduce experimental error.

2.4. Characterization of the Samples

The surface textures, worn surface morphology, and two-dimensional cross-sectional profile of the CuAl10Fe5Ni5 substrates and GCr15 balls after laser processing and friction tests were observed with a 3D noncontact laser microscope (OLYMPUS-OLS-5000, Tokyo, Japan). The worn surface morphologies of the CuAl10Fe5Ni5 samples and the GCr15 balls were analyzed by scanning electron microscopy (SEM, SIGMA, Oberkochen, Germany). The chemical composition of the worn surface on the GCr15 after the friction test was characterized via energy dispersive spectrometry (EDS, Bruker Nano XF Lash Detector 5010, Mannheim, Germany). A Raman spectrometer (Thermo Fisher Scientific DXR3, Waltham, MA, USA) with a 532 nm laser wavelength was used to detect and analyze the chemical composition and structure of the DLC coatings and worn surfaces. The oil contact angle on the sample surface was measured via a CMOS camera (GS3-U3-41C6C-C, FLIR Inc., Thief River Falls, MN, USA) and an adjustable zoom lens (Navitar Inc., Rochester, NY, USA, zoom 6000). Ra values were tested using an atomic force microscope (AFM, E-sweep, Tsukuba, Japan). Using a 3D noncontact laser microscope (OLYMPUS-OLS-5000, Tokyo, Japan) measurement of worn surface, it is easy to calculate wear volume. Combining the applied load and sliding distance we have given, and then using the mathematical equation, the wear rate (W) can be calculated as

where is the wear volume, mm3; L is the sliding distance, m; and F is the applied load, N.

3. Results and Discussion

3.1. Characterization of the Morphology and Contact Angle

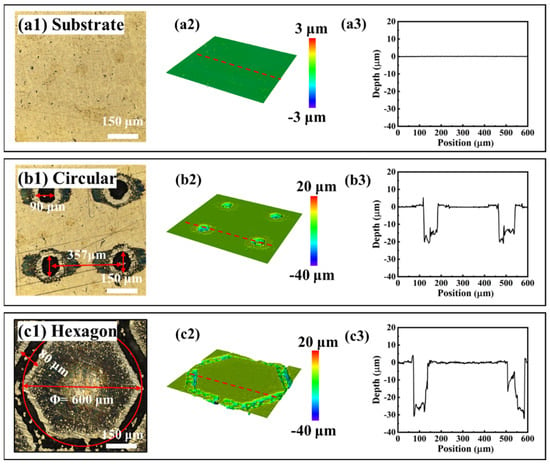

Figure 2 shows the surface 2D/3D images and dimple depth profile of the CuAl10Fe5Ni5 substrate and textured surface. Figure 2a1–a3 show that the surface of untreated CuAl10Fe5Ni5 is smooth without obvious protrusions. Figure 2b1–c3 show that the diameter of the circular texture is approximately 90 μm, and the depth is approximately 20 μm. The width of the hexagonal groove is approximately 80 μm, and the diameter of the outer circle is approximately 600 μm. As shown in Figure 2b1–c3, many metal oxide particles were present on the textured surface, and many burrs around the circular and hexagonal texture pits formed after laser surface processing. This suggests that a portion of the material removed by the laser underwent oxidation in air and subsequently redeposited onto the sample surface, whereas another fraction of the ablated material accumulated at the edges of the texture pits due to melting.

Figure 2.

The surface 2D/3D images and dimple depth profiles of the CuAl10Fe5Ni5 substrate and textured surface: (a1–a3) substrate; (b1–b3) circular texture; (c1–c3) hexagon texture.

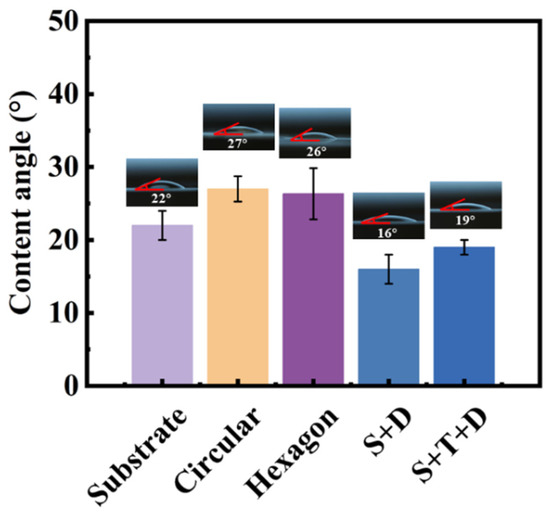

Figure 3 shows the oil contact angles of different samples. In Figure 3, the oil contact angle of the CuAl10Fe5Ni5 substrate is 22°. Compared with that of the CuAl10Fe5Ni5 substrate, the oil contact angle of the circular texture and the hexagonal texture is increased by approximately 5°. The greater the oil contact angle is, the weaker the wetting ability of the liquid on a solid surface [39]. The contact angle of the DLC coating (S + D) is 16°, and that of the textured DLC coating (S + T + D) is 19°. Compared with those of the CuAl10Fe5Ni5 substrate and textured surfaces, the optimal contact angle of the surface after DLC coating is lower, indicating that the DLC coating surface has better oil-wet characteristics. The smaller the oil contact angle, the better the lipophilicity [35]. Therefore, DLC-coated samples are more likely to form a continuous lubricating film on the surface of the DLC coatings during friction [40].

Figure 3.

Oil contact angles of different samples.

3.2. Influence of the Bionic Texture Shape on the Tribological Properties of the CuAl10Fe5Ni5 Surface

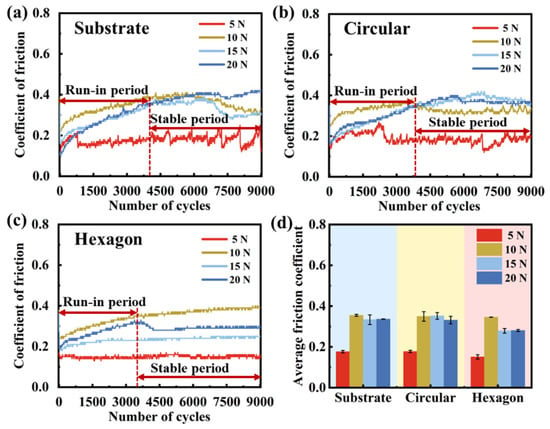

Figure 4 shows the friction coefficient curve and average friction coefficient of the CuAl10Fe5Ni5 substrate and textured surface under different loads. Figure 4a–c shows how, compared with that of the textured surface, the running-in period of the smooth CuAl10Fe5Ni5 substrate surfaces under different loads is longer. The textured surface can shorten the running-in period and quickly enter the stable stage. During the friction process, the texture has functions to store lubricating oil and wear debris, making the friction process more stable, which may be the reason why the texture surface enters the stable period faster. When the load is 5 N, the friction coefficient of the CuAl10Fe5Ni5 substrate and textured surface is the lowest, and the friction coefficient of the CuAl10Fe5Ni5 substrate surface continues to fluctuate, which may be caused by the processing quality of CuAl10Fe5Ni5. This phenomenon is significantly reduced after texture preparation on the substrate surface, especially on the hexagonal texture surface (Figure 4c). For the hexagonal texture surface, the friction coefficient curve is more stable and lower than that of the CuAl10Fe5Ni5 substrate and circular texture surface under the same load, which is due to the reduction in the contact stress on the hexagonal texture surface and results in a better lubrication film. Figure 4d shows the average friction coefficients of the CuAl10Fe5Ni5 substrate and textured surface under different loads. When the load increased from 5 N to 10 N, the average friction coefficients of these three surfaces significantly rose. This is attributed to the increased load leading to a greater number of microconvex bodies in contact with the sliding surfaces and a deeper embedding into the softer friction pair surfaces. However, the overall friction coefficient decreased under higher loads (15 N and 20 N). This can be attributed to the relatively low hardness of the CuAl10Fe5Ni5 material, which leads to plastic deformation during wear. The textures dissipate deformation pressure during the wear process, thereby reducing the generation of wear particles and decreasing the friction force [41,42]. At higher loads, textures facilitate the formation of a more effective lubricating film at the friction interface and enhance the lubricating performance. This reduced the coefficient of friction and resulted in less friction between surfaces. In addition, the average friction coefficient of the hexagonal textures is significantly lower than that of the other two surfaces under high loads. This can be attributed to the superior oil retention capability of continuous hexagonal textures compared with discontinuous textures. At high loads, the lubricating oil retained within the surface textures tends to overflow as the textures wear, leading to a secondary lubrication effect.

Figure 4.

Friction coefficient curves and average friction coefficients of the CuAl10Fe5Ni5 substrate and textured surface under different loads: (a) substrate; (b) circular texture; (c) hexagon texture; and (d) average coefficient of friction.

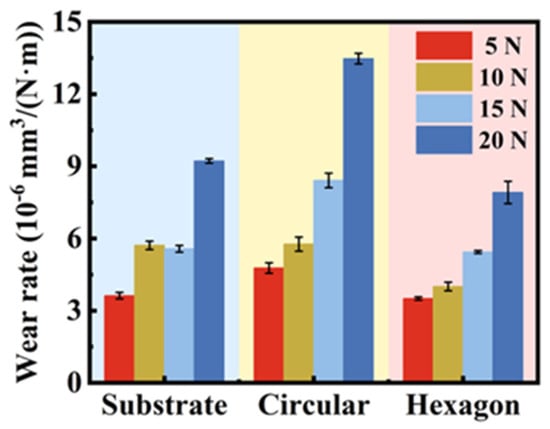

Figure 5 exhibits the wear rates of the CuAl10Fe5Ni5 substrate and textured surface under different loads. As shown in Figure 5, the wear rate of the CuAl10Fe5Ni5 substrate and textured surface increases with increasing load. Furthermore, while the friction coefficient of the circular texture surface is not significantly different from that of the smooth surface, the wear rate is generally greater. The wear rate of the hexagonal texture surface is the lowest among the three surfaces. Specifically, under higher loads of 15 N and 20 N, the wear rate decreases by 64% and 12%, respectively, compared with that of the smooth surface.

Figure 5.

Wear rate of the CuAl10Fe5Ni5 substrate and textured surface under different loads.

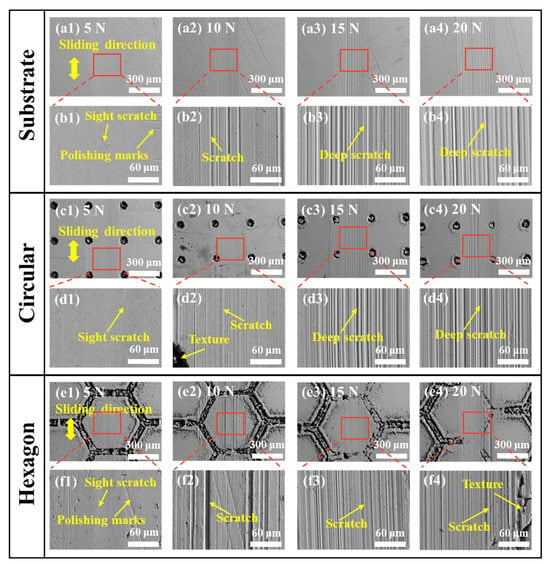

Figure 6 shows the SEM morphologies of the CuAl10Fe5Ni5 substrate and textured surface under different loads. Slight wear is found on the CuAl10Fe5Ni5 substrate (Figure 6b1) and textured surfaces (Figure 6d1,f1) when the load is 5 N. Numerous groove-like scratches are observed on the worn surfaces of these three samples under a load of 10 N, indicating that abrasive wear has occurred. This phenomenon is likely the primary cause of the abrupt increase in the friction coefficient when the load increased from 5 N to 10 N. Deep scratches were observed at 10 N between the smooth surface (Figure 6b2) and the hexagonal textured surface (Figure 6f2), possibly attributed to the relatively low hardness of CuAl10Fe5Ni5, which is easier to peel off during the friction process. The formation of hard oxide particles and granular oxides during friction leads to more severe scratches on the substrate. With a further increase in the load to 15 N and 20 N, the furrowing and wear depths of the substrate and textured surface increase. Compared with the other two surfaces, the overall hexagonal texture surface has fewer scratches and a relatively reduced degree of surface wear.

Figure 6.

SEM morphology of the wear scars of the CuAl10Fe5Ni5 substrate and textured surface under different loads: (a1–b4) substrate; (c1–d4) circular texture; and (e1–f4) hexagon texture.

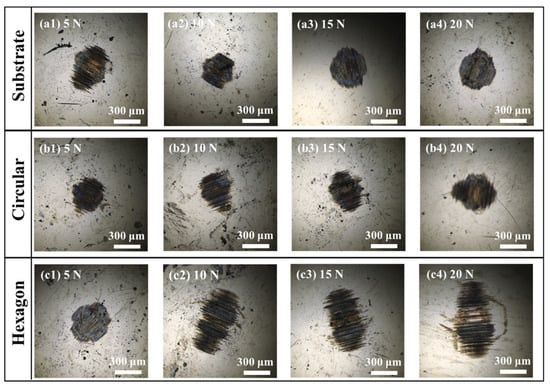

Figure 7 shows the optical worn morphology of the GCr15 steel balls under different loads. As shown in Figure 7, there are obvious scratches on the surface of the GCr15 steel ball. With the increasing load, the wear area and degree of wear of the GCr15 steel ball surface further increase, especially when the load increases to 15 N and 20 N. This corresponds to the wear rate shown in Figure 5. Under the same load, the surface of the GCr15 steel ball with a hexagonal texture is larger than that of the CuAl10Fe5Ni5 substrate and has a circular texture.

Figure 7.

Optical worn morphology of the GCr15 steel balls against CuAl10Fe5Ni5 substrate and textured surface under different loads: (a1–a4) substrate; (b1–b4) circular texture; and (c1–c4) hexagon texture.

3.3. Influence of Textured DLC Coatings on the Tribological Properties of the CuAl10Fe5Ni5 Surface

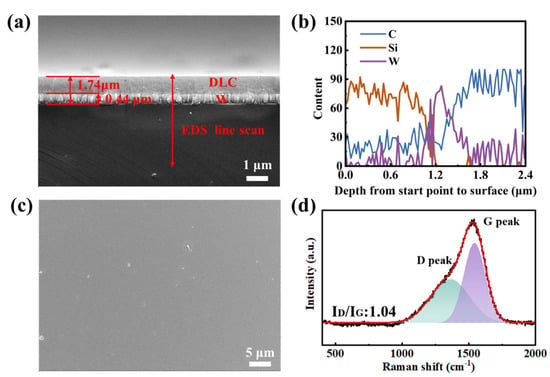

Figure 8 shows the SEM cross-section and surface morphology, corresponding EDS line analyses, and Raman spectra of the DLC coatings. As shown in Figure 8a, DLC coatings have a dense structure and no obvious defects, and an obvious transition layer structure can be observed between the substrate and the coating The thickness of the transition layer is approximately 0.44 μm and the DLC coating thickness is approximately 1.74 μm. Combined with the EDS analysis in Figure 8b, the transition layer is mainly W and the DLC coating is mainly C. Figure 8c shows that the surface morphology of DLC coating is smooth and flat, and few agglomerated particles can be seen. As shown in Figure 8d, the Raman analyses at 1347 cm−1 and 1538 cm−1 peaks exhibit obvious D and G peaks, and the ID/IG of the DLC coatings is 1.04, indicating the existence of DLC coatings composed of coexisting sp3 and sp2 networks [43,44].

Figure 8.

(a) Cross-section, (b) corresponding EDS line analyses, (c) surface morphology, and (d) Raman spectrum of the DLC coating.

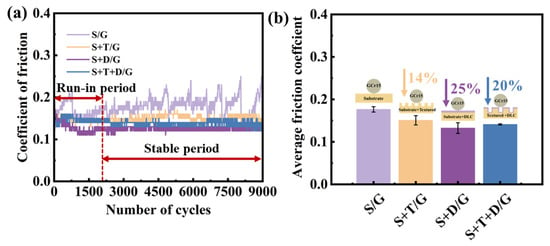

On the basis of the research above, a DLC coating on a hexagonal bionic textured surface can further enhance the friction and wear properties of the CuAl10Fe5Ni5 substrate surface. Figure 9 shows the friction coefficient curves and average friction coefficients for various CuAl10Fe5Ni5 surfaces. Figure 9a illustrates that the friction coefficient curve for the smooth surface (S) is both high and unstable. In contrast, the textured surface (S + T) has a significantly lower friction coefficient. The DLC-coated surface (S + D) and the textured DLC-coated surface (S + T + D) demonstrate consistently low and stable friction coefficients, with minimal fluctuations observed after an initial running-in period. As shown by the average friction coefficient in Figure 9b, both the texturing treatment and the texturing DLC coating treatment on the smooth substrate surface (S) significantly reduce the friction coefficient, and the friction coefficient of the DLC coating surface (S + D) is the lowest. The friction coefficient of the textured DLC coating (S + T + D) is lower than that of the hexagonal bionic textured surface (S + T) but slightly greater than that of the DLC coating surface (S + D).

Figure 9.

Friction coefficients of different CuAl10Fe5Ni5 surfaces: (a) friction coefficient curves and (b) average coefficient of friction.

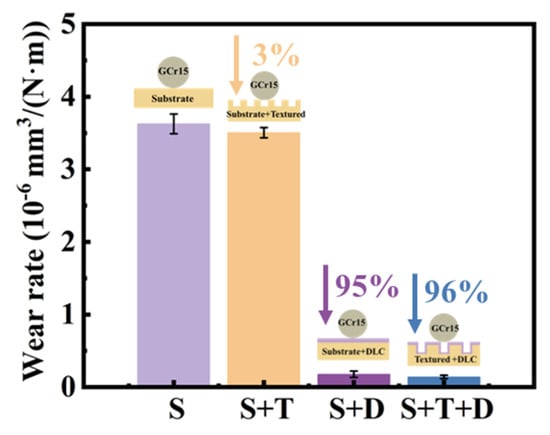

Figure 10 shows the wear rates of various CuAl10Fe5Ni5 surfaces. As shown in the Figure 10, the wear rate of the smooth substrate surface (S) can be reduced after post treatment with the hexagonal bionic texture (S + T), but the wear rate is reduced by only 3%. However, DLC coatings demonstrate significant advantages in enhancing wear resistance. Specifically, the wear rate of the DLC coating surface (S + D) is reduced by 95% relative to that of the smooth substrate surface (S), whereas that of the textured DLC coating (S + T + D) is further reduced by 96%. The significant decrease in the wear rate of the textured DLC coating (S + T + D) can be attributed to the hydrodynamic pressure generated by the hexagonal texture, which enhances the load-carrying capacity. This improvement effectively facilitates the storage of wear debris and lubricant. On the other hand, this is due to the high hardness and self-lubrication characteristics of DLC coatings [45]. Therefore, the DLC coating can reduce the wear effect of the material surface and improve the wear stability.

Figure 10.

Wear rates for different CuAl10Fe5Ni5 surfaces.

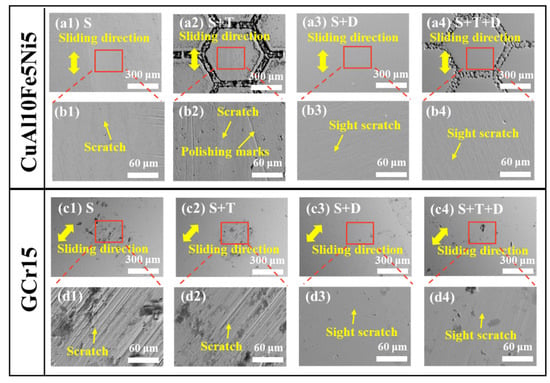

Figure 11 shows the SEM morphology of the wear scar of the GCr15 steel ball on the upper sample and CuAl10Fe5Ni5 on the lower sample after the friction and wear process. As shown in Figure 11a1,a2, scratches can be observed on the CuAl10Fe5Ni5 substrate and the hexagonal textured surface, and the corresponding worn surface of the GCr15 steel ball is severe, and obvious furrows and adhesion can be observed in the wear area (Figure 11c1,c2). However, the surfaces of the DLC coating (S + D) and textured DLC coating (S + T + D) showed slight scratches, and the corresponding degree of wear on the surface of the GCr15 steel balls was significantly reduced (Figure 11c3,c4), indicating that the DLC coating can significantly improve the wear resistance of the substrate.

Figure 11.

SEM morphology of sample surfaces with CuAl10Fe5Ni5 and GCr15: (a1–a4) S; (b1–b4) S + T; (c1–c4) S + D and (d1–d4) S + T + D.

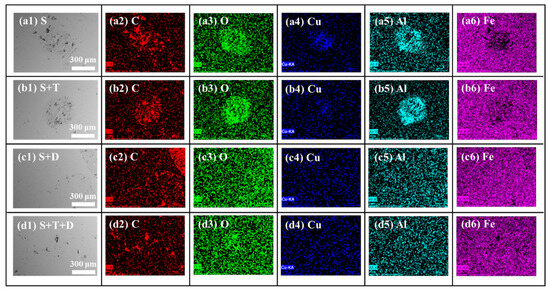

Figure 12 shows the element mapping of the worn surfaces of the GCr15 steel balls. As shown in Figure 12a1–b6, Al element enrichment and Fe element reduction were evident in the wear scars, indicating that a transfer film was formed on the surface of the GCr15 steel ball during the friction against the CuAl10Fe5Ni5 substrate and the textured CuAl10Fe5Ni5 surface. Additionally, a significant accumulation of O elements in the wear scars indicates that the friction process is accompanied by an oxidation reaction, and that oxidative wear occurs. However, Figure 12c1–d6 show that when the coated CuAl10Fe5Ni5 surface was worn slightly, no obvious element aggregation was found by EDS mapping, indicating that no element transfer or oxidation reactions occurred during the wear process. As shown in Figure 12c1–d6, after the GCr15 steel balls were rubbed with the DLC coating and textured DLC coating, no significant enrichment of Al or O was observed on the worn surface, indicating that the DLC coating can reduce the transfer and oxidative wear of the lower sample during friction.

Figure 12.

EDS spectra of the worn surfaces of the GCr15 steel balls: (a1–a6) S; (b1–b6) S + T; (c1–c6) S + D and (d1–d6) S + T + D.

3.4. Discussion

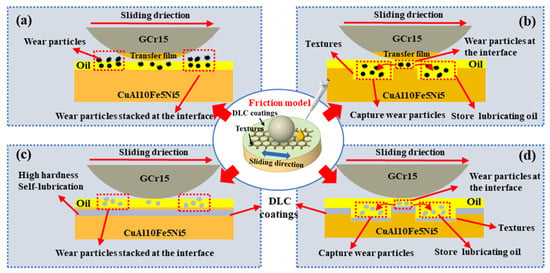

Figure 13 shows the schematic diagram of the wear mechanism of different CuAl10Fe5Ni5 surfaces under oil lubrication. For the CuAl10Fe5Ni5 substrate surface shown in Figure 13a, a significant accumulation of wear particles was observed at the contact interface. This accumulation interferes with the sliding process, leading to severe wear. When the surface is treated with hexagonal bionic texture (Figure 13b), the texture has the function of capturing wear debris to reduce abrasive wear and storing lubricating oil to supplement secondary lubrication, which can reduce the wear of the contact surface. In addition, a texture that reduces the contact area of the contact surface can also reduce the friction coefficient in the friction process to a certain extent. Because of the low hardness of CuAl10Fe5Ni5 and the high hardness of the GCr15 steel ball, CuAl10Fe5Ni5 easily transfers to transfer to the surface of the GCr15 steel ball during the friction process. For the DLC coating and the textured DLC coating in Figure 13c,d, the hardness of the DLC coating is greater than that of the other coatings, and the number of wear particles at the friction interface are significantly reduced. For the textured DLC coating, when wear particles are generated on the contact surface, they move along with the friction pair and are captured by the textures. Under oil lubrication conditions, the surface textures served dual functions as both wear debris was captured and lubricating oil was stored, thereby generating a secondary lubrication effect [36]. Owing to the relative movement between the friction surfaces and the extrusion deformation to a certain extent under the load, the lubrication fluid within the textures is progressively extruded, ensuring continuous lubrication of the friction pair surfaces. The lubrication fluid stored in the surface textures can be used as the secondary supply source of friction lubrication, which can significantly improve the lubrication state between contact surfaces. For the DLC coating (S + D) shown in Figure 13c, the anti-friction and wear resistance mechanisms primarily rely on the high hardness and self-lubricating properties of the DLC coating, enhancing the tribological performance of CuAl10Fe5Ni5. On this basis, the textured DLC coating (Figure 13d) has high hardness and self-lubrication, and the textured storage lubricating oil supplements the secondary lubrication and stores the wear debris to reduce the abrasive wear, so the tribological properties of the CuAl10Fe5Ni5 surface are further improved.

Figure 13.

Schematic diagram of the wear mechanism of different CuAl10Fe5Ni5 surfaces under oil lubrication: (a) S; (b) S + T; (c) S + D and (d) S + T + D.

4. Conclusions

In this work, the friction and wear behavior of various CuAl10Fe5Ni5 samples were evaluated against a GCr15 steel ball. The impact of texture shape on the tribological properties of CuAl10Fe5Ni5 surfaces under varying loads was investigated. The influence of textured DLC coatings on the tribological properties of CuAl10Fe5Ni5 surfaces was illustrated. The conclusions can be drawn as follows.

- Compared with substrate, texture reduced and inhibited the generation of wear particles under various loads, thereby enhancing the stability of the CuAl10Fe5Ni5 surface during friction and minimizing surface wear. Moreover, textures provided an excellent oil retention effect and promoted secondary lubrication, further reducing wear.

- The hexagonal texture exhibited excellent friction and wear resistance, particularly under high loads of 15 N and 20 N. Compared with a smooth surface, the average friction coefficient of the hexagonal textures decreased by 25% and 16%, respectively, whereas the wear rate was reduced by 64% and 12%, respectively.

- DLC coatings can significantly enhance the tribological properties of CuAl10Fe5Ni5 materials. Owing to the high hardness and self-lubricating characteristics of DLC coatings, the textured storage lubricating oil supplements secondary lubrication and stores wear debris to reduce abrasive wear. Compared with those of S, the friction coefficients of S + D and S + T + D were 25% and 20% lower, and the wear rates of S + D and S + T + D were 95% and 96% lower, respectively.

Author Contributions

Conceptualization, M.W.; methodology, M.W. and M.Z.; formal analysis, M.Z.; investigation, M.W. and M.Z.; data curation, M.Z.; writing—original draft preparation, M.W.; writing—review and editing, X.M. and X.P.; funding acquisition, M.W. and X.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the National Natural Science Foundation of China (Grant No. 52105217), the Natural Science Foundation of Zhejiang Province (Grant No. LQ22E050020), and the State Key Program of the National Natural Science Foundation of China (Grant No. U2241246).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Huttunen-Saarivirta, E.; Isotahdon, E.; Metsäjoki, J.; Salminen, T.; Carpén, L.; Ronkainen, H. Tribocorrosion behaviour of aluminium bronze in 3.5 wt.% NaCl solution. Corros. Sci. 2018, 144, 207–223. [Google Scholar] [CrossRef]

- Öztürk, S.; Sünbül, S.E.; Metoğlu, A.; Kürşat, İ.Ç.İ.N. Improvement of microstructure, tribology and corrosion characteristics of nickel-aluminum bronze by P/M method. Tribol. Int. 2020, 151, 106519. [Google Scholar] [CrossRef]

- Rashidi, M.M.; Ahmad, A.H. Investigation of nickel aluminium bronze castings properties by degassing agent technique. Mater. Sci. Eng. A 2019, 469, 012037. [Google Scholar]

- Lin, G.; Wang, H.; Wei, Y.; Zhang, Z.; Zhou, K. Effects of heat treatments on microstructure and properties of nickel-aluminum bronze fabricated by centrifugal casting. J. Mater. Res. 2016, 31, 3832–3840. [Google Scholar] [CrossRef]

- Nnakwo, C.; Obi, A.; Odo, J.U. Effect of heat treatment parameters on the structure and mechanical properties of aluminium bronze (Cu-10wt% Al). Am. J. Mater. Sci. Appl. A 2017, 5, 16–24. [Google Scholar]

- Nair, S.; Sellamuthu, R.; Saravanan, R. Effect of nickel content on hardness and wear rate of surface modified cast aluminum bronze alloy. Mater. Today 2018, 5, 6617–6625. [Google Scholar] [CrossRef]

- Tao, X.P.; Zhang, S.; Wu, C.L.; Zhang, C.H.; Zhang, J.B.; Liu, Y. Thermal stability and corrosion resistance in a novel nickle aluminum bronze coating by laser cladding. Mater. Res. Express 2018, 5, 116527. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, W.; Guo, Q.; Wang, N.; Chi, B.; Yu, J. Effect of picosecond laser surface texturing under babbitt coating mask on friction and wear properties of GCr15 bearing steel surface. Eng. Fail. Anal. 2024, 157, 107878. [Google Scholar] [CrossRef]

- Profito, F.J.; Vladescu, S.C.; Reddyhoff, T.; Dini, D. Numerical and experimental investigation of textured journal bearings for friction reduction. Tribol. Int. 2024, 195, 109643. [Google Scholar] [CrossRef]

- Butler-Smith, P.; Burtt, N.; See, T. The friction of surface textured cylinder liner segments modified by direct laser writing and direct laser interference patterning processes. J. Manuf. Process. 2024, 117, 366–374. [Google Scholar] [CrossRef]

- Schnell, G.; Studemund, H.; Thomas, R.; Seitz, H. Experimental investigations on the friction behavior of partially femtosecond laser-textured journal bearing shells. Tribol. Int. 2023, 188, 108764. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, Y.; Li, Z.; Zhan, X. Sealing performance and optimization design of squamous textured mechanical seal. Tribol. Int. 2024, 193, 109425. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, W.; Wang, M.; Sun, T.; Zhang, X.; Wu, Y.; Zheng, H. Attaining superhydrophobic and superoleophilic bronze surface by picosecond laser texturing and post-heat treatment. Opt. Laser Technol. 2024, 177, 111139. [Google Scholar] [CrossRef]

- Bharatish, A.; Rajkumar, G.R.; Gurav, P.; Babu, G.S.; Murthy, H.N.; Roy, M. Optimization of laser texture geometry and resulting functionality of nickel aluminium bronze for landing gear applications. Int. J. Lightweight Mater. Manuf. 2021, 4, 346–357. [Google Scholar] [CrossRef]

- Wu, G.; Zhu, L.; Chen, X.; Li, L.; Zhang, S.; Wang, Y.; Yao, J. Growth characteristics and wear properties of micro-arc oxidation coating on Ti-6Al-4V with different laser texture shapes. Surf. Coat. Technol. 2023, 475, 130108. [Google Scholar] [CrossRef]

- Yang, X.; Chen, W.; Zhang, Y.; Li, Z.; Yang, J.; Dai, B.; Qiu, Z. Tribological properties of MAO coating deposited on aluminum base bearing alloy with different texture shapes. Surf. Coat. Technol. 2024, 492, 131191. [Google Scholar] [CrossRef]

- Segu, D.Z.; Hwang, P. Friction control by multi-shape textured surface under pin-on-disc test. Tribol. Int. 2015, 91, 111–117. [Google Scholar] [CrossRef]

- Chen, Y.; Meng, J.; Gu, Z.; Wan, X.; Jiang, L.; Wang, S. Bioinspired multiscale wet adhesive surfaces: Structures and controlled adhesion. Adv. Funct. Mater. 2020, 30, 1905287. [Google Scholar] [CrossRef]

- Zhong, Y.; Zheng, L.; Gao, Y.; Liu, Z. Numerical simulation and experimental investigation of tribological performance on bionic hexagonal textured surface. Tribol. Int. 2019, 129, 151–161. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, T.; Zhou, H.; Chen, Z.; Yang, W.; Ren, L. Effects of different bionic units coupling on the sliding wear of gray cast iron. Surf. Coat. Technol. 2017, 309, 96–105. [Google Scholar] [CrossRef]

- Su, Y.; Ma, Y.; Huang, W.; Zhang, T.; Yu, W.; Hu, R.; Ruan, H. The effects of medium and friction pair on the tribological behavior of Mo-doped DLC films. Diam. Relat. Mater. 2024, 148, 111464. [Google Scholar] [CrossRef]

- Masuko, M.; Ono, T.; Aoki, S.; Suzuki, A.; Ito, H. Friction and wear characteristics of DLC coatings with different hydrogen content lubricated with several Mo-containing compounds and their related compounds. Tribol. Int. 2015, 82, 350–357. [Google Scholar] [CrossRef]

- Pires, M.S.T.; Doca, T.; Steier, V.F.; da Silva, W.M.; Júnior, M.O. Wear resistance of coated SAE 305 aluminum alloy under dry friction reciprocate sliding. Tribol. Lett. 2018, 66, 57. [Google Scholar] [CrossRef]

- Hao, T.; Du, J.; Su, G.; Zhang, P.; Sun, Y.; Zhang, J. Mechanical and cutting performance of cemented carbide tools with Cr/x/DLC composite coatings. Int. J. Adv. Manuf. Technol. 2020, 106, 5241–5254. [Google Scholar] [CrossRef]

- Mousavi, S.E.; Naghshehkesh, N.; Amirnejad, M.; Shammakhi, H.; Sonboli, A. Corrosion performance and tribological behavior of diamond-like carbon based coating applied on Ni-Al-bronze alloy. Trans. Nonferrous Met. Soc. China 2021, 31, 499–511. [Google Scholar] [CrossRef]

- Javidparvar, A.A.; Mosavi, M.A.; Ramezanzadeh, B. Nickel-aluminium bronze (NiBRAl) casting alloy tribological/corrosion resistance properties improvement via deposition of a Cu-doped diamond-like carbon (DLC) thin film; optimization of sputtering magnetron process conditions. Mater. Chem. Phys. 2023, 296, 127279. [Google Scholar] [CrossRef]

- Cicek, H. Wear behaviors of TiN/TiCN/DLC composite coatings in different environments. Ceram. Int. 2018, 44, 4853–4858. [Google Scholar] [CrossRef]

- Dhandapani, V.S.; Kang, K.M.; Seo, K.J.; Kim, C.L.; Kim, D.E. Enhancement of tribological properties of DLC by incorporation of amorphous titanium using magnetron sputtering process. Ceram. Int. 2019, 45, 11971–11981. [Google Scholar] [CrossRef]

- Zavaleyev, V.; Walkowicz, J.; Kuznetsova, T.; Zubar, T. The dependence of the structure and mechanical properties of thin ta-C coatings deposited using electromagnetic venetian blind plasma filter on their thickness. Thin Solid Film. 2017, 638, 153–158. [Google Scholar] [CrossRef]

- Wu, J.; Deng, J.; Bao, Y.; Zhang, Z. Synergistic effects of heat-assisted ultrasonic rolling textures and self-lubricating coatings on the friction and wear properties of AISI 52100 steel. Mater. Today Commun. 2024, 38, 108256. [Google Scholar] [CrossRef]

- Xing, Y.; Wu, Z.; Yang, J.; Wang, X.; Liu, L. LIPSS combined with ALD MoS2 nano-coatings for enhancing surface friction and hydrophobic performances. Surf. Coat. Technol. 2020, 385, 125396. [Google Scholar] [CrossRef]

- Wang, H.; Tian, L.; Zheng, J.; Yang, D.; Zhang, Z. The synergetic effects of laser texturing and super-hydrophobic coatings on improving wear properties of steel. Tribol. Int. 2022, 173, 107657. [Google Scholar] [CrossRef]

- Wang, R.; Deng, J.; Zhang, Z.; Sun, Q. Tribological properties of Ni3Al-Ti3SiC2-MoS2 composite films deposited on textured surfaces by electrohydrodynamic atomization. Wear 2022, 508, 204486. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Baykara, M.Z.; Martini, A. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear-a review. Tribol. Int. 2021, 155, 106792. [Google Scholar] [CrossRef]

- He, D.; He, C.; Li, W.; Shang, L.; Wang, L.; Zhang, G. Tribological behaviors of in-situ textured DLC films under dry and lubricated conditions. Appl. Surf. Sci. 2020, 525, 146581. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, X.; Du, Z.; Zhu, Z.; Wu, Z.; Liu, L. Synergistic effect of surface textures and DLC coatings for enhancing friction and wear performances of Si3N4/TiC ceramic. Ceram. Int. 2022, 48, 514–524. [Google Scholar] [CrossRef]

- Toro, A.; Abdel-Aal, H.A.; Zuluaga, E.; Cuervo, P.; Ballesteros, L.M.; Sánchez, J.C.; Rudas, J.S.; Isaza, C.; Misiolek, W.Z. Influence of surface morphology and internal structure on the mechanical properties and tribological response of Boa Red Tail and Python Regius snake skin. J. Mech. Behav. Biomed. Mater. 2021, 119, 104497. [Google Scholar] [CrossRef]

- Huang, Q.; Shi, X.; Xue, Y.; Zhang, K.; Gao, Y.; Wu, C. Synergetic effects of biomimetic microtexture with multi-solid lubricants to improve tribological properties of AISI 4140 steel. Tribol. Int. 2022, 167, 107395. [Google Scholar] [CrossRef]

- Baumann, R.; Heilmann, S.; Köberlin, D.; Füssel, U.; Lasagni, A.F. Influencing the contact angle during brazing by direct laser interference structured textures on the substrate surface. Mater. Lett. 2022, 13, 100129. [Google Scholar] [CrossRef]

- Guo, P.; Geng, Z.; Lu, Z.; Zhang, G.; Wu, Z. Probing the lubrication mechanism of rough diamond-like carbon films against silicon nitride under water. Tribol. Int. 2018, 128, 248–259. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, J.; Meng, Y.; Yue, H. Tribological performance of steel guideway with biomimetic hexagonal micro-textures. Surf. Eng. 2020, 36, 756–764. [Google Scholar] [CrossRef]

- Li, L.; Li, Z.; Xing, Z.; Guo, W.; Huang, Y.; Wang, H. Effect of femtosecond laser bionic texture on anti-wear properties of medical Ti-6Al-4 V. Tribol. Int. 2023, 190, 109062. [Google Scholar] [CrossRef]

- Kasiorowski, T.; Lin, J.; Soares, P.; Lepienski, C.M.; Neitzke, C.A.; De Souza, G.B.; Torres, R.D. Microstructural and tribological characterization of DLC coatings deposited by plasma enhanced techniques on steel substrates. Surf. Coat. Technol. 2020, 389, 125615. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, X.T.; Xie, H.; Hing, P. A phenomenological approach for the Id/Ig ratio and sp3 fraction of magnetron sputtered a-C films. Surf. Coat. Technol. 2000, 123, 256–260. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Liu, T.; Zhang, P. Effect of normal loads and mating pairs on the tribological properties of diamond-like carbon film. Wear 2021, 486, 204083. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).