Abstract

To address the inherent limitations of easy oxidation and unstable electrical properties in two-dimensional MXene-based flexible sensors, this study developed a MXene/GO/rGO (reduced graphene oxide) textile-based flexible sensor using a lamination method and in situ steam reduction technology. The sensor was constructed on a high-elasticity knitted polyester fabric, with MXene as the primary conductive layer, graphene oxide (GO) as the adhesive layer, and reduced graphene oxide (rGO) as the protective encapsulation surface layer. The tensile strain-sensing and electrothermal properties of the resulting e-textile were systematically characterized. The MXene/GO/rGO textile demonstrated outstanding electrical and mechanical performance, achieving a conductivity of 39.7 S·m−1, a gauge factors ranging from –3 to –1.6, and a controllable electrothermal heating range from 43 °C to 85 °C under currents of 0.02–0.05 A. Experimental results demonstrated that under applied currents of 0.02, 0.03, 0.04, and 0.05 A, the fabric reached temperatures of 43, 56, 73, and 85 °C, respectively, and remained constant over extended periods. In terms of strain sensing, the sensor exhibited a short response time (65 ms), high discriminability for different strain levels and stretching rates, and a consistent relative resistance change (ΔR/R0) under various stretching speeds (0.5, 1, 2, 4, and 6 mm/s). Compared with sensors based on a single conductive material, the MXene/GO/rGO polyester fabric sensor shows superior electrothermal and strain-sensing performance, indicating promising potential for applications in intelligent wearable textiles such as medical thermal therapy, sports monitoring, and health management.

1. Introduction

Flexible wearable electronic coatings have recently gained significant attention as multifunctional platforms for intelligent data acquisition and real-time health monitoring. By integrating sensing, signal-processing, and flexible substrate technologies, these coatings enable seamless human–computer interaction and continuous physiological monitoring in daily life [,,]. Textile-based substrates have attracted particular interest as ideal carriers for wearable electronic systems owing to their inherent softness, breathability, and mechanical adaptability. Compared with polymer films or paper-based flexible substrates, textiles provide superior air permeability and stretchability, ensuring long-term wearing comfort and reducing skin irritation. In particular, knitted fabrics—with their interlooped structure and high deformation tolerance—can sustain electrical continuity under repeated bending, compression, or stretching, which is highly desirable for strain and temperature sensing. Consequently, the development of textile-integrated conductive systems that preserve the intrinsic flexibility and comfort of fabrics while endowing them with multifunctional electrical performance has become a crucial direction in next-generation wearable electronics. The fabrication of conductive textiles generally follows two major routes: fabric-level surface coating and fiber-level intrinsic modification. The former constructs conductive networks on textile surfaces via scalable coating or printing methods, such as dipping, spraying, or vapor deposition [,]. The latter imparts electrical functionality to individual fibers by introducing conductive nanocomposites or embedding liquid-metal fillers within the fiber matrix [,]. While both strategies have achieved notable progress, challenges remain in achieving coatings that simultaneously exhibit high conductivity, flexibility, and environmental stability under mechanical deformation [].

Among the various conductive materials explored for such applications, two-dimensional MXenes have emerged as particularly promising candidates. MXenes, represented by Ti3C2Tx, possess high metallic conductivity, tunable surface terminations, and excellent mechanical flexibility, making them ideal for flexible sensing, shielding, and heating coatings [,]. However, their practical application is greatly hindered by chemical instability. MXene nanosheets are easily oxidized in the presence of water and dissolved oxygen, leading to the formation of TiO2, which progressively spreads over the surface and deteriorates electrical performance [,,,]. To address this issue, researchers have developed several stabilization strategies that can be broadly categorized into protective-layer encapsulation and surface functionalization. For instance, Zhuo et al. [] employed a polyimide coating to isolate MXene from moisture and oxygen, while Zeng et al. [] used tannic acid modification to improve oxidation resistance. Nevertheless, these approaches suffer from inherent drawbacks: encapsulation layers often reduce conductivity and flexibility, whereas functionalization processes are complex, difficult to scale, and may introduce surface defects that compromise performance [,]. Therefore, it remains crucial to design coating architectures that enhance MXene’s environmental stability without sacrificing its intrinsic electrical and mechanical advantages.

Graphene and its derivatives provide a complementary pathway to overcome these challenges []. Pristine graphene exhibits outstanding conductivity and mechanical strength but poor compatibility with polar solvents and polymeric substrates due to its non-polar carbon lattice. In contrast, oxidation yields graphene oxide (GO), which introduces abundant oxygen-containing functional groups, endowing the material with excellent hydrophilicity, dispersibility, and interfacial adhesion—essential for coating formation and layer uniformity [,,]. However, the conversion to GO also disrupts the π-conjugated network, resulting in diminished conductivity. Partial reduction of GO can effectively restore its electronic transport properties, yielding reduced graphene oxide (rGO) with improved conductivity while maintaining surface functionality []. rGO-coated polyester fabrics were successfully fabricated through a dip-coating and in situ reduction process [], demonstrating stable electrothermal behavior and strong adhesion, which highlight the potential of solution-based coating techniques for wearable conductive materials [].

Building upon these concepts, the present study proposes a laminated MXene/GO/rGO coating architecture that integrates the stability of GO and the conductivity of rGO with the high performance of MXene []. In this structure, GO acts as both an interfacial adhesive and a barrier layer, effectively isolating MXene from oxidative environments, while partial reduction to rGO establishes efficient electron-transport pathways across interfaces. Unlike previous MXene/graphene hybrids that rely on direct physical blending or co-deposition of conductive fillers—approaches that often produce poorly defined interfaces, require trade-offs between adhesion and conductivity, or introduce insulating binders—the lamination-based strategy decouples functions into distinct layers. The GO interlayer provides strong chemical and mechanical coupling to the polyester substrate and serves as a diffusion barrier against oxygen and moisture, whereas the MXene layer supplies high intrinsic conductivity and the outer rGO layer restores inter-sheet electronic contact after reduction. This spatial separation allows protection of MXene without substantially diluting the conductive network, improves coating adhesion and mechanical integrity under deformation, and enables independent control of each layer’s thickness and composition during scalable dip-coating. The laminated coatings were fabricated using a controllable dip-coating process, which ensures uniform surface coverage, strong interlayer adhesion, and mechanical robustness on polyester substrates. The resulting composite coatings exhibit high electrical conductivity, stable electrothermal output, and exceptional resistance to environmental degradation. Such performance confirms that the GO interlayer effectively suppresses MXene oxidation while maintaining overall coating flexibility. The approach is simple, scalable, and compatible with large-area textile processing, providing a new route toward the development of multifunctional MXene-based coatings. This design concept not only enriches the understanding of interfacial engineering in 2D-material-based systems but also offers practical value for wearable sensing, thermal management, and smart textile applications.

2. Experimental Section

To materialize the proposed laminated MXene/GO/rGO coating architecture, a series of experiments were conducted, beginning with the synthesis of core materials and followed by the fabrication of the flexible sensor. The details of the materials and instruments used are described below.

2.1. Materials

Graphite powder (Micro 850) was purchased from American Asbury Carbon Company, while Hydrochloric acid (HCl, 9M) was obtained from Huadong Medicine Co., Ltd., Hangzhou, China. Titanium aluminum carbide (Ti3AlC2, 400 mesh) was supplied by Titan Scientific Co., Ltd., Shanghai, China. Lithium fluoride (LiF) was provided by Macklin Biochemical Technology Co., Ltd., Shanghai, China. Sodium nitrate (NaNO3, 99%) was purchased from Lingfeng Biochemical Co., Ltd., Shanghai, China, and sulfuric acid (H2SO4, 98%) was obtained from Shuanglin Chemical Reagent Co., Ltd., Hangzhou, China. Potassium permanganate (KMnO4, 99.5%) was provided by Zhejiang Sanying Chemical Reagent Co., Ltd., Lanxi, Zhejiang, China. Hydrogen peroxide (H2O2, 30%) was purchased from Lingfeng Biochemical Co., Ltd., Shanghai, China. Hydroiodic acid (HI, 55%) was provided by Macklin Biochemical Technology Co., Ltd., Shanghai, China. Ethanol (CH3CH2OH, 55%–58%) was obtained from Shuanglin Biochemical Co., Ltd., Huzhou, China.

2.2. Instruments

A programmable triple-channel DC power supply (IT6322) was obtained from ITECH Electronics Co., Ltd., Nanjing, China. A textile electromagnetic shielding tester (FY800) was provided by Wenzhou Fangyuan Instrument Co., Ltd., Hangzhou, China. A digital multimeter (DMM6500) was purchased from Tektronix Technology (China) Co., Ltd., Shanghai, China. A dual-channel thermometer (UT325) was obtained from UNI-T Technology Co., Ltd., Dongguan, China. A stepper motor controller (KH-01) and a two-phase stepper motor driver (DM542) were both supplied by Ouli Transmission Components Co., Ltd., Dongtai, China.

2.3. Synthesis of MXene and GO

Lithium fluoride (LiF, 3.2 g) was dissolved in 40 mL of 9 M HCl in a PTFE beaker and magnetically stirred at 500–800 rpm in a 40 °C oil bath for 15 min. This etching mixture follows the widely adopted MILD etching strategy, where the controlled concentration of in situ-generated HF ensures efficient removal of the Al layer from Ti3AlC2 while preventing over-etching and structural degradation of Ti3C2Tx MXene. Such a LiF/HCl-to-MAX ratio has been demonstrated to offer high etching efficiency and stable MXene quality in previous studies []. Subsequently, Ti3AlC2 powder (2 g) was added to the solution and allowed to react for 48 h. The resulting suspension was then centrifuged approximately ten times to remove unreacted salts until the supernatant reached a pH of 6, ensuring thorough elimination of acidic residues. The obtained precipitate was collected, vacuum-filtered, and dried to produce clay-like multilayer MXene. Further delamination into few- to multilayer Ti3C2Tx nanosheets was achieved by bath sonication under a helium atmosphere to minimize oxidation []. Graphene oxide (GO) was synthesized using a modified Hummers’ method as previously reported [].

2.4. Fabrication of Flexible Sensor

High-elasticity knitted polyester (PET) fabrics (thickness: 0.063 mm, areal density: 82 g/m2, knitted structure) were used as the substrate for the flexible sensor. The fabrics were first cleaned and dried before coating. An aqueous MXene dispersion (10 mg·mL−1) was uniformly spray-coated on both sides of the polyester fabric using a 0.3 mm nozzle spray gun. During coating, the spraying parameters were carefully controlled to ensure homogeneous deposition: the working pressure was maintained at 0.18–0.22 MPa, the spraying distance at 12–15 cm, and the moving speed of the spray gun at approximately 5–7 cm·s−1. Each spraying pass deposited 0.8–1.2 mg of MXene solids per side, followed by vacuum drying at 65 °C for 10 min. This spraying–drying cycle was repeated until the desired MXene loading was achieved, forming the primary conductive layer. The samples were then weighed and their electrical resistance recorded. Subsequently, a graphene oxide (GO) aqueous dispersion (9 mg·mL−1) was applied using the same spraying parameters and drying procedure to form a uniform interfacial adhesive layer, with the solid mass ratio of MXene to GO controlled at 1:2 on a dry basis. After sequential coating, the fabrics were exposed to hydroiodic acid (HI) vapor for in situ partial reduction, converting GO into reduced graphene oxide (rGO). The HI vapor was generated by adding 4–5 drops of 55% HI solution into 60 mL of deionized water heated at 95 °C under gentle stirring. The coated fabrics were exposed to the vapor for 30 min, rinsed with ethanol and deionized water, and finally dried in a vacuum oven at 65 °C. The total coating add-on of the MXene/GO/rGO composite on the polyester fabric was approximately 10 ± 0.3 wt%, corresponding to an estimated laminated-layer thickness of 4–5 μm, as confirmed by cross-sectional SEM observations. This coating method ensured uniform surface coverage, strong interlayer adhesion, and stable electrical performance, while maintaining the inherent flexibility, softness, and air permeability of the polyester textile.

2.5. Characterization and Measurements

The electrical conductivity of the pristine and coated fabrics was measured using a four-probe resistance tester (SZT-2A, Shanghai Shuangxu Co., Ltd., Shanghai, China); each reported conductivity value is the average of ten measurements taken at randomly selected positions on the sample. Durability was evaluated via chemical immersion, washing, and ultrasonic treatments. Chemical stability tests were performed by immersing samples in 1 M HCl and 1 M NaOH for 6 h. Washing durability was investigated under two conditions: (i) deionized (plasma-treated) water and (ii) a mild detergent solution. For washing tests, square specimens (2 cm × 2 cm, ~0.045 g per sample) were immersed in 300 mL of the selected washing medium and agitated in a thermostatic magnetic stirrer/heater (XIUJILAB DF-101S) at 30 °C ± 3 °C with stirring ≈ 60 rpm for 10 min per cycle. The detergent solution was prepared by dissolving 0.045 g sodium dodecyl sulfate (SDS) and 0.045 g anhydrous sodium carbonate in 300 mL of water to simulate mild laundering conditions. After each wash cycle the samples were rinsed with deionized water, dried at 60 °C for 10 min, equilibrated to room conditions, and their electrical resistance measured; the normalized conductivity retention was calculated as σ/σ0 = R0/Rt (where R0 is the initial resistance and Rt is the resistance after washing). Ultrasonic durability was tested in a water-bath sonicator (40 kHz, 200 W) for up to 40 min, recording σ/σ0 at 5 min intervals. Air permeability was measured using a fully automatic breathability instrument (YG461E-III, Ningbo, China) in automatic mode with a test area of 20 cm2 and a pressure difference of 100 Pa; each specimen was measured at five positions and the average reported. Electrothermal performance was characterized by applying currents of 0.02–0.05 A using a programmable DC power supply (IT6322, ITECH Electronics Co., Ltd., Nanjing, China) and monitoring surface temperature with a dual-channel thermometer (UT325, UNI-T Technology Co., Ltd., Dongguan, China). Surface morphology and cross-sectional thickness of the laminated coatings were examined by field-emission scanning electron microscopy (FE-SEM, ZEISS GeminiSEM 360, Oberkochen, Baden-Württemberg, Germany) to evaluate nanosheet distribution and interfacial adhesion before and after HI reduction or durability tests.

3. Results

The structural morphology, durability, and multifunctional properties of the laminated MXene/GO/rGO textile were investigated as follows. The analysis focuses on the hierarchical architecture, conductive mechanism, and coupled electrothermal-sensing behavior of the fabricated electronic textile, providing a comprehensive understanding of its structure–performance relationship.

3.1. Preparation and MXene/GO/rGO Laminated Flexible Sensor

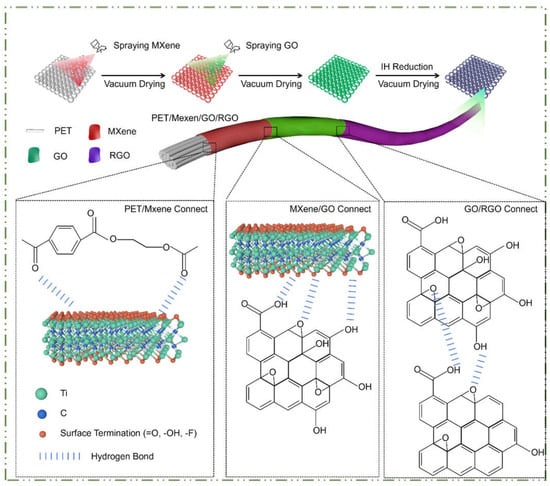

The overall preparation process of the laminated MXene/GO/rGO flexible sensor is illustrated in Figure 1. Initially, a uniform MXene dispersion was spray-coated onto both sides of a pre-cleaned polyester (PET) fabric substrate to serve as the primary conductive layer. Repeated cycles of spraying and vacuum drying ensured the formation of a continuous and compact conductive network on the textile surface. Subsequently, a GO aqueous dispersion was applied as an interfacial adhesive layer to enhance bonding between the conductive MXene layer and the outer rGO protective coating. The GO layer not only improved interfacial compatibility but also effectively prevented direct oxidation of MXene during subsequent processing. After the GO coating was dried, the samples were exposed to hydroiodic acid vapor for in situ partial reduction. This process converted GO into reduced graphene oxide (rGO), restoring partial conductivity while maintaining sufficient surface functionality and flexibility. The reduction also led to a smoother and denser outer surface, which served as a protective encapsulation layer, further stabilizing the MXene under environmental exposure. This hierarchical coating structure effectively combines the high conductivity of MXene with the adhesive and protective roles of GO and rGO, resulting in improved structural integrity and environmental durability. Moreover, the flexible textile retained excellent softness and air permeability, ensuring comfort for wearable applications while preserving outstanding electrical performance.

Figure 1.

Preparation process and schematic diagram of laminated mechanism for PET/MXene/GO/rGO laminated flexible sensor.

3.2. Conductive Mechanism of MXene/GO/rGO Electronic Textile

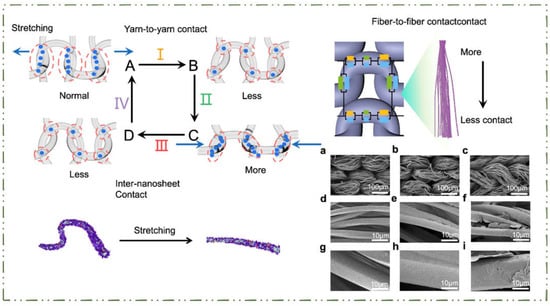

After the successful fabrication of the laminated structure, we then sought to understand the underlying mechanism governing its strain-sensing behavior. The structural evolution of the textile under strain, from macroscopic fabric geometry to microscopic nanosheet arrangement, is key to interpreting its electrical response. Figure 2 shows the structural evolution of the MXene/GO/rGO laminated textile sensor under tensile and compressive strain. On the macroscopic level, in the initial stage of stretching, the knitted loops remain compact, providing abundant contact points between yarns and resulting in low resistance. During stage A–B, as strain increases, the loop arcs gradually open, loop contact density decreases, and the number of conductive contact points is reduced, leading to an increase in resistance. In stage B–C, yarns slide and rub at the junctions under external force, causing the loops to unfold. The enhanced interlocking among polyester fibers increases yarn density and conductive contact points, thereby reducing resistance. When the applied stress is released (stage C–D), deformation begins to recover, the contact points decrease compared to the previous stage, and resistance rises again. Finally, in stage D–A, the fabric and contact return to its original configuration, and the resistance is fully restored []. From a microscopic viewpoint, in the relaxed state the loops are three-dimensionally crimped with close fiber contacts, resulting in limited exposed surface area and high nanosheet packing density. At the onset of stretching, yarn diameters decrease due to the Poisson effect, and the loop structure unfolds, increasing the exposed surface area and decreasing nanosheet density. Together, these effects account for the transient increase and subsequent decrease in resistance during strain sensing [,].

Figure 2.

Schematic illustration of the internal structure evolution in PET/MXene/GO/rGO laminated flexible sensor under tensile strain; SEM images of (a–c) overall yarn morphology, (d–f) multiple fiber regions, and (g–i) single fibers for the pristine knitted fabric, MXene/GO coated knitted fabric before HI reduction, and MXene/GO/rGO coated knitted fabric, respectively.

The morphological evolution and surface characteristics of the MXene/GO/rGO laminated textile before and after reduction were examined by SEM, as shown in Figure 2. The first column displays the pristine knitted fabric without coating. The fibers exhibit smooth surfaces and clear loop structures, highlighting the high porosity and elasticity of the substrate, which provides sufficient space and mechanical compliance for nanosheet deposition. The second column corresponds to the MXene/GO-coated textile before HI reduction. After deposition, the fiber surfaces become slightly rougher and are uniformly covered with overlapping nanosheet layers. The coating forms a continuous but relatively loose conductive network, which maintains flexibility while introducing preliminary electrical conductivity. The increased surface roughness facilitates better mechanical interlocking between the coating and fibers. The third column shows the MXene/GO/rGO textile after HI reduction. The coating becomes rougher, with nanosheets tightly stacked and firmly bonded to the fiber surfaces. The enhanced roughness and interfacial adhesion strengthen the mechanical stability of the coating, while the formation of rGO improves electrical contact between sheets, leading to a highly integrated and stable conductive network. From the overall fabric to multi-fiber and single-fiber levels, the comparison clearly indicates that the reduction process increases surface roughness and interfacial bonding strength. These morphological improvements collectively contribute to the superior electrothermal and strain-sensing performance described in the following sections.

3.3. Durability and Air Permeability

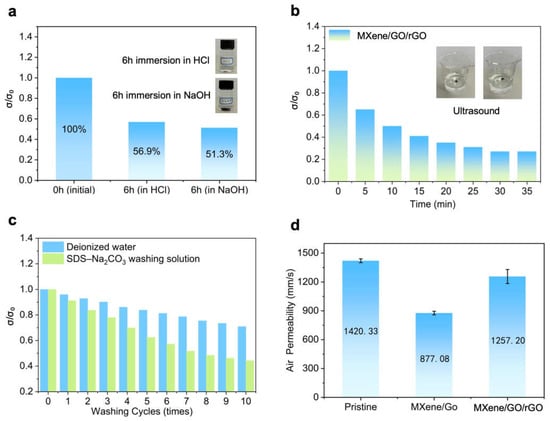

The air permeability of the MXene/GO/rGO textile was measured to assess the influence of the laminated coating on fabric breathability. As shown in Figure 3a, the pristine knitted fabric exhibited a high air permeability of 1420.33 mm·s−1 owing to its loose yarn spacing and open structure. After MXene and GO deposition, the permeability decreased to 877.08 mm·s−1 due to the partial blockage of inter-yarn pores by the laminated coating. Following HI reduction, the MXene/GO/rGO textile maintained a moderate air permeability of 1257.20 mm·s−1, which remains sufficient for wearable comfort. This result indicates that the laminated coating enhances conductivity while maintaining reasonable breathability, ensuring that the textile remains lightweight, flexible, and suitable for on-body applications. Furthermore, the chemical durability of the textile was evaluated by immersing samples in 1 M HCl and 1 M NaOH solutions for 6 h. As summarized in Figure 3b, the resistance increased from 410 Ω to 720 Ω (HCl) and 800 Ω (NaOH), corresponding to conductivity retention ratios (σ/σ0) of 0.569 and 0.513, respectively. These results demonstrate that more than half of the initial conductivity was preserved after exposure to both acidic and alkaline conditions, verifying the excellent chemical stability of the laminated MXene/GO/rGO coating. In addition, the washing durability of the laminated textile was evaluated under two conditions: deionized-water washing and detergent-assisted washing. As shown in Figure 3c, after ten repeated washing cycles in deionized water, the resistance increased from 420 Ω to 592.5 Ω, corresponding to a conductivity retention ratio of 0.709. This moderate resistance increase indicates that the MXene/GO/rGO laminated structure maintains over 70% of its initial conductivity, demonstrating reliable stability under water washing. To further simulate practical laundering conditions, an additional washing test was performed in a detergent solution containing sodium dodecyl sulfate (SDS) and sodium carbonate. Compared with pure water washing, the detergent environment induced a slightly larger increase in resistance, attributable to enhanced chemical interaction with the coating surface. Nevertheless, the textile preserved a high portion of its electrical performance after multiple washing cycles, confirming that the laminated MXene/GO/rGO architecture maintains structural integrity and functional robustness even under chemically assisted washing. These results highlight the potential of the coating for real wearable applications where repeated laundering is required. Subsequently, ultrasonic durability tests were conducted to simulate more severe mechanical vibration and friction conditions. The MXene/GO/rGO textile was subjected to ultrasonic treatment for up to 40 min, and the normalized conductivity (σ/σ0 = R0/Rt) was recorded at 5 min intervals. As shown in Figure 3d, the conductivity gradually decreased with prolonged sonication due to partial detachment of the outer nanosheets; however, the sample retained approximately 27% of its initial conductivity after 40 min, indicating strong coating adhesion and structural integrity under continuous ultrasonic stress. Simultaneously, the oxidation resistance of the laminated structure was verified by monitoring resistance variations before and after heating. The pristine MXene-coated fabric exhibited a sharp resistance increase from 60.3 kΩ to 82.4 kΩ after heating in air for 5 min, indicating severe oxidation and degradation of the conductive Ti3C2Tx network. In contrast, the MXene/GO/rGO laminated fabric showed a much smaller change, with resistance rising only from 460 Ω to 787 Ω after the same treatment. This approximately two orders of magnitude difference clearly demonstrates that the GO/rGO encapsulation effectively protects MXene from oxidation during thermal exposure. The GO/rGO bilayer acts as a compact diffusion barrier, restricting oxygen and moisture penetration and thereby retarding the transformation of Ti3C2Tx into TiO2. Overall, these results collectively confirm that the laminated MXene/GO/rGO architecture provides a favorable balance among conductivity, flexibility, breathability, and long-term durability. The synergistic protection afforded by the GO/rGO layers significantly enhances the chemical, mechanical, and environmental stability of the MXene-based coating, ensuring reliable performance for flexible and wearable electronic applications. The enhancement of MXene stability achieved through the GO adhesion layer and rGO protective layer in this work highlights the importance of rational material design in fully exploiting the performance potential of MXene. This multilayer protection strategy aligns well with design principles demonstrated in other MXene-based functional composites. For example, Topuz et al. [] incorporated Ti3C2Tx MXene with halloysite nanotubes (HNTs) in a chitosan matrix, significantly improving the antibacterial performance while maintaining favorable hydrophilicity and bioactivity. Although the two studies target different application scenarios—flexible electronics in this work and biomedical applications in their report—they collectively reinforce a central concept: constructing MXene-based hybrid architectures, whether with GO/rGO as in this study or with HNTs as in the literature, effectively mitigates the intrinsic limitations of MXene and unlocks its multifunctional potential. This provides valuable design guidance for the broader use of MXene in cross-disciplinary applications.

Figure 3.

(a) Conductivity retention (σ/σ0) of MXene/GO/rGO textile after immersion in 1 M HCl and 1 M NaOH for 6 h; (b) Conductivity retention (σ/σ0) of MXene/GO/rGO textile under ultrasonic treatment for 40 min; (c) Conductivity retention (R0/R) of MXene/GO/rGO textile after ten mild washing cycles; (d) Air permeability of pristine fabric, MXene/GO composite, and MXene/GO/rGO composite.

3.4. Electrothermal Performance and Morse Code–Based Communication

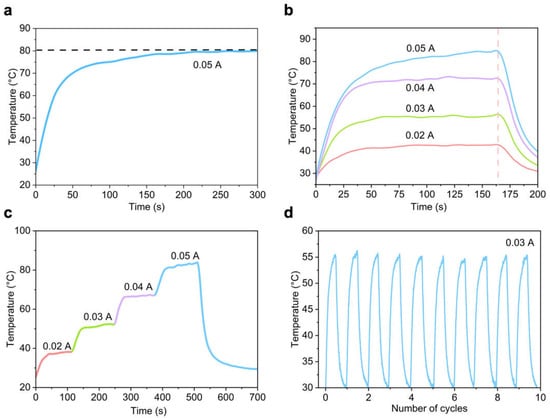

The electrothermal behavior of the MXene/GO/rGO textile was systematically evaluated under a fixed voltage of 20 V with applied currents of 0.02, 0.03, 0.04, and 0.05 A. As shown in Figure 4, the equilibrium surface temperature increased to approximately 45 °C, 60 °C, 75 °C, and 85 °C, respectively. All heating curves reached a steady state within ~150 s, indicating rapid Joule heating and uniform thermal distribution across the laminated conductive network. The stepwise heating response (Figure 4c) further demonstrates the controllability and repeatability of the temperature rise under sequential current loading. In addition, the on/off cycling test (Figure 4d) shows nearly identical temperature variations over ten cycles, confirming excellent operational stability and electrothermal durability. Quantitative analysis of the heating parameters was further performed. Using the measured resistance of the textile (R = 270 Ω) and the effective heating area (1 cm × 2 cm), the power density was calculated as P = I2R/A, following commonly adopted methods for flexible nanocarbon heaters [,]. At 0.05 A, the power density reached ~0.34 W·cm−2, within the high-performance range of MXene-based flexible heaters. The electrothermal conversion efficiency was evaluated using η = C·ΔT/(V·I·t) where the heat capacity C was estimated from the areal density and specific heat of polyester, following the standard thermal-energy balance approach []. Based on the measured equilibrium temperature and heating duration, the conversion efficiency was approximately 50%, consistent with reported values for MXene- and graphene-based textile heaters, indicating effective heat generation with limited thermal loss. Overall, the MXene/GO/rGO textile exhibits fast heating, high power density, and reliable thermal stability, making it promising for wearable thermal regulation and healthcare applications [,].

Figure 4.

Electrothermal performance of MXene/GO/rGO textile under a fixed voltage of 20 V: (a,b) temperature–time curves at different applied currents (0.02 A–0.05 A); (c) stepwise heating response under sequential current loading; (d) temperature stability over ten on/off cycles.

3.5. Strain-Sensing Performance

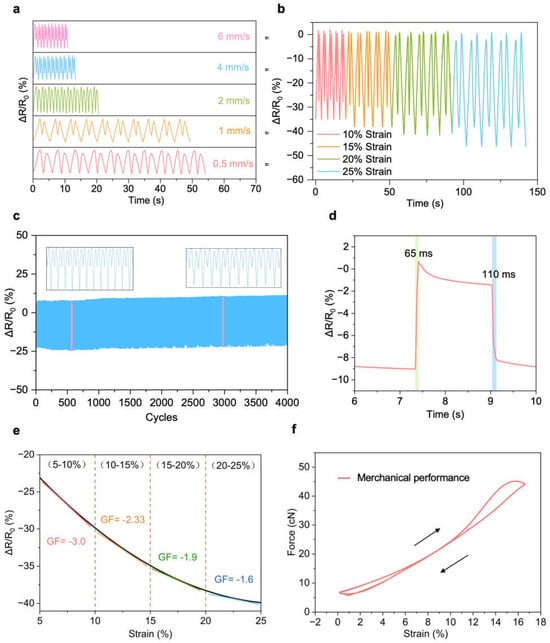

The MXene/GO/rGO laminated textile exhibited excellent strain-sensing capability and dynamic stability, as summarized in Figure 5. Figure 5a presents the normalized resistance variation (ΔR/R0) under different stretching speeds (0.5, 1, 2, 4, and 6 mm·s−1). The nearly overlapping response waveforms confirm that the laminated conductive network maintains structural integrity and stable electron transport across various deformation rates, demonstrating reliable dynamic sensing performance. As shown in Figure 5b, the relative resistance change (ΔR/R0) was evaluated under tensile strains of 10%, 15%, 20%, and 25%. The MXene/GO/rGO textile exhibited an electrical conductivity of 39.7 S·m−1, substantially higher than the unreduced MXene/GO sample. Based on the measured resistance variations, the gauge factors (GF = (ΔR/R0)/ε) were calculated as approximately −3 (10%), −2.33 (15%), −1.9 (20%), and −1.6 (25%), indicating a stable and strain-dependent piezoresistive response (Figure 5e). The resistance–strain curves show good repeatability and a monotonic dependence on strain amplitude, confirming the textile’s ability to differentiate multiple deformation levels. Long-term cyclic testing further revealed excellent durability (Figure 5c). After 4000 stretching–releasing cycles, the ΔR/R0 signal displayed negligible drift, verifying that the laminated MXene/GO/rGO coating maintains its mechanical robustness and conductive integrity under repeated loading. The transient response behavior was also assessed through finger-pressing tests (Figure 5d), showing a fast response time of 65 ms and a recovery time of 110 ms, indicative of high sensitivity and good reversibility. In addition to stretching stability, the MXene/GO/rGO laminated textile also exhibited minimal hysteresis, addressing practical concerns for wearable applications. The resistance–strain behavior was quantitatively analyzed to evaluate sensing linearity and hysteresis. The loading–unloading curves (Figure 5f) show a small hysteresis loop, suggesting efficient charge transport and rapid structural recovery during cyclic deformation. The nearly coincident forward and backward paths confirm that the MXene/GO/rGO network undergoes reversible microstructural reconfiguration with limited energy dissipation. This low hysteresis further supports the stable piezoresistive mechanism illustrated in Figure 2. Overall, these results demonstrate that the MXene/GO/rGO textile combines rapid response, strong repeatability, and long-term reliability, making it highly suitable for wearable and real-time strain-sensing applications [,].

Figure 5.

(a) Normalized resistance response (ΔR/R0) under different stretching speeds (0.5–6 mm·s−1); (b) ΔR/R0 responses under different tensile strains (10%–25%); (c) Durability over 4000 stretching–releasing cycles; (d) Dynamic response and recovery behavior under finger-pressing tests (response of 65 ms, recovery of 110 ms); (e) Gauge-factor analysis of the MXene/GO/rGO textile sensor; (f) Hysteresis behavior of the MXene/GO/rGO textile during the loading–unloading strain cycle.

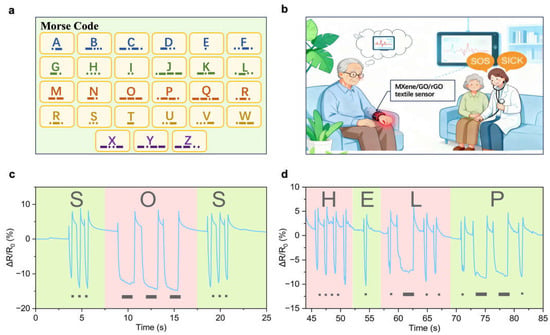

3.6. Application Demonstration: Morse Code Emergency Communication

To further demonstrate the real-world applicability of the MXene/GO/rGO laminated textile, a Morse-code–based intelligent emergency communication system was developed, as illustrated in Figure 6. Figure 6a presents the Morse code reference chart, where each alphabetic character corresponds to a combination of short and long signals (dots and dashes). Figure 6b schematically depicts the practical application scenario: the MXene/GO/rGO textile sensor is integrated into a wearable band on the forearm of an elderly individual. When the wearer performs intentional finger movements or light arm bending, the textile detects the mechanical deformation and translates it into resistance variations (ΔR/R0). These changes can be wirelessly transmitted and decoded as specific Morse code patterns. The generated real-time electrical signals are shown in Figure 6c,d, corresponding to the “SOS” and “HELP” messages, respectively. Distinct and repeatable resistance peaks were observed for each dot and dash, and the temporal spacing between signals accurately reproduced the Morse code structure. The stable and clearly distinguishable ΔR/R0 waveforms confirm the textile sensor’s high precision and reliability in converting mechanical input into coded electrical communication. This demonstration highlights the potential of MXene/GO/rGO intelligent textile sensors for wearable emergency communication and remote healthcare monitoring, particularly for elderly users or individuals with limited mobility. The integration of rapid strain sensing, stable electrothermal behavior, and wireless communication capability offers a promising strategy for next-generation interactive wearable systems.

Figure 6.

(a) Morse code reference chart; (b) Schematic illustration of the SOS emergency application based on the MXene/GO/rGO intelligent textile sensor integrated into a wearable band; (c,d) Real-time ΔR/R0 waveforms corresponding to Morse code “SOS” and “HELP” signals, demonstrating the textile’s ability for encoded communication and emergency alerting.

4. Conclusions

A laminated MXene/GO/rGO electronic textile was successfully fabricated by introducing a GO interlayer into MXene-coated polyester fabric via spray deposition, followed by partial reduction to rGO. The resulting textile exhibited outstanding electrothermal and strain-sensing performance, characterized by stable thermal behavior with distinct temperature increases under different voltages, rapid response (65 ms), and high sensitivity to varying strain levels and stretching rates. The sensor maintained reliable performance over repeated loading cycles, demonstrating excellent durability and flexibility. Furthermore, leveraging its superior sensing capability, the MXene/GO/rGO textile was integrated with information transmission technology to realize a Morse-code-based communication sensor, illustrating its feasibility for intelligent information interaction, wearable communication, and other smart textile applications. These results confirm that the proposed laminated coating architecture offers a simple and scalable approach for developing multifunctional, stable, and high-performance MXene-based wearable electronics.

Author Contributions

R.Z.: Writing—original draft, conceptualization and methodology. H.Z.: writing—original draft and data curation. J.H.: data curation and validation. R.H.: visualization and investigation. Y.W.: software, reviewing, and editing. Y.L.: software, reviewing, and editing. X.L.: software, reviewing, and editing. B.P.: supervision and writing—reviewing and editing. X.H.: conceptualization, methodology, formal analysis, investigation, visualization, writing—original draft, reviewing, and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by National Natural Science Foundation of China (NSFC 51803185), the Fundamental Research Funds of Zhejiang Sci-Tech University (25202146-Y).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

Author Birong Pi was employed by the company Ningbo Runhe High-Tech Material Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Heo, J.S.; Eom, J.; Kim, Y.H.; Park, S.K. Recent progress of textile-based wearable electronics: A comprehensive review of materials, devices, and applications. Small 2018, 14, 1703034. [Google Scholar] [CrossRef] [PubMed]

- Shao, B.; Chen, X.; Chen, X.; Peng, S.; Song, M. Advancements in MXene Composite Materials for Wearable Sensors: A Review. Sensors 2024, 24, 4092. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Liu, F.; Lin, Y.; Wang, J.; Zhang, C.; Cheng, H.; Chen, H. MXene-based flexible sensors for wearable applications. Soft Sci. 2025, 5, 33. [Google Scholar] [CrossRef]

- Horita, Y.; Kuromatsu, S.; Watanabe, T.; Suga, R.; Koh, S. Polydopamine-assisted dip-and-dry fabrication of highly conductive cotton fabrics using single-wall carbon nanotubes inks for flexible devices. Cellulose 2023, 30, 1971–1980. [Google Scholar] [CrossRef]

- Xue, P.; Tao, X.; Tsang, H. In situ SEM studies on strain sensing mechanisms of PPy-coated electrically conducting fabrics. Appl. Surf. Sci. 2007, 253, 3387–3392. [Google Scholar] [CrossRef]

- Zhou, N.; Jiang, B.; He, X.; Li, Y.; Ma, Z.; Zhang, H.; Zhang, M. A superstretchable and ultrastable liquid metal–elastomer wire for soft electronic devices. ACS Appl. Mater. Interfaces 2021, 13, 19254–19262. [Google Scholar] [CrossRef]

- Luo, M.; Chen, H.; Xia, M.; Wang, D.; Li, M. Preparation of elastic conductive composite fiber and its strain and temperature sensing properties. J. Text. Res. 2024, 45, 9–15. [Google Scholar]

- Molina, J. Graphene-based fabrics and their applications: A review. RSC Adv. 2016, 6, 68261–68291. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- VahidMohammadi, A.; Rosen, J.; Gogotsi, Y. The world of two-dimensional carbides and nitrides (MXenes). Science 2021, 372, eabf1581. [Google Scholar] [CrossRef]

- Tian, Y.; Hou, P.; Zhang, H.; Xie, Y.; Chen, G.; Li, Q.; Du, F.; Vojvodic, A.; Wu, J.; Meng, X. Theoretical insights on potential-dependent oxidation behaviors and antioxidant strategies of MXenes. Nat. Commun. 2024, 15, 10099. [Google Scholar] [CrossRef]

- Soomro, R.A.; Zhang, P.; Fan, B.; Wei, Y.; Xu, B. Progression in the oxidation stability of MXenes. Nano-Micro Lett. 2023, 15, 108. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.; Thakur, A.; Zahmatkeshsaredorahi, A.; Fang, Z.; Rad, V.; Shamsabadi, A.A.; Pereyra, C.; Soroush, M.; Rappe, A.M.; Xu, X.G.; et al. Stabilizing Ti3C2Tx MXene flakes in air by removing confined water. Proc. Natl. Acad. Sci. USA 2024, 121, e2400084121. [Google Scholar] [CrossRef] [PubMed]

- Eom, W.; Shin, H.; Jeong, W.; Ambade, R.B.; Lee, H.; Han, T.H. Surface nitrided MXene sheets with outstanding electroconductivity and oxidation stability. Mater. Horiz. 2023, 10, 4892–4902. [Google Scholar] [CrossRef] [PubMed]

- Zhuo, L.; Cai, Y.; Shen, D.; Gou, P.; Wang, M.; Hu, G.; Xie, F. Anti-oxidation polyimide-based hybrid foams assembled with bilayer coatings for efficient electromagnetic interference shielding. Chem. Eng. J. 2023, 451, 138808. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, B.; Lai, X.; Li, H.; Chen, Z.; Zeng, X.; Zhang, L. A multifunctional flame-retardant TA-MXene based nanocoating for cotton fabric. Prog. Org. Coat. 2024, 189, 108333. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, G.; Fang, L.; Wang, Z.; Wu, F.; Liu, G.; Wang, Q.; Nian, H. Surface-Modification Strategy to Produce Highly Anticorrosive Ti3C2Tx MXene-Based Polymer Composite Coatings: A Mini-Review. Materials 2025, 18, 653. [Google Scholar] [CrossRef]

- Mozafari, M.; Soroush, M. Surface functionalization of MXenes. Mater. Adv. 2021, 2, 7277–7307. [Google Scholar] [CrossRef]

- Liu, Y.; Fei, B.; Xin, J.H. Functionalization of fabrics with Graphene-based coatings: Mechanisms, approaches, and functions. Coatings 2023, 13, 1580. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef]

- Jin, C.; Bai, Z. MXene-based textile sensors for wearable applications. ACS Sens. 2022, 7, 929–950. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Lee, S.Y.; Zhang, Y.; Park, S.J.; Gu, J. Carbon-based radar absorbing materials toward stealth technologies. Adv. Sci. 2023, 10, 2303104. [Google Scholar] [CrossRef] [PubMed]

- Hummers Jr, W.S.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Hong, X.; Sun, W.; Zhang, S.; Tang, Z.; Zhou, M.; Guo, S.; Guo, X.; Zhao, W.; Wang, X.; Chen, H. Washable and multifunctional electronic textiles via in situ lamination for personal health care. Adv. Fiber Mater. 2024, 6, 458–472. [Google Scholar] [CrossRef]

- Olivieri, F.; Rollo, G.; De Falco, F.; Avolio, R.; Bonadies, I.; Castaldo, R.; Cocca, M.; Errico, M.E.; Lavorgna, M.; Gentile, G. Reduced graphene oxide/polyurethane coatings for wash-durable wearable piezoresistive sensors. Cellulose 2023, 30, 2667–2686. [Google Scholar] [CrossRef]

- Liu, X.; Chen, K.; Zhang, D.; Guo, Z. Stable and durable conductive superhydrophobic coatings prepared by double-layer spray coating method. Nanomaterials 2021, 11, 1506. [Google Scholar] [CrossRef]

- Lipatov, A.; Alhabeb, M.; Lukatskaya, M.R.; Boson, A.; Gogotsi, Y.; Sinitskii, A. Effect of synthesis on quality, electronic properties and environmental stability of individual monolayer Ti3C2 MXene flakes. Adv. Electron. Mater. 2016, 2, 1600255. [Google Scholar] [CrossRef]

- Abay, Z.M.; Wei, Y.; Tang, Z.; Liu, Y.; Chen, K.; Li, H.; Wang, Q.; Yuan, J.; Hu, P.; Lu, D.; et al. Versatile MXene/(GO-AgNWs) electronic textile enabled by mixed-scale assembly strategy. Nano Energy 2025, 139, 110963. [Google Scholar] [CrossRef]

- Rufang, Y.; Xinghua, H.; Chengyan, Z.; Zimin, J.; Junmin, W. Electrical heating properties of fabrics coated by reduced graphene oxide. J. Text. Res. 2021, 42, 126–131. [Google Scholar]

- Xu, J.; Li, Y.; Yan, F. Constructed MXene matrix composites as sensing material and applications thereof: A review. Anal. Chim. Acta 2024, 1288, 342027. [Google Scholar] [CrossRef]

- Topuz, M.; Karatas, E.; Ruzgar, D.; Akinay, Y.; Cetin, T. Ti3C2Tx MXene/halloysite nanotube functionalized films for antibacterial applications. J. Biomater. Sci. Polym. Ed. 2025, 1–15. [Google Scholar] [CrossRef]

- Xia, D.; Li, H.; Huang, P. Understanding the Joule-heating behaviours of electrically-heatable carbon-nanotube aerogels. Nanoscale Adv. 2021, 3, 647–652. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.-Y.; Zhang, T.-Y.; Lu, Q.; Wang, D.-Y.; Yang, Y.; Wu, X.-M.; Ren, T.-L. High-performance graphene-based flexible heater for wearable applications. RSC Adv. 2017, 7, 27001–27006. [Google Scholar] [CrossRef]

- Wang, Q.W.; Zhang, H.B.; Liu, J.; Zhao, S.; Xie, X.; Liu, L.; Yang, R.; Koratkar, N.; Yu, Z.Z. Multifunctional and water-resistant MXene-decorated polyester textiles with outstanding electromagnetic interference shielding and joule heating performances. Adv. Funct. Mater. 2019, 29, 1806819. [Google Scholar] [CrossRef]

- Pan, Y.; Li, H.; Du, Z. Electrical/optical dual-energy-driven MXene fabric-based heater with fast response actuating and human strain sensing. J. Mater. Sci. Technol. 2024, 197, 57–64. [Google Scholar] [CrossRef]

- Zheng, X.; Shen, J.; Hu, Q.; Nie, W.; Wang, Z.; Zou, L.; Li, C. Vapor phase polymerized conducting polymer/MXene textiles for wearable electronics. Nanoscale 2021, 13, 1832–1841. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, W.; Luan, S.; Wei, J.; Yang, Y.; Miao, J. Nanomaterials for smart wearable fibers and textiles: A critical review. iScience 2025, 28, 113126. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).