Abstract

In order to improve the sustainability of road pavements, transportation agencies should consider designing pavements with recycled materials such as reclaimed epoxy asphalt pavement. Epoxy asphalt has recently attracted significant attention from the pavement community as a superior-performing binder that can help achieve long-lasting pavements. The recyclability of a proven long-life pavement material, such as epoxy asphalt, has now become one concern in promoting the use of epoxy asphalt binder in road pavements. Due to its thermosetting nature, the usual process of reclaiming asphalt pavement cannot be performed on epoxy asphalt pavement. Recent studies have investigated utilizing reclaimed epoxy asphalt materials in asphalt mixtures as black rock. In light of this, examining the use of reclaimed epoxy materials in cement-concrete mixes is important. The use of reclaimed epoxy asphalt materials in pavement construction is expected to gain more popularity and become a new sustainable construction option in various sustainable pavement applications in the near future. The main objective of this study is to investigate the effects of incorporating 100% reclaimed epoxy asphalt (hereinafter referred to as “epoxy RAP”) and reclaimed diluted epoxy asphalt materials (hereinafter referred to as “diluted epoxy RAP”) into cement-concrete mixes on the performance of the mixtures. The study also examined the effects of replacing cement with 5% silica fume on the performance of reclaimed mixtures. Five different mixtures were fabricated and tested in terms of density, void content, permeability, and compressive strength. Results of the density test revealed that replacing 100% natural aggregates with epoxy RAP and diluted epoxy RAP materials reduced density by an average of 10%. However, void content was found to increase with the incorporation of epoxy RAP, even when replacing Portland cement with silica fume. Regarding permeability, mixtures containing 100% epoxy RAP and diluted epoxy RAP materials have significantly higher permeability values compared with the natural mix value. However, adding 5% silica fume significantly reduced the permeability. Compressive test results indicated that substituting 100% of aggregates with epoxy RAP or diluted epoxy RAP materials would reduce compressive strength by 55% on average. Furthermore, adding silica fume to reclaimed mixes was found to have no apparent effect on compressive strength.

1. Introduction

Designing pavement recycling with reclaimed asphalt pavement (RAP) is an important strategy for transportation agencies to improve the sustainability of road pavements. The recyclability of a proven long-life pavement material, such as epoxy asphalt, has recently become a concern in promoting the use of epoxy asphalt binder in road pavements, including flexible and rigid pavements. Reclaimed material fractions, including reclaimed asphalt aggregate, have been used in concrete road pavements in accordance with the literature [1]. Waste materials, such as tires, glass, plastics, and steel slag, are examples of reclaimed materials that have been put into cement-concrete pavements [2]. Natural waste materials have also been added to cement-concrete, such as dried plant residues, natural clay, and spinning waste [3]. Replacing virgin materials in the cement-concrete pavement with waste materials is a sustainable choice that conserves natural materials, disposes of excess waste material stockpiles, and reduces the cost of producing concrete mixtures.

RAP materials have been used to produce Portland cement-concrete [2,4,5,6]. The use of RAP in Portland cement-concrete brings economic and environmental benefits. It helps dispose of excess RAP stockpiles and lowers the production cost by reducing the quantity of virgin aggregates in the concrete mix [2,6]. The use of RAP as a replacement for virgin aggregate, however, affects the mechanical and durability properties [1,7,8,9]. The presence of binder film and agglomerated particles in RAP was found to be the main factors responsible for the reduction in the overall strength properties of cement-concrete [1]. Many studies have investigated the blend between Portland cement and asphaltene [3,10]. Using cement-bitumen composites as binding materials commonly causes degradation in their mechanical properties. However, adding bitumen to Portland cement could enhance the performance of cement for isolation and shielding applications, such as nuclear radiation shielding and radioactive waste disposal, to achieve protection against high radiation, as discussed in [3,10].

Regarding durability, incorporating RAP into cement-concrete mixes affects freeze-thaw durability and permeability [1,8]. Desired freeze and thaw resistance values could be observed when natural aggregates were partially replaced with RAP fractions [11]. The freeze and thaw resistance, however, would decrease when the RAP percentage increased in the concrete mix [11]. The permeability of concrete mixes was also observed to increase with the increase of RAP fractions in the mix, based on a study conducted by [8]. It was also found that adding fly ash to the concrete mix containing the RAP fraction significantly decreased the permeability.

Density has been found to change with the RAP fractions in the cement-concrete mix. Based on recent studies [12,13], density would decrease linearly with the increase in RAP percentage in the concrete mix. This is due to the replacement of heavy natural aggregates by light RAP fractions [1]. The reduction in density, however, is nominal in the sense that it does not have a significant effect on concrete mix performance [1].

As compressive strength is considered the main design criterion for concrete structural applications, most of the previous studies that investigated the inclusion of RAP in concrete mixes have highlighted the effect of RAP on compressive strength as a significant concern [1]. Based on previous studies, fractions of RAP up to 50% in Portland cement-concrete can meet the minimum strength requirement provided by local agencies [14,15,16]. However, using RAP in cement-concrete usually reduces the strength linearly with the increase in RAP fraction percentages in the mix. Based on several previous studies, utilization of 100% RAP for the production of cement-concrete mixes will cause a reduction in the compressive strength ranging between 60 and 80% compared to the control mixes [7,8,9]. The authors of [1] stated in their literature review that all studies agreed that the incorporation of 100% RAP in concrete mixes reduces compressive strength.

Several studies have also investigated the inclusion of RAP in other types of cement-concrete in terms of compressive strength. The authors of previous research [17] utilized 100% RAP in pervious cement-concrete mixes with and without fine crumb rubber. The results showed that the use of 100% RAP in pervious concrete caused a 60% reduction in compressive strength. Adding 5% of fine crumb rubber, however, offered similar performance in terms of compressive strength. In addition, various pavement applications that used RAP were evaluated using the compressive strength test. Another study by [18] studied the influence of the incorporation of 100% RAP in precast concrete mixes. Results showed that there was a 60% reduction in compressive strength compared with the control mix without RAP. The use of RAP in roller compacted concrete pavement (RCCP) has also been studied by several researchers [19,20,21,22]. Results showed that about a 50%–70% reduction in compressive strength was observed when 100% RAP was incorporated into RCCP mixes.

Although previous studies illustrated how incorporating RAP into cement-concrete mixes negatively affected the strength properties, some studies also revealed that the inclusion of RAP might enhance some properties, such as workability [4,5], toughness [4,9,19], and freeze and thaw resistance [23]. In addition, up to 50% of coarse RAP only or fine RAP only could be used in concrete mixes to achieve the minimum strength requirements in accordance with [1].

Recycled concrete aggregate (RCA) has been incorporated into asphalt mixtures [24]. On the other hand, conventional RAP fractions have been utilized in cement-concrete pavements in many studies over the last two decades [1]. However, reclaimed epoxy asphalt materials (“epoxy RAP”) particles have not been utilized in cement mixes as a replacement for natural aggregate. Unlike conventional asphalt binder, whose properties can be recovered, epoxy asphalt binder is a thermosetting material that undergoes a chemical change during curing, which is an irreversible material, and chemical changes occur when the material is exposed to heating [25,26,27]. Recent studies [28,29] have investigated the use of reclaimed epoxy asphalt materials in asphalt mixtures and showed promising results.

Epoxy asphalt has recently attracted significant attention from the pavement community as a superior-performing binder that can help achieve long-lasting pavements. The use of epoxy asphalt materials in road pavement construction is expected to gain more popularity and become a new sustainable construction option in various sustainable pavement applications in the near future. Due to the thermosetting nature of epoxy asphalt, however, the usual process of reclaiming conventional thermoplastic asphalt pavement cannot be performed on epoxy asphalt pavement after its service life [28,29]. This is one of the main concerns of transportation agencies when considering wide applications of epoxy asphalt on road pavements without compromising the goals of low environmental impact and sustainable development. It is, therefore, imperative to investigate and explore options for using reclaimed epoxy asphalt pavement materials (hereinafter referred to as “epoxy RAP”) in new civil engineering construction. In a prior study, the authors validated the feasibility of incorporating epoxy asphalt in new asphalt mixture designs [28,29]. Since cement-concrete is one of the most widely used construction materials in civil engineering [30,31,32,33,34], it is necessary to explore the option of using epoxy RAP in cement-concrete. Although prior studies have shown that the use of recycled materials in cement mixes usually has a negative impact on the mechanical properties of cement mixes, there are scenarios in which low-strength cement mixes can find their applications, such as parking lots, driveways, and pavement shoulders that are designed to be pervious.

The main objective of this study is to investigate the influence of incorporating epoxy RAP on the performance of pervious cement mixes. Since both undiluted epoxy asphalt (i.e., an original epoxy asphalt supplied by a manufacturer) and diluted epoxy asphalt (i.e., a mix of the original epoxy asphalt and a conventional asphalt binder) have been used in road pavement projects, both undiluted and diluted epoxy RAP will be included in this study to fully replace natural aggregates in pervious cement mixes.

2. Materials

The following materials are utilized in this research to fabricate all natural and reclaimed Portland cement-concrete specimens.

2.1. Portland Cement

Portland cement is one of the most common cement types used in the world as an essential ingredient in concrete. Ordinary Portland cement Type I is utilized in this research for all natural and reclaimed cement mixes. The material was obtained from a local cement supplier in Tampa, Florida. Through chemical reactions, the blend of Portland cement, water, and aggregates becomes a cement mix specimen that hardens and gains strength over time.

2.2. Silica Fume

Silica fume, in accordance with the National Precast Concrete Association (NPCA), is a powder pozzolanic material resembling cement that is widely used as a supplementary cementitious material in the production of Portland cement concrete. It has effects on concrete strength, workability, and durability. When added to the concrete mix with care, it can improve the concrete’s strength and durability and reduce the amount of concrete bleeding, which is free water pushed towards the concrete surface. In addition, the silica fume can typically decrease the air content of the concrete mix because of the increased amount of fine cementitious material in the mix. The quality of silica fume is specified by AASHTO M 307. According to the NPCA, silica fume and other supplementary cementitious materials have sustainable and economic benefits. For example, it reduces carbon emissions by reducing the amount of clinker required in the concrete mix. In addition, it reduces the life cycle cost by providing a longer life with less maintenance. The silica fume sample used in this study was obtained from a local supplier in Tampa, FL, USA.

2.3. Aggregate

This research was conducted using fractionated granite aggregates supplied by an aggregate supplier in Tampa, Florida. The resistance of aggregates against wear was tested using the Los Angeles Abrasion (the University of South Florida, Tampa, FL, USA) Machine, and the aggregate’s abrasion loss fell within the permissible 10% to 45% range in accordance with AASHTO T 96 specifications. Aggregates were used to develop natural concrete mixes and to manufacture epoxy RAP and diluted epoxy RAP materials.

2.4. Reclaimed Epoxy Asphalt Materials

Because of the lack of materials from the field, reclaimed epoxy asphalt materials (diluted and undiluted) were artificially designed and produced in the laboratory for this study. Parts A and B of the epoxy binder components, including parts A and B, were mixed with a ratio of 100/515 to produce epoxy asphalt, based on the instructions of the company that produces the product. The blend must be cured at 121 °C for 5 min before being poured onto aggregates. Then, open-graded friction coarse mixtures were developed and kept at 120 °C for 20 min before compaction to allow for some curing. For diluted epoxy binder, the epoxy binder blend was diluted with unmodified binder PG 67-22 and manually blended for two minutes at 125 °C before adding to aggregates in accordance with the literature [35]. The blends were then mixed with aggregates to develop HMA specimens.

Compacted epoxy and diluted epoxy asphalt mixtures were exposed to a longtime aging process in the laboratory to simulate aging in service and represent field materials for reliable performance tests in accordance with the literature [36]. According to the Strategic Highway Research Program (SHRP), four and eight days of aging at 85 °C in the laboratory are equivalent to eight and sixteen years of field aging. Following AASHTO R 30, the long-term aging operation used in this study is to age compacted specimens in an oven at 85 °C for 120 h (about five days). The aged specimens were then manually divided into parts, which were sieved into various size groups. The process for treating epoxy RAP materials began by manually fracturing the warm, aged sample into several smaller pieces. Then, using a hammer, each part was divided into a variety of sized pieces to simulate the actual crushing materials that would be produced during surface milling in the field.

3. Mix Design

Five pervious concrete mixes were prepared, including natural concrete mix (N), epoxy RAP concrete mix (ER), diluted epoxy RAP concrete mix (DER), epoxy RAP concrete mix with 5% silica fume (ER + S), and diluted epoxy RAP concrete mix with 5% silica fume (DER + S). The N mix (control mix) contained 100% natural aggregates, while all other reclaimed mixes, including ER, DER, ER + S, and DER + S, contained 100% epoxy RAP. For ER + S and DER + S mixes, 5% of cement was replaced by silica fume. Laboratory tests, including density, permeability, and compressive strength, were conducted on specimens of those mixes. The main objective of this study is to compare cement mixes containing epoxy RAP (undiluted/diluted) fractions to those of natural cement mixes without epoxy RAP. Then, the results of cement mixes containing epoxy RAP (hereinafter referred to as “epoxy RAP cement-concrete mixes”) might be compared to the results of cement mixes containing regular RAP (hereinafter referred to as “regular RAP cement-concrete mixes”) from previous studies. As regular RAP fractions have been utilized in several types of cement mixes, the pervious concrete type was selected in this research to be fabricated with epoxy RAP. Pervious concrete is a special type of concrete that has high porosity to allow quick water drainage through its body in accordance with ACI 522R-10. The use of pervious concrete for the construction of secondary roads, parking lots, and sidewalks is increasing because of its various environmental benefits. Examples of benefits include filtering storm water rapidly into the ground. Moreover, using pervious concrete on roadways reduces noise contamination by absorbing vehicle noise [37]. Based on the literature, there is no specific design procedure for pervious concrete [17,37]. The design of the pervious concrete mix in this research followed a previous study in the literature [37]. The material proportions of the pervious concrete mix are shown in Table 1. The theoretical density on an air-free basis equals the sum of every material’s weight in an actual cubic meter (kg/m3), as calculated below.

Table 1.

Concrete mix proportion.

4. Specimen Casting

The sample mold of cement mixes was selected based on the maximum aggregate size. Based on AASHTO M 23, a larger mold should be selected for mixes that have a larger maximum aggregate size. Since the maximum aggregate size was 2.36 mm, the 2-inch cubic mold (Figure 1) was selected in this study to fabricate cubic cement specimens with dimensions of 50.8 mm × 50.8 mm × 50.8 mm.

Figure 1.

Cubic molds for cement-concrete specimens.

Although the 2-inch cubic and other mold sizes are not standard molds for cement-concrete mixes, many studies have validated using several alternative molds, including the 2-inch cubic mold. A previous study conducted by [38] investigated the effect of mold size on the compressive strength of concrete specimens. Their results showed a clear linear relationship between mold size and strength, and some correction coefficients have been developed to make the results more accurate. Based on that study, it is deemed that the comparison of compressive strength results of virgin and epoxy RAP concrete mixes using specimens fabricated from the 2-inch cubic mold is valid in this study.

For the concrete mix, all materials except water were put together first in a mixer and left to blend for two minutes (Figure 2). Then, water was slowly added to the mixer to make sure that water was consistently poured over all the mix particles during mixing. After five minutes of mixing, the mix should be ready for sampling. There are many ways to mold concrete samples. Samples molded for this study followed the samples molded in the study of [39]. Three layers of concrete mix were poured into each cubic mold. Then the mix was tamped 25 times using a small tapping rod after each layer was poured. The same steps were followed for the other two layers. Then, samples were covered to prevent any hydration or dehydration processes from occurring due to the rain or the sun. Samples were then left for 24 h in molds at room temperature. The next day, samples were extracted from mold and put in a water tank for curing (Figure 3). The density of samples was measured after 7 days of curing, while permeability and compressive strength were tested after 28 days of curing.

Figure 2.

The concrete mixer.

Figure 3.

Water tank for cement mixes.

5. Laboratory Tests

5.1. Density Test

The density of a pervious cement-concrete specimen could be determined by dividing the mass of the dry concrete sample by its volume, as shown in Equation (1). An average density of the pervious concrete sample was calculated from three replicates in accordance with ASTM C 642.

where

- M = the mass of a dry concrete sample in air (g);

- V = the volume of the concrete sample (mm3).

5.2. Permeability Test

Permeability is one key performance indicator of pervious concrete since the concrete is designed for a drainage layer. Based on ACI 522R-10, there are two methods to investigate the permeability of pervious concrete, including a falling head test and a constant head test. The falling head method was used to determine the permeability using Equation (2). For each pervious concrete sample, three replicates were measured to calculate the average permeability.

where

- k = permeability coefficient (mm/s);

- a = cross section area of the specimen (mm2);

- l = length of the specimen (mm);

- A = cross-section area of the standpipe (mm2);

- t = recorded time for the water head to change from h1 to h2 (s);

- h1 = initial water head (mm);

- h2 = final water head (mm).

5.3. Compressive Strength

The compressive strength of cement-concrete is considered the main design criterion and quality control measure for concrete slabs for rigid pavements. The compressive strength in this study was measured on cubic samples using a compression machine (Figure 4). In the test, a compressive load was applied to a cubic specimen and increased continuously at a nominal rate of 0.2 N/. The test in this study was conducted at 25 °C in accordance with ASTM C 109, with three replicates for each sample.

Figure 4.

A compression testing machine.

6. Concrete Test Results and Discussion

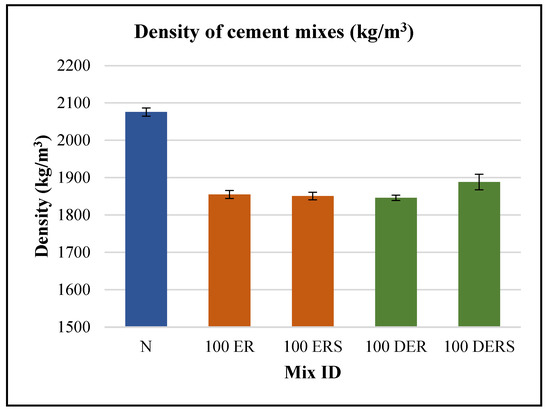

6.1. Density Test Results

The density of natural and epoxy RAP concrete mixes for this study was obtained and summarized in Table 2. As can be seen, the results are consistent with the previous statement that mixes with RAP particles have a lower density compared to natural concrete mixes. Results showed that incorporating 100% epoxy RAP and diluted epoxy RAP lowered the density by about 10%. This refers to the light weight of reclaimed particles compared with natural aggregate. Regular RAP binder coating around aggregates reduces the specific gravity of aggregate particles [1]. This coating might provide some benefits, such as reducing abrasion value and lowering aggregate crushing value [1]. Therefore, the replacement of heavy natural aggregates by light RAP particles would reduce the density of cured cement-concrete (“hardened density”). The reduction, however, has been observed to be nominal, as discussed in the literature. Results show that adding 5% silica fume to epoxy RAP mixes did not affect the concrete specimen’s density. This can be interpreted by the low content of silica fume added to the mix, which is only 5%. This is consistent with the American Concrete Institute’s (ACI) report on using silica fume in concrete [40].

Table 2.

Test results of density, permeability, and compressive strength of concrete samples.

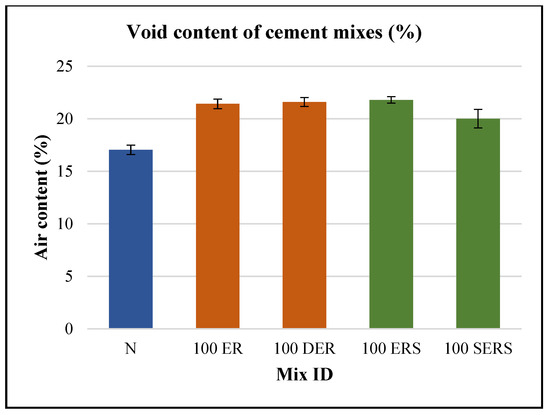

6.2. Void Content

In this study, air contents were calculated using Equation (3) in accordance with ASTM C 1688 (2014). Results, as presented in Table 2, show that adding 100% epoxy (undiluted/diluted) increased the void contents by about 25% compared with the control mix, which is consistent with the result from adding regular RAP to concrete mixes. Pervious concrete mixes are proportioned based on the aggregate blend and the type of installation. Based on NRMCA (2004), the air contents of pervious concrete should be between 15% and 25% of the concrete volume, which is satisfied with the current study results. Many studies showed that adding regular RAP to concrete mixes would increase air contents [9,11,13]. Results also show that replacing 5% of cement with silica fume did not noticeably affect the void contents of epoxy RAP mixes.

where

- T = theoretical density (kg/m3);

- D = the bulk density of a concrete specimen (kg/m3).

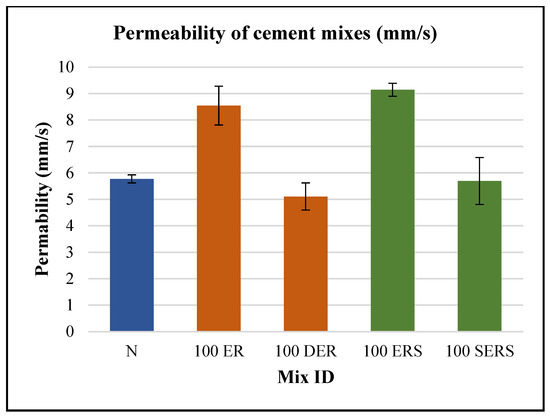

6.3. Permeability Test Results

The water permeability of the concrete is influenced by the inclusion of regular RAP materials and a supplementary cementitious material, as discussed in the literature [8]. Table 2 shows the effect of incorporating 100% epoxy RAP and 100% diluted epoxy RAP particles with and without the supplementary cementitious material. The results show that the permeability of both 100% epoxy RAP and 100% diluted epoxy RAP mixes increased by about 32% and 36%, respectively, compared with the control mix. The reason behind this increase refers to the increase in void content in reclaimed particles used in the cement mix, which allowed water to transmit faster through the pore spaces in reclaimed mixes. The results present, however, show that replacing only 5% of cement with silica fume in these mixes significantly decreased the permeability by around 40%, which made the permeability values close to the permeability of the control mix. This can be interpreted as the role of silica fume in filling pore spaces in the mix and retarding water transmission through the mix. The permeability results of pervious concrete mixes incorporating epoxy RAP particles were consistent with previous studies that used regular RAP in concrete mixes, as discussed in the literature. In addition, the significant effects of silica fume on the concrete permeability in this study were consistent with the ACI report on using silica fume in concrete mixes [40].

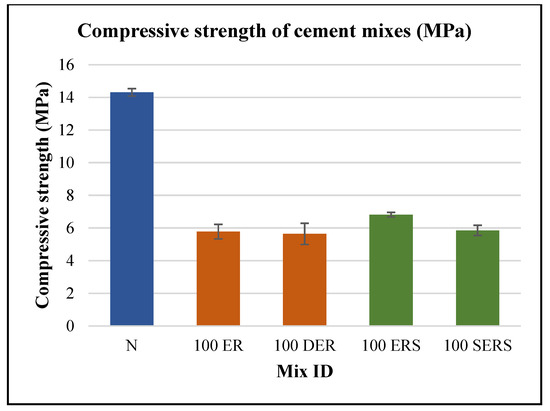

6.4. Compressive Strength Test Results

As all the previous studies highlighted the negative effect of regular RAP particles on the compressive strength of concrete mixes, the results of using epoxy RAP in this study were consistent with these studies. The compressive strength decreased nearly linearly with the RAP percentage. A reduction of 50%–70% has been reported in the compressive strength of regular RAP concrete with respect to the control mix [1]. Based on NRMCA (2004), the compressive strength of pervious concrete mixes varied in the range of 5.5 to 17.0 MPa. For this study, Table 2 shows the compressive strength results of incorporating 100% epoxy RAP (undiluted/diluted) with and without silica fume. Results showed that replacing 100% of natural aggregates with epoxy RAP and diluted epoxy RAP reduced the compressive strength by 59% and 52%, respectively. This can be interpreted by the weakness of the interfacial zone transition that occurred due to the existence of the aged epoxy RAP binder film around the aggregate particles. In addition, although silica fume has been used to provide cement mixes with high compressive strength based on ACI, it does not significantly affect the strength of concrete mixes that contain regular RAP, based on several previous studies [1,4,41]. In this study, utilizing 5% silica fume in epoxy RAP did not significantly affect the compressive strength, which is consistent with including silica fume in concrete mixes with regular RAP.

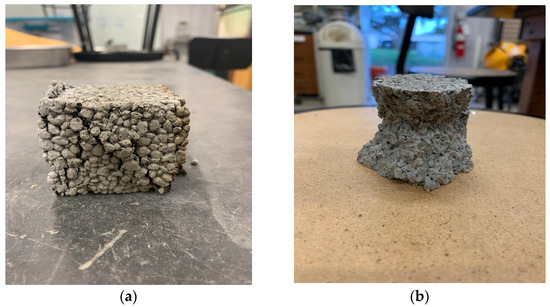

It can be concluded from the test results that epoxy RAP particles influence the properties of concrete mixes as much as regular RAP particles do. Based on the literature, the effect of epoxy RAP particles in concrete mixes with and without silica fume is consistent with the effect of regular RAP in concrete mixes. The reason could be that the binder films around RAP particles (including regular, epoxy, and diluted epoxy) are not exposed to heat before, during, and after mixing. Therefore, no interactions between cement and RAP binder occurred that could cause differences in properties. Figure 5 shows the failure of a natural cement mix and an epoxy RAP mix. It can be observed that the epoxy RAP mix had an internal failure before the sample broke, which indicates that the bonding between epoxy RAP material and cement is weak compared to the normal failure in the natural mix.

Figure 5.

The failure of the natural mix (a) and the epoxy RAP mix (b).

Figure 6, Figure 7, Figure 8 and Figure 9 summarize the effects of incorporating 100% epoxy RAP and 100% diluted epoxy RAP with and without silica fume in terms of density, air content, permeability, and compressive strength.

Figure 6.

The density test results of cement mixes.

Figure 7.

The void content of concrete mixes.

Figure 8.

Permeability test results of concrete mixes.

Figure 9.

The compressive strength test results of concrete mixes.

7. Conclusions

The incorporation of epoxy RAP and diluted epoxy RAP particles into pervious cement mixes has been studied in this research. The influence of adding silica fume on reclaimed mixes has also been investigated. Laboratory evaluation of mixes performance led to the following conclusions:

- The density test results showed that replacing natural aggregates with either 100% epoxy RAP or 100% diluted epoxy RAP particles reduced the density by an average of 10%. This is consistent with the density results of concrete mixes that contain regular RAP particles and can be explained by the light weight of reclaimed materials compared with the natural aggregate.

- Results showed that adding 5% silica fume to epoxy RAP mixes did not affect the concrete specimen’s density. This is expected as the content of silica fume utilized in this study is only 5% of cement. A larger content, however, may lead to a lower density as it has a lower specific gravity compared with Portland cement.

- Incorporating epoxy RAP and diluted epoxy RAP into cement mixes increased the air content by about 25% on average compared to the natural cement mix, even with the existence of silica fume. This can be interpreted by the high air content in recycled particles compared with natural aggregates.

- Permeability is significantly increased with mixes that have 100% of both epoxy RAP and diluted epoxy RAP materials compared to the natural mix. However, adding silica fume decreased the permeability to a value similar to that of the natural mix. This is due to the existence of microsilica fume particles that filled pore spaces in the epoxy RAP and diluted epoxy RAP particles.

- Test results showed that substituting 100% of natural aggregates with either epoxy RAP or diluted epoxy RAP would reduce the compressive strength by an average of 55%. The reason behind this refers to the presence of epoxy RAP binder film and agglomerated particles in epoxy RAP that negatively affected the interfacial transition zone between the particles and cement binder.

This study has investigated the effect of 100% undiluted/diluted epoxy RAP on pervious cement mixes. The potential applications of 100% epoxy RAP may include parking lots, driveways, backfill material, shoulder stones, and others. While this preliminary investigation provided results that showed the promise of using epoxy RAP and diluted epoxy RAP in cement mixes, the laboratory tests conducted in the study have not covered the full-scale performance evaluation of cement mixes due to the limitations of resources. A future study will be planned to include an investigation of the performance of cement mixes related to flexural strength. Moreover, the results show that there is a need for future work to investigate the interaction between epoxy RAP materials and cement paste at a microlevel. For example, the interfacial transition zone between the surface of epoxy RAP aggregate and cement paste should be studied to understand the reason behind the performance of epoxy RAP materials as an aggregate replacement. In addition, epoxy RAP binders and mixtures were artificially fabricated in the laboratory due to a lack of materials from the field. In the future, the authors will manage to obtain epoxy RAP materials from in-service epoxy asphalt pavements when they become available and incorporate the materials in performance testing and evaluation. Lastly, the environmental and economic benefits of undiluted/diluted epoxy RAP will be quantitatively analyzed through life-cycle cost analysis and life-cycle assessment once prediction of the performance trend of cement mixes containing epoxy RAP becomes feasible.

Author Contributions

M.A.: conceptualization, visualization, methodology, material preparation, supervision, and writing—original draft preparation. Q.L.: methodology, investigation, visualization, material preparation, and writing—reviewing and editing. A.E. (Asad Elmagarhe): visualization, methodology, and investigation. A.E. (Ahmed Elnihum): writing—reviewing and editing, and investigation. All authors commented on previous versions of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Researchers Supporting Project (No.: RSP2023R485), King Saud University, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the authors.

Acknowledgments

The authors extend their appreciation to the Researchers Supporting Project (No.: RSP2023R485), King Saud University, Riyadh, Saudi Arabia.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Debbarma, S.; Selvam, M.; Singh, S. Can flexible pavements’ waste (RAP) be utilized in cement concrete pavements?—A critical review. Constr. Build. Mater. 2020, 259, 120417. [Google Scholar] [CrossRef]

- Toghroli, A.; Shariati, M.; Sajedi, F.; Ibrahim, Z.; Koting, S.; Mohamad, E.T.; Khorami, M. A review on pavement porous concrete using recycled waste materials. Smart Struct. Syst. 2018, 22, 433–440. [Google Scholar] [CrossRef]

- Saleh, H.M.; Bondouk, I.I.; Salama, E.; Esawii, H.A. Consistency and shielding efficiency of cement-bitumen composite for use as gamma-radiation shielding material. Prog. Nucl. Energy 2021, 137, 103764. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Burdette, E.G. Mechanical properties of concrete containing recycled asphalt pavements. Mag. Concr. Res. 2006, 58, 313–320. [Google Scholar] [CrossRef]

- Shi, X.; Mukhopadhyay, A.; Liu, K.-W. Mix design formulation and evaluation of portland cement concrete paving mixtures containing reclaimed asphalt pavement. Constr. Build. Mater. 2017, 152, 756–768. [Google Scholar] [CrossRef]

- Singh, S.; Ransinchung, G.; Kumar, P. Feasibility study of RAP aggregates in cement concrete pavements. Road Mater. Pavement Des. 2019, 20, 151–170. [Google Scholar] [CrossRef]

- Delwar, M.; Fahmy, M.; Taha, R. Use of reclaimed asphalt pavement as an aggregate in Portland cement concrete. Mater. J. 1997, 94, 251–256. [Google Scholar]

- Hassan, K.E.; Brooks, J.J.; Erdman, M. The Use of Reclaimed Asphalt Pavement (RAP) Aggregates in Concrete; Woolley, G.R., Goumans, J.J.J.M., Wainwright, P.J., Eds.; Waste Management Series; Elsevier: Amsterdam, The Netherlands, 2000; pp. 121–128. [Google Scholar] [CrossRef]

- Huang, B.; Li, G.; Vukosavljevic, D.; Shu, X.; Egan, B.K. Laboratory Investigation of Mixing Hot-Mix Asphalt with Reclaimed Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2005, 1929, 37–45. [Google Scholar] [CrossRef]

- Saleh, H.M.; Bondouk, I.I.; Salama, E.; Mahmoud, H.H.; Omar, K.; Esawii, H.A. Asphaltene or Polyvinylchloride Waste Blended with Cement to Produce a Sustainable Material Used in Nuclear Safety. Sustainability. 2022, 14, 3525. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Ternary Concrete with Fractionated Reclaimed Asphalt Pavement. ACI Mater. J. 2015, 112, 155–163. [Google Scholar] [CrossRef]

- Abraham, S.M.; Ransinchung, G. Strength and permeation characteristics of cement mortar with Reclaimed Asphalt Pavement Aggregates. Constr. Build. Mater. 2018, 167, 700–706. [Google Scholar] [CrossRef]

- Papakonstantinou, C.G. Resonant column testing on Portland cement concrete containing recycled asphalt pavement (RAP) aggregates. Constr. Build. Mater. 2018, 173, 419–428. [Google Scholar] [CrossRef]

- Bilodeau, K.; Sauzeat, C.; Di Benedetto, H.; Olard, F.; Bonneau, D. Laboratory and in situ investigations of steel fiber-reinforced compacted concrete containing reclaimed asphalt pavement. In Proceedings of the Transportation Research Board 90th Annual Meeting, Washington, DC, USA, 23–27 January 2011. [Google Scholar]

- Brand, A.S.; Roesler, J.R.; Al-Qadi, I.L.; Shangguan, P. Fractionated Reclaimed Asphalt Pavement (FRAP) as a Coarse Aggregate Replacement in a Ternary Blended Concrete Pavement, ICT-12-008. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 2012. [Google Scholar]

- Bentsen, R.A.; Vavrik, W.A.; Roesler, J.R.; Gillen, S.L. Ternary blend concrete with reclaimed asphalt pavement as an aggregate in two-lift concrete pavement. In Proceedings of the 2013 International Concrete Sustainability Conference, Dubai, United Arab Emirates, 26–27 November 2013; pp. 6–8. [Google Scholar]

- David, T.K.; Chandrasegaran, R.; Nair, S.K. Modified Pervious Concrete Containing Recycled Asphalt Pavement and Waste Tire Rubber. IOP Conf. Ser. Mater. Sci. Eng. 2018, 371, 012011. [Google Scholar] [CrossRef]

- Erdem, S.; Blankson, M.A. Environmental performance and mechanical analysis of concrete containing recycled asphalt pavement (RAP) and waste precast concrete as aggregate. J. Hazard. Mater. 2014, 264, 403–410. [Google Scholar] [CrossRef]

- Modarres, A.; Hosseini, Z. Mechanical properties of roller compacted concrete containing rice husk ash with original and recycled asphalt pavement material. Mater. Des. 2014, 64, 227–236. [Google Scholar] [CrossRef]

- Settari, C.; Debieb, F.; Kadri, E.H.; Boukendakdji, O. Assessing the effects of recycled asphalt pavement materials on the performance of roller compacted concrete. Constr. Build. Mater. 2015, 101, 617–621. [Google Scholar] [CrossRef]

- Fakhri, M.; Amoosoltani, E. The effect of Reclaimed Asphalt Pavement and crumb rubber on mechanical properties of Roller Compacted Concrete Pavement. Constr. Build. Mater. 2017, 137, 470–484. [Google Scholar] [CrossRef]

- Debbarma, S.; Ransinchung, G.D.; Singh, S. Feasibility of roller compacted concrete pavement containing different fractions of reclaimed asphalt pavement. Constr. Build. Mater. 2019, 199, 508–525. [Google Scholar] [CrossRef]

- Thomas, R.J.; Fellows, A.J.; Sorensen, A.D. Durability Analysis of Recycled Asphalt Pavement as Partial Coarse Aggregate Replacement in a High-Strength Concrete Mixture. J. Mater. Civ. Eng. 2018, 30, 04018061. [Google Scholar] [CrossRef]

- Elmagarhe, A.; Lu, Q.; Alharthai, M.; Alamri, M.; Elnihum, A. Performance of Porous Asphalt Mixtures Containing Recycled Concrete Aggregate and Fly Ash. Materials 2022, 15, 6363. [Google Scholar] [CrossRef]

- Gaul, R. A long life pavement for orthotropic bridge decks in China. In New Technologies in Construction and Rehabilitation of Portland Cement Concrete Pavement and Bridge Deck Pavement; American Society of Civil Engineers: Reston, VA, USA, 2012; pp. 1–8. [Google Scholar] [CrossRef]

- Lu, Q.; Bors, J. Alternate uses of epoxy asphalt on bridge decks and roadways. Constr. Build. Mater. 2015, 78, 18–25. [Google Scholar] [CrossRef]

- Lu, Q.; Xin, C.; Alamri, M.; Alharthai, M. Development of porous asphalt mixture with bio-based epoxy asphalt. J. Clean. Prod. 2021, 317, 128404. [Google Scholar] [CrossRef]

- Alamri, M.; Lu, Q.; Xin, C. Preliminary Evaluation of Hot Mix Asphalt Containing Reclaimed Epoxy Asphalt Materials. Sustainability 2020, 12, 3531. [Google Scholar] [CrossRef]

- Alamri, M.; Lu, Q. Investigation on the inclusion of reclaimed diluted epoxy asphalt pavement materials into hot mix asphalt. Constr. Build. Mater. 2022, 361, 129710. [Google Scholar] [CrossRef]

- Etxeberria, M.; Marí, A.R.; Vázquez, E. Recycled aggregate concrete as structural material. Mater. Struct. 2007, 40, 529–541. [Google Scholar] [CrossRef]

- Abadel, A.A.; Alghamdi, H.; Alharbi, Y.R.; Alamri, M.; Khawaji, M.; Abdulaziz, M.A.M.; Nehdi, M.L. Investigation of Alkali-Activated Slag-Based Composite Incorporating Dehydrated Cement Powder and Red Mud. Materials 2023, 16, 1551. [Google Scholar] [CrossRef] [PubMed]

- Shoukry, H.; Perumal, P.; Abadel, A.; Alghamdi, H.; Alamri, M.; Abdel-Gawwad, H.A. Performance of limestone-calcined clay cement mortar incorporating high volume ferrochrome waste slag aggregate. Constr. Build. Mater. 2022, 350, 128928. [Google Scholar] [CrossRef]

- Alshaikh, I.M.H.; Abadel, A.A.; Sennah, K.; Nehdi, M.L.; Tuladhar, R.; Alamri, M. Progressive Collapse Resistance of RC Beam–Slab Substructures Made with Rubberized Concrete. Buildings 2022, 12, 1724. [Google Scholar] [CrossRef]

- Ahdal, A.Q.; Amrani, M.A.; Ghaleb, A.A.; Abadel, A.A.; Alghamdi, H.; Alamri, M.; Wasim, M.; Shameeri, M. Mechanical performance and feasibility analysis of green concrete prepared with local natural zeolite and waste PET plastic fibers as cement replacements. Case Stud. Constr. Mater. 2022, 17, e01256. [Google Scholar] [CrossRef]

- Alabaster, D.; Herrington, P.; Waters, J. Ultra long life low noise porous asphalt. J. Acoust. Soc. Am. 2012, 131, 3225. [Google Scholar] [CrossRef]

- Bell, C.A.; AbWahab, Y.; Cristi, M.E.; Sosnovske, D. Selection of Laboratory Aging Procedures for Asphalt-Aggregate Mixtures; Strategic Highway Research Program: Washington, DC, USA, 1994. [Google Scholar]

- Nguyen, D.H.; Sebaibi, N.; Boutouil, M.; Leleyter, L.; Baraud, F. A modified method for the design of pervious concrete mix. Constr. Build. Mater. 2014, 73, 271–282. [Google Scholar] [CrossRef]

- Memon, B.A.; Oad, M.; Buller, A.H.; Shar, S.A.; Buller, A.S.; Abro, F.U.R. Effect of Mould Size on Compressive Strength of Green Concrete Cubes. Civ. Eng. J. 2019, 5, 1181–1188. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Khoshnaw, G.; Ipek, S. Investigating properties of pervious concretes containing waste tire rubbers. Constr. Build. Mater. 2014, 63, 206–213. [Google Scholar] [CrossRef]

- Aldred, J.M.; Holland, T.C.; Morgan, D.R.; Roy, D.M.; Bury, M.A.; Hooton, R.D.; Olek, J.; Scali, M.J.; Detwiler, R.J.; Jaber, T.M. Guide for the Use of Silica Fume in Concrete; ACI 234R-06; ACI–American Concrete Institute–Committee: Farmington Hills, MI, USA, 2006. [Google Scholar]

- Abraham, S.M.; Ransinchung, G.D. Effects of Reclaimed Asphalt Pavement aggregates and mineral admixtures on pore structure, mechanical and durability properties of cement mortar. Constr. Build. Mater. 2019, 216, 202–213. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).