Abstract

Sb2Se3 is a typical V2VI3 binary chalcogenide compound characterized by a single crystalline phase and a fixed composition. Sb2Se3 displays a narrow energy gap ranging from 1.1 to 1.3 eV, which are quite optimal values for single-junction solar cells. Earth-abundant and non-toxic components make this material a good candidate for low-cost thin-film solar cells. In substrate configuration, a world record efficiency of 9.2% was recently obtained. Sb2Se3 thin films exhibit an accentuated predisposition to form (Sb4Se6)n ribbons along the [001] direction. This anisotropy heavily influences the charge transport of the photogenerated carriers. In this work, structural characterization of the Sb2Se3 films showed that the crystalline quality and preferential orientation are strongly dependent on the window layer used. To better understand the growth mechanism, Sb2Se3 thin films were deposited by close-spaced sublimation on five different window layers, such as CdS, CdS:F, CdSe, As2S3, and ZnCdS. Sb2Se3-based solar cells, realized in superstrate configuration on these different substrates, evidently demonstrate the influence of the Sb2Se3 preferential orientation on the photovoltaic parameters.

1. Introduction

Antimony selenide () is a very promising material for developing innovative high-efficiency thin film solar cells, since it is based on abundant and less toxic elements on the Earth’s crust than other materials suitable for the same application, such as CdTe and CIGS [1]. Moreover, it presents a good absorption coefficient () for the visible part of the solar spectrum [2], acceptable room temperature (RT) carrier mobility ( and ) [3,4,5], and a suitable band gap () [6] that falls near the maximum of the Schottky-Quiesser limit [7]. This material crystallizes in the orthorhombic structure, and it presents a unique quasi-one-dimensional structure, formed by () chains (ribbons) along the c-axis that are bounded by weak van der Walls forces [8].

The identification of a good window layer as an n-type partner coupled with a p-type , plays a crucial role to obtain high efficiency solar cells. In the last few years, different candidates have been checked to fill the gap; for example, Zinc oxide () [9] and Titanium dioxide () [10] window layers were tested in -based solar devices, reaching 5.93% and 5.5% power conversion efficiency (PCE), respectively. A world record PCE of 9.2% was achieved using cadmium sulphide (CdS) as the window layer in a substrate configuration solar cell, while a 7.6% record PCE was obtained in a superstrate configuration [11,12].

An optimal window layer should maximize the growth of the antimony selenide grains orthogonally to the substrate plane, such that the growth is oriented along the c-axis of the unit cell. This preferential spatial arrangement reduces the carrier recombination at the interface between two ribbons [13,14] during the normal operation of the final photovoltaic device. This requirement is due to the peculiar structure of : since ribbons interact with a strong covalent bond along , this guarantees a good carrier transport in that direction, while opposite behaviors are true for or directions, along which ribbons are bound by weak Van der Waals forces [13].

As far as we know from the literature, the Close-Spaced Sublimation (CSS) technique has already been widely used to deposit Sb2Se3 films in superstrate configuration thin-film solar cells. Despite this, a systematic study of how Sb2Se3 grows on different window layers has not yet been performed. For this reason, to study the effect of high-temperature deposition on the physical properties of Sb2Se3 films, the substrate has been varied as a CSS deposition parameter.

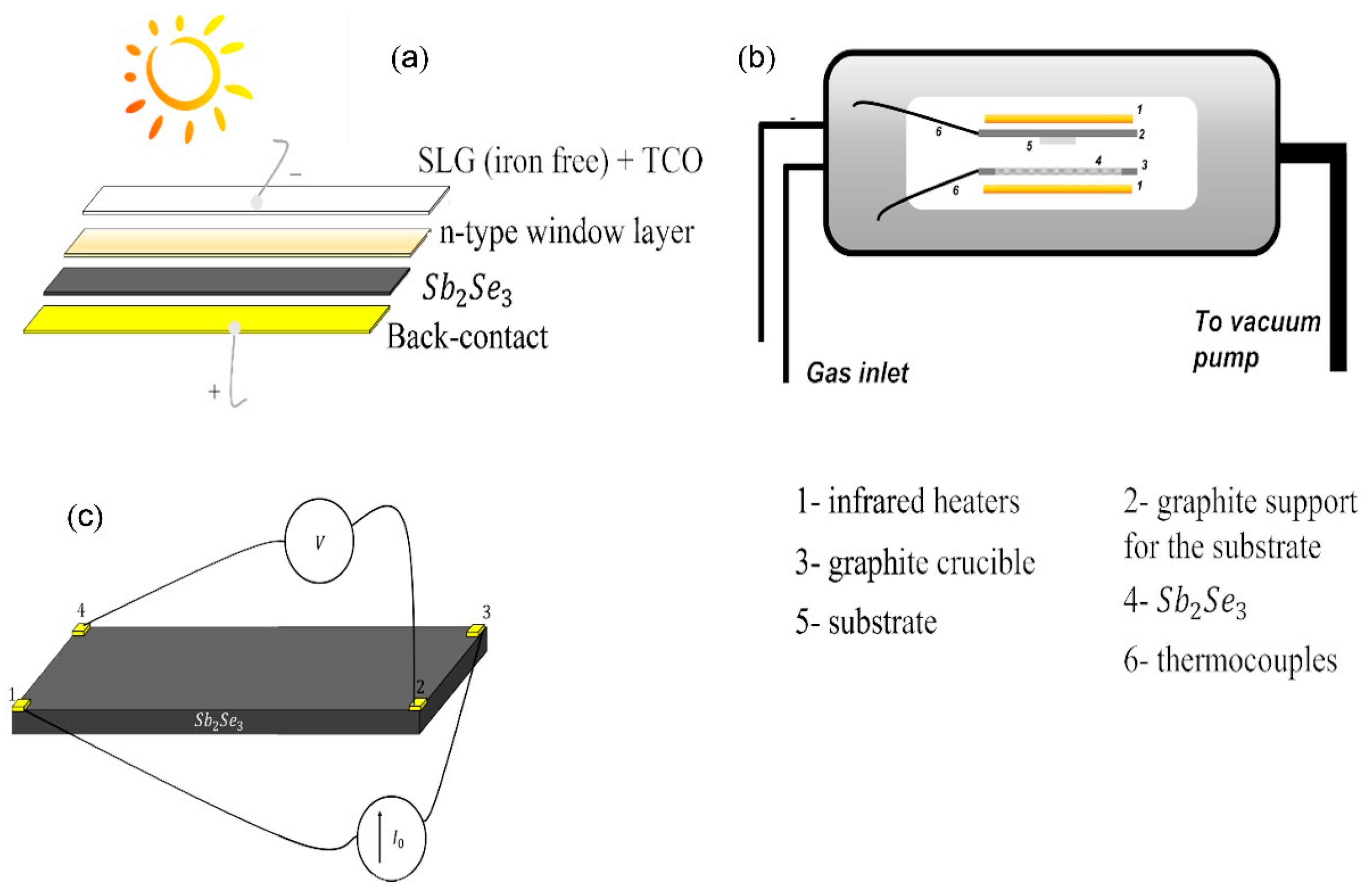

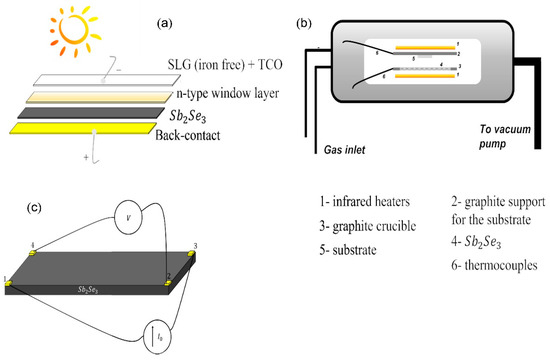

In this framework, five candidates used as window layers for Sb2Se3-based thin film solar cell in superstrate configuration (Figure 1a) were studied: cadmium sulphide (CdS), fluorine-cadmium sulphide (CdS:F), cadmium selenide (CdSe), zinc-cadmium sulphide ( and arsenic sulphide ().

Figure 1.

(a) The superstrate structure of the solar cells; (b) Sketch of CSS system; (c) van der Pauw measurement configuration.

Cadmium sulphide was considered because it has been successfully used for the same application in other thin-film solar cell technologies (CdTe and CIGS). Moreover, the actual world record PCE for -based solar cells has been achieved using CdS as window layer. For this reason, solar cells realized with CdS represent a good reference for all the other devices based on the different investigated window layers [12,15,16].

One of the main problems of using the CdS as a window layer for remains the lattice mismatch with the absorber that could be minimized with the introduction of a double buffer layer [17].

In the literature, it has also been reported that the presence of into the grain boundaries of CdS promotes the chemical stability of the material [18]. For exploiting this advantage, cadmium sulphide in an atmosphere of Ar + as sputtering process gas was deposited.

Selenium vacancies are generated during the deposition at substrate temperature of 360 °C. These vacancies could act as deep donor levels, lowering the photovoltaic parameters [19,20]. To verify the possible filling of selenium vacancies, CdSe was tested to encourage the interaction with the growing film, which could be effective for the diffusion of Se atoms.

Arsenic sulphide was used to exploit the quasi-rheotaxy growth of the film [21,22]. In the quasi-rheotaxy approach, atoms constituting the surface layers of any material move as if they were in a liquid state at temperatures up to 30% lower than the melting point. The material therefore does not melt, but the surface layers appear to be melted. This can give a high surface mobility to the adsorbed atoms and to the forming clusters. The high cluster mobility facilitates both coalescence and orientation, favoring large crystalline grain growth [23,24], and this is even more true in the case of a glassy system such as [25]. Quasi-rheotaxy preserves the advantages of rheotaxy, which consists of growing thin films on liquid surfaces, but it avoids its main disadvantage, the formation of droplets.

By introducing an appropriate percentage of zinc inside the CdS lattice, the transparency of the window layer in the visible region is increased. At the same time, Zn changes both the band alignment with antimony selenide and the resistivity that is increased [26]. A 15 at% of Zn has been estimated to be an optimal value to maximize transparency and make the resistivity of the window layer suitable for photovoltaic applications.

Starting from the collected data on the effects of the different compounds tested, the final goal of this work is to describe the preferential growth orientation of the crystalline grains along the plane (perpendicular to the ribbons axis) driven by the interaction with the window layers.

The obtained results show which are the best substrate for the Sb2Se3 growing, since there is a strict correlation between the photovoltaic parameters of the cells and the directions along which the ribbons grow. Probably, any improvement that the solar cell will exhibit in the future will be achieved by taking these results into account.

From this point of view, the strategy used is not limited to photosensitive devices but can be effective whenever one material is deposited on top of another. If the deposited material is strongly anisotropic, such as structures with reduced dimensions (1D and 2D), the method used in this work can give interesting results in the analysis of crystallinity and preferential orientations. This methodology can be used for the structural characterization of nanostructure-based devices such as nanoplateled LEDs [27], nanostructured solar cells [28], and more generally semiconductor nanodevices [29,30,31,32,33,34].

2. Materials & Methods

All the window layers were grown by low-temperature radiofrequency (r.f.) magnetron sputtering (MS) in a working Ar gas pressure of except for sample B, for which a partial pressure of was also introduced.

Samples with different window layers are indexed with capital letters, and the deposition parameters are described in Table 1.

Table 1.

The main sputtering parameters related to the deposition of the window layers.

Sample A: CdS film, 300 nm thick, deposited by sputtering at a temperature of 200 °C is characterized by a direct energy gap of 2.42 eV with a hexagonal crystal structure, which becomes cubic if annealed over 400 °C [35].

Sample B: CdS:F film, 300 nm thick, is deposited by sputtering at 200 °C in an Ar + CHF3 starting with a CdS target. The CdS:F film is characterized by a direct energy gap of 2.85 eV and a hexagonal crystal structure [36].

Sample C: CdSe film, 50 nm thick, deposited by sputtering at 200 °C in pure Ar, is characterized by a direct energy gap of 1.74 eV with a hexagonal crystal structure [37].

Sample D: As2S3 film, 50 nm thick, deposited by sputtering at 200 °C in pure Ar, is characterized by a direct energy gap of 2.35 eV with a monoclinic crystal structure [38].

Sample E: CdS + Zn0.15Cd0.85S (ZnCdS) films, in which the CdS film is the same as in sample A and the ZnCdS film, 50 nm thick, is deposited by sputtering at 200 °C in pure Ar. ZnCdS film with a direct energy gap of 2.64 eV with a hexagonal crystal structure [39].

The thicknesses of all these films were optimized to avoid a significant blue light absorption (e.g., ) and to prevent pinhole formation, which would affect the p-n junction behaviour [40,41,42].

Antimony selenide films were deposited by the close-spaced-sublimation (CSS) technique (Figure 1b) [43] using an argon partial pressure in the range 10–20 Pa. The crucible was heated at a temperature of Tc = 550 °C, and the substrate, even though not directly heated by an external source, reached a temperature of Ts = 360 °C due to convection and irradiation heating from the facing crucible. The typical distance between the crucible and substrate in CSS is . Since this distance is less than the mean free path of the sublimated particles, they do not experience scattering with the inert gas (Argon), and this condition grants fast, uniform thin film growth and high crystalline quality.

A substantial modification, which consists in the use of a compact block of , previously melted and resolidified, instead of granules, was implemented. The use of a compact block of is effective in getting a uniform heating of the material, avoiding any burst of microparticles from the source to the substrate. By using this CSS system, in 5 min deposition an film with a thickness of is obtained.

XRD measurements were performed using a linear detector LYNXEYE (Bruker, Karlsruhe, Germany) and the crystalline phase identification was carried out by the PDF4 + database (ICDD, Newtown Square, PA, USA).

Raman analyses were performed using a He-Ne laser with line emission at 632.8 nm. Laser is focused on samples, (similar to a finished cell in which only the layer that constitutes the back contact is missing) in a nearly backscattered geometry with a HORIBA-Jobin Yvon LabRam confocal micro-spectrometer (300 mm focal length spectrograph) equipped with an integrated Olympus BX40 microscope, with 4×, 10×, 50× Ultra Long Working Distance (ULWD) and 100× objectives. In order to perform a correct measurement, the set-up was calibrated using the Raman peak of silicon. Experimental data were manipulated by using LabSpec5 built-in software. The film are illuminated in confocal configuration, which means that only this layer is interested in the Raman measurement.

From the electrical point of view, on films, a four-point resistivity measurement was performed. In this case, was grown on an insulating material, such as sputtered zinc oxide, and the electrical contacts, formed by a 200 nm-thick film covered by a 100 nm-thick Pt film, were fabricated by a radiofrequency magnetron sputtering in the van der Pauw configuration [44] on the four corners of square-shaped samples having area (Figure 1c). The measurement was performed by injecting and extracting current into a pair of contacts using a Keithley 220 programmable current source instrument, while the electrical potential between the other pair of contacts was read by means of a Keithley 617 programmable electrometer.

The complete -based solar cell with 1 cm2 of active area, realized in superstrate configuration, starting from a low-iron soda lime glass as a substrate, is made by the following layers:

- 1.

- n-type part (all these films are MS deposited)

- a.

- Transparent Conducting Oxide (TCO) made up of an 800 nm thick ITO film

- b.

- high resistivity transparent (HRT) ZnO layer, 150 nm thick

- c.

- CdS, CdS:F, CdS + CdSe, CdS + , CdS + ZnCdS films representing the different window layers used for testing, whose thicknesses are described in Table 1.

- 2.

- p-type part

- a.

- Absorber layer– film, thick (CSS-deposited)

- b.

- Back contact– film, 200 nm thick covered by Pt film, 100 nm thick (both films are MS deposited)

The I-V characteristics of complete-solar cells were obtained by using a continuous LOT-Oriel solar simulator (Oriel, Irvine, CA, USA), equipped with an air mass AM1.5 filter and with a light power density supplied by a 600 W Xenon lamp (Oriel, Irvine, CA, USA). A calibrated pyranometer was used as a reference, and the measurements were made at the standard temperature of 298 K. Short-circuit current density () values, non-corrected for the spectral mismatch, were measured over a calibrated shunt resistor supplied by a Keithley 4200-SCS instrument (Tektronix, Solon, OH, USA).

3. Results and Discussion

3.1. Structural Characterization

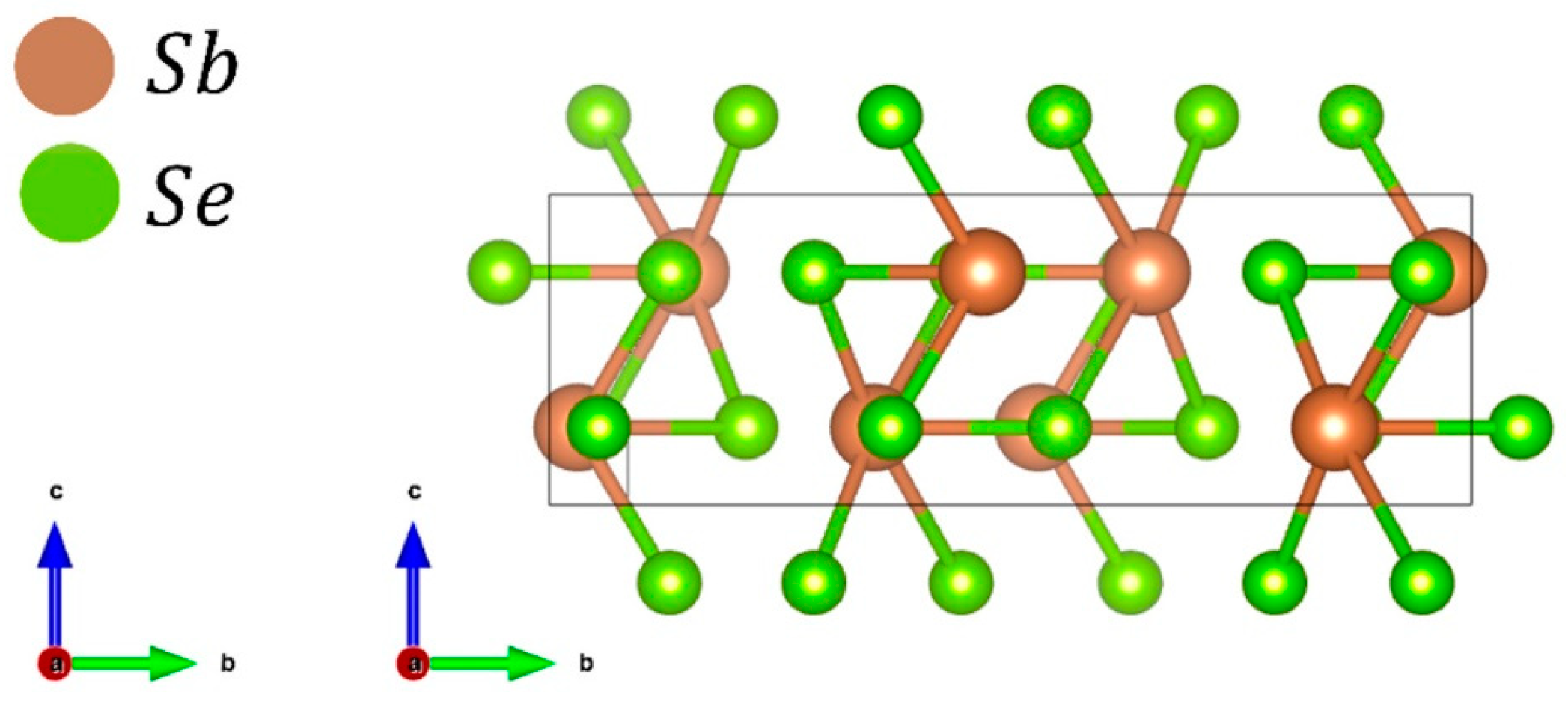

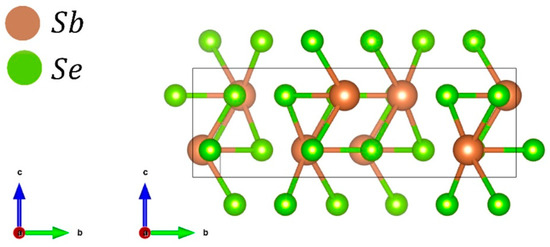

The reference card used to analyse the experimental XRD pattern of thin film is JCPDS 15-0861, which refers to Pbnm space group, as shown in Figure 2 by using the VESTA tool [45].

Figure 2.

Spatial representation of atoms in crystal structure referred to orthorhombic Pbnm space group.

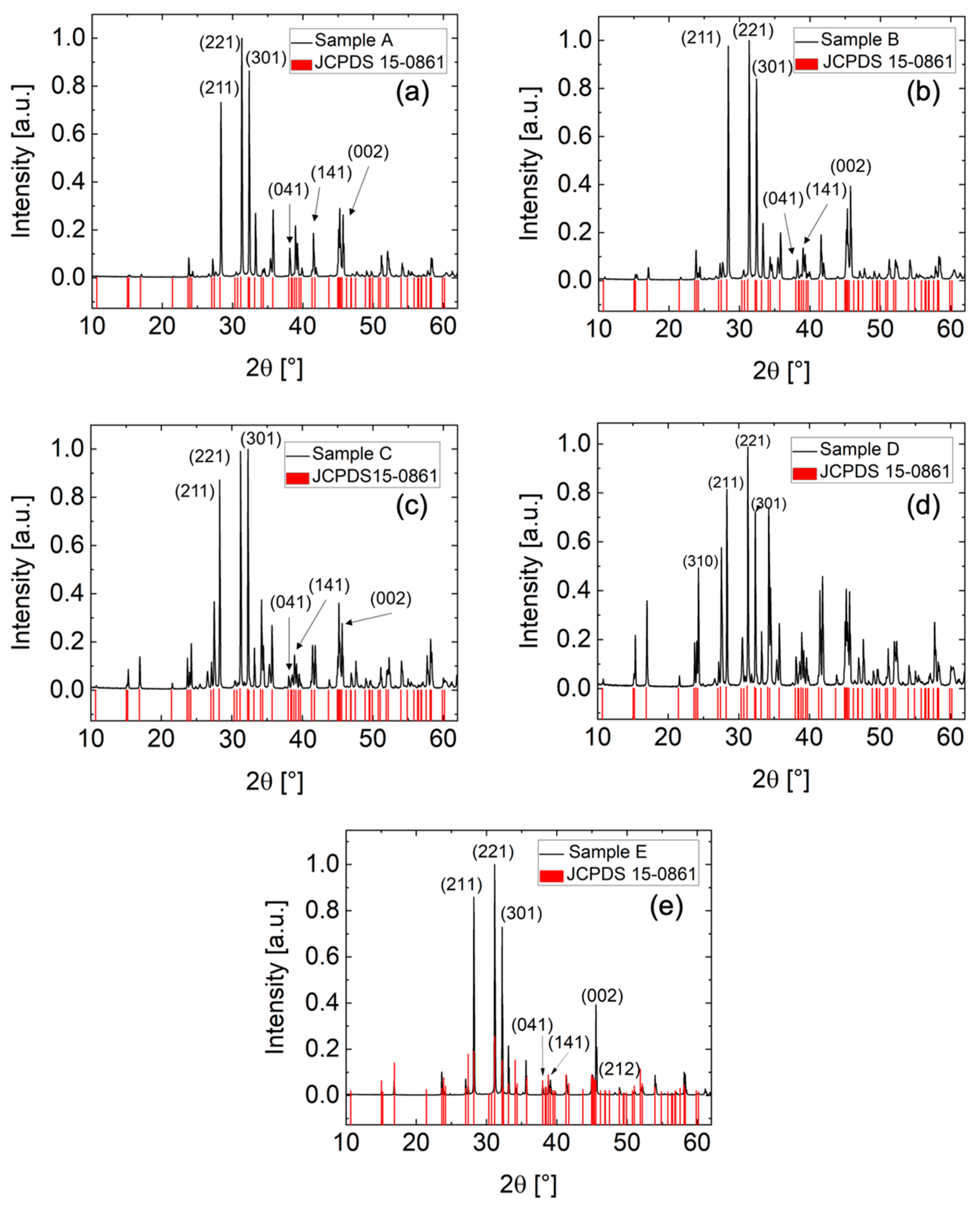

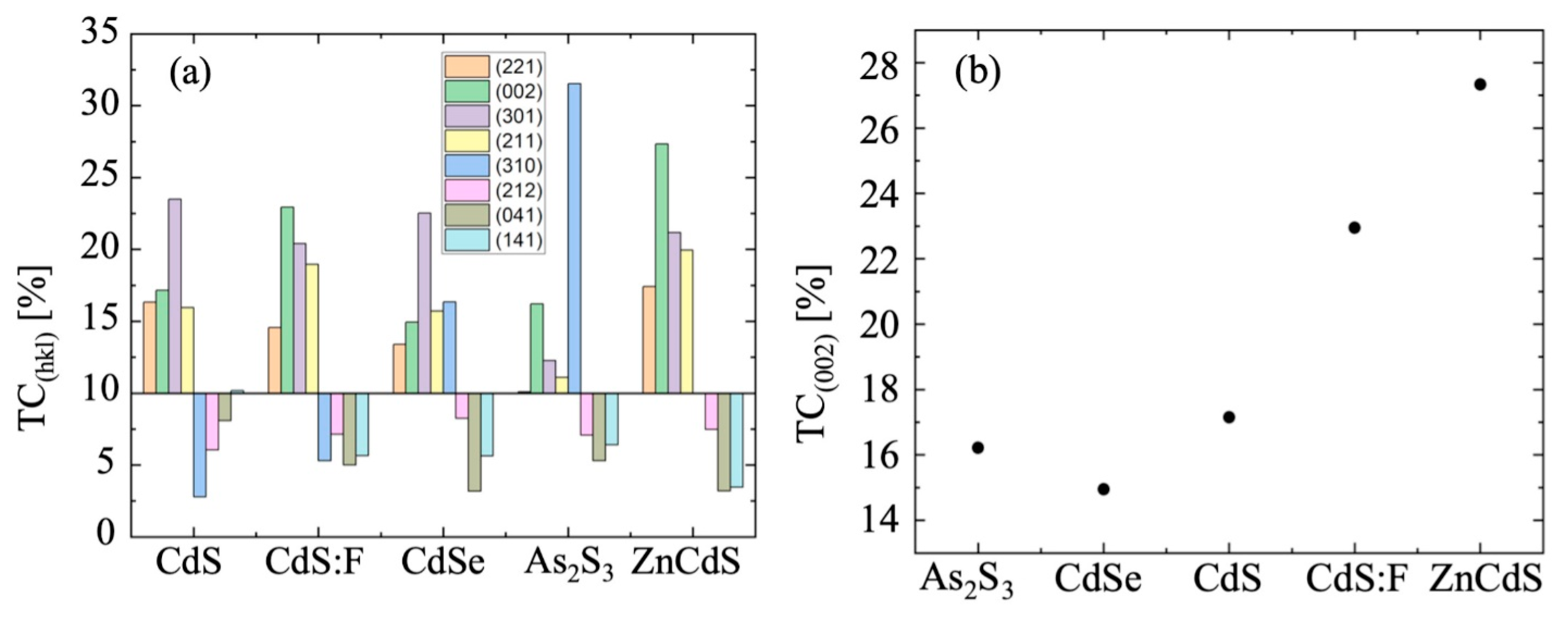

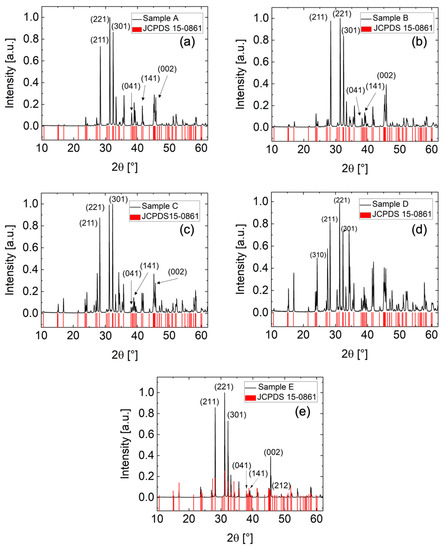

To evaluate the preferential orientation of the crystalline grains, the most representative planes in the XRD patterns reported in Figure 3 ((221), (301), (211), (002), (310), (212), (041), and (141)) were selected to estimate the texture coefficient () associated with the (hkl) plane (following [46]])

where is the experimental peak intensity related to the selected plane, is the intensity of the same plane reported in the reference card and n is the total number of chosen planes.

Figure 3.

XRD spectra of Antimony selenide films grown on (a) CdS, (b) CdS:F, (c) CdSe, (d) As2S3 and (e) ZnCdS.

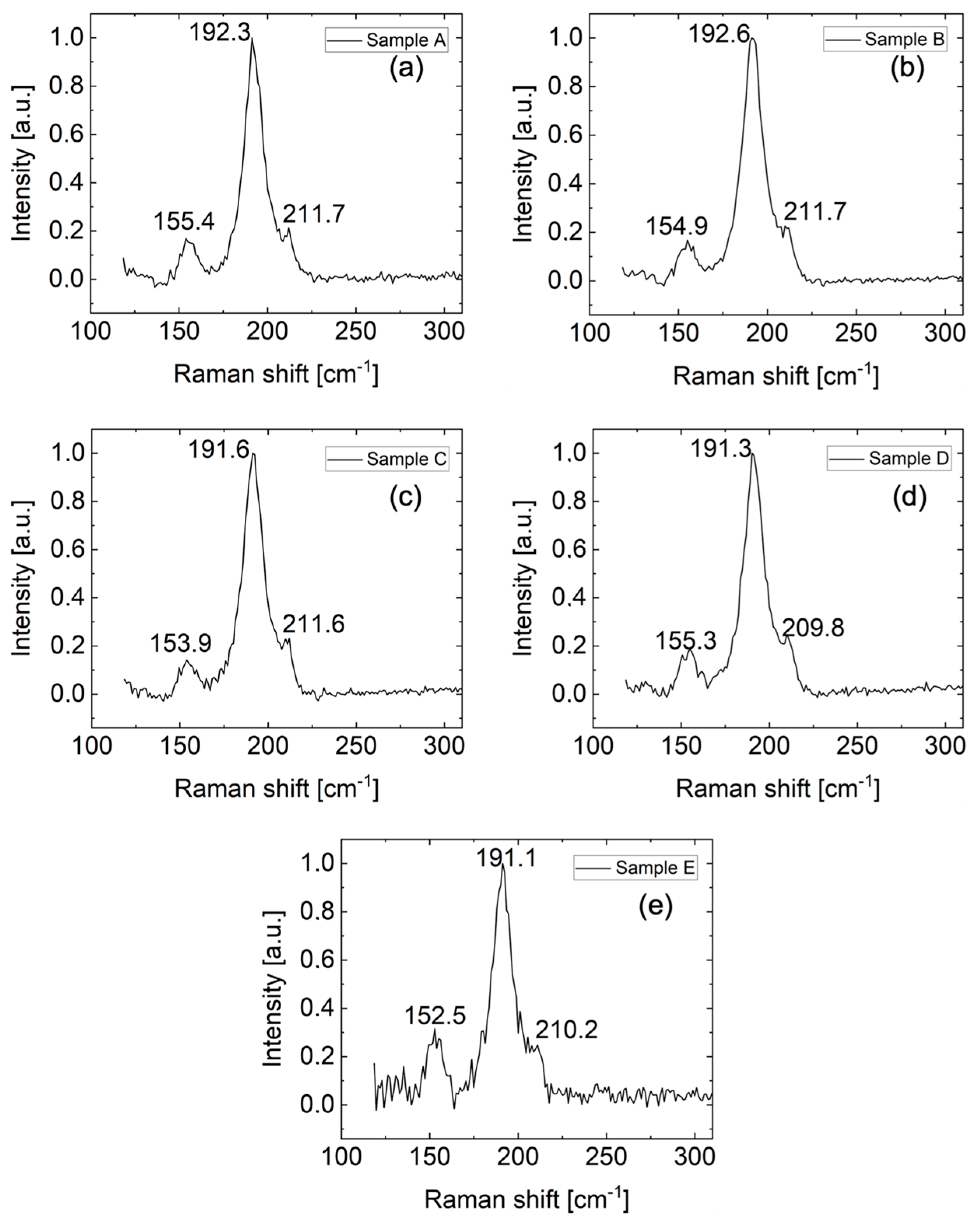

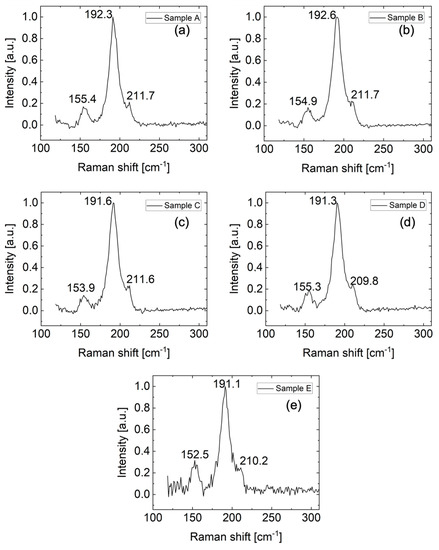

By comparing these XRD patterns with the reference card JCPDS 15-0861, it is evident that in the analysed films there aren’t secondary phases, in agreement with the Raman spectra reported in Figure 4. RT Raman analysis shows that three peaks exist in all samples at , and that corresponds to Bxg, and Ag Raman active vibrational modes [47].

Figure 4.

Antimony selenide Raman spectra grown on (a) CdS, (b) CdS:F, (c) CdSe, (d) As2S3 and (e) ZnCdS.

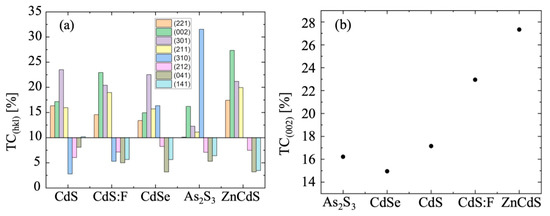

By imposing a threshold of 10% as the minimum TC for every plane taken into consideration from the XRD [48], it is evidenced in Figure 5a that the investigated samples show diffraction peaks corresponding to the (301), (221), (002), and (211) planes.

Figure 5.

(a) Texture coefficient for different crystalline planes; histograms under the 10% line have to be considered as negative values with respect to 10%; (b) Trend of the texture coefficient of the (002) plane as a function of different window layers.

In particular, the analysis of texture coefficient values shows that there are preferential reflections from different planes, namely (301) for samples A (CdS) and C (CdSe), while for samples B (CdS:F) and E (ZnCdS) it is (002).

Since this material crystallizes in the orthorhombic phase, with ribbons stacked in parallel in the direction [6], this is believed to be the direction in which charge transport is favoured [47,49]. Sample D (), in which was grown by exploiting the quasi-rheotaxia phenomenon, conversely shows a very high , almost negligible in other samples, except for sample C. As depicted in Figure 5b, the growth along the [001] direction is strongly window layer dependent, and it seems favoured by window layers containing zinc, reaching the maximum value of 27% for the texture coefficient of sample E.

3.2. Electrical Characterization

To estimate the RT resistivity of the films, grown on an insulating ZnO layer, a 4-point measurement in the van der Pauw configuration was performed.

Referring to Figure 1c and permuting the pairs of contacts, it is possible to determine the resistivity from the following equation [44]:

where:

- is the sample thickness

- is the resistivity

- is the average resistance over the possible pairs combinations of contacts and . The same is true for .

The resistivity resulted to be in dark conditions with an uncertainty of about .

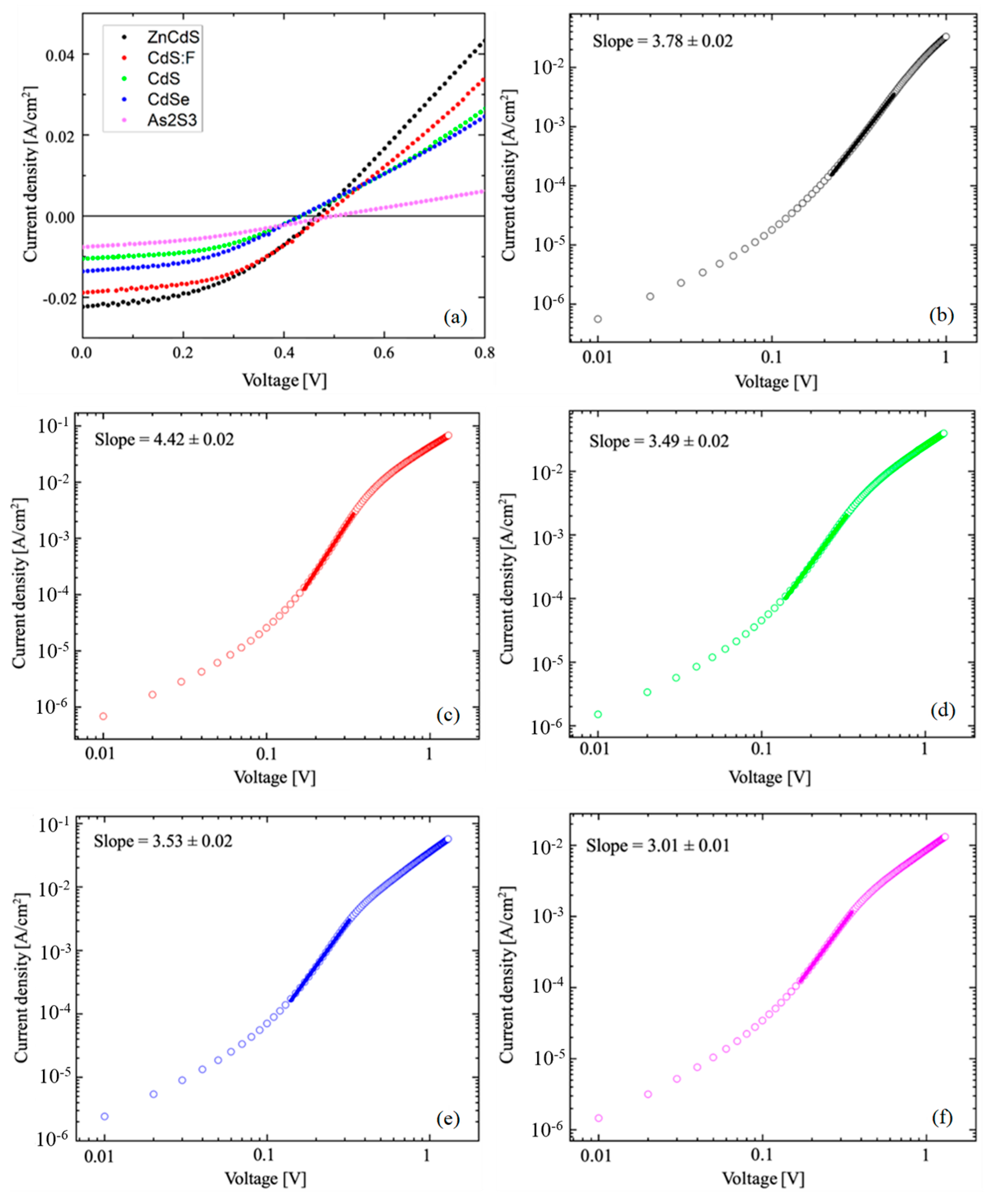

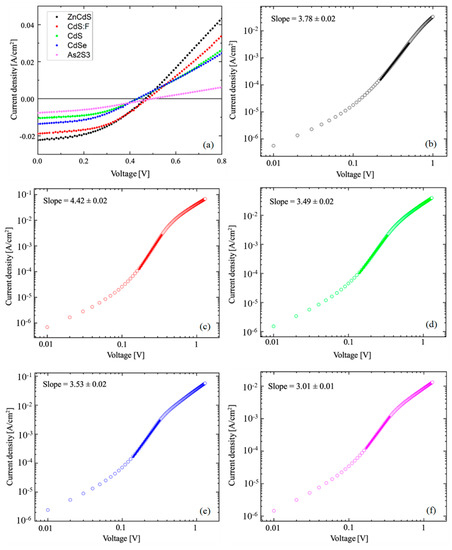

The J-V characteristics related to the complete devices with different window layers are reported in Figure 6a. From the J-V characteristics, it is possible to know the main photovoltaic parameters: the photocurrent and the shunt resistance , the photovoltage and the series resistance , are all estimated from the J-V curve.

Figure 6.

(a) J-V characteristics of the solar cells fabricated with different window layers; (b–f) Dark J-V curves in scale. The fit (solid lines) was performed to extract the Trap Filling Limit Voltage (VTFL) value (see text). (b) ZnCdS; (c) CdS:F; (d) CdS; (e) CdSe; (f) As2S3.

In order to determine the trap density of near to the top of the valence band and to the bottom of the conduction band [50], we have used the Space-Charge-Limited Current method. This method consists of measuring the J-V curve of the solar cell in dark conditions with symmetric ohmic contacts [51,52]. The intermediate voltage region, where the slope of the curve is higher than 2, is the trap-filled limit region, suitable to determine the number of traps [53,54]. From Figure 6b–f, the value of the Trap Filling Limit Voltage () was evaluated by using the following equation [55].

where is the vacuum dielectric constant, is the relative dielectric constant (estimated to be [54], is the electron charge and is the antimony selenide film thickness.

The measured photovoltaic parameters given in Table 2 are in agreement with the literature for this type of solar cell [56,57], except for sample D, which is characterized by a very high photovoltage and very poor photocurrent with high series resistance and a consequently low fill factor. This result has been considered a direct consequence of the crystallization of grown on arsenic sulphide well evidenced by the low texture coefficient.

Table 2.

Main photovoltaic parameters of solar cells realized with different window layers. The experimental errors are lower than .

From the equation

it is possible to determine the hole density in dark conditions, using the obtained resistivity value of about and, for the mobility a value of [3].

The obtained value for p is about , about one order of magnitude higher than the estimated trap concentration. It is therefore necessary to reduce the number of traps and increase the hole spatial density to improve the solar cell behavior.

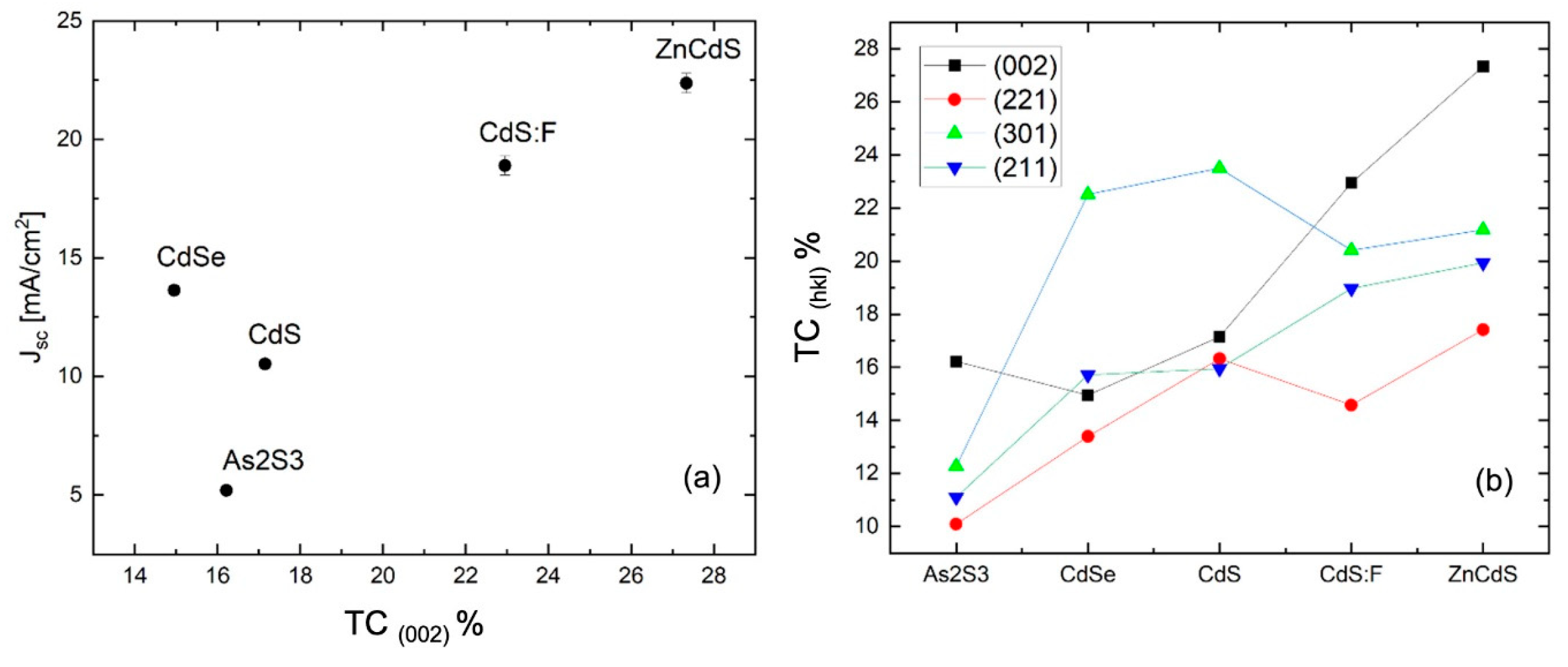

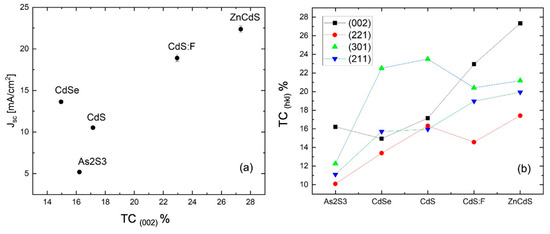

A connection between the texture coefficient TC and the photovoltaic parameters is inferred by plotting versus the corresponding to the [001] growth direction (Figure 7a). For samples B and E, where the preferential growth is along the direction, the current increases with the texture coefficient referred to as plane , while for the other samples is lower due to a more pronounced random arrangement of the grains. In fact, even if the for the CdS window is higher than for CdSe, the photocurrent is lower, because its flow depends also on the other planes, in particular (preferential for both) and . The last consideration suggests that for obtaining a good , it is not sufficient that the film grows preferentially with the plane parallel to the substrate ([001] is the growth direction) but also that the occurrence of other growth directions is limited in favor of the . Fill factor and do not exhibit such dependence because they are more strongly dependent on the high number of defects (traps) in the film.

Figure 7.

(a) Short circuit current density as a function of the TC(002) for different window layers; (b) TCs behavior of the main diffraction peaks for different window layers.

4. Conclusions

A systematic study of the interaction between different window layers (CdS, CdS:F, CdSe, Zn0.15Cd0.85S and As2 S3) deposited by sputtering and CSS-deposited Sb2Se3 was carried out. For the first time, the coupling between the materials of the window and absorber layers, deposited by the chosen techniques, was correlated.

Sb2Se3 films, grown on different window materials, show similar compositional and morphological properties but different preferential grain orientations, as evidenced by XRD and Raman measurements.

The combination of these techniques reveals that thin films do not present secondary crystalline phases. Through the texture coefficient evaluation, a trend between the TC(002) and the window layers on which the films were grown has been evidenced. In particular, the preferential growth direction is the [001] if and are used as window layers.

From the J-V characteristics, the main photovoltaic parameters were extrapolated, and a trend of was observed; in particular, increases with the TC value for the (002) plane. For the other samples, a strong contribution from the other planes was observed. The other photovoltaic parameters, such as and FF, are also strongly affected by the high number of traps in the antimony selenide film. Due to this fact, it is not possible to evaluate a substantial trend between the TC(002) and these parameters.

Although, for a further increase in the efficiencies on those devices, more studies are needed regarding window layers aiming to reduce by adjusting the lattice mismatch at the heterojunction interface.

Author Contributions

Conceptualization, A.B.; Validation, D.S., A.P., S.M. and A.B.; Investigation, S.P., G.F., S.M. and S.V.; Data curation, S.P.; Writing–original draft, S.P. and G.F.; Writing – review & editing, D.S., S.M., R.F. and A.B.; Supervision, A.P., R.F. and A.B. All authors have read and agreed to the published version of the manuscript.

Funding

The activity carried out from RSE has been financed by the Research Fund for the Italian Electrical System under the Contract Agreement between RSE S.p.A. and the Ministry of Economic Development-General Directorate for the Electricity Market, Renewable Energy and Energy Efficiency, Nuclear Energy in compliance with the Decree of 16 April 2018.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to thank Laura Fornasini and Danilo Bersani at the Department of Mathematical, Physical and Computer Science–University of Parma, for useful discussion on Raman measurements.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, C.; Li, K.; Tang, J. Ten years of Sb2Se3 thin film solar cells. Solar RRL 2022, 6, 2200094. [Google Scholar] [CrossRef]

- Chen, C.; Li, W.; Zhou, Y.; Chen, C.; Luo, M.; Liu, X.; Zeng, K.; Yang, B.; Zhang, C.; Han, J.; et al. Optical properties of amorphous and polycrystalline Sb2Se3 thin films prepared by thermal evaporation. Appl. Phys. Lett. 2015, 107, 043905. [Google Scholar] [CrossRef]

- Lin, L.Y.; Jiang, L.Q.; Qiu, Y.; Fan, B.D. Analysis of Sb2Se3/CdS based photovoltaic cell: A numerical simulation approach. J. Phys. Chem. Solids 2018, 122, 19–24. [Google Scholar] [CrossRef]

- Madelung, O. Semiconductors: Data Handbook; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Zhou, Y.; Leng, M.; Xia, Z.; Zhong, J.; Song, H.; Liu, X.; Yang, B.; Zhang, J.; Chen, J.; Zhou, K.; et al. Solution-processed antimony selenide heterojunction solar cells. Adv. Energy Mater. 2014, 4, 1301846. [Google Scholar] [CrossRef]

- Mavlonov, A.; Razykov, T.; Raziq, F.; Gan, J.; Chantana, J.; Kawano, Y.; Nishimura, T.; Wei, H.; Zakutayev, A.; Minemoto, T.; et al. A review of Sb2Se3 photovoltaic absorber materials and thin-film solar cells. Solar Energy 2020, 201, 227–246. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed balance limit of efficiency of P-n junction solar cells. J. Appl. Phys. 1961, 32, 510. [Google Scholar] [CrossRef]

- Mamta; Singh, Y.; Maurya, K.K.; Singh, V.N. A review on properties, applications, and deposition techniques of antimony selenide. Sol. Energy Mater. Sol. Cells 2021, 230, 111223. [Google Scholar] [CrossRef]

- Wang, L.; Li, D.B.; Li, K.; Chen, C.; Deng, H.X.; Gao, L.; Zhao, Y.; Jiang, F.; Li, L.; Huang, F.; et al. Stable 6%-efficient Sb2Se3 solar cells with a ZnO buffer layer. Nat. Energy 2017, 2, 17046. [Google Scholar] [CrossRef]

- Phillips, L.J.; Savory, C.N.; Hutter, O.S.; Yates, P.J.; Shiel, H.; Mariotti, S.; Bowen, L.; Birkett, M.; Durose, K.; Scanlon, D.O.; et al. Current enhancement via a TiO2 window layer for CSS Sb2Se3 solar cells: Performance limits and high VOC is with the G. IEEE J. Photovolt. 2019, 9, 544–551. [Google Scholar] [CrossRef]

- Wen, X.; Chen, C.; Lu, S.; Li, K.; Kondrotas, R.; Zhao, Y.; Chen, W.; Gao, L.; Wang, C.; Zhang, J.; et al. Vapor transport deposition of antimony selenide thin film solar cells with 7.6% efficiency. Nat. Commun. 2018, 9, 2179. [Google Scholar] [CrossRef]

- Li, Z.; Liang, X.; Li, G.; Liu, H.; Zhang, H.; Guo, J.; Chen, J.; Shen, K.; San, X.; Yu, W.; et al. 9.2%-efficient core-shell structured antimonyselenide nanorod array solar cells. Nat. Commun. 2019, 10, 125. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Chen, S.; Qin, S.; Liu, X.; Chen, J.; Xue, D.-J.; Luo, M.; Cao, Y.; Cheng, Y.; et al. Thin-film Sb2Se3 photovoltaics with oriented one-dimensional ribbons and benign grain boundaries. Nat. Photonics 2015, 9, 409–415. [Google Scholar] [CrossRef]

- Wang, Y.; Ji, S.; Shin, B. Interface engineering of antimony selenide solar cells: A review on the optimization of energy band alignments. J. Phys. Energy 2022, 4, 044002. [Google Scholar] [CrossRef]

- Oliveira, A.J.N.; Teixeira, J.P.; Ramos, D.; Fernandes, P.A.; Salomé, P.M.P. Exploiting the optical limits of thin-film solar cells: A review on light management strategies in Cu(In,Ga)Se2. Adv. Photonics Res. 2022, 3, 2100190. [Google Scholar] [CrossRef]

- Bosio, A.; Pasini, S.; Romeo, N. The history of photovoltaics with emphasis on CdTe solar cells and modules. Coatings 2020, 10, 344. [Google Scholar] [CrossRef]

- Mamta; Maurya, K.K.; Singh, V.N. Enhancing the performance of an Sb2Se3-based solar cell by dual buffer layer. Sustainability 2021, 13, 2320. [Google Scholar] [CrossRef]

- Romeo, N.; Bosio, A.; Menossi, D.; Catellani, C.; Dharmadasa, R.; Romeo, A. High efficiency Cu(In,Ga)Se2/CdS thin film solar cells obtained with precursors sputtered from InSe, GaSe and Cu targets. Thin Solid Films 2013, 535, 88–91. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, X.; Yang, Y.; Xue, D.-J.; Li, D.-B.; Chen, C.; Lu, S.; Gao, L.; He, Y.; Beard, M.C.; et al. Enhanced Sb2Se3 solar cell performance through theory-guided defect control. Res. Appl. 2017, 25, 861–870. [Google Scholar] [CrossRef]

- Wijesinghe, U.; Longo, G.; Hutter, O.S. Defect engineering in antimony selenide thin film solar cells. Energy Adv. 2023, 2, 12–33. [Google Scholar] [CrossRef]

- Romeo, N.; Cozzi, S.; Tedeschi, R.; Bosio, A.; Canevari, V.; Tagliente, M.A.; Penza, M. High quality ZnS:Mn thin films grown by quasi-rheotaxy for electroluminescent devices. Thin Solid Films 1999, 348, 49–55. [Google Scholar] [CrossRef]

- Romeo, N. Quasi-rheotaxy: Growth of large crystalline Grain thin films on quasi-liquid substrates. J. Cryst. Growth 1981, 52, 692–698. [Google Scholar] [CrossRef]

- Romeo, N. Quasi-rheotaxial growth of large crystalline grain thin films on low cost substrates for photovoltaic applications. Prog. Cryst. Growth Charact. 1984, 9, 169–183. [Google Scholar] [CrossRef]

- Romeo, N.; Canevari, V.; Sberveglieri, G.; Tosi, A.; Camanzi, A. Quasi-rheotaxy a new technique to grow large grain thin films on low cost amorphous substrates. Rev. Phys. Appliquée 1981, 16, 11–14. [Google Scholar] [CrossRef]

- Borisova, Z.U. Glassy Semiconductors; Springer: Berlin/Heidelberg, Germany, 1981. [Google Scholar]

- Li, G.; Li, Z.; Liang, X.; Guo, C.; Shen, K.; Mai, Y. Improvement in Sb2Se3 solar cell efficiency through band alignment engineering at the buffer/absorber interface. ACS Appl. Mater. Interfaces 2019, 11, 828–834. [Google Scholar] [CrossRef]

- Xiao, P.; Huang, J.; Yan, D.; Luo, D.; Yuan, J.; Liu, B.; Liang, D. Emergence of nanoplatelet light-emitting diodes. Materials 2018, 11, 1376. [Google Scholar] [CrossRef]

- Chen, G.; Ning, Z.; Ågren, H. Nanostructured solar cells. Nanomaterials 2016, 6, 145. [Google Scholar] [CrossRef] [PubMed]

- Frontiers of Nanoscience; Ritchie, D.A., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 20, ISBN 1876-2778. [Google Scholar]

- Romeo, N.; Fermi, F.; Tedeschi, R.; Bosio, A.; Canevari, V.; Cozzi, S. Large grain electroluminescent ZnS:Mn thin films grown by quasi-rheotaxy on insulating materials. Thin Solid Films 2001, 384, 138–145. [Google Scholar] [CrossRef]

- Chopade, P.; Jagtap, S.; Gosavi, S. Material properties and potential applications of CdSe semiconductor nanocrystals. In Nanoscale Compound Semiconductors and Their Optoelectronics Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 105–153. ISBN 9780128240632. [Google Scholar]

- Khan, Z.H. (Ed.) Emerging Trends in Nanotechnology; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Lee, J.; Mathai, M.; Jain, F.; Papadimitrakopoulos, F. Layer-by-layer growth of CdSe-based nanocrystal light-emitting diodes. J. Nanosci. Nanotechnol. 2001, 1, 59–64. [Google Scholar] [CrossRef]

- Pattini, F.; Rampino, S.; Mezzadri, F.; Calestani, D.; Spaggiari, G.; Sidoli, M.; Delmonte, D.; Sala, A.; Gilioli, E.; Mazzer, M. Role of the substrates in the ribbon orientation of Sb2Se3 films grown by low-temperature pulsed electron deposition. Sol. Energy Mater. Sol. Cells 2020, 218, 110724. [Google Scholar] [CrossRef]

- Moon, B.S.; Lee, J.H.; Jung, H. Comparative studies of the properties of CdS films deposited on different substrates by R.F. Sputtering. Thin Solid Films 2006, 511–512, 299–303. [Google Scholar] [CrossRef]

- Romeo, N.; Bosio, A.; Canevari, V. The role of CdS preparation method in the performance of CdTe/CdS thin film solar cell. In Proceedings of the 3rd World Conference on Photovoltaic Energy Conversion, Osaka, Japan, 11–18 May 2003; pp. 469–470. [Google Scholar]

- Ninomiya, S.; Adachi, S. Optical properties of cubic and hexagonal CdSe. J. Appl. Phys. 1995, 78, 4681–4689. [Google Scholar] [CrossRef]

- Tan, W.C.; Solmaz, M.E.; Gardner, J.; Atkins, R.; Madsen, C. Optical characterization of A-As2S3 thin films prepared by magnetron sputtering. J. Appl. Phys. 2010, 107, 033524. [Google Scholar] [CrossRef]

- Kumar, S.; Rajpal, S.; Sharma, S.K.; Kumar, S.R. Influence of annealing on ZnCdS thin films: Structural and optical properties. AIP Conf. Proc. 2021, 1, 040015. [Google Scholar]

- Guo, L.; Zhang, B.; Li, S.; Montgomery, A.; Li, L.; Xing, G.; Zhang, Q.; Qian, X.; Yan, F. Interfacial engineering of oxygenated chemical bath–deposited CdS window layer for highly efficient Sb2Se3 thin-film solar cells. Mater. Today Phys. 2019, 10, 100125. [Google Scholar] [CrossRef]

- Ge, J.; Koirala, P.; Grice, C.R.; Roland, P.J.; Yu, Y.; Tan, X.; Ellingson, R.J.; Collins, R.W.; Yan, Y. Oxygenated CdS buffer layers enabling high open-circuit voltages in earth-abundant Cu2BaSnS4 thin-film solar cells. Adv. Energy Mater. 2017, 7, 1601803. [Google Scholar] [CrossRef]

- Meysing, D.M.; Wolden, C.A.; Griffith, M.M.; Mahabaduge, H.; Pankow, J.; Reese, M.O.; Burst, J.M.; Rance, W.L.; Barnes, T.M. Properties of reactively sputtered oxygenated cadmium sulfide (CdS:O) and their impact on CdTe solar cell performance. J. Vac. Sci. Technol. A Vac. Surf. Film. 2015, 33, 021203. [Google Scholar] [CrossRef]

- Romeo, N.; Bosio, A.; Canevari, V.; Podestà, A. Recent progress on CdTe/CdS thin film solar cells. Sol. Energy 2004, 77, 795–801. [Google Scholar] [CrossRef]

- Van der Pauw, L.J. A method of measuring specific resistivity and hall effect of discs of arbitrary shape. Semicond. Devices Pioneer. Pap. 1958, 13, 174–182. [Google Scholar]

- Momma, K.; Izumi, F. VESTA3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 2011, 44, 1272–1276. [Google Scholar] [CrossRef]

- Krautmann, R.; Spalatu, N.; Gunder, R.; Abou-Ras, D.; Unold, T.; Schorr, S.; Krunks, M.; Oja Acik, I. Analysis of grain orientation and defects in Sb2Se3 solar cells fabricated by close-spaced sublimation. Solar Energy 2021, 225, 494–500. [Google Scholar] [CrossRef]

- Vidal-Fuentes, P.; Guc, M.; Alcobe, X.; Jawhari, T.; Placidi, M.; Pérez-Rodríguez, A.; Saucedo, E.; Roca, V.I. Multiwavelength excitation raman scattering study of Sb2Se3 compound: Fundamental vibrational properties and secondary phases detection. 2D Mater. 2019, 6, 045054. [Google Scholar] [CrossRef]

- Spaggiari, G.; Pattini, F.; Bersani, D.; Calestani, D.; de Iacovo, A.; Gilioli, E.; Mezzadri, F.; Sala, A.; Trevisi, G.; Rampino, S. Growth and structural characterization of Sb2Se3 solar cells with vertical Sb4Se6 ribbon alignment by RF magnetron sputtering. J. Phys. D Appl. Phys. 2021, 54, 385502. [Google Scholar] [CrossRef]

- Chen, C.; Bobela, D.C.; Yang, Y.; Lu, S.; Zeng, K.; Ge, C.; Yang, B.; Gao, L.; Zhao, Y.; Beard, M.C.; et al. Characterization of basic physical properties of Sb2Se3 and its relevance for photovoltaics. Front. Optoelectron. 2017, 10, 18–30. [Google Scholar] [CrossRef]

- Adinolfi, V.; Yuan, M.; Comin, R.; Thibau, E.S.; Shi, D.; Saidaminov, M.I.; Kanjanaboos, P.; Kopilovic, D.; Hoogland, S.; Lu, Z.H.; et al. The in-gap electronic state spectrum of methylammonium lead iodide single-crystal perovskites. Adv. Mater. 2016, 28, 3406–3410. [Google Scholar] [CrossRef] [PubMed]

- Le Corre, V.M.; Duijnstee, E.A.; el Tambouli, O.; Ball, J.M.; Snaith, H.J.; Lim, J.; Koster, L.J.A. Revealing charge carrier mobility and defect densities in metal halide perovskites via space-charge-limited current measurements. ACS Energy Lett. 2021, 6, 1087–1094. [Google Scholar] [CrossRef] [PubMed]

- Duijnstee, E.A.; Ball, J.M.; le Corre, V.M.; Koster, L.J.A.; Snaith, H.J.; Lim, J. Toward understanding space-charge limited current measurements on metal halide perovskites. ACS Energy Lett. 2020, 5, 376–384. [Google Scholar] [CrossRef]

- Peng, W.; Miao, X.; Adinolfi, V.; Alarousu, E.; el Tall, O.; Emwas, A.-H.; Zhao, C.; Walters, G.; Liu, J.; Ouellette, O.; et al. Engineering of CH3NH3PbI3 perovskite crystals by alloying large organic cations for enhanced thermal stability and transport properties. Angew. Chem. 2016, 128, 10844–10848. [Google Scholar] [CrossRef]

- Liang, G.X.; Luo, Y.d.; Chen, S.; Tang, R.; Zheng, Z.H.; Li, X.J.; Liu, X.S.; Liu, Y.K.; Li, Y.F.; Chen, X.Y.; et al. Sputtered and selenized Sb2Se3 thin-film solar cells with open-circuit voltage exceeding 500 MV. Nano Energy 2020, 73, 104806. [Google Scholar] [CrossRef]

- Chen, K.; Wu, P.; Yang, W.; Su, R.; Luo, D.; Yang, X.; Tu, Y.; Zhu, R.; Gong, Q. Low-dimensional perovskite interlayer for highly efficient lead-free formamidinium tin iodide perovskite solar cells. Nano Energy 2018, 49, 411–418. [Google Scholar] [CrossRef]

- Spalatu, N.; Krautmann, R.; Katerski, A.; Karber, E.; Josepson, R.; Hiie, J.; Acik, I.O.; Krunks, M. Screening and optimization of processing temperature for Sb2Se3 thin film growth protocol: Interrelation between grain structure, interface intermixing and solar cell performance. Sol. Energy Mater. Sol. Cells 2021, 225, 111045. [Google Scholar] [CrossRef]

- Rijal, S.; Li, D.B.; Awni, R.A.; Xiao, C.; Bista, S.S.; Jamarkattel, M.K.; Heben, M.J.; Jiang, C.S.; Al-Jassim, M.; Song, Z.; et al. Templated growth and passivation of vertically oriented antimony selenide thin films for high-efficiency solar cells in substrate configuration. Adv. Funct. Mater. 2022, 32, 2110032. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).