Abstract

Here we report the optimization of the fabrication conditions for AuNi bimetallic catalysts supported on self-ordered titania nanotube arrays (AuNi-TiO2ntb). A series of efficient AuNi-TiO2ntb catalysts with small amounts of Au in the range of 1.74 to 15.7 μgAu·cm−2 have been fabricated by anodization, electroless Ni plating, and galvanic displacement techniques. The electrocatalytic activity of the catalysts has been evaluated for BH4− ion oxidation in an alkaline medium using cyclic voltammetry and chronoamperometry. The performance of a NaBH4-H2O2 fuel cell with Ni-TiO2ntb and AuNi-TiO2ntb anode catalysts has been investigated at different temperatures. It was found that the electrocatalytic activity of AuNi-TiO2ntbs catalysts was improved remarkably when the Ni layer of 100 and 400 nm was used for the deposition of Au crystallites. The Ni-TiO2ntb catalyst generates the maximum power density values of ca. 85–121 mW·cm−2 at a temperature of 25–55 °C, whereas the AuNi-TiO2ntb catalysts that have the Au loading of 3.07 and 15.7 μgAu·cm−2 achieve the power density values of ca. 104–147 and 119–170 mW·cm−2, respectively, at a temperature of 25–55 °C.

1. Introduction

Despite the high price of borohydrides, manifested as either alternative anodic fuels (direct borohydride fuel cells (DBFCs)) or alternative hydrogen sources (indirect borohydride fuel cells (IDBFCs)), borohydride fuel cells became the subject of many current research studies once again [1,2,3,4,5,6,7,8]. Concerning other types of fuel cells, DBFCs are of particular value for their high theoretical capacity and specific energy density, i.e., 5.6 Ah/g and 9.3 Wh/g, respectively. Moreover, the theoretical voltage of 1.64 V for DBFC is much higher than that of other fuel cells using hydrogen (1.24 V) or methanol (1.19 V) as fuel. One more significant feature is power performance at ambient temperature. These essential advantages have initiated vigorous research with the aim of finding appropriate conditions for the best run of borohydride fuel cells. Great attention is dedicated to the fabrication of electrocatalysts with high catalytic activity for BH4− ion oxidation. It is well-known that gold (Au) is the best electrocatalyst for BH4− ion oxidation proceeding with an eight-electron process, and this has been widely investigated [9,10,11,12,13,14,15,16]. However, the borohydride oxidation reaction (BOR) on Au has rather sluggish kinetics that is far more inferior than those of Pt, Pd, or Ni [1,5,10,15]. The performance of the BOR on those catalysts has been extensively overviewed in several comprehensive reviews and reports [1,5,7,9,10], highlighting their drawbacks and advantages. Therein it has been pointed out that Au/C requires high potentials (above 0.8V vs. RHE) to achieve mass transfer-limiting current. In contrast, for Pt/C and Ni/C, the BOR current increases at relatively low potentials, but the hydrogen evolution reaction (HER) becomes dominant and limits the BOR’s efficiency. Olu et al. [5] compared the BOR activity of different materials and have found that for carbon-supported nanoparticles, Ni clearly outperforms all other catalysts (including Pt) at low potentials. However, this catalyst (Ni/C) becomes most inactive during anodic polarisation because of surface oxide formation. Meanwhile, the variation of the open circuit potential (OCP) value was found to be in the series of Ni/C < Pd/C < Pt/C < Au/C and driven by the competition between the HER and BOR [5]. The main drawback during the BOR is significant and problematic hydrogen generation that is always detected not only at low but also high potentials. This leads to serious drawbacks in terms of fuel efficiency and system/cell safety [15]. These findings of H2 formation have been confirmed by DEMS studies using deuterium-labeled fuel [14] on Pt/C and Au/C. They showed that at low potentials, H2 generation occurs due to the mixed potential between BOR and HER, whereas at high potentials, H2 is formed from BD4− when the electrode surface is poisoned by surface oxides or BHx intermediates [9,10]. In this light, the composition of the anode materials for the BOR, as well as the sodium borohydride concentration and the operating conditions, become the key factors significantly contributing to the performance of a direct borohydride fuel cell [5,6,7,8]. Thus, the oxidation of BH4− ions in an alkaline medium has been investigated on various Au electrocatalysts, including a highly dispersed Au on high surface area carbon silk or carbon blacks [17,18], carbon-supported Au hollow nanospheres [19], colloidal Au, and Au alloys on reduced graphene oxide or carbon nanotubes [20,21,22,23,24]. Although various nanostructured conductive carbon-based materials, including carbon nanotubes, nanofibers, and mesoporous carbon, have been used as supports for catalysts (particularly to reduce the use of precious metals), a number of drawbacks, such as carbon’s narrow microporosity, traces of impurities, low mechanical and thermal stability, and predisposition to corrosion [25], make them unviable for a wide range of applications. Moreover, most of these high performance conventional carbon materials are extracted from fossil fuels using energy-intensive and tedious synthetic processes that are not only environmentally unfriendly, but also quite expensive, making their commercialization unviable. Furthermore, additional activation of carbon by doping with heteroatoms (e.g., N, P, B, S, Fe, etc.) is required to improve the catalytic activity [26,27,28] since the electrochemical activity of pure carbon materials is weak.

While significant progress has been made in the development of carbon-based noble and non-noble metal catalysts, their activity, performance, and stability in fuel cells are still not comparable to those of Pt-based materials [29]. For this reason, non-carbon materials have been investigated as catalyst supports for fuel cells. Many metal oxides, including group IV and V metal oxides overviewed in ref. [29], have been proposed as catalyst substrates to replace carbon since they are chemically stable in acid electrolytes and could act well as oxygen reduction reaction (ORR) catalysts. However, in their bulk form, they exhibit extremely low ORR activity due to low conductivity and lack of adsorption sites, requiring additional efforts to activate the surface by modification, doping, alloying, or other treatments, pointing to a clear correlation between the catalyst activity, shape, size, composition, and the method used to synthesize the catalyst.

Metal oxide-based nanomaterials such as TiO2, ZnO, SnO2, etc. (particularly TiO2 and ZnO) have also been investigated for a variety of functional applications due to their physical and chemical characteristics, such as a large number of phases with different structures and a wide range of optical and electrical characteristics (including high chemical stability, suitable band gap, etc.). Among them, ZnO-based materials have been the most extensively investigated oxides for attractive physicochemical and optoelectronic properties, and photocatalytic performance that is supposed to be similar to that of the most promising titanium oxides strongly depending on their fabrication techniques [30,31]. However, the electrocatalytic activity of Zn-based catalysts has not been as satisfactory as desired considering alkaline fuel cell applications. It has been found that although the OCP of Zn in an alkaline sodium borohydride solution is much more negative than that of the other metals and the oxidation current increases dramatically at a relatively negative potential (at −1.06 V vs. SCE), at higher potentials, the Zn surface gets covered by a layer of Zn oxide, which drastically reduces the oxidation rate of the sodium borohydride ions [32]. It has been supposed that modifying the Zn catalyst surface by alloying or creating core−shell structures can improve the catalyst performance. The modified Zn catalyst surface after alloying with Co has been shown to catalyze the direct oxidation of sodium borohydride ions, but it was not sufficiently stable for long-term cycling due to dissolution of Zn at higher potentials [33]. Recently, the unique hierarchical leaf-shaped Ni@Zn structure has been developed. It showed high stability and selectivity for the oxidation of borohydride ions due to the increased electroactive surface area, the improved adsorption of reactants, and the inhibition of Ni oxidation, which were associated with the unique hierarchical structure and the introduction of Zn [34].

SnO2 has also been proposed as a potential support for electrocatalysts in fuel cells [35]. B. Šljukić, et al. [36] proposed the SnO2-carbon composites as supports for PdNi nanoparticle electrocatalysts with the aim of using them in alkaline borohydride solutions. They evaluated the number of electrons exchanged for BOR and found that it varied in the range from 1.9 for PdNi/(SnO2-graphene) to 3.4 for PdNi/(SnO2-KB300), which is well below the maximum theoretically predicted eight-electron oxidation reaction. Meanwhile, J. Ma, et al. [37] developed an ultra-thin tin dioxide layer on the cobalt oxide support (SnO2/Co3O4) and applied it as an anode catalyst for the direct borohydride fuel cell. They have found that the catalytic ability for the BOR was greatly improved and the estimated electron transfer number n equaled 5.82. This excellent catalytic performance of the catalysts for the BOR was attributed to the interaction between Sn and Co oxides at the SnO2/Co3O4 interface.

Among non-carbon materials, the titania nanotube surface has recently been accepted as a promising alternative to carbon-based supports due to the ease of preparation, high orientation, large surface area, high uniformity, non-toxicity, chemical stability, and low cost of production [38,39,40]. TiO2 nanotubes are excellent materials for catalyzing certain reactions, such as ORR [29,41,42], or for use in fuel cells, such as direct methanol or direct ethanol fuel cells [43]. This choice is driven by the fact that TiO2 nanotubes exhibit strong metal support interactions, high specific surface area, high chemical stability, and high catalytic activity [43]. Moreover, the porous TiO2-based catalysts can efficiently boost the mass transfer rate and supply ample ion transfer channels during the ORR process [42]. The surface structure also strongly influences the activity of metal oxides for the ORR reaction. It has been shown that the ORR activity on the TiO2 catalyst prepared by heat treatment increased with the increase in the specific crystalline structure, such as the TiO2 (rutile) (110) plane [44]. An increase in the catalytic performance of TiO2 nanotubes doped by cobalt and iron and prepared by hydrothermal and reduction methods was attributed to the creation of a higher number of active sites [41].

The different properties of TiO2-based materials, such as the surface area, crystallographic structure, conductivity, and many others, depend on the applied synthesis method. Among them are electrochemical anodization, which typically can be provided in either aqueous or organic-based electrolytes [40,41,42,43,44,45,46,47,48,49,50,51], hydrothermal treatment [50,51], microwave-assisted synthesis [52], sol-gel [53], etc. Usually, TiO2 demonstrates relatively poor electrical conductivity, which can be greatly increased by the anodization of TiO2 nanotubes. The obtained materials exhibit good conductivity and efficient dispersion of metal nanoparticles [50]. Heteroatom doping is another quite effective approach to improving the catalytic properties of TiO2 nanotubes [47]. Similarly, modification of TiO2 nanotubes with various combinations of noble or non-noble metals with transition metal oxides such as Fe-Ni [54] or Fe-Co [41] also leads to high activity, underlining the fact that TiO2 nanotubes have been prepared by different methods. Fe-Ni (oxy) hydroxides were loaded by the electrochemical deposition method on TiO2 nanotubes prepared by two-step anodization, followed by thermal treatment, while Fe-Co nanoparticles were deposited by the reduction method on TiO2 nanotubes prepared by the hydrothermal method.

Various strategies for synthesizing high performance TiO2-based catalysts have attracted much research interest, each with its inherent advantages and disadvantages [42,55]. For example, although hydrothermal synthesis can produce crystallized nanoparticles of the desired shape and size with enhanced chemical activity, the synthesis is carried out under high pressure, requires expensive autoclaves, is difficult to control and raises safety concerns [42,51,52,55]. The sol-gel method is a quite attractive one, given its relatively low cost, easy control process and the density and homogeneity of the products produced, but it is a time-consuming process using harmful and toxic organic solutions [53,55]. Microwave-assisted synthesis of TiO2-based materials is an advantageous, highly effective, fast, environmentally friendly method that allows for the fabrication of nanostructures of various shapes and sizes. Moreover, uniform microwave heating gives a homogeneous, uniform particle size distribution. However, it is dependent on microwave heating frequencies and therefore, carries the risk of creating an impure synthesized compound. Among the other techniques, the electrochemical anodization of titanium oxides, due to its low cost and simple preparation, has been the most widely used method over the past decades. This method allows for easy control of the morphological structure of TiO2 nanotubes by varying the anodization parameters, such as applied voltage, synthesis time, temperature, and electrolyte composition [55,56]. In addition, the further application of the simple post-treatment technique can be used to achieve the required crystalline phase by transferring it from an amorphous one [41,48].

Unfortunately, there are very few studies focusing on the use of TiO2 nanotubes as catalyst supports for the BOR or direct borohydride fuel cells (DBFC) [57,58,59]. Ponce-de-Leon, et al. [57] have shown that the TiO2 nanotubes prepared by alkaline hydrothermal treatment of TiO2 anatase and modified by gold showed similar catalytic activity towards the oxidation of borohydride ions as the commercially available Au/C and Au foil electrodes. It should be noted that the loading of Au on titanate nanotubes was 5-fold lower than that of the Au/C electrode. Recently, Au nanoparticles, which were dispersed over a nanotubular TiO2 matrix, have been used as a highly efficient catalyst system for the degradation of dyes, water−gas shift reaction, electrochemical oxygen reduction, glucose oxidation, CO oxidation, and others [38]. M.H. Gouda, et al. [60] developed composite membranes based on PVA, PEO, and PVP doped with sulphated TiO2 nanotube and phosphated TiO2 by the impregnation−calcination method and investigated for the direct borohydride fuel cells. Composite membranes such as this showed higher mechanical resistance, lower water absorption, higher thermal stability, higher oxidative stability, and lower permeability to borohydride ions compared to Nafion. Improved properties were attributed to stronger interfacial adhesion of agents of the polymer matrix of composite membranes by forming more hydrogen bonds and ionic interactions between acids groups of doping agents and amine groups of PVP, which improved their breaking resistance when compared with the undoped membrane. Moreover, the doped patterns showed better conductivity and revealed a more amorphous structure when compared to undoped SO4–TiO2 and PO4–TiO2 particle membranes.

Our previous publication showed that the titania nanotubes or flat surfaces used as a support for the Au(Ni) catalysts allow for the fabrication of efficient catalysts for the oxidation of BH4− ions [58]. In addition, the developed AuNi-TiO2ntb catalyst exhibited not only significantly higher borohydride oxidation currents, but also a significantly lower peak potential when compared to a flat surface, indicating higher BOR activity. Meanwhile, hardly visible borohydride oxidation on an unmodified titanium surface was observed. This work is a continuation of our previous studies. Here, we are investigating the optimization of the fabrication of the efficient AuNi-TiO2ntb catalysts for the oxidation of BH4− ions in more detail. TiO2ntb has been synthesized through anodization techniques without any further treatment, followed by the deposition of the AuNi bimetallic layer onto it. A series of AuNi bimetallic layers with various contents of Au and Ni have been deposited on the TiO2ntb via electroless Ni plating and galvanic displacement techniques [60,61,62,63,64,65]. The catalytic performance of the AuNi-TiO2ntb catalysts fabricated under various conditions was investigated for BH4− ion oxidation in an alkaline medium using cyclic voltammetry (CV) and chronoamperometry (CA) and compared with those for the bare Au electrode. The fabricated catalysts were also employed as the anode catalyst in the direct borohydride−hydrogen peroxide (NaBH4-H2O2) fuel cell.

2. Materials and Methods

2.1. Chemicals

Analytical grade chemicals were used: Ti foil of 99.7% purity and 0.127 mm thick, NH4F (98%), NaBH4 (96%), HAuCl4 (99.9% Au) (all from Sigma-Aldrich Supply, Taufkirchen, Germany), HCl (37%), H2SO4 (96%), NaOH (98.8%) (all from Chempur Company, Karlsruhe, Germany), NiSO4 (99%), NH2CH2COOH (glycine) (99%), NaH2PO2 (sodium hyphophosphite) (97%), and CH2(COONa)2 (disodium malonate) (98%) (all from Alfa Aesar, Kandel, Germany). Nafion®N117 membrane was purchased from DuPont (Wilmington, DE, USA).

2.2. Fabrication of Catalysts

A three-step process was used for the preparation of AuNi-TiO2ntb catalysts: (i) anodization of titanium sheets according to the procedure described in [58,66]; (ii) electroless Ni deposition on the prepared TiO2ntb, and (iii) the deposition of Au crystallites on the Ni-TiO2ntb electrode by means of partial galvanic displacement of the electroless Ni coating with Au. Before anodization, the Ti sheets were degreased with ethanol, rinsed with deionized water, and dried in an Ar stream. After rinsing with deionized water, the sheets with TiO2 nanotube arrays were dried. Electroless plating of Ni adlayers on the TiO2ntb electrode was performed according to the following procedures: (a) activation of the TiO2ntb electrode in the 1.17 mM PdCl2 solution for 60 s; (b) subsequent rinsing of the treated surface with deionized water; (c) dipping of the activated TiO2ntb electrode into the Ni plating solution for various periods. Conditions of the catalyst preparation are given in Table 1.

Table 1.

Conditions of Ni-TiO2ntb and AuNi-TiO2ntb catalysts fabrication.

For the deposition of Au crystallites, the prepared Ni-TiO2ntb electrodes were immersed in the Au-containing solution for various periods following the rinsing of the treated surface with deionized water (Table 1).

2.3. Physical Characterization

The surface morphology and composition of the samples were examined using a scanning electron microscope EVO-50 (Carl Zeiss SMT, Oberkochen, Germany) and a SEM/FIB workstation Helios Nanolab 650 (FEI, Eindhoven, The Netherlands) with an energy dispersive X-ray (EDX) spectrometer INCA Energy 350 X-Max 20 (Oxford Instruments, High Wycombe, UK). STRATAGEM software (version 6.7) and EDX K-ratios for Ni, P, Ti, and O K alpha lines and Au L alpha lines were used for the estimation of Au metal loading.

XPS analysis was carried out using an “ESCALAB MKII“ spectrometer (VG Scientific, Southeast, UK) using X-radiation of Al Kα (1486.6 eV, pass energy of 20 eV). The samples were etched in the preparation chamber by ionized argon at a vacuum of 5 × 10−4 Pa to obtain depth profiles. An accelerating voltage of ca. 1.0 or 4.0 kV and a beam current of 20 or 100 μA·cm−2, respectively, were used, corresponding to an etching rate of ca. 4 or 20 nm·min−1, respectively.

For the determination of the elemental composition of coatings, the Au4f7/2, Ni2p3/2, Ti2p3/2, P2p, and O1s spectra were recorded. The empirical elemental sensitivity factors were taken from [67], and the spectra obtained were compared with the standard ones [68].

2.4. Electrochemical Measurements

BH4− ion oxidation was investigated using a three-electrode electrochemical cell where the fabricated AuNi-TiO2ntb catalysts (geometric area of 2 cm2) were employed as working electrodes. A Pt sheet was used as a counter electrode and an Ag/AgCl/KCl electrode was used as a reference. The presented current densities were normalized to the geometric area of the catalysts.

All electrochemical measurements were conducted with a Metrohm Autolab potentiostat PGSTAT 100 (Metrohm, Utrecht, The Netherlands). Cyclic voltammograms (CVs) were recorded in a 0.05 M NaBH4 + 1 M NaOH. The electrode potential was scanned from the stationary Es value in the anodic direction up to 0.6 V at a potential scan rate of 10 mV·s−1. The chronoamperometric curves for the AuNi-TiO2ntb catalysts were recorded at a constant potential of −0.3 V for 2 min.

2.5. Fuel Cell Test Experiments

Ni-TiO2ntb and AuNi-TiO2ntb catalysts (geometric area of 2 cm2) were used as the anode material and a Pt sheet as the cathode catalysts in the NaBH4-H2O2 fuel cell. The anolyte composition was 1 M NaBH4 + 4 M NaOH and the catholyte contained 5 M H2O2 + 1.5 M HCl. To prevent H2O2 decomposition and possible loss of BH4− by hydrolysis during storage, the catholyte solution was prepared immediately before the measurements. For separation of the anodic and cathodic compartments of the single direct NaBH4-H2O2 fuel cell, a Nafion®N117 membrane was used. The active area of the membrane was ca. 30 cm2.

Fuel cell test measurements were performed using a PAR 273A potentiostat (Princeton Applied Research, Inc., Oak Ridge, TN, USA) with the associated PowerSTEP software package (version 2.41). A saturated calomel electrode (SCE) was used as a reference electrode (Metrohm 6.0701.100, Hanna Instruments Ltd., Bedfordshire, UK). The cell polarization curves were recorded at temperatures between 25 and 55 °C.

3. Results and Discussion

3.1. Morphology of Catalysts

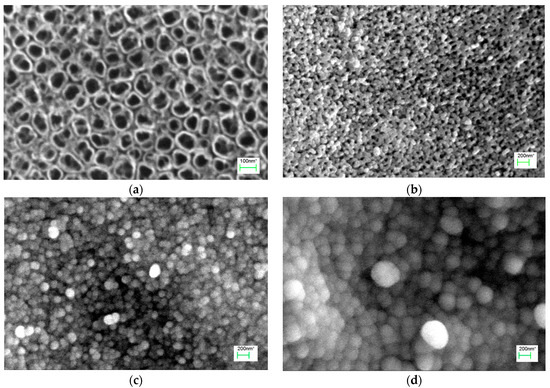

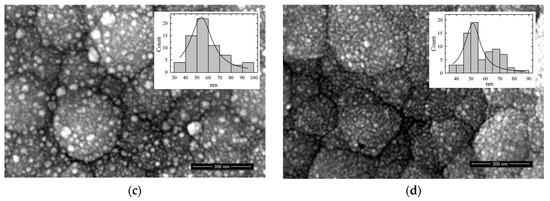

The self-ordered TiO2ntbs (Figure 1a) were obtained using the anodic oxidation of the Ti surface in an aqueous H2SO4 solution containing some NH4F. The average tube diameter was about 100 nm and the thickness of the titania layers was ~350 nm. The Ni adlayers of different thicknesses were deposited on the TiO2ntb surface. The typical images are presented in Figure 1b–d, from which it is evident that just after 5 s of deposition, the TiO2ntb surface is not completely covered by Ni layers, while just after 20 s and 60 s of deposition, the TiO2ntb surface is covered by Ni layers. As also seen from Figure 1c,d, the granular morphology is characteristic of a number of deposits.

Figure 1.

The surface morphology of: (a) TiO2ntb, (b–d) Ni-TiO2ntbs fabricated by the dipping of the TiO2ntb in the Ni plating solution operated at 85 °C for (b) 5, (c) 20, and (d) 60 s.

It was found that the size of Ni granules depends on the time of deposition; approximately 50–100 nm in size Ni granules were formed within 20 s, while the increase in the immersion time to 60 s results in the formation of Ni species that are twice as large. The thickness of the deposited Ni sublayers on the TiO2ntb surface was ca. 10, 100, and 400 nm after their immersion in the Ni plating solution for 5, 20, and 60 s, respectively.

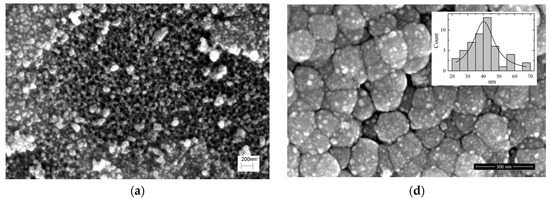

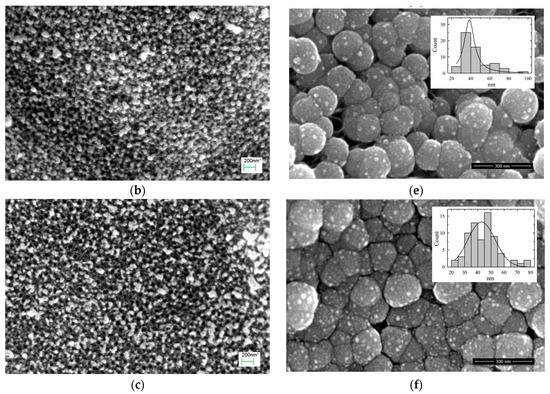

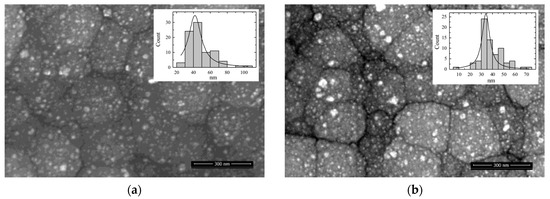

As evident from the SEM images presented in Figure 2, the dipping of Ni-TiO2ntb electrodes into the Au-containing solution results in the deposition of numerous Au crystallites on the Ni surface, while the size and distribution of Au crystallites depends on the thickness of the deposited Ni sublayer on the TiO2ntb and the dipping time in the Au-containing solution. After immersion of the TiO2ntb surface completely covered by the Ni layer in the Au-containing solution for 10–60 s and 10–300 s, the Au crystallites with the average size of ca. 40 and 50 nm, respectively, were deposited onto the latter surface (the insets in Figure 2d–f and Figure 3). They were quite uniform in size and well-separated. While the separate islands of larger Au crystallites were deposited after immersion of the TiO2ntb surface partly covered by the Ni layer (Figure 1b) in the Au plating solution for 60, 300, and 1800 s, respectively (Figure 2a–c).

Figure 2.

The surface morphology of: (a–c) AuNi-TiO2ntbs were fabricated by the dipping of TiO2ntb in the Ni plating solution operated at 85 °C for 5 s, followed by their dipping in Au-containing solution at 25 °C for (a) 60, (b) 300, and (c) 1800 s. (d–f) AuNi-TiO2ntb catalysts were fabricated by the dipping of TiO2ntb in the Ni plating solution operated at 85 °C for 20 s, followed by their dipping in the same Au plating solution at 25 °C for (d) 10, (e) 20, and (f) 60 s. The insets in (d–f) present the Au nanoparticle distribution.

Figure 3.

The surface morphology of: AuNi-TiO2ntb fabricated by the dipping of TiO2ntb in the Ni plating solution operated at 85 °C for 60 s, followed by their dipping in the Au plating solution at 25 °C for (a) 10, (b) 20, (c) 60, and (d) 300 s. The insets present the histograms of Au nanoparticle distribution.

Energy-dispersive X-ray analysis was used to get information on the bulk composition of the prepared catalysts. It confirms the presence of Au, Ni, P, Ti, and O in the catalysts. The obtained data from EDX analysis are presented in Table 2. The dipping time of TiO2ntb in the Ni plating solution significantly influences the composition of the deposited Ni coating. Extending the modification time of TiO2ntb with Ni allows the rise of the Ni content in the coating and, consequently, the incorporation of more P into the deposit (Table 2). The increase in the modification time has a similar effect on the deposited Au content. In contrast, the content of both titanium and oxygen decreases with increasing modification time. When the immersion time of TiO2ntb in a Ni plating solution was 60 s, the content of Ni in the coating remained almost unchanged, regardless of the Au deposition time. Moreover, the best performance of the catalyst for BH4− ion oxidation was determined for AuNi-TiO2ntb catalysts containing relatively low Au loadings of 1.74 to 4.86 μgAu·cm−2 with the developed Ni layer on the titanium surface in the range of 10 to 400 nm in size. This points to the fact that one of the main reasons for the improved BH4− ion oxidation could be attributed to the Au-Ni synergistic effect [69].

Table 2.

The surface composition of the AuNi-TiO2ntb catalysts determined by EDX analysis. The catalysts were prepared by dipping TiO2 ntb in the Ni plating solution at 85 °C for X s, followed by immersion in the Au plating solution at 25 °C for Y s.

On the other hand, atomic and electronic structures have been proved to be efficient methods to optimize the catalytic performance of materials. Atomic defect engineering, especially vacancy defect introduction, has been considered as an efficient approach to regulating catalysts’ atomic and electronic structures. The defective structure could enhance the activities of the oxidation of catalysts due to the exposure of a significant number of active sites [70]. To get some information on the chemical composition of the near-surface region of the sample (i.e., the elements present in the few nm of the sample) and to determine the oxidation state of each element, XPS analysis was also performed. The summarized data for the Ni-TiO2ntb and AuNi-TiO2ntb electrodes are given in Table 3 and Table 4, respectively.

Table 3.

The surface composition of the Ni-TiO2ntb catalysts was determined by XPS analysis. The Ni-TiO2ntb electrodes were prepared by dipping TiO2ntb electrodes in the Ni plating bath at 85 °C for (a) 20 and (b) 60 s.

Table 4.

The surface composition of AuNi-TiO2ntb catalysts determined by XPS analysis. The AuNi-TiO2ntb (a) electrode was fabricated by dipping TiO2ntb in the Ni plating bath at 85 °C for 20 s, followed by dipping the prepared Ni-TiO2ntb electrode in an Au plating solution for 60 s. (b) and (c) electrodes were fabricated by dipping TiO2ntb in the Ni plating bath at 85 °C for 60 s, followed by dipping the prepared Ni-TiO2ntb electrodes in an Au plating solution for (b) 60 and (c) 300 s.

In most cases, initially (without sputtering), two peak binding energies of the Ni2p3/2 electrons appeared for the AuNi-TiO2ntb electrode (Table 4). One occurs at 852.3 ± 0.1 eV due to the presence of metallic Ni [67,68] and the other occurs at 855.6 ± 0.1 eV, attributed to the Ni-oxygenated compounds. The content of NiOx was found to be dependent on the Ni layer depth. Both for 20 and 60 s deposits, the surface of the Ni layer contained approximately 9 at.% NiOx. Sputter etching of all studied samples shows that the deeper Ni layers yielded only one peak binding energy of 852.4 eV, indicating that metallic Ni dominates.

The O1s spectrum (in the absence of sputtering) shows a single binding energy peak at 531.0 ± 0.3 eV for the AuNi-TiO2ntb electrode fabricated by dipping TiO2ntb in the Ni plating bath at 85 °C for 20 s, followed by dipping the prepared Ni-TiO2ntb electrode in a Au plating solution for 60 s. Another AuNi-TiO2ntb electrode was obtained by dipping TiO2ntb in the Ni plating bath at 85 °C for 60 s, followed by dipping the prepared Ni-TiO2ntb electrode in a Au plating solution for 300 s (Table 4). Two peak binding energies are determined in O1s spectra at 532.6 eV and 530.8 for the AuNi-TiO2ntb electrode, fabricated by dipping TiO2ntb in the Ni plating bath at 85 °C for 60 s, followed by dipping the prepared Ni-TiO2ntb electrode in a Au plating solution for 60 s (Table 4). The lower binding energy of O1s at 530.8 eV is characteristic of the surface lattice oxygen in Ni-O. Meanwhile, higher binding energies at 531.0 ± 0.3 eV are attributed to the oxygen vacancies or defects existing on the surface [71,72]. These oxygen vacancies have been shown to increase the electronic conductivity of the electrode and promote the catalytic efficiency [72]. The presence of oxygen vacancies on the surface of the AuNi-TiO2ntb electrode may be a factor contributing to its efficiency and one more reason for the improved oxidation of BH4− ions. However, given that the Ni content is almost the same in all the samples tested, the synergistic effect of Au-Ni may be the main reason for the better oxidation of BH4− ions. Moreover, it is necessary to point out some features inherent to XP spectra interpretation. The main trouble is that we cannot exclude the oxidation by air during sample transfer and therefore, the XP spectra can be influenced at least partially by oxygen. Therefore, it is hardly possible to propose an unambiguous treatment of the results obtained in the case when Ar+ sputtering was not applied.

The determined binding energy of Ti2p3/2 spectra at 459.2 eV for AuNi-TiO2ntb electrodes fabricated by dipping TiO2ntb in the Ni plating bath at 85 °C for 20 s, followed by dipping the prepared Ni-TiO2ntb electrode in a Au plating solution for 60 s indicates that the titanium surface has the features associated with valence states of Ti4+ that exist in the coating. To avoid the influence of surface oxide impurities on the XPS result, the XPS measurement performed at a 4 nm depth from the sample surface is more reliable. They point to the fact that the Ti2p3/2 spectra can be deconvoluted by assuming the contribution of Ti°, Ti2+, Ti3+, and Ti4+, as shown in Table 4, indicating the features are related to several valence states of Ti [73]. The binding energy of titanium at around 453~454 eV is attributed to the metallic state of Ti; whereas, binding energies for Ti2+ at ~455.3 eV and Ti3+ at ~457.8 eV may be ascribed to the TiO and titanium suboxide, respectively. The binding energies near 458.7–459.2 eV may be attributed to Ti4+ as TiO2 [73].

Only the peak binding energy of the Au4f7/2 electron (Eb = 83.6 eV), assigned to metallic gold [67,68], was detected in the XPS spectra for the investigated AuNi-TiO2ntbs (not shown here). From these spectra, the depth profiles of the Au contents were studied, varying both the thickness of the Ni layer and dipping time in the Au plating solution. The results obtained are presented in Table 4. From these results, the following conclusion can be drawn: an increase in the thickness (deposition time) of the Ni layer has a significant role in the depth of Au when dipping time in the Au plating bath was 60 s. In this case, the thickness of Au was approximated at ~44 nm.

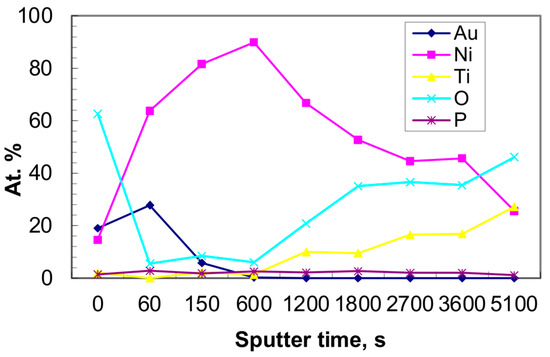

Sputter-etch AES profiles were obtained on various deposit locations. Figure 4 depicts the thickness distribution of Au, Ni, and Ti, obtained by sputter etching of a ~44 nm diameter indicative location, from the surface down to the substrate. The Au:Ni atomic ratio of the first few surface layers detected by AES (before sputtering) is ca. 1:2. The depth profiles prove that Au exists in the interior of the layer together with Ni. According to the sputter-etch AES profile shown in Figure 4, the TiO2ntb substrate is reached after ca. 20 min of sputtering. The amount of ca. 0.37 and 0.87 at.% of Au were detected in the AuNi film layer depth of ca. 44 nm.

Figure 4.

Auger sputter-etch depth profiles of elements at a AuNi layer on a TiO2ntb surface. The TiO2ntb electrode was immersed in the Ni plating bath at 85 °C for 20 s, followed by dipping of the prepared Ni-TiO2ntb electrode in an Au plating solution for 60 s.

3.2. Investigation of the Oxidation of BH4− Ions

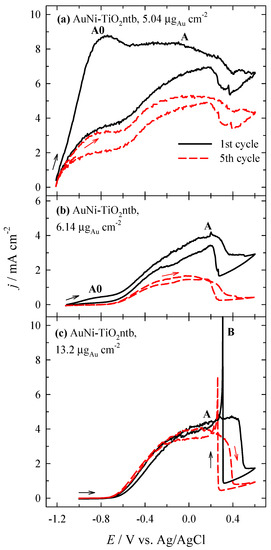

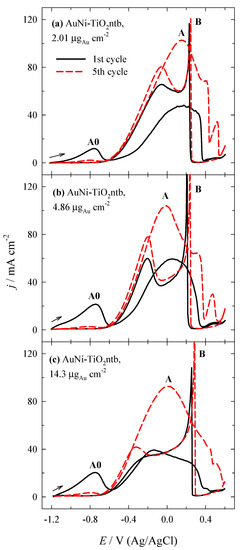

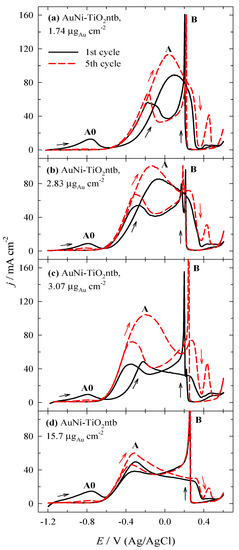

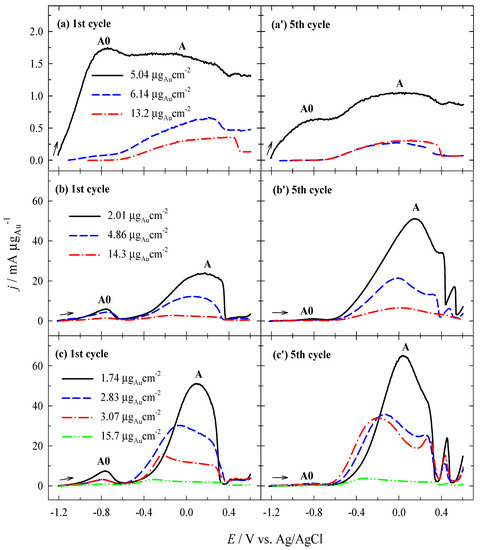

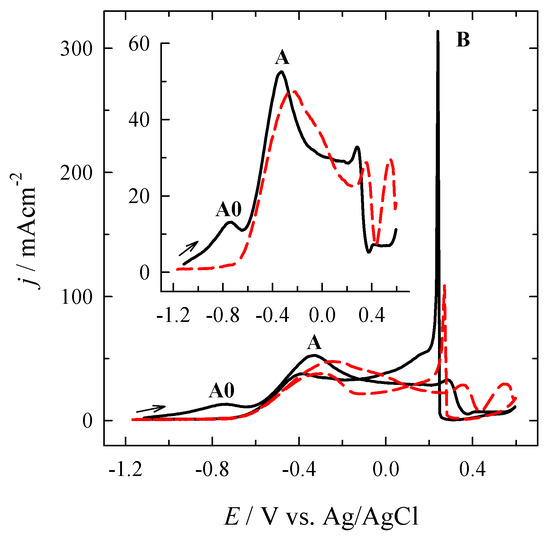

The catalytic activity of the AuNi-TiO2ntb catalysts fabricated under different conditions was studied towards the BH4− ion oxidation in the alkaline media by CV (Figure 5, Figure 6 and Figure 7). All the catalysts show the electrocatalytic activity towards the oxidation of BH4− ions. Obviously, two peaks: peak A0 at more negative potential values and another peak A at more positive potential values, are seen in the tested potential window on all the catalysts. Those peaks correspond to the oxidation of H2, generated from NaBH4 hydrolysis and direct BH4− ion oxidation, as described in the literature [9,17,19]. Figure 5 shows the CVs for the AuNi-TiO2ntb catalysts prepared with a thinner Ni layer and the Au loading of 5.04 (Figure 5a), 6.14 (Figure 5b), and 13.2 (Figure 5c) μgAu·cm−2. The current densities for BH4− ions on those catalysts decreased with long-term cycling, whereas, in contrast, the current densities increased on the catalysts with the thicker Ni layers (Figure 6 and Figure 7). The catalysts created on the thicker Ni layer of about 100 and 400 nm deposited onto the TiO2ntb surface, with the Au loadings in the range of 1.74 to 15.7 μgAu·cm−2 (Figure 6 and Figure 7) showing current densities for BH4− ion oxidation about 10–20 times higher compared to the catalysts prepared with the thinner Ni layer, indicating the increased activity and stability of catalysts (Figure 6 and Figure 7). Notably, the electrocatalytic activity improved remarkably as the thicker Ni layer was used for the deposition of Au crystallites. The enhanced activity of those catalysts may be related with the synergistic effect of Au crystallites with Ni [69]. Atomic ratios Au:Ni varied from 1:28 to 1:350 and from 1:33 to 1:618 for AuNi-TiO2ntb catalysts with the Au loadings in the range of 2.01 to 14.30 μgAu·cm−2 and 1.74 to 15.7 μgAu·cm−2, respectively (Table 2). A very small amount of Au crystallites associated to Ni induces increased BH4− ion oxidation.

Figure 5.

CVs were recorded on the different AuNi-TiO2ntb catalysts in a 0.05 M NaBH4 + 1 M NaOH solution at 25 °C at 10 mV·s−1. AuNi-TiO2ntbs were fabricated by the dipping of TiO2ntb in the Ni plating solution operated at 85 °C for 5 s, followed by their dipping in the Au plating solution for time (s): (a) 60, (b) 300, and (c) 1800.

Figure 6.

CVs were recorded on the different AuNi-TiO2ntb catalysts in a 0.05 M NaBH4 + 1 M NaOH solution at 25 °C at 10 mV·s−1. AuNi-TiO2ntbs were fabricated by the dipping of TiO2ntb in the Ni plating solution operated at 85 °C for 20 s, followed by their dipping in the Au plating solution for time (s): (a) 10, (b) 20, and (c) 60.

Figure 7.

CVs were recorded on the different AuNi-TiO2ntb catalysts in a 0.05 M NaBH4 + 1 M NaOH solution at 25 °C at 10 mV·s−1. AuNi-TiO2ntbs were fabricated by the dipping of TiO2ntb in the Ni plating solution operated at 85 °C for 60 s, followed by their dipping in the Au plating solution for time (s): (a) 10, (b) 20, (c) 60, and (d) 300.

The activity of the prepared catalysts for BH4− ion oxidation was also determined in terms of the mass of deposited Au. Considering the mass activity of the catalysts, the normalized current density values by the Au loadings for each catalyst are shown in Figure 8.

It is seen that when the Au loadings are increased on the surface of the created catalysts, BH4− ion oxidation (peak current density A) is decreased. The catalysts produced with lower Au loadings show greater electrocatalytic activity for the oxidation of BH4− ions (Figure 8b,c). The currents are about 13 and 33 times higher on the AuNi-TiO2ntb catalysts, which have the Au loading of 2.01 and 1.74 μgAu·cm−2 (Figure 8b,c), respectively, compared with those containing the Au loading of 5.04 μgAu·cm−2 (Figure 8a). Notably, atomic ratios Au:Ni for those catalysts with a Au loading of 2.01, 1.74, and 5.04 µg·cm−2 are 1:350, 1:618, and 1:3.6, respectively (Table 2). A significantly higher atomic ratio Au:Ni induces more pronounced activity of those catalysts for BH4− ion oxidation due to the synergetic effect of the Au crystallites and Ni.

3.3. Stability of Catalysts

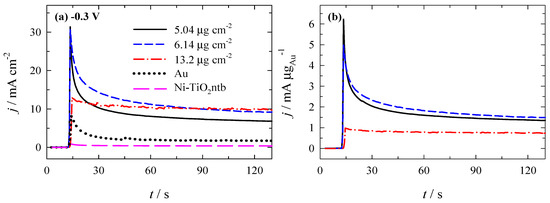

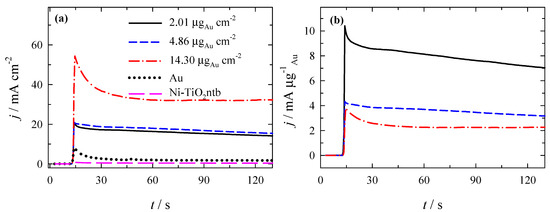

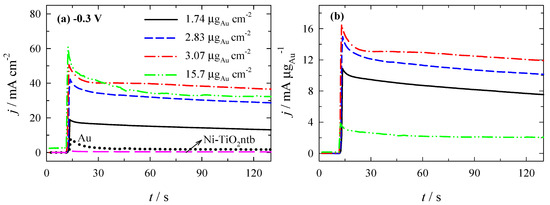

The stability of prepared catalysts was observed from chronoamperometric measurements and compared to bulk Au and Ni-TiO2ntb (Figure 9, Figure 10 and Figure 11). The AuNi-TiO2ntb catalysts in all cases show a slight current decay for BH4− ion oxidation. At the end of the experimental period (t = 130 s), the current densities of all the AuNi-TiO2ntb catalysts are higher than that of Au and Ni-TiO2ntb, indicating their superior stability and significantly higher catalytic activity for BH4− ion oxidation.

Figure 9.

(a) Chronoamperometry curves for the Au (dotted line), Ni-TiO2ntb (long dash line), and AuNi-TiO2ntb catalysts were recorded in a 0.05 M NaBH4 + 1 M NaOH solution at 25 °C. AuNi-TiO2ntbs were prepared by dipping TiO2ntb in the Ni plating solution operated at 85 °C for 5 s, followed by their dipping in the Au plating solution for time (s): 60 (solid line), 300 (dashed line), and 1800 (dash−dot-dashed line). The potential was held at E = 0 for 10 s, then set to −0.3 V for 2 min. (b) Chronoamperometry curves were normalized by the Au loadings for each AuNi-TiO2ntb catalyst.

Figure 10.

(a) Chronoamperometry curves of the Au (dotted line), Ni-TiO2ntb (long dash line), and AuNi-TiO2ntb catalysts were recorded in a 0.05 M NaBH4 + 1 M NaOH solution at 25 °C. AuNi-TiO2ntbs were prepared by dipping TiO2ntb in the Ni plating solution operated at 85 °C for 20 s, followed by their dipping in the Au plating solution for time (s): 10 (solid line), 20 (dashed line), and 60 (dash−dot-dashed line). The potential was held at E = 0 for 10 s, then set to −0.3 V for 2 min. (b) Chronoamperometry curves were normalized by the Au loadings for each AuNi-TiO2ntb catalyst.

Figure 11.

(a) Chronoamperometry curves of the AuNi-TiO2ntb catalysts in a 0.05 M NaBH4 + 1 M NaOH solution at 25 °C. AuNi-TiO2ntbs were prepared by the dipping of TiO2ntb in the Ni plating solution operated at 85 °C for 60 s, followed by their dipping in the Au plating solution for time (s): 10 (solid line), 20 (dashed line), 60 (dash-dotted line), and 300 (dash−dot-dotted line). The potential was held at E = 0 for 10 s, then set to −0.3 V for 2 min. (b) Chronoamperometry curves were normalized by the Au loadings for each AuNi-TiO2ntb catalyst.

The electrocatalytic stability of the AuNi-TiO2ntb catalyst was examined herein by numerous cycling in a 0.05 M NaBH4 + 1.0 M NaOH solution between −1.1 and 0.6 V at 10 mV·s−1. Figure 12 shows CVs after long-term potential cycling (after 6 h) for the AuNi-TiO2ntb catalyst that has the Au loading of 15.7 μgAu·cm−2. After the six-hour continuous cycling, the value of anodic peak A related to BH4− ion oxidation was slightly lowered and slightly shifted toward positive values. Thus, long cycling results in the disappearance of the first anodic peak A0. Hence, it may be suggested that the fabricated electrode is electrocatalytically active and stable after long-term cycling.

Figure 12.

The CVs were recorded on the AuNi-TiO2ntb catalyst (15.7 μgAu·cm−2) in a 0.05 M NaBH4 + 1 M NaOH solution at 25 °C at 10 mV·s−1. First cycle (solid line) and the one after six hours of subsequent cycling (dashed line).

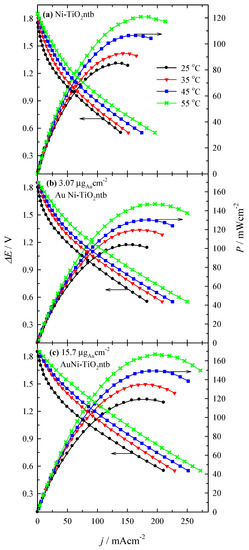

3.4. Fuel Cell Test

Direct alkaline NaBH4-H2O2 single fuel cell tests were carried out by employing the prepared Ni/TiO2ntb and AuNi-TiO2ntb catalysts, which have the Au loadings of 3.07 and 15.7 μgAu·cm−2 as the anode catalyst at temperatures from 25 to 55 °C. Figure 13 shows the obtained fuel cell polarization curves and the corresponding power densities against the current density.

Figure 13.

Cell polarization ąnd power density curves for the NaBH4-H2O2 fuel cell using Ni-TiO2ntb and AuNi-TiO2ntb as anode catalysts at different temperatures. Anolyte consisted of 1 M NaBH4 + 4 M NaOH and catholyte consisted of 5 M H2O2 + 1.5 M HCl.

Notably, in all cases, peak power density values increase with the increase in NaBH4-H2O2 fuel cell temperature. During the cell discharge process, small bubbles of hydrogen and oxygen were observed at the surface of the electrodes due to the chemical decomposition of BH4− and H2O2 at the anode and cathode, respectively. The fuel cell displayed an open circuit voltage of ca. 1.9 V using the investigated catalysts. The summary of the main electrochemical parameters for the NaBH4-H2O2 fuel cell is given in Table 5.

Table 5.

Summary of the main cell electrochemical parameters for NaBH4-H2O2 fuel cell using Ni-TiO2ntb and AuNi-TiO2ntb anode catalysts obtained at different temperatures.

The Ni-TiO2ntb catalyst generates the peak power density values of ca. 85–121 mW cm−2 at the temperatures of 25–55 °C, whereas the AuNi-TiO2ntb catalysts that have the Au loading of 3.07 and 15.7 μgAu·cm−2 achieve the greater peak power density values of ca. 104–147 and 119–170 mW·cm−2, respectively, at the temperatures of 25–55 °C. Considering the Au loading used in the fuel cell test, the specific peak power density of 33.8–47.9 and 7.6–10.6 mW·μgAu−1 at 25–55 °C are obtained using the AuNi-TiO2ntb catalyst that has the Au loading of 3.07 and 15.7 μgAu·cm−2, respectively.

4. Conclusions

A series of efficient AuNi-TiO2ntb catalysts, which have small amounts of Au in the range from 1.74 to 15.7 μgAu·cm−2, have been prepared using low-cost and straightforward techniques, such as electrochemical anodization, electroless metal plating, and galvanic displacement. It was found that the electrocatalytic activity of AuNi-TiO2ntb catalysts remarkably improved after the thicker Ni layer was used for the deposition of Au crystallites. The catalysts created on the thicker Ni layer of about 100 and 400 nm deposited on the TiO2ntb surface, with the Au loadings in the range of 1.74 to 15.7 μgAu·cm−2 showing current densities towards BH4− ion oxidation about 10–20 times higher compared to the catalysts prepared with the thinner Ni layer. The greatest electrocatalytic performance for BH4− ion oxidation was observed with the AuNi-TiO2ntb catalysts prepared such with the Au loadings of 1.74 to 4.86 μgAu·cm−2.

The performance of a NaBH4-H2O2 fuel cell with Ni-TiO2ntb and AuNi-TiO2ntb anode catalysts has been investigated at different temperatures. The anode fuel is 1 M NaBH4 + 4 M NaOH and the cathode fuel is 5 M H2O2 + 1.5 M HCl. The highest peak power density of 166.9 mW·cm−2 has been obtained at a temperature of 55 °C using the AuNi-TiO2ntb anode catalyst that has the Au loading of 15.7 μgAu·cm−2, whereas a specific peak power density of 47.9 mW·μgAu−1 attained the AuNi-TiO2ntb catalyst with lower a Au loading of 3.07 μgAu·cm−2. Considering the low Au loadings, the prepared AuNi-TiO2ntb catalysts are promising materials and can be used for the development of direct NaBH4-H2O2 fuel cells.

Author Contributions

This study was conducted through the contributions of all authors. Conceptualization, L.T.-T., A.B. and E.N.; methodology, A.S., A.Z. and Z.S.; formal analysis, A.B., D.Š. and V.K.; investigation, A.B., Z.S. and A.Z.; data curation, A.B., L.T.-T. and D.Š.; writing—original draft preparation, L.T.-T., Z.S. and V.K.; writing—review and editing, E.N.; visualization, V.K. and L.T.-T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by a grant (No. ATE-03/2010) from the Research Council of Lithuania (LMTLT).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to thank Aloyzas Sudavičius for their help with XPS measurements.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Oshchepkov, A.; Bonnefont, A.; Maranzana, G.; Savinova, E.R.; Chatenet, M. Direct borohydride fuel cells: A selected review of their reaction mechanisms, electrocatalysts, and influence of operating parameters on their performance. Curr. Opin. Electrochem. 2022, 32, 100883–100895. [Google Scholar] [CrossRef]

- Hu, B.; Xu, C.; Chen, P.; Yu, J.; Hu, B.; Xiang, Q.; Cen, Y.; Liu, Y.; Yu, D.; Chen, C. Efficient nickel catalyst with preferred orientation and microsphere for direct borohydride fuel cell. Int. J. Hydrog. Energy 2021, 46, 27516–27528. [Google Scholar] [CrossRef]

- Oh, T.H. Effect of cathode conditions on performance of direct borohydride–hydrogen peroxide fuel cell system for space exploration. Renew. Energy 2021, 178, 1156–1164. [Google Scholar] [CrossRef]

- Yin, X.; Wang, Q.; Duan, D.; Liu, S.; Wang, Y. Amorphous NiB alloy decorated by Cu as the anode catalyst for a direct borohydride fuel cell. Int. J. Hydrog. Energy 2019, 44, 10971–10981. [Google Scholar] [CrossRef]

- Olu, P.-Y.; Job, N.; Chatenet, M. Evaluation of anode (electro) catalytic materials for the direct borohydride fuel cell: Methods and benchmarks. J. Power Sources 2016, 327, 235–257. [Google Scholar] [CrossRef]

- Celik, C.; Boyaci, S.F.G.; Sarac, H.I. Influences of sodium borohydride concentration on direct borohydride fuel cell performance. J. Power Sources 2010, 195, 2599–2603. [Google Scholar] [CrossRef]

- Santos, D.M.F.; Sequeira, C.A.C. Sodium borohydride as a fuel for the future. Renew. Sustain. Energ. Rev. 2011, 15, 3980–4001. [Google Scholar] [CrossRef]

- Kadioglu, T.; Turkmen, A.C.; Ata, K.C.; Akay, R.G.; Tikiz, I.; Celik, C. Investigation of the performance of a direct borohydride fuel cell with low Pt/C catalyst loading under different operating conditions. Int. J. Hydrog. Energy 2020, 45, 35006–35012. [Google Scholar] [CrossRef]

- Olu, P.Y.; Bonnefont, A.; Braesch, G.; Martin, V.; Savinova, E.R.; Chatenet, M. Influence of the concentration of borohydride towards hydrogen production and escape for borohydride oxidation reaction on Pt and Au electrodes—Experimental and modelling insights. J. Power Sources 2018, 375, 300–309. [Google Scholar] [CrossRef]

- Braesch, G.; Bonnefont, A.; Martin, V.; Savinova, E.R.; Chatenet, M. Borohydride oxidation reaction mechanisms and poisoning effects on Au, Pt and Pd bulk electrodes: From model (low) to direct borohydride fuel cell operating (high) concentrations. Electrochim. Acta 2018, 273, 483–494. [Google Scholar] [CrossRef]

- Backović, G.; Milikić, J.; De Negri, S.; Saccone, A.; Šljukić, B.; Santos, D.M.F. Enhanced borohydride oxidation kinetics at gold-rare earth alloys. J. Alloys Compd. 2021, 857, 158273–158282. [Google Scholar] [CrossRef]

- Sukackienė, Z.; Balčiūnaitė, A.; Tamašauskaitė-Tamašiūnaitė, L.; Pakštas, V.; Selskis, A.; Norkus, E. Development of new nanostructured Au/Co/Cu and Au/CoB/Cu catalysts and studies of their catalytic activity. J. Electrochem. Soc. 2015, 162, 734–745. [Google Scholar] [CrossRef]

- Sukackienė, Z.; Balčiūnaitė, A.; Tamašauskaitė-Tamašiūnaitė, L.; Selskis, A.; Jasulaitienė, V.; Norkus, E. Investigation of sodium borohydride oxidation on CoB/Cu and CoBW/Cu modified with Au nanoparticles. Chemija 2015, 26, 141–147. [Google Scholar]

- Jusys, Z.; Behm, R.J. Borohydride electrooxidation over Pt/C, AuPt/C and Au/C catalysts: Partial reaction pathways and mixed potential formation. Electrochem. Commun. 2015, 60, 9–12. [Google Scholar] [CrossRef]

- Olu, P.-Y.; Bonnefont, A.; Chatenet, M. Borohydride oxidation reaction (BOR) at Pt and Au electrodes: From experimental insights to mechanism and kinetic modeling. Encycl. Interfac. Chem. 2018, 384–392. [Google Scholar] [CrossRef]

- Iotov, P.I.; Kalcheva, S.V.; Kanazirski, I.A. On the enhanced electrocatalytic performance of PtAu alloys in borohydride oxidation. Electrochim. Acta 2013, 108, 540–546. [Google Scholar] [CrossRef]

- Amendola, S.C.; Onnerud, P.; Kelly, M.T.; Petillo, P.J.; Sharp-Goldman, S.L.; Binder, M. A novel high power density borohydride-air cell. J. Power Sources 1999, 84, 130–133. [Google Scholar] [CrossRef]

- Chatenet, M.; Micoud, F.; Roche, I.; Chainet, E. Kinetics of sodium borohydride direct oxidation and oxygen reduction in sodium hydroxide electrolyte. Part I. BH4− electrooxidation on Au and Ag catalysts. Electrochim. Acta 2006, 51, 5459–5467. [Google Scholar] [CrossRef]

- Ojani, R.; Valiollahi, R.; Raoof, J.-B. Au hollow nanospheres on graphene support as catalyst for sodium borohydride electrooxidation. Appl. Surf. Sci. 2014, 311, 245–251. [Google Scholar] [CrossRef]

- Atwan, M.H.; Macdonald, C.L.B.; Northwood, D.O.; Gyenge, E.L. Colloidal Au and Au-alloy catalysts for direct borohydride fuel cells: Electrocatalysis and fuel cell performance. J. Power Sources 2006, 158, 36–44. [Google Scholar] [CrossRef]

- Martins, M.; Sljuki, B.; Metin, O.; Sevim, M.; Sequeira, C.A.C.; Sener, T.; Santos, D.M.F. Bimetallic PdM (M = Fe, Ag, Au) alloy nanoparticles assembled on reduced graphene oxide as catalysts for direct borohydride fuel cells. J. Alloys Compd. 2017, 718, 204–214. [Google Scholar] [CrossRef]

- Wang, B.; Wang, G.; Cao, D.; Ye, K.; Cheng, K.; Zhu, K.; Liu, Y.; Zhang, D. A flexible and highly effective paper based gold electrode for sodium borohydride electrocatalysis. Int. J. Hydrog. Energy 2017, 42, 22814–22820. [Google Scholar] [CrossRef]

- Song, C.; Li, B.; Cheng, K.; Ye, K.; Zhu, K.; Cao, D.; Wang, G. Synthesis and investigation of a high-activity catalyst: Au nanoparticles modified metalic Ti microrods for NaBH4 electrooxidation. Int. J. Hydrog. Energy 2018, 43, 3688–3696. [Google Scholar] [CrossRef]

- Caglar, A.; Cogenli, M.S.; Yurtcan, A.B.; Kivrak, H. Effective carbon nanotube supported metal (M = Au, Ag, Co, Mn, Ni, V, Zn) core Pd shell bimetallic anode catalysts for formic acid fuel cells. Renew. Energy 2020, 150, 78–90. [Google Scholar] [CrossRef]

- Castanheira, L.; Dubau, L.; Mermoux, M.; Berthomé, G.; Caqué, N.; Rossinot, E.; Chatenet, M.; Maillard, F. Carbon corrosion inproton-exchange membrane fuel cells: From model experiments to real-life operation in membrane electrode assemblies. ACS Catal. 2014, 4, 2258–2267. [Google Scholar] [CrossRef]

- Zhao, R.; Chen, Y.; Huang, S. Doping engineering on carbons as electrocatalysts for oxygen reduction reaction. Fundam. Res. 2021, 1, 807–823. [Google Scholar] [CrossRef]

- Quílez-Bermejo, J.; Morallón, E.; Cazorla-Amorós, D. Metal-free heteroatom-doped carbon-based catalysts for ORR: A critical assessment about the role of heteroatoms. Carbon 2020, 165, 434–454. [Google Scholar] [CrossRef]

- Xu, H.; Yang, J.; Ge, R.; Zhang, J.; Li, Y.; Zhu, M.; Dai, L.; Li, S.; Li, W. Carbon-based bifunctional electrocatalysts for oxygen reduction and oxygen evolution reactions: Optimization strategies and mechanistic analysis. J. Energy Chem. 2022, 71, 234–265. [Google Scholar] [CrossRef]

- Shao, M.; Chang, Q.; Dodelet, J.-P.; Chenitz, R. Recent advances in electrocatalysts for oxygen reduction reaction. Chem. Rev. 2016, 116, 3594–3657. [Google Scholar] [CrossRef] [Green Version]

- Goktas, S.; Goktas, A. A comparative study on recent progress in efficient ZnO based nanocomposite and heterojunction photocatalysts: A review. J. Alloys Compd. 2021, 863, 158734. [Google Scholar] [CrossRef]

- Mikailzade, F.; Türkan, H.; Önal, F.; Zarbali, M.; Göktaş, A.; Tumbul, A. Structural and magnetic properties of polycrystalline Zn1−xMnxO films synthesized on glass and p-type Si substrates using sol–gel technique. Appl. Phys. A 2021, 127, 408. [Google Scholar] [CrossRef]

- Santos, F.D.M.; Sequeira, C.A.C. Zinc anode for direct borohydride fuel cells. J. Electrochem. Soc. 2010, 157, B13–B19. [Google Scholar] [CrossRef]

- Tamašauskaitė-Tamašiūnaitė, L.; Lichušina, S.; Balčiūnaitė, A.; Zabielaitė, A.; Šimkūnaitė, D.; Vaičiūnienė, J.; Stalnionienė, I.; Žielienė, A.; Selskis, A.; Norkus, E. Zinc-cobalt alloy deposited on the titanium surface as electrocatalysts for borohydride oxidation. J. Electrochem. Soc. 2015, 162, F348–F353. [Google Scholar] [CrossRef]

- Hu, B.; Chen, P.; Xu, C.; Meng, J.; Cai, J.; Yang, Y.; Zhang, B.; Yu, D.; Zhou, X.; Chen, C. Hierarchical leaf-shaped Ni@Zn bimetallic catalyst with high stability and selectivity for borohydride oxidation. Appl. Catal. B Environ. 2022, 307, 121183. [Google Scholar] [CrossRef]

- Dou, M.; Hou, M.; Liang, D.; Lu, W.; Shao, Z.; Yi, B. SnO2 nanocluster supported Pt catalyst with high stability for proton exchange membrane fuel cells. Electrochim. Acta 2013, 92, 468–473. [Google Scholar] [CrossRef]

- Šljukić, B.; Martins, M.; Kayhan, E.; Balčiūnaitė, A.; Şener, T.; Sequeira, C.A.C.; Santos, D.M.F. SnO2-C supported PdNi nanoparticles for oxygen reduction and borohydride oxidation. J. Electroanal. Chem. 2017, 797, 23–30. [Google Scholar] [CrossRef]

- Ma, J.; Li, J.; Yang, S.; Lu, H.; Liu, L.; Wang, R. Ultrathin veil-like SnO2 supported Co3O4 nanoparticles for direct borohydride fuel cell anode. J. Power Sources 2020, 453, 227866. [Google Scholar] [CrossRef]

- Sandoval, A.; Zanella, R.; Klimova, T.E. Titania nanotubes decorated with anatase nanocrystals as support for active and stable gold catalysts for CO oxidation. Catal. Today 2017, 282, 140–150. [Google Scholar] [CrossRef]

- Shi, Z.; Tan, Q.; Wu, D. Enhanced CO2 hydrogenation to methanol over TiO2 nanotubes-supported CuO-ZnO-CeO2 catalyst. Appl. Catal. A Gen. 2019, 581, 58–66. [Google Scholar] [CrossRef]

- Zhuang, C.; Song, Z.; Yu, Z.; Zhang, C.; Wang, J.; Liu, Y.; Zhao, Q. Photoelectrochemical performance of TiO2 nanotube arrays modified with Ni2P Co-catalyst. Int. J. Hydrog. Energy 2021, 46, 4981–4991. [Google Scholar] [CrossRef]

- Chaturvedi, A.; Kundu, P.P. Synthesis of Co-Fe nanoparticle supported on titanium oxide-nanotubes (TiO2-NTs) as enhanced oxygen reduction reaction electrocatalyst. Mater. Today Proceed. 2021, 45, 5518–5522. [Google Scholar] [CrossRef]

- Mao, H.; Zhang, F.; Du, M.; Dai, L.; Qian, Y.; Pang, H. Review on synthesis of porous TiO2-based catalysts for energy conversion systems. Ceram. Int. 2021, 47, 25177–25200. [Google Scholar] [CrossRef]

- Abdullah, M.; Kamarudin, S.K. Titanium dioxide nanotubes (TNT) in energy and environmental applications: An overview. Renew. Sustain. Energy Rev. 2016, 76, 212–225. [Google Scholar] [CrossRef]

- Kim, J.-H.; Ishihara, A.; Mitsushima, S.; Kamiya, N.; Ota, K.-I. Catalytic activity of titanium oxide for oxygen reduction reaction as a non-platinum catalyst for PEFC. Electrochim. Acta 2007, 52, 2492–2497. [Google Scholar] [CrossRef]

- Lincho, J.; Gomes, J.; Kobylanski, M.; Bajorowicz, B.; Zaleska-Medynska, A.; Martins, R.C. TiO2 nanotube catalysts for parabens mixture degradation by photocatalysis and ozone-based technologies. Process. Saf. Environ. Prot. 2021, 152, 601–613. [Google Scholar] [CrossRef]

- Gomes, J.; Lincho, J.; Mazierski, P.; Miodyńska, M.; Zaleska-Medynska, A.; Martins, R.C. Unexpected effect of ozone on the paraben’s mixture degradation using TiO2 supported nanotubes. Sci. Total Environ. 2020, 743, 140831–140844. [Google Scholar] [CrossRef]

- Mazierski, P.; Nischk, M.; Gołkowska, M.; Lisowski, W.; Gazda, M.; Winiarski, J.M.; Klimczuk, T.; Zaleska-Medynska, A. Photocatalytic activity of nitrogen doped TiO2 nanotubes prepared by anodic oxidation: The effect of applied voltage, anodization time and amount of nitrogen dopant. Appl. Catal. B Environ. 2016, 196, 77–88. [Google Scholar] [CrossRef]

- Kowalski, D.; Kim, D.; Schmuki, P. TiO2 nanotubes, nanochannels and mesosponge: Self-organized formation and applications. Nano Today 2013, 8, 235–264. [Google Scholar] [CrossRef]

- Nischk, M.; Mazierski, P.; Gazda, M.; Zaleska, A. Ordered TiO2 nanotubes: The effect of preparation parameters on the photocatalytic activity in air purification process. Appl. Catal. B Environ. 2014, 144, 674–685. [Google Scholar] [CrossRef]

- Noha, K.-J.; Namb, I.; Hana, J.W. Nb-TiO2 nanotubes as catalyst supports with high activity and durability for oxygen reduction. Appl. Surf. Sci. 2020, 521, 146330–146337. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, Q.; Cao, D.; Zhao, S.; Xu, W.; Li, C.; Wang, Y. CdTe and Ag nanoparticles co-modified TiO2 nanotube arrays for the enhanced wastewater treatment and hydrogen production. J. Environ. Chem. Eng. 2022, 10, 107207–107219. [Google Scholar] [CrossRef]

- Hsieh, B.-J.; Tsai, M.-C.; Pan, C.-J.; Su, W.-N.; Rick, J.; Chou, H.-L.; Lee, J.-F.; Hwang, B.-J. Tuning metal support interactions enhances the activity and durability of TiO2-supported Pt nanocatalysts. Electrochim. Acta 2017, 224, 452–459. [Google Scholar] [CrossRef]

- Mathloom, A.A.L.; Abed, A.A. Titanium dioxide thin film prepared by sol-gel technique. J. Educ. Pure Sci. Univ. Thi-Qar 2019, 9, 241–258. [Google Scholar]

- Xu, Y.; Ahmed, R.; Lin, Q.; Zangari, G. (Photo) electrochemical water oxidation at anodic TiO2 nanotubes modified by electrodeposited NiFe oxy-hydroxides catalysts. Electrochim. Acta 2019, 308, 91–98. [Google Scholar] [CrossRef]

- Puga, M.L.; Venturini, J.; Caten, C.S.; Bergman, C.P. Influencing parameters in the electrochemical anodization of TiO2 nanotubes: Systematic review and meta-analysis. Ceram. Int. 2022, 48, 19513–19526. [Google Scholar] [CrossRef]

- Roy, P.; Berger, S.; Schmuki, P. TiO2 nanotubes: Synthesis and applications. Angew. Chem. Int. Ed. 2011, 50, 2904. [Google Scholar] [CrossRef]

- Ponche-de-Leon, C.; Bavykin, D.V.; Walsh, F.C. The oxidation of borohydride ion at titanate nanotube supported gold electrodes. Electrochem. Commun. 2006, 8, 1655–1660. [Google Scholar] [CrossRef]

- Tamašauskaitė-Tamašiūnaitė, L.; Balčiūnaitė, A.; Šimkūnaitė, D.; Selskis, A. Self-ordered titania nanotubes and flat surfaces as a support for the deposition of nanostructured Au-Ni catalyst: Enhanced electrocatalytic oxidation of borohydride. J. Power Sources 2012, 202, 85–91. [Google Scholar] [CrossRef]

- Balčiūnaitė, A.; Tamašauskaitė-Tamašiūnaitė, L.; Santos, D.M.F.; Zabielaitė, A.; Jagminienė, A.; Stankevičienė, I.; Norkus, E. Au nanoparticles modified Co/titania nanotubes as electrocatalysts for borohydride oxidation. Fuel Cells 2017, 17, 690–697. [Google Scholar] [CrossRef]

- Gouda, M.H.; Gouveia, W.; Elessawy, N.A.; Šljukić, B.; Nassr, A.B.A.A.; Santos, D.M.F. Simple design of PVA-based blend doped with SO4 (PO4)-functionalised TiO2 as an effective membrane for direct borohydride fuel cells. Int. J. Hydrog. Energy 2020, 45, 15226–15238. [Google Scholar] [CrossRef]

- Volochanskyi, O.; Svecov, M.; Bartůněk, V.; Prokopec, V. Electroless deposition via galvanic displacement as a simple way for the preparation of silver, gold, and copper SERS-active substrates. Colloids Surf. A Physicochem. Eng. Asp. 2021, 616, 126310–126317. [Google Scholar] [CrossRef]

- Milazzo, R.G.; Privitera, S.M.S.; Scalese, S.; Mirabella, S.; Bongiorno, C.; Lombardo, S.A.; Rimini, E. New insight into Pt nucleation mechanism on Si surface during galvanic displacement deposition. J. Phys. Chem. Solids 2021, 148, 109722–109730. [Google Scholar] [CrossRef]

- Bian, W.; Liu, Z.; Lian, G.; Wang, L.; Wang, Q.; Zhan, J. High reliable and robust ultrathin-layer gold coating porous silver substrate via galvanic-free deposition for solid phase microextraction coupled with surface enhanced Raman spectroscopy. Anal. Chim. Acta 2017, 994, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.Y.; Kim, D.G.; Jang, I.; Kim, N.D.; Yoo, J.S.; Kim, P. Synthesis of hollow structured PtNi/Pt core/shell and Pt-only nanoparticles via galvanic displacement and selective etching for efficient oxygen reduction reaction. J. Ind. Eng. Chem. 2022, 111, 300–307. [Google Scholar] [CrossRef]

- Chen, C.S.; Wu, C.-H.; Fan, T.-L.; Hsieh, Y.-C.; Tso, K.-C.; Lee, J.-F.; Wu, P.-W. Pt deposition on Ni-based superalloy via a combination of galvanic displacement reaction and chemical reduction. Mater. Chem. Phys. 2020, 254, 123475–123482. [Google Scholar] [CrossRef]

- Tian, T.; Xiao, X.; Liu, R.; She, H.; Hu, X. Study on titania nanotubes arrays prepared by titanium anodization in NH4F/H2SO4 solution. J. Mater. Sci. 2007, 42, 5539–5543. [Google Scholar] [CrossRef]

- Wagner, C.D.; Riggs, W.M.; Davis, L.E.; Moulder, J.E. Handbook of X-ray Photoelectron Spectroscopy; Perkin—Elmer Corporation: Waltham, MA, USA, 1978; p. 190. [Google Scholar]

- Available online: http://srdata.nist.gov/xps (accessed on 20 April 2022).

- Luna, A.L.; Novoseltceva, E.; Louarn, E.; Beaunier, P.; Kowalska, E.; Ohtani, B.; Valenzuela, M.A.; Remita, H.; Colbeau-Justin, C. Synergetic effect of Ni and Au nanoparticles synthesized on titania particles for efficient photocatalytic hydrogen production. Appl. Catal. B Environ. 2016, 191, 18–28. [Google Scholar] [CrossRef] [Green Version]

- He, Q.; Wan, Y.; Jiang, H.; Pan, Z.; Wu, C.; Wang, M.; Wu, X.; Ye, B.; Ajayan, P.M.; Song, L. Nickel vacancies boost reconstruction in nickel hydroxide electrocatalyst. ACS Energy Lett. 2018, 3, 1373–1380. [Google Scholar] [CrossRef]

- Gao, M.Y.; Sun, C.B.; Lei, H.; Zeng, J.R.; Zhang, Q.B. Nitrate-induced and in situ electrochemical activation synthesis of oxygen deficiencies-rich nickel/nickel (oxy)hydroxide hybrid films for enhanced electrocatalytic water splitting. Nanoscale 2018, 10, 17546–17551. [Google Scholar] [CrossRef]

- Chen, X.; Li, P.; Jin, Z.; Meng, Y.; Yuan, H.; Xiao, D. Tri-metallic phytate in situ electrodeposited on 3D Ni foam as a highly efficient electrocatalyst for enhanced overall water splitting. J. Mater. Chem. A 2017, 5, 18786–18792. [Google Scholar] [CrossRef]

- Peng, W.-C.; Chen, Y.-C.; He, J.-L.; Ou, S.-L.; Horng, R.-H.; Wuu, D.-S. Tunability of p- and n-channel TiOx thin film transistors. Sci. Rep. 2018, 8, 9255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).